Page 1

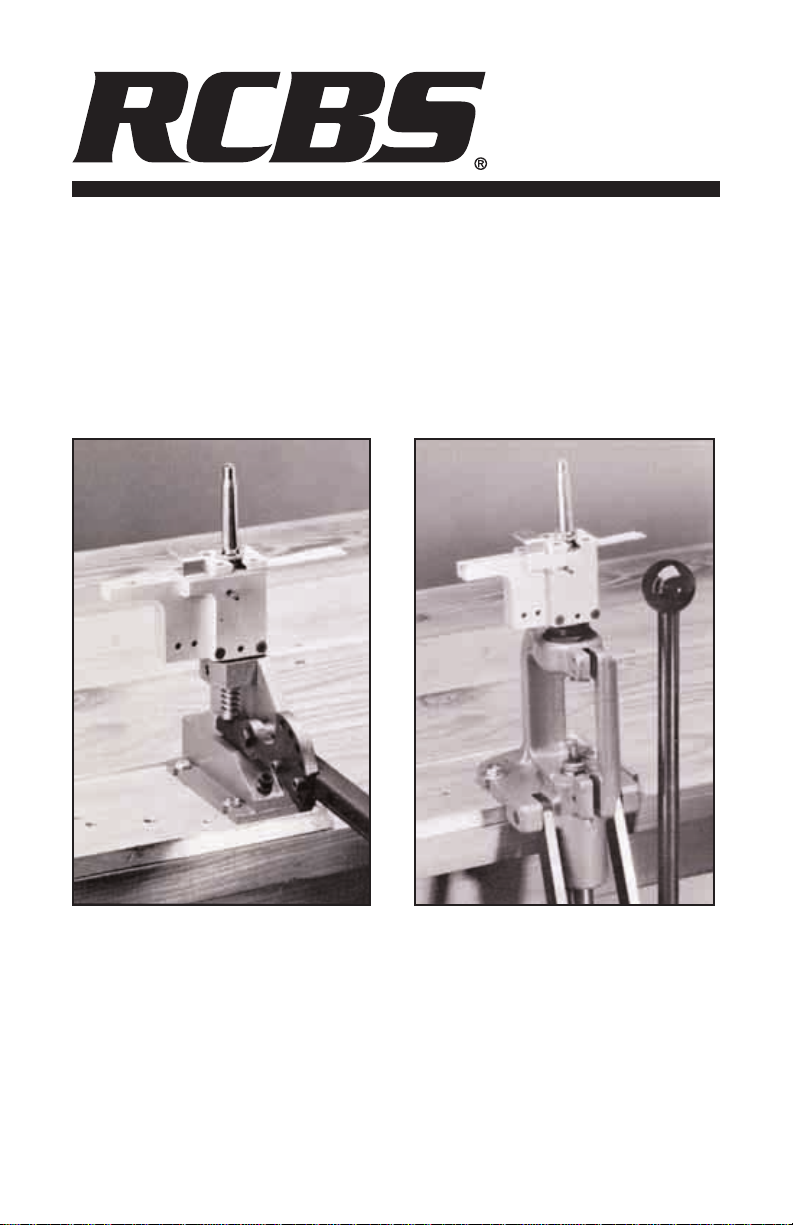

APS Bench-Mounted Priming Tool APS Press-Mounted Priming Tool

PRODUCT INSTRUCTIONS

APS

TM

PRIMING TOOL

Page 2

IMPORTANT

Before using the APS Priming Tools

from RCBS, read this instruction

manual carefully to learn how to

safely operate the products. Failure

to properly operate the tools may

result in personal injury and/or equipment damage. If you have read these

instructions and still do not understand some operation, call us at 800533-5000 or 530-533-5191 and a

technician will assist you. Our customer service hours are listed on the

back side of this instruction manual.

These instructions contain specific

safety and operating information. It

should be considered a permanent

part of your reloading equipment and

remain with the equipment at all times

for easy reference.

SAFETY

Reloading is an enjoyable and rewarding hobby that can be conducted

safely. But, as with any hobby, carelessness or negligence can make

reloading hazardous. This product

has been designed from the beginning with the user’s safety in mind.

When reloading, safety rules must

be followed. By observing these rules,

the chance of a hazardous occurrence causing personal injury or

property damage is minimized.

GENERAL

• Use all equipment as the manufacturer recommends. Study the

instructions carefully and become

thoroughly familiar with the operation of the product. If you do not

have written instructions, request

a copy from the equipment manufacturer.

• Don’t take short cuts. Attempting

to bypass established procedures

is an invitation to an accident.

• Observe “good housekeeping” in the

reloading area. Keep tools and

components neat, clean and orderly.

Promptly and completely clean up

any powder spills.

• Reload only when you can give

your undivided attention. Do not

reload when fatigued or ill. Develop

a reloading routine to avoid mistakes. Don’t rush – load at a

leisurely pace.

• Always wear adequate eye protection to protect your eyes from flying particles. You assume

unnecessary risk when reloading

without wearing safety glasses.

PRIMERS AND POWDER

• Store primers and powder beyond

the reach of children and away

from heat, dampness, open flames

and electrical equipment.

• DO NOT use primers of unknown

identity.

• Keep primers in the original factory container until ready to use.

Return unused primers to the same

factory packaging for safety and

to preserve their identity.

• DO NOT store primers in bulk. The

blast of just a few primers is sufficient to cause serious injury to

anyone nearby.

• DO NOT force primers. Use care

in handling primers.

• DO NOT smoke while handling

powder or primers.

LOADING DATA

• Use only laboratory tested reloading data. We highly recommend

the use of the SPEER Reloading

Manual.

• OBSERVE ALL WARNINGS

ABOUT THE USE OF MAXIMUM

LISTED LOADS.

RECORD KEEPING

• Keep complete records of reloads.

Apply a descriptive label to each

box showing the date produced,

and the primer, powder and bullet used. Labels for this purpose are

packed with SPEER bullets. Never

attempt to guess at the identity of

your ammunition.

2

Page 3

• This product is intended for use

by persons familiar with proper

handloading practices and their

own loading equipment. If you are

uncertain as to the operation of

any of your equipment, contact the

equipment manufacturer for additional assistance.

Because RCBS has no control over

the choice of components, the manner in which they are assembled,

the use of this product, or the guns

in which the resulting ammunition

may be used, no responsibility –

either expressed or implied – is

assumed for the use of ammunition

reloaded with this product.

GENERAL INFORMATION

ABOUT APS PRIMING

The APS Priming System is an entirely

new way to prime cases. It’s fast, it’s

safe and it’s convenient. This revolutionary system eliminates the handling of loose primers and the

contamination that goes with it. Plus,

it insures a smooth feed and a highly

sensitive feel with every primer seated.

There are two APS tools; one is

bench-mounted

and the other is

press-mounted. Each one is designed

to fit specific reloading needs. The

bench-mounted

tool is for the reloader

who likes to prime cases on a separate dedicated piece of equipment.

This way the priming tool is always

ready to use when you need it. The

press-mounted tool works the same

way as the bench-mounted tool except

it attaches to your reloading press.

It has standard 7/8x14 threads to fit

in the die station.

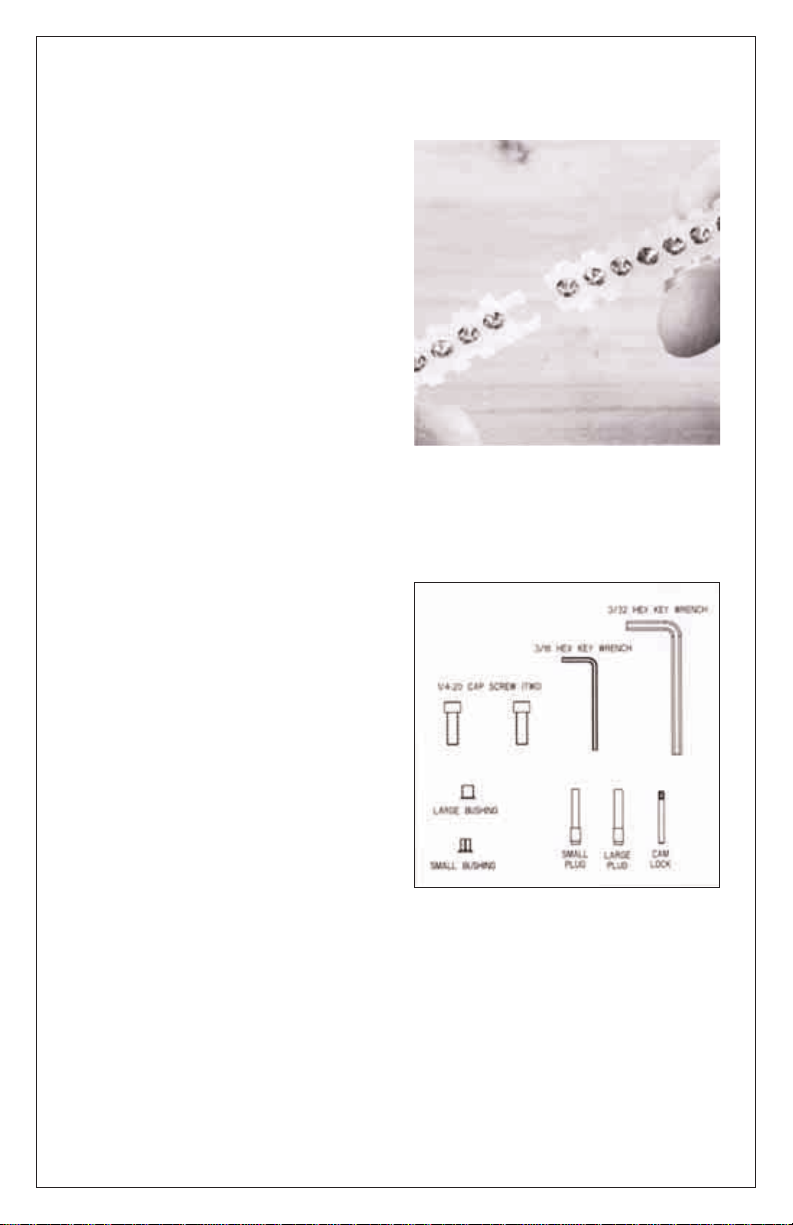

Both tools use the new APS primer

strips. Each strip is color-coded for

identification and holds 25 primers.

With each handle stroke, a fresh

primer is seated into the case and

the primer strip advances through

the APS body to position another

primer for seating. The primer strips

are designed to connect to each other

for continuous feed. See photo #3.

Please call us if you have any questions at any time while assembling or

operating this equipment.

APS BENCH-MOUNTED

PRIMING TOOL INSTRUCTIONS

Carefully unpack the priming tool

and look for the following items:

• APS bench-mounted tool

• APS handle

• One small bushing

• One large bushing

• Small primer plug

• Large primer plug

• Cam lock pin

3

Photo #3

Page 4

• Hex key wrench, 3/32

• Hex key wrench, 3/16

• 1/4-20 socket head cap screw (2)

Securely fasten the APS tool to a

sturdy bench using the four slots in

the base. This APS tool can also be

mounted to an RCBS Accessory Base

Plate-2. Mounting the priming tool

to a solid surface like the base plate

gives the tool added stability.

Using the two cap screws attach the

operating handle so it is in a comfortable position. The mounting holes

allow you to position the handle from

below horizontal to vertical. See

photo #4.

Now, select the correct size primer

plug for the primer size you will be

using. There is a small primer plug for

seating small primers and a large

primer plug for seating large primers.

Each primer plug has a shoulder on

it and is bigger on one end. See photo

#4. IMPORT ANT: LOWER THE HAN-

DLE ON THE PRIMING TOOL

BEFORE YOU INSERT THE LARGE

END OF THE PRIMER PLUG INTO

THE HOLE ON TOP OF THE TOOL.

If you tried to install the primer plug

before you read these instructions, you

probably did not first lower the handle. And if that’s the case, you’ll notice

that the primer plug has disappeared

down inside the body of the tool. If that

happens, you’ll need to disassemble the tool to retrieve the primer

plug. To do this, remove the four flat

head screws on the top cap. Lift off

the top cap and the top plate and

then remove the plug. Reinstall the top

plate correctly for clearance and

safety and replace the top cap and the

four flat head screws. And the next

time, remember to lower the operating handle before installing the primer

plug. Make sure you seat the primer

plug firmly in the cam hole.

Next, select the correct size plastic

bushing for the primer size you will

be using. There is a small bushing for

small primers and a large bushing

for large primers. Here’s a quick way

to tell which is the large bushing and

which is the small. Just remember

the small bushing has a seam, the

large bushing is smooth. These bushings center the primer when the

primer rod pushes a primer up through

the shell holder.

Take the correct size plastic bushing

in one hand and the shell holder you

will be using in the other and place

the bushing into the bottom of the

shell holder. See photo #5. Then

raise the handle and insert the shell

4

Photo #4

Photo #5

Page 5

holder and bushing into the slot on the

tool. By rotating the shell holder

counter-clockwise while pressing

unit firmly to the rear of the slot.

Peel a strip from the package of APS

primers and take a look at the ends.

One end of the strip is cut square

and the other end has two little hooks

on it. See photo #6. The end with the

hooks is the end that feeds into the

tool. Hold the strip so the primers

are anvil-side-up and insert the strip

into the tool until it clicks in place.

See photo #6. If the strip does not

slip in easily, it is probably because

the “step” where the hooks connect

to the strip is hitting the face of the tool.

To help it into position, you may need

to lift up on the square cut (left) end

of the strip to get the step under the

edge of the tool. If the strip is inserted

backwards (square end first) the

primer plug can wedge in the strip

and you will have to disassemble.

Insert a case into the shell holder

and lower the handle to seat a primer.

Then STOP with the handle down!

Insert the the cam lock pin to adjust

the primer depth. See photo #7. The

cam lock pin will stop the strip from

advancing while making this adjustment. Use the primer adjustment

screw on the base of the priming

tool. Raise the handle and remove

case and check for primer seating

depth. Turn screw clockwise for

deeper seating depth and counterclockwise for less seating depth. See

photo #7. The adjustment screw limits the handle travel at the seating

depth you want (flush – .004 deep)

and prevents crushing primers. If

you did not use the pin to stop the strip

from advancing, another primer is

in place to be seated. Do not return

the primed case to the shell holder

and try to seat the primer deeper

without clearing the second primer

from the machine. Remove and discard the second primer.

Once you are satisfied with the primer

seating depth you are ready to prime

cases. With the handle down, pull

the cam lock pin out of the tool and

start priming. Be sure to operate the

handle through the full stroke – all

the way up and all the way down.

Remember, the primer strips are

designed to connect to each other. So

for continuous primer feeding, just

connect another strip onto the end

of the strip in the tool when there is

at least one inch of the ramp available

to support the new strip. See photo

#8. The strip can be removed at any

point in the process by pushing or

pulling the strip through the right-hand

side of the tool.

5

Photo #6

Photo #7

Page 6

APS PRESS-MOUNTED

PRIMING TOOL INSTRUCTIONS

Carefully unpack the press-mounted

tool and look for the following items:

• APS press-mounted tool

• One small bushing

• One large bushing

• Small primer plug

• Large primer plug

• Cam lock pin

• Adjustment rod assembly

• 7/8-14 lock nut

• Hex key wrench 3/32

To install the APS Press-Mounted

Priming Tool, first install 7/8-14 nut

on the tool adapter. See photo #9.

Thread the tool into your reloading

press approximately seven turns. The

ramp on the tool should be pointing to

the left. Then tighten the lock nut.

Install the adjustment rod assembly

into the ram of the press just like a

shell holder. See photo #10. Slowly

lower the press handle to the bottom of its travel. If it stops before

reaching the bottom of its travel,

stop, raise the handle and either

adjust the toolhead up a couple of

turns, and/or the adjustment rod

down. See photo #10.

Now, select the correct size primer

plug for the primer size you will be

using. There is a small primer plug for

6

Photo #9

Photo #10

Photo #8

Page 7

seating small primers and a large

primer plug for seating large primers.

Each primer plug has a shoulder on

it and is bigger on one end. See

photo #11. IMPORTANT: LOWER

THE HANDLE ON THE PRESS

BEFORE YOU INSERT THE LARGE

END OF THE PRIMER PLUG INTO

THE HOLE ON TOP OF THE TOOL.

If you tried to install the primer plug

before you read these instructions,

you probably did not first lower the

handle. And if that’s the case, you’ll

notice that the primer plug has disappeared down inside the body of

the tool. If that happens, you’ll need

to disassemble the tool to retrieve

the primer plug. To do this, remove

the four flat head screws on the top

cap. Lift off the top cap and top plate

and remove the plug. Reinstall the top

plate correctly for clearance and

safety and replace the top cap and the

four flat head screws. And next time,

remember to lower the operating

handle before installing the primer

plug. Make sure to seat the primer

plug firmly in the cam hole.

Next, select the correct size plastic

bushing for the primer size you will

be using. There is a small bushing for

small primers and a large bushing

for large primers. Here’s a quick way

to tell which is the large bushing and

which is the small. Just remember

the small bushing has a seam, the

large bushing is smooth. These bushings center the primer when the

primer rod pushes a primer up through

the shell holder.

Take the correct size plastic bushing

in one hand and the shell holder you

will be using in the other and place

the bushing into the bottom of the

shell holder. See photo #12. Then

raise the handle and insert the shell

holder and bushing into the slot on the

tool by rotating the shell holder

counter-clockwise while pressing

unit firmly to the rear of the slot.

Peel a strip from the package of APS

primers and take a look at the strip

ends. One end of the strip is cut

square and the other end has two

little hooks on it. See photo #13. The

end with the hooks is the end that

feeds into the tool. Insert the strip

into the tool until it clicks in place. See

photo #13. If the strip does not slip

in easily, it is probably because the

step where the hooks connect to the

strip is hitting the face of the tool.

To help it into position, you may need

to lift up on the square cut (left) end

of the strip to get the step under the

edge of the tool.

7

Photo #12

Photo #11

Page 8

Insert a case into the shell holder and

lower the handle slowly and carefully.

The press handle should go all the

way to the bottom with very little resistance. Remember you have the

mechanical advantage of compound

leverage. More than enough leverage to crush primers, bend the

primer plug and bend the rim of

the case – so don’t force it! If the

handle stops part way down, insert

the cam lock pin. The cam lock pin will

stop the strip from advancing while

making this adjustment. See photo

#14. Then lift the handle back up and

turn the adjustment rod in the shell

holder depth adjustment assembly

down a little and try again. When the

handle travels easily to the bottom

of its stroke, check the primer seating

depth. For high primers, back the

adjustment rod out a little. If the primer

cup is flattened (crushed), turn the

adjustment rod down a little further

until you get the correct seating depth.

When the proper priming seating

depth is achieved (flush – .004 deep)

with the handle all the way down,

remove the cam lock pin. Then raise

the handle and tighten the 1/4-28

lock nut.

You’re now ready to prime cases.

Remember, the primer strips are

designed to connect to each other.

So for continuous primer feeding,

just connect another strip onto the

end of the strip in the tool when there

is at least one inch of the ramp available to support the new strip. See

photo #15. The strip can be removed

at any point in the process by pushing or pulling the strip through the

right-hand side of the tool.

PRIMER STRIP COLOR ID

CHART

APS Primer Strips are color-coded to

prevent confusion and misidentification. To minimize the number of colored

primer strips, we not only used the

8

Photo #14

Photo #15

Photo #13

Page 9

various colors for designating primer

type but also for primer size. For example, there are two white primer strips;

one for large pistol primers and one for

small pistol primers.

White Primer Strip:

#300 Large Pistol, Standard

#500 Small Pistol, Standard

Red Primer Strip:

#350 Large Pistol, Magnum

#550 Small Pistol, Magnum

Yellow Primer Strip:

#200 Large Rifle, Standard

#400 Small Rifle, Standard

Blue Primer Strip:

#250 Large Rifle, Magnum

#450 Small Rifle, Magnum

Black Primer Strip:

#BR2 Large Rifle, Benchrest

#BR4 Small Rifle, Benchrest

Orange Primer Strip:

#34 7.62mm (Military)

#41 5.56mm (Military)

CUSTOMER SERVICE

After reading these instructions, if

you have any questions or need additional help in using the APS Priming

Tools, call us at the factory. We’ll be

glad to help.

APS STRIP LOADER

INSTRUCTIONS

The APS Strip Loader is for those

reloaders who may have a supply of

CCI primers in conventional traytype packaging and now, because

of the APS Priming Tools, they need

those primers loaded into strips. As

the name implies, the strip loader

allows you to fill empty primer strips

with your favorite primers. With each

push of the handle the strip loader will

quickly seat 25 primers into a strip.

After loading the strips with primers

the strips are ready to be used in an

APS Priming Tool.

The tape covering CCI strips of APS

primers is an important safety feature

of the packaging. The tape serves

to prevent the detonation of a single primer from causing detonation

of other primers in close proximity.

Always cover loaded primer strips, not

in use, with APS tape. Never store

quantities of loaded primer strips

without covering them with tape.

Covering the primers with APS tape

also serves to protect them from contamination during storage. To apply

the tape, simply peel the backing

from a section from the tape. Lay

the tape on a flat surface with the

adhesive surface up. Lay up to four

loaded strips, side-by-side, anvil side

down and press firmly into place.

IMPORTANT: Before you operate

the strip loader it is vitally important

that you read these instructions and

fully understand how this product

works. Become familiar with the

loader by going through a few “dry

runs.” Along with these instructions

there are some handy tips and suggestions that will make the tool easier to use.

Carefully unpack the strip loader and

look for the following items:

• Strip loader assembly

• Handle lever

• Tray lid

• Strips

• Tape

Place the strip loader on a flat sur-

face and attach the handle lever as

shown in photo #16. You may need

to depress or push down on the primer

seating bar so the handle lever will

slip into the four slots at the back of

the tool. See photo #16. Under the

primer seating bar you’ll see there are

25 pins...one for each hole in the

primer strip. These pins help to locate

the empty strips in the tool and to

position the primers in the strip. Once

the handle lever is installed, push

down on the lever and watch what

9

Page 10

happens. While pushing on the handle lever, notice the 25 pins will retract

allowing insertion of strip.

Now it’s time to try a “dry run.” Don’t

put any primers on the tray just yet.

The dry run will help you become

comfortable with installing and removing the primer strip from the tool.

With a little practice you’ll soon learn

the “feel” for how far to depress the

handle lever.

First, take an empty strip in your

right hand. Hold it by the square end

and with the flat side of the strip facing up. See photo #17. Now, with

your left hand, push part way down

on the handle lever until the 25 pins

are just flush with the bottom of the

primer channel. See photo #18. At the

same time insert the empty strip into

the loader from the right-hand side of

the tool. The strip should slide right

into the tool. See photo #19. If it does

not, it is because the handle lever is

not pressed down far enough or is

pressed down too far. Try moving

Photo #18

Photo #19

10

Photo #16

Photo #17

Page 11

the handle lever up or down until the

strip feeds into the loader. Slide the

strip into the loader leaving about

1'' of the strip out of the tray. Do not

release the lever. Attach another

strip by inserting the hooks of the

strip into the square end of the first

strip. See photo #20. This will help you

to position the first strip fully into the

loader. There are two little guide

marks etched into the tray, one on

the left side of the tool and one on

the right side of the tool. These

marks are used to line up the strips

as shown in photo #21. These should

help you to position the strip over the

top of the 25 pins. Move the strip

in and out of the tool and keep in

mind that the goal is to align the

holes in the strip with the pins.

Practice these steps until you’re

comfortable with the process.

Now you’re ready to add primers to

the tray. Make sure there is an

empty strip correctly positioned

in the loader. Also make sure the

strip is the correct color and size

for the primer being loaded. Never,

ever, under any circumstances,

load primers into a strip that is

not the correct color for the primer

being loaded. See the color coding

chart on page 9 for the correct

color. Using the wrong color strip

can lead to misidentification of

the primers. Using the wrong

primers in a handload can create

a dangerous condition that could

result in damage to your firearm

and physical injury. Place a pack-

age of primers upside down on the

grooved surface of the loader and

slide the sleeve off the primer package. See photo #22. Shake the strip

loader right to left so the specially

grooved surface flips all the primers

right-side up (anvil side up). Place the

tray lid on the strip loader.

Photo #21

Photo #20

Photo #22

11

Page 12

Next, tilt the strip loader away from

you until there is a primer in each

hole of the strip (you may need to

rock the tool to the left and right to

move the primers into position.) See

photo #23. Then tilt the tool towards

you to move all the extra primers

back away from the strip. Check to

confirm there is a primer in each

hole, but no extra primers are in the

strip area. See photo #24.

To seat the primers into the strip,

first read and then follow the steps

listed below. (Remember the dry run.)

• Be sure there is a primer in each

hole of the strip.

• Press down on the handle lever

(apply firm, even pressure). See

photo #25.

• Do not release the pressure on

the handle lever.

• Slowly raise the handle lever while

gently pushing on the right end of

the strip with the empty strip. See

photo #26.

• As the lever raises, you will be

able to push the strip through the

tool with the empty strip.

• Attach another empty strip to the

second strip as described above, and

repeat these steps. See photo #27.

12

Photo #23

Photo #24

Photo #25

Photo #26

Page 13

If the primer strip does not come out

check to be certain the primers

are seated deep enough. If primers

are not seated to flush or below, they

will not function in the APS tools.

Continue this process until you have

filled all the strips you need. Return

any unused primers to their original

factory packaging.

The tape covering CCI strips of APS

primers is an important safety feature

of the packaging. The tape serves

to prevent the detonation of a single primer from causing detonation

of other primers in close proximity.

Always cover loaded primer strips, not

in use, with APS tape. Never store

quantities of loaded primer strips

without covering them with tape.

Covering the primers with APS tape

also serves to protect them from contamination during storage. To apply

the tape, simply peel the backing

from a section from the tape. Lay

the tape on a flat surface with the

adhesive surface up. Lay up to four

loaded strips, side-by-side, anvil side

down and press firmly into place.

See photo #28.

If you have any questions or are having difficulty, don’t struggle, ask the

folks who built it. Call 1 (800) 533-

5000.

Helpful hints…

1. You may have to straighten strip if

flat surface is bowed.

2. It helps to have a strip in place on

each end while using the strip

loader.

3. You may wish to color the etched

guide marks with a felt pen for

better visibility.

4. If strips do not index correctly in the

APS tool, check:

a. strip inserted correctly (hook

end first)

b. to see that strips have not devel-

oped physical damage from

misuse.

13

Photo #27 Photo #28

Page 14

14

Page 15

Page 16

7200528/0803

CCI • SPEER • RCBS

OUTERS • RAMLINE • ORBEX • FEDERAL

PRECISIONEERED®RELOADING EQUIPMENT

We think that we make the very best

reloading equipment in the world.

If you agree, please tell your friends.

If you disagree, tell us - we want to do something about it!

Customer Service

1-800-533-5000

(US or Canada) or

530-533-5191

Hours: Monday - Thursday, 6:30am - 3:00pm (hours may vary)

e-mail: rcbs.tech@atk.com • www.rcbs.com

RCBS • 605 Oro Dam Blvd. • Oroville, CA 95965

Loading...

Loading...