Page 1

Disassembly of the LxxWD250

Page 2

Disassembly of the LxxWD250

• Use the following disassembly instructions and

you will not need to lay the unit down on it’s front.

Page 3

Disassembly of the LxxWD250

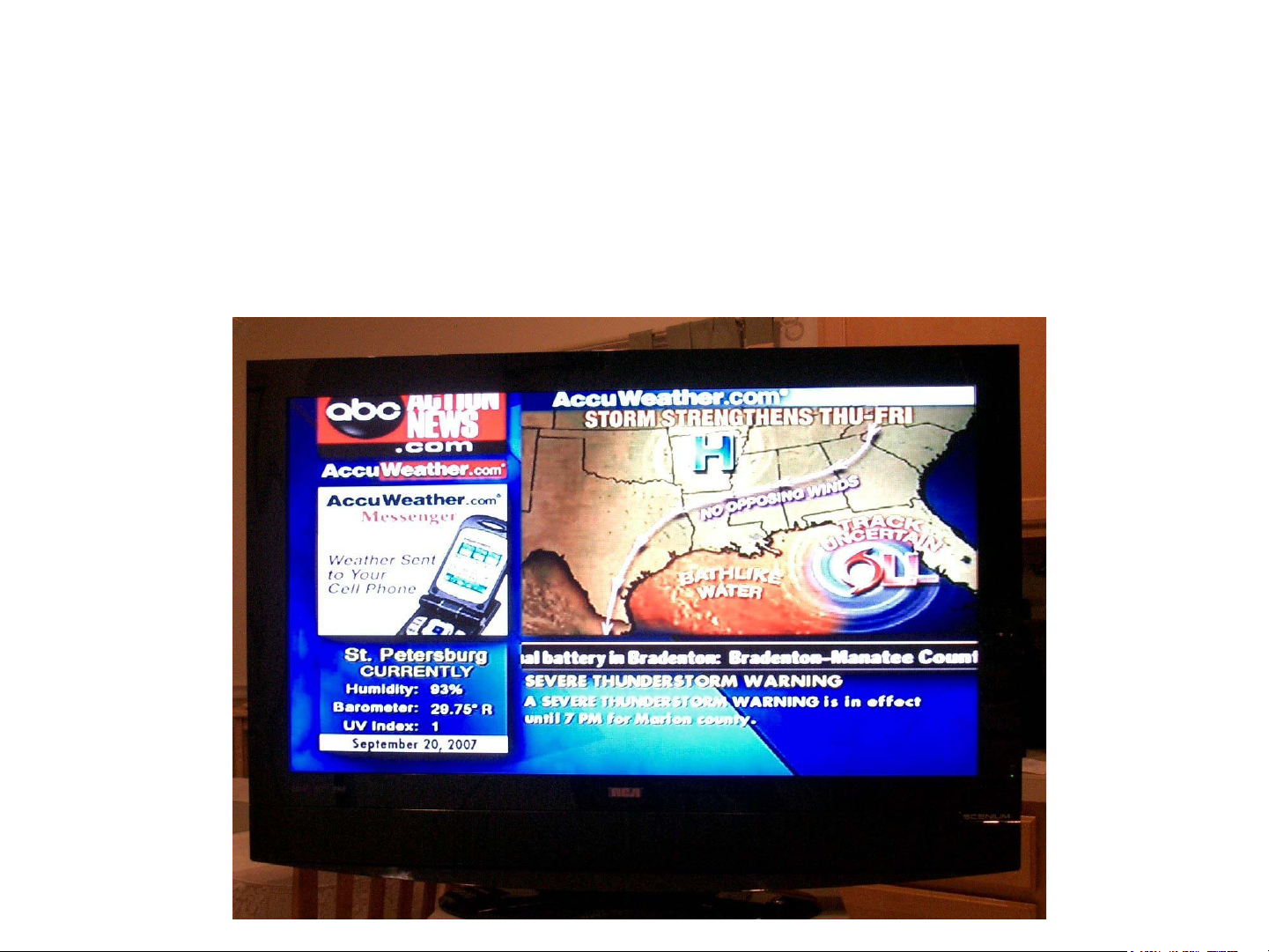

• Stand unit up right on work table.

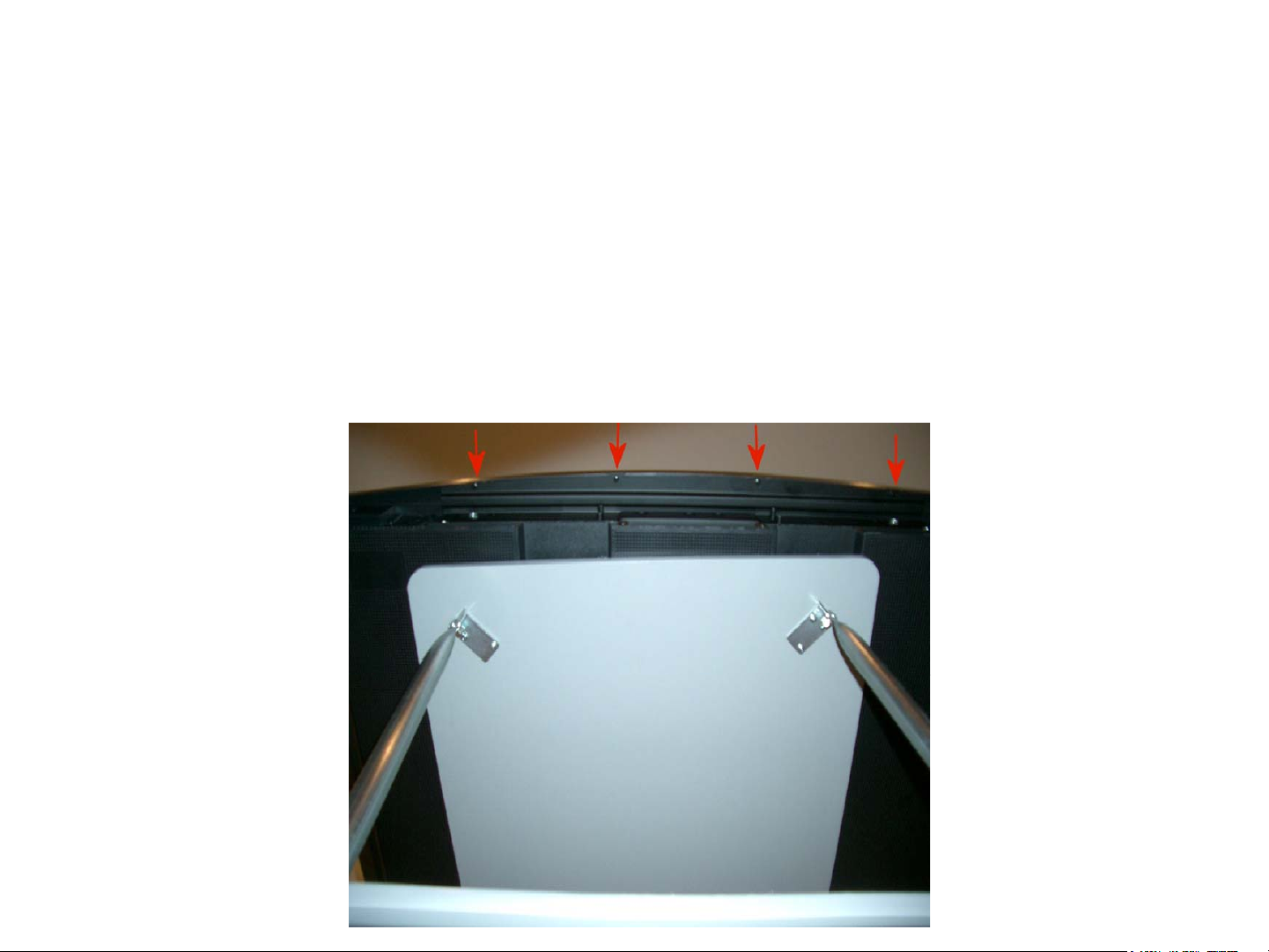

• Remove all screws mark by an arrow. (8-14

depending on screen size)

Page 4

Disassembly of the LxxWD250

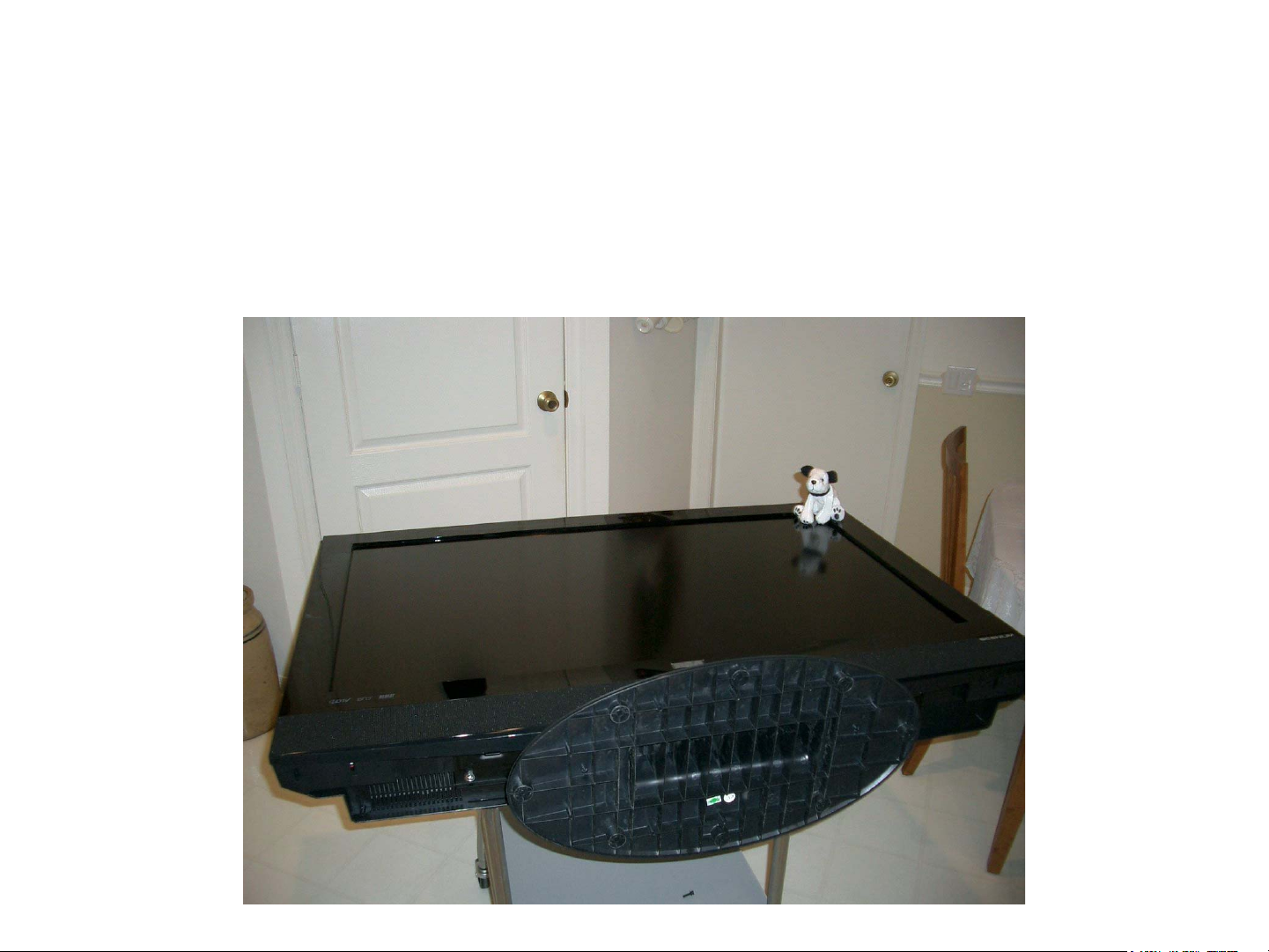

• Lay unit on back.

Page 5

Disassembly of the LxxWD250

• Remove screws and base. (4 screws)

Page 6

Disassembly of the LxxWD250

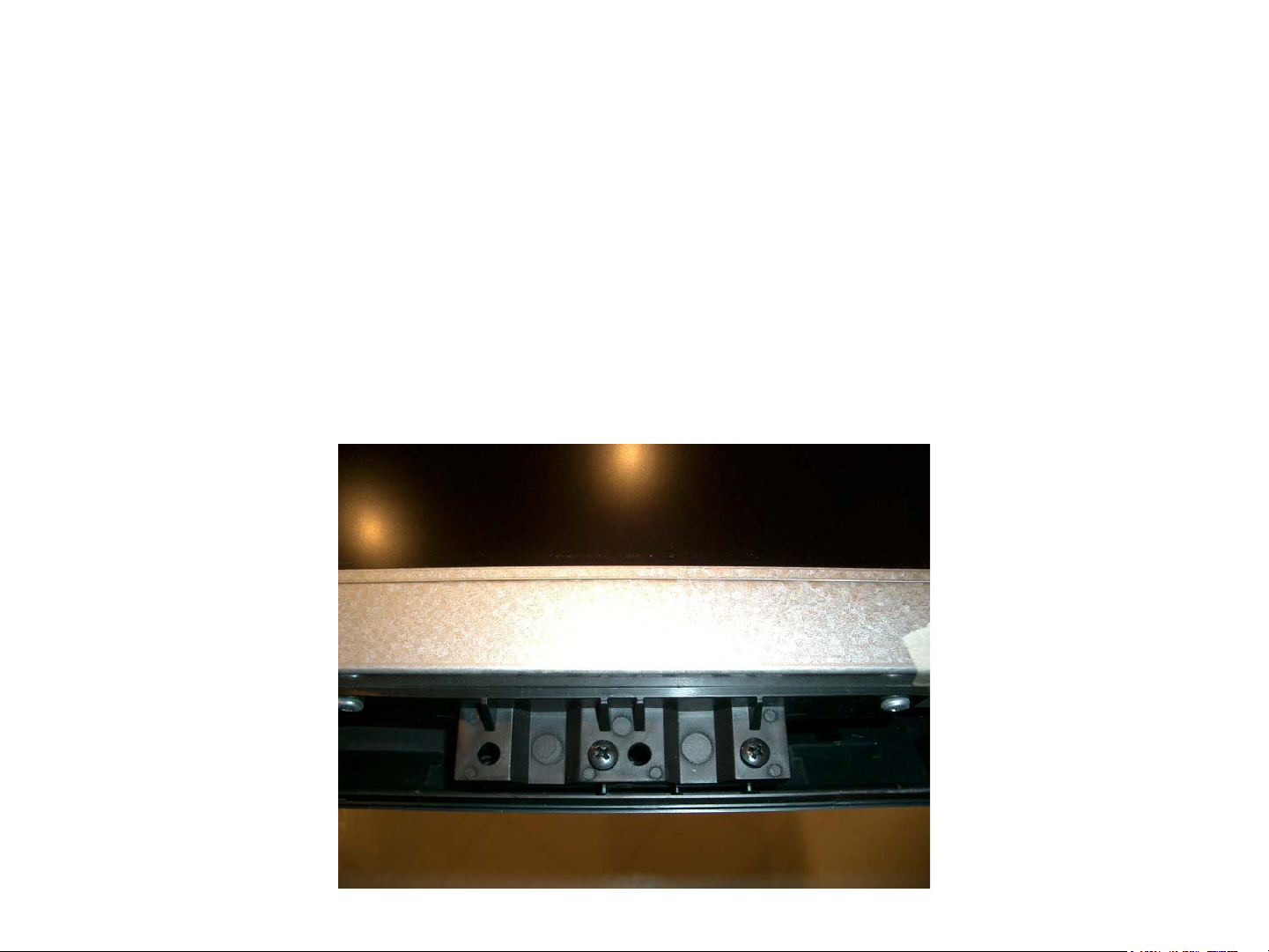

• From under base mounting plate remove 4

screws that hold mask (screen frame) in place.

• DO NOT remove large silver screws!

Page 7

Disassembly of the LxxWD250

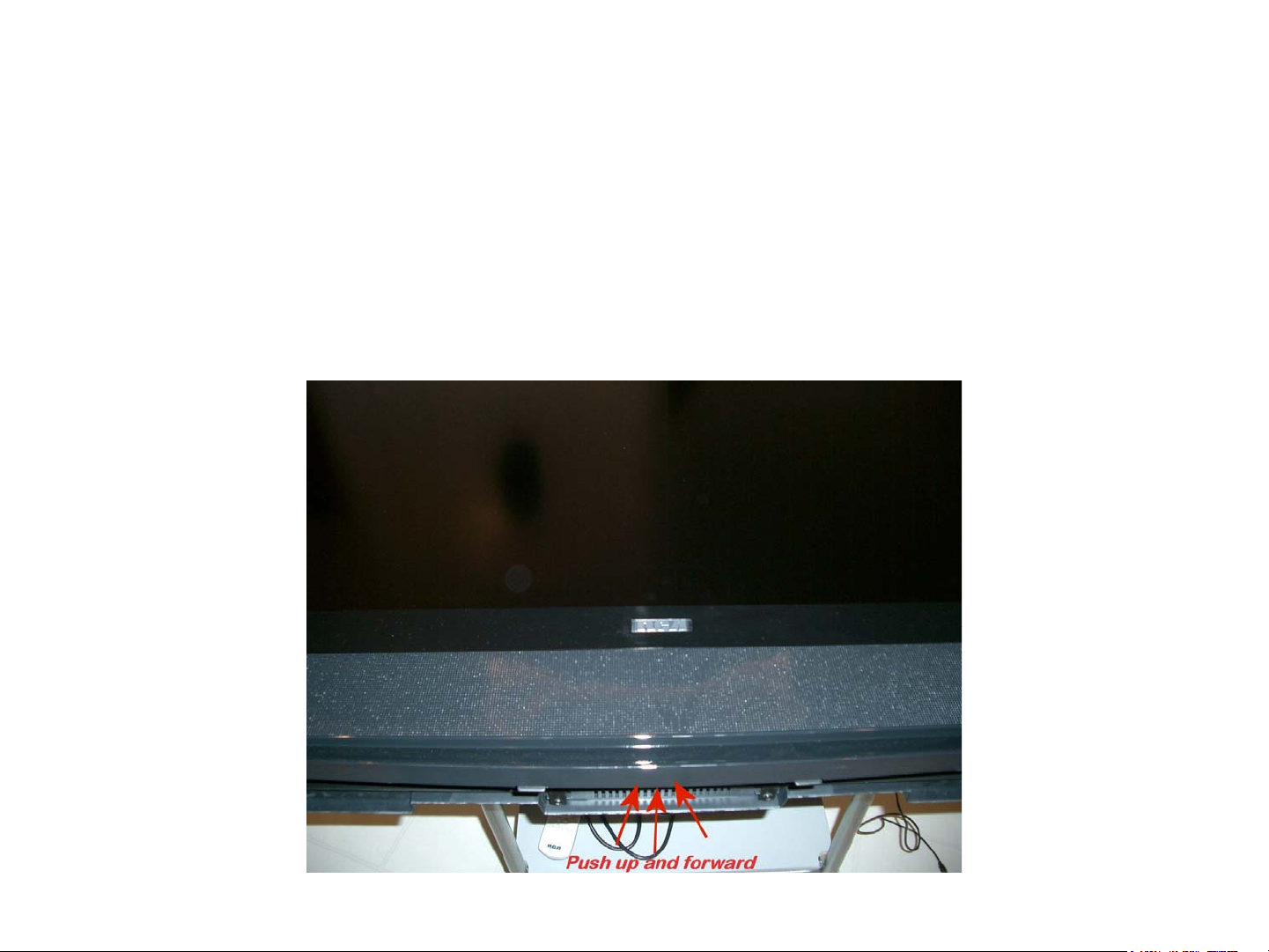

• Grasp bottom center of Mask (screen frame) and

gently, slowly lift up and forward.

Page 8

Disassembly of the LxxWD250

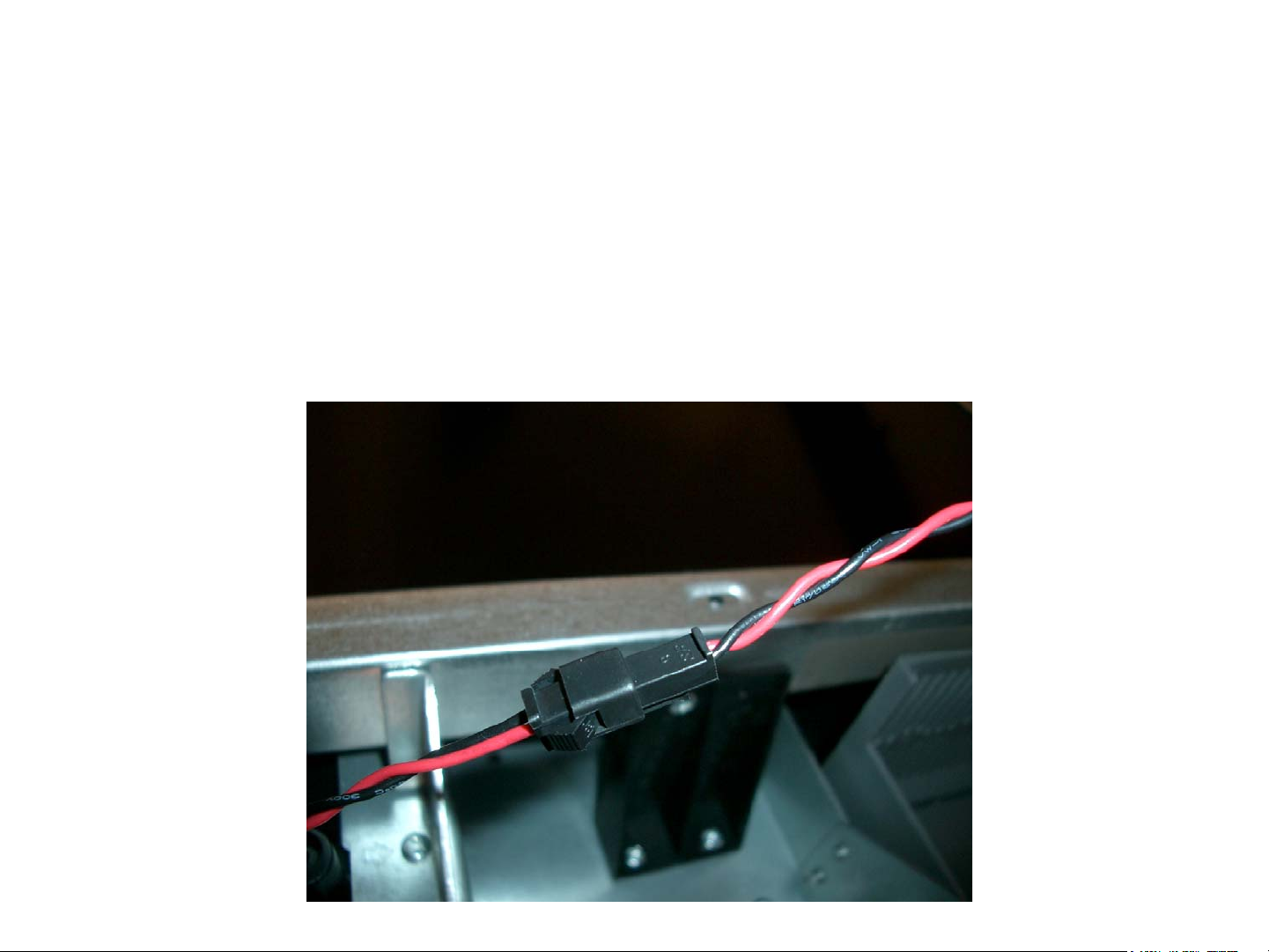

• Disconnect speaker wire connectors. (2 cables)

Pay attention to which wire goes to left and right

speakers.

Page 9

Disassembly of the LxxWD250

• Remove 2 screws from each display mount. 2

mounts on the left and the right side of display

assembly. (Top right mount shown below)

Page 10

Disassembly of the LxxWD250

• Remove 2 screws each from the two bottom

mounts of screen display assembly.

• DO NOT Remove any other screws from unit.

Page 11

Disassembly of the LxxWD250

• Grasp bottom of display assembly and pull up

and forward. Assembly will hinge upwards.

• Do not pull up more than 12 to 24 inches.

Careful not to pull wires taught. You can pull

plugs from connectors!

Page 12

Disassembly of the LxxWD250

• Using a dowel rod or curtain rod that is 18 to 22

inches in length, ½ inch or larger diameter, prop

up display assembly as shown in picture below.

Page 13

Disassembly of the LxxWD250

Page 14

Disassembly of the LxxWD250

Careful not to pull cable too tight else plug will separate from connector!

Page 15

Page 16

P810

Alignments

Entering the Factory Service mode

Turn the instrument OFF. Then press the Vol - button on the

remote and Vol - on the keypad simultaneously. Hold the

buttons for approximately 10 seconds until the instrument

turns ON. Using the remote if you want to select an item,

press the Up (^) and Down (v) buttons. Adjust the setting

value using the Left (<) and Right (>) key. Press the Clear

button to return to the main menu after adjusting a value.

Press the Clear button or select Go Back the menu to exit

the Factory Service mode.

Clear RRT: Clears the Regional Ratings Table. Select OK to

clear the table.

Test Pattern

The Test Pattern menu will display either a multiple color

bar or a flat color screen. Each display will be visible for

approxitimately 5 seconds. Use the arrow up or down on the

remote to select Test Pattern from the menu. Then use the

OK button on the remote to enter the next menu. Select Go

Back to return to the previous menu.

Local Upgrades/Applications: Will search for software up

grades, then initiate the upgrade process.

Current Software Info: Displays the current software version

and the date of install.

Video Alignment

The Cut Off alignment is used to define the color

coordinates for low level luminance. The Whitepoint is

used to define the color coordinates for bright luminance

This alignment must be completed using Line Input

(CVBS).

Multiple Color: Select, then select OK to display multiple

bands of color.

Main Menu

The Main Menu includes the following features:

Dealer Service Menu: This is at the very top of the screen. It

contains the current software version loaded in the instrument.

Go Back: Returns to the previous menu.

Test Pattern: Menu will bring up color test screens.

Speaker Test: Press OK for a 5 second test tone.

Operating Hours: Displays the hours of operation

NVM Initialise: Clears the NVM. This function resets all

customer settings to a out of box condition. Press the OK

button to start the process.

Reset Operating Hours: Resets the operating hours to 0.

Current Software Info: Displays the current software

version.

Software Upgrade: Allows for software upgrades.

Single Color: Will bring up 2 options.

Manual: Select which color to display (Red, Green, Blue,

White and Black). Press the OK button on the remote to

display the pattern.

Software Upgrade

Software upgrades are installed by the use of a generic USB

device. Specific instructions related to software updates will

be released within the software data package.

1. Enter the Factory Service mode.

2. Select VIDEO from the menu, then select Normal from

the Color Temperature sub-menu.

NOTE: It is only necessary to perform the Cut Off and White

Point Alignments with the Color Temperature set to

the Normal position. The values for Cool and Warm

are interpolated based on the Normal settings.

3. Insert a grey test pattern with a 10 to 20 Nits luminance

level.

4. Using a Color TV Analyzer meaure the coordinates at

the center of the screen. Adjust Red Offset, B Offset and

Green Offset for x = 0.280 +/- 5%, y = 0.290 +/- 5%

5. Insert a 50IRE (or 150 nits) grey test pattern.

6. Using a Color TV Analyzer measure the coordinates at

the center of the screen. Adjust R Gain, G Gain and B

Gain for x = 0.280 +/- 5%, y = 0.290 +/- 5%.

NOTE: It may necessary to switch between the Cut Off and

White Point Alignments in order to achieve the

proper alignment.

Picture: Customer Picture Menu

Video Alignment: Video Alignemt Menu

Automatic: Select, then select OK to scroll through the

different color screens (Red, Green, Blue, White and Black).

Will continue to scroll through the patterns until the OK button

is press.

Page 2-1

8. Exit the Service Menu by press the Clear button on the

remote.

Page 2-2

Page 17

P810

Alignments

Brightness Alignment

1. Enter the Factory Service mode.

2. Select VIDEO from the menu, then select Brightness.

3. Insert a pluge test pattern thru RF with a 2% setup

background with a 0% and 4% bar.

4. Adjust the Brightness so that the 0% bar is invisible

with the 4% bar visible.

5. Exit the Factory Mode by pressing Clear on the remote.

Peak White Adjustment

The Peak White alignment must be completed to the

following standards.

1. Enter the Factory Service mode.

2. Select VIDEO from the menu, then select Peak White.

3. Input a test pattern with a 100% white centered pad on

a dark background.

4. Using a Color TV Analyzer measure the luminance

level (Y[nit]) of the white pad. Adjust with the Scaling

Contrast the Light Output Level (PW Level) for 400

Nits + 20%/- 10%.

Defective Pixel Specification

A pixel is defined as three elements or dots, one red, one

blue, and one green. Thus one bright pixel is three bright

adjacent dots. No bright pixels are allowed but 3 bright

dots are allowed subject to the following:

The bright dots must be viewable on normal program

material (not static test patterns) when viewed at a distance

of five feet from a point perpendicular to the center of the

screen at eye level. The panel is considered defective if

the pixels are viewable and they are within ¼” of another

bright dot.

Also, no more than eight dark dots, and no dark pixels

will be accepted when viewed under the same conditions.

Page 18

P810 BLOCK DIAGRAM

C om ponent Input 1

C om ponent Input 2

Re ar C inch

FA V

DS UB

VG A

ED ID

EEP R O M

L-R

ED ID

EE PR O M

L-R

HD MI

HD M I / ADC

TD A 9975

A nalog Fr on t E nd

PN X 3000

EDI D

EE PR O M

DDR

SD R A M

16M x 16

D ig ita l A /V In pu t LV D S

Flash

512K b

S tandby uP 80C 51

IR KB

PN X 2015

A udio

S erial A /V Input

TU N N E L

Processor

Flat P anel Display

Audio Am p

D igital-A n alog F ront E nd

TD 13660

AT S C, NTS C, QAM

O O B Tu ner

uP C 3200 G R

Ch annel Decoder

FD C FA T

NX T2003

Tu ne r

DE NC

IF

Monitor Out

PN X 8550

US B 1.1

T ran sp o rt S trea m

CI Co ntrol

STV 0701

POD

DDR

S DRAM

2x 8M x 16

E EPR OM

8K x 8

NA ND

EE PR OM

32M x 16

Page 19

P810 Base Exploded View

1

1

2

3

5

6

4

BRACKET FOOT

BASE

MACHINE SCREW

BASE PANEL

SCREW

FOOT PAD

2

3

4

5

6

Page 20

P810 Chassis Exploded View

20

27

25

23

29

22

3

17

18

14

15

4

16

30

2

24

9

1

8

26

21

ASM BRACKET

10

7

5

34

36/37

12

11

13

1

2

SCREW M/C B 4 X 8

LEFT BRACKET

3

4

SCREW M/C B 4 X 8

5

RIGHT BRACKET

6

SCREW M/C B 4 X 8

BRACKET

7

8

SCREW TRIANGLE M/C B 3X8

SCREW TRIANGLE M/C B 3X8

9

10

SCREW TRIANGLE M/C B 3X8

11

POWER BRACKET

12

SCREW TRIANGLE M/C B 3X8

13

SCREW TRIANGLE M/C B 3X8

14

BRACKET

15

SCREW TRIANGLE M/C B 3X8

16

BRACKET POWER SOCKET

SCREW B 4 X 15 AB

17

18

SCREW M/C F 3 X 10

TWIST TIE NY66

19

20

SCREW TRIANGLE M/C B 3X8

21

SPONGE

22

SPONGE

23

TERMINAL BAR

SCREEN COVER

24

25

SCREW TRIANGLE M/C B 3X8

26

SCREW TRIANGLE M/C B 3X8

27

SCREW TRIANGLE M/C B 3X8

SCREW TRIANGLE M/C B 3X8

29

30

SCREW TRIANGLE M/C B 3X8

34

SCREW TRIANGLE M/C B 3X8

36

SPACER SUPPORT

37

FIBER SINK

6

Page 21

P810 Front Cabinet Exploded View

1

11

2

8

7

6

3

4/5

9

1

SPONGE

SCREW S/T B 3 X 8 AB

2

3

SCREW S/T B 3 X 10 AB

4

SCREW S/T B 3 X 10 AB

SCREW S/T B 3 X 10 AB

5

10

6

FRONT CABINET

7

INLAY KEY

8

PUSH BUTTON

REAR AV COVER

9

10

LUCENCY BAR

SCREW S/T B 3 X 10 AB

11

Page 22

P810 Rear Cabinet Exploded View

4

6

3

3

4

5

5

6

REAR CABINET

MODEL PLATE

SCREW S/T B 4 X 15 AB

SCREW M/C B 4 X 8

Page 23

P810 INTERCONNECT DIAGRAM

1 GND 11 GLINK-IR-OUT

2 YPbPr2-Y 12 GLINK-TXD

3 GND 13 GLINK-RXD

4 YPbPr2-PB 14 A-PLOP

5 GND 15 P50

6 YPrPb2-PR 16 SCL-MM

7 GND 17 SDA-MM

8 SPI-1 18 LED2

9 HSYNC-HIRATE 19 LIGHT-SENSOR

10 SPI-OUT 20 COM-SND

1 GND 21 +5V2-STBY

2 AV2/AV4_G-Y 22 CVBS-TER-OUT

3 GND 23 GND

4 AV2/AV4_B-PB 24 AUDIO-IN1-L

5 AV2/AV4_R-PR 25 AUDIO-IN1-R

6 GND 26 GND

7 +8V6-SW 27 AUDIO-IN2-L

8 GND 28 AUDIO -IN2-R

9 Y-CVBS-MON-OU 29 GND

10 GND 30 FRONT-Y-CVBS

11 N/C 31 GND

12 GND 32 FRONT-C

13 AUDIO-OUT2-L 33 GND

14 AUDIO-OUT2-R 34 AUDIO-IN3-L

15 GND 35 AUDIO-IN3-R

16 AUDIO-HDPH-L 36 GND

17 AUDIO-HDPH-R 37 AUDIO-IN4-L

18 GND 38 AUDIO-IN4-R

19 AV1-CVBS 39 GND

20 GND 40 GND

RIGHT

SPEAKER

LEFT

SPEAKER

BA003

BA004

BA001

Audio

Amp

Board

BA002

1

BV020

1

+12VDD

PGND

AM & DC

Board

(WD22/WD250)

AMP_L_IN

GND_BTL

AMP_R_IN

AGND

AMUTE

A-PLOP

1

20

Power Interface Board

BP700

1

5V

GND

8V6

12V

1

1

1D40 1M46

1M52

Digital Board

1E62

BP600

1M03

GND

Main

+12VDD

1

PGND

AC

IN

CON1

Power

Board

GND

5.2V_STBY

1

GND

LIGHT-ON-OUT

1

BACKLIGHT-CONTROL

1

CON3

12V

GND

P-ON

CN2

GND

1

+24V

CON4

+24V

GND

CN1

LCD Panel

AV Board

BV500

FAV_L

AGND

FRONT_C

Board

AGND

FAV_R

BV500

1

FAV_CVBS

AGND

1

FAV

BQ002

HP_L

BA202

BU001

BV010

1

HP_R

AGND

1

VDISP

1

VDISP

3

VDISP

1

1E40

1G50

40

5

CTRIL-DISP1

7

CTRIL-DISP3

9

TXPNXA+

11

TXAC+

13

TXPNXB-

15

GND

17

TXPNXC+

19

TXPNXCLK-

21

GND

23

TXPNXD+

25

TXPNXE-

27

GND

29

SDA_I2C4_DISP

31

SCL_I2C4_DISP

LED_1

1

VBUS

USB-

1

USB+

AGND

1M65

1E42

AGND

1

LED_2

GND

RC

+5V2_STBY

1

Keyboard

BK001

VDISP

VDISP

VDISP

CTRIL-DISP2

CTRIL-DISP4

TXPNXA-

GND

TXPNXB+

TXPNXC-

GND

TXPNXCLK+

TXPNXD-

GND

TXPNXE+

GND

BK002

2

4

6

8

10

12

14

16

18

20

22

24

26

28

30

32

GND

1

IR_1

5V

G_LED

R_LED

1

IR

Board

BK102(P1)

KEYBOARD

GND

P2 (WD22/250)

Page 24

P810 CONNECTOR LOCATION GUIDE DIAGRAM

A u d io A m p lifie r B o a rd

PO D

S tereo Ja c k

Ou t

SP DIF

Pow er Interface

Mon itor OutCo mpon ent 1Co mp onent 2Re ar A/V

Po we r

Int e r f ac e

Pa ne l

Inv erter

VG A

Pow er S upply

Mainboa rd

HDMI with L /R

I/O B o ard

US B

HDMI

LV DS

NT S C /AT S C

Tu ner

FAV

S

Video

HP

US B

Page 25

Dead Set

Troubleshooting

Start

Measure Pin 3

of CON 2 for

+5Vdc.

+5V present?

YES

Press Power

Switch, monitor

CON 3 Pin 7 for

+5V

+5V present?

YES

Check CON 3

Pin 1 for +12V

Pins 5/6 for +24V

NO

Suspect Main

SMPS

NO

BK001

Function DC Voltage

Power 2.7

Channel + 1.4

Channel - 0.84

Volume + 2.2

Volume - 1.8

Menu 2.5

No Key Press 2.9

Using the chart to the right,

verify the correct voltage on

pin 6 of BK001 for each FPA key

YES

press.

Voltages

Correct?

NO

Suspect Main

SMPS

NO

Monitor BP700 for the following

Voltages

Correct?

YES

voltages.

Pins 1/2 for +5V

Pin 4 for +8.6V

Pins 6/7 for +12V

Voltage

Correct?

YES

Suspect Digital

Board

NO

Troubleshoot

Digital Board

Suspect Power

Interface Board

Troubleshoot

FPA and Key

scan circuit

Page 26

Video OK

No Audio

Start

With the set

Powered On,

check BA001

Pin 1 for +12V

Voltage

present?

YES

Check BA002

Pins 1 and 3 for

audio signal

Signal

present?

YES

Check BA002

Pins 5 for 0V

Pin 6 for-0.2V

NO

NO

Suspect Main

SMPS Board

Suspect Digital

Board

Suspect Speakers

YES

Voltages

present?

YES

Check for Signal

on BA003 and

BA004

Signal

present?

NO

NO

Suspect Digital

Board

Suspect Audio Amp

Board

Check the Sound

Menu. Make sure

Internal Speakers

is checked.

Page 27

Sound OK

No Video

Start

With the set

Powered On,

check 1M03

Pin 1 for +8.5V

Pin 3 for +5V

All voltages

present?

YES

Check CON 3

Pins 5/6 for +24V

Voltages

present?

YES

Check signals

on 1G50

NO

NO

Suspect Digital

Board

Suspect Main

SMPS Board

Signals

present?

YES

Suspect LCD

Panel

NO

Suspect Digital

Board

Page 28

P810

VOLTAGE CHARTS

AUDIO AMP BOARD

AV BOARD

100AB 200AB 300AB 400AB

#NIP

CD

STLOV

#NIP

CD

STLOV

#NIP

CD

STLOV

#NIP

17.11 16.5 19.5 10.6

20.0

20.0 29.5 20.6

35.5

40.0

510.0

622.0-

200QB 010VB 020VB 005VB

CD

STLOV

#NIP

CD

STLOV

#NIP

CD

STLOV

#NIP

CD

STLOV

#NIP

CD

STLOV

#NIP

CD

STLOV

10.0 10.0 620.0 10.0 10.0

20.0

30.0

24.1 720.0 22.1 20.0

30.0 820.0 30.0 30.0

44.1 920.0 42.1 40.0

54.1 032.3 50.0 50.0

60.0 130.0 62.1 60.0

75.8 230.0 70.0

80.0 330.0 80.0

95.4 430.0 93.3

010.0 530.0 010.0

119.0 630.0 110.0

210.0 730.0 213.3

316.3 830.0 313.2

416.3 930.0 4122.0-

510.0 040.0 512.3

610.0 610.0

710.0 710.0

810.0 815.4

910.0 9114.0

020.0 022.3

129.4

220.0

320.0

Page 5-1

420.0

520.0

Page 5-1

Page 29

P810

VOLTAGE CHARTS

FRONT AV BOARD

202AB 100UB 005VB

#NIP

CD

STLOV

#NIP

CD

STLOV

10.0 11.5 10.0

20.0

30.0

20.0 20.0

30.0 30.0

40.0 40.0

50.0 50.0

#NIP

60.0

70.0

IR BOARD

201KB

NUR

CD

STLOV

#NIP

CD

STLOV

#NIP

201KB

FFO

CD

STLOV

10.0 10.0

23.3

39.4

48.1

512.0

23.3

39.4

48.1

50.2

LCD PANEL

#NIP

10.42 10.42 181.0

20.42

30.42

40.42 40.42

50.42 50.0

1NC 2NC

CD

STLOV

#NIP

20.42 22.0

30.42

1NC

)THGILKCAB(

CD

STLOV

#NIP

CD

STLOV

60.0 60.0

70.0 70.0

80.0 80.0

KEY BOARD

100KB

#NIP

CD

12.2 REWOP7.2 10.0 10.0

25.4

30.0

43.3

59.4

69.2

90.0 90.0

010.0 010.0

114.8

100KB

6NIP

STLOV

NOITCNUF

CD

STLOV

200KB

NUR

#NIP

CD

STLOV

200KB

211.5

FFO

#NIP

CD

STLOV

+HC4.1 23.3 23.3

-HC48.0 39.4 39.4

+LOV2.2 48.1 48.1

-LOV8.1 512.0 50.2

UNEM5.2

70.0

Page 5-2

Page 5-2

Page 30

P810

VOLTAGE CHARTS

MAIN BOARD

04D1 05G1 04E1 24E1

#NIP

CD

STLOV

#NIP

CD

STLOV

#NIP

CD

STLOV

#NIP

CD

STLOV

#NIP

CD

STLOV

#NIP

CD

STLOV

24E1

6NIP

NOITCNUF

CD

STLOV

26E1 30M1 64M1 25M1 56M1

#NIP

CD

STLOV

#NIP

CD

STLOV

#NIP

CD

STLOV

#NIP

CD

STLOV

#NIP

1CN 19.4 620.0 10.0 620.0 12.2 REWOP7.2 10.0 14.8 10.0 16.5 11.5

2CN

30.0

4CN

50.0

6CN

29.4 72CN 24.1 720.0 25.4 +HC4.1 22.1 2CN 20.0 20.0 20.0

39.4 82CN 30.0 820.0 30.0 -HC48.0 30.0 31.5 35.8 35.5 30.0

49.4 920.0 44.1 920.0 43.3 +LOV2.2 42.1 40.0 46.11 40.0 40.0

59.4 03CN 54.1 032.3 59.4 -LOV8.1 50.0 5CN 51.5 510.0 50.0

6CN 13CN 60.0 130.0 69.2 UNEM5.2 62.1 6CN 60.0 622.0-

71.5 70.0 230.0 75.8 230.0 70.0 70.0 78.4 79.4

81.5 80.0 80.0 330.0 80.0 8CN 8CN

91.5 90.0 95.4 430.0 93.3 9CN 96.11

010.0 010.0 010.0 530.0 010.0 01CN 01CN

CD

STLOV

11CN 110.0 119.0 630.0 110.0 116.11

21CN 212.1 210.0 730.0 213.3

312.1 316.3 830.0 313.2

410.0 416.3 930.0 4122.0-

513.1 510.0 040.0 512.3

612.1 610.0 610.0

710.0 710.0 710.0

813.1 810.0 815.4

911.1 910.0 9114.0

020.0 020.0 022.3

122.1 129.4

222.1 220.0

320.0 320.0

423.1 420.0

522.1 520.0

Page 5-3

Page 5-3

Page 31

P810

VOLTAGE CHARTS

MAIN SMPS BOARD

006PB 007PB

#NIP

CA

STLOV

17.11 11.5

20.0

#NIP

21.5

30.0

45.8

50.0

67.11

77.11

POWER INTERFACE BOARD

1NOC

)SNIPSSORCA(

CD

STLOV

#NIP

CA

STLOV

2NOC 3NOC

#NIP

CD

STLOV

#NIP

CD

STLOV

10.121 1CN 19.11

20.121

20.0 20.0

39.4 30.0

4CN 40.0

50.42

60.42

78.4

Page 5-4

Page 5-4

Page 32

P810

WAVEFORMS

BA003 Pin 1 - Audio Amp Board BA004 Pin 1 - Audio Amp Board BV010 Pin 9 - AV Board

1E40 Pin 9 - Main Board

BV010 Pin 14 - AV Board

1E40 Pin 14 - Main Board

BV020 Pin 10 - AV Board

1E62 Pin 10 - Main Board

1G50 Pin 7 - Main Board 1G50 Pin 8 - Main Board

BV010 Pin 13 - AV Board

1E40 Pin 13 - Main Board

1G50 Pin 9 - Main Board

1G50 Pin 10 - Main Board 1G50 Pin 11 - Main Board 1G50 Pin 12 - Main Board

Page 5-1Page 5 - 1

Page 33

P810

WAVEFORMS

1G50 Pin 13 - Main Board 1G50 Pin 15 - Main Board 1G50 Pin 16 - Main Board

1G50 Pin 19 - Main Board 1G50 Pin 21 - Main Board 1G50 Pin 22 - Main Board

1G50 Pin 18 - Main Board

1G50 Pin 24 - Main Board

1G50 Pin 25 - Main Board CN3 - CN10 Pin 1 LCD Panel CN3 - CN10 Pin 2 LCD Panel

Page 5-2Page 5 - 2

Loading...

Loading...