Page 1

COWBOY DIES

PRODUCT INSTRUCTIONS

Page 2

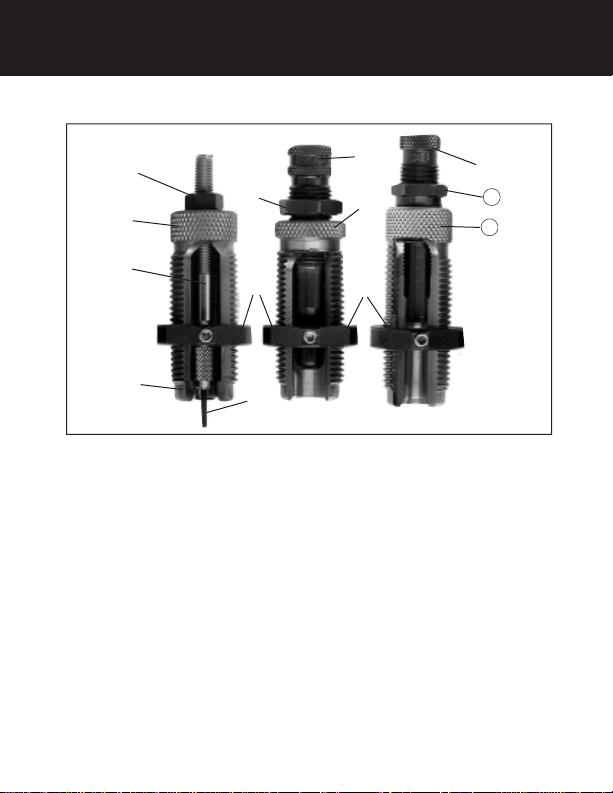

PARTS LIST FOR 3 DIE SET

➃

➀

➂

➄

➉

➈

➇

➅

➁

➅

1

11

➆

Note: The photo above is not the actual RCBS Cowboy Die set, but represents the components of a three die set.

KEY PART # DESCRIPTION

1 709644 Lock Ring 1/2-20

2 – Sizer Die

3 709617 Decapping Rod

4 709618 Decap Pin Holder

5 90164 Decapping Pin

6 709646 Lock Ring 7/8-14

7 709645 Lock Ring 9/16-18

8 – Expander

9 – Expander Die Body

10 – Seater Plug

11 – Seater Die Body

Page 3

IMPORTANT: READ THIS SECTION FIRST

Before using the RCBS Cowboy Dies, read the instruction manual carefully to fully learn

how to safely operate the related reloading equipment. Failure to properly operate certain

reloading equipment can result in severe personal injury and/or equipment damage. If you

have read these instructions and still do not understand some operation, call us at 1-800-

533-5000 and a technician will assist you. This instruction manual contains specific safety

and operating information. It should be considered a permanent part of your reloading

equipment and remain with the equipment at all times for easy reference.

SAFETY

Reloading is an enjoyable and rewarding hobby that can be conducted safely. But, as with

any hobby, carelessness or negligence can make reloading hazardous. This product has

been designed from the beginning with the user’s safety in mind. When reloading, safety

rules must be followed. By observing these rules, the chance of a hazardous occurrence

causing personal injury or property damage is minimized.

GENERAL

• Use all equipment as the manufacturer recommends. Study the instructions carefully

and become thoroughly familiar with the operation of the product. If you do not

have written instructions, request a copy from the equipment manufacturer.

• Don’t take short cuts. Attempting to bypass established procedures is an invitation

to an accident.

• Observe “good housekeeping” in the reloading area. Keep tools and components

neat, clean and orderly. Promptly and completely clean up primer and powder spills.

• Reload only when you can give your undivided attention. Do not reload when

fatigued or ill, or under the influence of medications or alcohol. Develop a reload

ing routine to avoid mistakes which may prove hazardous. Don’t rush - load at a

leisurely pace.

• Always wear adequate eye protection to protect your eyes from flying particles. You

assume unnecessary risk when reloading without wearing safety glasses.

LOADING DATA

• Use only laboratory tested reloading data. We highly recommend the current

SPEER Reloading Manual.

• OBSERVE ALL WARNINGS ABOUT THE USE OF MAXIMUM LISTED

LOADS.

PRIMERS AND POWDER

• Store primers and powder beyond the reach of children and away from heat, dampness, open flames and electrical equipment. Avoid areas where static electricity is evident.

• Do not use primers of unknown identity. Scrap unknown primers in accordance with

applicable regulations.

• Keep primers in the original factory container until ready to use. Return unused

primers to the same factory packaging for safety and to preserve their identity. Primer

Page 4

packaging is designed to provide safe storage.

• DO NOT store primers in bulk. The blast of just a few hundred primers is sufficient

to cause serious injury to anyone nearby.

• DO NOT force primers. Use care in handling primers.

• DO NOT have more than one can of powder on the bench at one time. Powder

cans should be stored away from the bench to avoid picking up the wrong one.

• DO NOT use any powder unless its identity is positively known. The only positive

identification is the manufacturer’s label on the original canister. Discard all mixed

powders and those of uncertain identity.

• If you use a powder measure, replace the lids on both the powder hopper and powder

can after the powder hopper has been filled.

• When using a powder measure, settle the powder in the powder hopper before charging any cases. Throw and check the weight of at least ten charges. This will assure you

that the correct powder charge is being thrown.

• When you finish a reloading session, pour any remaining powder back into its original factory container. This will preserve the identity and shelf life of the powder.

• DO NOT smoke while reloading.

RECORD KEEPING

• Keep complete records of reloads. Apply a descriptive label to each box showing the

date produced, and the primer, powder and bullet used. Labels for this purpose are

packed with SPEER bullets.

Never attempt to guess at the identity of your ammunition.

Because RCBS has no control over the choice of components,

the manner in which they are assembled, the use of this product,

or the guns in which the resulting ammunition may be used,

we assume no responsibility, expressed or implied, for the

use of ammunition reloaded with this product.

Page 5

FEATURES

RCBS Cowboy Dies match tough steel to the tough jobs. The die bodies are

machined and hardened until they’re tough enough to meet our standards, yet

smooth enough to handle the most delicate brass case.

Sizer dies are vented to avoid case damage and are made to absolutely precise

tolerances. And there’s extra muscle where it counts, in the headed decapping

pin. Expander decapping units are designed so the decapping pin can be

replaced, if necessary. Seater dies have a unique design which aligns the bullet

with the case mouth an instant before seating.

Interior polishing helps brass work smoothly with

very little friction and cannot chip or peel with age.

All RCBS Cowboy Dies feature a solid brass lock

ring that allows tight control over precise adjustments. RCBS dies are manufactured with the standard 7/8”-14 thread and are designed for use with a

shell holder having a lip thickness of 0.125”. Any

variations of these dimensions may cause headspace

or insufficient sizing problems.

GENERAL INFORMATION

Reloading rifle or pistol ammunition with lead (non-jacketed) bullets requires a

3-Die Set. The first die sizes and decaps the case. The second die expands the

case neck to the correct diameter to securely hold the lead bullet and flare the

case mouth to avoid shaving lead off the bullet. The third die seats and crimps

the bullet

PACKAGING

All RCBS Cowboy Dies are packaged in

convenient and attractive traditional

storage boxes specially designed by

RCBS to protect your dies in shipment

and during storage. A sturdy cradle

holds the dies firmly in place to prevent

damage and rolling around. Each box

contains a label for recording your

favorite loads and can be adhered to the

inside lid for quick reference. The die

caliber is listed on the outside of the box

for easy identification.

A label is provided with each die box for

recording your favorite loads.

Page 6

CUSTOMER SERVICE

All RCBS Cowboy Dies are carefully checked and thoroughly inspected before

shipping. Each die will reload fired cases from any standard chamber of the caliber stamped on the die. Should the die perform unsatisfactorily, call or write to

RCBS, explaining the problem in detail. In most cases we can help you overcome the problem without the inconvenience and expense of returning the dies.

If necessary, we will authorize the return of the dies. Do not attempt to alter the

dies in any way.

Cowboy seater plugs are designed to fit bullets cast in RCBS Cowboy Bullet

Moulds. It is impossible to make one seater plug fit every possible variation in

bullet style and weight. If the seater plug furnished with the seater die does not

fit the bullet you are using, a custom seater plug will have to be produced.

Please provide us with t

wo sample bullets – both will be returned with the new

seater plug – along with your order and payment. Be sure to specify caliber and

1/2”-20 thread size. Call, e-mail or write RCBS Customer Service for current

price so that you can include payment and avoid any unnecessary delay. Note:

We do not keep bullets on file, so you must send samples to guarantee a perfect

fit.

Send your order and payment with securely packed sample bullets to:

RCBS Customer Service

Custom Seater Plug

605 Oro Dam Blvd.

Oroville, CA 95965-5718

The seater plug for Cowboy calibers can be removed by screwing the seater

plug up and out of the die after the lock ring has been loosened.

A case stuck in the sizer die may be removed with an RCBS Stuck Case

Remover–available from your RCBS dealer. Or you may return the sizer die

along with your name and address. We will remove the stuck case or replace the

die under terms of the RCBS Lifetime Warranty.

PREPARING THE DIES

Some sizer dies for bottleneck type cases contain a small vent hole through

which trapped air escapes during resizing. Sometimes the vent hole will plug up

with factory polishing material. This material will scratch and dent cases unless it

is removed. To clean, unscrew the decap unit from the die. Insert a straightened

paper clip, needle or similar object into the vent hole. This will push the material

into the die body. The debris can then be easily removed by cleaning the inside

of the die using a patch saturated with Outers Solvent. Reassemble the die.

IMPORTANT: We find that most scratching of the die interior is caused by

Page 7

nickel cases or grit on the brass surface. If you are using nickel pistol cases, we

recommend that you use a carbide sizer die. This die is hard enough to resist

the scratching that nickel cases cause. The best method for cleaning brass cases

of grit is to tumble them. Tumbling the cases will clean the surface and prevent

scratching the internal die surface. Your cases should be cleaned periodically to

protect both your dies and the chamber of your firearms. The RCBS Vibratory

Case Cleaner is recommended for cleaning cases. Before storing dies, lightly

spray them with Outers Tri Lube or Metal Seal to protect them from rust.

PREPARING THE CASES

Clean and inspect cases before lubricating and

sizing. Discard any cases with indications of a

split neck or partial head separation. Check cases

for the correct overall length. If necessary, trim

after sizing. If bullets are to be crimped, it is

imperative that cases be trimmed to the same

overall length. Trimmed case mouths should be

deburred and lightly chamfered inside and out

with an RCBS Deburring Tool or use the RCBS

Three Way Cutter in your case trimmer.

Cases must be properly lubricated before sizing.

Over-lubrication will result in a dented case

shoulder. Improper or no lubrication will result in

a case stuck in the sizer die. For best results use

RCBS Case Slick Spray Lube or Case Lube-2 applied to an RCBS Case Lube Pad.

Case mouths should be very lightly lubricated with an RCBS Case Neck Brush.

These accessories are available from your dealer as individual items or combined

in the RCBS Case Lube Kit. Do not lubricate the shoulders of bottle-neck type cases.

After the cases are lubricated they

are ready to go through the

reloading steps.

3-DIE SET FOR BOTTLENECK RIFLE AND

PISTOL CASES

The decapping pin is adjusted

by loosening the small lock ring

at the top of the die and turning

the decapping unit until the desired setting is obtained. When the decapping

Lightly chamfer the case mouth with

a Deburring Tool to remove rough

edges for easier bullet seating.

Roll cases on an RCBS Case Lube Pad for proper lubrication.

Page 8

unit is adjusted correctly, the decapping pin will protrude below the bottom of

the die just enough to reliably knock out the spent primer (approx. 1/4”). Trim

cases after the sizing and expanding operation. We suggest trimming 10 thousandths less than the maximum length. The next step is to prime the case and

then fill it with the predetermined powder charge. Then seat the bullet. Usually

the reloader performs one operation at a time on each lot of cases; sizing and

decapping, priming and filling them with powder and then seating the bullets.

SIZING WITH CARBIDE SIZER DIES

Screw the Sizer Die into the press until the die touches the top of the shell

holder when the shell holder is brought up to the top of the press stroke.

Tighten the large lock ring. DO NOT CAM OVER.

SIZING WITH STANDARD STEEL SIZER DIES

Screw the Sizer Die into the press until the die touches the top of the shell

holder when the shell holder is brought up to the top of the press stroke. Be

sure all play is removed from the press leverage system. To do this, adjust the

die as above, lower the shell holder and set the die 1/8 to 1/4 of a turn lower.

Set the large lock ring. The decapping unit is adjusted by loosening the small

lock ring at the top of the die and turning the decapping rod until the desired

setting is obtained. When the decapping unit is adjusted correctly, the decapping pin will protrude below the bottom of the die just enough to reliably

knock out the spent primer (approx. 1/4”).

Important: Do not allow the decapping unit to contact the web of the case.

EXPANDING

Screw the expander die into the press until the die touches the top of the shell

holder when the shell holder is brought up to the top of the press stroke. Place

PLEASE NOTE:

A Tungsten Carbide Sizer Die will give a lifetime of perfect service if

properly cared for. However, the die will not withstand severe

impact, such as dropping. The shell holder should never strike the

bottom of the die. When using a Carbide Sizer Die it is not necessary

to lubricate a pistol straight-wall case. Screw the die into the press

until it just touches the shell holder. DO NOT CAM OVER.

Page 9

a sized case in the

shell holder and

run it into the

expander die. The

case mouth should

be expanded and

flared (belled) just

enough to accept

the bullet when

placed on top of

the case. The expander is tapered and may be adjusted for

more or less flaring (belling) by loosening the lock ring

on top of the die and turning the expander up or down.

BULLET SEATING AND CRIMPING FOR

ROLL CRIMP

IMPORTANT: Please read instructions carefully. Do not

adjust the seater die down against the shell holder as it will distort or crush the

case. If the bullet you are using has a crimping groove, the bullet can be seated

and crimped using the following instructions. Before proceeding, cases must be

trimmed to the same overall length to assure a consistent crimp. The crimping

feature is machined into the seater die body. It is not a special attachment to

the seater plug. The die must be moved up or down to obtain the proper crimp

adjustment. To adjust, the seater die, place a sized, primed and powder-charged

case into the shell holder and run it to the top of the press stroke.

Screw the seater die into the press until you feel it touch the mouth of the

case. Back the die up one full turn and set the large lock ring. This will leave a

gap between the bottom

of the die and the shell

holder. Next, lower the

case and insert a bullet

in the case mouth.

Slowly run the case and

bullet into the seater die.

Check the bullet for

proper seating depth. If

the bullet is not seated

properly, adjust the

Screw the sizer die into the

reloading press.

Notice the sizer die is adjusted so

it contacts the shell holder.

The standard RCBS steel die is shown on

the left. The carbide insert is visible in the

carbide sizer die on the right.

Seater dies in our 3-die sets

use a “through-the-top”

style seater plug as shown

above.This allows for easy

cleaning.

Page 10

seater plug until the proper depth (in the middle of the crimp groove) is

obtained.

Next, adjust the die to crimp. While the uncrimped cartridge is still in the

seater die, unscrew the seater plug several turns. Screw the seater die downward

until you feel it touch the mouth of the case. Lower the reloaded cartridge and

adjust the seater die down about 1/8th of a turn. Run the reloaded cartridge

into the die and then check the crimp. If more crimp is needed, repeat the preceding step by adjusting the die downward 1/8th of a turn at a time. Overcrimping of the cartridge will cause bulging and may affect chambering. After

you are satisfied with the crimp, run the completed cartridge into the seater die,

set the large lock ring and then lower the seater plug until it touches the bullet.

Tighten the seater plug lock ring. Once the seater die is properly adjusted, the

bullet is seated and crimped in one operation.

Page 11

REPLACEMENT PARTS

The Decapping Unit (Key 3, 4, & 5) and Decapping Pins (Key 5) may be available

from your dealer. If not, they and all other replacement parts should be ordered from

RCBS Customer Service. See the back panel of this instructions booklet for phone

number or address.

3-Die 3-Die 3-Die Carbide

Full Length Roll Crimp Roll Crimp Decap Decap

Caliber Set Set Set Unit Pin

.25-20 Winchester 11850 – – 09628 90164

.30-30 Winchester 14650 – – 09628 90164

.32 S&W Long/.32 S&W – – 21451 09628 90164

.32 Winchester Special 15750 – – 09628 90164

.32-20 Winchester – 18151 – 09628 90164

.32-40 WCF 32550 – – 09628 90164

.357 Magnum/.38 Spec. – – 18251 09628 90164

.38 S&W – 20351 – 09628 90164

.38-40 WCF – 35651 – 09628 90164

.38-55 Winchester – 36551 – 09628 90164

.40-65 Winchester-410” – 36651 – 09628 90164

.44 S&W Russian/.44 Special – – 18651 09628 90164

.44-40 WCF – 18851 – 09628 90164

.45 S&W Schofield/.45 Colt – – 19151 09628 90164

.45-70 U.S. Gov’t – 20951 – 09628 90164

PLEASE NOTE:

These instruction photos are for general die use and information. The photos shown may not necessarily portray exact

RCBS Cowboy Dies, however the information is accurate and

useful.

Please call RCBS Customer Service for any questions:

1-800-533-5000

Page 12

PRECISIONEERED®RELOADING EQUIPMENT

We think that we make the very best

reloading equipment in the world.

If you agree, please tell your friends.

If you disagree, tell us - we want to do something about it!

Customer Service

1-800-533-5000 (US or Canada) or 530-533-5191

Hours: Monday - Thursday, 6:30am - 3:00pm (hours may vary)

e-mail: rcbs.tech@atk.com • www.rcbs.com

RCBS • 605 Oro Dam Blvd. • Oroville, CA 95965

CCI • SPEER • RCBS

OUTERS • RAMLINE • ORBEX • FEDERAL

7200496/0104

Loading...

Loading...