Page 1

USE AND MAINTENANCE

MANUAL

Page 2

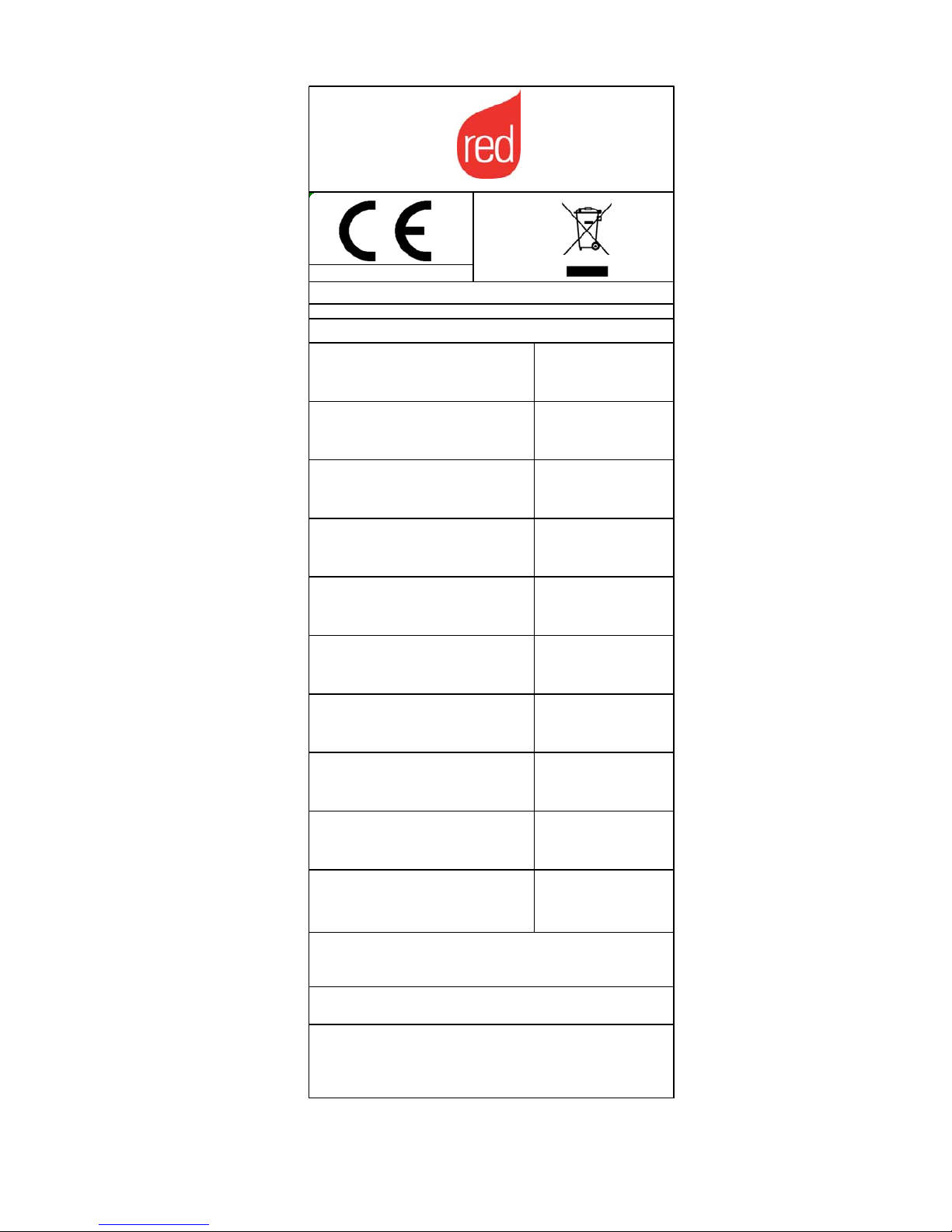

EN 14785 - 2006

Art. 15a B-VG / BImSchV / VKF AEAI

Potencia nom inal:

Potência nom inal:

Nomina l heat output:

Brændværdi:

Emisión CO ( al 13% de O2):

Emi ssão CO (13% de O2):

CO e mission (at 13% O2)

CO e mission (ved 13% O2):

Eficiencia:

Eficiencia:

Efficiency:

Virkningsgrad:

Tempe ra dura humos:

Tem p retura dos fumos:

Flue ga s tempera ture:

Røggastemperatur:

Partícul as dispersadas

Partículas

Dust

Støv

Asorbimiento electrico max:

Max. elektrisk effekt:

Tensión de funcionamie nto:

Tensão e l ectrica funcionam ento:

Rated voltage:

Netspænding:

Distanci as de seguridad (retro):

Distancia de segurança (trasiera):

Sa fety clare n ce distance (back):

Sikkerhedsafstand (bag):

Distanci as de seguridad (late rales):

Distancia de segurança (lateral):

Safety clarence distance (side):

Sikkerhedsafstand (side):

Via La Croce 8, I - 33074 Vigonovo di Fontanafredda (PN) Italy.

10

Regensburger und Münchener BStV erfüllt.

PRIMULA HYDRO / O RC HIDEA HYDRO

M ax 21,0 (17,0k W - 4,0kW)

M in 4,4kW ( 3,0kW - 1,4kW)

1,7 m g/ Nm 3 (13% O2)

1,2 mg/ M J

150°C

P max

P min

92,5%

95,0%

P max

P min

0,012%

0,040%

230 V - 50 Hz.

420 W

(Med. 120 W)

Potência electrica absorbida:

Max. electrical power supply:

Presión máxima de agua:

2,5 bar

Pressão máx i ma da á gua:

Permissible max. water pressure:

Ma x. vandtryk:

Producto conforme a la instalación de tubos múltiples. Produto conforme

para instalação em condutas multiplas . Appliance suitable for installation in

a shared flue. Apparatet kan bruges i en røggassamleledning.

Utilizar sólo con combustibles adaptados. Utilizar somente combustivel

adaquado. Use only recom mended fuels. Anvend kun anbefalede

brændsler.

Leer y se guir las instrucciones! Leia a tentamente e siga a s

instruções! Leggere e seguire le istruzioni! Read and follow the

operating instructions! Følg fabrikantens brugervejledning!

COD: 8901020900

100 mm

100 mm

Page 3

red

PELLET STOVES

Contents

INSTALLATION AND USE MANUAL

page

3

Contents Technical service - Rights reserved - Reproduction prohibited

INTRODUCTION .................................................................................................................................... 5

1. WARNINGS AND GUARANTEE CONDITIONS ..................................................................................... 6

1.1. SAFETY INSTRUCTIONS .................................................................................................................. 6

1.2. OPERATING WARNINGS .................................................................................................................. 7

1.3. GUARANTEE CONDITIONS .............................................................................................................. 8

1.3.1. Limitations ............................................................................................................................... 8

1.3.2. Exclusions ................................................................................................................................ 8

2. THEORETICAL NOTIONS FOR INSTALLATION ................................................................................ 10

2.1. Pellets .......................................................................................................................................... 10

2.2. PRECAUTIONS FOR INSTALLATION ................................................................................................ 11

2.3. OPERATING AREA ......................................................................................................................... 12

2.4. CONNECTION TO THE EXTERNAL AIR INTAKE ................................................................................ 12

2.5. CONNECTION OF SMOKE DISCHARGE PIPE .................................................................................... 13

2.6. CONNECTION TO THE FLUE PIPE ................................................................................................... 14

2.7. CONNECTION TO AN EXTERNAL FLUE WITH INSULATED OR DOUBLE-WALL PIPE ............................. 14

2.8. CONNECTION TO THE FLUE PIPE ................................................................................................... 14

2.9. OPERATING PROBLEMS CAUSED BY DRAUGHT DEFECTS IN THE FLUE ............................................. 15

2.10. PLUMBING CONNECTION ........................................................................................................... 16

3. INSTALLATION AND ASSEMBLY ...................................................................................................... 17

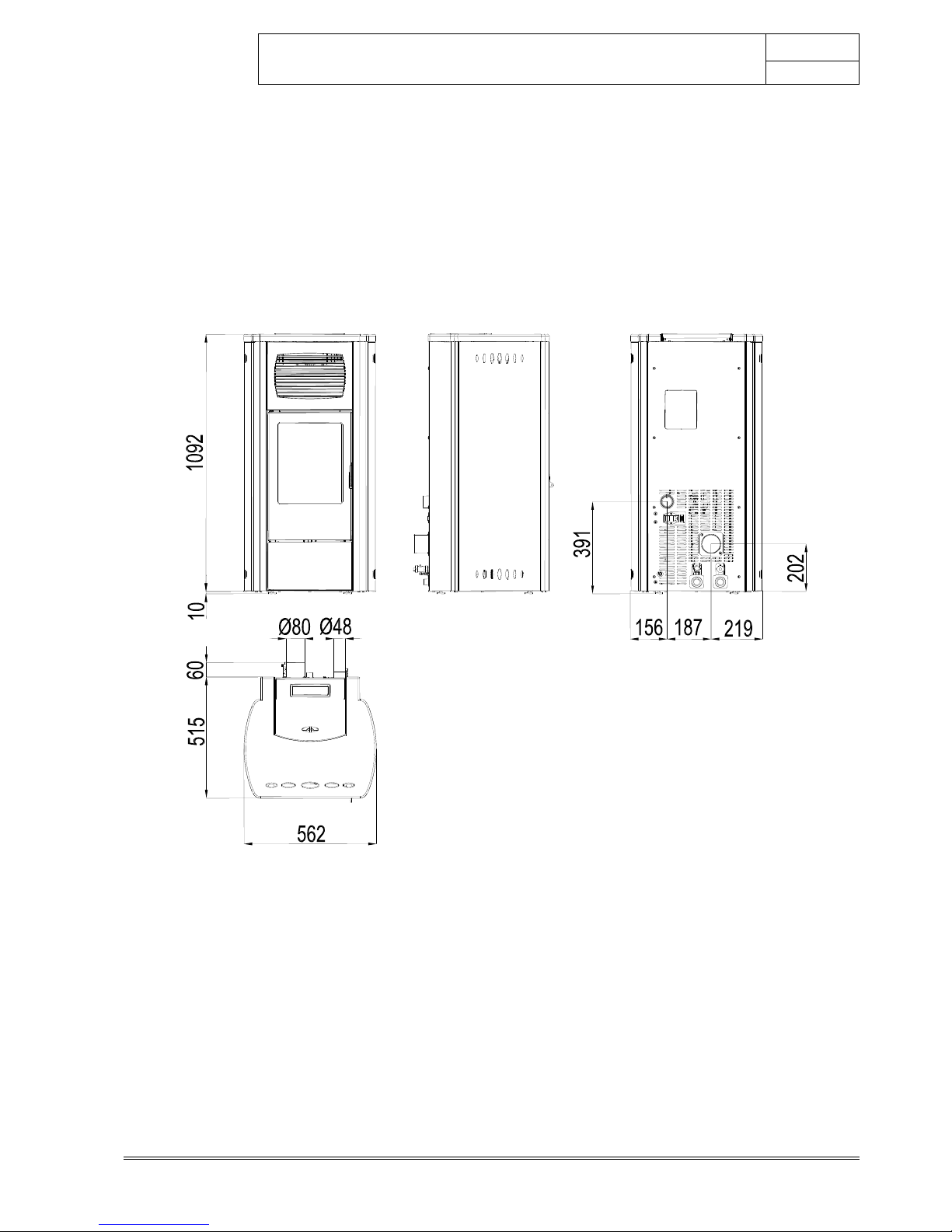

3.1. DRAWINGS AND TECHNICAL CHARACTERISTICS ............................................................................ 17

3.1.1. PRIMULA /ORCHIDEA Hydro ................................................................................................... 17

3.1.2. Technical characteristics ......................................................................................................... 18

3.2. PREPARATION AND UNPACK ING ................................................................................................... 19

3.3. LATERAL CLADDING ASSEMBLY ..................................................................................................... 21

3.4. PLUMBING SYSTEM CONNECTION ................................................................................................. 23

3.4.1. Connections to the system ...................................................................................................... 24

3.4.2. System filling ......................................................................................................................... 25

3.4.3. Water characteristics .............................................................................................................. 25

3.5. EXAMPLE INSTALLATION DIAGRAMS ............................................................................................. 26

3.5.1. Heating installation diagram .................................................................................................... 26

3.5.2. Heating installation diagram in combination with a boiler ........................................................... 27

3.5.3. Heating installation in combination with a storage tank .............................................................. 27

4. OPERATION ..................................................................................................................................... 28

4.1. PRE-LIGHTING WARNINGS ............................................................................................................ 28

4.2. PRE-LIGHTING CHECK .................................................................................................................. 29

4.3. LOADING THE PELLETS ................................................................................................................. 29

4.4. CONTROL PANEL .......................................................................................................................... 29

4.5. SETTINGS TO CARRY OUT BEFORE FIRST LIGHTING ...................................................................... 30

4.5.1. SETTING CURRENT TIME ........................................................................................................ 30

4.5.2. Memorization of recipe on stove. ............................................................................................. 30

4.6. CONTROL OF WATER TEMPERATURE IN BOILER ............................................................................ 31

4.7. FIRST LIGHTING .......................................................................................................................... 31

4.7.1. Lighting the stove................................................................................................................... 31

4.7.2. Extinguishing the stove ........................................................................................................... 32

4.8. VIEW OF THE FLAMES .................................................................................................................. 32

4.8.1. The shape ............................................................................................................................. 32

4.8.2. The colour ............................................................................................................................. 33

4.8.3. The character ........................................................................................................................ 33

4.9. OPERATION ................................................................................................................................. 33

4.9.1. Operating concept .................................................................................................................. 33

4.9.2. Operating modes .................................................................................................................... 34

4.9.2.1. Internal thermostat - Position of internal room sensor ......................................................... 35

4.9.2.2. Operation by means of external thermostat ....................................................................... 35

Page 4

red

PELLET STOVES

Contents

INSTALLATION AND USE MANUAL

page

4

Contents Technical service - Rights reserved - Reproduction prohibited

4.9.2.3. Connection of external thermostat .................................................................................... 35

4.9.3. Setting of ECO-STOP mode ..................................................................................................... 35

4.9.3.1.

Activation /de-activation of ECO-STOP mode

...................................................................... 37

4.9.3.2. OPERATION TO BE CARRIED OUT BY THE INSTALLER ....................................................... 37

4.9.4. Programmed mode (with timer) ............................................................................................... 37

4.9.4.1.

Start day (code on display UT 01)

..................................................................................... 37

4.9.4.2.

Clock (code on display UT 02 and UT 03)

........................................................................... 38

4.9.4.3.

Programme

..................................................................................................................... 39

4.10. EXAMPLE OF PROGRAMMING ..................................................................................................... 41

4.11. SAFETY DEVICES ....................................................................................................................... 43

4.11.1. Alarm signalling .................................................................................................................. 45

4.11.2. Other signals on the display ................................................................................................. 46

4.12. SHUTTING THE STOVE DOWN ................................................................................................... 46

5. MAINTENANCE AND CLEANING ...................................................................................................... 47

5.1. DAILY AND WEEKLY CLEANING BY THE USER ................................................................................. 47

5.1.1. Before each lighting ................................................................................................................ 47

5.1.2. Check every 2/3 days ............................................................................................................. 47

5.1.3. Cleaning the glass .................................................................................................................. 47

5.1.4. Clean the exchanger and the undergrate space every 2/3 days. ................................................. 48

5.2. PERIODIC CLEANING BY A SPECIALISED TECHNICIAN .................................................................... 49

4.1.1.1.

CLEANING THE EXCHANGER AND PIPE UNIT (SUITE/MUSA and CLUB):

............................... 49

5.2.1. Shutting the stove down (end of season) ................................................................................. 50

5.2.2. Check of internal components ................................................................................................. 50

6. PROBLEMS / CAUSES / SOLUTIONS ............................................................................................... 52

7. ELECTRICAL DIAGRAMS .................................................................................................................. 55

7.1. ELECTRICAL DIAGRAM OF PRIMULA ORCHIDEA Hydro WITH NO DOMESTIC HOT WATER KIT ........... 55

Page 5

red

PELLET STOVES Chapter 1

INSTALLATION AND USE MANUAL

page

5

Introduction Technical service - Rights reserved - Reproduction prohibited

INTRODUCTION

Dear Customer,

We wish to thank you for choosing one of our products, specifically a

stove from the Pellet line.

In order to get the best performance from your stove and to

enjoy to the full the warmth and the sense of well-being which

the flame will diffuse through the home, we recommend that

you read this booklet carefully before lighting the s

tove for the first time.

While thanking you again, may we remind you that the stove MUST

NOT be used by children, and that they must always be kept at a safe

distance from it!

Revisions to the publication

In order to improve the product, to keep this publication up to date the

manufacturer reserves the right to make modifications without any

advance notice. Any reproduction, even in part, of this manual without

the consent of the manufacturer is prohibited.

Care of the manual and how to consult it

Take good care of this manual and keep it in a place which can

easily and quickly be reached.

If this manual should be lost or destroyed, or if it is in poor

condition, ask for a copy from your retailer or directly from the

manufacturer, providing product identification data.

Information which is essential or that requires special attention is

shown in bold text.

Italic text

is used to call your attention to other paragraphs in the

manual or for any additional clarifications.

SYMBOLS USED IN THE MANUAL

ATTENTION

This warning sign indicates that the message to which it

refers should be carefully read and understood, because

failure to comply with what these notices say can cause

serious damage to the stove and put the user's safety at

risk.

INFORMATION

This symbol is used to highlight information which is

important for proper stove operation. Failure to comply with

these provisions will compromise use of the stove and its

operation will not be satisfactory.

OPERATING SEQUENCES:

Indicates a sequence of buttons to be pushed to access

menus or to make adjustments.

MANUAL

Indicates that you should carefully read this manual or the

related instructions.

Page 6

red

PELLET STOVES Chapter 1

INSTALLATION AND USE MANUAL

page

6

Warnings and guarantee conciliations Technical service - Rights reserved - Reproduction prohibited

1. WARNINGS AND GUARANTEE CONDITIONS

1.1. SAFETY INSTRUCTIONS

Installation of the stove, making the electrical

connections, checking its operation, and

maintenance are all tasks which should be carried

out by qualified and authorised personnel.

Install the stove in accordance with the

regulations in force in your local area, region and

country.

This apparatus cannot be used by people

(including children with limited physical,

sensorial or mental abilities or with little

experience and know-how unless they have been

viewed or instructed on the use of the apparatus

by the person responsible for its safety.

For the correct use of the stove and of the electronic

apparatus connected to it, and to prevent accidents, the

instructions given in this booklet must always be

followed.

Use, adjustment and programming must be carried out

by adults. Errors or incorrect settings may cause

hazardous conditions and/or poor operation.

Before beginning any operation, the user, or whoever is

preparing to operate on the stove, must have read and

understood the entire contents of this instruction

booklet.

The stove is to be used only for its intended purpose.

Any other use is to be considered improper and

therefore hazardous.

Do not use the stove for standing on or as any kind of

support.

Do not put clothes to dry on the stove Any clothes

hangers and suchlike must be kept a suitable distance

from the stove. Danger of fire.

The user is fully liable for improper use of the product,

thus releasing the company from all civil or penal

liabilities.

Any tampering or replacement that is unauthorised or

not using original spare parts for the stove could be

hazardous to the user and releases the company from

any civil or penal liability.

Most of the surfaces of the stove are extremely hot (the

door, the handle, the glass, smoke discharge pipes etc.).

Avoid coming into contact with these parts, therefore,

without adequate protective clothing or suitable

implements, such as gloves with thermal protection or

implements which keep the hands cool.

Under no circumstances should the stove be run

with the door open or the glass broken.

Do not touch the stove with wet hands, in view of the

fact that it is an electrical appliance. Always disconnect

the supply cable before doing anything to the unit.

Page 7

red

PELLET STOVES Chapter 1

INSTALLATION AND USE MANUAL

page

7

Warnings and guarantee conciliations Technical service - Rights reserved - Reproduction prohibited

Before carrying out any cleaning or maintenance

operation, make sure in advance that the stove is

disconnected from the mains electricity supply, by

turning off the main switch located on the back of the

stove, or by unplugging the supply cable.

The stove must be electrically connected to a system

equipped with an effective earth conductor.

The system must be of adequate rated capacity for the

stated electrical power of the stove.

Incorrect installation or poor maintenance (not

compliant with the provisions set out in this manual)

may cause damage to persons, animals or objects. The

company is not civilly or criminally liable in these cases.

1.2. OPERATING WARNINGS

Shut the stove down in the event of a breakdown or

bad running.

Pellets must not be fed manually into the burner.

Accumulated unburnt pellets in the burner after each

"failed ignition" must be removed before igniting it

again.

Do not wash the inside of the stove with water.

Do not wash the stove with water. The water could get

inside the unit and damage the electrical insulation and

cause electric shocks.

Do not expose your own body to hot air for extended

periods. Do not overheat the room you are in and

where the stove is installed. This could cause injuries

and health problems.

Do not expose plants or animals to a direct hot air flow.

There could be harmful effects on them.

Do not put any fuels in the hopper but wood pellets.

Install the stove in a location with adequate means of

fire-prevention and equipped with all services such as

power supply (air and electricity) and fume discharge.

If there is a fire in the flue pipe, extinguish the stove,

disconnect it from the power supply and never open

the door. Then contact the competent authorities.

If the stove and the ceramic cladding are in storage, it

should be in a place that is free of damp, and they

should not be exposed to extremes of temperature.

It is inadvisable to base the stove directly on the floor,

and if the floor is made of flammable material, it must

be suitably insulated.

Do not light the stove with flammable materials if the

ignition system breaks down.

Page 8

red

PELLET STOVES Chapter 1

INSTALLATION AND USE MANUAL

page

8

Warnings and guarantee conciliations Technical service - Rights reserved - Reproduction prohibited

INFORMATION

For any problems, please contact your dealer or

company qualified and authorised personnel and always

request original spare parts for repairs.

Only use the fuel recommended by the company (for

ITALY only 6mm diameter pellets whereas for the other

European countries, pellets with a diameter of 6-8 mm)

and only supplied by the automatic feed system.

Periodically check and clean the smoke outlet ducts

(connection to the flue pipe).

The pellet stove is not a cooking appliance.

Always keep the cover of the fuel hopper closed.

Keep this instruction manual carefully because it must

stay with the stove throughout its working life. If the

stove is sold or transferred to another user, always

make sure that the booklet goes with the product.

If lost, please request a copy from your dealer or from

the company.

1.3. GUARANTEE CONDITIONS

The company guarantees the stove, excluding the

components which are subject to normal, for a period

of two years from the date of purchase, as proved by a

supporting document which gives the name of the vendor

and the date on which the sale took place. The guarantee is

conditional on the guarantee certificate being filled in and

returned within 8 days, and requires that the product be

installed and tested by a specialised installer, according to

the detailed instructions given in the instruction booklet

supplied with the product.

The term 'guarantee' is to be understood to denote the freeof-charge replacement or repair of parts recognised to

have been defective at the start by reason of

manufacturing defects.

1.3.1. Limitations

The above guarantee does not cover components relating to electrical

and electronic parts, or fans, on which the guarantee period is 1 year

from the purchase of the product, documented as specified above. The

guarantee does not cover parts subject to normal wear such as

gaskets, glass, and any parts with can be removed from the firebox.

The replacement parts will be guaranteed for the remainder of the

guarantee period starting from the date of purchase of the product.

1.3.2. Exclusions

Variations in colour in the painted or ceramic parts, and crackling of the

glaze on the ceramics, do not constitute grounds for a claim under the

guarantee, as they are natural characteristics of the material and of the

use of the product.

The guarantee will not cover all parts which are found to be faulty due

to negligence or careless use, incorrect maintenance, installation not

conform with that specified by the company (see relative chapters in

this manual for use).

Page 9

red

PELLET STOVES Chapter 1

INSTALLATION AND USE MANUAL

page

9

Warnings and guarantee conciliations Technical service - Rights reserved - Reproduction prohibited

The company is not liable for any damages caused directly or indirectly,

to persons, animals or objects consequent to the non-observance of all

the instructions given in this manual, especially the cautions relating to

installation, use and maintenance.

If the product does not perform correctly, contact your local retailer

and/or importer.

Damage caused by transport and/or handling is excluded from the

guarantee.

For installation and use of the product, reference must be made

exclusively to the booklet supplied.

The guarantee will be invalidated in the event of damage caused by

tampering with the appliance, atmospheric agents, natural disasters,

electrical discharges, fire, defects in the electrical system, and caused

by lack of, or incorrect, maintenance in terms of the manufacturer's

instructions.

CLAIMS UNDER THE GUARANTEE

the request for action under the guarantee must be

addressed to the retailer, who will forward the claim

technical assistance service.

The company is not liable in the event that the

product and any other accessory is improperly used

or modified without authorisation.

Only original spare parts must be used for all

replacements.

Page 10

red

PELLET STOVES Chapter 2

INSTALLATION AND USE MANUAL

page

10

Theoretical notions for installation Technical service - Rights reserved - Reproduction prohibited

2. Theoretical notions for installation

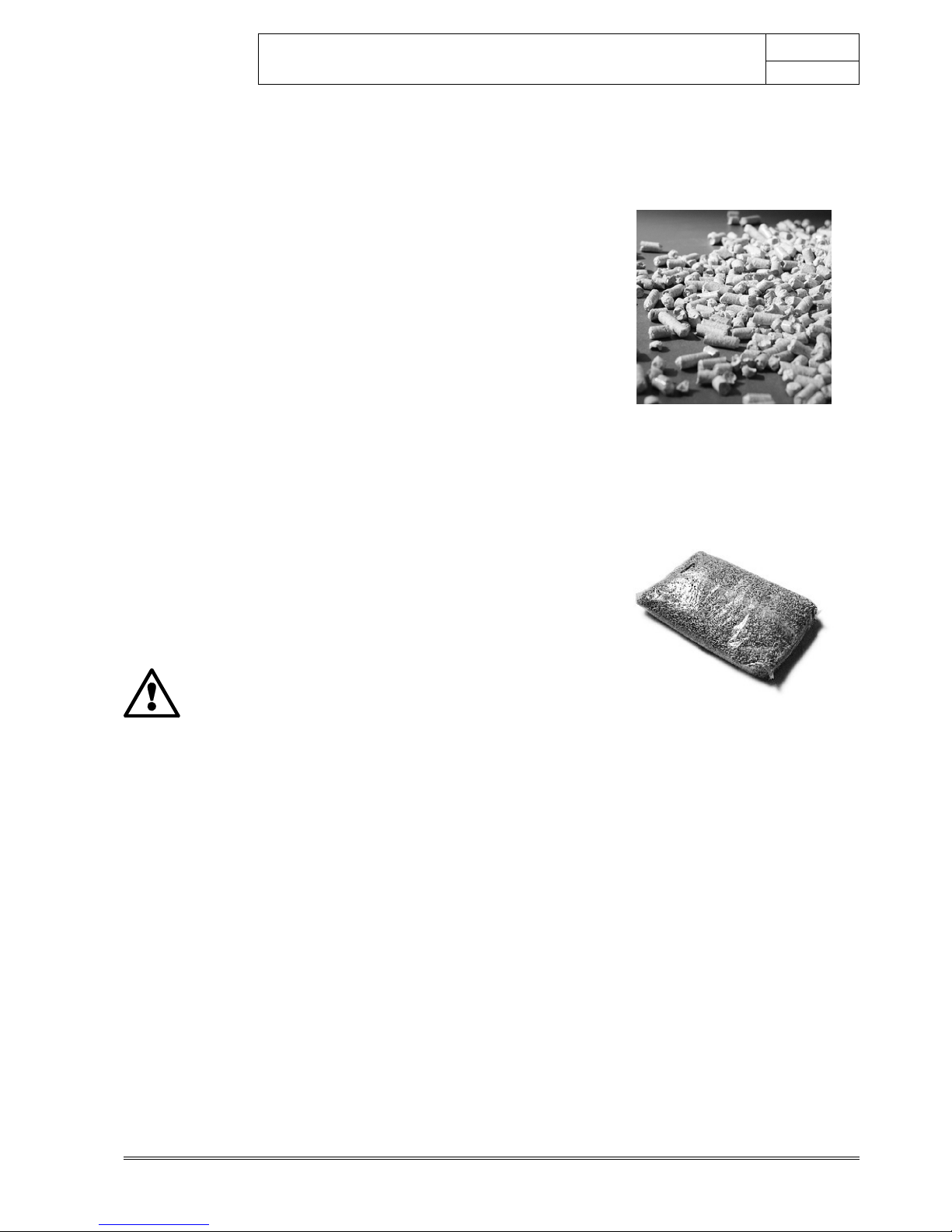

2.1. Pellets

Wood pellets are manufactured by hot-extruding compressed sawdust which

is produced during the working of natural dried wood. The compactness of

the material comes from the lignin which is contained in the wood itself, and

allows the production of pellets without the use of glues or binders.

The market offers different types of pellet with characteristics which

vary depending on what mixture of woods is used. The diameter varies

between 6 mm and 8 mm, with a standard length in the range 5 mm to

30 mm. Good quality pellets have a density which varies between 600

kg/m3 and 750 kg/m3, with a moisture content which varies from 5%

to 8% by weight.

Besides being an ecological fuel (exploiting timber residues to the

maximum and achieving cleaner combustion than is possible with fossil

fuels), pellets also have technical advantages. While good-quality

timber has a calorific power of 4.4 kW/kg (with 15% moisture,

therefore after about 18 months' seasoning), the equivalent figure for

pellets is 4.9 kW/kg.

To ensure good combustion, the pellets must be stored in an area that

is free of humidity and protected from dirt. The pellets are usually

supplied in 15 kg. sacks, so storing them is very convenient.

Good quality pellets ensure good combustion, thus lowering the

emission of harmful agents into the atmosphere.

The poorer the quality of the fuel, the more

frequently will intervention be necessary for cleaning

the internal parts, such as the grate and the

combustion chamber.

The main certifications of quality for pellets in the European market are

DINplus and Ö-Norm M7135; these ensure respect of:

Calorific power: 4.9 kW/kg

Water content: max 10% of weight

Percentage of ashes: max 0,5% of weight

Diameter: 5 – 6mm

Length: max 30mm

Contents: 100% untreated wood, with no added bonding

substances (bark percentage 5% max)

Packaging: in sacks made from ecologically compatible or

biologically decomposing material

Fuel pellets

15 Kg sack of fuel

Page 11

red

PELLET STOVES Chapter 2

INSTALLATION AND USE MANUAL

page

11

Theoretical notions for installation Technical service - Rights reserved - Reproduction prohibited

The company strongly recommends the use of

certified fuel for its stoves (DINplus and Ö-Norm

M7135).

The use of fuel of inferior quality or not conforming

to the specification given above compromises the

running of your stove and can therefore lead to the

termination of the guarantee and of the

manufacturer's responsibility for the product.

Pellet stoves only work with pellets having a

diameter of 6-8 mm with a length ranging from 5mm

to max 30 mm.

2.2. PRECAUTIONS FOR INSTALLATION

IMPORTANT!

Installation and assembly of the stove must be

carried out by qualified personnel.

The stove must be installed in a suitable position to allow the normal

operations of opening and ordinary maintenance.

The site must be:

capable of providing the environmental conditions for operation

equipped with power supply 230V 50 Hz

capable of taking an adequate system for smoke discharge

provided with external ventilation

provided with an earth connection complying with CEI 64-8

The stove must be connected to a flue pipe or an internal or

external vertical duct conforming to current standards UNI

7129 - 7131 9615.

The stove must be positioned in such a way that the electrical

plug is accessible.

IMPORTANT!

The stove must be connected to a flue pipe or a

vertical duct which can discharge the fumes at the

highest point of the building.

The fumes are however derived from the combustion

of wood products, and if they come into contact with

or close to walls, they can make dirty marks.

Also take care because the fumes are very hot but

almost invisible, and can cause burns on contact.

The holes for the passage of the smoke pipe and for

the intake of air from outside should be made before

positioning the stove unit.

Page 12

red

PELLET STOVES Chapter 2

INSTALLATION AND USE MANUAL

page

12

Theoretical notions for installation Technical service - Rights reserved - Reproduction prohibited

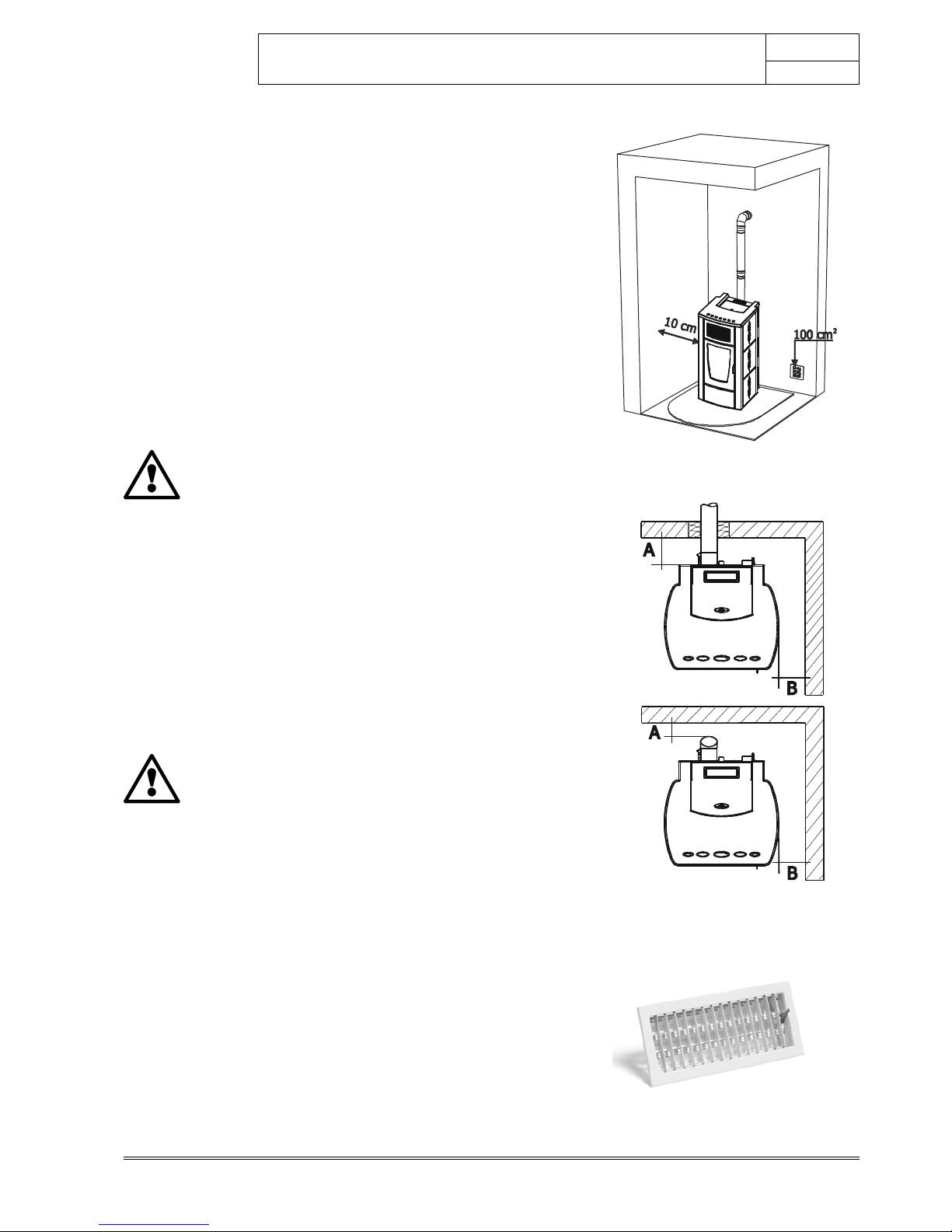

2.3. OPERATING AREA

For proper functioning and a good temperature distribution, the stove

should be positioned in a location where it is able to take in the air

necessary for combustion of the pellets (about 40 m

3

/h must be

available), as laid down in the standard governing the installation and

in accordance with local national standards.

The volume of the room must not be less than 30 m

3.

The air must come in through permanent openings made in walls (in

proximity to the stove) which give onto the outside, with a minimum

cross-section area of 100 cm

2

. These openings must be made in such a

way that it is not possible for them to be obstructed in any way.

Alternatively, the air can be taken from rooms adjacent to the one

which needs ventilating, as long as they are provided with an air intake

from the outside, and are not used as bedrooms or bathrooms, and

provided there is no fire risk such as there is for example in garages,

woodsheds, and storerooms, with particular reference to what is laid

down in current standards.

It is not permissible to install the stove in bedrooms,

bathrooms, or in a room where another heating

appliance is installed (fireplace, stove etc.) which

does not have its own independent air intake.

Locating the stove in a room with an explosive

atmosphere is prohibited.

The floor of the room where the stove is to be

installed must be strong enough to take its weight.

If the walls are not flammable, position the stove with a clearance to

the rear of at least 10 cm.

For flammable walls, keep a minimum distance of 10 cm at the rear

"A", 10 cm on the sides "B" and 150 cm at the front.

If the room contains objects which are believed to be particularly

delicate, such as drapes, sofas and other furniture, their distance from

the stove should be considerably increased.

If the flooring is made of wood, provide a floor

protection surface in compliance with current

national standards.

2.4. CONNECTION TO THE EXTERNAL AIR INTAKE

It is essential that at least as much air must be able to flow into the

room where the stove is installed as is required for proper combustion

in the appliance and for the ventilation of the room. This can be

effected by means of permanent openings in the walls of the room to

be ventilated, which give onto the outside, or by single or collective

ventilation ducts.

For this purpose, on the external wall near the stove, a hole must be

made with a minimum free cross-section of 100 cm². (equivalent to a

round hole of 12 cm diameter or a square hole 10x10 cm), protected by

a grille on the inside and the outside.

The air intake must also:

communicate directly with the room where the stove is installed

be protected by a grille, metal mesh or suitable guard, as long as

this does not reduce the area below the minimum.

be positioned in such a way as to be impossible to obstruct

Example of pellet stove installation

Example of pellet stove installation (for

flammable walls)

Page 13

red

PELLET STOVES Chapter 2

INSTALLATION AND USE MANUAL

page

13

Theoretical notions for installation Technical service - Rights reserved - Reproduction prohibited

1

2

It is not compulsory to connect the air intake directly

with the stove (so that it draws air directly from

outside), but it is essential at all events to ensure an

airflow of 50 cubic metres per hour by the use of a

hole of the dimensions given.

See standard UNI 10683.

2.5. CONNECTION OF SMOKE DISCHARGE PIPE

When making the hole for the passage of the smoke discharge pipe, it

is necessary to take into account the possible presence of flammable

materials. If the hole will be going through a wall made of wood or any

other material which is sensitive to heat, the INSTALLER MUST first

of all use the special wall union (diam.13cm 13cm minimum) and

properly insulate the pipe of the stove that passes through it, using

adequate insulation materials (thickness 1.35cm with minimum thermal

conductivity of 0.07 W/m°K).

The same is true if the stove pipe must run through vertical or

horizontal stretches passing in proximity (min.20cm) to the heatsensitive wall

As an alternative we recommend the use of insulated pipe, which can

also be used on the outside to avoid condensation.

The combustion chamber works in low pressure. The smoke duct for

the discharge of fumes will also be under low pressure when connected

to an efficient flue pipe as directed.

Pipes and unions with suitable gaskets must always

be used, to guarantee a hermetic seal.

All sections of the smoke duct must be inspectable and

removable to enable periodic internal cleaning. Tee

connectors with inspection caps should be used.

Position the stove bearing in mind all the instructions and

considerations above.

IMPORTANT!

All 90 degree changes of direction in the flue pipe

must be fitted with suitable tee connectors to allow

the possibility of inspection. (see accessories for

pellet stove)

It is absolutely prohibited to fit a grille on the end of

the discharge pipe, because it could lead to poor

running of the stove.

FOR CONNECTION TO THE FLUE PIPE, NOT MORE

THAN 2-3 METRES OF HORIZONTAL PIPE MUST BE

USED AND NOT MORE THAN THREE 90° CURVES

MUST BE USED

IT IS ALSO ADVISABLE NOT TO EXCEED 6 METRES IN

LENGTH WITH THE PIPE Ø 80 mm

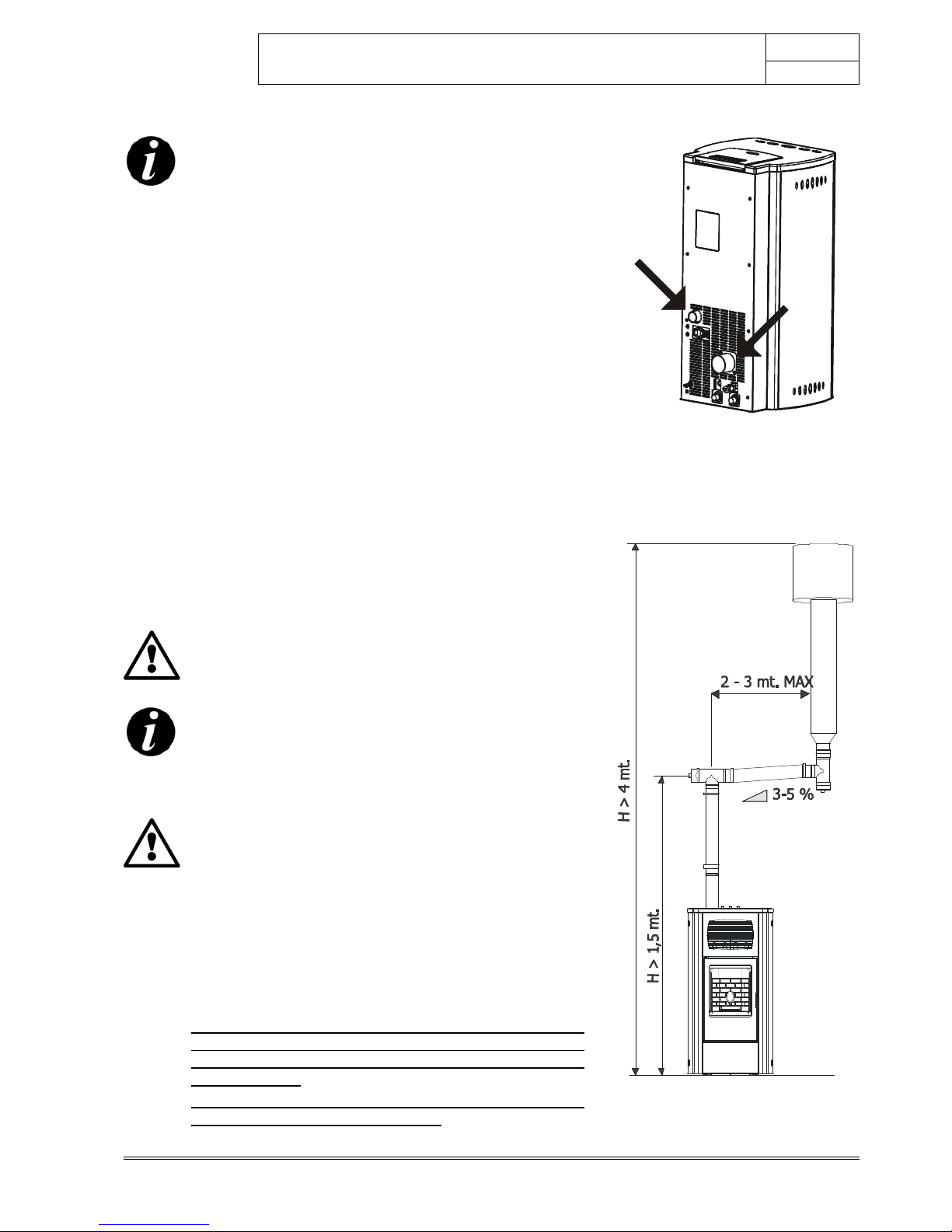

Example of pellet stove installation

Rear view of a pellet stove (example)

1) Combustion air intake

2) Smoke outlet

Page 14

red

PELLET STOVES Chapter 2

INSTALLATION AND USE MANUAL

page

14

Theoretical notions for installation Technical service - Rights reserved - Reproduction prohibited

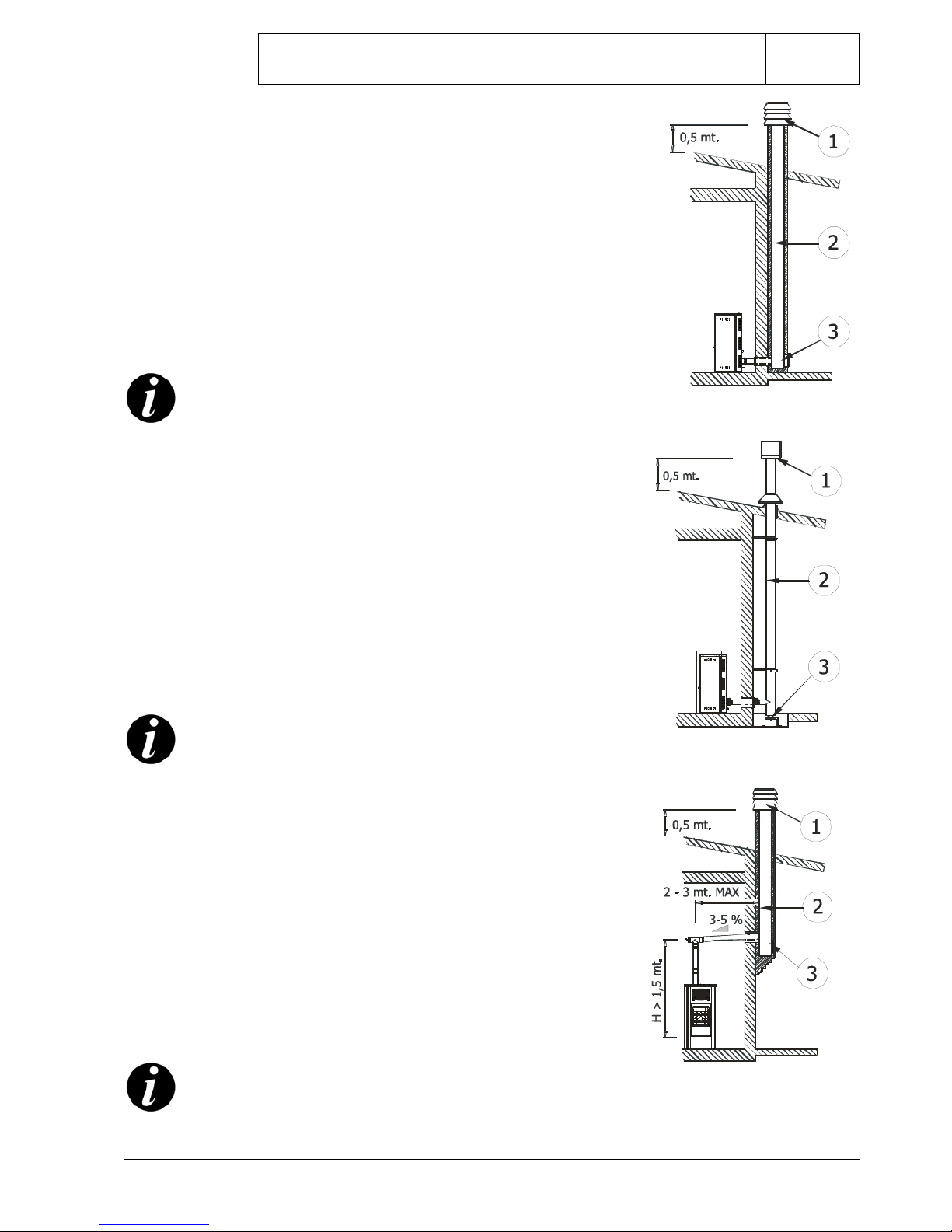

2.6. CONNECTION TO THE FLUE PIPE

The flue pipe must have internal dimensions not larger than 20 x 20

cm, or diameter 20 cm. In the event of larger dimensions, or of the

flue pipe being in poor condition (for example cracks, poor insulation,

etc.), it is advisable to fit a stainless steel pipe of suitable diameter

inside the flue pipe throughout its length, right up to the top.

Check with suitable instruments that there is a minimum draught of 10

Pa.

At the bottom of the flue pipe, provide an inspection cap to allow

periodic checking and cleaning, which must be done annually.

Make a gas-tight connection to the flue pipe, using pipes and

connectors as recommended by us.

You must ensure that a windproof cowl should be fitted which complies

with the standards in force.

This type of connection ensures the evacuation of the

fumes even in the event of a temporary power cut.

2.7. CONNECTION TO AN EXTERNAL FLUE WITH

INSULATED OR DOUBLE-WALL PIPE

The external fluepipe must have internal dimensions of minimum

10x10 cm or 10 cm diameter, and maximum 20x20 cm or 20 cm

diameter.

Check with suitable instruments that there is a minimum draught of 10 Pa.

The only type of pipe which is permissible is insulated (double-walled)

stainless steel, smooth on the inside, fixed to the wall. Flexible stainless

steel pipe must not be used. At the bottom of the flue pipe, provide an

inspection cap to allow periodic checking and cleaning, which must be

done annually. Make a gas-tight connection to the flue pipe, using

pipes and connectors as recommended by us.

You must ensure that a windproof cowl should be fitted which complies

with the standards in force.

This type of connection ensures the evacuation of the

fumes even in the event of a temporary power cut.

2.8. CONNECTION TO THE FLUE PIPE

For proper functioning, the connecting pipe between the stove and the

chimney or flue duct must have a slope of not less than 3% in the

horizontal stretches, the length of which must not exceed 2/3

metres, and the vertical distance between one tee connector and

another (change of direction) must not be less than 1.5m.

Check with suitable instruments that there is a minimum draught of 10

Pa.

At the bottom of the flue pipe, provide an inspection cap to allow

periodic checking and cleaning, which must be done annually.

Make a gas-tight connection to the flue pipe, using pipes and

connectors as recommended by us.

You must ensure that a windproof cowl should be fitted which complies

with the standards in force.

This type of connection ensures the evacuation of the

fumes even in the event of a temporary power cut.

1) Windproof cowl

2) Flue pipe

3) Inspection

1) Windproof cowl

2) Flue pipe

3) Inspection

1) Windproof cowl

2) Flue pipe

3) Inspection

Page 15

red

PELLET STOVES Chapter 2

INSTALLATION AND USE MANUAL

page

15

Theoretical notions for installation Technical service - Rights reserved - Reproduction prohibited

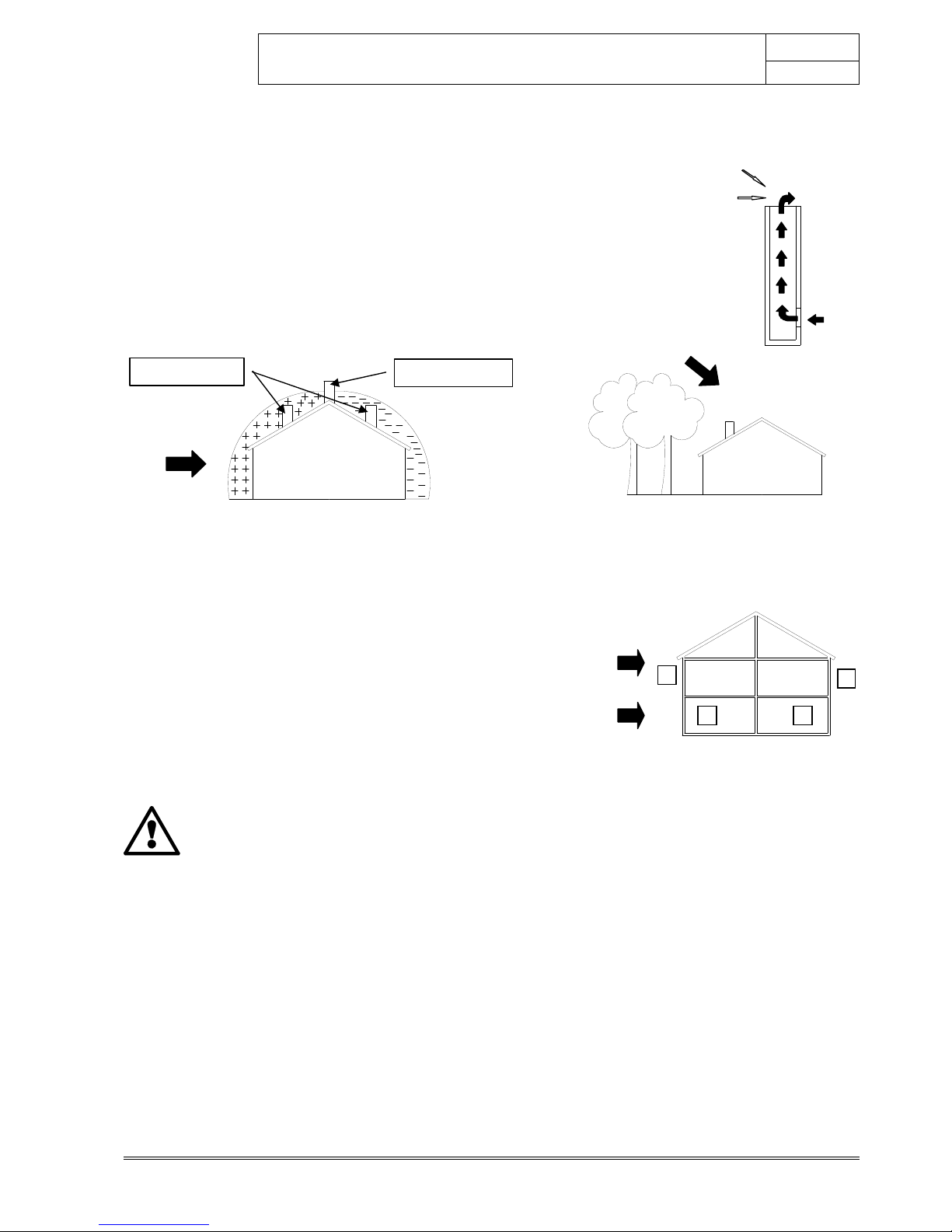

2.9. OPERATING PROBLEMS CAUSED BY DRAUGHT

DEFECTS IN THE FLUE

Of all the weather and geographical conditions which affect the

operation of a flue pipe (rain, fog, snow, altitude a.s.l., exposure to

sunlight, direction of facing), the wind is unquestionably the most

decisive. In fact, along with thermal depression caused by the

difference in temperature inside and outside of the chimney, there is

another type of depression or over-pressure: dynamic pressure caused

by the wind. An updraft always increases depression and hence

draught. A crosswind increases depression provided the cowl has been

installed properly. A downdraft always decreases depression, at times

inverting it.

Besides the direction and force of the wind, the position of the flue and

the cowl with respect to the roof of the building and the surrounding

landscape is important.

The wind also influences the operation of the chimney indirectly by

creating high-pressure and low-pressure zones, not only outside the

building but inside as well. In rooms directly exposed to the wind (2),

an indoor high-pressure area can be created which can augment the

draught in stoves and fireplaces, but it can be counteracted by the

external high pressure if the cowl is situated on the side exposed to the

wind (1). On the other hand, in the rooms on the opposite side from

the direction of the wind (3), a dynamic depression can be created

which competes with the natural thermal depression developed by the

chimney, but this can be compensated for (sometimes) by locating the

flue on the opposite side from the direction of the wind (4).

IMPORTANT!

The operation of the pellet stove is noticeably

sensitive to the conformation and position of the flue

which is adopted.

Hazardous conditions can only be overcome by

suitable setting-up of the stove carried out by

qualified personnel.

1

2 3

4

E.g. Crosswind 2: 8 m/sec

Depression of 30Pa

E.g. Downdraft at 45° of

8m/sec. Overpressure of 17

Pa

1-2 = High-pressure zones

3-4 = Low-pressure zones

WIND

Least favourable points

Most favourable position

WIND

Downdraft

High-pressure

Low-pressure zone

Page 16

red

PELLET STOVES Chapter 2

INSTALLATION AND USE MANUAL

page

16

Plumbing connection Technical service - Rights reserved - Reproduction prohibited

2.10. PLUMBING CONNECTION

IMPORTANT!

The connection of the stove to the plumbing system

must be carried out ONLY

by specialized personnel

who are capable of carrying out installation properly,

in compliance with current standards in the country

of installation.

If installation of the stove will involve interaction

with another, pre-existing system complete with

heating equipment (gas boiler, methane boiler, fuel

oil boiler, etc.), it is even more advisable to call in

qualified personnel, who subsequently will be

responsible for conformity of the system with current

applicable law.

The Company will not be held responsible for

damage to persons or things in the event of failed or

incorrect operation if the aforementioned warnings

are not complied with.

For connection of the plumbing system to the stove, the user should

refer to chapter 3, INSTALLATION AND ASSEMBLY; specifically,

paragraph 3.4, CONNECTION TO PLUMBING SYSTEM

Page 17

red

PELLET STOVES Chapter 3

INSTALLATION AND USE MANUAL

page

17

Installation and assembly Technical service - Rights reserved - Reproduction prohibited

3. INSTALLATION AND ASSEMBLY

3.1. DRAWINGS AND TECHNICAL CHARACTERISTICS

3.1.1. PRIMULA /ORCHIDEA Hydro

Page 18

red

PELLET STOVES Chapter 3

INSTALLATION AND USE MANUAL

page

18

Installation and assembly Technical service - Rights reserved - Reproduction prohibited

3.1.2. Technical characteristics

Technical characteristics PRIMULA - ORCHIDEA Mod. HYDRO

Overall thermal power Max.

21 kw (18056 kcal) / 17,0 kw (14617 kcal)

Overall thermal power Min.

4,4 kw (3784 kcal) / 3,0 Kw (2580 kcal)

Yield at maximum

92,5%

Yield at minimum

95,0%

Temperature of exhaust smoke at maximum

150°C

Temperature of exhaust smoke at minimum

71°C

Dust

1,7 mg/Nm3 (13% O2)

1,2 mg/MJ

CO at 13%O

²

at minimum and maximum

0.040 — 0.012%

CO2 at minimum and maximum

7,03% – 12,49%

Mass of smoke at minimum and maximum

4,5 – 11 g/sec

Suggested draught at max power

0,10 mbar – 10 Pa

Suggested draught at min power

0,05 mbar – 5 Pa

Hopper capacity

44 litri

Fuel pellet type

Pellet diameter 6-8 mm. Length range 5/30 mm

Pellet consumption per hour

Min ~ 0,9 kg/h * Max. ~ 4 kg/h *

Operating time between re-fuelling

Al min ~ 28 h * Al max. ~ 7 h *

Heatable volume m3

366/40 – 418/35 – 487/30 **

Combustion air inlet

External diameter 50 mm.

Smoke outlet

External diameter 80 mm.

Maximum absorbed electrical power

Max. 420 W – Med. 120 W

Power supply frequency and voltage

230 Volt / 50 Hz

Net weight

190 Kg.

Weight with packaging

200 Kg.

* Data that may vary depending on the type of pellets used.

**Heatable volume based on demand of cal/m

3

40-35-30 (respectively 40-35-30 Kcal/h for m3)

Appliance suitable for installation in a shared flue.

Page 19

red

PELLET STOVES Chapter 3

INSTALLATION AND USE MANUAL

page

19

Installation and assembly Technical service - Rights reserved - Reproduction prohibited

3.2. PREPARATION AND UNPACK ING

PRIMULA and ORCHIDEA stoves are delivered with two different

types of packing:

PRIMULA stoves has one package

o It contains the stove and the steel sides with the

profiles (Fig.1)

ORCHIDEA stove has two packages

o One contains the stove

o One contains the ceramics (fig.2). In this case there

will be a single pack for the structure (the cardboard

with the ceramics will be placed above the packaging

with the structure)

Open the packaging, remove the four screws that secure the base of

the stove to the pallet, two to the right and two to the left (see figure

3), and position the stove in the selected place, ensuring that it is

complies with the above instructions.

The stove body or unit must always be kept in a vertical position when

moved, and moved only using carts. Special care must be used to

protect the door and the glass from impacts that would damage them.

Moving the product must always be done with care. If possible, unpack

the stove in the area where it is going to be installed.

The materials which make up the packaging are not toxic or harmful,

so no special procedures for disposal by required.

Their storage, disposal or possible recycling are therefore the responsibility

of the final user, in compliance with current legislation on the subject.

Do not store the stove unit or its cladding without their packaging.

Position the stove without its cladding and connect it to the flue pipe.

Use the four adjustable feet (J) to get the stove correctly levelled so

that the smoke outlet (S) is lined up with the connecting pipe (H) .

Figure 2 - Example of packing for

ceramics

Figure 3 - Removing packaging screws

Figure 1 – Example of packaging stove

+ steel sides Primula

Page 20

red

PELLET STOVES Chapter 3

INSTALLATION AND USE MANUAL

page

20

Installation and assembly Technical service - Rights reserved - Reproduction prohibited

Once the operations for connection are complete, assemble the

cladding (ceramics or steel sides).

If the stove needs to be connected to a discharge pipe which goes

through the rear wall (to connect up with the flue), take the greatest

care to make sure that the joint is not stressed.

If the smoke outlet of the stove is forced or used

improperly to lift it or position it, the operation of the

stove can be damaged irreparably.

1. Turn the feet clockwise to

lower the stove

2. Turn the feet counter-

clockwise to lower the

stove

Page 21

red

PELLET STOVES Chapter 3

INSTALLATION AND USE MANUAL

page

21

Installation and assembly Technical service - Rights reserved - Reproduction prohibited

3.3. LATERAL CLADDING ASSEMBLY

Assembly of profiles to insert steel sides (PRIMULA)

Remove, on the upper part, the cast iron top (A).

Take the side (B) (pay attention that it enters in the part under the

plugs (F) and secure it to the upper sheet metal of the stove with the

bracket (C) and the four screws (D). Two screws secure the bracket

(C) on the stove and two secure the bracket (C) to the side (B).

Repeat the same operation for both sides. Reposition the cast iron top.

A

B

C

D

B

Figure 4 - PRIMULA stove sides

Page 22

red

PELLET STOVES Chapter 3

INSTALLATION AND USE MANUAL

page

22

Installation and assembly Technical service - Rights reserved - Reproduction prohibited

Inserting the ceramic sides (ORCHIDEA)

Remove, on the upper part, the cast iron top (A).

Take the six ceramics (B) from the box (see page 19 section 3.2) and

insert them into the profile (C) where the guide is, from the top

downwards

Repeat the same operation for both sides. Reposition the cast iron top.

(fig.5)

A

B

C

C

We recommend the use of small velcro felt disks to

apply to the tips of the ceramics to avoid contact

between them.

We recommend installing the ceramics after

installation of the stove is complete.

Figure 5 – ORCHIDEA stove sides

Page 23

red

PELLET STOVES Chapter 3

INSTALLATION AND USE MANUAL

page

23

Installation and assembly Technical service - Rights reserved - Reproduction prohibited

3.4. PLUMBING SYSTEM CONNECTION

IMPORTANT!

The connection of the stove to the plumbing system

must be made ONLY

by specialized personnel who

are capable of carrying out installation properly, in

compliance with current standards in the country of

installation.

The company will not be held responsible for damage

to persons or things in the event of failed operation if

the aforementioned warning is not complied with.

CONNECTION DIAGRAM FOR PRIMULA–ORCHIDEA HYDRO

STOVE

A1=Heating water delivery 3/4”M

A2=Heating water return 3/4”M

C=Safety valve 3 bar – 1/2”F

E=System emptying 1/2”F

Page 24

red

PELLET STOVES Chapter 3

INSTALLATION AND USE MANUAL

page

24

Installation and assembly Technical service - Rights reserved - Reproduction prohibited

3.4.1. Connections to the system

Make the connections to the corresponding fittings shown in the

diagram on the previous page. Make sure the pipes are not placed

under tension or undersized.

IMPORTANT

IT IS STRONGLY RECOMMENDED TO WASH THE

ENTIRE SYSTEM BEFORE CONNECTING IT IN ORDER

TO GET RID OF RESIDUES AND DEPOSITS.

Upstream from the stove, always install shutters so

as to disconnect it from the plumbing system should

it be necessary to move it, or when it requires

routine and/or special maintenance.

Connect the stove using hoses so that the stove is

not too strictly connected to the system, and to allow

slight movements.

The pressure discharge valve (C) is always connected

to a water drain pipe. The pipe must be adequate to

support the water's high temperature and pressure.

A = TAP

B = DOMESTIC SYSTEM

C = PRESSURE DISCHARGE

D = FLEXIBLE PIPES

Pressure discharge valve (3 bar)

Page 25

red

PELLET STOVES Chapter 3

INSTALLATION AND USE MANUAL

page

25

Installation and assembly Technical service - Rights reserved - Reproduction prohibited

End piece with a

filling tap (D)

and pressure gauge (M)

(accessory)

Grey plug loos ened

1 turn

Red plug blocked

3.4.2. System filling

To fill the system, the stove can be equipped with an end piece

(optional)

with a non-return valve (D), for manual filling of the heating

system (if the

optional

is not installed, the filling tap on the main boiler

will be used). During this operation, any air in the system is released

from the automatic vent valve located under the top.

To ensure the valve vents correctly, it is advisable to loosen the grey

cap one turn and to keep the red cap blocked

(see figure)

The filling pressure of the system WHEN COLD must be

1 bar.

During operation, if the system pressure drops (due to evaporation of

dissolved gases in the water) to values lower than the minimum

indicated above, the user must use the filling tap to bring the pressure

back up to its normal pressure.

For proper operation of the stove WHEN HOT, the pressure in the

boiler must be1.5 bar.

To monitor system pressure, the end piece

(optional)

is

equipped with a pressure gauge (M).

Upon completion of this operation, always close the tap.

3.4.3. Water characteristics

The characteristics of the water used to fill the system are very

important to prevent the build-up of mineral salts and the formation of

incrustations along the pipes, in the boiler and in the heat exchangers.

Therefore, please GET YOUR PLUMBER'S ADVICE

CONCERNING:

Hardness of water circulating in the system, to prevent

problems of incrustation and limescale, especially in the

domestic water heat exchanger. (> 25° French)

Installation of a water softener (if water hardness

exceeds 25° French)

Filling the system with treated water (demineralised).

Possibly providing an anti-condensation circuit.

Installation of plumbing bumpers to prevent banging

along the fittings and pipes.

If you have very extensive systems, with a large amount of water, or

which require frequent refilling, the installation of water softening

systems.

It should be remembered that incrustations

drastically reduce performance due to low thermal

conductivity.

Filling tap (D)

Pressure gauge (M)

Vent valve under the top

Page 26

red

PELLET STOVES Chapter 3

INSTALLATION AND USE MANUAL

page

26

Installation and assembly Technical service - Rights reserved - Reproduction prohibited

3.5. EXAMPLE INSTALLATION DIAGRAMS

The following diagrams are to be used only as a

guideline. For proper connection, always follow the

notes for the plumbing and heating installer. The

plumbing system must meet local, regional or

national requirements. Installation and verification

of operation is to be performed only by specialized,

authorized personnel.

The company will not be held liable for noncompliance with the provisions listed above.

3.5.1. Heating installation diagram

PERFORMANCE:

HEATING WITH STOVE

S

T

VS

P

VE

V

V

sc

T

SE

230V 50HZ

R

ARARARA

RP

Flt

A

V

V

M

SYSTEM DELIVERY

PRESSURE SAFETY DISCHARGE

SYSTEM RETURN

SYSTEM REFILL

CONFIGURATION: PRIMULA/ORCHIDEA WITH DOMESTIC HOT WATER KIT

SYSTEM OF SYSTEM WITH CLOSED TANK ONLY FOR HEATING BY MEANS OF RADIATORS

SIGNATURFORKLARING:

SE Electronic card

S Automatic vent

M Pressure gauge

VS Vent valve, 3 bar

V Valve

P Pump

VD One-way valve

T Measurement of boiler temperature

VE Expansion tank, 1.5 bar of 6 l

W 3-way motorized valve

SC Plate heat exchanger

F Flow switch

C Methane gas boiler

B Boiler

BA Storage boiler

RA Radiators

PR Radiant panels

PS Solar panels

A Pounding absorber

RP Pressure reduction valve

Vsc Boiler/system discharge valve

Flt System filter

Add Softener

Page 27

red

PELLET STOVES Chapter 3

INSTALLATION AND USE MANUAL

page

27

Installation and assembly Technical service - Rights reserved - Reproduction prohibited

R

230V 50HZ

SE

S

VS

P

VE

T

Vsc

B

T

RA RA RA RA

Flt

Add

A

RP

V

V

M

V

SYSTEM DELIVERY

SYSTEM RETURN

COLD DOMESTIC

WATER INLET

HOT DOMES TIC W ATER OUTLET

PRESSURE SAFETY

DISCARGE

SYSTEM REFILL

R

230V 50HZ

S

VS

P

VE

VT

T

C

PS

BA

PR

PR

SE

R

ARARARA

Vsc

Flt

Add

A

RP

V

V

M

HOT DOMESTIC

WATER OUT LET

PRESSURE SAFETY

DISCHARGE

SYSTEM REFILL

SYSTEM DELIVERY

SYSTEM RETURN

COLD DOM ES T IC

WATER INLE T

3.5.2. Heating installation diagram in combination with a boiler

PERFORMANCE:

HEATING WITH STOVE

PRODUCTION OF DOMESTIC

HOT WATER WITH BOILER

CONFIGURATION: PRIMULA/ORCHIDEA WITHOUT DOMESTIC HOT WATER KIT COMBINED WITH BOILER

HEATING WITH STORAGE SYSTEM PRODUCTION OF DOMESTIC HOT WATER WITH STORAGE SYSTEM

SIGNATURFORKLARING:

SE Electronic card

S Automatic vent

M Pressure gauge

VS Vent valve, 3 bar

V Valve

P Pump

VD One-way valve

T Measurement of boiler temperature

VE Expansion tank, 1.5 bar of 6 l

W 3-way motorized valve

SC Plate heat exchanger

F Flow switch

C Methane gas boiler

B Boiler

BA Storage boiler

RA Radiators

PR Radiant panels

PS Solar panels

A Pounding absorber

RP Pressure reduction valve

Vsc Boiler/system discharge valve

Flt System filter

Add Softener

3.5.3. Heating installation in combination with a storage tank

PERFORMANCE:

HEATING WITH STORAGE SYSTEM

PRODUCTION OF DOMESTIC HOT

WATER WITH STORAGE SYSTEM

CONFIGURATION: PRIMULA/ORCHIDEA WITHOUT DOMESTIC HOT WATER KIT COMBINED WITH STORAGE SYSTEM WITH BOILER AND SOLAR PANELS

SYSTEM DIAGRAM WITH CLOSED TANK FOR HEAT ING WITH RADIATORS OR RADIANT PANELS AND FOR THE PRODUCTION OF DOMESTIC HOT WATER

SIGNATURFORKLARING:

SE Electronic card

S Automatic vent

M Pressure gauge

VS Vent valve, 3 bar

V Valve

P Pump

VD One-way valve

T Measurement of boiler temperature

VE Expansion tank, 1.5 bar of 6 l

W 3-way motorized valve

SC Plate heat exchanger

F Flow switch

C Methane gas boiler

B Boiler

BA Storage boiler

RA Radiators

PR Radiant panels

PS Solar panels

A Pounding absorber

RP Pressure reduction valve

Vsc Boiler/system discharge valve

Flt System filter

Add Softener

Page 28

red

PELLET STOVES Chapter 4

INSTALLATION AND USE MANUAL

page

28

Operation Technical service - Rights reserved - Reproduction prohibited

4. OPERATION

4.1. PRE-LIGHTING WARNINGS

ATTENTION!

Installation is to be made only with connection to a

flue pipe. Therefore, the following evaluation criteria

for identification of installation are to be considered

compliant with standards.

For complex or articulated installations, we

recommend you contact specialized personnel or

authorized service centres.

The company does not recommend other types of

installation, where smoke is not discharged into a flue

pipe, and will not be held liable for any malfunctions

or anomalies.

Do not touch the stove during the first lighting, as it is

during this phase that the paint sets. If you touch the

paint, you may expose the steel surface.

If necessary, touch up the paint with the aerosol spray in

the original colour (see the section "Accessories for pellet

stoves").

It is good practice to provide plenty of ventilation in the

room during the initial lighting, as the stove will give off a

small amount of smoke and smell of paint.

Do not stay near the stove, and as previously mentioned,

ventilate the room. The smoke and the smell of paint will

vanish after about one hour of operation. There are no

health risks involved.

Make sure the plumbing system is sealed perfectly and

that there are no leaks or pressure drops.

Make sure that all cut-off valves between the stove and

the system are open.

Make sure you have vented all air out of the system

before start-up.

Make sure that internal devices work properly (flow

switches, thermostats, etc.). Make sure that the

combustion chamber and the flue pipe are clean, and that

the plumbing circuit is free of obstructions.

The stove will be subject to expansion and

contraction during the stages of lighting and cooling

down, and may therefore make slight creaking noises.

This phenomenon is absolutely normal, the structure

being made of sheet steel, and must not be

considered a defect but rather a characteristics.

The basic settings ensure proper operation and

prevent overheating during the first ignitions.

Page 29

red

PELLET STOVES Chapter 4

INSTALLATION AND USE MANUAL

page

29

Operation Technical service - Rights reserved - Reproduction prohibited

4.2. PRE-LIGHTING CHECK

Check that all the safety conditions described above have been met.

Make sure you have read and completely understood the contents of

this instruction booklet.

Remove all components from the firebox of the stove

and from the door. They may catch fire otherwise. This

includes the instruction booklet and various stickers.

Check that the grate for pellet combustion is correctly positioned, rests

properly on the base, and that it has not moved during handling of the

product.

Check that the electrical connection is correct (230 V 50 Hz), and turn

on the main switch located on the rear panel of the stove.

Check that on the control panel the display is lit up with the message

OFF / "CURRENT TIME".

4.3. LOADING THE PELLETS

Fuel is loaded from the upper part of the stove by opening a door. Pour

the pellets in the hopper. When empty, it will hold about two 15-kg

sacks.

This is easier if performed in two steps:

Pour half of the contents into the hopper and wait for the fuel

to settle on the bottom.

Then pour in the rest

Never remove the protective grille from inside the

hopper. When loading pellets, keep the bag from

coming into contact with hot surfaces.

4.4. CONTROL PANEL

INDEX OF BUTTONS AND INDICATOR LIGHTS

BUTTONS

1. Decrease set temperature / programming functions

2. Increase set temperature / programming functions

3. Scrolling of programming menu to increase/variation of speed

ventilation to increase

4. Scrolling of programming menu to decrease/diagnostics of smoke fan

ventilation to decrease

5. Stove lighting / shutdown

6. Set temperature of air and water thermostats / access programming menus

INDICATOR LIGHTS

7. General alarm (see specification)

8. Display D1-D2

9. Timer active/inactive indicator light

10. Indicator light that indicates when the thermostat calls for power

11. Water pump active/inactive indicator light

12. Heating system active indicator light

13. Domestic water system active indicator light

14. Heat exchanger in operation indicator light

15. Feed screw active/ inactive indicator light

16. NOT ACTIVE

17. Ignition plug in operation indicator light

SET

TURBO

1

2

64

3

5

!

Page 30

red

PELLET STOVES Chapter 4

INSTALLATION AND USE MANUAL

page

30

Operation Technical service - Rights reserved - Reproduction prohibited

SET

TURBO

1264

3

5

!

16

:

Ut 02

SET

TURBO

1264

3

5

!

:

10

Ut 03

SET

TURBO

1264

3

5

!

- - - -

set

SET

TURBO

1264

3

5

!

+ 3

set

set

+ 3

4.5. SETTINGS TO CARRY OUT BEFORE FIRST

LIGHTING

Set the main switch on the rear of the stove to position (I).

The display (8) of the control panel will show the message OFF and the

CURRENT TIME.

If the time shown is not correct, it can be reset by the procedure

described below.

You should keep in mind that the current time is only

needed when you carry out weekly programming

using the TIMER (see corresponding chapter). If the

time is not set correctly, this does not in any way

affect stove operation.

4.5.1. SETTING CURRENT TIME

In rapid sequence, press the buttons and to access technical

parameter

UT01

. If you again press the button , you will access item

UT02, which shows the hours. Use the buttons

or to decrease or

increase the hours.

To confirm the hour selected and move on to selection of the minute,

press key

. (you will see the item

UT03

)

Use keys

or to decrease/increase the minute (steps of 1 minute).

To confirm the set time and exit, press

4.5.2. Memorization of recipe on stove.

THE PROCEDURE FOR SELECTING THE RECIPE IS

ACTIVE ONLY WHEN THE STOVE IS NOT LIT.

Press in rapid succession, or simultaneously, the buttons and .

“SET” will appear on the display, alternatingly with the recipe number.

The recipes are +3;+2;+1;0;-1;-2;-3.

Alternatively, if the display shows the message "- - - -", it indicates that

no recipe is currently selected (first lighting).

To exit from the menu without making changes, press key

or key

, or wait 120 seconds without pressing a key.

To modify or set a new recipe, press the buttons

or in order to

find the desired recipe according.

To confirm the selection you have made, you must

press the button

until the display once again

shows the time and the message “OFF”.

The default recipe for the stove is 0, for all versions

and for all countries.

SET

TURBO

1

2

64

3

5

!

day 1

Ut 01

Phase 2: To choose the desired recipe, press

the indicated button

First access to recipe selection menu

Phase 1: Example of access to recipe menu

and display of previous setting

Page 31

red

PELLET STOVES Chapter 4

INSTALLATION AND USE MANUAL

page

31

Operation Technical service - Rights reserved - Reproduction prohibited

SET

TURBO

1

2

64

3

5

!

on

4.6. CONTROL OF WATER TEMPERATURE IN

BOILER

The stove is already set with a series of standard parameters that allow

it to operate properly (water temperature 65°C and ambient

temperature 22°C). However, the user can change these parameters in

the following way:

The following parameters can be set:

T Ambient This is the temperature that you want to attain in the

room where the stove is installed. To adjust it, press

ONCE on the button

“SET” and change the

values using the buttons

or

T H

2

O = Maximum temperature of water in boiler. Upon reaching

this temperature, the stove will reduce its performance to

prevent overheating. The default temperature is 65°C

and it can not be set below 40°C or over 80°C.

To adjust it, press TWICE in rapid succession on the

button

“SET” and change the values using the

buttons

or

It is not advisable to set the temperature below

50/55°C so as to prevent the formation of

condensation in the boiler

4.7. FIRST LIGHTING

You are now ready to light your stove.

The following is a brief description of how to light and extinguish your

stove to satisfy your curiosity and expectations.

4.7.1. Lighting the stove

To light the stove from the panel, press the button for a few

seconds.

After about 15 minutes, the display (8) will show the ambient

temperature on the upper display and the water temperature

in the boiler on the lower display. The stove is now LIT.

If you have completed the lighting phase and there is no flame (the

stove is not lit), the display (8) will show the message “Alarm no

ignition” accompanied by an intermittent sound alarm. In this case,

turn the stove off by pressing for a few seconds on the button

.

The display (8) will show the message “Off / current time".

Check the grate. Are there pellets?

If this is the first lighting, the fuel which has to

travel from the hopper to the grate is not arriving in

time or in the properly programmed amount. In this

case the grate will either be empty or will contain

very few pellets.

REMOVE ANY PELLETS FROM THE BURNER AND

REPEAT IGNITION BY PRESSING FOR A FEW

SECONDS ON THE BUTTON

.

System pressure temperature setting

Setting of ambient temperature

SET

TURBO

1

2

64

3

5

!

18°C

43°C

SET

TURBO

1264

3

5

!

AM B

22°C

SET

TURBO

1264

3

5

!

H2O

70°C

Stove on and working at full power

Page 32

red

PELLET STOVES Chapter 4

INSTALLATION AND USE MANUAL

page

32

Operation Technical service - Rights reserved - Reproduction prohibited

SET

TURBO

1264

3

5

!

OFF

20 41

:

After repeated ignitions, if no flame appears even though there is a

correct supply of pellets, there may be a problem with the components

of the stove or installation may not be correct.

REMOVE THE PELLETS FROM THE BURNER AND

CONTACT AN AUTHORISED TECHNICIAN.

4.7.2. Extinguishing the stove

The stove can be extinguished at any time and in any position.

To extinguish the stove, press the key

for several seconds.

NEVER SHUT THE STOVE DOWN BY CUTTING OFF THE

ELECTRICITY SUPPLY: Always let it complete the

shutdown cycle, otherwise damage could be caused

to the structure, and also problems with lighting in

the future.

4.8. VIEW OF THE FLAMES

In order to get proper operation from the stove, you need to be able to

interpret the appearance of the flame. Characteristics which the user

should take into consideration are basically the following:

The shape

The colour

The character

4.8.1. The shape

In normal combustion the flame should have a tapered shape, a

lively character, with the tips of the flames basically vertical or pushed

towards the back of the firebox. You should get the impression that the

flame is being drawn upwards.

Conversely, a flame which swells outwards at the base, with a thin

character, with a point that appears to wander, could be a symptom of

bad setting as regards loading of the fuel and/or extraction of the

fumes, or could indicate that the flue is obstructed or that there are

down-draughts which impede the proper evacuation of the smoke.

In this case there will ALWAYS be operating problems. Request

assistance from specialized personnel or advice from technicians.

Page 33

red

PELLET STOVES Chapter 4

INSTALLATION AND USE MANUAL

page

33

Operation Technical service - Rights reserved - Reproduction prohibited

4.8.2. The colour

The colour is in some ways linked to the shape of the flame. A colour

which varies from orange to yellow, with dark tips to the flame, is liable

to be a swollen flame (as described above), lacking in oxygen or at

least indicative of faulty combustion. As the colour changes towards

light yellow - white, the shape of the flame alters, becoming thinner

and showing the presence of higher levels of oxygen.

4.8.3. The character

Liveliness or weakness is in any case closely connected to the shape of

the flame.

4.9. OPERATION

4.9.1. Operating concept

When you light the stove using the button , after the initial ignition

phase of about 15 minutes, during which the display (8) shows the

intermediate phases “FAN ACC – LOAD WOOD – FIRE ON“, the stove

will start running in AUTOMATIC mode at medium power, and it will

make a first check of the temperature to be reached.

The ambient temperature is shown on the upper display (8) of the

panel, whereas the temperature of the water in the boiler is indicated

on the lower one alternating with the message H

2

O

In this operating mode, you can vary only the desired room

temperature using the buttons

and .

The main purpose of the stove is to bring the room

temperature as measured by the thermostat (internal or

external) up to the temperature set by the user.

Then, based on the room temperature, it performs the

following evaluation:

Room temperature < Thermostat temperature ?

YES

This means that the stove must heat the room. Therefore, it will

begin gradually raising its flame power until it is at its maximum.

NO

This means that the stove has achieved its objective in heating the

room. Therefore, it will decrease its power to a minimum, and it

will leave it there until the room temperature again drops below

the temperature set in the thermostat, unless the ECO-STO

function is enabled (see paragraph 4.9.3)

For proper operation, it is indispensable for the room

thermostat (internal or external) to measure the

temperature reliably, since the correct operation is

based almost exclusively on the aforementioned

control.

INCORRECT COMBUSTION

Shape:

swollen, overflowing, not compact

Character:

Weak - feeble

Colour:

Orange - yellow

Adjustment of thermostat temperature (temperature to

be reached in the room)

SET

TURBO

1264

3

5

!

SET

22°C

SET

TURBO

1

2

64

3

5

!

18°C

43°C

Stove on and working at full power

NORMAL COMBUSTION

Shape:

Tapered, vertical, compact

Character:

Lively

Colour:

Yellow - Light yellow - White

Page 34

red

PELLET STOVES Chapter 4

INSTALLATION AND USE MANUAL

page

34

Operation Technical service - Rights reserved - Reproduction prohibited

SET

TURBO

1

2

64

3

5

!

Al ar

4.9.2. Operating modes

The AUTOMATIC mode lets you set a certain temperature to be

reached. In this operating mode the stove will automatically vary the

thermal power provided so as to keep the temperature in the room

constantly at the previously set value.

As previously described, the temperature is adjusted using the buttons

and , in steps of 1 degree centigrade.

Also front ventilation, which is active in automatic mode only when the

stove is hot, is divided into 5 speeds. It can be controlled using the

buttons

and . The speed of the fan will be shown for a few

seconds on the display (8).

This setting will be maintained at the next lighting.

Operating example:

If the ambient temperature measured by the local probe on the stove is

15°C, and the temperature set on the thermostat is 22°C, the stove will

sequentially go to maximum power. Upon reaching the requested fixed

temperature (22°C), the stove will go back to minimum power or it will

enter ECO-STOP mode

(See paragraph 4.9.3)

It must be remembered however that the temperature keyed into the

thermostat is only indicative, and it is up to the user to find the correct

setting in the location where the stove is installed (for example, to

achieve 22°C in the room, it may be necessary to set the thermostat on

the stove to 20°C). This is because the ambient thermostat is located

near the body of the stove; therefore, it detects the heat radiated from

the stove.

In this mode, lighting and shutdown are performed by the user, by

pressing button

for a few seconds.