Page 1

THE GRAND

PROGRESSIVE SHOTSHELL

RELOADING PRESS

PRODUCT INSTRUCTIONS

Page 2

IMPORTANT

Before using the RCBS Shot Shell Press, read these instructions carefully to fully learn how to safely operate the

related reloading equipment. Failure to properly operate certain reloading equipment can result in severe personal

injury and/or equipment damage.

If you have any questions while assembling or operating this tool,

call us at 1-800-533-5000 or 1-530-533-5191

Monday - Thursday 6:30 a.m. to 3:00 p.m. Pacific Time

The instruction manual contains specific safety and operating information. It should be considered a permanent

part of your reloading equipment and remain with the equipment at all times for easy reference.

SAFETY

Reloading is an enjoyable and rewarding hobby that can

be conducted safely. But, as with any hobby, carelessness

or negligence can make reloading hazardous. This product

has been designed from the beginning with the user’s

safety in mind. When reloading, safety rules must be

followed. By observing these rules, the chance of a

hazardous occurrence causing personal injury or

property damage is minimized.

GENERAL

• Use all equipment as the manufacturer recommends.

Study the instructions carefully and become thoroughly

familiar with the operation of the product. If you do not

have written instructions, request a copy from the

equipment manufacturer.

• Don’t take short cuts. Attempting to bypass established

procedures is an invitation to an accident.

• Observe “good housekeeping” in the reloading area.

Keep tools and components neat, clean and orderly.

Promptly and completely clean up primer and powder

spills.

• Reload only when you can give your undivided attention.

Do not reload when fatigued or ill, or under the influence

of medications or alcohol.

• Develop a reloading routine to avoid mistakes which may

prove hazardous. Don’t rush - load at a leisurely pace.

• Always wear adequate eye protection to protect your

eyes from flying particles. You assume unnecessary risk

when reloading without wearing safety glasses.

LOADING DATA

• Use only laboratory tested reloading data. There are

many lab tested shotshell manuals available. Always

follow the load data exactly as it is published

in any shotshell reloading manual.

• Never substitute components

• OBSERVE ALL WARNINGS ABOUT THE USE OF

MAXIMUM LISTED LOADS

• Store primers and powder beyond the reach of children

and away from heat, dampness, open flames and electrical

equipment. Avoid areas where static electricity is evident.

• Do not use primers of unknown identity.

• Dispose of unknown primers in accordance with

applicable regulations.

• Keep primers in the original factory container until ready to

use. Return unused primers to the same factory packaging

for safety and to preserve their identity. Primer packaging is

designed to provide safe storage.

• DO NOT store primers in bulk. The blast of just a few

hundred primers is sufficient to cause serious injury to

anyone nearby.

• DO NOT force primers. Use care in handling primers.

• DO NOT have more than one can of powder on the bench

at one time. Powder cans should be stored away from the

bench to avoid picking up the wrong one.

• DO NOT use any powder unless its identity is positively

known. The only positive identification is the manufacturer’s

label on the original canister. Discard all mixed powder

and those of uncertain identity.

• Always replace the lids on both the powder hopper and

shot hoppers after they have been filled.

• When you finish a reloading session, pour any remaining

powder back into its original factory container. This will

preserve the identity and shelf life of the powder.

• DO NOT smoke while reloading.

RECORD KEEPING

• Keep complete records of reloads. Apply a descriptive

label to each box showing the date produced, and the

primer, powder, wad and shot used.

Never attempt to guess at the identity of your

ammunition.

PRIMERS AND POWDER

Because RCBS has no control over the choice of components, the manner in which they are assembled,

the use of this product, or the guns in which the resulting ammunition may be used, we assume no responsibility,

expressed or implied, for the use of ammunition reloaded with this product.

Page 3

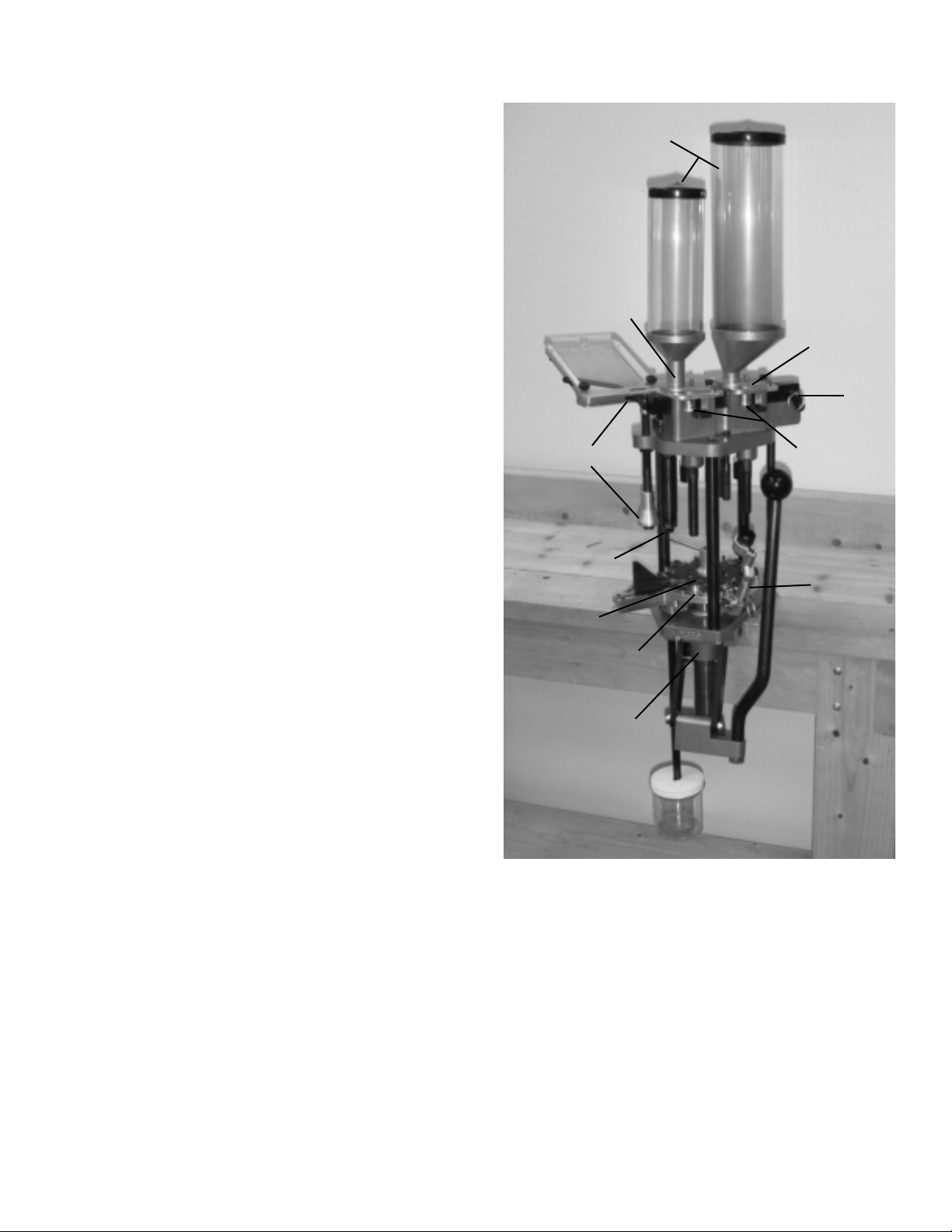

1 POWDER SYSTEM - Hull activated, no hull, no powder.

No need to manually turn powder on and off. No spillage of

powder can occur.

2 SHOT SYSTEM - Hull activated, no hull, no shot. No need

to manually turn shot on and off. No spillage of shot when

problems occur.

3 CASE HOLDERS - Easy removal of hull at all stations.

Universal 12 and 20 gauge case holders allows cases to

be sized down around the rim.

• The combination of the Powder System, Shot System and

the Case Holders allows the user to reload one shell

without fear of spillage.

4 PRIMING SYSTEM - Allows only one primer to feed at a

time and is an extremely reliable primer feed system.

5 STEEL SIZE RING - Provides complete resizing of high

and low base hulls. Not found in most presses.

• AUTO INDEX - Simple and very reliable automatic indexing

system that can be easily removed for manual indexing.

6 TILT-OUT WAD GUIDE - For easy and convenient feeding

of wads.

• MASSIVE FRAME - With compound leverage for smooth

solid feel.

7 QUICK DRAIN SYSTEM - Both powder and shot hoppers

have three locating positions. Off, on, and a forward drain

position for quick and convenient removal.

8 QUICK CHANGE - Of powder and shot bushings. Changes

over in less than one minute.

9 POWDER CHARGE - Is easy to check because the powder

station is directly in front of the press and it is easy and

convenient to remove the powder charge hull.

10 LARGE OPEN FRAME - Designed for convenient easy

access to all 8 stations.

• EASY CONVERSION - Changing from 12 gauge to 20

gauge is quick and easy with our convenient conversion kit.

11 SHOT & POWDER HOPPERS - Holds 25 pounds of shot

and 1 pound of powder.

THE “GRAND”

11

1

2

4

5

9

3

10

7

6

8

89001 THE GRAND, 12 ga. Shotshell Press

89003 THE GRAND, 20 ga. Shotshell Press

89005 Shotshell Press Conversion Kit, 20 ga.

89007 Shotshell Press Conversion Kit, 12 ga.

89010 Riser Stand

89100 Charge Bar

For shot and powder bushing

information see page 14.

Page 4

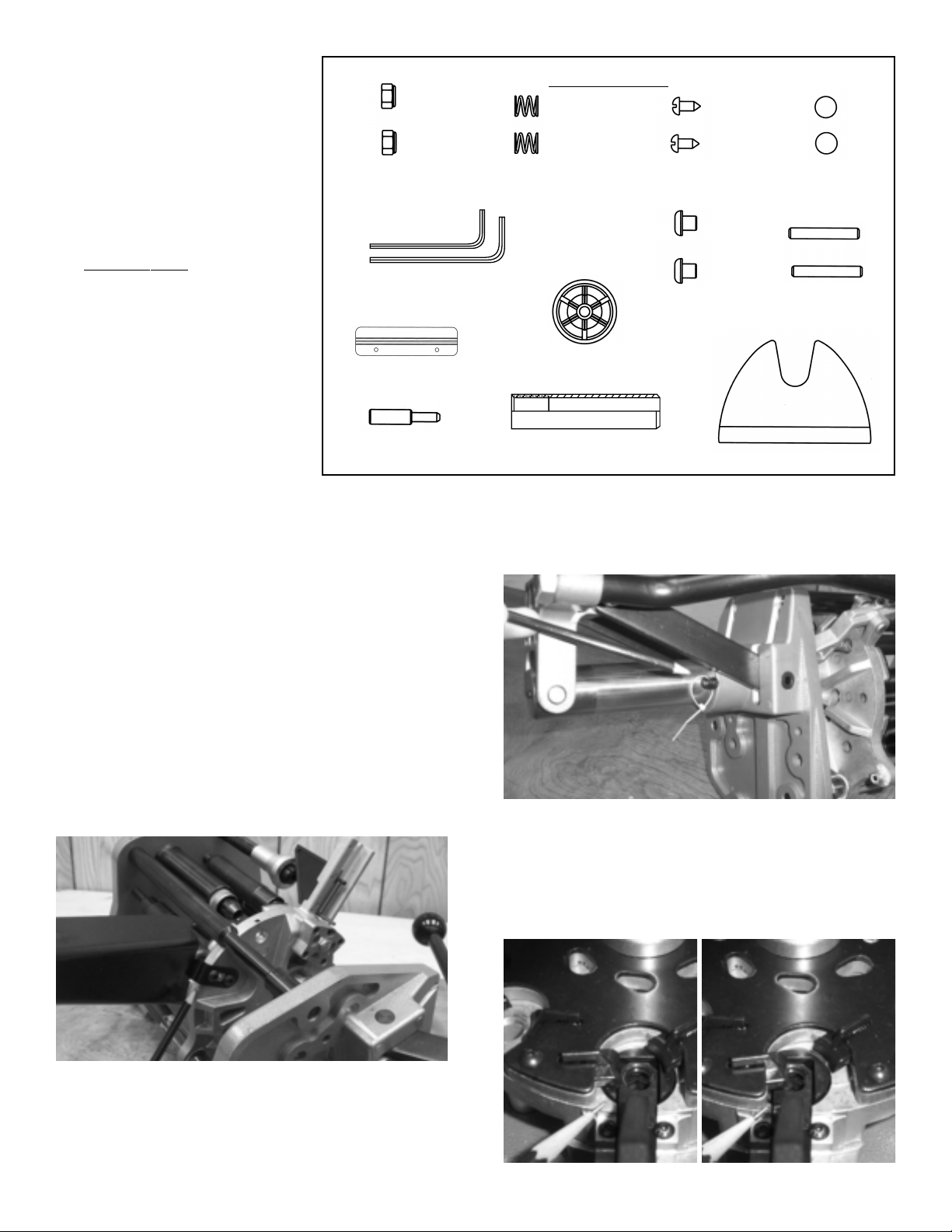

UNPACKING THE GRAND

A. Shot Hopper

B. Spent Primer Tube Assembly

C. Powder Hopper

D. Drain Tube (Clear Rubber Hose)

E. Press Assembly

F. Wad Box

Video

Wad Box Bracket

Discharge Chute

Primer Tray

Bag 1, P

#

8 x 3/8 Wood Screw

1/4-28 x 1/4 BHCS

3/8 Detent Ball

Detent Spring

Shotshell Crimp Starter 12 Ga., 6 Pt

Shotshell Primer Shut Off Pin

10-24 x 1-1/4 SHSS

10-24 Nyloc Nut

Shotshell Press Powder Baffle

Hex Wrench, 5/32

Hex Wrench, 3/32

arts List

10-24 NYLOC NUT

189063

ALLEN WRENCH 3/32, 109635

ALLEN WRENCH 5/32, 181150

WAD BOX BRACKET

789013

PRIMER SHUT OFF PIN

789039

BAG 1 PARTS

DETENT SPRING

187153

CRIMP STARTER 12 GA., 6PT

189020

LOWER SHOT TUBE - LONG, 12 GA.

789100

#8 X 32 WOOD SCREW

189064

1/4-28 X 1/4 BHCS

189073

3/8 DETENT BALL

187152

10-24 X 1-1/4 SHSS

189062

POWDER BAFFLE 189037

Your Grand is set up at the factory for the following loads:

12 GA. LOAD INFORMATION

Federal Gold Medal 23/4"

452 powder bushing, CCI 209M primer, Federal 12S3 wad,

1

/8oz.#71/2shot bushing

1

hull, 17.5 gr. Red Dot,

20 GA. LOAD INFORMATION

Winchester 23/4" hull, 16.0 gr. Unique, 381 powder bushing, CCI

209M primer,Winchester WAA20 wad,

A Hydraulic conversion unit is also available for The Grand

shotshell press. For pricing and information, contact RCBS

direct at 1-800-533-5000.

As you remove press from box, take caution not to lay press

against primer channel.

that the primer channel extends upward as shown below. Lay

press on opposite side so that the primer channel extends

upward as shown.

(photo 1)

7

/8oz #71/2shot bushing.

Lay press on opposite side so

➞

After laying press on bench, remove plastic tie securing the

Lockout pin to the Ram of the press and remove Lockout pin.

(photo 2)

included), to secure press when not in use.

The Lockout pin can be used with a small lock (not

2

CAUTION: SHELL PLATE POSITION

Care must be taken that the shell plate is always in the

proper position.

cycling.

Press must never be partially indexed, this results in damage

to the Case Holders. Rotate Shell Plate and feel for Index Ball

to position properly.

(photo 3)

right

Check index position before

wrong

1

3

4

1

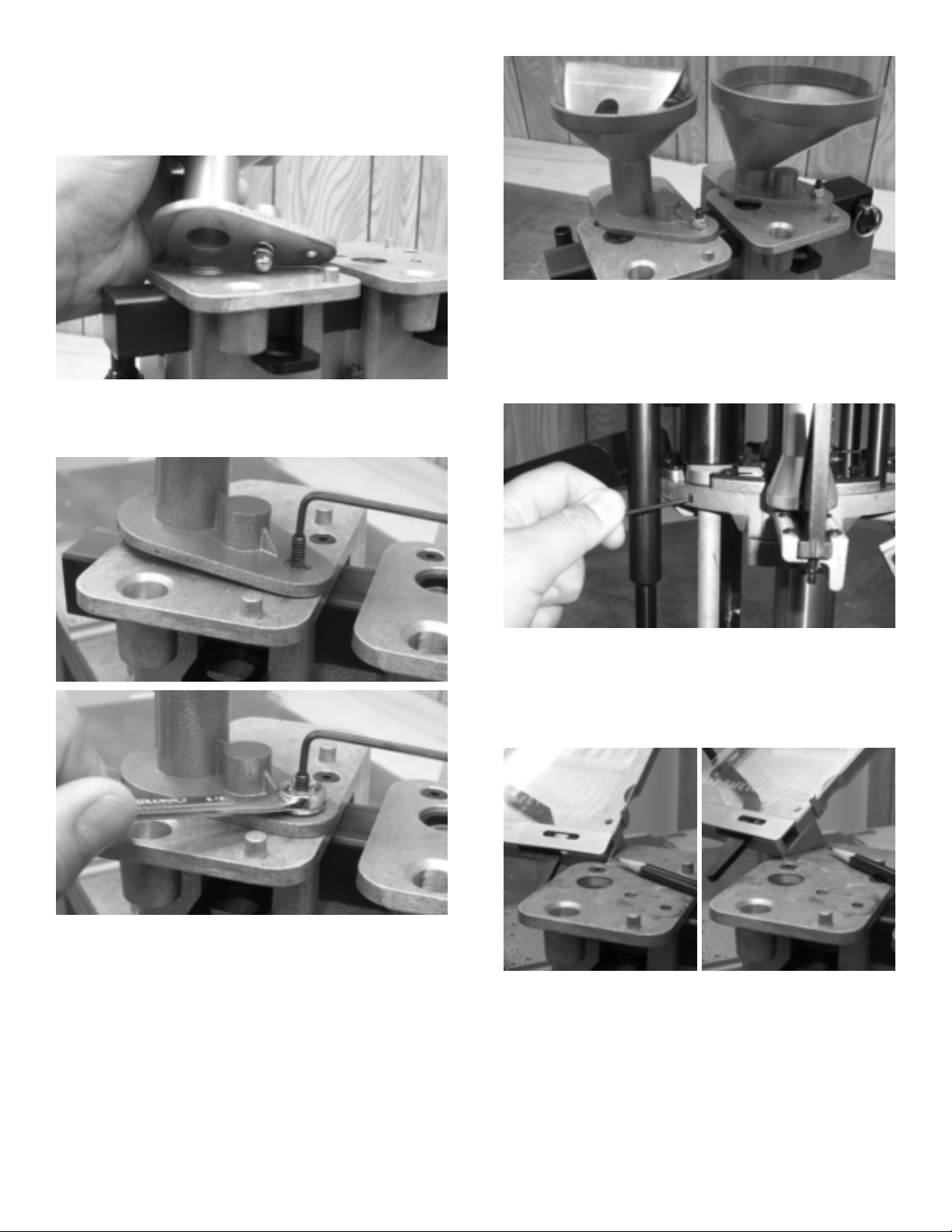

Page 5

PRESS MOUNTING

Step 1 Attach Discharge Chute to the bottom of the Shell

Plate Holder as shown in photo 1. Use two 1/4-28 x

Button Head Cap Screws and 5/32 hex wrench.

Step 2 Mount your press to a solid bench. Presses mounted

to a weak or flexible bench are a safety hazard and will not

produce a consistent loaded round. The Grand press is

designed with two sets of mounting holes, three larger holes

(two of these holes for mounting to an optional RCBS

Accessory Base Plate-2 part number 09280) or four small

holes for the optional RCBS Riser Stand part number 89010.

1

/

4

5

Select an area on your bench with approximately one-foot

clearance on each side of The Grand. Install press with three

3

/8" bolts or four 1/4" bolts, length to be determined by the

thickness of your bench (mounting hardware not included).

The press can also be mounted on our optional Riser Stand,

which raises the press four inches above your bench (Riser

Stand part number 89010)

The front edge of your bench must have a minimum of 11/2" of

clearance to allow the press handle to cycle completely. The

optional Riser Stand angles forward off your bench to allow the

complete cycle of the press handle. Insure that the toggle

block does not strike the face of your bench.

(see photo 6).

LOADED ROUND CONTAINMENT

For presses mounted directly to the bench, you may want to

drill a 3" hole just off the end of the Discharge Chute and

catch your loaded rounds beneath the bench.

7

Use of the optional Riser Stand allows the loaded rounds to

drop into a container on top of the bench (Riser Stand and

container not included).

8

POWDER AND SHOT SYSTEM

The Grand 12 gauge comes with one #452 powder bushing

1

and a 1

with one

To change bushings, before powder and shot are added, just

remove charge bar locking pin

bar to the right. This allows the removal of the charge bar to

change bushings

/8oz.#71/2shot bushing. The 20 gauge Grand comes

#

381 powder bushing and a 7/8 oz.#71/2shot bushing.

(photo 10)

(photo 9)

.

and slide the charge

6

9

10

2

Page 6

INSTALL POWDER AND SHOT HOPPERS

The Powder Hopper (smaller diameter tube) is to be mounted on

the left and the Shot Hopper (larger diameter tube) on the right.

Install detent spring then ball into hopper funnel assembly and

install on the press as shown in photo 11.

11

1

Install 10-24 x 1

base and into the top of the shut off plate. Install 10-24 Nyloc

nut to secure hopper funnel base to top of press. Use 3/32 hex

wrench and 3/8 wrench (not provided).

/4" set screw securely through hopper funnel

➞

14

Note: In OFF position

INSTALL SPENT PRIMER TUBE ASSEMBLY

Raise ram to the top of the press stroke and install the tube as

shown in photo 15. Tighten the setscrew to secure the tube.

Do not over tighten, use 3/32 hex wrench.

12

13

Funnels must be tightly secured but be able to pivot between

OFF, ON and DRAIN positions. Install powder baffle through

the top of the powder hopper as shown in photo 14.

15

INSTALL PRIMER TRAY

With ram still raised to the top of the press stroke, place Primer

Tray on Primer Tube as shown in photo 16. Primer Tray is held

in place by its own weight. Primer Tray body is to the left of the

Powder Shut Off Plate and does not ride on top of the plate

(photos 16 & 17)

right

.

16

wrong

17

3

Page 7

Install Wad Box Bracket approximately six inches from the

right side of the press to provide clearance between the

handle and the box

be flush with the bench top. Attach using the two 8x32 Wood

Screws provided. Hang Wad Box on Bracket.

(photo 18)

. The top of the Bracket should

18

PRESS FUNCTIONS BY STATION

The Grand is an eight-station auto indexing progressive

shotshell reloader. All functions occur on the upstroke of the

Ram with the exception of indexing, which occurs on the down

stroke of the Ram. The Index Arm may be removed for manual

indexing of the press.

STATION 1

Full length resizing and spent primer removal. Resizing is

accomplished with a steel sizing ring

(photo 20)

.

Install Primer Shut Off Pin into Primer Tray (

Assembly is complete.

➞

photo 19)

.

20

STATION 2

Priming. Primers are fed from the Primer Tray to the Primer

Drop Tube

(photo 21)

.

21

Primer is dropped from the Primer Drop Tube Collet to the

Primer Transfer Bar

(photo 22)

.

19

22

4

Page 8

Primer Transfer Bar delivers the primer to the primer station

(photo 23)

.

STATION 5

Shot Drop and Wad Seating. Case activated, will not drop a

shot charge without a hull with a wad present. Drop Tube (A),

driven by the bottom of the wad cup, drives the Shot Shut Off

gate (B) to drop the shot charge

present or a hull with no wad

assembly does not activate the Shot Shut Off gate. The Wad is

seated at the top of the stroke.

(photo 26)

(photo 27)

. If no hull is

, the Drop Tube

➞

23

Primer is seated at the top of the stroke.

STATION 3

Powder Charge. Case activated, will not drop powder if a hull is

not present. Drop Tube (A) drives the Powder Shut Off gate (B)

to drop the powder charge

Drop Tube assembly does not activate the Powder Shut Off gate.

(photo 24)

B

. If no hull is present, the

➞

➞

A

24

STATION 4

Wad insertion

(photo 25)

.

A

B

➞

26

➞

27

NOTE: No wad present.

STATION 6

Crimp Start. An 8 point Crimp Starter is installed at the factory

(photo 28)

accessory box.

. A 6 point Crimp Starter is included in the

25

28

5

Page 9

STATION 7

Crimp. The Crimp Die is pre-adjusted for Federal Gold Medal

Hulls with a Federal 12S3 wad

other components may require adjustments.

(photo 29)

. NOTE: The use of

29

STATION 8

Final Crimp. Removes “nail head.” Loaded round is radiused

(tapered) at the nose at the top of the downstroke

and ejected at the end of the upstroke as the Case Holder

Plate indexes

(photo 31)

.

(photo 30)

30

FILL POWDER AND SHOT HOPPERS

The next step is to load the Powder Hopper. The Powder

Hopper is the smaller diameter tube on the left. Be sure the

Hopper is in the ON (middle) position as shown in photo 32.

Remove the cap and pour the powder into the Powder Hopper.

The Powder Hopper will hold approximately one pound of

powder (varies based on powder type). After filling the Powder

Hopper, replace the cap.

31

DRY CYCLE PRESS

Before adding shot, powder and primers, take some time to

cycle a few hulls in the press. Advance the case from one

station to the next by cycling the press handle with a SLOW,

STEADY and COMPLETE

press indexes. The Grand press does not require a lot of effort

to index the press when returning the handle forward.

stroke. Get a feel for how easily the

32

Adding shot is the next step.The Shot Hopper is the larger

diameter tube on the right. Be sure the Hopper is in the ON

(middle) position. Remove cap and place a funnel (not included)

in the top of the Shot Hopper and pour the shot into the Shot

Hopper.The Shot Hopper will hold a full 25 pound bag of shot.

After filling the Shot Hopper, remove funnel and replace cap.

size shot is the largest shot size that The Grand will accommodate.

FILL PRIMER TRAY

Loading the primer tray is next. Insure that Primer Shut Off Pin

is installed into Primer Transfer Arm. Next, pull the press

handle all the way down (NOTE: Insure Case Holder Plate is

indexed properly). Lift the Primer Tray off the Priming Tube.

The Primer Tray can be laid flat on the bench for easy loading

of the primers. The front end of the Primer Tray that attaches

to the Drop Tube should extend beyond the edge of your

bench

(photo 33)

. This will allow the Primer Tray to lay flat.

#

5

CAUTION: Shell Plate must never be partially indexed, this

results in damage to the Case Holder Plate. Turn Case Holder

Plate and feel for index ball to position

When cycling the press, always use full stroke of the handle

and the Case Holder Plate will always properly align itself.

(see photos 3 & 4)

.

33

6

Page 10

Open the Primer Tray Lid. Place a sleeve of 209 primers

upside down on the Primer Tray. Slide the outer sleeve off to

the rear.You will need to slightly raise the outer sleeve to clear

the Primer Tray Lid. The primers will be properly oriented.

Properly close the Primer Tray Lid and replace Primer Tray

onto Priming Tube. (Tip: Drop four to five primers manually

into the Primer Drop Tube before installing the loaded Primer

Tray. This acts as a “reserve” supply should you have a primer

“bridge” in the Primer Tray during operation of the press.)

FILL WAD BOX

Fill wad box with appropriate type wads.

PRESS OPERATION – SINGLE ROUND

With your right hand on the Handle Ball, pick up an empty hull

with your left hand and insert into station 1 by sliding the hull

base flat on the Shell Plate Holder (A), under the two Case

Holders (B). The Case Holders will self-align the hull for the

sizing and spent primer removal operation

(photo 34)

.

Caution must be taken when loading one round at a time

with The Grand shot shell press. Press vibration causes

powder and shot to settle and pack into the charge

bushings. The powder and shot charges can be increased

by up to 12%. Do not use the first powder and shot charges

after several empty cycles of the press handle.

COMPONENT ADJUSTMENT SECTION

If using other than Federal Gold Medal 23/4" hulls, Federal

12S3 wads, CCI 209M primers, Alliant Red Dot powder or 1

1/8 oz of

necessary. If loading 3

removed and the press indexed manually.

1. Powder or Shot Bushing change Refer to section

2. Sizing The Grand is shipped with the Size Die adjusted for

#

71/2shot, a few simple adjustments may be

Powder and Shot Charge Bushing Change

proper hull ejection pressure. Rough handling during shipping

can cause this to change. If excessive pressure is felt during

resizing or hulls stick up in the Sizing Die please readjust.

Proper setting is with one to three threads showing. Simply

screw up or down the top portion of the Sizing Die

1

/2" hulls, the Index Arm must be

, page 9.

(photo 35)

.

B

➞

B

➞

A

34

Remove Primer Shut Off Pin from the Primer Tray and place in

hole in bottom left corner of the Primer Tray for storage.

Smoothly lower the Handle. This resizes and deprimes the hull

in Station 1. Raise the Handle completely, this will index the

hull to Station 2. Reinstall the Primer Shut Off Pin into the

Primer Tray, this prevents an excessive amount of primers from

being fed into the Primer Drop Tube.

Lower the Handle and this will prime the hull in Station 2.

Raise the Handle completely and index the hull to Station 3.

Make sure that your Powder Hopper is in the ON position.

Lower the Handle and the hull will actuate the powder drop

system allowing a charge to fill the hull. Raise the Handle

completely and index the hull to Station 4.

Place a wad into the Wad Guide of the tilt out Wad Guide

Carrier with your right hand and then lower the Handle. This

inserts a wad into the hull. Raise the Handle completely and

index the hull to Station 5.

Make sure that the Shot Hopper is in the ON position. Lower

the Handle, the inserted wad in the hull will actuate the shot

drop system allowing a shot charge to fill the hull. The wad is

also being seated at this point.

Lowering and raising the Handle three more times will start the

crimp, crimp, final (taper) crimp and eject the loaded round.

Notice the ease of loading just one round, powder and shot

are dropped only when a hull was present. You can continue to

practice one at a time or begin your continuos progressive

loading process.

35

3. Priming Station Adjustment The Primer Stem Assembly

is under spring tension to compensate for varying internal

base wad heights between hull manufacturers. Should it

become necessary to adjust primer depth, the Primer

Seater Body Assembly can be moved up or down. To make

this adjustment, loosen the top

up or down in

seating depth is achieved

1

/4turn increments until desired primer

3

/4" lock nut and screw rod

(photo 36)

.

36

7

Page 11

4. Powder Station Adjustment Once again, due to base wad

height, it may be necessary to adjust the Powder Drop Tube

to obtain proper Powder Shut Off Gate movement. With a

hull present and the Handle lowered, the Shut Off Gate

should be flush to

photo 37)

grasp the Upper Drop Tube with the fingers of one hand and

unscrew the Lower Drop Tube with the fingers of the other

hand

. To make this adjustment, with an empty station 3,

(photo 38)

1

/4" inset with the Top Plate casting

. Secure with brass lock ring.

(“A”

31/2" hulls, remove top lock nut (D) and socket head cap screw

on Wad Guide Arm and raise upper half of Wad Guide Arm.

Position upper half of Wad Guide Arm to clear the hull and

reinstall socket head cap screw and nut.You must also raise

the Wad Starter Rod. Due to shot cup length of some 1

and greater wads, you may have to manually insert wads. First,

remove the Wad Carrier arm and remove the Wad Guide.You

then place a wad into the Wad Guide and place over the hull

mouth. Cycle the press. The Wad Guide must then be removed

from the Wad Starter Rod and the process repeated.

1

/4oz.

➞

A

➞

37

D

➞

A

C

B

➞

➞

39

38

5. Wad Insertion Adjustment If wad petals contact Wad Starter

Rod (A), loosen nut (B)

petal clears, retighten nut. This prevents folding over of the

wad petal as it is inserted into the hull. If the Wad Carrier is

not centered over the hull, crushed hulls, damaged wads or

broken Wad Fingers may result. To center the Wad Carrier,

place a fired 2

shell plate holder assembly at station 3, this will prop up the

plate and more easily allow adjustment. Loosen the lower lock

nut on the adjustment set screw and adjust the set screw (C)

until the Wad Guide is centered to slightly forward under the

Starter Rod

3

/4" hull between the bottom casting and the

(see photo 39A)

(photo 39)

and adjust rod up until wad

, retighten lock nut. To load 3" or

39A

8

Page 12

6. Shot Drop and Wad Seating Station Adjustment

shot is the largest size The Grand will dispense. Larger shot

sizes must be weighed separately and manually put into the

hull prior to the Crimp Start station. Due to varying base wad

heights and design, as well as wad design, it may be

necessary to adjust the Lower Shot Tube to obtain proper

wad seating depth. Adjust by grasping the Upper Drop Tube

with the fingers of one hand and unscrew the Lower Drop

tube with the fingers of the other hand

brass lock ring. Shot Shut Off Gate movement will typically be

1

/4" out to all the way in. For 12 gauge hulls with tapered

from

internal bases such as Winchester AA red or gray, Remington

STS or Nitro 27, etc., a longer Lower Shot Tube has been

provided to achieve proper wad seating depth. (NOTE:

Improper wad seating depth will cause hull collapse/buckling

or crimp problems at Station 7).

For proper wad seating, 20 gauge loaders need to adjust a

1

gap of

tubes.

/4" to 5/16" between the Upper and Lower Shot Drop

(photo 40)

#

. Secure with

5 size

40

➞

C

42

9. Final Crimp Adjustment Final crimp is an up or down

adjustment to radius the end of the loaded round. Loosen

the top lock nut (D)

up or down and retighten lock nut.

10. Case Eject Adjustment The Press is preset for proper

case eject. Should adjustment become necessary, using a

5

/16" hex key wrench, loosen the socket head cap screw in

the top of the Eject Rod Holder, position the Case Eject

Arm to just clear the final crimp die and retighten the cap

screw. (CAUTION: Do not use the Case Eject Rod to try to

tighten the Eject Rod Holder!)

(see photo 41)

DRAIN SHOT AND POWDER HOPPERS

Place the flexible drain tube on the boss below the hopper you

wish to empty. Place a container beneath the drain tube. Rotate

the Hopper to the DRAIN position and the Hopper will empty in

a matter of seconds

(photo 43)

, adjust Final Crimp die

.

7. Crimp Start Adjustment Crimp start is an up or down

adjustment. Loosen the top lock nut (A) and adjust Crimp

Start assembly up or down, retighten lock nut

Too much Crimp Start can cause a bulge on the side at

the top of the hull during crimp. Not enough crimp start can

leave a hole in the center of your hull after crimp.

(photo 41)

D

➞

➞

A

8. Crimp Adjustment Crimp is also an up or down

adjustment. The crimp depth is controlled by loosening lock

(see photo 41)

nut (B)

up or down and retighten lock nut. If hulls bulge or collapse

during crimp, reduce crimping spring pressure. To reduce

crimp spring pressure, adjust nut (C)

the bottom of the Top Plate. If the crimp is concave or

dished, add spring pressure. If the crimp is peaked, reduce

crimp spring pressure and check that wad is seated to the

correct depth. (NOTE: If wads are not seated deep

enough, the shot column will be too high in the hull thus

causing problems with crimp.)

, adjusting the Crimp Die assembly,

(photo 42)

➞

➞

B

B

41

up towards

.

43

POWDER AND SHOT BUSHING CHANGE

The Grand shot shell press uses replaceable powder and shot

bushings to control charge weights. Carefully check the charge

weights thrown as they can vary based on powder type, age of

powder and type of shot used.

Empty charge bar for bushing change.To change Powder or

Shot bushings, but staying with the same type of powder and

size of shot, move Hoppers to the OFF position. If you are

changing type of powder or shot, DRAIN hoppers first. You must

then remove the powder and shot left in the Charge Bar. With the

press clear of hulls, place a fired hull in station 3 and a fired hull

with a wad in Station 5. Lower the Handle, dropping the charges

in the charge bar. Raise the Handle completely, remove the hulls,

empty hulls and replace back into Stations 3 and 5. Lower and

raise the Handle once more. Remove and empty the hulls. Your

Charge Bar is now cleared. Remove the Charge Bar locking pin

and the slide to the right allowing changing of the Bushings.

9

Page 13

(CAUTION: Be sure to support underneath the Charge Bar to

keep from dropping the Bushings out the bottom.)

Install appropriate Powder and Shot Bushings, the Shot

Bushing is the larger diameter of the two and should be on the

right side, reinstall the Charge Bar. (NOTE: The windows on the

Charge Bar allow you to see what type of bushings that you

have installed, the windows should face the front of the press.)

Reinstall Charge Bar Locking Pin through the Index Shaft

Bracket and Charge Bar. (NOTE: Lowering the Handle slightly,

allows movement of the Push Rod, allowing the Locking Pin to

be installed through the Index Shaft Bracket easier.)

TROUBLESHOOTING

1. Hulls:

Split or crushed hulls are not to be used. Out of round

hulls may catch on Size Ring or Primer Seat Die. Return to

round before using.

2. Indexing:

The Case Holder Plate indexing is set at the factory. Should

adjustment become necessary, adjust the adjustment screw

up or down. Indexing can be affected if errant shot finds its

way into the Case Holder Plate or under the Indexing Arm

(see photo 44)

.

45

5. Primers do not transfer from Primer Tray to Drop Tube:

Remove Lock Pin from Primer Tray.

Primer Tray may not be seated properly on Drop Tube.

photos 16 & 17

Charge Bar not making full and proper travel. The Handle

is not being cycled completely or check Index Shaft and

Brackets for wear or looseness.

Broken Primer Transfer Arm. (see

6. Primer Tray fell off press:

Improperly seated or the Primer Shut Off Pin was not

inserted when single rounds were loaded. If the Primer Shut

Off Pin is not inserted, primers will continue to feed into the

Drop Tube, the Drop Tube fills with primers (@25) and works

the Primer Tray up and off the press

.

#

7 below)

(see photo 46)

See

.

44

3. Adjusting the upper bushing of the size die will increase or

decrease the amount force used to push the hull from the

Size Die. Adjust so you feel the minimal amount of force to

size but enough to eject the spent primer and push the hull

from the Size Ring.

4. Hull stuck in the Size Die:

Typically not enough spring pressure. Adjust the upper

bushing of the Size Die down to push the hull from the Size

Die. High base brass may require more hull ejection spring

pressure. If hull ejection pressure is at a maximum setting

and the hulls continue to stick in the Size Die, inspect Case

Holders for damage or this may be a sign that there is base

wad separation in the hull. Inspect the offending hull, if base

wad separation is noticed, discard hull. CAUTION: If this hull

is loaded, the base wad may separate when fired and lodge

in the barrel causing damage to the firearm and potential

injury to the shooter.

(see photo 45.)

We’re here to help!

If you have any questions, call RCBS Customer Service at

1-800-533-5000, Monday - Thursday, 6:30 a.m. to 3:00 p.m.

46

7. Primers found on top of press:

Broken Transfer Arm. This is usually caused when the Primer

Drop Tube is filled with primers and the top primer wedges

between the Transfer Arm and the Drop Tube.The Charge

Bar pushes the Transfer Arm to the left and breaks off the

right side that is contained inside the Primer Tray. With the

right side of the Transfer Arm broken off, primers will

eventually push out the broken piece and also fall out onto

the top of the press instead of down into the Drop Tube.

10

Page 14

8. Primers do not drop from Collet to Transfer Bar:

Check Collet for damage or burrs.

Check Primer Transfer Bar for damage or burrs.

Loosen lock nut (B) on the top of the Primer Drop Tube

and adjust down in

freely. Retighten lock nut

the Primer Drop Tube Assembly too far down may cause

damage to the Primer Transfer Bar.)

1

/4turn increments until primers drop

(photo 47)

.(CAUTION: Adjusting

B

➞

9. Primers drop from the Primer Transfer Bar before

reaching the end of its travel:

The Primer Sleeve in the lower casting may not have

returned upward. Foreign material may be lodged in the

assembly. Remove Primer Seater Casting, inspect for

damage, clean (or replace damaged parts) and reinstall.

10. Hulls stick below Case Holder Plate after priming,

causing press not to index:

Use of very low base brass hulls is typically the cause. The

Primer Seat Die outer body is clearing the Case Holders

before the brass portion of the hull is exposed. Loosen

Lock Nut (A) and lower outer die body down in

increments until problem solved

11. Hull mouths catch going into the Primer Seat Die:

Hulls are either not round or there is a slight die body

alignment problem. Return hull mouth to “round” condition.

To realign, remove primers, insert a hull in Station 2, loosen

lock nut (A,

into Primer Seat Die, with Handle at very bottom of stroke,

retighten lock nut (A).

photo 49

), lower Handle while guiding hull up

(photo 49)

1

/4turn

.

47

48

A

➞

12. Powder below the shell plate at Station 3:

Hull is missing primer.

Check to insure that primer supply has not run out.

Check for damage to Primer Transfer Bar that may cause

primers to drop in sideways onto Primer Seat Plug.

13. Inconsistent powder charges:

Foreign material may have made its way into the powder

bushing. We have seen strings from shot bags, seals from

the powder canister and pieces of plastic.

Lower drop tube may not be adjusted to basewad in hull to

provide full travel of Shut Off.

Index Shaft and Brackets may be worn or loose causing

the Charge Bar to not make complete left and right

movements.

14. Hulls pop out at Station 4 - wad insertion:

The Wad Guide is not returning up. Remove cap screw

and washer

see that the three springs are stacked properly. Check that

Wad Starter Rod is not adjusted too far up. If Wad Starter

Rod is too far up, it will not insert the wad past the Wad

Guide. The wad sticks in the Wad Guide and when the

Wad Carrier tips back, the hull is pulled from the press.

Adjust Wad Starter Rod to just clear wad petals as Wad

Guide tips inward.

(photo 50)

, remove Wad Guide and check to

49

11

Page 15

50

15. Wads crush hull mouths upon insertion:

Check Wad Guide for missing wad fingers. Replace if

fingers are missing.

Check alignment of Wad Carrier Arm. At the insertion

position, the Wad Guide should be centered to slightly

forward of center in relationship to the Wad Starter Rod

above it. See

16. Inconsistent shot charges:

Index Shaft and Brackets may be worn or loose causing

the Charge Bar to not make complete left and right

movements.

The Shot bushings were calibrated to soft lead shot.

Chilled or Magnum shot has a higher antimony content

and though the shot size may be

less mass for the same volume versus soft lead. Bushings

may be enlarged to drop a larger volume of shot or

sleeved to reduce the volume of shot.

17. Hulls collapse at Station 7 – crimp:

Wads are not seated deeply enough causing the shot

column to be too high. The crimp die cannot push the

crimp closed over the shot column, exerts excessive force

and collapses the side of the hull.

Too much crimp pressure, reduce crimp spring force.

#

5

(page 8)

of Component Adjustment section.

#

8 or #7.5 etc., there is

May be sporadic due to a damaged Case Holder, only

affects one of the eight case holder stations. If multiple

Case Holders are damaged, it will happen more frequently.

Damaged Case Holder(s) need to be replaced.

20. Hard ejection of loaded round at Station 8:

Typically caused by a damaged case holder. The Case

Holder does not retract causing extra force to be used to

eject round. If multiple Case Holders are damaged, it will

happen more frequently. Damaged Case Holder(s) need to

be replaced. Remove hulls from press. Using a

wrench, loosen socket head cap screw inside of Case

Eject Rod Holder

(CAUTION: Note position of Case Eject Rod, if it is not

positioned properly upon reattachment, damage may

occur). Remove Case Holder Plate Assembly by lifting

counter clockwise from Shell Plate Holder. Remove eight

8-32 button head cap screws with provided

off top plate, replace damaged Case Holders and

reassemble. Insure all Case Holders retract freely before

tightening the screws. Reinstall onto press ensuring Case

Eject Rod is in the correct position

(photo 52)

and remove from press

(photo 53)

5

/16" hex

3

/32" wrench. Lift

.

52

right wrong

18. Hull sticks up into Crimp Die at Station 7:

Crimp Die is adjusted down too far and/or Crimp Spring

force is excessive. Reduce spring pressure by backing off

nut above spring

seated deeply enough

high, not allowing for proper crimp.

Case Holders may be damaged and must be replaced.

19. Hull sticks up into Taper Crimp Die at Station 8:

Excessive taper crimp being applied-loosen top lock nut

and raise die.

Or as above, improper wad depth, causing too high of a

shot column.

(See photo 42)

(Station 5)

. Also, if the wad is not

, the shot column is too

51

21. Case Eject Rod broken:

As above, the extra force necessary to eject the loaded

round with damaged case holders puts extra force on the

Case Eject Rod, causing it to break. Also, after removing

and cleaning under the Case Holder Assembly, the Case

Eject Holder was aligned improperly under a die station,

when the handle is cycled, the die breaks off the eject rod.

22. Powder or shot is dropped without a hull present:

Shut Off is stuck to the rear. Shut Offs, Charge Bar and

housing may need to be cleaned. Powder dust residue

may cause the Shut Off to bind. Also, If your shot is very

dusty, this also causes the Shut Off to bind.

RECLAIMED SHOT!

12

53

DO NOT USE

Page 16

MAINTENANCE

Three areas that require more frequent lube are the Shell

Plate Assembly,

Carrier and the

grease will suffice.

The Case Holder Assembly must be removed to properly

lubricate. Follow

on how to properly remove and replace the Shell Plate

Holder Assembly.

(photo 1)

(photo 3)

Troubleshooting #20, page 12

contact area of the

back Support Rod. Any light oil or

(photo 2)

for directions

A

Wad

4

1

5

B

B

2

C

3

Periodic cleaning of the Charge Bar channel, Shut Off channel

and Upper Drop Tube holes in the Upper Casting will lessen

down time due to damaged or worn parts.

To clean these areas, drain and remove Powder and Shot

hoppers. Drain Powder and Shot bushings and remove Charge

Bar. Remove the Powder and Shot Shut Off Plates. This allows

complete access to the areas that require cleaning. When

reassembling, make sure that the Shut Off Plates are on the

correct side. The Shot Shut Off Plate goes on the right side

and has a rubber washer installed in the hole. Also, make sure

that the extension in the back of the Shut Off is surrounded by

the return spring.

6

7

13

Page 17

89100 THE GRAND, Charge Bar

POWDER CHARGE WEIGHT IN GRAINS

GRAINS 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43

Accurate Solo 1000 387 399 411 420 432 438 447 459 474

Accurate Solo 1250 369 384 396 408 420 429 441 453 459 471 480 492 501 510 516 525 537 543 555 558

Accurate No. 2 Improved 357 366 378 387 396 408 417

Accurate Nitro 100 375 387 399 411 423 435 447 456 465

DuPont 700-X 402 414 429 441 453 465 471 486 498

DuPont PB 366 390 402 414 426 435 447 456 465 474 486

DuPont SR 7625 345 381 390 402 414 426 438 444 453 462 474 486

DuPont 800-X 372 390 402 414 423 429 438 447 459 468 480 507 525 534 549 558

DuPont SR 4756 366 408 426 435 447 459 471 480 525 534 549 558 580 588

DuPont 4227 366 390 408 414 420 426 435 441 447 453 462 468 474 480 486 498

Alliant American Select 417 423 432 447 456 468 477 483

Alliant Red Dot & E3 405 423 438 453 468 480 489 498 510 519

Alliant Green Dot 390 405 420 435 447 456 468 480 492 501 513 522 534 549 558

Alliant Unique 354 369 381 393 405 414 423 435 444 453 465 474 483 492 501 510

Alliant Herco 369 381 393 405 414 426 438 450 462 471 477 489 498 513 522 531 549 558 564 573 588 594

Alliant Blue Dot 366 372 381 390 396 408 414 423 435 441 447 459 468 474 483 489 495 501 510 516 522 531 534 543 549 555

Alliant 2400 291 300 312 324 330 339

Hodgdon Clays 429 441 456 468 483 495 507

Hodgdon International 375 390 402 414 423 435 447 459 471 483 495 507

Hodgdon Universal 342 354 366 378 390 402 411 420 429 438 447 456 468 480 489 501

Hodgdon HS-6 300 309 318 327 336 345 357 360 366 375 381 387 393 402 408 414 423 429

Hodgdon HS-7 318 330 339 348 357 363 369 378 384 390 396 405 411 417 423 429 438 444 450

Hodgdon Titewad 384 396 408 420 432 441 453 462 474 486 492

Hodgdon Longshot 300 309 318 330 345 348 357 366 372 381 390 396 405 414 423 429 435 444 450 459 465 471 480 486 492 498

Hodgdon Titegroup 324 330 343 351 360 369 378 387 396 405

Winchester 540 300 309 318 327 336 345 360 366 381 402 408 414 423 429 435 441 444 450 459 465 471

Winchester 571 318 390 396 423 429 438 444 450 456 462 468 474 480 486

Winchester Super Target 414 429 438 450 459 471 480

Winchester Super Lite 345 354 363 372 381 390 402

Winchester Super Field 327 345 354 420 426 432 441 450 456 462

HOW TO SELECT BUSHINGS FOR HALF GRAIN CHARGES:

Powder bushings are identified by numbers that correspond to

the size of their inside diameter. (For instance, the inside

diameter of the #456 bushing is .456 inches.) Bushings for

powder charges in half-grain increments can be calculated from

this chart. Simply “split the difference” between the two evengrain bushings, and select the bushing nearest the result.

Example: To find the bushing for 18 1/2 grains of Alliant Red

Dot powder, note that bushing #468 gives a charge of 18 grains

THE GRAND, Powder Bushings

Part Number Bushing# Part Number Bushing# Part Number Bushing# Part Number Bushing#

89111 354 89119 408 89127 438 89135 462

89112 360 89120 414 89128 441 89136 465

89113 366 89121 420 89129 444 89137 468

89114 372 89122 423 89130 447 89138 471

89115 381 89123 426 89131 450 89139 474

89116 390 89124 429 89132 453 89140 480

89117 396 89125 432 89133 456 89141 486

89118 402 89126 435 89134 459 89142 498

THE GRAND, Lead Shot Bushings

For Field Loads #6’s

Compensates for tighter packing

of smaller shot size.

Part Number Bushing Description

89170 7/8 oz.

89171 1 oz.

89172 1-1/8 oz.

89173 1-1/4 oz.

89174 1-3/8 oz.

89175 1-1/2 oz.

INTERCHANGEABLE

CHARGE BUSHINGS

For use with THE GRAND

shotshell reloader.

Designed so shot and

powder bushings cannot be

accidentally reversed in the

charge bar. The bushings

make it easy to change

from one load to another.

14

and that bushing #480 gives 19 grains. Split the difference

between 468 and 480, and the result is 474. Thus, the correct

bushing for 18 1/2 grains of Red Dot is bushing #474.

All charges listed on this chart are an average of several loads,

weighed following the complete reloading cycle. Powders used

in establishing these loads were from ballistic samples supplied

by the manufacturer or sealed tins of recent manufacture.

Charges may vary slightly due to operator's technique and/or

powder variables.

THE GRAND, Lead Shot Bushings

For Target Loads

Calibrated to measure maximum legal loads

for trap and skeet shooting.

Part Number Bushing Description

89188 7/8 oz. #9

89189 1 oz. #7-1/2

89190 1 oz. #8

89191 1-1/8 oz. #7-1/2

89192 1-1/8 oz. #8

89193 1-1/8 oz. #8-1/2

89194 1-1/8 oz. #9

Page 18

# Description Part # Qty

THE GRAND PARTS LIST • NOVEMBER 2003

1 SS Frame 789000 1

2 SS Top Plate 789001 1

3 SS Support Rod 789023 2

4 SS Support Rod Turned 789031 1

5 3/8-16 x 1 Flat Head Cap Screw 188750 3

6 Link Pin Left 788258 1

7 Link Pin Right 788257 1

8 SS Ram 789020 1

9 Detent Ball 187152 3

10 Detent Spring 187153 3

11 1/4-28 x 3/8 Socket Head Set Screw 187219 1

12 SS Lock Out Pin 789022 1

13 Link 188719 2

14 SS Toggle Block 789002 1

15 7/16-20 Nyloc Nut 188108 2

16 Toggle Block Pin 788256 1

17 SS Ram Pin 789021 1

18 Handle 786862 1

19 Handle Ball 109121 1

20 5/8-18 Hex Nut 109136

21 SS Charge Bar 789018 1

22 SS Powder Bushing SEE CHART

23 SS Shot Bushing SEE CHART

24 SS Shut Off Plate Powder 789062 1

25 SS Shut Off Plate Shot 789010 1

26 Rubber Washer 189039 1

27 10-24 x 1/2 Flat Head Cap Screw 189077 4

28 10-24 x 1-1/4 Socket Head Set Screw 189062 2

29 10-24 Nyloc Nut 189063 2

30 SS Shut Off 189019 2

31 SS Spring 189061 2

32 SS Self Locking Pin 189036 2

33 8-32 x 1/4 Button Head Cap Screw 188041 10

34 SS Index Shaft Bracket 789006 1

35 8-32 x 3/4 Button Head Cap Screw 187221 1

36 8-32 Nyloc Nut 189078 1

37 SS Charge Bar Index Shaft 789047 1

38 SS Charge Bar Push Rod Upper 789045 1

39 1/4-28 Hex Nut 109604 1

40 SS Charge Bar Push Rod Lower 789046 1

41 1/4-20 Nyloc Nut 189072 1

42 3/16 x 1 Clevis Pin 189038 1

43 SS Index Arm 789009 1

44 SS Powder Funnel 789011 1

45 SS Powder Hopper 189031 1

46 SS Powder Hopper Cap 189029 1

47 SS Powder Baffle 189037 1

48 SS Shot Funnel 789012 1

49 SS Shot Hopper 189030 1

50 SS Shot Hopper Cap 189028 1

51 SS Spent Primer Bottle Cap 789016 1

52 SS Decap Tube 789030 1

53 SS Spent Primer Bottle 189032 1

54 1/4-28 x 1 Flat Head Cap Screw 189075 3

55 1/4-28 Hex Nut 189604 2

56 SS 10/32 x 1/4 Socket Head Set Screw 109099 1

57 SS Spring 189055 1

58 SS Primer Seater Casting 189026 1

59 6-32 x 5/8 Socket Head Cap Screw 198964 4

60 1/4-28 x 1/2 Hex Head Bolt 189067 1

61 SS Primer Transfer Bar 789102 1

62 SS Spring 189054 1

63 1/8 x 1 Roll Pin 189079 1

64 6-32 x 1/4 Button Head Cap Screw 189066 6

65 SS Primer Sleeve 189025 1

66 SS Primer Plug 789034 1

67 SS Case Holder Plate 12 GA. 789004 1

67 SS Case Holder Plate 20 GA. 789110 1

68 SS Case Holder Top Plate Cap 789005 1

69 SS Case Holder 12 GA. 189015 16

69 SS Case Holder 20 GA. 789109 16

70 SS Spring 189052 16

71 8-32 x 5/16 Button Head Cap Screw 186147 9

72 SS Eject Rod Holder 12 GA. 789054 1

72 SS Eject Rod Holder 20 GA. 789119 1

73 SS Eject Rod 789055 1

74 3/8-16 x 1-1/2 Socket Head Cap Screw 189074 1

75 SS Shell Plate Holder 789003 1

76 SS Discharge Chute 789017 1

77 1/4-28 x 1/4 Button Head Cap Screw 189073 2

78 SS Green Wad Box 189033 1

Wad Carrier Assy 12 GA. 789078, 20 GA. 789132

79 SS Wad Carrier Bottom 789008 1

# Description Part # Qty

80 SS Wad Carrier Top 789007 1

81 5-40 x 3/4 Socket Head Cap Screw 189068 1

82 5-40 Hex Nut 189069 1

83 10-24 Hex Nut 189086 1

84 10-24 x 1-1/4 Socket Head Set Screw 189062 1

85 SS Spring 189058 1

86 SS Wad Guide 12 GA. 189016 1

86 SS Wad Guide 20 GA. 189017 1

87 SS Spring 189057 3

88 8-32 Flat Washer 189080 2

89 SS Primer Drop Tube Assy 789096 1

90 SS 5/8-18 Lock Ring 789059 1

91 SS Transfer Bar Actuator 789033 1

92 1/4-28 x 1/4 Socket Head Set Screw 189076 1

93 SS Primer Dispenser Collet 189024 1

Primer Tray Assy 789087

94 SS Primer Tray Bottom 189027 1

95 SS Primer Tray Frame 789014 1

96 10-32 x 1/4 Socket Head Cap Screw 187687 2

97 SS Primer Tray Base 789015 1

98 10-32 x 5/8 Socket Head Cap Screw 186624 2

99 SS Primer Feed Bar 189034 1

100 SS Spring 189061 1

101 SS Primer Shut Off Pin 789039 1

102 SS Primer Tray Lid 189035 1

Size Die Assy 12 GA. 789071, 20 GA. 789128

103 SS Size Die Bushing 789025 1

104 SS Spring 189053 1

105 SS Hull Extractor 12 GA. 789029 1

105 SS Hull Extractor 20 GA. 789112 1

106 SS Decap Rod Assy 789072 1

107 SS Size Die Body 789024 1

108 SS 1-3/8-12 Lock Ring 789058 1

109 SS Size Ring 12 GA. 789026 1

109 SS Size Ring 20 GA. 789111 1

Primer Body Assy 12 GA. 789074, 20 GA. 789129

110 1/2-13 Hex Nut 189081 2

111 Snap Ring 180052 1

112 SS Primer Body Bushing 789038 1

113 SS Primer Body 789037 1

114 SS Primer Stem Washer 789063 1

115 SS Spring 189056 1

116 SS Primer Stem Assy 12 GA. 789075 1

116 SS Primer Stem Assy 20 GA. 789130 1

Powder Tube Assy 789076

117 SS Upper Drop Tube 789101 1

118 SS Drop Tube Lock Ring, Brass 789056 1

119 SS Powder Tube Lower 789042 1

Shot Drop Tube Assy 12 GA. 789077, 20 GA. 789131

117 SS Upper Drop Tube 789101 1

118 SS Drop Tube Lock Ring, Brass 789056 1

122 SS Shot Tube Lower 12 GA. 789044 1

122 SS Shot Tube Lower 20 GA. 789115 1

Wad Starter

120 3/8-16 Hex Nut 189082 1

121 SS Wad Starter 12 GA. 789043 1

121 SS Wad Starter 20 GA. 789114 1

Crimp Starter Assy 12 GA. 789091, 20 GA. 789133

120 3/8-16 Hex Nut 189082 1

123 SS Crimp Start Rod 789048 1

124 SS Crimp Starter 12 GA. 8 POINT 189021 1

124 SS Crimp Starter 20 GA. 8 POINT 189023 1

125 SS Crimp Starter 12 GA. 6 POINT 189020 1

125 SS Crimp Starter 20 GA. 6 POINT 189022 1

126 8-32 x 1/2 Socket Head Cap Screw 187227 1

Crimp Closer Assy 12 GA. 789082, 20 GA. 789134

120 3/8-16 Hex Nut 189082 2

127 SS Crimp Closer Washer 789051 1

128 SS Spring 189059 1

129 SS Crimp Closer Sleeve 12 GA. 789049 1

129 SS Crimp Closer Sleeve 20 GA. 789116 1

130 SS Crimp Closer Plunger 12 GA. 789050 1

130 SS Crimp Closer Plunger 20 GA. 789117 1

Final Crimp Assy 12 GA. 789083, 20 GA. 789135

120 3/8-16 Hex Nut 189082 2

131 SS Final Crimp Rod 789052 1

132 SS Final Crimp Sleeve 12 GA. 789053 1

132 SS Final Crimp Sleeve 20 GA. 789118 1

133 SS Wad Box Bracket 789013 1

134 #8 x 1/2 Wood Screw 189064 2

Not Pictured

SS Drain Tube 789019 1

122 SS Lower Shot Tube - Long 789100 1

15

Page 19

16

Page 20

PRECISIONEERED®RELOADING EQUIPMENT

We think that we make the very best

reloading equipment in the world.

If you disagree, tell us - we want to do something about it!

If you agree, please tell your friends.

Customer Service

1-800-533-5000

(US or Canada) or

530-533-5191

Hours: Monday - Thursday, 6:30am - 3:00pm (hours may vary)

e-mail: rcbs.tech@atk.com • www.rcbs.com

RCBS • 605 Oro Dam Blvd. • Oroville, CA 95965

OUTERS • RAMLINE • ORBEX • FEDERAL

CCI • SPEER • RCBS

7201339/0205

Loading...

Loading...