Page 1

PRECISIONEERED RELOADING EQUIPMENT

We think that we make the very best reloading equipment in the world. If you

agree, please tell your friends. If you disagree, tell us we want to do

something about it!

Customer Service

1-800-533-5000 (US or Canada) or 530-533-5191

Hours: Monday - Thursday, 6:30am - 4:00pm Pacific Time

(hours may vary)

e-mail: rcbs.tech@atk.com or visit our website at www.rcbs.com

RCBS 605 Oro Dam Blvd. East Oroville, CA 95965

ALLIANT POWDER - CCI - CHAMPION TRAPS & TARGETS

EAGLE - ESTATE CARTRIDGE - FEDERAL AMMUNITION

FUSION AMMUNITION - GUNSLICK PRO - NITREX - OUTERS

RCBS – RAMLINE - SHOOTERS RIDGE - SPEER – WEAVER

7200545/0210

12

QUICK CHANGE HIGH CAPACITY

POWDER MEASURE

*Shown with optional Powder

baffle – sold separately

WARNING: NOT FOR USE WITH BLACK POWDER!

PRODUCT INSTRUCTIONS

Page 2

WARNING

Before using the RCBS Quick Change High Capacity Powder Measure, read

these instructions carefully to fully learn how to safely operate the related

reloading equipment. Failure to properly operate the related reloading equipment

can result in severe personal injury and/or equipment damage.

If you have any questions while assembling or operating this tool,

Call us at 1-800-533-5000 or 1-530-533-5191

Monday – Thursday 6:30 am – 4:00 pm Pacific Time

(hours may vary)

Or email us at rcbs.tech@atk.com

This instruction manual contains specific safety and operating information. It

should be considered a permanent part of your reloading equipment and remain

with the equipment at all times for easy reference.

LIMITED LIFETIME WARRANTY

Your Quick Change High Capacity Powder Measure is warranted to be free from

defects in material or workmanship for as long as the original owner owns it. This

warranty is extended only to the original consumer purchaser. All RCBS products

are intended for non-commercial use by hobbyists. Any other use of these

products will void the warranty. Should you believe that your QC HC Powder

Measure is defective in material or workmanship, you must return it to

Ammunition Accessories Inc. through its Oroville operation (hereinafter “Oroville

Operations”) postage paid for evaluation. If defective, the product will be repaired

or replaced at Oroville Operations’ option, at no charge.

Send a dated proof of purchase to Oroville Operations for return shipping and

handling, along with the QC HC Powder Measure to:

Ammunition Accessories Inc.,

Oroville Operations

605 Oro Dam Blvd East

Oroville, California 95965

Warranty services cannot be provided without meeting the above requirements.

THIS LIMITED LIFETIME WARRANTY DOES NOT COVER DEFECTS OR

DAMAGE RESULTING FROM: CARELESSNESS, MISUSE, COMMERCIAL

USE, ABUSE, IMPROPER INSTALLATION, MODIFICATION, OR NORMAL

WEAR AND TEAR. THE IMPLIED WARRANTIES OF MERCHANTABILITY AND

FITNESS FOR A PARTICULAR PURPOSE ARE LIMITED TO THE DURATION

OF THIS LIMITED LIFETIME WARRANTY. OROVILLE OPERATIONS IS NOT

LIABLE FOR DAMAGES IN EXCESS OF THE PURCHASE PRICE OF THE

PRODUCT AND UNDER NO CIRCUMSTANCES SHALL OROVILLE OPERATIONS BE LIABLE FOR CONSEQUENTIAL OR INCIDENTAL DAMAGES.

HOWEVER, SOME STATES DO NOT ALLOW LIMITATIONS ON INCIDENTAL,

OR CONSEQUENTIAL DAMAGES, SO THE ABOVE LIMITATION OR

EXCLUSION MAY NOT APPLY TO YOU.

2

11

Page 3

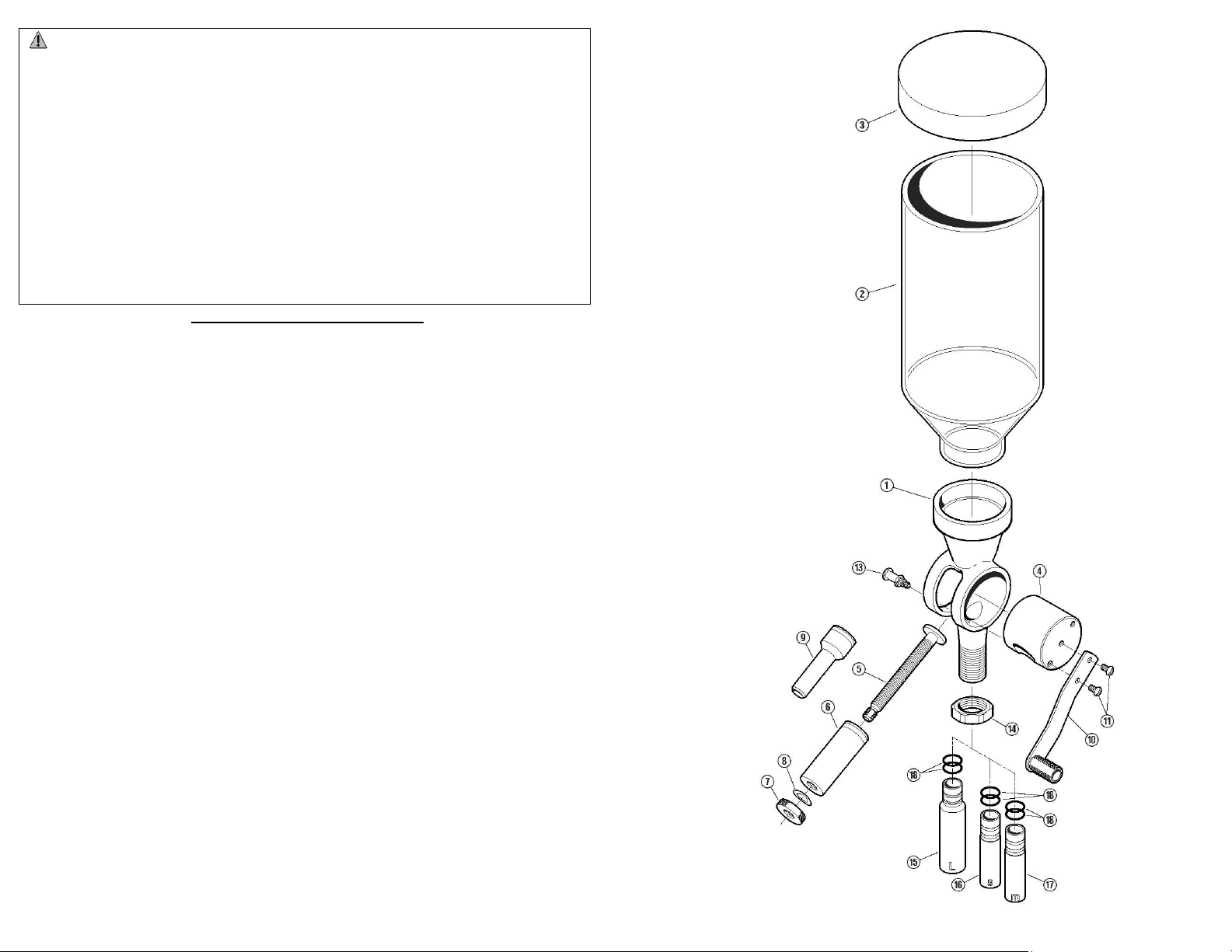

Key# Description Part # Qty

1 QC HC Main Casting 7709026 1

2 QC HC Powder Hopper 7109027 1

3 QC HC Powder Hopper Cap 7189028 1

4 QC HC Measuring Cylinder 7798849 1

5 QC HC Metering Screw 7798851 1

6 QC HC Metering Screw Bushing 7798850 1

7 Metering Screw Lock Ring 7709014 1

8 Bow Washer 7109260 1

9 QC HC Drain Tube 7798853 1

10 Handle Assembly 7709027 1

11 Handle Screws 7109019 2

13 QC Locking Pin Assembly 7798856 1

14 7/8"-14 Hex Lock Ring 7109187 1

15 Drop Tube Large .50 cal 7198854 1

16 Drop Tube Small .22-.270 cal 7198852 1

17 Drop Tube Medium .30-45 cal 7198853 1

18 "O" Ring 7138285 6

The above warranty provides the sole and exclusive warranty available to the

customer in the event of a defect in material or workmanship in the reloading

press. This warranty gives you specific legal rights, and you may also have other

rights which vary from State to State.

SAFETY

Reloading is an enjoyable and rewarding hobby that can be conducted safely.

But, as with any hobby, carelessness or negligence can make reloading

hazardous. This product has been designed from the beginning with the user's

safety in mind. When reloading, safety rules must be followed. By observing

these rules, the chance of a hazardous occurrence causing personal injury or

property damage is minimized.

GENERAL

• Use all equipment as the manufacturer recommends. Study the instructions

carefully and become thoroughly familiar with the operation of the product. If

you do not have written instructions, request a copy from the equipment

manufacturer.

• Do not take short cuts. Attempting to bypass established procedures is an

invitation to an accident.

• Observe "good housekeeping" in the reloading area. Keep tools and

components neat, clean and orderly. Promptly and completely clean up primer

and powder spills.

• Reload only when you can give your undivided attention. Do not reload when

fatigued or ill, or under the influence of medications or alcohol.

• Develop a reloading routine to avoid mistakes which may prove hazardous. Do

not rush - load at a leisurely pace.

• Always wear adequate eye protection to protect your eyes from flying particles.

You assume unnecessary risk when reloading without wearing safety glasses.

LOADING DATA

• Use only laboratory tested reloading data. We highly recommend the current

SPEER Reloading Manual.

• OBSERVE ALL WARNINGS ABOUT THE USE OF MAXIMUM LISTED

LOADS

WARNING/CAUTION

PRIMERS AND POWDER

• Store primers and powder beyond the reach of children and away from heat,

dampness, open flames and electrical equipment. Avoid areas where static

electricity is evident.

• DO NOT use primers of unknown identity.

• Dispose of unknown primers in accordance with applicable regulations.

• Keep primers in the original factory container until ready to use. Return unused

primers to the same factory packaging for safety and to preserve their identity.

Primer packaging is designed to provide safe storage.

10

3

Page 4

• DO NOT store primers in bulk. The blast of just a few hundred primers is

sufficient to cause serious injury to anyone nearby.

• DO NOT force primers. Use care in handling primers.

• DO NOT have more than one can of powder on the bench at one time. Powder

cans should be stored away from the bench to avoid picking up the wrong one.

• DO NOT use any powder unless its identity is positively known. The only

positive identification is the manufacturer's label on the original canister.

Discard all mixed powders and those of uncertain identity.

• DO NOT attempt to prime military cartridge cases with crimped/staked primer

pockets until the crimp/staking has been removed with a reamer or by swaging.

Attempting to seat primers into staked/crimped primer pockets can result in

primer detonation, which can cause serious personal injury.

• DO NOT decap live primers. This is extremely dangerous and can result in

primer detonation causing serious personal injury.

• If you use a powder measure, replace the lids on both the powder hopper and

powder can after the powder hopper has been filled.

• When using a powder measure, settle the powder in the powder hopper before

charging any cases. Throw and check the weight of at least ten charges. This

will assure you that the correct powder charge is being thrown.

• When you finish a reloading session, pour any remaining powder back into its

original factory container. This will preserve the identity and shelf life of the

powder.

• DO NOT smoke while reloading.

RECORD KEEPING

• Keep complete records of reloads. Apply a descriptive label to each box

showing the date produced, and the primer, powder and bullet used. Labels for

this purpose are packed with SPEER bullets.

• Never attempt to guess at the identity of your ammunition.

Because RCBS has no control over the choice of components, the manner in

which they are assembled, the use of this product, or the firearms in which the

resulting ammunition may be used, we assume no responsibility, expressed or

implied, for the use of ammunition reloaded with this product.

Key# Description Part # Qty

1 QC PM Lock Pin Retainer 7798847 1

2 QC PM Lock Pin 7798846 1

3 QC PM Lock Knob 7798848 1

4 Century Spring 7109029 1

WARNING: NOT FOR USE WITH BLACK POWDER!

GENERAL INFORMATION

The Quick Change High Capacity Powder Measure will perform two powder

charging tasks in one fast, simple operation. With cycling of the handle it

accurately measures powder within a fraction of a grain and swiftly dispenses it

into cases, one after another. Powder pours uniformly from the powder hopper

into the measuring cylinder, through the drop tube and into the case. This

eliminates the hazards of overloads caused by clogging when charges are

dumped into cases. You can change from one charge to another quickly and

4

9

Page 5

DRAINING POWDER HOPPER

It is not necessary to empty the powder hopper each time you change charges

unless a different powder is required.

Powder should not be left in the measure as it will deteriorate and may clog and

jam the measuring cylinder and etch the powder hopper. The measure can be

emptied without taking it off the bench or reloading press by using the provided

Quick Change High Capacity Drain Attachment.

Dispense the remaining charge and hold the handle in the “up” position. Loosen

the knurled Lock Pin Retainer, pull the Lock Knob and remove the Metering

Screw Assembly. Align the Lock Pin hole on the side of the Drain Attachment

and insert into the Metering Cylinder, release the Lock Knob. Try to rotate the

Drain Attachment to insure that the Lock Pin is in place. Tighten the knurled

Locking Pin Retainer. Place the correct powder container near the end of the

Drain Attachment and slowly bring the handle down. The powder will flow

through the Measuring Cylinder and Drain Attachment and back into your powder

container.

CAUTION: If the handle is in the “down” position when the Metering Assembly is

removed, the powder will flow through the Measuring Cylinder and spill out of the

powder measure!

easily by pulling the pin and changing Metering Assemblies. Metering

Assemblies can be left preset for future charges.

The powder level is visible at all times through a large two pound capacity plastic

powder hopper.

The measuring cylinder has a precision-ground surface and slides into the honed

main casting for a precise fit. The lower portion of the main casting has the

standard 7/8”-14 threads and may be used on an optional Powder

Measure/Piggyback Stand.

A powder measure is basically a device which measures powder by volume and

not by weight. However, before you start throwing a given charge with this

powder measure, the first charge must always be weighed on a powder scale to

arrive at the desired charge. Accurate powder measure charges will also depend

upon the size and uniformity of the powder kernels used, and how smoothly and

uniformly you operate the powder measure handle.

Ball and flake powders will measure very evenly. Long and short kernel sticktype powders are more difficult to measure consistently, and it is imperative that

you follow a set routine when throwing charges of these powders.

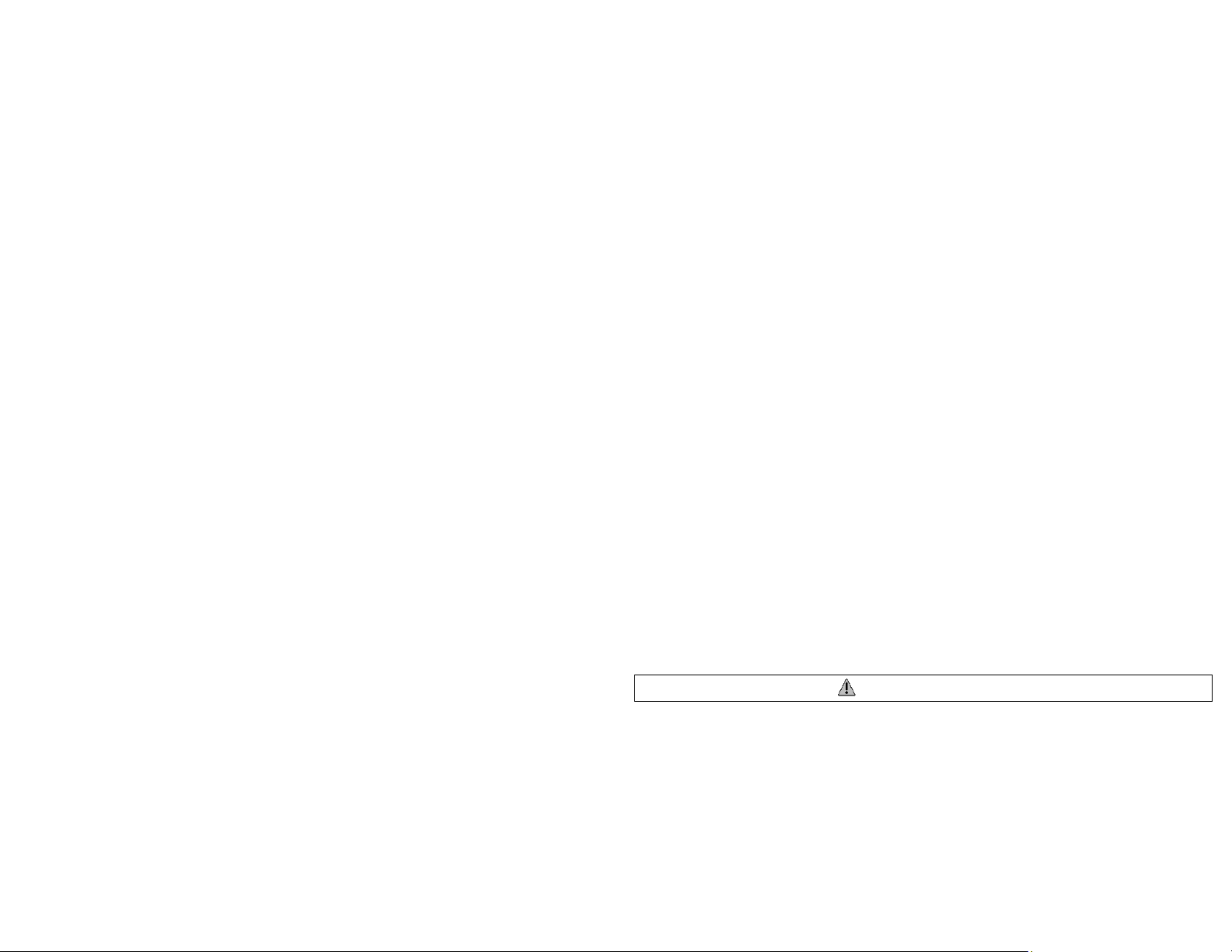

TO ASSEMBLE

To prepare the Quick Change High Capacity Powder Measure for use, the

measuring cylinder, measuring screw, drain attachment, inside of main

casting and powder funnel portion of main casting must be cleaned to

remove the factory applied rust preventative. Failure to do so will cause

inconsistent powder charges.

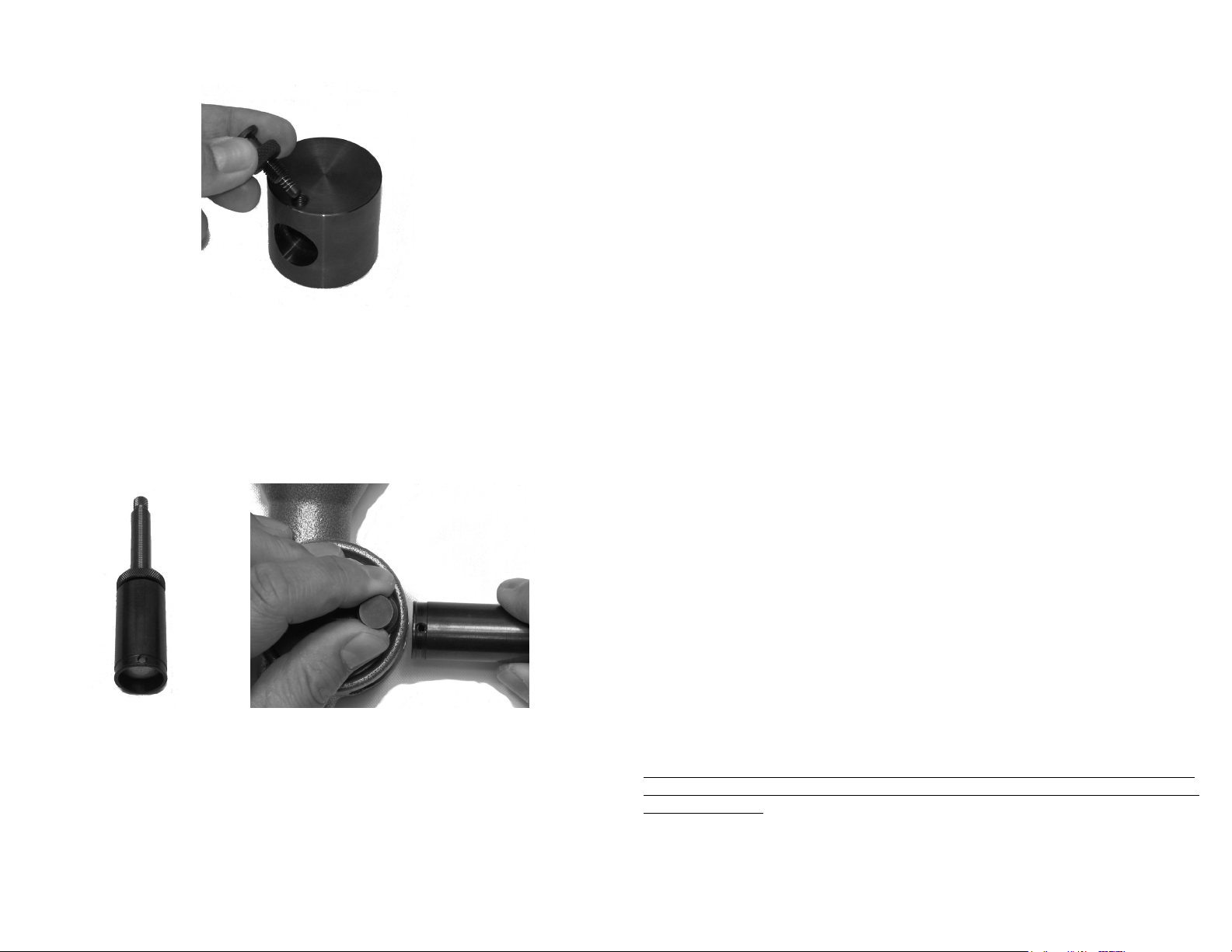

Drain Attachment installation position Powder hopper “drain” position

TO REMOVE A CYLINDER

To remove a measuring cylinder for cleaning, first empty the powder hopper.

Loosen the knurled Lock Pin Retainer, pull the Lock Knob and remove the Drain

Tube. You can then either remove the two handle screws and handle or unscrew

the Lock Pin Assembly and carefully slide out the measuring cylinder.

Do not attempt to remove the powder hopper from the main casting.

8

Install the Quick Change Locking Pin assembly a few threads into the single

threaded through hole on the side of the Measuring Cylinder. Carefully insert the

assembly into the main casting, this is a precise fit, do not force the cylinder into

the casting. Insert screws through the handle and attach to the measuring

cylinder on the opposite side of the Locking Pin. The Powder Measure can be set

5

Page 6

up for right or left handed use depending on which way you slide in the

assembly.

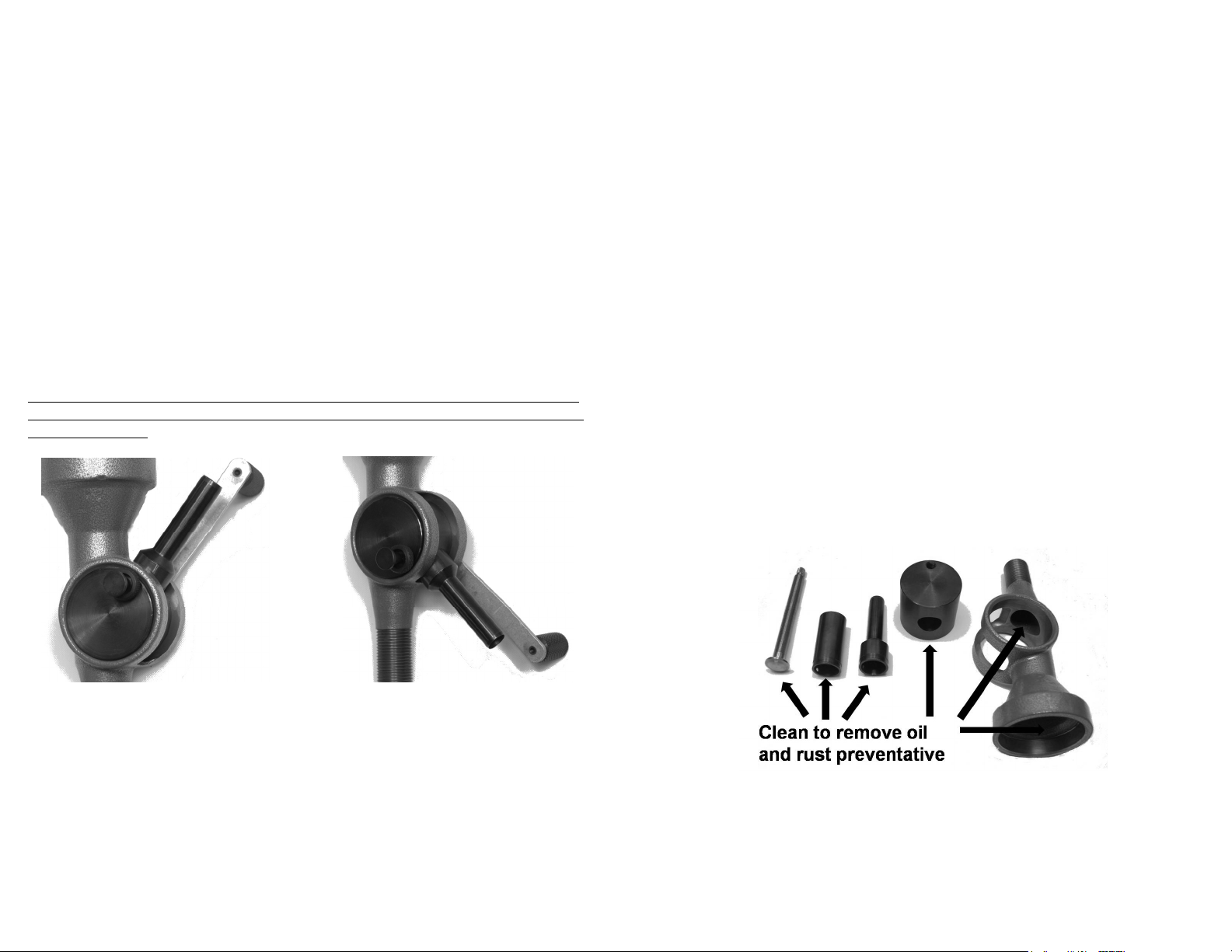

Installing Locking Pin

The Metering Assembly will dispense up to 250 grains of smokeless powder.

You will notice a tapered hole on the side of the Metering Screw Assembly body,

this is the locking point for the Quick Change Locking Pin. Pull the Locking Pin,

align the hole in the Metering Screw body with the Locking Pin, insert into the

Metering Cylinder and release the Locking Pin. Try to rotate the Metering

Assembly Body to insure that it has been locked in place. Tighten the knurled Pin

Retainer.

Metering assembly Aligning locking pin hole on metering assembly

The Powder Measure can be mounted on an optional Powder Measure Stand,

available from your reloading dealer. Three friction fit drop tubes are furnished;

one with a small hole for .22 to 270 calibers, and one with a large hole for .30 to

.45 caliber and a very large drop tube for .50 caliber. The QC Funnel Extended

Drop Tube or Adapters also fits for a more precise fit to your cartridge case.

6

TO USE

Before attempting to throw a series of powder charges, set the powder measure

for the maximum charge and run about a pound of powder through it. This will

deposit a film on the inside of the measure and help the powder flow through

more evenly and consistently.

Be sure you use the same uniform movements for each powder charge. To

throw a charge, raise the handle until it comes to the end of the stroke with a light

tap. Then lower the handle in the same manner. This tap at the end of each

stroke helps to settle the powder uniformly in the measure.

A dependable powder scale should be used to set the first charges in the powder

measure as follows: throw a powder charge directly into the scale pan by raising

the handle and lowering it. Weigh the charge. If it is too heavy, adjust the

measuring screw “in” with the handle in the down position. If the charge is too

light, adjust the measuring screw “out”. When you arrive at the exact charge you

need, lock the metering screw in place with the knurled lock nut on the shaft.

Now you’re ready to throw a series of charges. Additional QC High Capacity

Metering assemblies can be purchased so that you can leave them preset to

your favorite charges, thus allowing for quick powder changeovers.

As a precaution, throw every tenth charge into the scale pan and weigh it to be

sure of consistency.

METERING ASSEMBLY CHANGE

If the same powder is to be used, but you wish to change out the Metering

Assembly for another one that is preset for different charge, it is not necessary to

empty the powder hopper.

Dispense the remaining charge and hold the handle in the “up” position. Loosen

the knurled Lock Pin Retainer, pull the Lock Knob and remove the Metering

Screw Assembly. Align the Lock Pin hole on the side of the Metering Screw

Assembly and insert into the Metering Cylinder, release the Lock Knob. Try to

rotate the Metering Screw Assembly to insure that the Lock Pin is in place.

Tighten the knurled Locking Pin Retainer. As a precaution, dispense a charge

and weigh it to be sure that you have installed the correct preset Metering Screw

Assembly.

CAUTION: If the handle is in the “down” position when the Metering Assembly is

removed, the powder will flow through the Measuring Cylinder and spill out of the

powder measure!

7

Loading...

Loading...