Page 1

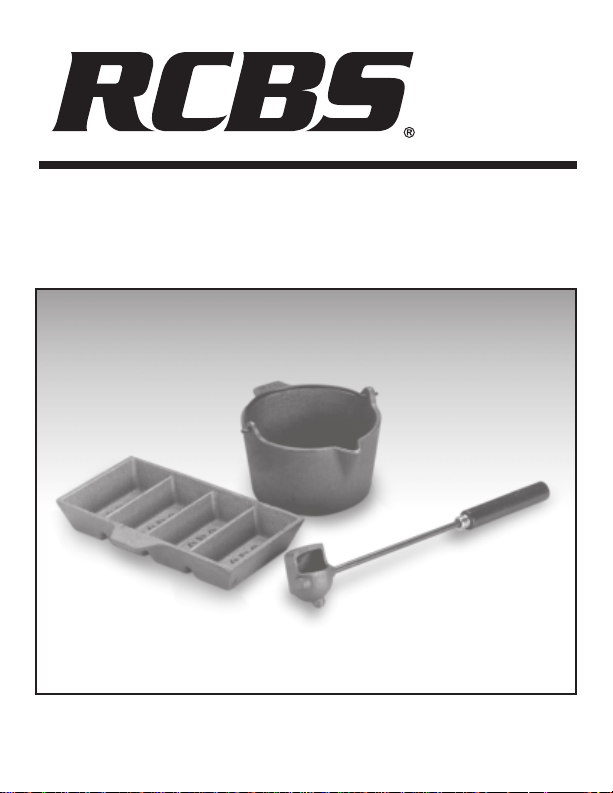

BULLET CASTING

ACCESSORIES

PRODUCT INSTRUCTIONS

Page 2

WARNING: Melting lead and casting lead

objects will expose you and others in the

area to lead, which is known to cause birth

defects, other reproductive harm and cancer.

REDUCING EXPOSURE: Lead contamination in the

air, in dust, and on your skin is invisible.

and pregnant women away during use and until cleanup

is complete. Risk can be reduced — but not eliminated

— with strong ventilation; washing hands immediately

after use of these products before eating or smoking;

and careful cleaning of surfaces and floors with disposable wipes, after lead dust has had a chance to settle.

Use a lead-specific cleaner with EDTA, or a highphosphate detergent (like most detergents sold for

electric dishwashers), and bag wipes for disposal.

USE STRONG VENTILATION

Keep children

Page 3

LEAD POT

This large, heavy-duty cast iron pot is used to

melt and blend bullet casting alloys and holds

approximately ten pounds of metal. To use:

Place Lead Pot on most any source of heat

designed to melt lead. Place metal ingots in

the pot and in a few minutes you will have

molten metal ready to cast bullets. The Lead

Pot has a bale handle. The pouring spout minimizes

dripping. Tab lifter can be conveniently gripped with tongs or pliers

when pouring metal. The Lead Pot also has a flat stable bottom to

prevent tipping.

LEAD DIPPER

The Lead Dipper allows easy stirring, scooping and pouring of bullet alloy.

Large capacity bowl holds enough alloy to fill multiple cavity moulds. It

features a comfortable handle that stays cool. The pouring spout is

contoured to fit bullet mould sprues and eliminate air pockets. To avoid

damage, don't apply direct heat to bowl.

INGOT MOULD

Heavy-duty cast iron Ingot Mould forms four,

easy-to-use ingots of bullet alloy. You save

the time of having to mix an alloy every

time you cast bullets. By mixing large

amounts in advance you can have the

correct alloy ready for the next casting

session. The unique design ensures rapid

cooling. The tab lifter can be gripped with tongs

or pliers for ease in handling. Approximate cooling time is ten minutes.

Page 4

PRECISIONEERED® RELOADING EQUIPMENT

We think that we make the very best

reloading equipment in the world.

If you disagree, tell us - we want to do something about it!

If you agree, please tell your friends.

Customer Service

1-800-533-5000

(US or Canada) or

530-533-5191

Hours: Monday - Thursday, 6:30am - 3:00pm (hours may vary)

e-mail: rcbs.tech@atk.com • www.rcbs.com

RCBS • 605 Oro Dam Blvd. • Oroville, CA 95965

OUTERS • RAMLINE • ORBEX • FEDERAL

CCI • SPEER • RCBS

7200590/0603

Loading...

Loading...