Page 1

ROCK CHUCKER

SUPREME PRESS

PRODUCT INSTRUCTIONS

Page 2

SAFETY

Reloading is an enjoyable and rewarding hobby that can be conducted safely. But carelessness or negligence can make reloading hazardous. This product has been designed from the

beginning with the user’s safety in mind.

When reloading, some safety rules must be followed. By observing these rules, the chance of a

hazardous occurrence causing personal injury or property damage is minimized.

GENERAL

• Use all equipment as the manufacturer recommends. Study the instructions carefully and become

thoroughly familiar with the operating of the tool. Don’t take shortcuts.

• Observe “good housekeeping” in the reloading area. Keep tools and components neat, clean and

orderly. Promptly and completely clean up primer and powder spills.

• Reload only when you can give your undivided attention. Do not reload when fatigued or ill. Develop

a reloading routine to avoid mistakes. Avoid haste — load at a leisurely pace.

• Always wear adequate eye protection.

• If any unusual resistance is encountered when moving the operating handle, STOP IMMEDIATELY and

investigate the cause. To proceed against unusual resistance may damage equipment and/or cause

serious personal injury!

LOADING DATA

• Use only laboratory tested reloading data. We highly recommend the use of the SPEER Reloading

Manual or RCBS.load reloading software.

• OBSERVE ALL WARNINGS ABOUT THE USE OF MAXIMUM LISTED LOADS.

PRIMERS AND POWDER

• Store primers and powder beyond the reach of children and away from heat, dampness, open flames,

and electrical equipment.

• DO NOT use primers of unknown identity.

• Keep primers in original factory container until ready to use. Return unused primers to the same factory

packaging for safety and to preserve their identity.

• DO NOT store primers in bulk. The blast of just a few hundred primers is sufficient to cause serious injury

to anyone nearby.

• DO NOT force primers. Use care in handling primers.

• DO NOT use any powder unless its identity is positively known. Discard all mixed powders and those

of uncertain or unknown identity.

• If you use a powder measure, replace the lids on both the powder hopper and powder can after the

powder hopper has been filled.

• Before charging cases, settle the powder in the powder hopper. Load and check the weight of at least

ten charges. This will assure you that the correct powder charge is being loaded.

• After a reloading session ends, pour the remaining powder back in its original factory container. This

will preserve the identity and shelf life of the powder.

• DO NOT smoke while handling powder or primers.

RECORD KEEPING

• Keep complete record of reloads. Apply a descriptive label to each box showing the date produced, and

the primer, powder and bullet used. Labels for this purpose are packed with SPEER bullets.

Since RCBS has no control over the choice of components, the manner in which they are assembled, the

use of this press, or the firearms in which the resulting ammunition may be used, no responsibility, either

expressed or implied, is assumed for the use of ammunition reloaded with this press.

INTRODUCTION

The Rock Chucker Supreme Press has been designed specifically for heavy-duty reloading,

case forming, and bullet swaging. It is engineered to handle the largest and longest magnums

down to .17 caliber. The compound leverage system of the Rock Chucker Supreme Press can fulllength resize cases with less effort than other presses neck size. Using RCBS Case Forming Dies

this press will form .30-06 cases into many other calibers.

Page 3

By combining the famous RCBS block “O” frame with the compound leverage system, the

Rock Chucker Supreme will develop work pressure that would spring other presses out of alignment. To insure alignment under these pressures, the Rock Chucker press frame provides a full

four inches of ram-bearing surface to rigidly support the one inch diameter main ram. The

compound leverage action is similar to that of a power punch press. As the handle pressure

increases, the leverage is compounded, building up a maximum work pressure in the main ram as

it travels the full length of the stroke. The toggle block, links and pins are engineered to withstand

the punishment of heavy-duty reloading. The handle is made of solid steel and features a comfortable ball-type handle grip. The Rock Chucker Supreme Press has standard 7/8-14 thread for most

popular reloading dies and accessories.

ACCESSORIES

The Rock Chucker Supreme Press is designed to utilize a primer arm. This priming system is

equipped with interchangeable primer plugs and sleeves for seating large and small primers.

The Primer Catcher keeps spent primers from dropping to the floor and is easily removed for

emptying.

UNPACKING

Unpack the press carefully and look for the items listed below. Refer to the parts list for

identification.

• Press

• Handle

• Primer Catcher

• Accessory Pack: Contains handle nut, Primer Arm, large and small primer plugs and sleeves, coil spring

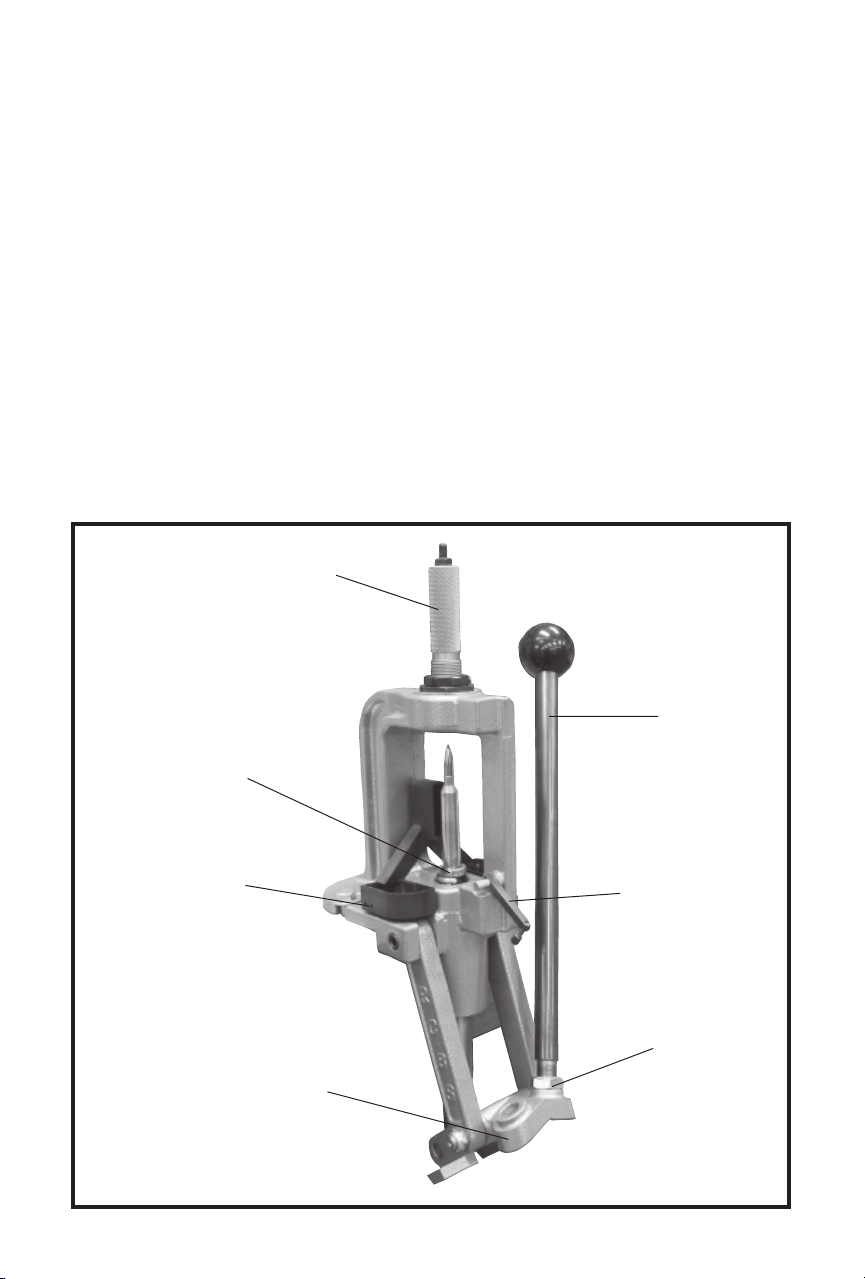

RELOADING DIE

(Not Included)

SHELL HOLDER

PRIMER

CATCHER

TOGGLE BLOCK

HANDLE

PRIMER ARM

HANDLE

LOCK NUT

Page 4

INSTALLATION

Mount the Rock Chucker Supreme Press to a sturdy workbench or table with two 3/8” bolts of

sufficient length to penetrate the press base and bench.

Attach the handle nut to handle. Install the threaded portion of the handle to either the right or

left side of the toggle block and lock down with the handle nut. See photo #1. The handle nut must

remain tight at all times to avoid damage to the handle and toggle.

Install the Primer Arm as show in photo #2.

Slip the primer catcher between the ram and rear portion of the frame. Snap the feet of the

primer catcher into slots on the side of the press frame. See photo #3.

The Rock Chucker Supreme press ram accepts removable type shell holders. To install, insert

the shell holder into the ram and twist slightly to the left. To remove, twist slightly to the right. See

photo #4.

WARNING

TO AVOID INJURY, READ AND FOLLOW THESE SAFE PRIMING PRACTICES.

DO NOT ATTEMPT TO PRIME MILITARY CARTRIDGE CASES WITH CRIMPED PRIMER

POCKETS UNTIL THE CRIMP HAS BEEN REMOVED WITH A COUNTER SINK, A

SPECIAL REAMER OR BY SWAGING. PRIMERS SEATED INTO CRIMPED POCKETS

ARE SUBJECT TO DEFORMATION WHICH CAN CAUSE MISFIRES AND EVEN

DETONATION DURING SEATING WHICH CAN CAUSE SERIOUS PERSONAL INJURY.

DO NOT ATTEMPT TO SEAT PRIMERS AGAINST EXCESSIVE RESISTANCE WHICH

MIGHT CAUSE DETONATION AND POSSIBLE SERIOUS PERSONAL INJURY. CHECK

TO BE CERTAIN THAT THE CASE WAS NOT PREVIOUSLY PRIMED, THAT THE FIRED

PRIMER WAS REMOVED, THAT A PORTION OF THE PRIMER CUP WALL MIGHT STILL

BE IN THE PRIMER POCKET AND THAT YOU ARE USING THE CORRECT SIZE PRIMER.

DO NOT MODIFY THE PRIMING SYSTEM IN ANY MANNER OR ATTEMPT TO USE

SIMILAR PARTS OR PRIMING SYSTEMS FROM OTHER MANUFACTURER’S. TO DO SO

COULD RESULT IN PRIMER DETONATIONS RESULTING IN SERIOUS PERSONAL

INJURY.

NEVER SEAT A PRIMER INTO A POWDER CHARGED CASE.

DECAPPING LIVE PRIMERS IS EXTREMELY DANGEROUS AND IS NOT

RECOMMENDED.

PRIMING

To use the primer arm, first make sure the correct size primer plug and sleeve are in position.

To install the primer plug and sleeve, drop the primer plug through the sleeve. Place the spring on

the primer arm body. Thread the plug and sleeve into the primer arm body and tighten the

assembly with a small nail or paper clip through the cross hole in the primer plug. Do not over

tighten. Check from time to time to be sure the primer plug remains tight.

Insert lubed case into shell holder, lower the press handle to size the case and remove the

spent primer. To prime, simply place the correct size primer, anvil side up, into the primer sleeve.

See photo #5. Then, gently and slowly raise the press handle. As the case is drawn out of the die,

the primer arm will guide into the slot in the ram, the case will be lowered onto the live primer,

seating it to the bottom of the primer pocket. See photo #6.

After the primer is seated, lower the press handle enough to allow removal of the case from the

shell holder. Be sure not to lower the handle too far or the decapping pin in the die will push the

live primer back out. Always inspect the primed case to make certain the primer is properly seated.

The Rock Chucker Supreme does not accept the Auto Primer Feed accessory (9550, 9580).

MAINTENANCE

This press was lubricated at the factory. However, it is necessary to lubricate all moving parts

from time to time with gun oil. If rust spots appear, swab lightly with gun oil and wipe dry. Care

should be taken not to apply oil where it could come in contact with primer pockets or primers. Oil

will deactivate primers. It is a good practice to clean the press prior to lubrication to remove grit

and other residue. You will note ease at which the epoxy enamel paint wipes clean. This finish is

impervious to oil and is extremely chip and fade resistant.

Page 5

Photo 1 Photo 2

Photo 3 Photo 4

Photo 5 Photo 6

Page 6

ROCK CHUCKER SUPREME

PRESS PARTS LIST

Key Part# Description

1 709193 Frame

2 788902 Linkage Arm (2)

3 709127 Link Pin, Left

4 709128 Link Pin, Right

5 709196 Toggle Block

6 709197 Toggle Block Pin

7 187212 7/16-20 Nyloc Nut (2)

8 709194 Ram

9 109112 Ram Clip Spring

10 788255 Ram Pin

11 187219 1/4-28 x 3/8" Setscrew

12 709198 Handle

Key Part# Description

13 109121 Handle Ball

14 109136 5/8-18 Hex Jam Nut

15 709138 Press Bushing

16 709195 RC IV Primer Arm Pin

17 109145 Primer Catcher Front

18 109146 Primer Catcher Back

19 788212 Primer Arm

20 709506 Primer Sleeve, LG

20 709507 Primer Sleeve, SM

21 709554 Primer Plug, LG

21 709555 Primer Plug, SM

22 109508 Primer Plug Spring

Page 7

REFERENCE TABLE

Primer

Shell

Holder

Caliber

17 Remington 10 Small

218 Bee 1 Small

22 Hornet 12 Small

22 K-Hornet 12 Small

22 Remington Jet 6 Small

22 Savage High-Power 2 Large

22-250 (22 Varminter) 3 Large

220 Swift 11 Large

221 Remington Fireball 10 Small

222 Remington 10 Small

222 Remington Magnum 10 Small

223 Remington (5.56mm) 10 Small

5.6mm x 50 Rimmed 6 Small

240 Weatherby Magnum 3 Large

243 Winchester 3 Large

6mm PPC 32 Small

6mm Remington (244 Remington) 3 Large

25 Auto (25 ACP) 29 (6) Small

25-06 3 Large

25-20 Winchester 1 Small

25-35 Winchester 2 Large

250 Savage (250-3000 Savage) 3 Large

257 Roberts 3/11 Large

257 Roberts Improved 40º 3/11 Large

257 Weatherby Magnum 4 Large

260 Remington 3 Large

264 Winchester Magnum 4/26 Large

6.5mm-06 3 Large

6.5mm x 54 Mannlicher-Schoenmauer 9 Large

6.5mm x 55mm Swedish Mauser 2 Large

6.5mm x 57mm Mauser 3 Large

6.5mm x 68Smm 34 (5) Large (2)

270 Weatherby Magnum 4 Large

270 Winchester 3 Large

270 Winchester Short Magnum 43 Large

280 Remington (7mm Exp. Rem.) 3 Large

284 Winchester 3 Large

7mm Bench Rest Remington 3 Small

7mm Remington Magnum 4/26 Large

7mm Remington Short Action Ultra Magnum 38/4 Large

7mm Remington Ultra Magnum 38/4 Large

7mm Shooting Times Westerner 4 Large

7mm Thompson/Center Ugalde 10 Small

7mm Weatherby Magnum 4 Large

7mm Winchester Short Magnum 43 Large

7mm-08 Remington 3 Large

7 x 57mm Mauser (7mm Mauser) 3/11 Large

7 x 64mm Brenneke 3 Large

7 x 65mm Rimmed 26 Large

7-30 Waters 2 Large

30 M-1 Carbine 17 Small

30 Luger (7.65mm Luger) 16 Small

30 Mauser (7.63mm Mauser) 16 Small

30 Remington 19 Large

30-06 Springfield 3 Large

30-30 Winchester 2 Large

30-338 Winchester Magnum 4 Large

30-357 Aet 6 Small

30-378 Weatherby Magnum 14 (5) Large

30-40 Krag 7 Large

300 H&H Magnum 4 Large

300 Remington Short Action Ultra Magnum 38/4 Large

300 Remington Ultra Magnum 38/4 Large

300 Savage 3 Large

300 Weatherby Magnum 4 Large

300 Winchester Magnum 4/26 Large

300 Winchester Short Magnum 43 Large

303 British 7 Large

307 Winchester 2 Large

308 Norma Magnum 4 Large

308 Winchester 3 Large

Number

Plug &

Sleeve

Size

Shell

Holder

Caliber

7.5mm xx 54 French MAS 2 Large

7.5mm Schmidt-Rubin 2 Large

7.62 x 39mm .308/.311 32 Large

7.62 x 54Rmm Russian .308/.311 13 (5) Large

7.65 x 53mm Belgian Mauser 3 Large

7.7 x 58mm Japanese Arisaka 3/2 Large

32 Automatic (7.65mm Auto) 17 Small

32 H&R Magnum 23 Small

32 Smith & Wesson Long 23 Small

32 Winchester Special 2 Large

32-20 Winchester 1 Small

32-40 Winchester 2 Large

8mm Remington Magnum 4 Large

8mm-06 3 Large

8 x 57mm Mauser (8mm Mauser) 3 Large

8 x 68Smm Magnum 34 (5) Large (2)

338 Lapua 14/37 (7) Large

338 Remington Ultra Magnum 38/4 Large

338 Winchester Magnum 4 Large

338-06 3 Large

338-378 Weatherby Magnum 14 Large

340 Weatherby Magnum 4 Large

348 Winchester 5 (5) Large

35 Remington 9 Large

35 Whelen 3 Large

350 Remington Magnum 4 Large

356 TSW 16 Small

356 Winchester 2 Large

357 Magnum 6 Small

357 Remington Maximum 6 Small

357 SIG 27 Small

358 Winchester 3 Large

9mm FAR 16 Small

9mm Luger 16 Small

9mm Makarov 16 Small

9 x 21mm 16 Small

9.3 x 62mm Mauser 3 Large (2)

9.3 x 74Rmm 4 Large

375 H&H Magnum 4 Large

375 Remington Ultra Magnum 38/4 Large

375 Winchester 2 Large

376 Steyr 42 Large

378 Weatherby Magnum 14 (5) Large

38 Colt Super Auto 39 Small

38 Special 6 Small

380 Automatic (ACP) 10 Small

38-40 Winchester 35 (5) Large

38-55 Winchester & Ballard 2 Large

40 S&W 27 Small

40-65 Shiloh Sharps-408" 14 (5) Large

400 CorBon 3 Large

405 Winchester 24 Large

10mm Auto 27 Large

41 Magnum 30 Large

416 Remington Magnum 4 Large

416 Rigby 37 (5) Large

44 Magnum 18 Large

44 Special 18 Large

444 Marlin 28 Large

44-40 Winchester 35 (5) Large

45 Automatic (45 ACP) 3 Large

45 Colt 20 Large

45-70 U.S. Government 14 (5) Large

450 Marlin 4 Large

454 Casull 20 Small

458 Winchester Magnum 4 Large

460 Weatherby Magnum 14 (5) Large

475 Linebaugh 1.400” 40 (5) Large

480 Ruger 40 Large

50 Action Express 33 (5) Large

Number

Plug &

Sleeve

Size

Primer

IMPORTANT: If the caliber of dies you require are not listed, it can be special ordered. RCBS Shell Holder numbers do not correspond to

those of other manufacturers. When two Shell Holder numbers are listed, the most popular is shown first. It may be necessary to use the

alternate, depending on the manufacturer and/or lot of cases being used. The numbers in ( ) in the table indicates the following: (1) Order

Shell Holder by caliber. (2) Cases may be Berdan primed. Depriming and priming must be done by hand. If cases were formed from cases

having boxer-type primer, use the appropriate Shell Holder for the caliber. (4) Not available. (5) Auto 4x4 Shell Plate not available. (6) Auto

4x4 and Five-Station Shell Plates not available. (7) Use #14 for Lapua brass, #37 for Norma brass.

Page 8

SHELL HOLDER CHART

Note: RCBS Shell Holder numbers do not correspond to those of other manufacturers.

09201 Number 1:

218 Bee

25-20 Winchester

32-20 Winchester

09202 Number 2:

22 Savage High Power

25-35 Winchester

6.5mm x 55 Swedish Mauser

7-30 Waters

30-30 Winchester

307 Winchester

7.5mmx54 French MAS

7.5mmx55 Schmidt-Rubin

32 Winchester Special

32-40 Winchester

356 Winchester

375 Winchester

38-55 Winchester & Ballard

09203 Number 3:

22-250 (22 Varminter)

240 Weatherby Magnum

243 Winchester

6mm Remington (244 Remington)

25-06

250 Savage (250-3000 Savage)

257 Roberts

257 Roberts Improved (40º) 1

260 Remington

6.5mm-06

6.5mm x 57

270 Winchester

280 Remington (7mm Exp. Rem.)

284 Winchester

7mm Bench Rest Remington

7mm-08 Remington

7mmx57 Mauser (7mm Mauser)

7mmx64 Brenneke

30-06 Springfield

300 Savage

308 Winchester

7.65mm x 53 Mauser (Belgian)

7.7mm x 58 Japanese Arisaka

8mm-06

8mm x 57 Mauser (8mm Mauser)

338-06

35 Whelen

358 Winchester

9.3mm x 62 Mauser

400 CorBon

45 Automatic (.45 ACP)

Note: RCBS Shell Holder numbers do not correspond to those of other manufacturers. Important: The boxed numbers shown in the table indicate the

following: 1 Shoulder angle of improved version. 3 Some Browning, DWM Lapua, Norma, RWS and Sako cases require an RCBS #26 Shell Holder.

09204 Number 4:

257 Weatherby Magnum

264 Winchester Magnum 3

270 Weatherby Magnum

7mm Remington Magnum 3

7mm Shooting Times Westerner

7mm Weatherby Magnum

30-338 Winchester Magnum

300 Holland & Holland Magnum

300 Weatherby Magnum

300 Winchester Magnum 3

308 Norma Magnum

8mm Remington Magnum

338 Winchester Magnum

340 Weatherby Magnum

350 Remington Magnum

9.3mm x 74 Rimmed

375 Holland & Holland Magnum

416 Remington Magnum

450 Marlin

458 Winchester Magnum

09205 Number 5:

348 Winchester

09206 Number 6:

22 Remington Jet

5.6mm x 50 Rimmed

30-357 AET

357 Magnum

357 Remington Maximum

38 Special

09207 Number 7:

30-40 Krag

303 British

09208 Number 8:

45 Auto Rim

09209 Number 9:

6.5mmx54 Mannlicher-Schoenauer

35 Remington

09210 Number 10:

17 Remington

221 Remington Fire Ball

222 Remington

222 Remington Magnum

223 Remington (5.6mm)

7mm Thompson/Center Ugalde

380 Auto Pistol

09211 Number 11:

220 Swift

09212 Number 12:

22 Hornet

22 K-Hornet

09213 Number 13:

7.62mm x 54R Russian

09214 Number 14:

30-378 Weatherby Magnum

338 Lapua

338-378 Weatherby Magnum

378 Weatherby Magnum

40-65 Shiloh-Sharps

45-70 U.S. Government

460 Weatherby Magnum

09215 Number 15:

6.5mm x 50 Japanese Arisaka

09216 Number 16:

30 Luger (7.65mm Luger)

30 Mauser (7.65mm Mauser)

356 TSW

9mm Luger

9mm Makarov

9mm x 21

9mm FAR

09217 Number 17:

30 M1 Carbine

32 Auto (7.65mm Automatic)

09218 Number 18:

44 Magnum

44 Special

09219 Number 19:

30 Remington

09220 Number 20:

45 Colt

454 Casull

09221 Number 21:

303 Savage

09222 Number 22:

11mm Mauser

43 Spanish

09223 Number 23:

32 Harrington & Richardson Mag

32 Smith & Wesson Long

09224 Number 24:

405 Winchester

09225 Number 25:

8mm Nambu

09226 Number 26:

7mm x 65 Rimmed

09227 Number 27:

357 SIG

40 S & W

10mm Auto

09228 Number 28:

444 Marlin

09229 Number 29:

25 Automatic (25 ACP)

09230 Number 30:

41 Magnum

09231 Number 31:

50-70 U.S. Government

09232 Number 32:

6mm PPC

7.62mm x 39

09233 Number 33:

50 Action Express

09234 Number 34:

6.5mm x 68S

8mm x 68S Magnum

99235 Number 35:

38-40 Winchester

44-40 Winchester

99236 Number 36:

45 Winchester Magnum

99237 Number 37:

416 Rigby

99238 Number 38:

7mm Remington Short Action

Ultra Mag

7mm Remington Ultra Magnum

300 Remington Short Action

Ultra Mag

338 Remington Ultra Magnum

375 Remington Ultra Magnum

99239 Number 39:

38 Colt Super Automatic

99240 Number 40:

475 Linebaugh 1.400"

480 Ruger

99241 Number 41:

404 Jeffery

99242 Number 42:

376 Steyr

99243 Number 43:

270 Winchester Short Magnum

7mm Winchester Short Magnum

300 Winchester Short Magnum

PRECISIONEERED® RELOADING EQUIPMENT

Customer Service

1-800-533-5000

(US or Canada) or

530-533-5191

Hours: Monday - Thursday, 6:30am - 3:00pm (hours may vary)

e-mail: rcbs.tech@atk.com • www.rcbs.com

RCBS • 605 Oro Dam Blvd. • Oroville, CA 95965

OUTERS • RAMLINE • ORBEX • FEDERAL

CCI • SPEER • RCBS

7200533/0104

Loading...

Loading...