Page 1

LUBE DIE

PRODUCT INSTRUCTIONS

Page 2

SAFETY

Reloading is an enjoyable and rewarding hobby that is easily conducted with safety. But carelessness or negligence can make reloading

hazardous. This product has been designed from the beginning with

the user’s safety in mind.

As with any reloading operation, some safety rules must be followed. By observing these few rules, the chance of hazardous occurrence causing damage or injury becomes extremely remote.

GENERAL

• Use the reloading equipment as the manufacturer recommends.

Study the instructions carefully and become thoroughly familiar

with the operation of the product. Don’t take short cuts.

• Observe “good housekeeping” in the reloading area. Keep tools

and components neat, clean and orderly. Promptly and

completely clean up primer and powder spills.

• Reload only when you can give your undivided attention. Do not

reload when fatigued or ill. Develop a reloading routine to avoid

mistakes. Avoid haste—load at a leisurely pace.

• Always wear adequate eye protection. You assume unnecessary

risk when reloading without wearing safety glasses.

LOADING DATA

• Use only laboratory tested reloading data. We highly recommend

the use of the SPEER Reloading Manual.

• OBSERVE ALL WARNINGS ABOUT THE USE OF MAXIMUM

LISTED LOADS.

PRIMERS AND POWDER

• WARNING: Primers are designed to explode and will do so when

subjected to heat or percussion.

• DO NOT decap live primers.

Page 3

• Never attempt to seat or reseat a primer in a loaded round.

• Store primers and powder beyond the reach of children and away

from heat, dampness, open flames and electrical equipment.

• DO NOT use primers of unknown identity. Dispose of unknown

primers in accordance with applicable regulations.

• Keep primers in original factory container until ready to use.

Return unused primers to the same factory packaging for safety

and to preserve their identity.

• DO NOT store primers in bulk. The blast of just a few hundred

primers is sufficient to cause serious injury to anyone nearby.

• DO NOT force primers. Use care in handling primers.

• DO NOT use any powder unless its identity is positively known.

Discard all mixed powders and those of uncertain or unknown

identity.

• If you use a powder measure, replace the lids on both the powder

hopper and powder can after the powder hopper has been filled.

• Before charging cases, settle the powder in the powder hopper.

Throw and check the weight of at least ten charges. This will

assure you that the correct powder charge is being thrown.

• After a reloading session ends, pour the remaining powder back

in its original factory container. This will preserve the identity and

shelf life of the powder.

• DO NOT smoke while handling powder or primers.

RECORD KEEPING

• Keep complete records of reloads. Apply a descriptive label to each

box showing the date produced, and the primer, powder and bullet

used. Labels for this purpose are packed with SPEER bullets.

Since RCBS has no control over the choice of components, the

manner in which they are assembled, the use of this product, or the

guns in which the resulting ammunition may be used, no responsibility,

either expressed or implied, is assumed for the use of ammunition

reloaded with this product.

Page 4

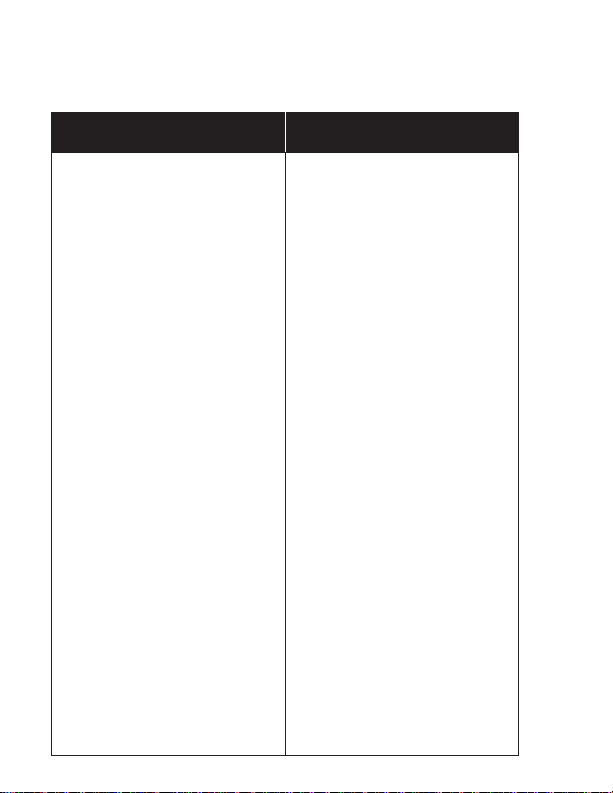

LUBE DIE COMPATIBILITY CHART

Use the chart below to determine which Lube Die to use for a

specified caliber. If a number is not indicated, then a Lube Die is not

available for that caliber.

17 Remington 1

218 Bee —

22 Hornet —

22K-Hornet —

22 Remington Jet —

22 Savage High-Power 3

22-250 Remington (22 Varminter) 2

220 Swift 3

221 Remington Fire Ball 1

222 Remington 1

222 Remington Magnum 1

223 Remington (5.56mm) 1

5.6 x 50mm Rimmed —

240 Weatherby Magnum 2

243 Winchester 2

6mm PPC 1

6mm Remington (244 Remington) 2

25 Auto (25 ACP) —

25-06 2

25-20 Winchester —

25-35 Winchester 3

250 Savage (250-3000 Savage) 2

257 Roberts 2

257 Roberts Improved 40° 2

257 Weatherby Magnum 4

260 Remington 2

264 Winchester Magnum 4

6.5mm-06 2

6.5 x 52mm Carcano 3

6.5 x 54mm MannlicherSchoenmauer —

6.5 x 55mm Swedish Mauser 2

6.5 x 57mm Mauser 2

6.5 x 68Smm 4

270 Weatherby Magnum 4

270 Winchester 2

280 Remington (7mm Exp. Rem.) 2

284 Winchester 4

7mm Bench Rest Remington 2

7mm Remington Magnum 4

7mm Remington Ultra Magnum –

7mm Shooting Times Westerner 4

7mm Thompson/Center Ugalde 1

7mm Weatherby Magnum 4

7mm-08 Remington 2

7 x 57mm Mauser (7mm Mauser) 2

7 x 64mm Brenneke 2

7 x 65mm Rimmed 2

7-30 Waters 3

30 M-1 Cabine —

30 Luger (7.65mm Luger) —

30 Mauser (7.63mm Mauser) —

30 Remington 3

30-06 Springfield 2

30-30 Winchester 3

30-338 Winchester Magnum 4

30-378 Weatherby Magnum —

30-40 Krag —

300 H&H Magnum 4

300 Remington Ultra Magnum —

300 Savage 2

300 Weatherby Magnum 4

300 Winchester Magnum 4

303 British —

307 Winchester 2

308 Norma Magnum 4

Lube

Caliber Die

Lube

Caliber Die

Page 5

308 Winchester 2

7.5mm x 54 French MAS 2

7.5mm x 55 Schmidt-Rubin —

7.62 x 39mm .308/.311 3

7.62 x 54Rmm Russian .308/.311 —

7.65 x 53mm Belgian Mauser 2

7.7 x 58mm Japanese Arisaka 2

32 Automatic (7.65mm Auto) —

32 H&R Magnum —

32 Smith & Wesson Long —

32 Winchester Special 3

32-20 Winchester —

32-40 Winchester 3

8mm Lebel French Revolver —

8mm Remington Magnum 4

8mm-06 2

8 x 57mm Mauser (8mm Mauser) 2

8 x 68Smm Magnum —

338 Lapua —

338 Remington Ultra Magnum —

338 Winchester Magnum 4

338-06 2

338-378 Weatherby Magnum —

340 Weatherby Magnum 4

348 Winchester —

35 Remington 3

35 Whelen 2

350 Remington Magnum 4

356 TSW —

356 Winchester 2

357 Magnum —

357 Remington Maximum —

357 SIG 3

358 Winchester 2

9mm Luger —

9mm Makarov —

9 x 21 —

9 x 23mm Winchester —

9.3 x 62mm Mauser 2

9.3 x 74Rmm —

375 H&H Magnum 4

375 Winchester 3

376 Steyr 4

378 Weatherby Magnum —

38 Casull 2

38 Colt Super Auto —

38 Smith & Wesson —

38 Special —

380 Automatic (ACP) —

38-40 Winchester —

38-55 Winchester & Ballard 3

40 S&W —

40-65 Shiloh Sharps-408" 4

400 CorBon 2

405 Winchester 3

10mm Auto —

41 Magnum 4

416 Remington Magnum —

416 Rigby —

44 Magnum —

44 Special —

444 Marlin —

44-40 Winchester —

45 Automatic (45 ACP) 2

45 Colt —

45-70 U.S. Government 4

450 Marlin 4

454 Casull —

458 Winchester Magnum 4

460 Weatherby Magnum —

475 Linebaugh 1.400" —

50 Action Express —

50-70 U.S. Government —

Lube

Caliber Die

Lube

Caliber Die

Page 6

Push the rubber seal ring up to

expose the fill hole.

Fill the Lube Die with RCBS Case

Lube-2.

GENERAL INFORMATION

Lubricating cases prior to resizing is an important and necessary step in the

reloading process. The use of the RCBS Lube Die eliminates the sometimes

unpleasant method of lubricating cases by hand. With the Lube Die a cartridge

is lubricated and decapped in a single motion.

• Faster and easier than hand lubricating

• Keeps hands clean when reloading

• Less handling of cases prior to reloading

• Standard 7/8-14 thread fits most presses

• Easy to refill with RCBS Case Lube-2

The RCBS Lube Die can be use in single-stage presses or progres

sive reloading tools with a minimum of four stations.

There are four Lube Dies available. Each Lube Die lubes and decaps the

case in one operation. See the Lube Die Compatibility Chart for the correct

Lube Die to use.

The following instructions are for using the Lube Die in a progressive

reloading tool with a minimum of four stations.

PREPARING THE LUBE DIE

Lay the Lube Die on its side. Push the rubber seal ring toward the top of the

Page 7

die until the fill hole in the die is exposed. Insert the top of the Case Lube-2 bottle in the fill hole and give the bottle one good squeeze to force the Case Lube2 into the Die.

INSTALLING THE LUBE DIE

The Lube Die is installed in the first station of the progressive reloading

press. Allow about 1/32" (approximately 1/2turn) between the bottom of the Lube

Die and the shell plate when the ram is at the top of the stroke. Position the

lube fill hole toward the front of the press so that it is easily accessible when

it's time to refill. The decapping pin should extend about 3/16" below the bottom

of the die. The Lube Die must sit in the press about 30 minutes to allow the

Case Lube-2 to saturate the felt lubricating bushing. Leave the fill hole uncovered until the felt bushing is saturated with lubricant. Failure to allow time for

the lubricant to saturate the felt bushing can result in a case being stuck in the

sizer die.

The decapping pin should extend 3/16" below the bottom of the Lube Die.

Page 8

INSTALLING THE RELOADING DIE SET

The sizer die should be installed at station 2. The expander-decapping unit

in the sizer die must be backed up so that it will not decap the newly seated

primer. Or , you can remove the decapping pin entirely. Powder charging should

take place at station 3. The seater die should be installed in station 4.

Adjust the decapping pin in the sizer die to avoid decapping the newly

seated primer.

USING THE LUBE DIE

Cases must be properly lubricated prior to resizing or they will stick in the

sizer die. Excessive lubricant will cause dented or collapsed shoulders on bottle neck cases. Before reloading, check the felt lubricating bushing for lubricant. This is easily done by running an unlubricated case into the Lube Die.

Remove the case from the die and inspect it carefully. There should be a light

film of lubricant all around the case with none on the case shoulder. If there

appears to be an excessive amount of lubricant on the case, run several cases

through the die to soak up the excessive lubricant. Wipe the cases clean with

a damp cloth and repeat if necessary. When you are satisfied the proper level

of lubrication has been obtained, you are ready to proceed with reloading.

One filling of the Lube Die with lubricant will last for 100 to 250 cases,

depending on the case size. Add lubricant as soon as you detect increased sizing pressure and a noticeable absence of lubricant on the case.

Page 9

HELPFUL HINTS

• Do not over-fill the lube retainer with case resizing lubricant. As a

general guide, squeeze (with light pressure) the Case Lube-2

bottle for 8 to 10 seconds when filling the lube retainer.

• Slide the rubber seal ring above the fill hole to increase the flow of

lubricant while reloading.

LUBE DIE STORAGE

The die may be left in the reloading press or stored in its plastic storage

box. The die should be stored in the vertical position when full of lubricant. A

case must be left in the die to prevent lubricant leakage. Prior to using the die

again, remove the case and follow the procedures outlined in “USING THE

LUBE DIE.” If excessive lubricant collects on the decapping unit, remove it

from the die and wipe with a damp cloth.

Page 10

Key Part # Description

1 87570 Hex Lock Nut 12-28

2 ✦ Lube Die Body

3 87571 Seal Ring

4 87501 Die Lock Ring 7/8-14

5 87562 Lube Retainer (#1, 2 & 3)

5 87564 Lube Retainer #4

6 87556 Felt Lubricating Bushing #1

6 87557 Felt Lubricating Bushing #2

6 87558 Felt Lubricating Bushing #3

6 87559 Felt Lubricating Bushing #4

7 81015

“

O” Ring Seal

8 87568 Lube Die Decapping Unit

✦

Not available separately

LUBE DIE PARTS LIST

Page 11

How can anyone improve on something as basic as a plastic

box? We figured out about eight ways and included them in five different sized ammo boxes. RCBS plastic ammo boxes offer unique

features that make all others obsolete, including a one-piece

hinge, recessed latch, label for identifying contents, interlocking

tabs, flush exterior and more. Great for securely packing, storing,

carrying and dispensing most popular rifle or pistol cartridges. See

the chart below for part numbers and descriptions of the five different sizes.

PART # DESCRIPTION

86901 AmmoBox, Small Rifle

86902 AmmoBox, Medium Rifle

86903 AmmoBox, Large Rifle

86905 AmmoBox, Medium Pistol

86906 AmmoBox, Large Pistol

See your local dealer or contact RCBS for further information.

PLASTIC AMMO BOXES FROM RCBS

Page 12

PRECISIONEERED®RELOADING EQUIPMENT

CCI • SPEER • RCBS

OUTERS • RAMLINE • ORBEX • FEDERAL

7200541/0304

We think that we make the very best

reloading equipment in the world.

If you agree, please tell your friends.

If you disagree, tell us - we want to do something about it!

Customer Service

1-800-533-5000

(US or Canada) or

530-533-5191

Hours: Monday - Thursday, 6:30am - 3:00pm (hours may vary)

e-mail: rcbs.tech@atk.com • www.rcbs.com

RCBS • 605 Oro Dam Blvd. • Oroville, CA 95965

Loading...

Loading...