Page 1

INSTALLATION AND SET UP

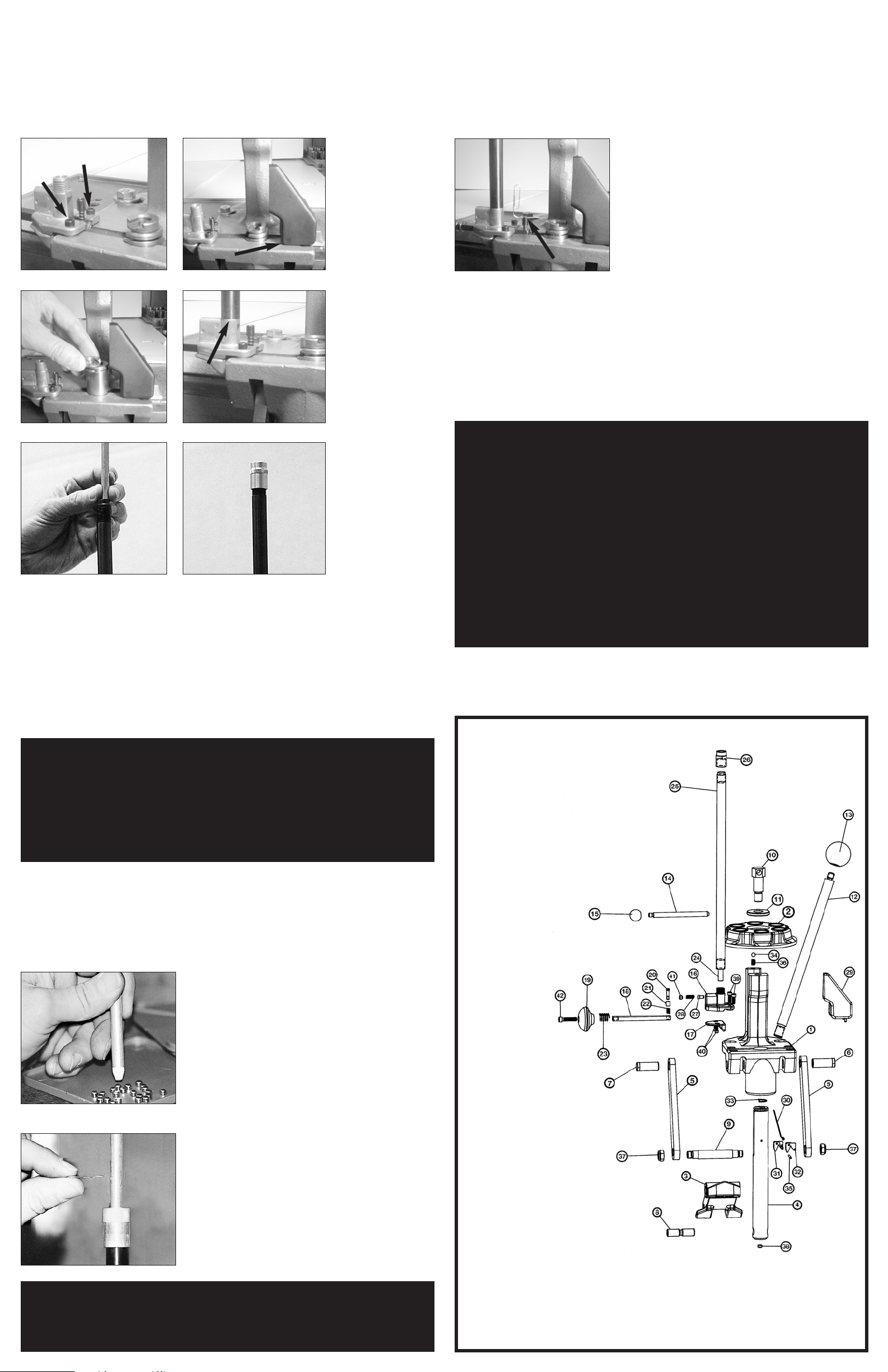

Mount the Turret Press to a sturdy workbench or table with two 3/8” bolts of sufficient length to

penetrate the press base and bench.(Note: This set up can be used for a right or left handed

person). Install the threaded portion of the handle through the toggle block.The handle must

remain tight at all times to avoid damage to the handle and toggle block. Install the Primer

Dispenser Assembly as shown in photo 1. Finger tighten the two 8-32x1/2 socket headcap

screws. Align the primer transfer bar in the slot to obtain full movement. Center primer plug and

sleeve in shell holder

and tighten the 832x1/2 Socket Head

Cap Screw.

Slide the dispenser

bottom until it rests

against the Turret

frame and tighten the

two 5-40x3/8 Socket

1

3

5

Insert the appropriate sized priming tube (large or small) into the safety tube as shown in

photo 5.

Seat the primer tube until it bottoms out in the Safety Tube. Approximately 1/4” of the primer

tube will protrude above the safety tube. Now install the tube cap by screwing it onto the safety

tube. See photo 6.

2

4

6

Head Cap Screws.

Note: The small

Primer Plug was

installed at the

factory.

Slip the primer catcher

into place on the

press in the holes provided. See photo 2.

The Turret Press ram

accepts removable

type shell holders. To

install, insert the shell

holder into the ram

and twist slightly to

the left. To remove,

twist slightly to the

right. See photo 3.

Screw the safety tube

onto the Primer

Dispenser until hand

tight as shown in

photo 4.

PRIMING ON YOUR TURRET PRESS

Start by sizing and depriming a case. Lower the ram approximately half the stroke. Next,

with your free hand, pull out on the primer transfer bar until it picks up a primer. With the

ram still in half stroke position, push the primer transfer bar into the slot in the press ram

until it stops. While holding the Transfer bar in, lower the ram until the primer is fully seated.

Now release the transfer bar as you lower the handle and raise the ram. This will spring the

transfer bar out of the slot in the ram.

PRIMER SIZE CHANGEOVER

Select the correct primer plug and sleeve (large or

small). Drop the Primer Plug through the sleeve. Place

the spring on the primer plug. Screw the Primer Plug

into the transfer bar. Tighten the assembly with a small

nail or a straightened paper clip through the hole in

the Primer Plug. Do not over tighten. See photo 9.

Remove the safety tube cap. Remove the empty tube

9

inside the safety tube. Install the correct tube, large or

small, inside the safety tube.See photo 5. Install the

safety tube cap onto the safety tube. See photo 6.

MAINTENANCE

This press was lubricated at the factory. However, it is necessary to lubricate all moving

parts from time to time with gun oil. If rust spots appear, swab lightly with gun oil and wipe

dry. Care should be taken not to apply oil where it could come in contact with primer pockets or primers. Oil will deactivate primers. It is a good practice to clean the press prior to

lubrication to remove grit and other residue. You will note the ease at which the epoxy

enamel paint wipes clean. This finish is impervious to oil and is extremely chip and fade

resistant.

WARNING:

TO AVOID INJURY, READ AND FOLLOW THESE SAFE PRIMING PRACTICES:

•DO NOT attempt to prime military cartridge cases with crimped primer pockets until

the crimp has been removed with a counter sink, a special reamer or by swaging.

Primers seated into crimped pockets are subject to deformation which can cause

misfires and even detonation during seating which can cause serious personal injury.

•DO NOT attempt to seat primers against excessive resistance which may cause

detonation and possible serious personal injury. Check to be certain that the case

was not previously primed, that the fired primer was removed, that a portion of the

primer cup wall is not still in the primer pocket and that you are using the correct

size primer.

•DO NOT modify the priming system in any manner or attempt to use similar parts or

priming systems from other manufacturers. To do so could result in primer

detonations resulting in serious personal injury.

•NEVER seat a primer into a powder charged case.

•Decapping live primers is extremely dangerous and is not recommended.

FILLING THE PRIMER TUBE

WARNING:

Care must be taken when loading the primer feed tube. Do not force primers because

of the stacked condition of the primers, if one should ignite, all the primers in the tube

will explode, causing an extreme hazard. No more than five pounds of force should be

applied when picking up primers with the primer feed tube (this can be checked using

a bathroom scale). If difficult primer pick-up should occur, investigate the cause and

clear the condition or return the primer feed tube to RCBS for correction. Always wear

eye protection when handling primers.

We recommend the RCBS Primer Tray-2 to be used in conjunction with the primer feed

tube. This plastic primer tray and cover have been designed to orient primers for fast, easy

handling and primer pick-up.

Step 1. Scatter the primers onto the grooved surface of the primer tray. Then, gently shake

the tray horizontally until all the primers are positioned anvil side up. Place the cover on the

tray, while holding the tray and cover together, turn the tray upside down.

The primers will now be oriented anvil side down for

easy pick-up with the appropriate size priming tube

assembly. See photo 7.

Step 2. Insert the primer feed tube cotter pin into the

cross hole before picking up any primers.

WARNING: It is the responsibility of the operator to

insure that all primers are properly oriented.

7

8

Attempting to seat a primer upside down in a case

may cause the primer to detonate, causing serious

personal injury or damage to the equipment. Primer

residue is dangerous when exposed to heat, impact

and/or static electricity. Therefore, it is important to

keep the primer tubes clean. We recommend periodic

cleaning with soap and warm water.

Step 3. Use the plastic tipped end of the tube opposite

the cotter pin for primer pick-up. After filling, place the

tube, cotter pin end down, onto the top of the safety

tube cap. While holding the tube, remove the cotter

pin, dropping the primers into the top of the safety

tube cap. Be sure all primers are transferred into the

Priming Tube. See photo 8.

Questions? Call Customer Service at

1-800-533-5000

Monday - Friday 6:30am - 4pm Pacific Time

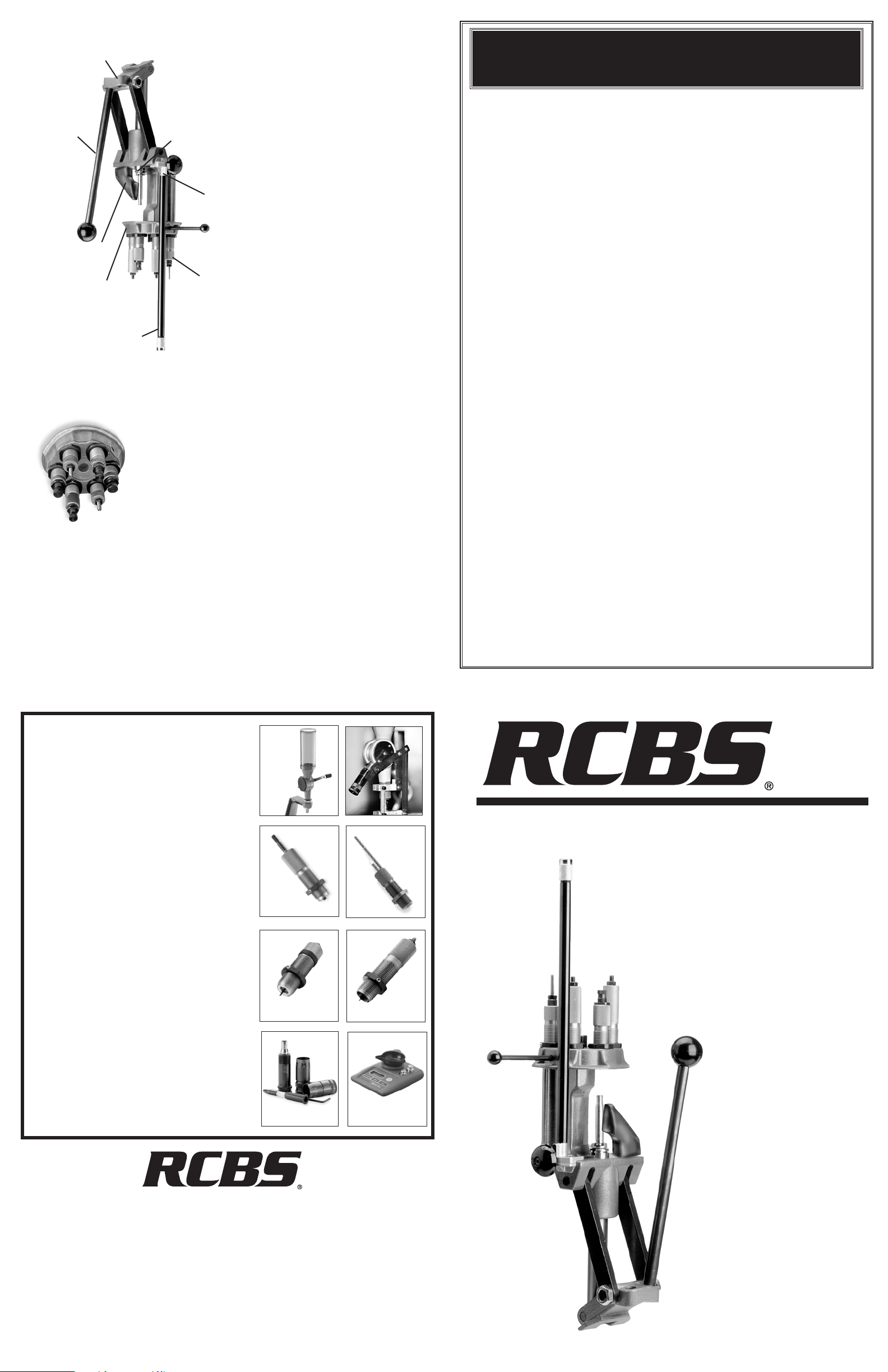

TURRET PRESS PARTS LIST

KEY PART # DESCRIPTION

1 788250 Press Frame

2 788251 Turret Head

3 788252 Toggle Block

4 788254 Ram

5 188719 Links (2)

6 788257 Link Pin Right

7 788258 Link Pin Left

8 788255 Ram Pin

9 788256 Toggle Block Pin

10 788260 Turret Head Bolt

11 788261 Turret Head Washer

12 788259 Press Handle

13 187414 Handle Ball

14 788262 Turret Pin

15 180054 LAMII Handle Knob

16 788253 Primer Dispenser

17 188104 Dispenser Bottom

18 788263 Primer Transfer Bar

19 198943 Palm Knob

20 709554 APF Primer Plug Lg

709555 APF Primer Plug Sm

21 709506 APF Primer Sleeve Lg

709507 APF Primer Sleeve Sm

22 109508 APF Primer Plug Spring

23 188107 Primer Transfer Bar Spring

24 788924 Primer Tube Large

788923 Primer Tube Small

709581 Primer Tube Subassembly Lg (not shown)

709582 Primer Tube Subassembly Sm (not shown)

25 788264 Safety Tube

26 788265 Tube Cap

27 709595 APF Stop Pin

28 109596 APF Coil Spring

29 788277 Primer Catch Assembly

30 188105 Primer Deflector

31 188102 Primer Deflector Insert Left

32 188103 Primer Deflector Insert Right

33 109112 Ram Clip Spring

34 187152 Detent Ball

35 788266 Deflector Pin

36 187153 Detent Spring

37 188108 7/16 Nyloc Nuts (2)

38 187219 1/4-28x3/8 Socket Head Cap Screw

39 187227 8-32x1/2 Socket Head Cap Screw (2)

40 188109 5-40x3/8 Socket Head Cap Screw (2)

41 109591 1/4-28x3/16 Cup Point Set Screw

42 187211 10-32x1” Socket Head Cap Screw

Page 2

Toggleblock

Handle

Catcher

Primer

Turret

or implied, for the use of ammunition reloaded with this product.

resulting ammunition may be used, we assume no responsibility, expressed

which they are assembled, the use of this product, or the guns in which the

Because RCBS has no control over the choice of components, the manner in

Never attempt to guess at the identity of your ammunition.

Turret Pin Assembly

Shell Holder

Hex Keys 3/32 & 9/64 (One each)

Primer Plug Spring (One)

Primer Plug Sleeve Large

Primer Plug Large

8-32x1/2” SHCS (Two)

Dispenser

Primer

• Bag #2

Primer Dispenser Assembly

• Bag #1:

• Primer Catcher

• Safety Tube

• Primer Tube Assembly Small

Reloading Dies

• Primer Tube Assembly Large

• Primer Tube Small

• Primer Tube Large

• Handle

Primer Tubes

Safety Tube/

• Press Frame Assembly

for identification.

items listed below. Refer to the parts list

Unpack the press carefully and look for the following

UNPACKING

permitting two or more calibers to be set up at the same time.

can be obtained in the mounting sequence of dies and powder measures,

will find through experimentation that many multiple combinations

dies and other accessories come packaged with these items. You

mounted. The instructions for the use and set-up of the reloading

The dies and/or RCBS Uniflow Powder Measure can now be

threaded reloading dies, with no bushings or adapters required.

The RCBS Turret Head is made to accept standard 7/8”-14

RCBS TURRET HEAD

while you change calibers by using our quick change turret heads.

The RCBS Turret Head makes it easy to maintain your die set-up

RCBS TURRET HEAD QUICK CHANGEOVER

n’t work, we will fix it or replace it free. No time limit, no questions asked and no fine print.

can be used). This press is covered by the RCBS Lifetime Warranty. If it ever breaks or doesfor other tools. The Turret Head exchanges easily with the removal of one bolt (a 3/4" socket

and set-up. The Turret handle is also used to remove the turret head, eliminating the need

to 200 rounds per hour with the turret. Dies can be left in the turret to eliminate teardown

progressive reloading. With Dies pre-set in the turret, you can increase your output from 50

The new RCBS Turret Press now gives you a choice between single stage or

RCBS TURRET PRESS

and the primer, powder and bullet used. Labels for this purpose are packed with SPEER bullets.

• Keep complete records of reloads. Apply a descriptive label to each box showing the date produced,

RECORD KEEPING

• DO NOT smoke while reloading.

This will preserve the identity and shelf life of the powder.

• When you finish a reloading session, pour any remaining powder back into its original factory container.

is being thrown.

Throw and check the weight of at least ten charges. This will assure you that the correct powder charge

• When using a powder measure, settle the powder in the powder hopper before charging any cases.

powder hopper has been filled.

• If you use a powder measure, replace the lids on both the powder hopper and powder can after the

manufacturer’s label on the original canister. Discard all mixed powders and those of uncertain identity.

• DO NOT use any powder unless its identity is positively known. The only positive identification is the

away from the bench to avoid picking up the wrong one.

• DO NOT have more than one can of powder on the bench at one time. Powder cans should be stored

• DO NOT force primers. Use care in handling primers.

to anyone nearby.

• DO NOT store primers in bulk. The blast of just a few hundred primers is sufficient to cause serious injury

storage.

factory packaging for safety and to preserve their identity. Primer packaging is designed to provide safe

• Keep primers in the original factory container until ready to use. Return unused primers to the same

regulations.

• Do not use primers of unknown identity. Scrap unknown primers in accordance with applicable

electrical equipment. Avoid areas where static electricity is evident.

• Store primers and powder beyond the reach of children and away from heat, dampness, open flames and

PRIMERS AND POWDER

• OBSERVE ALL WARNINGS ABOUT THE USE OF MAXIMUM LISTED LOADS.

Manual.

• Use only laboratory tested reloading data. We highly recommend the current SPEER Reloading

LOADING DATA

unnecessary risk when reloading without wearing safety glasses.

• Always wear adequate eye protection to protect your eyes from flying particles. You assume

prove hazardous. Don’t rush - load at a leisurely pace.

the influence of medications or alcohol. Develop a reloading routine to avoid mistakes which may

• Reload only when you can give your undivided attention. Do not reload when fatigued or ill, or under

orderly. Promptly and completely clean up primer and powder spills.

• Observe “good housekeeping” in the reloading area. Keep tools and components neat, clean and

• Don’t take short cuts. Attempting to bypass established procedures is an invitation to an accident.

copy from the equipment manufacturer.

thoroughly familiar with the operation of the product. If you do not have written instructions, request a

• Use all equipment as the manufacturer recommends. Study the instructions carefully and become

GENERAL

is minimized.

these rules, the chance of a hazardous occurrence causing personal injury or property damage

beginning with the user’s safety in mind. When reloading, safety rules must be followed. By observing

carelessness or negligence can make reloading hazardous. This product has been designed from the

Reloading is an enjoyable and rewarding hobby that can be conducted safely. But, as with any hobby,

SAFETY

nent part of your reloading equipment and remain with the equipment at all times for easy reference.

instruction manual contains specific safety and operating information. It should be considered a permado not understand some operation, call us at 1-800-533-5000 and a technician will assist you. This

result in severe personal injury and/or equipment damage. If you have read these instructions and still

operate the related reloading equipment. Failure to properly operate certain reloading equipment can

Before using the RCBS Turret Press, read the instruction manual carefully to fully learn how to safely

IMPORTANT: READ THIS SECTION FIRST

ACCESSORIES

Uniflow Powder Measure 09010

Features an adjustable cylinder. Iron and steel construction ensures long life and accuracy. See photo 10.

Case Activated Linkage Kit 98911

It automatically activates dispensing a charge with every

pull of the handle only when a case is present under the

Uniflow Powder Measure. See photo 11.

Lock Out Die 87540

The Lock-Out Die detects a “no powder” or a

“double charge” condition in the progressive reloading

process. See photo 12.

Powder Checker Die 87590

A simple, effective way to visually check powder charges

before seating a bullet when you use a

progressive press. Shows low and high charges.

See Photo 13.

Lube Die

Decaps and lubes cases in one step. Eliminates time and

mess associated with lubing cases. Four sizes cover 45

popular calibers. Refer to our RCBS Catalog for a complete list of caliber sizes. See Photo 14.

Universal Decapping Die 87580

Quickly removes primers from case before cleaning.

Handles calibers 22 through 45. See photo 15.

Precision Mic 09440

Accurately reads your chamber headspace and bullet

seating depth to 0.001 of an inch. See photo 16.

10

12

14

11

TURRET PRESS

13

15

Micro Pro Scale 86040

This new sleek scale is compact, lightweight and

portable. Option of AC powered or 9v battery.

See photo 17.

PRECISIONEERED®RELOADING EQUIPMENT

We think that we make the very best

reloading equipment in the world.

If you agree, please tell your friends.

If you disagree, tell us - we want to do something about it!

Customer Service

1-800-533-5000 (US or Canada) or 530-533-5191

Hours: Monday - Friday, 6:30am - 4:00pm Pacific Time

e-mail: rcbstech@atk.com • www.rcbs.com

RCBS • 605 Oro Dam Blvd. • Oroville, CA 95965

CCI • SPEER • RCBS

OUTERS • RAMLINE • ORBEX • FEDERAL

201279/0404

16

17

PRODUCT INSTRUCTIONS

Page 3

RCBS Primer Tubes

SAFETY REMINDER

Dear Valued Customer:

RCBS has received two reports of customers using tools to tap on live primers stuck in primer tubes.

In rare circumstances, primers can become lodged in tubes that are obstructed, damaged or improperly

maintained. As called out in the instruction manuals accompanying all RCBS primer tubes, RCBS

would like to remind its customers to never force or pound/tap on live primers, tap or pound on

loaded primer tubes or otherwise attempt to clear obstructions on your own. Doing so can cause

serious injury.

If you experience a feeding problem in a primer tube, follow these steps:

1. Ensure no primers are in the white plastic pickup tip.

2. Remove the white tip with pliers.

3. If possible, carefully pour the primers out of the tube and return primers to original

packaging. Do not use the tube.

4. If a stuck primer(s) remains, handle with care and take to your local hazardous waste

disposal facility.

5. Replacement tubes can be purchased online at RCBS.com or through an authorized dealer.

Warranty claims can be made by calling RCBS at 1-800-533-5000.

To avoid primer feeding problems, always follow these precautions:

Before use, always inspect tube for damage or interior obstructions.

Never use bent, damaged or obstructed tubes.

Ensure tube is free from primer residue buildup. Periodically clean inside of tube using soap

and warm water.

March 14, 2013

Loading...

Loading...