Page 1

INSTALLATION GUIDE GB

Translation of the original instructions

PELLET BOILER

LOGIKA 25-35

LOGIKA 25-35 REFILL

PART 1 - ASSEMBLY

Page 2

II

TABLE OF CONTENTS

TABLE OF CONTENTS ...................................................................................... II

INTRODUCTION ............................................................................................. 1

1WARNINGS AND WARRANTY CONDITIONS ...................................................... 2

2INSTALLATION INSTRUCTIONS ..................................................................... 6

3DRAWINGS AND TECHNICAL CHARACTERISTICS .............................................14

4 UNPACKING ............................................................................................18

5 POSITIONING ..........................................................................................22

6 INSTALLATION AND ASSEMBLY OF BOILER ...................................................24

7 INSTALLATION AND ASSEMBLY OF TANK ......................................................46

8 ASSEMBLY OF BOILER AESTHETICS UNIT .....................................................58

9 ASSEMBLY OF TROLLEY .............................................................................63

10 ASSEMBLY OF AESTHETICS UNIT OF REFILL TANK ........................................65

11 ASSEMBLY OF AESTHETICS UNIT OF MANUAL TANK .....................................71

Page 3

1

INTRODUCTION

Technical Dept. - All rights reserved - Reproduction is prohibited

Dear Customer,

Thank you for having chosen our product.

In order to make the most of this product and ensure its maximum eciency, you are advised to read this manual carefully

before initial use.

REVISIONS TO THE PUBLICATION

The content of this manual is strictly technical and the property of MCZ Group Spa.

No part of this manual can be translated into another language and/or altered and/or reproduced, even partially, in another form, by

mechanical or electronic means, photocopied, recorded or similar, without prior written approval from MCZ Group Spa.

The company reserves the right to make changes to the product at any time without prior notice. The proprietary company reserves its

rights according to the law.

CARE OF THE MANUAL AND HOW TO CONSULT IT

• Take care of this manual and keep it in an easily accessible place.

• Should the manual be misplaced or ruined, request a copy from your retailer or directly from the authorised Technical Assistance

Department.

• The "text in bold" must be read with particular care.

• The "text in italics" draws attention to other sections in this manual or clarications.

• “NOTE” provides the reader with additional information.

SYMBOLS USED IN THE MANUAL

ATTENTION:

Read the relative message with care because failure to observe the information provided could result in

serious damage to the product and danger to the persons who use it.

INFORMATION:

failure to comply with these provisions will compromise the use of the product.

OPERATING SEQUENCES:

sequence of buttons to be pressed to access the menus or make adjustments.

MANUAL

carefully read this manual or the relative instructions.

Page 4

2

1-WARNINGS AND WARRANTY CONDITIONS

SAFETY PRECAUTIONS

• Installation, electrical connection, functional verication and maintenance must only be performed by qualied or

authorised personnel.

• Install the product in accordance with all the local and national laws and Standards applicable in the relative place,

region or country.

• This product is not intended for use by persons (including children) with reduced physical, sensory or mental

capabilities, or lack of experience and knowledge, unless they are supervised or trained on how to use the product by

a person responsible for their safety.

• Use only the type of fuel recommended by the rm. The product must not be used as an incinerator. It is strictly forbidden to use

liquid fuel.

• The instructions provided in this manual must always be complied with to ensure the product and any electronic appliances

connected to it are used correctly and accidents are prevented.

• The user, or whoever is operating the product, must read and fully understand the contents of this installation guide before

performing any operation. Errors or incorrect settings can cause hazardous conditions and/or poor operation.

• Do not put linen on the product to dry. Any clothes horses or similar objects must be kept at a safe distance from the product. Fire

hazard.

• All liability for improper use of the product is entirely borne by the user and relieves the Manufacturer from any civil and criminal

liability.

• Any type of tampering or unauthorised replacement with non-original spare parts could be hazardous for the operator's safety and

relieves the company from any civil and criminal liability.

• Most of the surfaces of the product can become extremely hot (the door, handle, ue pipes, etc.). Avoid touching these parts

without appropriate protective clothing or devices like heat insulated gloves.

• It is forbidden to use the product with its door open.

• The product must be powered by a system that is equipped with an eective earth system.

• Switch the product o in the event of a fault or malfunctioning.

• Do not wash the product with water. The water could get inside the unit and damage the electrical insulation and cause electric

shocks.

• Do not put any fuel other than wood pellets in the hopper.

• Install the product in rooms that are adequately protected against re and equipped with all the utilities such as supplies (air and

electricity) and smoke outlets.

• In the event of re in the chimney, turn o the device, disconnect it from the mains and do not open the hatch. Then contact the

competent authorities.

• It is recommended not to remove the feet that support the product in order to guarantee adequate insulation, especially if the

ooring is made of ammable material.

• If the ignition system is faulty, do not force ignition with ammable materials.

• Special maintenance must only be performed by authorised and qualied personnel.

• Assess the static conditions of the surface on which the weight of the product will rest and provide suitable insulation if it is made of

ammable material (e.g. wood, tted carpet or plastic).

Page 5

3

1-WARNINGS AND WARRANTY CONDITIONS

Technical Dept. - All rights reserved - Reproduction is prohibited

INFORMATION:

Please contact the retailer or qualied personnel authorised by the company to resolve a problem.

• only fuel stipulated by the company must be used.

• Check and clean the smoke outlet pipes regularly (connection to the chimney).

• Always keep the cover of the fuel hopper closed.

• Keep this instruction manual in a safe place, as it should accompany the stove along its entire life cycle. If it is sold or transferred to

another user, always make sure that the manual accompanies the product.

INTENDED USE

The product only works with wood pellets and must be installed indoors.

WARRANTY CONDITIONS

The rm guarantees the product, with the exception of parts subject to normal wear specied below, for two years from the date

of purchase, provided that proof of purchase is supplied in a document specifying the name of the retailer and the date the sale was made

and that the completed guarantee certicate was sent within 8 days of said purchase. The product must also be installed and tested by

a specialised tter and in accordance with the detailed instructions provided in the instruction manual that accompanies the product.

The guarantee covers the replacement or free repair of parts recognised as being faulty at source due to manufacturing defects.

RESTRICTIONS

The guarantee does not cover parts subject to normal wear such as gaskets, glass, and any parts with can be removed from the rebox.

Replaced parts will be covered by the warranty for the remaining period of the warranty in force as from the date of purchase of the

product.

EXCLUSIONS

The warranty does not cover any par t that may be faulty as a result of negligence or careless use, incorrect maintenance or installation that

does not comply with the company's instructions (see the relative chapters in this user manual).

The company declines all liability for any damage which may be caused, directly or indirectly, to persons, animals or objects as

a consequence of non compliance with all the prescriptions specied in the manual, especially warnings regarding installation,

use and maintenance of the appliance.

If the product does not work correctly, contact your local retailer and/or importer.

Damage caused during transport and/or when handled is excluded from the warranty.

The supplied installation guide is the only reference for installation and product use.

The warranty will be rendered null and void in the event of damage caused by tampering, atmospheric agents, natural disasters, electrical

discharges, re, defects in the electrical system, and maintenance not being performed at all or as indicated by the manufacturer.

Page 6

4

1-WARNINGS AND WARRANTY CONDITIONS

INTERVENTION REQUEST

The company declines all liability if the product and any other accessory is used incorrectly or altered without

authorisation.

All parts must be replaced with original spare parts.

The request must be sent to the retailer who will forward it to the Technical Assistance Department.

SPARE PARTS

Use only original spare parts. The retailer or service centre can provide all the useful information regarding spare parts.

It is recommended not to wait for the parts to be worn before having them replaced. It is important to perform regular maintenance.

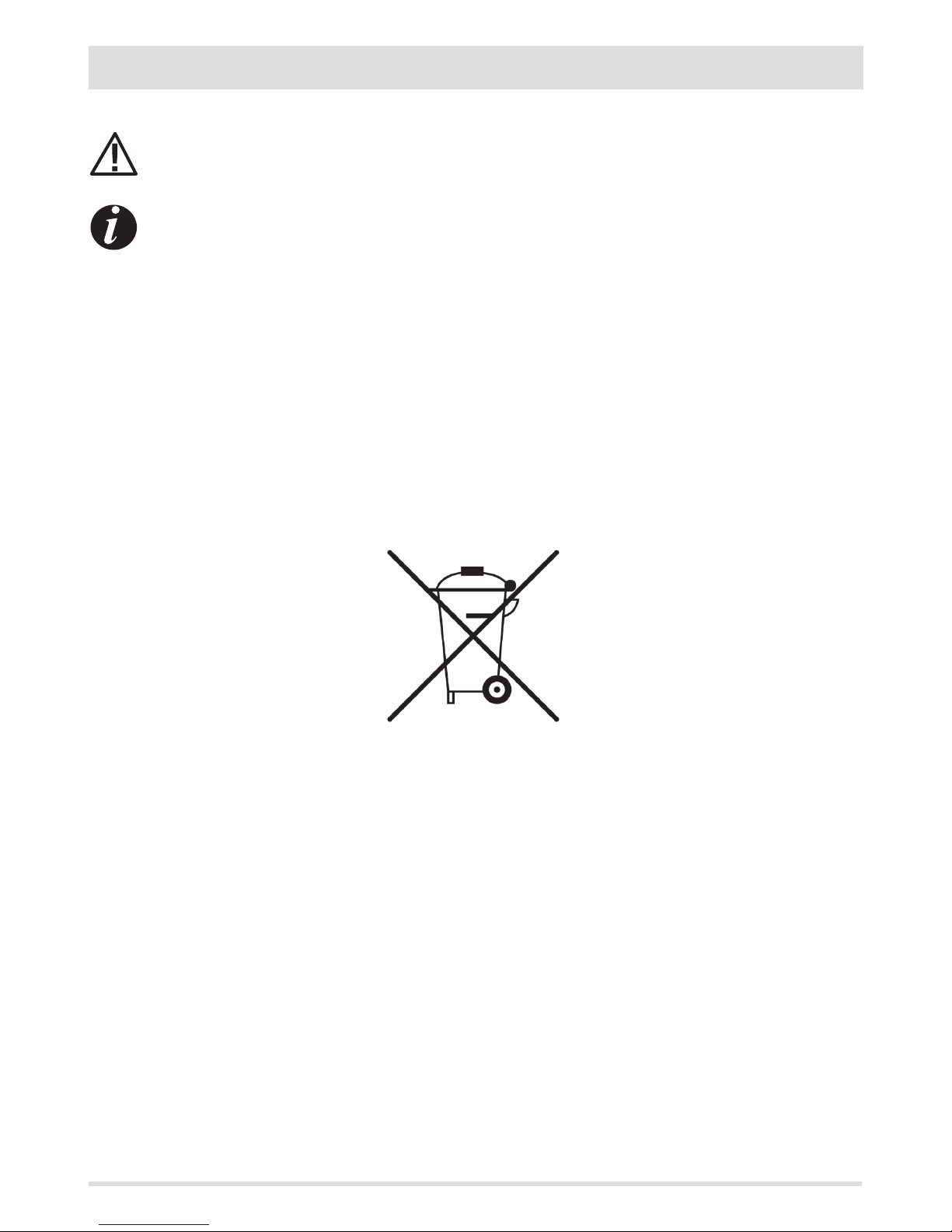

PRECAUTIONS FOR CORRECT DISPOSAL OF THE PRODUCT IN ACCORDANCE WITH THE EUROPEAN DIRECTIVE

2002/96/EC AND ITS SUBSEQUENT AMENDMENT 2003/108 EC.

At the end of its working life, the product must not be disposed of as urban waste.

It must be taken to a special dierentiated waste collection centre set up by the local authorities or to a retailer that provides this service.

Disposing of the product separately prevents possible negative consequences for the environment and health deriving from inappropriate

disposal and allows its materials to be recovered in order to obtain signicant savings in energy and resources.

As a reminder of the need to dispose of appliances separately, the product is marked with a crossed-out wheeled dustbin.

Page 7

5

1-WARNINGS AND WARRANTY CONDITIONS

Technical Dept. - All rights reserved - Reproduction is prohibited

RULES ON INSTALLATION

The product is a boiler that uses wood pellets.

It must be installed as per the following standards:

Legislative Decree no. 93 of 25 February 2000

Implementation of Directive 97/23/EC (PED) on pressure equipment.

FIELD OF APPLICATION: devices that use liquid fuels (naphtha, gas oil, fuel oil) and solids.

LAW NR. 46 of 5 March 1990 and relative applicable regulations, Presidential Decree 447 of 6 December 1991 (and subsequent

amendments) and M.D. 37 of 22 January 2008.

Rules on safety of the systems.

FIELD OF APPLICATION: with unlimited heat capacity.

Standard UNI 10847 of 03/2000.

Single ue systems for generators that use solid and liquid fuel. Maintenance and checks. Guidelines and procedures

FIELD OF APPLICATION: systems that use solid and liquid fuel.

LAW NR. 10 of 09 January 1991 and relative applicable regulations, Presidential Decree 412 of 26 August 1993 (and subsequent

amendments), Presidential Decree 551 of 21 December 1999.

Regulation implementing amendments to Presidential Decree 412 on the design, installation, use and maintenance of technical systems

of buildings for containing energy consumption.

FIELD OF APPLICATION: with unlimited heat capacity.

LAW 186 of 01.03.1968

Installation standard IEC 6408 / II ed.

Electrical systems with rated voltage not exceeding 1000 V AC and 1500 V DC.

Installation standard IEC 64-8 / I ed.

Electrical systems for residential buildings and similar.

Standard UNI 10683 of 09/2005.

Systems fuelled by wood or other solid biofuel.

Installation requirements.

FIELD OF APPLICATION: Systems fuelled by wood or other solid biofuel with heat output of the rebox of less than 35 kW.

Installation must be carried out with reference to the diagram of the heating system prepared in accordance with the

standards and local recommendations in force:

• For the heating system - EN 303-5 (September 2012) - Part 5: Heating boilers for solid fuels, manually and automatically stoked,

nominal heat output of up to 500 kW - Terminology, requirements, testing and marking

• Local requirements for connection to the chimney.

• Local requirements for re-ghting standards.

• For electrical parts - EN 60335 "Safety of electrical household appliances and similar"

Part 1 - General requirements

Part 2 - Particular standards for appliances with gas, gas oil and solid fuel burners without electrical connections.

Page 8

6

2-INSTALLATION INSTRUCTIONS

The requirements in this section relate to the provisions of the Italian standard of installation UNI 10683. In any case, always observe the

domestic rules in force.

PELLETS

Wood pellets are manufactured by hot-extruding compressed sawdust which is produced during the working of natural dried wood. The

compactness of the material is guaranteed by the lignin contained in the wood itself and allows pellets to be produced without glue or

binders.

The market oers dierent types of pellets with characteristics that vary according to the wood mixtures used. The diameter varies

between 6 and 8 mm, with a standard length ranging from 5 to 30 mm. A good quality pellet has a density of between 600 and 750 or

more kg/metres cubed and a water content that accounts for 5 to 8% of its weight.

Pellets have technical advantages besides being an ecological fuel, as the wood residue is used completely, thereby achieving cleaner

combustion than that of fossil fuels.

Good-quality wood has a caloric value of 4.4 kW/kg (15% moisture, after about 18 months of seasoning), whereas that of pellets is 4.9

kW/kg. To ensure good combustion, the pellets must be stored in a dry place and protected from dirt. Pellets are usually supplied in 15 kg

bags, therefore, storing them is very convenient.

Good quality pellets guarantee good combustion, thereby decreasing harmful emissions into the atmosphere.

The poorer the quality of the fuel, the more often the internal parts of the brazier and combustion chamber must

be cleaned.

The main certications of quality for pellets in the European market are DINplus, Ö-Norm M7135, Pellet gold; these ensure respect of:

• caloric value: 4.9 kWh/kg.

• Water content: max 10% of the weight.

• Percentage of ash: max 0.5% of the weight.

• Diameter: 5 – 6 mm.

• Length: max 30 mm.

• Content: 100% untreated wood without the addition of binding substances (max 5% bark).

• Packaging: in sacks made from ecologically compatible or biologically decomposing material.

The company strongly recommends using certied fuel for its products (DINplus, Ö-Norm M7135 or Pellet Gold).

Poor quality pellets or others that do not comply with that specied previously compromises the operation of your

product and can therefore render the warranty and product liability null and void.

15 Kg BAGS OF FUEL

Page 9

7

2-INSTALLATION INSTRUCTIONS

Technical Dept. - All rights reserved - Reproduction is prohibited

PRECAUTIONS REGARDING INSTALLATION

IMPORTANT!

Product installation and assembly must be carried out by qualied personnel.

The product must be installed in a suitable place for it to be regularly opened and routine maintenance to be performed.

The site must be:

• compliant for proper operation.

• Equipped with an adequate smoke expulsion system.

• Equipped with ventilation intake from outside.

• Equipped with 230V 50 Hz power supply with an EC compliant earth system.

The product must be connected to a chimney or vertical duct, either inside or outside, that conforms to the standards in

force. The product must be positioned in such a way that the electrical socket is accessible.

IMPORTANT!

The product must be connected to a chimney or a vertical duct that can expel the smoke at the highest point of the

building.

The fumes are however derived from the combustion of wood products, and if they come into contact with or close

to walls, they can make dirty marks. Moreover, utmost attention is required as they are almost invisible but very hot

and can cause burns. The holes of the external air inlet and the smoke outlet pipe must be drilled before positioning

the product.

THE OPERATING ENVIRONMENT

For correct operation and even distribution of heat, the product must be placed where the air required for combustion can ow.

The volume of the room should be no less than 15 m3

These openings (air inlets) must be made in such a way that it is impossible for them to be obstructed in any way.

The air can also be taken from rooms adjacent to the one which needs ventilating, as long as they are provided with an air intake from the

outside, and are not used as bedrooms or bathrooms, and provided there is no re risk such as there is for example in garages, woodsheds,

and storerooms where inammable material is kept, with reference to what is laid down in current standards.

If the product is placed too close to the wall it could cause overheating and damage the plaster (yellowing, cracking,

etc.).

Page 10

8

2-INSTALLATION INSTRUCTIONS

POSITIONING AND RESTRICTIONS

In the case of simultaneous installation with other heating appliances, provide appropriate air inlets for each one (according to the

instructions of each product).

The product cannot be installed (except for sealed or closed operation appliances with external ducted combustion

air intake):

• in bedrooms or bathrooms;

• in rooms where there are liquid fuel appliances with continuous or intermittent operation that draw the

combustion air from the room they are installed in;

• in rooms where there are B-type gas heating appliances, with or without domestic hot water production and

interconnecting rooms;

• where another heating appliance is installed without an independent air ow.

It is forbidden to place the product in an explosive atmosphere.

The air inlet must also:

• be protected with a grid, metal mesh, etc. without reducing the net section.

• Be positioned in such a way so as not to be obstructed.

• Allow maintenance to be performed.

• Be directly interconnected with the room where the product is installed.

• In the case of ducting, up to 3.5 linear metres, increase the cross-section by about 5%, whereas for longer ducts, increase it by 15%.

Remember that the ventilation grilles always feature an indication of the useful cross-section in cm2 on one side.

When choosing the grille and size of the hole, check that the useful section of the grille is larger or equal to the

section required by the company for product operation.

IMPORTANT!

The air ow can also be drawn from an adjacent room to that of the room where the product is installed, provided

the air can ow freely through permanent openings interconnected with the outside; air inlets connected to thermal

units, garages, kitchens or bathrooms must be avoided.

BOILER ROOM

Check that the room meets the requirements and provisions of the standards in force. There must also be a ow of at least enough air in

the room for normal combustion. Vents must be installed in the walls of the room that meet the following requirements:

• Increase the cross-section by at least 6 cm2 for each 1 kW The minimum cross-section of the opening must not, however, measure less

than 100 cm The cross-section can also be calculated using the following equation:

S = K * Q ≥ 100 cm

2

Where “S” is in cm2, “Q” in kW, “K” = 6 cm2/kW

• The opening must be located at the base of an external wall, preferably opposite the one with the outlet for combusted gases.

Heat-sensitive or ammable objects cannot be placed near the product. Keep such objects at a minimum distance of

80 cm from the outermost point of the product.

Page 11

9

2-INSTALLATION INSTRUCTIONS

Technical Dept. - All rights reserved - Reproduction is prohibited

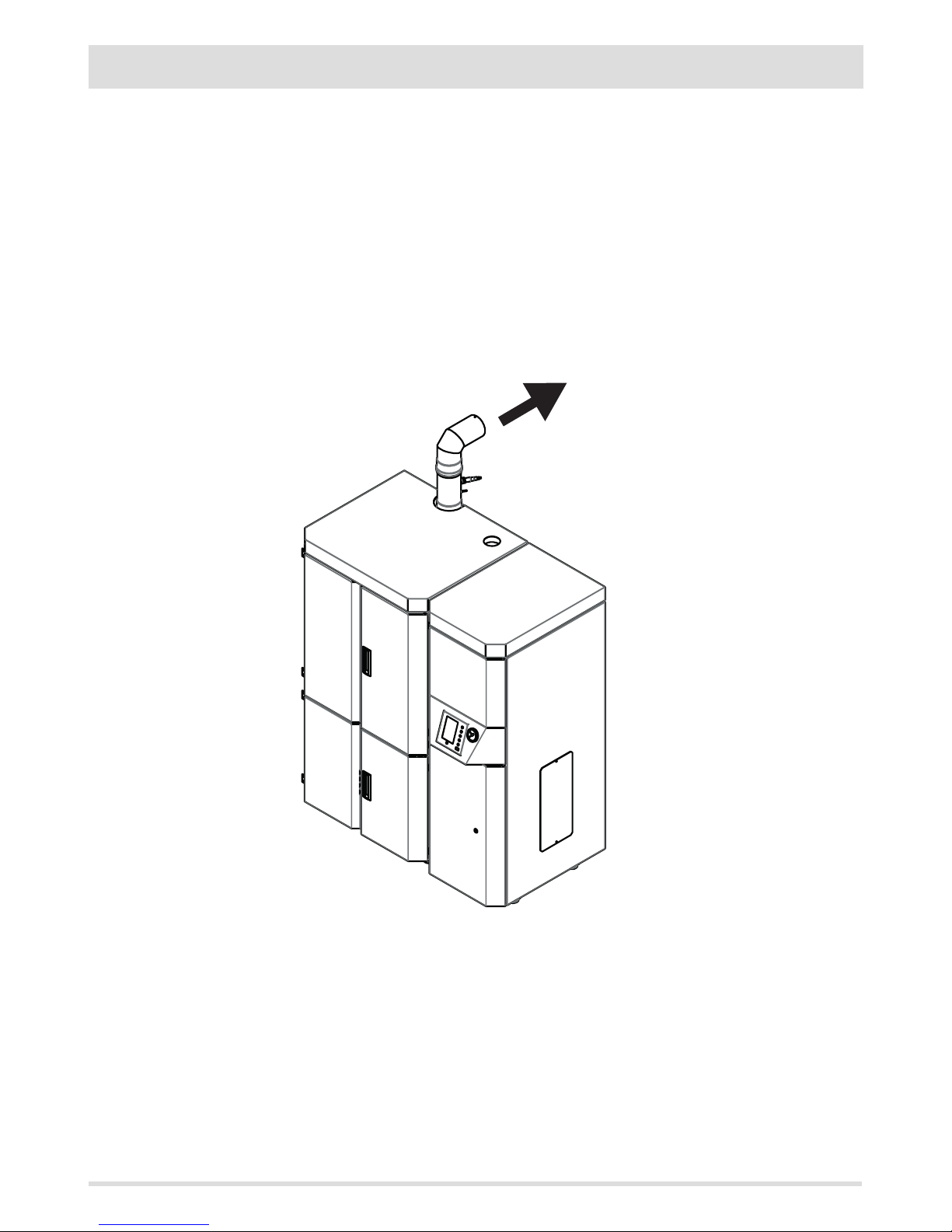

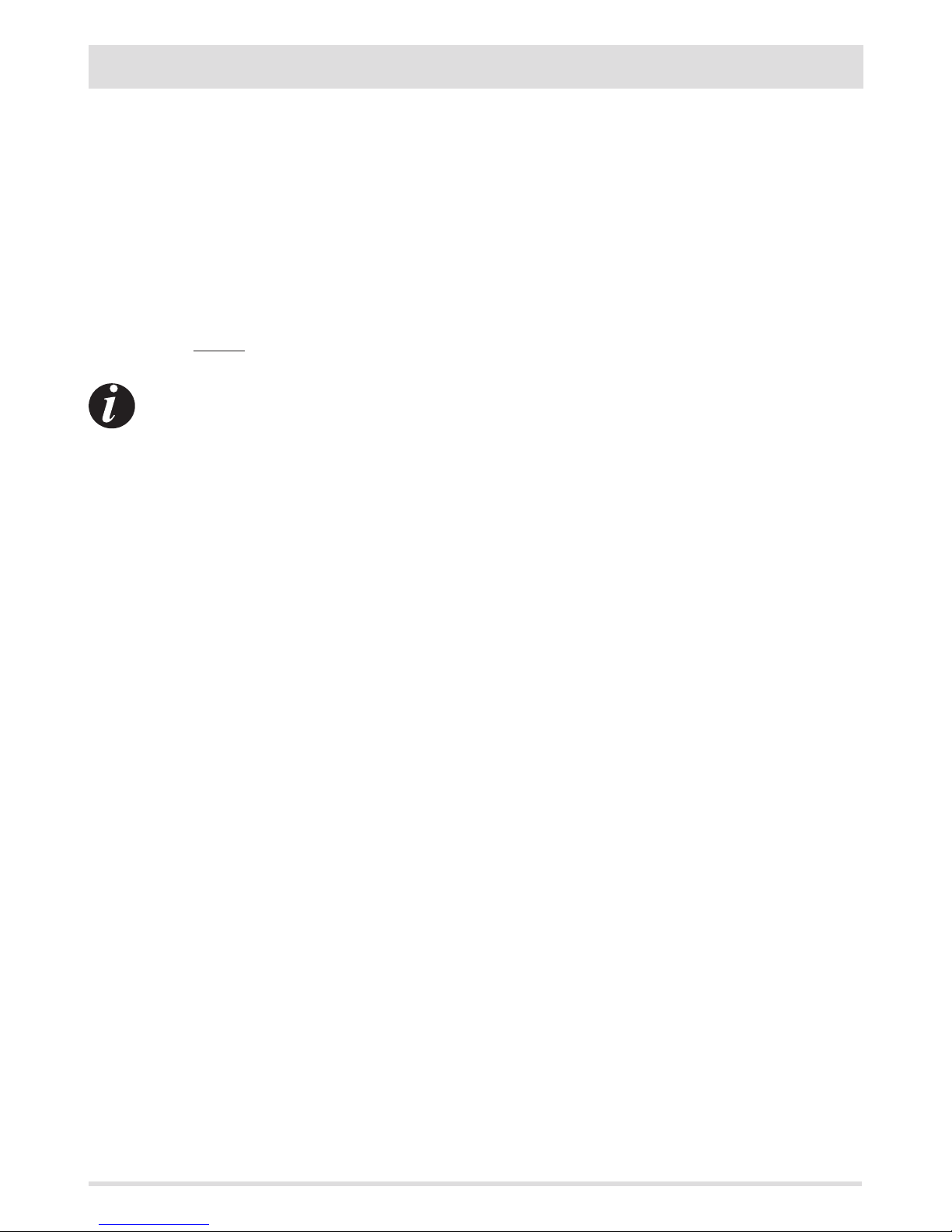

SMOKE OUTLET

CONNECTION OF THE SMOKE EXHAUST DUCT

When making the hole for the passage of the smoke discharge pipe, it is necessary to take into account the possible presence of ammable

materials. If the hole has to be in a wall made of wood or other thermolabile material, THE INSTALLER MUST rst set up the relative wall

tting (diameter 13 cm minimum) and insulate the pipe of the product passes with appropriate insulating material (1.3 - 5 cm thick with

minimum heat conductivity of 0.07 W/m°K).

The same minimum distance must be applied if the pipe of the product must pass through vertical or horizontal sections near the

thermolabile wall.

It is recommended to use an insulated double-wall pipe in external sections in order to prevent condensation from forming.

The combustion chamber works in negative pressure.

Page 12

10

H > 1,7 m

2-INSTALLATION INSTRUCTIONS

EXAMPLE OF PELLET STOVE INSTALLATION

Always use pipes and ttings with appropriate seals that guarantee tightness.

It must be possible to inspect all sections of the ue duct and they must be removable for periodic internal cleaning (T-tting with

inspection hole).

Position the product considering all the above requirements and instructions.

IMPORTANT!

The connection between the appliance and chimney must meet these conditions:

• the smoke duct must be at least category T200 (or higher if required by the smoke temperature of the appliance)

and P1-type (airtight).

• All bends at 90° (max. 3) of the fume outlet duct must, if possible, use T-shaped ttings with inspection points.

(See pellet product accessories).

• It is strictly forbidden to t a mesh at the end of the exhaust pipe as it could cause the product to malfunction

(due to clogging).

• It is forbidden to use counter-sloping pipes.

• The horizontal section of the smoke duct must not be longer than 2-3 m.

• It is also recommended not to exceed 6 metres in length with the pipe Ø 100 mm.

• The smoke duct must not cross rooms in which it is forbidden to install combustion appliances.

Page 13

11

2-INSTALLATION INSTRUCTIONS

Technical Dept. - All rights reserved - Reproduction is prohibited

CONNECTION TO THE CHIMNEY

The chimney is the fundamental element for smoke expulsion and must therefore comply with the following requirements:

• be waterproof and thermally insulated.

• Be made of suitable materials that resist mechanical stress over time, heat, the eects of the combustion products and any possible

condensation.

• Have a vertical set-up with deviations from the axis of no more than 45° and free of bottlenecks.

• Must be suitable for the specic operating conditions of the product and have the CE marking (EN1856-1, EN1443).

• Must be adequately sized for the draught/smoke expulsion requirements that are necessary for the product to operate correctly

(EN13384-1).

• The internal section is preferably circular.

• In the case of a pre-existing product that has been used, it must be cleaned.

• The chimney must not be shared with other appliances.

The chimney is fundamental for correct operation and safety of your product.

Below are certain rules on correct installation. Any alternative congurations must be suitably sized in accordance with the general

method of calculation of UNI EN 13384-1.

Page 14

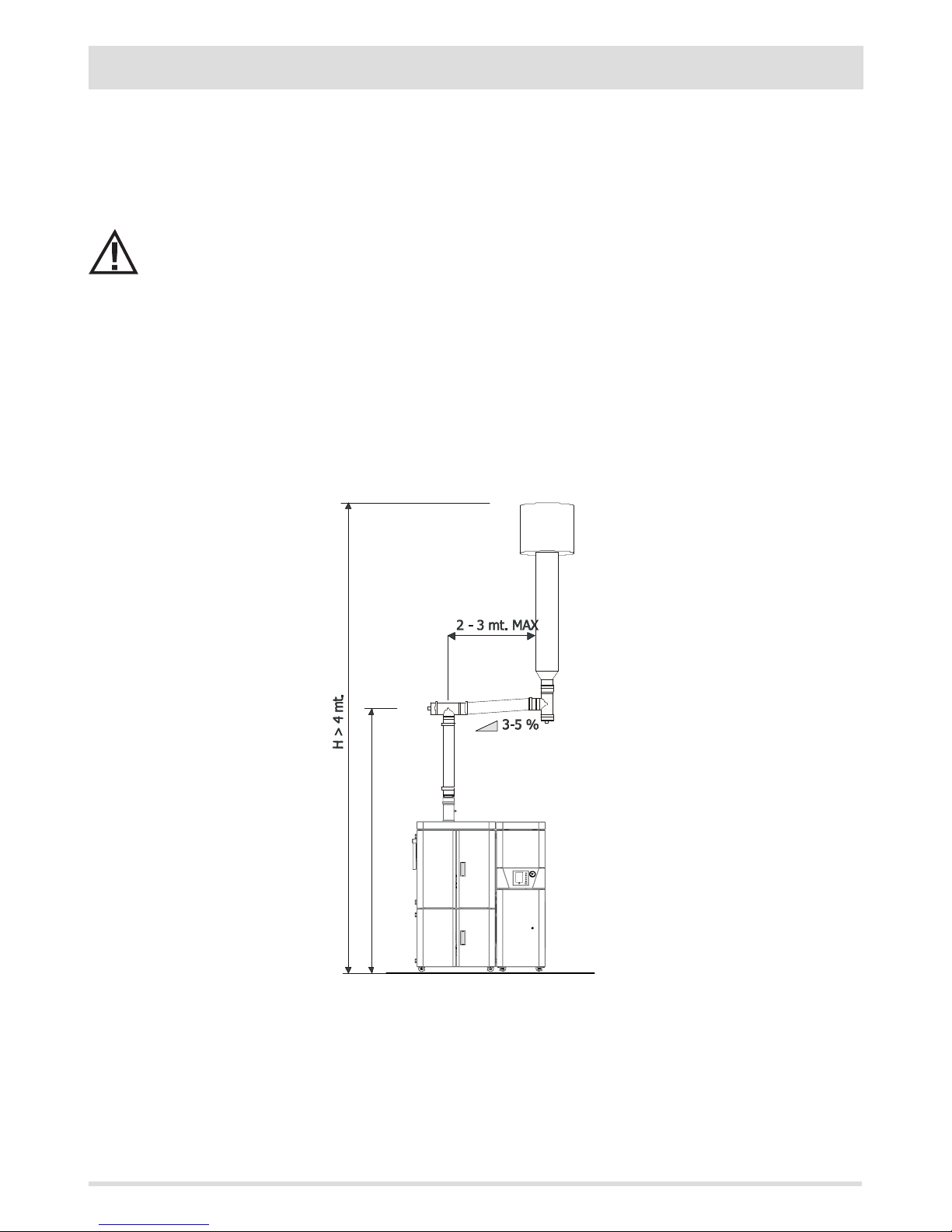

12

3-5 %

2 - 3 mt. MAX

0,5 mt.

H

>

1

,

5

m

t

.

3

2

1

0,5 mt.

2

1

3

3-5 %

2 - 3 mt. MAX

0

,5 mt.

H

>

1

,5

m

t

.

3

2

1

0,5 mt.

1

2

3

0,5 mt.

2

1

3

3-5 %

2 - 3 mt. MAX

0

,5 mt.

H

>

1

,5

m

t

.

3

2

1

2-INSTALLATION INSTRUCTIONS

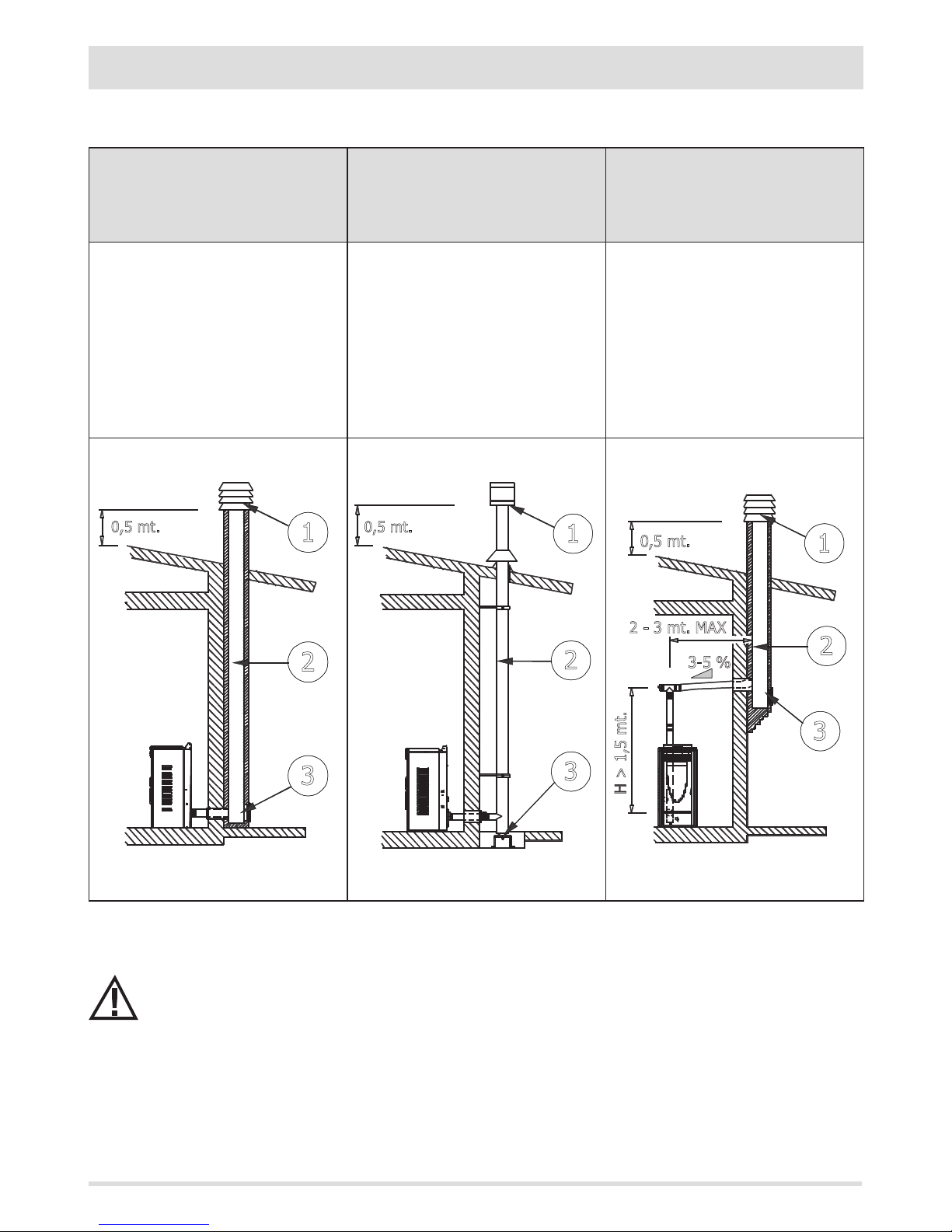

CONNECTIONS

CONNECTION TO THE CHIMNEY CONNECTION TO AN

EXTERNAL DUCT WITH INSULATED OR

DOUBLE-WALL PIPE

CONNECTION TO THE CHIMNEY

The inside of the chimney should measure

no more than 20x20 cm or 20 cm in

diameter; in the case of a larger chimney,

or a chimney in poor condition (e.g. with

cracks, insucient insulation, etc.), it is

advisable to insert a stainless steel pipe of

suitable width that extends from the base

to the very top of the chimney.

The inside of the external duct must

measure a minimum of 15x15 cm, or 15

cm in diameter, and a maximum of 20x20

cm, or 20 cm in diameter.

Only stainless steel insulated (doublewall) pipes must be used, which are

smooth on the inside and xed to the

wall. Flexible stainless steel pipes must

not be used.

The connection between the product and

the chimney or the smoke duct must not

have an inclination that is less than 3% in

the horizontal sections, which must have

a maximum overall length of 2/3 m. The

vertical section between one T-tting and

another (angle) must not be less than

1.5 m.

1) WINDPROOF CHIMNEYPOT 2) CHIMNEY 3) INSPECTION

• Use adequate instruments to verify that there is a minimum draught of 5 Pa.

• Set-up an inspection hole at the bottom of the chimney to perform periodic checks and cleaning, which must

be done annually.

• The connection to the chimney must be sealed and the ttings and pipes recommended by us must be used (CE

marked in accordance with EN1856-2 with the minimum requisites: T200 and P1).

• You must ensure that a windproof chimneypot is installed in accordance with the regulations in force.

• This type of connection guarantees smoke expulsion even in the event of a temporary power cut.

Page 15

13

A B

1

2 3

4

2-INSTALLATION INSTRUCTIONS

Technical Dept. - All rights reserved - Reproduction is prohibited

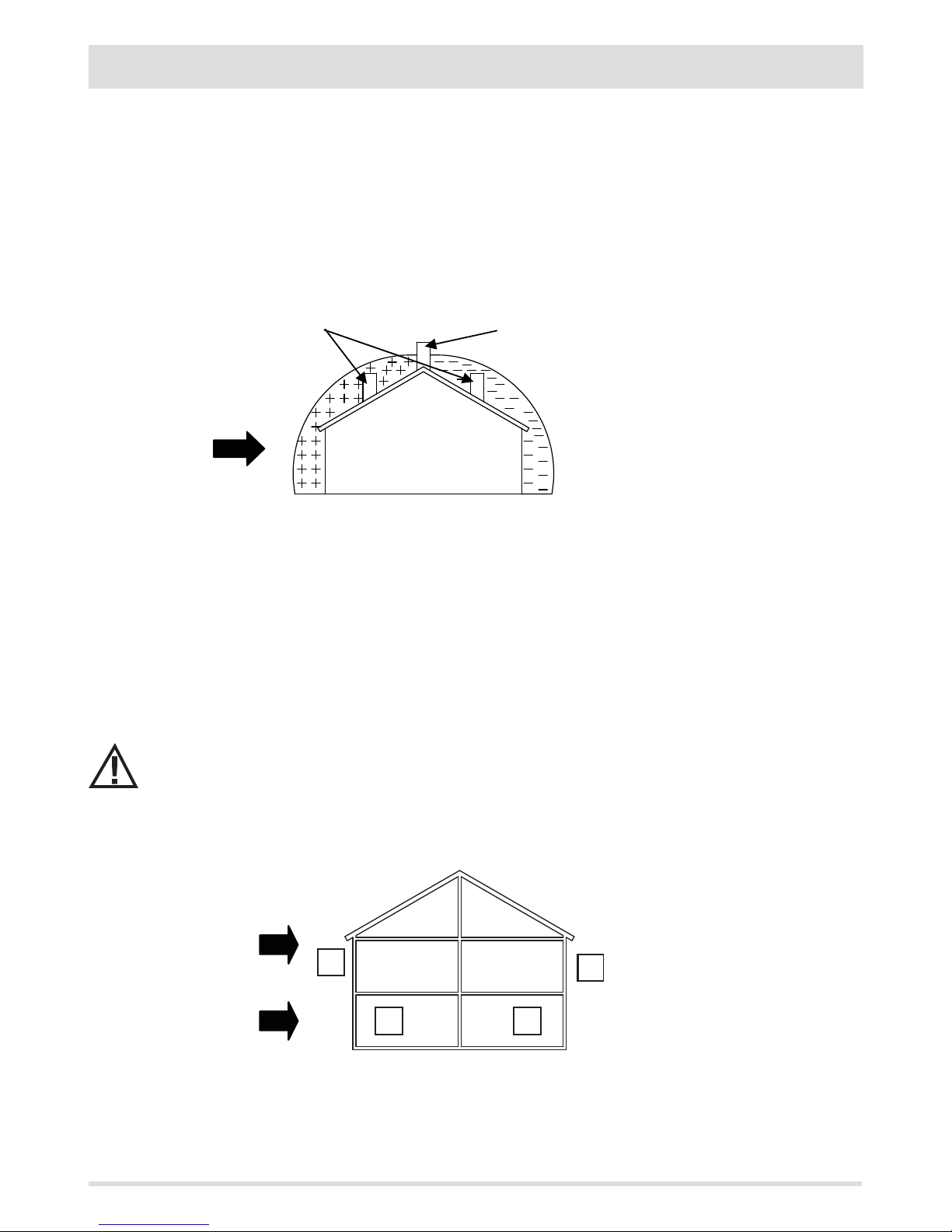

OPERATING PROBLEMS RELATED TO DRAUGHT DEFECTS IN THE CHIMNEY

Of all the weather and geographical conditions which aect the operation of a ue pipe (rain, fog, snow, altitude a.s.l., exposure to

sunlight, direction of facing), the wind is unquestionably the most decisive. In fact, along with thermal depression caused by the dierence

in temperature inside and outside of the chimney, there is another type of depression or over-pressure: dynamic pressure caused by the

wind. An updraft always increases depression and therefore the draught. A horizontal wind increases depression provided the chimneypot

has been installed properly. A downdraft always decreases depression, at times inverting it.

Besides the direction and force of the wind, the position of the chimney and the chimneypot with respect to the roof of the building and

the surrounding landscape is also important.

The wind also inuences the operation of the chimney indirectly by creating high-pressure and low-pressure zones, not only outside the

building but inside as well. An internal overpressure can be created in rooms that are directly exposed to the wind (2), which can enhance

the draught in the boiler, however, it can be counteracted by the external overpressure if the chimneypot is situated on the side exposed to

the wind (1). On the other hand, a dynamic depression can be created in rooms that are opposite the wind direction (3), which competes

with the natural thermal depression generated by the chimney, however, this can be compensated for (sometimes) by placing the smoke

duct opposite the wind direction (4).

IMPORTANT!

The operation of the product is signicantly aected by the ue layout and position.

Hazardous conditions can only be resolved by qualied personnel setting the product appropriately.

A=LESS FAVOURABLE POINTS

B=MOST FAVOURABLE POINT

WIND

Page 16

14

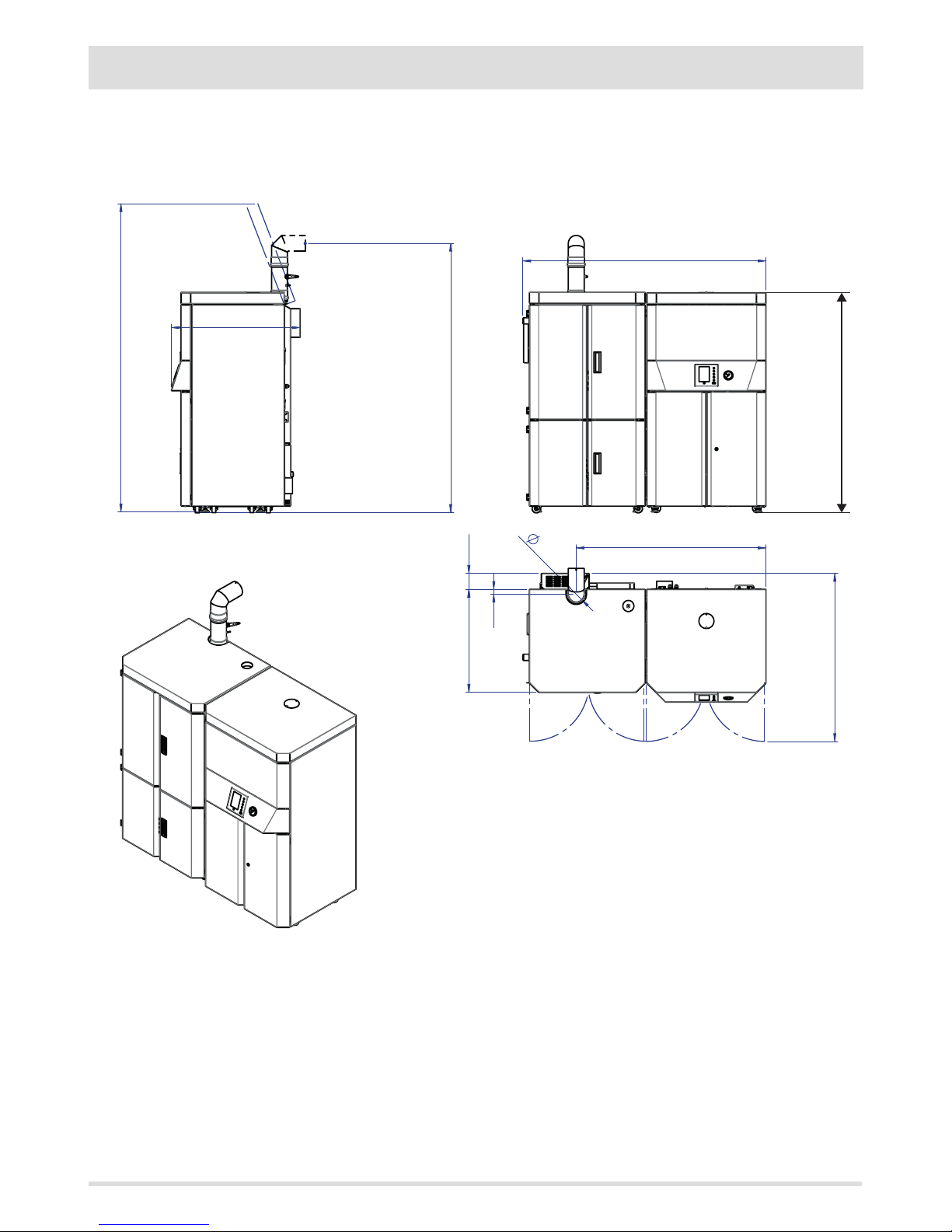

1540

1385

815

1950

MIN.1700

100

1200

650 100

30

1060

3-DRAWINGS AND TECHNICAL CHARACTERISTICS

DRAWINGS AND CHARACTERISTICS

DIMENSIONS OF LOGIKA 25-35 HYDRO (dimensions in mm)

N.B. The 90° bend is not provided with the boiler.

Page 17

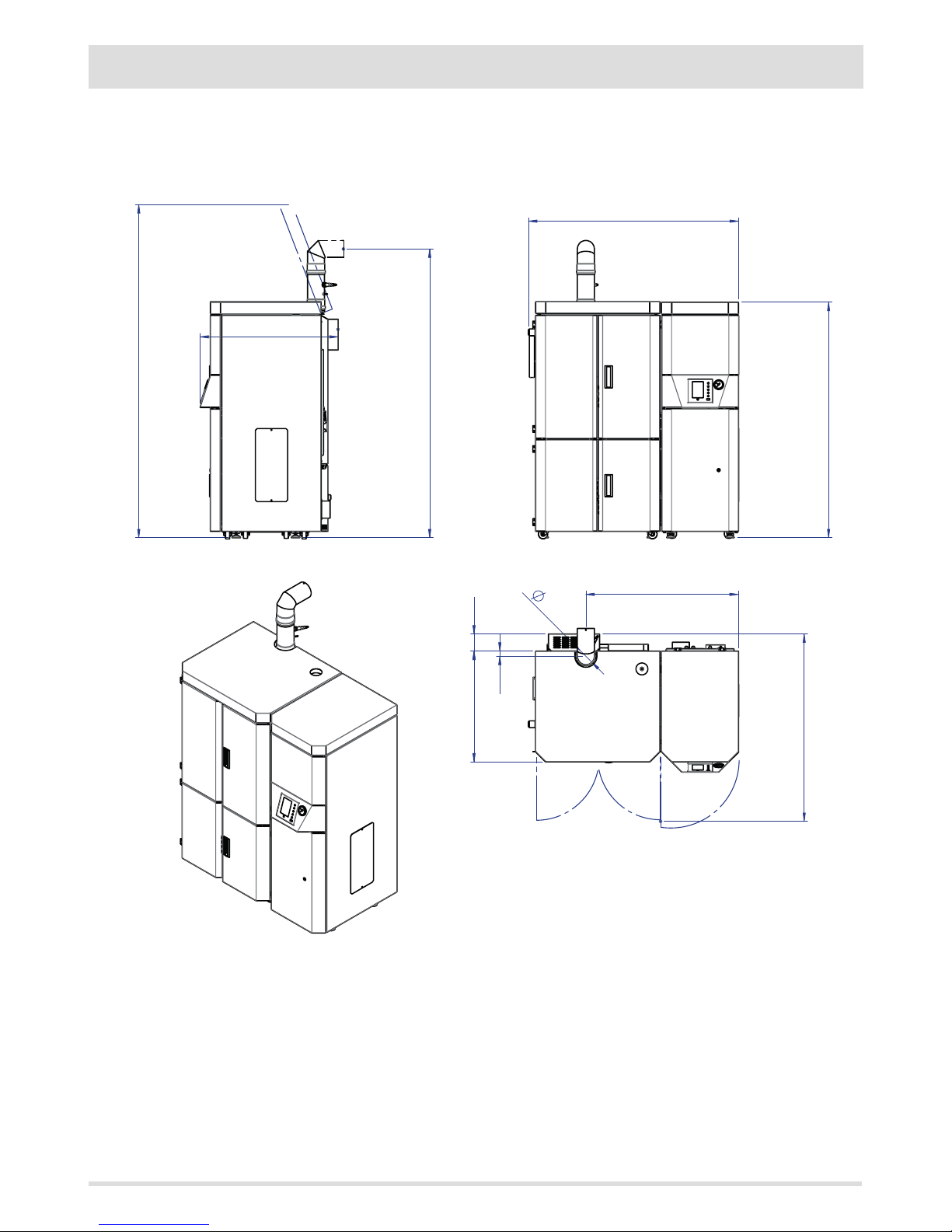

15

1235

1385

815

1950

MIN.1700

100

900

650 100

30

1100

3-DRAWINGS AND TECHNICAL CHARACTERISTICS

Technical Dept. - All rights reserved - Reproduction is prohibited

DIMENSIONS OF LOGIKA 25-35 REFILL HYDRO (dimensions in mm)

N.B. The 90° bend is not provided with the boiler.

Page 18

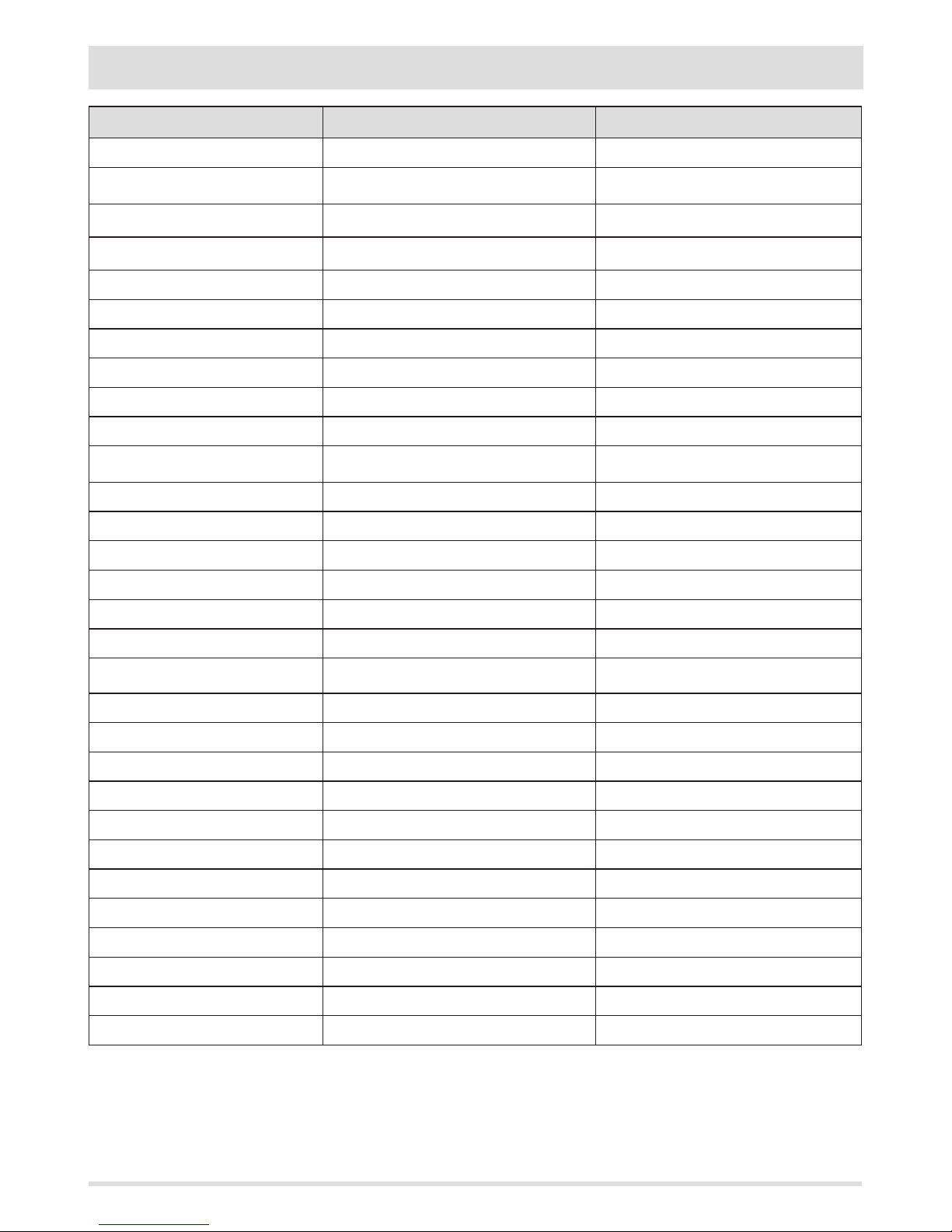

16

3-DRAWINGS AND TECHNICAL CHARACTERISTICS

TECHNICAL CHARACTERISTICS LOGIKA 25 LOGIKA 35

Product class (EN 303-5/2012) 5 5

Rated thermal capacity of the rebox 25.8 kW (22188 kcal/h) 33.8 kW (29068 kcal/h)

Nominal output power: 24.8 kW (20726 kcal/h) 32.1 kW (27606 kcal/h)

Minimum output power 8.3 kW (7138 kcal/h) 8.3 kW (7138 kcal/h)

Eciency at Max 96.1% 95.0%

Eciency at Min 91.2% 91.2%

Temperature of exhaust smoke at Max 100°C 120°C

Temperature of exhaust smoke at Min 60°C 60°C

Max congurable temperature 80°C 80°C

Max operating temperature 95°C 95°C

Particles/OGC/Nox (10%O2) 39 mg/Nm3 - 1.1 mg/Nm

3 -

163.4 mg/Nm

3

33.1 mg/Nm3 - 0.3 mg/Nm

3 -

179.5 mg/Nm

3

CO at 10% O2 at Min and at Max 0.024 - 0.009% 0.024 - 0.006%

CO2 at Min and at Max 5.89 - 10.2% 5.8 - 10.38%

Recommended draught at Max power 0.10 mbar - 10 Pa 0.10 mbar - 10 Pa

Recommended draught at Min power 0.05 mbar - 5 Pa 0.05 mbar - 5 Pa

Smoke mass 16.4 g/sec 21.0 g/sec

Tank capacity 210 litres (manual feed tank) 210 litres (manual feed tank)

Type of pellet fuel Pellet diameter 6-8 mm and size 5/30 mm Pellet diameter 6-8 mm and size 5/30 mm

Pellet hourly consumption Min ~ 1.5 kg/h* - Max ~ 5.3 kg/h* Min ~ 1.5 kg/h* - Max ~ 7 kg/h*

Autonomy At min ~ 100 h* - At max ~ 29 h* At min ~ 100 h* - At max ~ 22 h*

Heatable volume m

3

518/40 - 592/35 - 691/30** 690/40 - 789/35 - 920/30**

Water content 90 litres 90 litres

Max operating temperature 3 bar - 300 kPa 3 bar - 300 kPa

Combustion air inlet 80 mm 80 mm

Smoke outlet 100 mm 100 mm

Air outlet 100 cm

2

100 cm

2

Rated electrical power (EN 60335-1) 180 W (Max 960 W) 180 W (Max 960 W)

Supply voltage and frequency 230 Volt / 50 Hz 230 Volt / 50 Hz

Net weight 705 kg (with tank) 705 kg (with tank)

Weight with packaging 725 kg 725 kg

* Data that may vary depending on the type of pellets used.

** Volume that can be heated, according to the power requirement in m3 (respectively 40-35-30 Kcal/h per m3)

Page 19

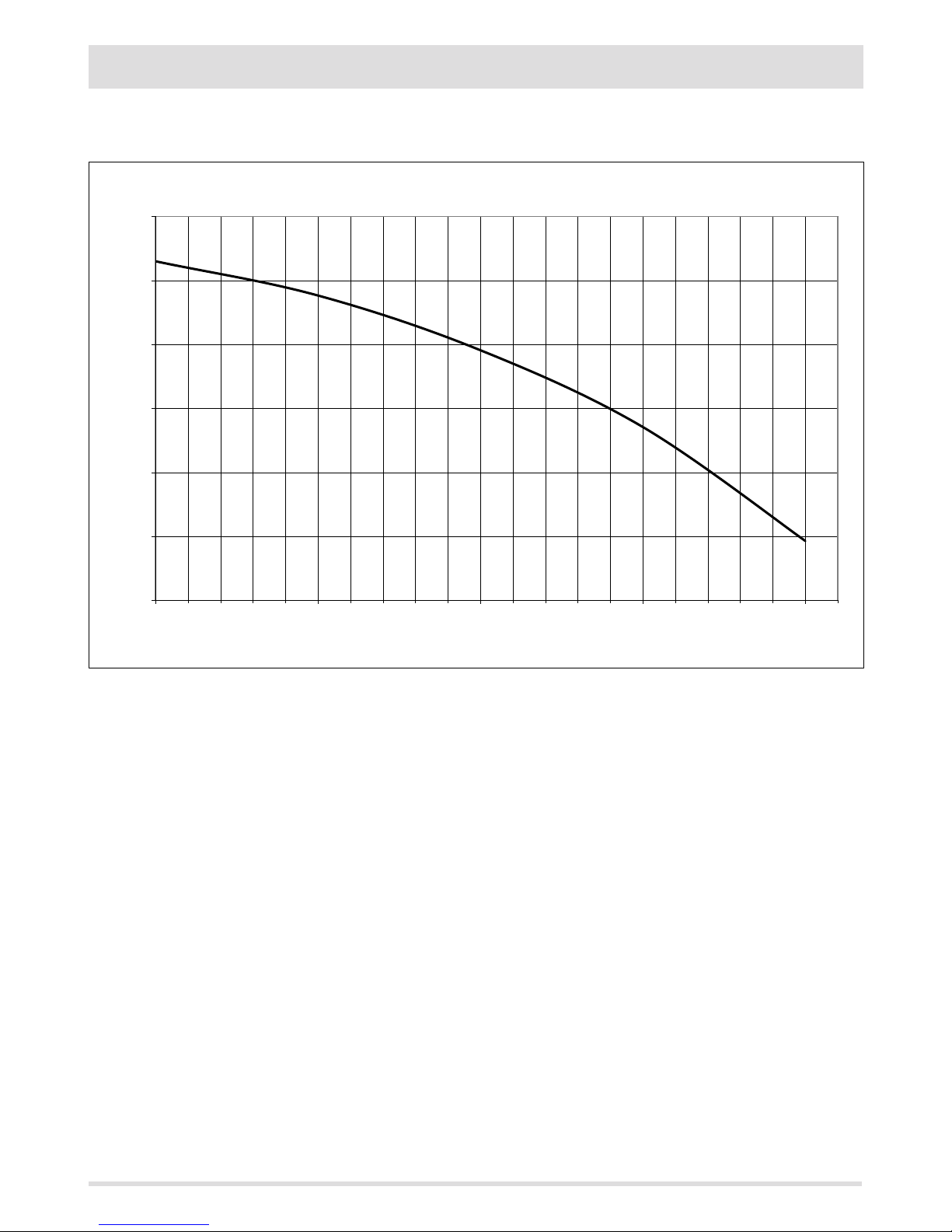

17

0

100

200

300

400

500

600

0 500 1000 1500 2000

A

B

3-DRAWINGS AND TECHNICAL CHARACTERISTICS

Technical Dept. - All rights reserved - Reproduction is prohibited

Residual head

A = Residual Head (mbar)

B = Load (l/h)

Page 20

18

CBA

E

D

4 - UNPACKING

PREPARATION AND UNPACKING

The LOGIKA boiler is delivered inclusive of all if electrical and mechanical components and already tested at the factory:

Install the boiler in the area set aside for it, making sure it conforms to the requirements. The body of the boiler must only ever be carried

upright with a trolley. The product must always be moved with care. If possible, unwrap the boiler near the chosen place of installation.

The packaging materials are neither toxic nor harmful, and therefore no particular disposal measures are required.

After removing all the packaging, check that the boiler is complete and not damaged. If in doubt, contact the retailer.

PACKAGING OF THE LOGIKA 25/35 BOILER

The Logika boiler is delivered in three dierent packages (and with additional packages for accessories), depending on the model:

• A - structure of the boiler (1 pack)

• B - tank (1 pack)

• C - casing of the boiler/tank (1 pack)

Easyclean kit accessories (on request)

• D - automatic ash outlet (1 pack)

• E - automatic turbolator (1 pack)

The following documents are provided in the package:

• Plant booklet

• Instruction booklet

• Annex G - Technical test report for thermal plant of less than 35 kW.

• Warranty

Page 21

19

k j

4 - UNPACKING

Technical Dept. - All rights reserved - Reproduction is prohibited

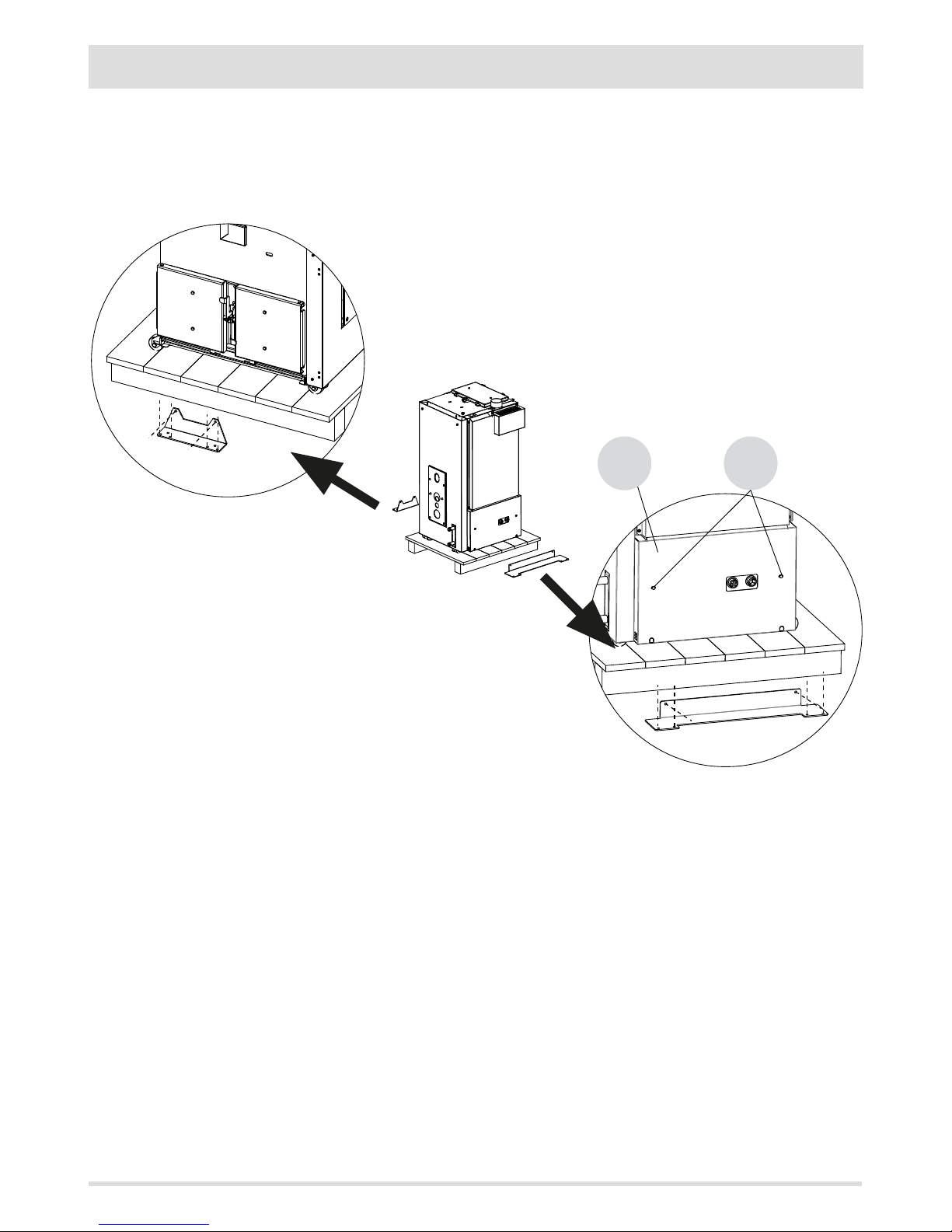

UNPACKING THE STRUCTURE OF THE BOILER

TOOLS: 10 mm face or box spanner

Open the package and remove the two front and back brackets, removing the two screws between each bracket and the boiler and the

two screws that fasten the bracket to the pallet.

Remove the rear bracket, undoing the screws "j" and taking o panel "k" to access the area more easily.

Put the panel "k" back in place when you have done.

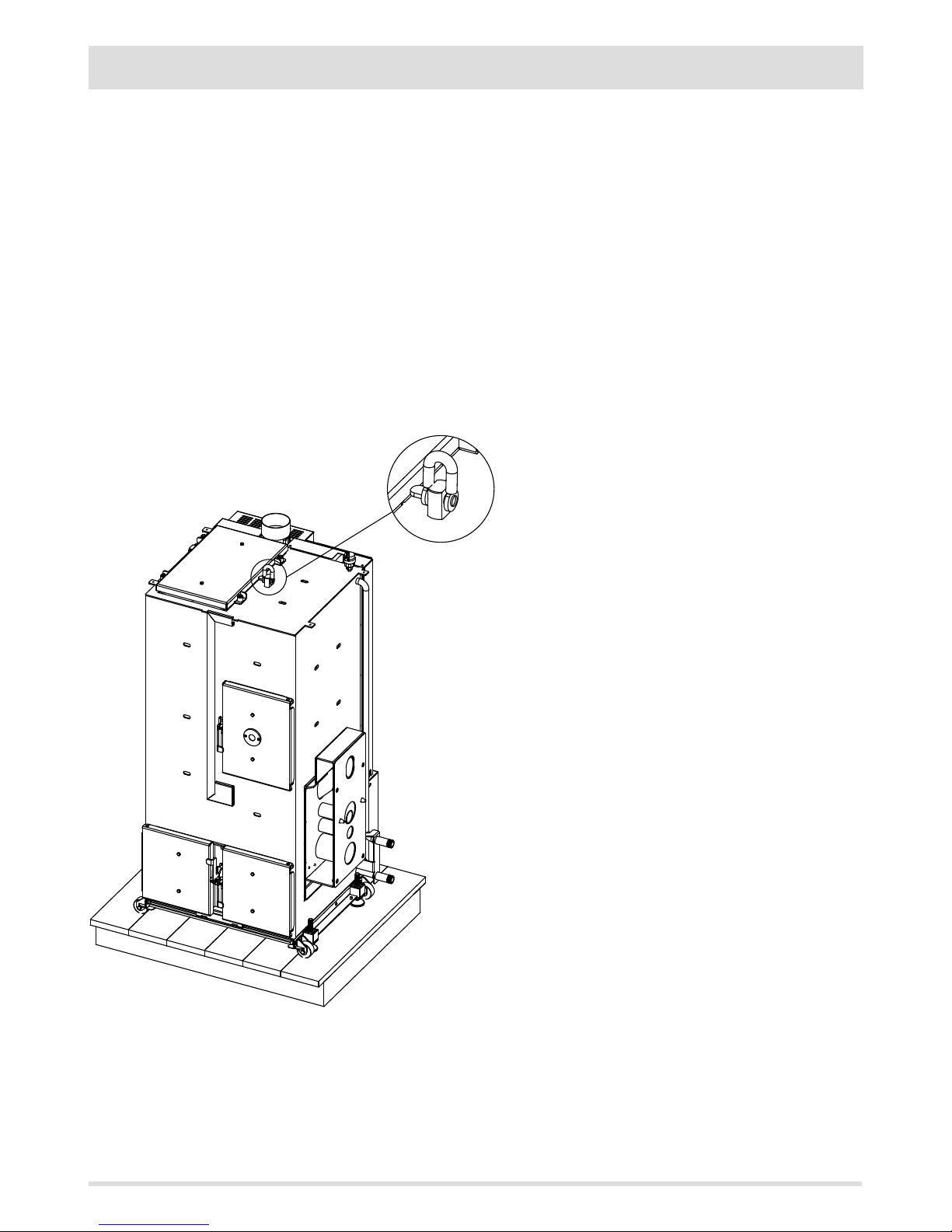

FIGURE 1 - STRUCTURE OF LOGIKA 25-35 BOILER

REMOVAL SCREWS OF PACKAGE

FRONT VIEW

REAR VIEW

Page 22

20

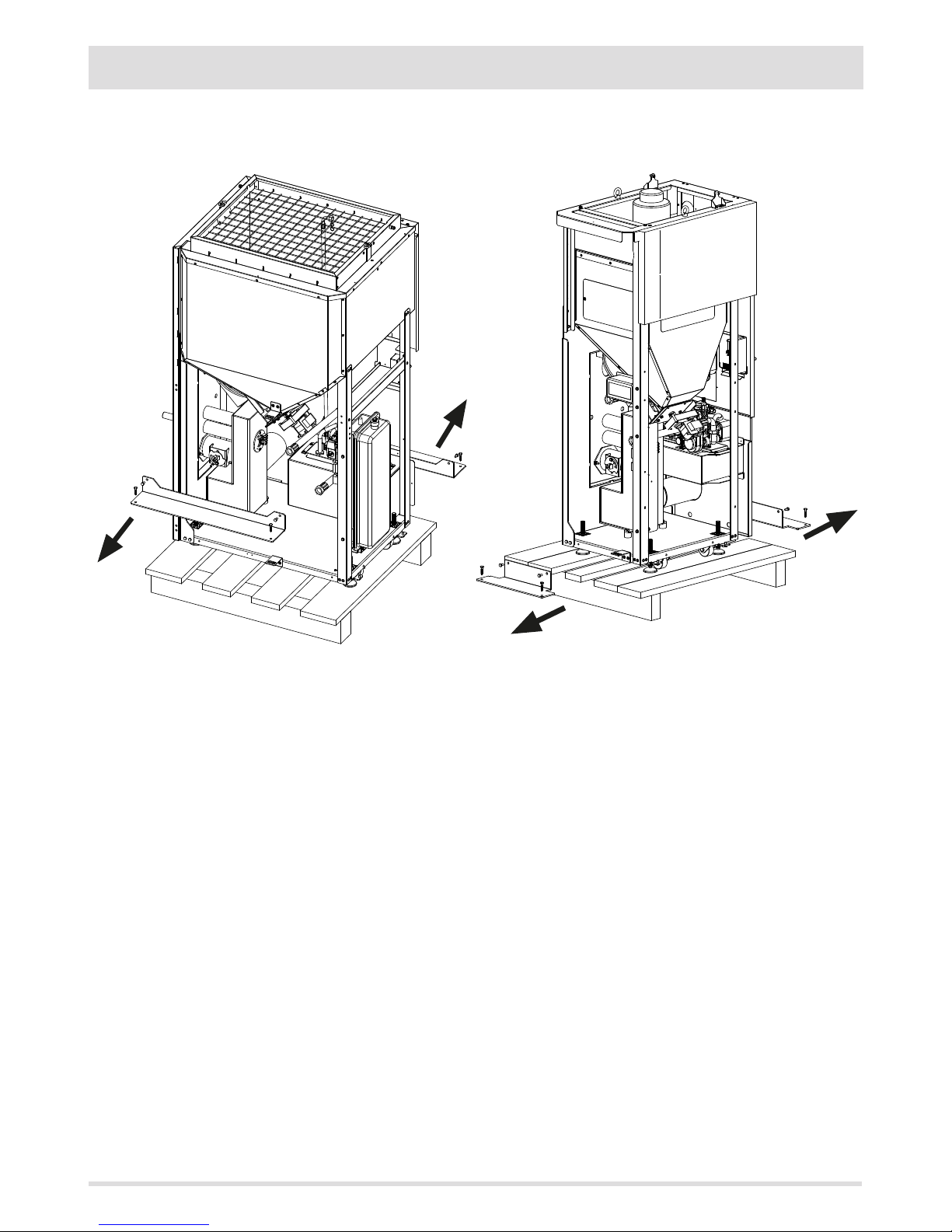

4 - UNPACKING

UNPACKING THE TANK

Open the package and remove the two screws between the bracket and the boiler and the two screws that fasten the bracket to the pallet.

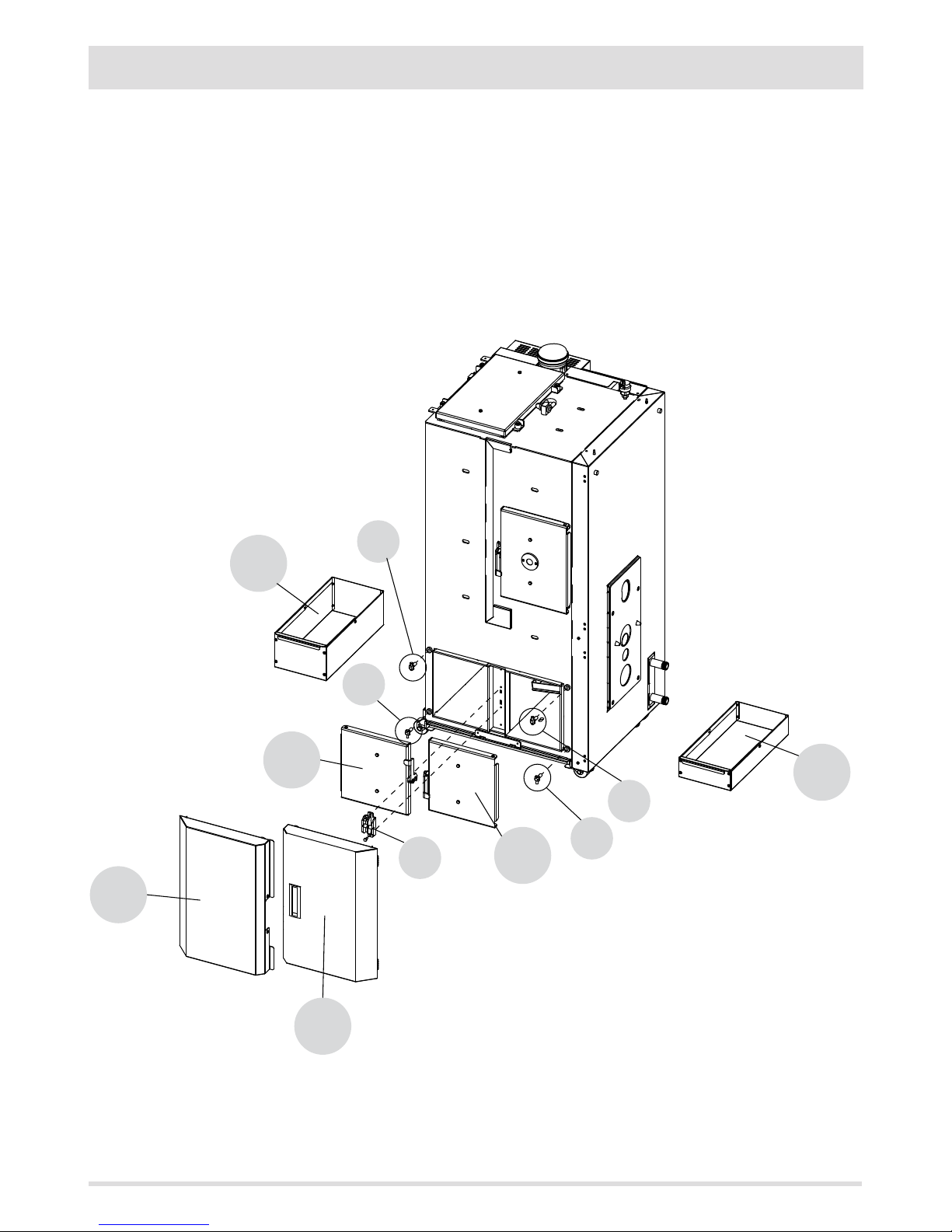

UNPACKING THE COMPLETE CASING

The package of the casing contains the following material:

• BOILER AESTHETICS UNIT

COMPLETE RIGHT-HAND DOOR (1)

COMPLETE RH PANEL (6)

COMPLETE LEFT-HAND DOOR (2)

COMPLETE LEFT-HAND PANEL (5)

COMPLETE BOTTOM RIGHT-HAND DOOR (3)

COMPLETE LEFT-HAND DOOR (4)

COMPLETE TOP DOOR (COVER) (7)

• MANUAL TANK AESTHETICS UNIT

COMPLETE RIGHT-HAND PANEL (12)

COMPLETE LEFT-HAND PANEL (11)

COMPLETE LEFT-HAND DOOR (9)

COMPLETE RIGHT-HAND DOOR (8)

BOTTOM REAR PROTECTION (14)

FRONT PANEL (10)

• MANUAL LEVER FOR CLEANING TURBOLATORS

FIGURE 2 - LOGIKA 25-35 BOILER MANUAL TANK

REMOVAL SCREWS OF PACKAGE

FIGURE 2 - LOGIKA 25-35 BOILER REFILL TANK

REMOVAL SCREWS OF PACKAGE

Page 23

21

4 - UNPACKING

Technical Dept. - All rights reserved - Reproduction is prohibited

EASYCLEAN KIT PACKAGE

AUTOMATIC TURBOLATOR KIT

ACTUATOR

FEEDER

PLASTIC CAP

AUTOMATIC ASH OUTLET KIT

• EASYCLEAN ASH OUTLET KIT

ASH DOOR SUPPORT 2 X PIECES (see piece "a" page 34)

MICROSWITCH SUPPORT BRACKET 1 X PIECE (see piece page 35)

CENTRAL DOOR SUPPORT 1 X PIECE (see piece "b" page 34)

LOCK CONNECTION 2 X PIECES (see piece “y”page 34)

AUGER ASSEMBLY KIT 2 X PIECES (see page 27)

ASH TRAY ASSEMBLY 2 X PIECES (see piece "c" page 34)

TROLLEY DRAWER ASSEMBLY 1 X PIECE (see page 63)

• BOLTS AND SCREWS KIT

Page 24

22

815

1950

MIN.300

MIN.1700

1063

MIN. 300

300

~400

1000

652

MIN.600

1385

815

1950

MIN.300

MIN.1700

1105

MIN. 300

300

~400

1000

652

MIN.600

1385

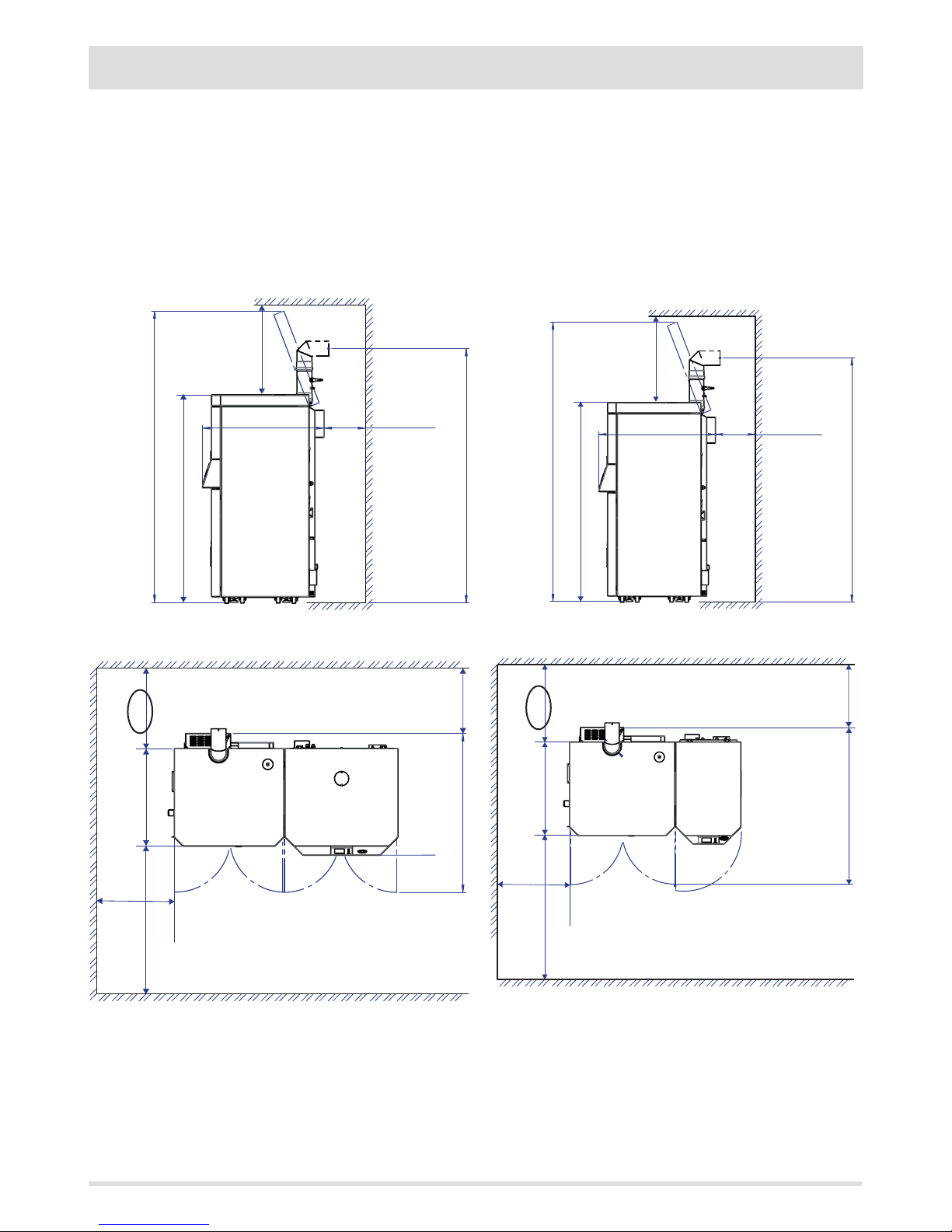

5 - POSITIONING

REQUIREMENTS FOR INSTALLATION OF THE PLANT - POSITIONING

The most important thing to do before installation of the LOGIKA boiler is to set aside a suitable area that meets the minimum requirements

for installation.

• the minimum clearance in front of the product for the purpose of cleaning, maintenance, etc. must be 1000 mm;

• the minimum permissible distance between the back of the product and a wall must be 400 mm;

• the minimum distance between the top of the product and the ceiling must be 600 mm to ensure easy access to the heat exchanger

for the purpose of cleaning and maintenance (e.g. for removing ash);

• the minimum clearance between the product and the wall (side) must be 300 mm.

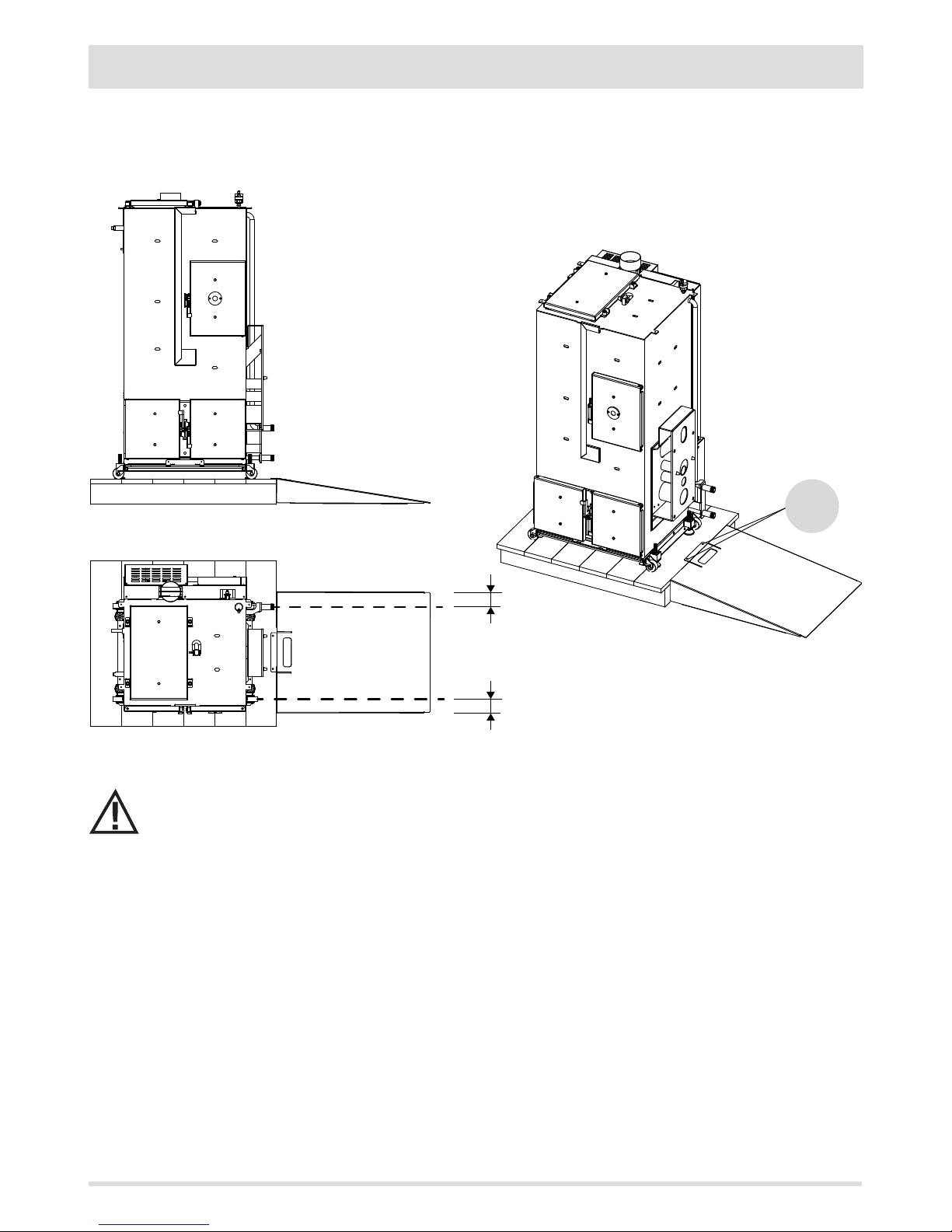

MINIMUM REQUIREMENTS FOR LOGIKA BOILER AND MANUAL TANK MINIMUM REQUIREMENTS FOR LOGIKA BOILER AND REFILL TANK

Page 25

23

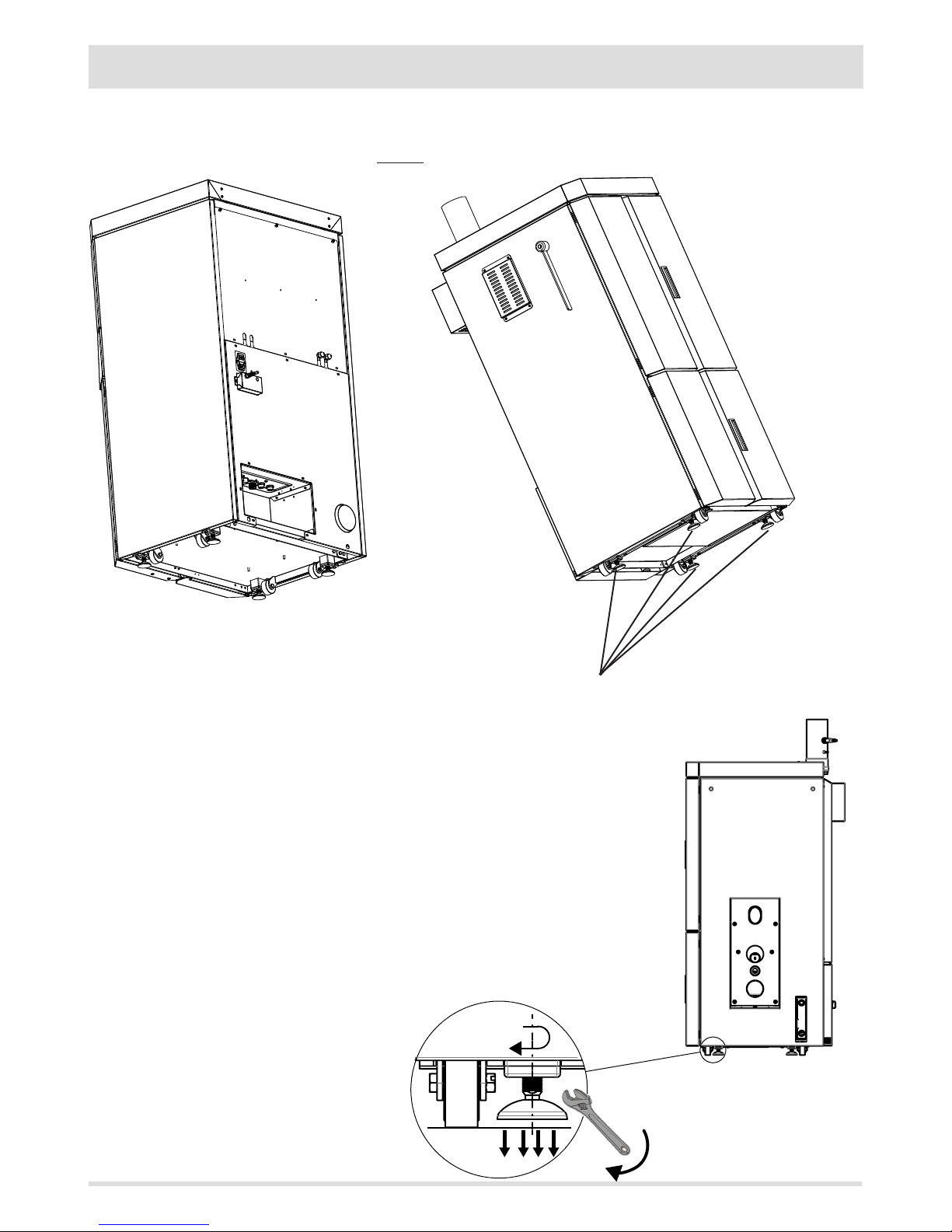

5 - POSITIONING

Technical Dept. - All rights reserved - Reproduction is prohibited

FOOT

1. TURN THE FEET CLOCKWISE TO LOWER THE PRODUCT.

2. TURN THE FEET ANTI-CLOCKWISE TO RAISE THE PRODUCT.

FOOT ADJUSTMENT

Adjustable feet are mounted at the point of the wheels on the base of the boiler and tank.

It is possible to unscrew the foot with a spanner to stabilise the structure.

Page 26

24

6 - INSTALLATION AND ASSEMBLY OF BOILER

Instructions on how to install the structure of the LOGIKA boiler:

a. Positioning on the ground (lifting or slide).

b. Put the tank and boiler in the room where they are to be installed (but NOT in their denitive position).

c. Check and install any additional kits (automatic turbolators/automatic ash outlet).

d. Assembly of the right-hand side of the boiler.

e. Denitive installation with reference to the diagram showing the minimum requirements.

f. Assemble probe pipe 100 at boiler outlet.

g. Assemble the lambda probe and connect it to the boiler connector.

h. Connect the pressure gauge pipe to the pressure outlet.

a) Positioning on the ground (lifting or slide).

After unpacking the structure it is possible to move the boiler in two ways:

1) using the lifting hook on the boiler and a hoister.

WEIGHT ABOUT 500 KG

Page 27

25

x

==

6 - INSTALLATION AND ASSEMBLY OF BOILER

Technical Dept. - All rights reserved - Reproduction is prohibited

2) using the slide (sold as an accessory).

Put the slide against the pallet and fasten it on with the two screws at pos. x in the gure, aligning it with the wheels of the boiler. The

slide can be fastened onto the pallet with the screws removed from the brackets that previously held the boiler on the pallet.

ATTENTION!

The support surface of the slide must be made of cement or at least be of an equivalent consistency.

b) Put the boiler in the installation area and position it in accordance with the denitive measurements recommended above

Page 28

26

A

B

D

C

4

3

F

F

F

F

E

6 - INSTALLATION AND ASSEMBLY OF BOILER

c) Install any additional kits (automatic turbolators and/or automatic ash outlet).

Certain parts have to be removed in order to install the automatic ash cleaning kit.

Remove from the boiler structure unit:

• Ash drawer A and B

• Doors C and D

• unit F

• unit E

Remove from the boiler casing unit:

• Doors 3 and 4.

Page 29

27

g

h

h

g

K

K

6 - INSTALLATION AND ASSEMBLY OF BOILER

Technical Dept. - All rights reserved - Reproduction is prohibited

Remove both the augers (K) from the package containing the automatic ash cleaning kit. At this point, remove screw "h" (spanner 10)

and remove carrier "g".

Attention!!

The auger is now no longer secured. To move it, hold it at the front with one hand to avoid dropping it.

Page 30

28

k j

z

6 - INSTALLATION AND ASSEMBLY OF BOILER

Undo the screws "j" to remove panel "k" at the back of the boiler.

Remove the two caps "z" (using a 25 mm spanner or adjustable pliers).

Page 31

29

K

K

j

j

K

K

K

6 - INSTALLATION AND ASSEMBLY OF BOILER

Technical Dept. - All rights reserved - Reproduction is prohibited

Insert both the auger units (K), making sure the shaft of the auger does not slide at the front. Remove the two gaskets "j" and put them

in again after assembling the doors "c" (see page 34).

Page 32

30

A

C

g

h

6 - INSTALLATION AND ASSEMBLY OF BOILER

It is necessary to put the auger all the way into the structure of the boiler (see gure 1) in order to prevent the shaft of the auger from

coming out of the hole at the back. Next, secure the shaft by re-inserting the carrier "g" and the screw "h" which were removed before

the auger was inserted in the structure of the boiler.

Page 33

31

h

90°

ok

~10 mm

3 mm

6 - INSTALLATION AND ASSEMBLY OF BOILER

Technical Dept. - All rights reserved - Reproduction is prohibited

Turn the auger by hand to move the screw "h" to a 90 degree angle to the vertical.

Repeat this operation with the other auger.

FIG. 1 - APPROX. 10 MM – CORRECT POSITIONING OF THE FEED SCREW

Page 34

32

m

m

t

h

m

m

uu

1

2

6 - INSTALLATION AND ASSEMBLY OF BOILER

Take the geared motors "m" out of the package of the trolley drawer.

Make sure that the screw is securely fastened on the ground side (see detail "u") of the shaft of the geared motor, to

prevent it from turning on empty.

Connect an electrical cable with 6.3x0.8 female faston terminals and faston covers to the geared motor. Connect the other end of the

cable with Suko plug to the mains socket. The at side of the shaft of the geared motor should be perpendicular with the screw "h" (pos.

2) of the carrier. Next, after disconnecting the cable from the geared motor, insert the shaft in the protruding part of the auger. Tighten

the screw "h" (spanner 10).

Page 35

33

m

m

t

t

6 - INSTALLATION AND ASSEMBLY OF BOILER

Technical Dept. - All rights reserved - Reproduction is prohibited

In the accessories kit there is also a cable for connecting the geared motors "m". It is necessary to insert the terminal in the remote board

"t" and the fastons in the geared motor "m".

Caution!

While the terminal for the remote board "t" has a set position, the two cables that lead to the geared motor can be

connected either left or right.

Page 36

34

a

a

b

y

c

c

c

c

a

a

b

y

6 - INSTALLATION AND ASSEMBLY OF BOILER

The two doors and brackets in the Easyclean kit are pre-assembled in the interest of ease. They need to be disassembled, however, to make

them easier to install. Take the two side brackets "a" and fasten them onto the structure of the boiler with the screws provided in the kit

using the top and bottom holes (spanner 17).

Take the central support "b" and tting "y" and fasten these onto the structure of the boiler.

After assembling all the brackets, take the doors "c", put them on the protruding bolts of the auger and fasten them back on the brackets

applying slight pressure towards the boiler in order to counteract the resistance of the gasket.

Take the gaskets "j" and insert them in the auger to the back of the doors.

Page 37

35

v

v

S

t

17

h

6 - INSTALLATION AND ASSEMBLY OF BOILER

Technical Dept. - All rights reserved - Reproduction is prohibited

Pull the cable about 30 cm out from the side. Take the micro-switch from the accessory package kit and, before fastening it onto the ash

tray, remove the two screws “v” and low box “s”. Feed the cable from the left side of the boiler through the hole in the box “s” and connect

it to the microswitch. Screw the column "h" onto the right-hand hole of the LH door. Assemble the micro-switch and fasten it on with

washer and nut. It must be parallel with the structure of the boiler.

NOTE: This operation can be done when the left-hand side has already been assembled. If the kit is not available, leave the cable in the

side.

CONNECTION TERMINALS FOR MICROSWITCH POS.t

HOLE FOR CABLE PASSAGE

FASTENING OF MICROSWITCH TO

ASH TRAY

30 cm

Page 38

36

t

t

2

1

f f

6 - INSTALLATION AND ASSEMBLY OF BOILER

At the back of the boiler, connect the cable from the side to the terminal of the board as shown. The microswitch is now connected.

1 - Remove the bridge.

2 - Insert the cable from side “f ”

Page 39

37

6 - INSTALLATION AND ASSEMBLY OF BOILER

Technical Dept. - All rights reserved - Reproduction is prohibited

Take the two columns from the trolley package. Insert the seat at the base of the column with the screw of the boiler. At the top, fasten

the column onto the structure with the screw provided.

ATTENTION: This operation can be done when both the sides of the boiler are available.

Page 40

38

A

X

X

X

X

G

G

G

z

6 - INSTALLATION AND ASSEMBLY OF BOILER

When the additional kit for automatic tubulators is also present.

The operations to be done are:

• Remove the protection "z" (detail G) from the left-hand side of the boiler, undoing the 4 screws "x".

• Knock out the pre-perforated panel "A".

Page 41

39

a

a

25 mm

b

b

j

k

6 - INSTALLATION AND ASSEMBLY OF BOILER

Technical Dept. - All rights reserved - Reproduction is prohibited

• Calibrate the actuator.

Set up the limit switch before inserting the actuator on the pin of the boiler

1. Press the clutch key and turn the vise anti-clockwise to the end of the scale.

2. Slacken the screw "a" and turn the piece anti-clockwise as shown in the drawing until the limit switch is 25 mm above the actuator

and then re-close the screw.

3. Slacken also the two bolts "b" to facilitate subsequent insertion of the pin of the boiler.

• Turn the pin protruding from the boiler using a hand or adjustable pliers.

• Insert the actuator as far as possible on the bracket "k" taking care with insertion on insert "j".

Page 42

40

c

d

c

1

2

6 - INSTALLATION AND ASSEMBLY OF BOILER

• Insert the cable from the actuator in the duct on the left-hand panel of the boiler coating at the point of the actuator installation

hole.

• This cable comes out from the rear bottom part of the boiler. Take the three red, white and black wires and connect them to the

terminal with reference to the colours of the other three wires already in place.

• Remove modular support "c" from the back of the boiler (lift and slide out) (point 1 in the gure).

• Take the feeder and screws out of the turbolator kit.

• Fasten the feeder "d" on support "c" without forcing the screws (point 2 in the gure).

• In the electrical wiring locate the sheath containing the four wires with terminals at the ends.

Page 43

41

A

D

C

B

c

d

6 - INSTALLATION AND ASSEMBLY OF BOILER

Technical Dept. - All rights reserved - Reproduction is prohibited

• Remove the terminals and connect the wires to the feeder as shown in the diagram:

A = black wire to connect to V-

B = red wire to V+

C = blue wire to neutral N

D = brown wire to L

• Reassemble everything in position, putting the support back in its seat (inserting it and pushing it downwards).

• Refasten the protection "z".

• Remove the handle for manual cleaning of the turbolators, slackening the screw (with a Phillips screwdriver).

• Put the rubber cap, provided in the automatic turbolator kit, in the hole in the place of the handle.

Page 44

42

b

a

Z

p

p

6 - INSTALLATION AND ASSEMBLY OF BOILER

d) assembly of the right-hand side of the boiler (OBLIGATORY before connecting the boiler to the tank).

Take hold of the right-hand side "Z" and put it up against the boiler. The side to be used is easily recognisable because it has a hole in the

middle.

At the bottom, t the holes in the side on the pins "p" of the boiler.

Page 45

43

k

f

x

6 - INSTALLATION AND ASSEMBLY OF BOILER

Technical Dept. - All rights reserved - Reproduction is prohibited

When installing the side of the boiler make sure the pin on side “x” engages in slot “f” at the back of the boiler.

Fasten the panel at the top with the two screws provided.

Assemble the two rubbers "k" in the pack of bolts and screws on the manual/rell tank.

e) denitive installation with reference to the diagram showing the minimum requirements.

Refer to the minimum clearances for the choice of model in the boiler installation diagrams.

Page 46

44

g

p

s

f

T

A

B

6 - INSTALLATION AND ASSEMBLY OF BOILER

f) assembly of the smoke pipe and lambda probe

Take the packages containing the pipe and lambda probe out of the rebox holder in the boiler. Assemble the probe on the probe as

follows:

• slide the plastic hood "p" o the probe "s".

• screw the probe "s" onto the thread "f" on the pipe "T".

• Check that the gasket “g” is on the intake of pipe “T”. If this is not present, you need to request it. Pipe “T” should not be assembled

without the gasket.

ATTENTION! Fasten on the lambda probe with care.

Next, insert the probe pipe on the smoke outlet pipe of the boiler as shown in the gure.

T = Pipe diameter 100

f = pipe thread

p = plastic cap

s = probe

g = gasket

A = PROBE PIPE

B = SMOKE OUTLET PIPE

Page 47

45

6 - INSTALLATION AND ASSEMBLY OF BOILER

Technical Dept. - All rights reserved - Reproduction is prohibited

g) assemble the lambda probe and connect it to the boiler connector.

Connect the piston pin of the probe on the connector at the top of the boiler.

h) connect the pressure gauge pipe to the pressure outlet.

Connect the transparent pipe from the top part of the boiler to the pressure connector.

Page 48

46

7 - INSTALLATION AND ASSEMBLY OF TANK

Instructions on how to install the structure of the tank:

a. Positioning on the ground (lifting or slide).

b. Put the tank in the room where it is to be installed (but NOT in its denitive position).

c. assembly of left side of the tank

d. Hydraulic connection of the tank to the boiler

e. mechanical connection between tank and boiler

f. insertion of spark plug

g. electrical and hydraulic connection of the control panel to the tank

h. electrical connection between tank and boiler

i. hydraulic connection between tank and water mains (supply-return-sanitary-lling)

l. hydraulic feed of boiler and check for leaks

k. assembly of aesthetics unit of boiler

m. assembly of trolley drawer, if easyclean kit is present

n. assembly of aesthetic unit of tank

o. hydraulic connection between the tank and water mains

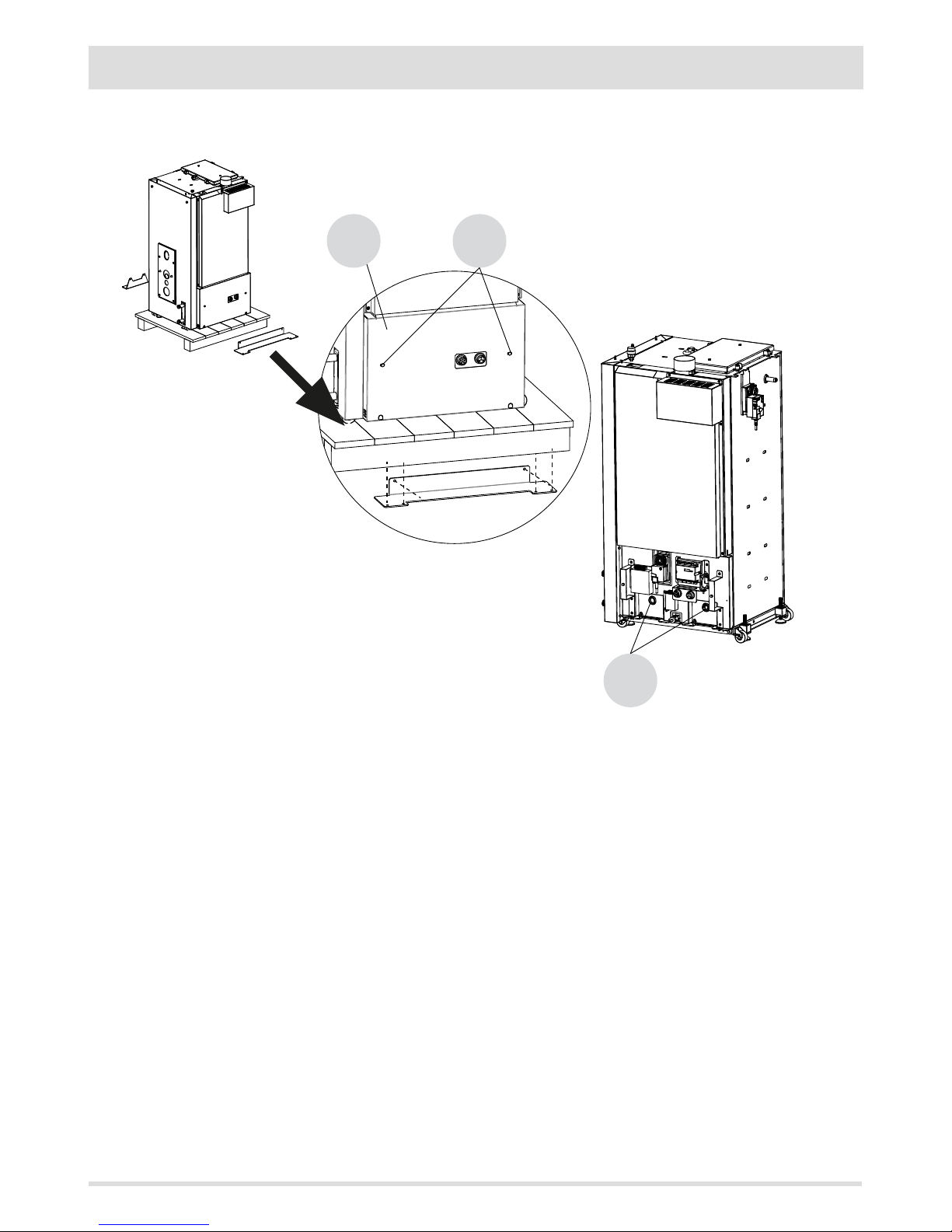

a) Positioning on the ground (lifting or slide).

Open the package and remove the two front and back brackets, removing the two screws between each bracket and the tank and the two

screws that fasten the bracket to the pallet. After unpacking the structure it is possible to move the tank in two ways:

1) by means of the two lifting points on the tank.

ATTENTION! Do not use a single lifting point: use both at the same time.

WEIGHT 150 KG

Page 49

47

x

=

=

7 - INSTALLATION AND ASSEMBLY OF TANK

Technical Dept. - All rights reserved - Reproduction is prohibited

2) using the slide (sold as an accessory).

Put the slide against the pallet and fasten it on with the two screws at pos. x in the gure, aligning it with the wheels of the tank. The slide

can be fastened onto the pallet with the screws removed from the brackets that previously held the tank on the pallet.

REFILL TANK

ATTENTION!

The support surface of the slide must be made of cement or at least be of an equivalent consistency.

Page 50

48

x

=

=

7 - INSTALLATION AND ASSEMBLY OF TANK

MANUAL TANK

Same procedure as for the Rell tank.

b) Put the choice of tank (Rell or manual) in the installation area and with reference to the denitive measurements recommended

above (see page 22)

Page 51

49

x

y

S

v

v

7 - INSTALLATION AND ASSEMBLY OF TANK

Technical Dept. - All rights reserved - Reproduction is prohibited

c) assembly of left side of the tank (manual/rell) (OBLIGATORY before connecting the tank to the boiler).

Take the left side "S" and put it next to the tank. The side to be used is easily recognisable because it has two holes in the middle.

At the base of the panel are two holes "x" to be put on the references "y" at the base of the structure of the tank. Fasten the panel at the

top with the two screws provided, position "v".

ASSEMBLY OF SIDE PANEL (REFILL TANK)

Page 52

50

y

x

S

v

7 - INSTALLATION AND ASSEMBLY OF TANK

ASSEMBLY OF SIDE PANEL (MANUAL TANK)

Page 53

51

u

u

k

7 - INSTALLATION AND ASSEMBLY OF TANK

Technical Dept. - All rights reserved - Reproduction is prohibited

d) hydraulic connection of the tank to the boiler

The hydraulic kit is already installed on the tank. Simply remove the two exible pipes in the pellet tank and connect them to the two

pipes in the boiler.

• Remove the exible pipes.

• Find the gasket "k" (provided).

• Identify the exible pipe with red marking "u" and connect it to the relative one of the boiler using gasket "k".

Page 54

52

x

x

x

x

7 - INSTALLATION AND ASSEMBLY OF TANK

e) mechanical connection between tank and boiler

Put the tank and boiler in their denitive position.

Next, connect the tank to the boiler with the four screws "x" already mounted on the boiler.

Page 55

53

7 - INSTALLATION AND ASSEMBLY OF TANK

Technical Dept. - All rights reserved - Reproduction is prohibited

f) insertion of spark plug

Locate the spark plug loosely tted in the tank and insert it fully, and fasten it in place with the two screws provided, as shown in the

gure. Apply gentle pressure to counteract the resistance of the spring and push the ange all the way down onto the structure.

DETAIL OF FASTENING OF SPARK PLUG (MANUAL TANK)

DETAIL OF FASTENING OF SPARK PLUG (REFILL TANK)

Page 56

54

P

n

m

o

7 - INSTALLATION AND ASSEMBLY OF TANK

g) electrical and hydraulic connection of the control panel to the tank

Manual tank

Locate the main instrument panel "P" with control panel "n" and pressure gauge "m" which is in the tank package, and proceed with

electrical and hydraulic installation.

Connect the cable of the control panel "n" to the printed circuit board pos. "o" and the capillary of the pressure gauge "m" to the hydraulic

kit.

Attention! It is not possible to assemble the instrument panel "P" until the sides of the tank have been assembled. Put it down on the

ground for time being.

CENTRAL PANEL WITH CONTROL PANEL AND PRESSURE GAUGE (manual tank) ELECTRICAL CONNECTION OF CONTROL PANEL (manual tank)

POSITION FOR ELECTRICAL CONNECTION OF CONTROL PANEL (manual

tank)

Page 57

55

p

n

m

o

7 - INSTALLATION AND ASSEMBLY OF TANK

Technical Dept. - All rights reserved - Reproduction is prohibited

Rell tank

Connection of control panel.

POSITION FOR ELECTRICAL CONNECTION OF CONTROL PANEL (rell tank)

ELECTRICAL CONNECTION OF CONTROL PANEL (rell tank)CENTRAL PANEL WITH CONTROL PANEL AND PRESSURE GAUGE (rell

tank)

Page 58

56

R

C

T

7 - INSTALLATION AND ASSEMBLY OF TANK

Connection of pressure gauge.

a) Remove tting "R" from the tip of the capillary "C".

b) Unscrew tting "T" on the hydraulic unit.

c) Insert tting "T" on the capillary by means of the slot.

d) Screw tting "T" onto the hydraulic unit.

Manual tank

Rell tank

CONNECTION OF PRESSURE GAUGE TO HYDRAULIC KIT (manual tank)

CONNECTION OF PRESSURE GAUGE TO HYDRAULIC

KIT (rell tank)

C = PRESSURE GAUGE CAPILLARY

R = FITTING ON CAPILLARY

T = FITTING MOUNTED ON HYDRAULIC UNIT

Page 59

57

7 - INSTALLATION AND ASSEMBLY OF TANK

Technical Dept. - All rights reserved - Reproduction is prohibited

h) electrical connection between tank and boiler

Connect the two piston pins of the tank to the piston pins of the boiler. The connection of the piston pin on the boiler is recognisably

dierent (see image below). It is necessary to put the piston pin in the socket and to turn the locking ring clockwise until it is stops.

The connections are not the same and cannot, therefore, be inverted. Do not apply unnecessary force.

PIN CABLES FROM TANK TO BE CONNECTED TO

BOILER

PISTON PIN PISTON PIN CONNECTOR AT BACK OF BOILER

Page 60

58

6

7

5

3

1

2

4

8 - ASSEMBLY OF BOILER AESTHETICS UNIT

BOILER AESTHETICS UNIT

i) hydraulic connection between tank and water mains (supply-return-sanitary-lling)

(RESPONSIBILITY OF SPECIALISED HYDRAULIC TECHNICIAN)

l) hydraulic supply to boiler and checking for leaks (RESPONSIBILITY OF SPECIALISED HYDRAULIC TECHNICIAN).

k) assembly of aesthetics unit of boiler

After completing steps "i" and "l", assemble the aesthetics unit of the boiler.

For convenience, the panels are identied with the numbers in the picture.

Page 61

59

p

5

o

5

t

h

f

x

8 - ASSEMBLY OF BOILER AESTHETICS UNIT

Technical Dept. - All rights reserved - Reproduction is prohibited

First of all, locate the left side panel "5" and fasten it onto the structure of the boiler. At the bottom, t the holes "o" in the side on the

pins ''p'' of the boiler.

At the top of the panel, instead, insert the two aps ("h") in the gaps (detail "t") and fasten them on with the two screws.

When installing the side of the boiler make sure the pin on side “x” engages in slot “f” at the back of the boiler.

NOTE: If the accessory kit (automatic ash outlet) is not present, leave the cable (for connecting the micro-switch) in the panel.

ASSEMBLY OF LEFT-HAND SIDE PANEL OF BOILER

Page 62

60

7

7

s

v

5

8 - ASSEMBLY OF BOILER AESTHETICS UNIT

After fastening the left panel on the boiler, locate the top cover "7" and feed the pins "s" above the two side panels of the boiler into the

ttings "v" at the base of cover "7".

ASSEMBLY OF TOP COVER OF BOILER

Page 63

61

1

2

g

g

z

b

a

8 - ASSEMBLY OF BOILER AESTHETICS UNIT

Technical Dept. - All rights reserved - Reproduction is prohibited

At this point, locate the two top doors "1" and "2" and fasten them onto the boiler. Doors "1" and "2" are already tted with hinges.

Fasten the two hinges "z" onto the structure of the boiler using the holes "g" and screws provided in the package of the manual/rell tank.

ASSEMBLY OF TOP DOORS OF BOILER

Tools: Screwer with cross inser t "a" or Phillips screwdriver

"b".

Page 64

62

3

4

m

n

8 - ASSEMBLY OF BOILER AESTHETICS UNIT

If the Easyclean kit is not available, repeat this procedure for the two bottom doors "3" and "4". In this case, too, doors "3" and "4" are

already tted with hinges. Fasten the two hinges "n" onto the structure of the boiler at the point of the holes "m".

ASSEMBLY OF BOTTOM DOOR OF BOILER

Page 65

63

i

z

A

p

9 - ASSEMBLY OF TROLLEY

Technical Dept. - All rights reserved - Reproduction is prohibited

m) if the easyclean kit is present, assemble the trolley drawer.

Complete the assembly of the automatic ash outlet kit by inserting the trolley.

• To facilitate the operation, at least for the rst few times, remove the door "z" (FIGURE A) of the trolley to permit better visibility.

• Adjust the foot "p" of the trolley to tilt it very slightly (FIGURE B).

FIGURE BFIGURE A

Page 66

64

~13 mm

9 - ASSEMBLY OF TROLLEY

• Open doors "1" and "2".

• Hold the trolley with both hands and move it up to the structure of the boiler (FIGURE 1).

• Engage the intakes of the trolley in the two protruding augers (FIGURE 2).

• Use one hand to lift handle "i" and another to push the trolley towards the boiler.

• Lower handle "i" to secure the trolley onto the structure.

• CHECK: The auger intake should protrude about 13 mm further out than the intake of the trolley (FIGURE 3).

• Re-assemble the top door "z" of the trolley.

FIGURE 1

FIGURE 2

FIGURE 3

Page 67

65

11

12

10

8

E

9

10 - ASSEMBLY OF AESTHETICS UNIT OF REFILL TANK

Technical Dept. - All rights reserved - Reproduction is prohibited

n) assembly of aesthetic unit of tank

Rell tank

For convenience, the panels are identied with the numbers in the picture.

REFILL TANK AESTHETICS UNIT

Page 68

66

11

k

y

10 - ASSEMBLY OF AESTHETICS UNIT OF REFILL TANK

Locate the right side panel "11" and insert the holes "y" at the base of the panel on the pins "k" on the structure of the tank.

ASSEMBLY OF RIGHT-HAND SIDE PANEL (REFILL TANK)

Page 69

67

E

f

f

g

g

A

B

10 - ASSEMBLY OF AESTHETICS UNIT OF REFILL TANK

Technical Dept. - All rights reserved - Reproduction is prohibited

The central instrument panel "E" with control panel and pressure gauge has already been connected to the hydraulic kit and printed circuit

board (see dedicated pages). Once the right panel has been mounted, it can be assembled on the structure of the tank by engaging parts

"g" in holes "f".

HOW TO INSERT INSTRUMENT PANEL "E":

ASSEMBLY OF CENTR AL PANEL (REFILL TANK)

A = INSERT

B = PUSH DOWN

Page 70

68

g

f

f

9

y

10 - ASSEMBLY OF AESTHETICS UNIT OF REFILL TANK

The top panel "9" has the same fastening system as central panel "E". Insert the hooks "g" in the holes "f" on the structure of the tank.

Use screw "y" (provided) to secure the top of the panel "9".

ASSEMBLY OF TOP PANEL (REFILL TANK)

Page 71

69

8

8

t

u

s

10 - ASSEMBLY OF AESTHETICS UNIT OF REFILL TANK

Technical Dept. - All rights reserved - Reproduction is prohibited

The bottom door "A" is already tted with hinges (detail "t") to be fastened onto the structure of the tank using the holes present (detail

"u") and the screws provided.

IMPORTANT: Door "8" should be positioned with the lock "s" to the right.

ASSEMBLY OF DOOR (REFILL TANK)

Page 72

70

t

u

12

12

x

z

10 - ASSEMBLY OF AESTHETICS UNIT OF REFILL TANK

In order to fasten cover “12” already tted with hinges (detail “t”) it is necessary to fasten it rst to the holes “u” in the structure of the tank

(with the screws provided) then engage the ring on piston “x” on pin “z”. Repeat this procedure for the second piston.

ASSEMBLY OF DOOR (REFILL TANK)

Page 73

71

13

12

8

9

11

p

14

10

11 - ASSEMBLY OF AESTHETICS UNIT OF MANUAL TANK

Technical Dept. - All rights reserved - Reproduction is prohibited

MANUAL TANK

For convenience, the panels are identied with the numbers in the picture.

MANUAL TANK AESTHETICS UNIT

Page 74

72

12

k

y

11 - ASSEMBLY OF AESTHETICS UNIT OF MANUAL TANK

Locate the right side panel ''12'' and insert the holes ''y'' at the base of the panel on the pins ''k'' on the structure of the tank.

ASSEMBLY OF RIGHT-HAND SIDE PANEL (MANUAL TANK )

Page 75

73

s

t

p

11 - ASSEMBLY OF AESTHETICS UNIT OF MANUAL TANK

Technical Dept. - All rights reserved - Reproduction is prohibited

The central instrument panel ''p'' with control panel and pressure gauge has already been connected to the hydraulic kit and printed

circuit board (see dedicated pages). After assembling also the right panel with holes "s" it is possible to install it on the structure of the

tank by engaging the parts "t".

ASSEMBLY OF CENTR AL PANEL (MANUAL TANK)

Page 76

74

f

g

10

y

11 - ASSEMBLY OF AESTHETICS UNIT OF MANUAL TANK

The top panel ''10'' has the same fastening system as central panel ''p''. Insert the hooks ''g'' in the holes ''f'' on the structure of the tank.

Use screw ''y'' (provided) to secure the top of the panel ''10''.

ASSEMBLY OF TOP PANEL (MANUAL TANK)

Page 77

75

u

t

9

8

11 - ASSEMBLY OF AESTHETICS UNIT OF MANUAL TANK

Technical Dept. - All rights reserved - Reproduction is prohibited

At this point, locate the two bottom doors "8" and "9" and fasten them onto the structure of the tank. Doors ''8'' and ''9'' are already tted

with hinges. Fasten the two hinges “t” onto the structure of the tank at the point of the holes ''u' '.

Doors “8” and “9” should be assembled with the ground part on the outside.

ASSEMBLY OF DOOR (MANUAL TANK)

Page 78

76

14

14

11 - ASSEMBLY OF AESTHETICS UNIT OF MANUAL TANK

Fasten the rear panel "14" onto the structure of the tank with the screws provided.

ASSEMBLY OF REAR PANEL (MANUAL TANK)

Page 79

77

z

t

13

13

x

u

11 - ASSEMBLY OF AESTHETICS UNIT OF MANUAL TANK

Technical Dept. - All rights reserved - Reproduction is prohibited

In order to fasten the cover ''13'', which is already tted with hinges (detail ''t''), attach it rst to the holes (detail ''u'') on the structure

of the tank (with the screws provided) and then engage the ring of the piston ''x'' on pin ''z''. Repeat the procedure for the second piston.

o) hydraulic connection between the tank and water mains (RESPONSIBILITY OF A SPECIALIST TECHNICIAN)

It is advisable to connect the tank and system with exible pipes.

ASSEMBLY OF COVER (MANUAL TANK)

Page 80

REV. 08901231800 20/11/2012

Via La Croce n°8

33074 Vigonovo di Fontanafredda (PN) – ITALY

Telefono: +39 0434/599599 r.a.

Fax: +39 0434/599598

Internet: www.mcz.it

e-mail: info.red@mcz.it

Page 81

INSTALLATION GUIDE GB

Translation of the original instructions

PELLET BOILER

LOGIKA 25-35

LOGIKA 25-35 REFILL

PART 2 - OPERATION AND CLEANING

Page 82

II

TABLE OF CONTENTS

TABLE OF CONTENTS ...................................................................................... II

1 PLUMBING CONNECTION ............................................................................ 1

2 FILLING THE SYSTEM .................................................................................. 2

3 GENERAL WARNINGS ................................................................................. 4

4 LOADING THE PELLETS ............................................................................... 7

2 MENU OPTIONS ........................................................................................ 9

6 ADJUSTMENTS MENU ...............................................................................17

7 SYSTEM CONFIGURATION ..........................................................................18

8 ELECTRICAL CONNECTION .........................................................................22

9 STARTUP/SHUTDOWN ............................................................................23

10 SAFETY DEVICES AND ALARMS .................................................................24

11 MAINTENANCE AND CLEANING .................................................................28

12 TROUBLESHOOTING ................................................................................34

13 WIRING DIAGRAM ..................................................................................37

Page 83

1

1 - PLUMBING CONNECTION

Technical Dept. - All rights reserved - Reproduction is prohibited

PLUMBING CONNECTION

IMPORTANT:

The connections depend on the type of hydraulic kit installed and the type of system conguration.

IMPORTANT!

The boiler must be installed by qualied personnel who can testify to the conformity of the system in accordance

with the applicable laws in force.

The Company will not be held responsible for damage to persons or things in the event of failed or incorrect operation

if the aforementioned warnings are not complied with.

IMPORTANT!!!

CLEAN THE ENTIRE SYSTEM BEFORE CONNECTING THE BOILER, IN ORDER TO REMOVE ALL RESIDUE AND DEPOSITS.

Upstream from the stove, always install shutters so as to disconnect it from the plumbing system should it be

necessary to move it, or when it requires routine and/or special maintenance.

Connect the stove using hoses so that the stove is not too strictly connected to the system, and to allow slight

movements.

CLEANING THE SYSTEM

In order to protect the thermal system against harmful corrosion, scale or deposits, it is essential to clean the system in accordance with

standard UNI-CTI 8065 before installing the appliance, using appropriate products like Sentinel X300 (new systems), X400 and X800 (old

systems) or Fernox Cleaner F3.

Complete instructions are provided with the products but it is possible to contact the manufacturer SENTINEL PERFORMANCE SOLUTIONS

LTD or FERNOX COOKSON ELECTRONICS directly for further information. After cleaning the system, it is recommended to use Sentinel X100

or Fernox Protector F1 inhibitors to protect it against corrosion and deposits.

It is important to check the concentration of the inhibitor after making any changes to the system and during maintenance checks,

following the recommendations of the manufacturers (the retailers can oer tests).

The outlet of the safety valve has to be connected to a collection intake for purging in the event of maintenance.

Attention: Failure to clean the thermal system or to use an adequate inhibitor will invalidate the warranty of the

appliance and of the other accessories like the pump and valves.

Page 84

2

2- FILLING THE SYSTEM

FILLING THE SYSTEM

Fill the system slowly to allow air bubbles to pass through the vent holes of the heating system. For closed circuit heating systems, the

lling pressure of the system at cold and the pre-ination pressure of the expansion tank must be the same.

• The water used for lling the heating system must be decontaminated and not contain air.

Attention!

Do not mix heating water with incorrect concentrations of anti-freeze or anti-corrosion substances! This could

damage the gaskets and cause noise during operation.

After making all the hydraulic connections, pressure-test the seals by lling the boiler.

Before lling, check the lling pressure of the expansion tank.

This must be done with care by doing the following:

• open the air vent valves of the radiators, boiler and system;

• gradually open the lling tap of the system, making sure that any automatic air vent valves in the system work correctly;

• close the vent valves of the radiators as soon as water comes out;

• check at the pressure gauge of the system that the pressure reaches 1 bar approx.

• close the lling tap of the system and then open the vent valves of the radiators again to purge any air;

• check the seal of all the connections;

• after starting up the boiler for the rst time and bringing the system up to temperature, stop the pumps and repeat the air purging

procedure;

• allow the system to cool down and, if necessary, bring water pressure back up to 1 bar;

Page 85

3

R U K

2- FILLING THE SYSTEM

Technical Dept. - All rights reserved - Reproduction is prohibited

Fill the heating system manually using the tap with check valve in the hydraulic kit.

• Connect or plug the H2O hot outlet "U".

• Connect the H2O cold input "K" to the system.

• Open the tap "R".

This operation does not need to be done if the system already has an automatic or manual lling valve.

During this operation, any air in the system is released from the automatic vent valve located at the top of the body of the boiler.

To allow the valve to purge, unscrew the side cap by 1/2 a turn. (see gure)

The lling pressure of the system WHEN COLD must be 1 bar.

Upon completion of this operation, always close the tap.

PURGE VALVE WITH SIDE CAP

UNSCREWED BY 1 TURN

Page 86

4

3 - GENERAL WARNINGS

GENERAL PRECAUTIONS

The electrical safety of the system is guaranteed only when this is connected correctly to an ecient earthing system installed in

accordance with the safety standards in force: the pipes of the gas, water and heating systems do not constitute a suitable earth system.

It is necessary to ensure this essential safety requirement; if in doubt, have a qualied technician test the electrical system with care

because the manufacturer of the boiler does not assume responsibility for damage caused by the absence of an earthing system.

A qualied technician should check that the electrical system is compatible with the max consumption of the system, checking in

particular that the cross-section of the cables of the system is compatible with the power consumption of the loads.

The use of any component that requires electrical energy requires compliance with certain essential rules like:

• do not touch the appliance with wet and/or damp parts of the body and/or when barefoot;

• do not pull on the electrical cables;

• do not expose the appliance to the elements (rain, sun, etc.);

• do not allow children or inexperienced persons to use the appliance.

Connection to 230V power supply.

The installation of additional electrical components of the boiler requires electrical connection to a230V - 50Hzpower supply: This

connection must be done in accordance with the national standards in force.

Danger!

Electrical installation must be entrusted to a single qualied technician.

Before making the connections or carrying out any work on the electrical parts, always turn o the power supply

and make sure it cannot be turned on again accidentally.

The power cable must be replaced only by an authorised technician. Failure to observe the above could compromise the safety of the

appliance.

ELECTRICAL CONNECTION

Connect the power cable rst to the back of the tank and then to the electrical mains.

The main switch at the back is simply for turning on the boiler.

It is recommended to disconnect the power cable when the boiler is not used.

ELECTRICAL CONNECTION

Page 87

5

3 - GENERAL WARNINGS

Technical Dept. - All rights reserved - Reproduction is prohibited

BEFORE START-UP

GENERAL PRECAUTIONS

After a long period of inactivity, use a vacuum cleaner with long tube to remove any traces of pellets in the tank that could

have absorbed humidity and are no longer suitable for combustion.

The rst start-up may not be successful as the feed screw is empty and does not always manage to load the required

amount of pellets in the brazier to reach the threshold temperature, despite the presence of re.

It is good practice to guarantee eective ventilation in the room during the initial start-up, as the boiler will emit

some smoke and smell of paint.

Page 88

6

6

3 - GENERAL WARNINGS

OPENING THE DOOR OF THE FIREBOX

OPENING/CLOSING THE DOOR OF THE FIREBOX

ATTENTION!