RCBS The Grand User Manual

THE GRAND

PROGRESSIVE SHOTSHELL RELOADING PRESS

P R O D U C T I N S T R U C T I O N S

IMPORTANT

Before using the RCBS Shot Shell Press, read these instructions carefully to fully learn how to safely operate the related reloading equipment. Failure to properly operate certain reloading equipment can result in severe personal injury and/or equipment damage.

If you have any questions while assembling or operating this tool, call us at 1-800-533-5000 or 1-530-533-5191

Monday - Thursday 6:30 a.m. to 3:00 p.m. Pacific Time

The instruction manual contains specific safety and operating information. It should be considered a permanent part of your reloading equipment and remain with the equipment at all times for easy reference.

SAFETY

Reloading is an enjoyable and rewarding hobby that can be conducted safely. But, as with any hobby, carelessness or negligence can make reloading hazardous. This product has been designed from the beginning with the user’s safety in mind. When reloading, safety rules must be followed. By observing these rules, the chance of a hazardous occurrence causing personal injury or

property damage is minimized.

GENERAL

•Use all equipment as the manufacturer recommends. Study the instructions carefully and become thoroughly familiar with the operation of the product. If you do not have written instructions, request a copy from the equipment manufacturer.

•Don’t take short cuts. Attempting to bypass established procedures is an invitation to an accident.

•Observe “good housekeeping” in the reloading area. Keep tools and components neat, clean and orderly. Promptly and completely clean up primer and powder spills.

•Reload only when you can give your undivided attention. Do not reload when fatigued or ill, or under the influence of medications or alcohol.

•Develop a reloading routine to avoid mistakes which may prove hazardous. Don’t rush - load at a leisurely pace.

•Always wear adequate eye protection to protect your eyes from flying particles. You assume unnecessary risk when reloading without wearing safety glasses.

LOADING DATA

•Use only laboratory tested reloading data. There are many lab tested shotshell manuals available. Always follow the load data exactly as it is published

in any shotshell reloading manual.

•Never substitute components

•OBSERVE ALL WARNINGS ABOUT THE USE OF MAXIMUM LISTED LOADS

•Store primers and powder beyond the reach of children and away from heat, dampness, open flames and electrical equipment. Avoid areas where static electricity is evident.

•Do not use primers of unknown identity.

•Dispose of unknown primers in accordance with applicable regulations.

•Keep primers in the original factory container until ready to use. Return unused primers to the same factory packaging for safety and to preserve their identity. Primer packaging is designed to provide safe storage.

•DO NOT store primers in bulk. The blast of just a few hundred primers is sufficient to cause serious injury to anyone nearby.

•DO NOT force primers. Use care in handling primers.

•DO NOT have more than one can of powder on the bench at one time. Powder cans should be stored away from the bench to avoid picking up the wrong one.

•DO NOT use any powder unless its identity is positively known. The only positive identification is the manufacturer’s label on the original canister. Discard all mixed powder and those of uncertain identity.

•Always replace the lids on both the powder hopper and shot hoppers after they have been filled.

•When you finish a reloading session, pour any remaining powder back into its original factory container. This will preserve the identity and shelf life of the powder.

•DO NOT smoke while reloading.

RECORD KEEPING

•Keep complete records of reloads. Apply a descriptive label to each box showing the date produced, and the primer, powder, wad and shot used.

Never attempt to guess at the identity of your ammunition.

PRIMERS AND POWDER

Because RCBS has no control over the choice of components, the manner in which they are assembled, the use of this product, or the guns in which the resulting ammunition may be used, we assume no responsibility,

expressed or implied, for the use of ammunition reloaded with this product.

1POWDER SYSTEM - Hull activated, no hull, no powder. No need to manually turn powder on and off. No spillage of powder can occur.

2SHOT SYSTEM - Hull activated, no hull, no shot. No need to manually turn shot on and off. No spillage of shot when problems occur.

3CASE HOLDERS - Easy removal of hull at all stations. Universal 12 and 20 gauge case holders allows cases to be sized down around the rim.

•The combination of the Powder System, Shot System and the Case Holders allows the user to reload one shell without fear of spillage.

4PRIMING SYSTEM - Allows only one primer to feed at a time and is an extremely reliable primer feed system.

5STEEL SIZE RING - Provides complete resizing of high and low base hulls. Not found in most presses.

•AUTO INDEX - Simple and very reliable automatic indexing system that can be easily removed for manual indexing.

6TILT-OUT WAD GUIDE - For easy and convenient feeding of wads.

•MASSIVE FRAME - With compound leverage for smooth solid feel.

7QUICK DRAIN SYSTEM - Both powder and shot hoppers have three locating positions. Off, on, and a forward drain position for quick and convenient removal.

8QUICK CHANGE - Of powder and shot bushings. Changes over in less than one minute.

9POWDER CHARGE - Is easy to check because the powder station is directly in front of the press and it is easy and convenient to remove the powder charge hull.

10LARGE OPEN FRAME - Designed for convenient easy access to all 8 stations.

•EASY CONVERSION - Changing from 12 gauge to 20 gauge is quick and easy with our convenient conversion kit.

11SHOT & POWDER HOPPERS - Holds 25 pounds of shot and 1 pound of powder.

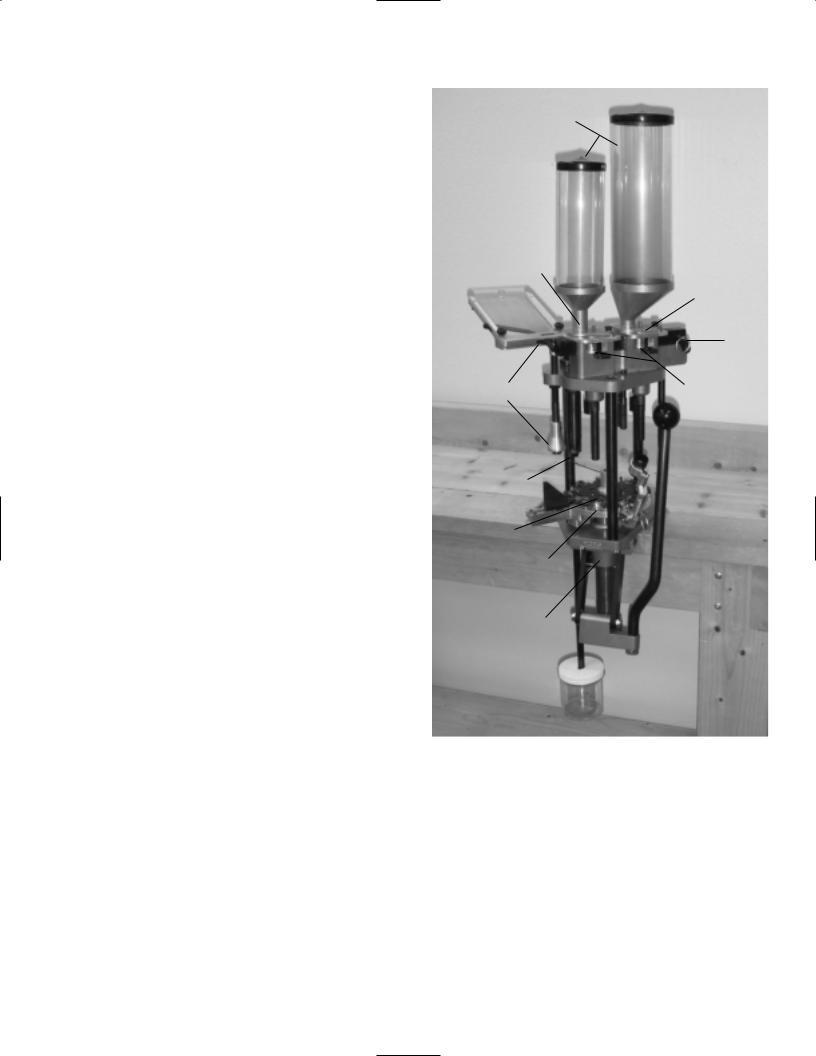

THE “GRAND”

11

1

2

8

4 |

7 |

5

6

6

9

3

10

89001 THE GRAND, 12 ga. Shotshell Press

89003 THE GRAND, 20 ga. Shotshell Press

89005 Shotshell Press Conversion Kit, 20 ga.

89007 Shotshell Press Conversion Kit, 12 ga.

89010 Riser Stand

89100 Charge Bar

For shot and powder bushing information see page 14.

UNPACKING THE GRAND

A.Shot Hopper

B.Spent Primer Tube Assembly

C.Powder Hopper

D.Drain Tube (Clear Rubber Hose)

E.Press Assembly

F.Wad Box

Video

Wad Box Bracket

Discharge Chute

Primer Tray

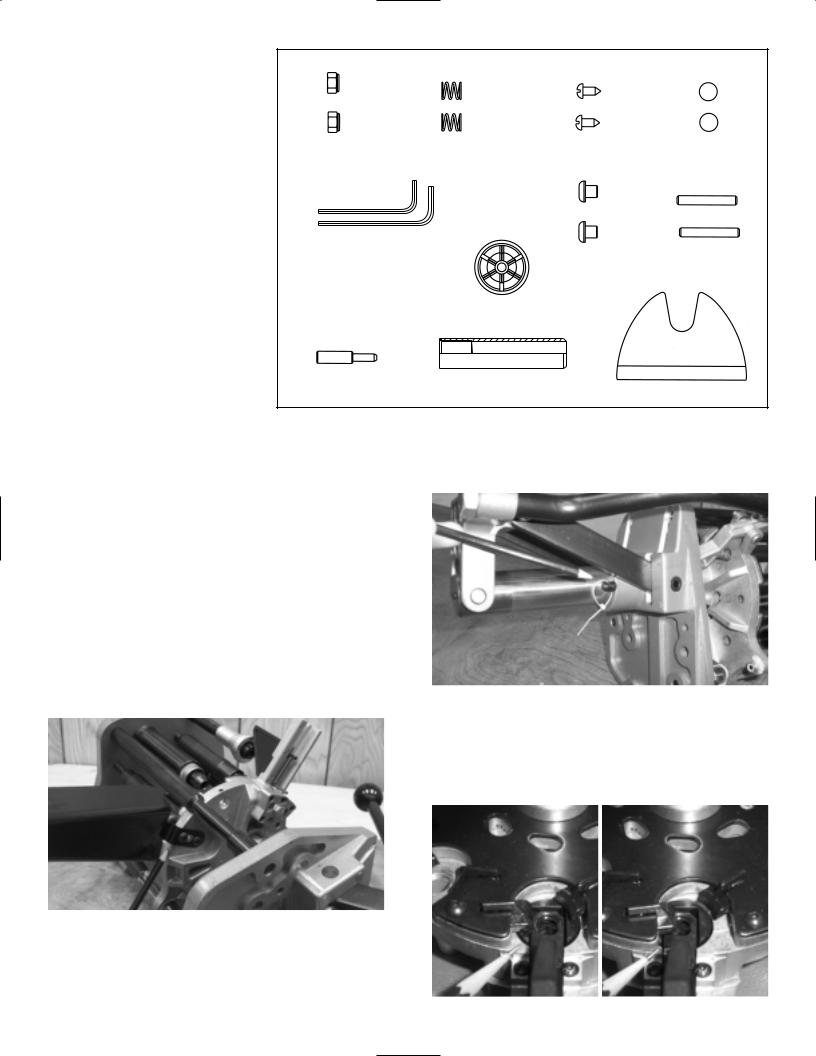

Bag 1, Parts List

#8 x 3/8 Wood Screw 1/4-28 x 1/4 BHCS 3/8 Detent Ball Detent Spring

Shotshell Crimp Starter 12 Ga., 6 Pt Shotshell Primer Shut Off Pin 10-24 x 1-1/4 SHSS

10-24 Nyloc Nut

Shotshell Press Powder Baffle Hex Wrench, 5/32

Hex Wrench, 3/32

BAG 1 PARTS

10-24 NYLOC NUT |

DETENT SPRING |

#8 X 32 WOOD SCREW |

3/8 DETENT BALL |

|

189063 |

187153 |

189064 |

187152 |

|

|

|

|

|

|

|

|

|

|

|

ALLEN WRENCH 3/32, 109635 |

|

|

ALLEN WRENCH 5/32, 181150 |

1/4-28 X 1/4 BHCS |

10-24 X 1-1/4 SHSS |

|

189073 |

189062 |

CRIMP STARTER 12 GA., 6PT WAD BOX BRACKET 189020

CRIMP STARTER 12 GA., 6PT WAD BOX BRACKET 189020

789013

PRIMER SHUT OFF PIN |

LOWER SHOT TUBE - LONG, 12 GA. |

POWDER BAFFLE 189037 |

789039 |

789100 |

Your Grand is set up at the factory for the following loads:

12 GA. LOAD INFORMATION

Federal Gold Medal 23/4" hull, 17.5 gr. Red Dot,

452 powder bushing, CCI 209M primer, Federal 12S3 wad, 11/8 oz. #7 1/2 shot bushing

20 GA. LOAD INFORMATION

Winchester 23/4" hull, 16.0 gr. Unique, 381 powder bushing, CCI 209M primer, Winchester WAA20 wad, 7/8 oz # 71/2 shot bushing.

A Hydraulic conversion unit is also available for The Grand shotshell press. For pricing and information, contact RCBS direct at 1-800-533-5000.

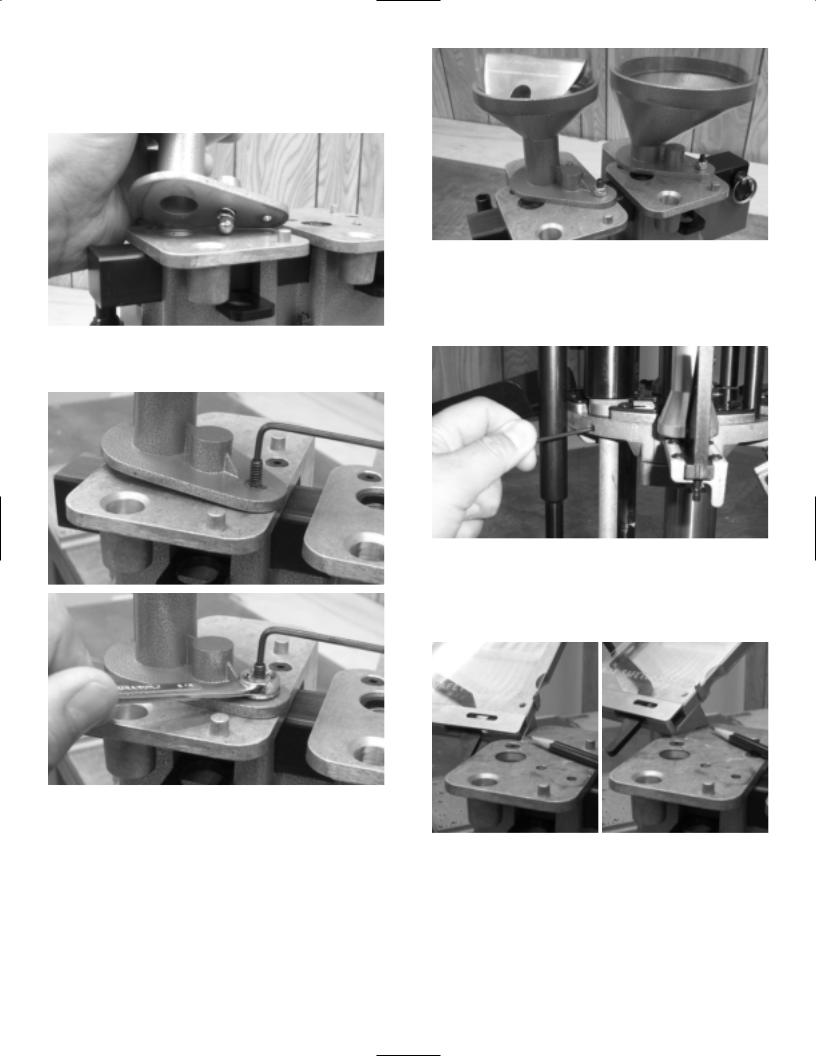

As you remove press from box, take caution not to lay press against primer channel. (photo 1) Lay press on opposite side so that the primer channel extends upward as shown below. Lay press on opposite side so that the primer channel extends upward as shown.

After laying press on bench, remove plastic tie securing the Lockout pin to the Ram of the press and remove Lockout pin. (photo 2) The Lockout pin can be used with a small lock (not included), to secure press when not in use.

2

CAUTION: SHELL PLATE POSITION

Care must be taken that the shell plate is always in the proper position. (photo 3) Check index position before cycling.

Press must never be partially indexed, this results in damage to the Case Holders. Rotate Shell Plate and feel for Index Ball to position properly.

right wrong

1

3 |

4 |

1

PRESS MOUNTING

Step 1 Attach Discharge Chute to the bottom of the Shell Plate Holder as shown in photo 1. Use two 1/4-28 x 1/4 Button Head Cap Screws and 5/32 hex wrench.

Step 2 Mount your press to a solid bench. Presses mounted to a weak or flexible bench are a safety hazard and will not produce a consistent loaded round. The Grand press is designed with two sets of mounting holes, three larger holes (two of these holes for mounting to an optional RCBS Accessory Base Plate-2 part number 09280) or four small holes for the optional RCBS Riser Stand part number 89010.

5

Select an area on your bench with approximately one-foot clearance on each side of The Grand. Install press with three 3/8" bolts or four 1/4 " bolts, length to be determined by the thickness of your bench (mounting hardware not included). The press can also be mounted on our optional Riser Stand, which raises the press four inches above your bench (Riser Stand part number 89010) (see photo 6).

The front edge of your bench must have a minimum of 11/2" of clearance to allow the press handle to cycle completely. The optional Riser Stand angles forward off your bench to allow the complete cycle of the press handle. Insure that the toggle block does not strike the face of your bench.

6

LOADED ROUND CONTAINMENT

For presses mounted directly to the bench, you may want to drill a 3" hole just off the end of the Discharge Chute and catch your loaded rounds beneath the bench.

7

Use of the optional Riser Stand allows the loaded rounds to drop into a container on top of the bench (Riser Stand and container not included).

8

POWDER AND SHOT SYSTEM

The Grand 12 gauge comes with one #452 powder bushing and a 11/8 oz. #71/2 shot bushing. The 20 gauge Grand comes with one #381 powder bushing and a 7/8 oz. #71/2 shot bushing. To change bushings, before powder and shot are added, just remove charge bar locking pin (photo 9) and slide the charge bar to the right. This allows the removal of the charge bar to change bushings (photo 10).

9

10

2

INSTALL POWDER AND SHOT HOPPERS

The Powder Hopper (smaller diameter tube) is to be mounted on the left and the Shot Hopper (larger diameter tube) on the right.

Install detent spring then ball into hopper funnel assembly and install on the press as shown in photo 11.

11

Install 10-24 x 11/4 " set screw securely through hopper funnel base and into the top of the shut off plate. Install 10-24 Nyloc nut to secure hopper funnel base to top of press. Use 3/32 hex wrench and 3/8 wrench (not provided).

12

14

Note: In OFF position

INSTALL SPENT PRIMER TUBE ASSEMBLY

Raise ram to the top of the press stroke and install the tube as shown in photo 15. Tighten the setscrew to secure the tube. Do not over tighten, use 3/32 hex wrench.

15

INSTALL PRIMER TRAY

With ram still raised to the top of the press stroke, place Primer Tray on Primer Tube as shown in photo 16. Primer Tray is held in place by its own weight. Primer Tray body is to the left of the Powder Shut Off Plate and does not ride on top of the plate

(photos 16 & 17).

13

Funnels must be tightly secured but be able to pivot between OFF, ON and DRAIN positions. Install powder baffle through the top of the powder hopper as shown in photo 14.

right |

16 wrong |

17 |

3

Loading...

Loading...