Page 1

USER'S

GUIDE

CO

Page 2

To reduce the risk of electric shock, do

not remove cover (or back). No user

serviceable parts inside. Refer servicing

to qualified service personnel.

i_ This symbol indicates

"dangerous voltage"

inside the product that

presents a risk of electric

shock or personal injury.

_ll his symbol indicates

important instructions

accompanying the product.

WARNING

To reduce the risk

of fire or shock

hazard, do not

expose this TV to

rain or moisture.

Caution: To reduce the risk of electric shock, match wide blade of plug

to wide slot, fully insert.

Attention: Pour _viter les chocs 61ectriques, introduire la lame la plus

large de la fiche dans la borne correspondante de la prise et pousser

jusq_ au fond.

• Operate TV only on 120 volts, 60 Hz AC power (normal house power).

• FCC Regulations state that unauthorized changes or modifications to this

equipment may void the user's authority to operate it.

abl:e "rv Installer: This reminder is provided to call your attention to Article 820-40 of the National |

lectrical Code (Section 54 of the Canadian Electrical Code, Part 1) which provides guidelines for

]

proper grounding and, in particular, specifies that the cable ground shall be connected to the

rounding system of the building as close to the point of cable entry as practical,

_._1HOMSON CONSUMER ELECTRONICS

103:}0 North Meridian Street

Indianapolis, IN 46290

©1996 Thomson Consumer Electronics, Inc.

Trademark(s)® Registered

Marca(s) Registrada(s)

Printed in U.S.A.

TOCOM 1511223A

The following materials were used in printing

this publication:

.nu. z_P.Trams SOY INK

Page 3

STEP 1

Unpack the TV and remote control.

IMPORTANT INFORMATION: OPTIONAL STAND

Matching stands were designed to be used with 25 inch and larger table

model TV(s) included in this book. The recommended stands are provided

wiith hardware to secure the TV to the stand so that it cannot be easily

pushed off, pulled of,f or tipped over. Your RCA dealer can help you choose

the appropriate stand for your TV.

Caution: If you choose not to use the stand recommended for your TV,

take precautions that the stand or other furniture the TV is placed on is

properly located and of adequate size and strength to prevent the TV from

accidentally being pushed off, pulled off, or tipped over. This could cause

damage to the TV and/or personal injury.

Page 4

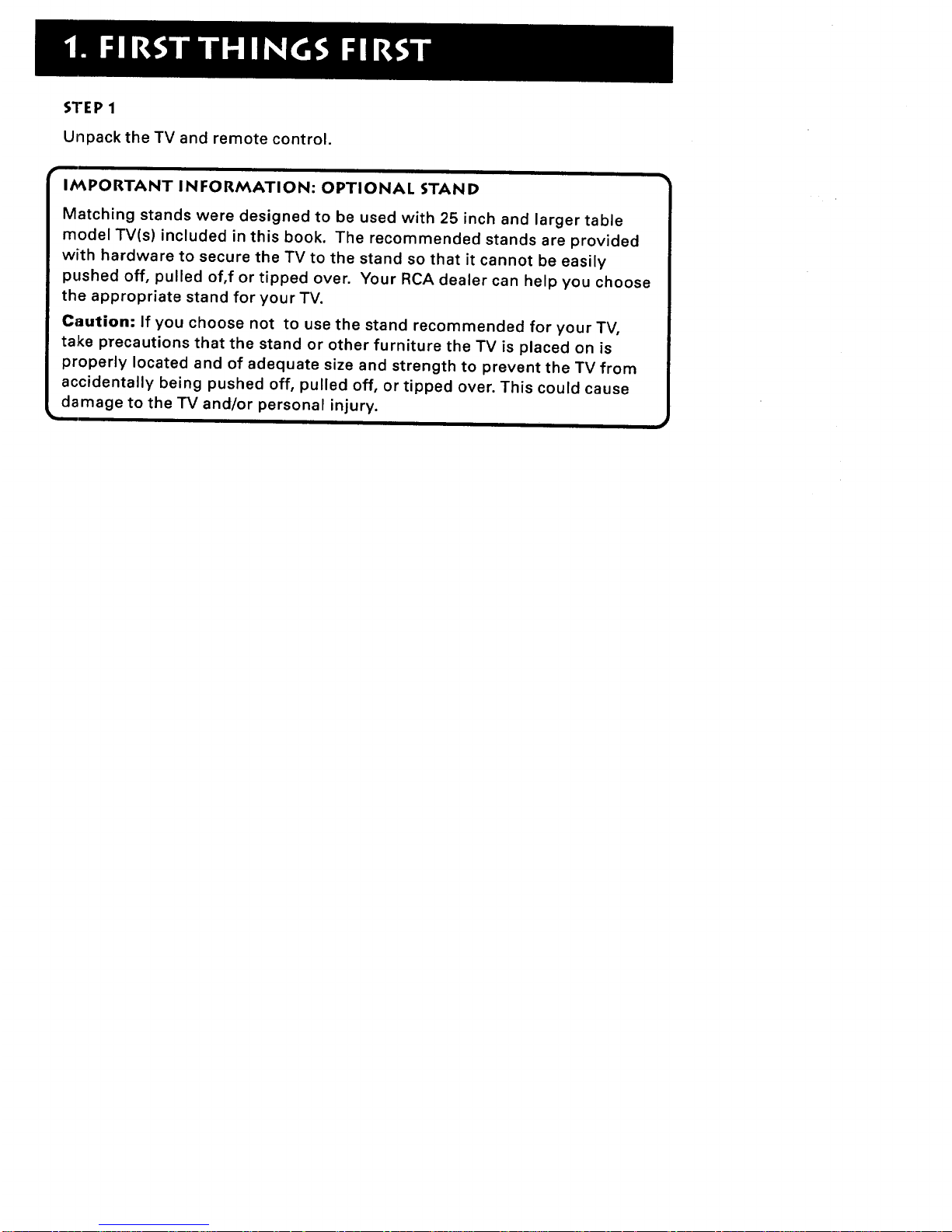

STEP 2:

Connect your TV. This is a basic

connection from an antenna, cable

box, or VCR to your TV. Connect the

cable from your cable system or off-air

antenna to the cable-in jack on the

back of the TV, as shown.

ANTENNA, CABLE,CABLE BOX OR VGR

STEP 3:

Plug in the TV. Plug the end of the power cord into the wall

outlet, matching the wide blade of the plug with the wide

slot in the outlet. Be sure to insert the plug completely.

STEP 4

Put batteries in the remote.

• Remove the battery compartment cover from

the back of the remote.

• Insert two AAA batteries as shown, matching

the + and- ends of each battery in the

compartment.

• Replace the cover.

STEP 5

Turn on the TV.

• Press TV on the remote.

Read the next section, Using the Menu System, which is a brief overview of

the basic rules for getting around in the menus using the remote or TV's front

control panel.

Page 5

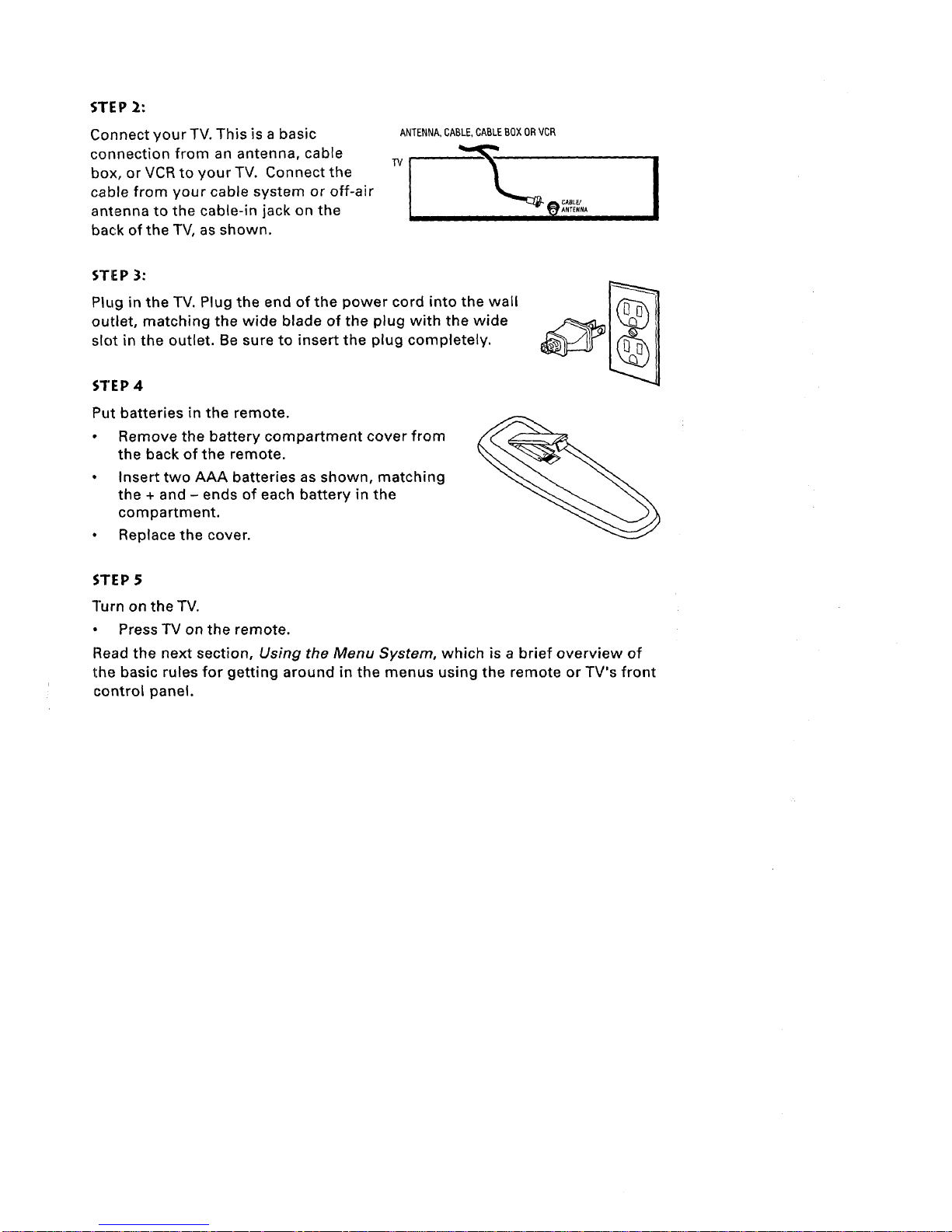

THE MENU RULE: POINTAND SELECT

You only need to know one rule to use the on-screen menus and control

panels: point and select.

WHAT IS POINT AND SELECT?

The point and select method has two steps.

1. Point to a menu item using the MOVE arrows on

the remote. (The CHAN/VOL buttons on the

remote.)

2. Select a menu item by pressing MENU.

Selecting an item tells the TV's menu system to go

ahead and make the change or go to a place you

have indicated. (You can also select an item by

pressing the corresponding number button on the

remote.)

/%

VOL CHAN VOL

CHAN

MENU

,Once you know how to point and select your way through the menus, you

can apply this rule in the menu control panels, which do the real work in the

menu system.

The setup routine walks you through the steps needed to configure the TV.

These steps allow you to select a menu language, complete the auto channel

search, which puts available cable TV or antenna signals into the TV's

memory, label the channels and set the parental controls. After you select a

menu language, you can skip any of the remaining steps and return to them

later.

BEGIN SETUP

1. Press MENU to bring up the Main menu.

2. Point to Setup and press MENU. The first Setup screen comes up, asking

you to select a language.

Setu

3. Point to your preferred language by pressing the up and down arrows

until the language is highlighted in green.

4. Press MENU to select the language.

5. A screen appears asking if you would like the TV to search for all

channels.

6. Complete the Setun rn_Jtin,, ,,, ,-L,;...... • ......

Page 6

TV MAIN MENU

The Main menu is your gateway to controlling the TV. It lets you adjust the

TV's audio, picture quality, screen, time functions and channel settings.

TV MAIN MENU

To select any other menu item:

1. Press MENU to bring up the TV's Main menu.

2. Point to any menu item by pressing the up and down arrows until the

item is highlighted in green.

3. Press MENU to select the item and a new menu comes up.

To exit any menu screen, point to Exit and press MENU, or press CLEAR.

THE AUDIO MENU

The Audio menu lets you adjust the way the TV sounds.

Audio

Mute Turns off the TV's sound. Press MENU to toggle the Mute feature

between ON and OFF.

IXS Stereo An innovative method for stereo sound effect 1

providing

m

l

The sound delivered by your television is XS Stereo. This patented process /

suppresses noise, restores the dynamic range and electronically expands the/

stereo signal to create a more spacious sound effect. J

Stereo Press MENU to toggle the Stereo feature between ON and OFF.

On Sound is reproduced in stereo or mono, whichever is being broadcast.

Off Sound is reproduced in mono.

THE PICTURE QUALITY MENU

The Picture Quality menu contains the controls that adjust the TV's picture.

Picture qualit

Page 7

There are five slider controls for adjusting the way the picture looks. Use the

left and right arrow buttons to adjust the controls.

Contrast Adjusts the difference between light and dark areas of the picture.

Color Adjusts the richness of the color.

Tint Adjusts the balance between the red and green levels.

Black Level Adjusts the brightness of the picture.

Sharpness Adjusts the crispness of edges in the picture.

Auto Color Displays the current setting (ON or OFF). This feature

automatically corrects the color of the picture. Select Off if you prefer to

adjust the picture with the Picture Controls. Use the MENU button to toggle

between the choices.

Reset Picture Controls Resets the picture controls to their original settings.

THE SCREEN MENU

The Screen menu contains the controls that let you adjust the Closed-Caption

mode, Closed-Caption display and menu language.

Screen

Closed-Caption Display Displays a choice list that lets you choose the way

closed captioning information is shown on the screen. Use the MENU button

to toggle between the choices.

Off No captioning information displayed.

On Captioning information shown always, when available.

On When Sound is Muted Displays captioning information, when

available, whenever you press the MUTE button. The captioning

information is not displayed when the sound is not muted.

Closed-Caption Mode Displays a choice list that lets you choose which

captioning mode is used for displaying captioning information. Use the

MENU button to toggle between the choices: COl and CC2.

Menu Language Lets you select the language of your choice: English,

French or Spanish. Use the MENU button to toggle between the choices.

Page 8

THE CHANNEL MENU

The Channel menu contains all the commands used to control your channels,

including custom-building your channel list and setting parental controls.

Channel

Signal Type Displays a choice list that lets you select the current antenna

type.

Antenna Choose this if you are currently using an off-air antenna for

UHF/VHF TV signals.

Cable TM Choose this if you are currently using cable or a cable box for

TV signals.

Auto Channel Search Displays a control panel that lets you tell the TV to

search automatically for all the channels available through the antenna input.

When the TV finds an active channel, it places it in the channel list; inactive

channels (weak stations or channels with no signal at all) will be removed

from the channel list.

Lists and Labels Displays a control panel that lets you custom-build your

channel scan list, choose a four-character label for each channel, and decide

whether each channel is "parent-approved." Use the up, down, left and right

arrows to enter settings and create labels. Press MENU to exit.

Lists and LabeLs

Page 9

scan list. You can enter the channel number directly using the

number buttons.

Chart Labels Use the up and down arrows to enter a four-character label

for each channel.

Scan List Only the channels included in the Scan list are available when

you scan up and down using the CHAN buttons. Use the up and down

a_rrows to indicate whether the channel number indicated is included

(YES) or is not included (NO) in the channel scan list.

Parent Approved Use the up and down arrows to choose whether the

clhannel indicated should be shown when the Parental Control feature is

turned on. Select YES to indicate that the channel can be shown at any

time, regardless of whether Parental Control is turned on. Select NO to

indicate that the front panel cannot tune to that channel when Parental

Control is turned on. Important: You must turn the Parental Control

feature ON in the Parental Control control panel.

Parental Control Displays a choice list that lets you adjust the Parental

Control feature.

On The front panel CHAN buttons will tune only to channels that you have

marked as "Parent Approved" in the Lists and Labels control panel.

Important: When Parental Control is on, the TV's front panel no longer

provides access to the menus. Parents may prefer to hide the remote and

let children use the front panel to change channels.

Off The TV shows all channels, whether they are marked as "Parent

Approved" or not.

THE TIME MENU

The Time menu contains the controls that let you set the time and schedule

the 7rv to turn off and on at specific times.

Time

Sleep Timer Displays a control panel that lets you select the amount of time

you want to give the TV before it shuts itself off. Use the up and down arrows

to in,crease or decrease the sleep timer by 15 minute increments. Press

MENU to exit.

Timer

Schedule Displays a control panel that lets you set up a schedule for turning

the TV on and off automatically. Make sure to turn the schedule On in the

control panel. Use the up and down arrows and number buttons to change

the settings. Use the left and right arrows to move across the control panel.

You must first set the clock to use the scheduling feature.

Schedute

Set Time Displays a control panel that lets you enter the current time. Use

the up and down arrows and number buttons to set the time. Press MENU to

exit

Page 10

Thereareseveralindicatorsthat comeupwhenyou changechannelsor press

the DISPLAY button. This display is called the Channel Marker. The Channel

Marker shown below is just an example of what your screen may look like,

08:59 Displays the current time.

WRTV Displays the label assigned to the current channel.

06 Displays the current channel.

Sleep Displayed when the Sleep Timer has been set.

Stereo Displayed when the current channel is broadcasting in Stereo.

CC Displayed when Closed Captioning is available on the current channel.

Mute Displayed when you mute the audio.

Schedule Displayed when the TV is scheduled to turn on.

01',',30 Displayed to count down time left on the commercial skip (SKIP) timer.

Page 11

POWER Turns the TV on and off.

DISPLAY Brings up channel information. Press

repeatedly to see detailed program information,

if .available.

MUTE Turns off the TV's sound. Press again to

restore the sound.

PREV CH Returns you to the previous channel.

VOL - or VOL + Decreases or increases the TV's

volume. Also used as left and right arrows.

CHAN ^ or CHAN v Scans up or down through

the current channel list. Press once to change

the channel up or down; press and hold to

continue changing channels. Also used as up

and down arrows.

CLEAR Removes any menu or display from the

screen and returns you to TV viewing.

MENU Brings up the Main menu. When in the

menu system, selects highlighted items or

returns you to the previous menu.

RESET Returns all picture quality controls to

their original settings.

(0-9) Number Buttons Enters channel

numbers and time settings directly though the

remote control. To enter a two-digit channel,

press the two digits. To enter a three-digit

channel, press and hold the first digit, then add

the second two. Example: to tune to channel

1:23, press and hold 1, press 2, then press 3.

INPUT (on some models) Press to toggle

POWER

MUTE PREVCH

© ©

VOL H_AN VOL

CHAN

CLEAR MENU RESET

g35

through the available input sources (CH3, CH4, etc.).

SKIP Press once before changing channels and the TV will wait 30 seconds

before returning you to the original channel. Press repeatedly to add more

time.

Page 12

FRONT PANEL

VOI. < Decreases the volume. When in the

menu system, VOL < is used to point left to

items and adjust menu controls.

VOL > Increases the volume. When in the

menu system, VOL > is used to point right to

items andadjust menu controls.

CHAN ^ Scans up through the channel list.

In the menu system, it points up to items and adjusts menu controls.

CHAN v Scans down through the current channel list. In the menu system, it

points down to items and adjusts menu controls.

MENU Brings up the Main menu. When in the menu system, it selects

highlighted items. Also returns you to the previous menu.

If you turn Parental Control on, the front panel no longer provides access to

the menus. For more information, see Parental Control in the Channel menu

on the back side of these instructions.

POWER Turns the TV on and off.

The front panel shown is a typical button layout. The exact look of the buttons

may be different from those on the front of your TV.

Page 13

ON-SCREENPROGRAMDETAILS

Programproviders have the option of sending information through the

airwaves along their programs. If this information is available, the TV can

display it up when you press DISPLAY on the remote. To display the on-screen

program details:

1. Press DISPLAY once to bring up the channel marker.

2. Press DISPLAY again to bring up the program title, the program's length,

elapsed time and other program details such as the story line and

whether Closed-Captioning is available.

3. Press DISPLAY again to clear the screen.

Whether all (or any) of the program details are displayed depends on whether

the program provider has sent the information along with the program.

CLOSED CAPTIONING

Many programs are encoded with closed-captioning information, which lets

you display the audio portion of a program as text on the TV screen. You can

tell the TV to display closed captioning: a) never, b) whenever it is available,

or c) whenever the MUTE button is pressed.

The TV offers two closed-captioned modes. Select CC1 for full translation of

the primary language in your area. Select CC2 for secondary language

translation, simplified English, or whatever is being broadcast in your area.

Closed captioning is not available on all channels at all times. Only specific

programs encoded with closed-captioning information are applicable. When a

program is closed captioned, the letters CC are displayed in the channel

marker.

Page 14

WHAT YOUR WARRANTY COVERS:

• Any defect in material or workmanship.

FOR HOW LONG AFTER YOUR PURCHASE:

• 90 days for labor charges.

• ,One year for parts.

• "Two years for picture tube.

The warranty period for rental units begins with the first rental.

WHAT WE WILL DO:

Pay any Authorized RCA Television Servicenter the labor charges to repair

,your television.

Pay any Authorized RCA Television Servicenter for the new or, at our

option, refurbished replacement parts and picture tube required to repair

your television.

HOW YOU GET SERVICE:

• Request home service from any Authorized RCA Television Servicenter. To

identify your nearest Authorized RCA Television Servicenter, ask your

Dealer, look in the Yellow Pages, or call 1-800-336-1900.

• Show the service technician your evidence of purchase date.

WHAT YOUR WARRANTY DOES NOT COVER:

• Acts of God, such as but not limited to lightning damage.

• Customer instruction. (Your User's Guide clearly describes how to install,

adjust, and operate your television. Any additional information should be

obtained from your Dealer.)

• Installation and related adjustments.

• Signal reception problems not caused by your television.

• l_amActA frnm mi.qlL_A nr n_.nlAr_t_

Page 15

• Remote control batteries.

• A television that has been modified or incorporated into other products or

is used for institutional or other commercial purposes.

• A television purchased or serviced outside the U.S.A.

PRODUCT REGISTRATION:

• Please complete and mail the Product Registration Card packed with your

set. It will make it easier to contact you should it ever be necessary. The

return of the card is not required for warranty coverage.

HOW STATE LAW RELATES TO THIS WARRANTY:

• This warranty gives you specific legal rights, and you also may have other

rights that vary from state to state.

WHAT IF YOU PURCHASED YOUR TELEVISION OUTSIDE THE U.S.A.:

• This warranty does not apply. See your dealer for details.

Page 16

Troubles sometimes are caused by simple "faults" that you can correct

without the help of a service technician. If you experience any difficulty with

your TV, check a few basic remedies before calling your service technician.

TV WILL NOTTURN ON OR CONTROLS DON'T WORK

• Check to make sure it is plugged in.

• Check the wall receptacle (or extension cord) to make sure it is "live" by

plugging in something else.

• Try unplugging set for two minutes and then plug it back in and turn it on

again.

PROBLEMS WITH REMOTE

• Maybe something is between the remote and the remote sensor.

• Maybe the remote is not aimed directly at the TV's remote sensor.

• Maybe remote batteries are weak, dead or installed incorrectly. Try

replacing batteries correctly.

• Remove batteries and hold down one or more buttons for several

seconds. Install the batteries and try remote.

TURNS ON OR OFF WHILE PLAYING

Schedule function may have been activated.

Electronic protection circuit may have been activated because of a power

surge. Wait 30 seconds and then turn on again. If this happens

frequently, the voltage in your house may be abnormally high.

Page 17

• Check schedule on/off function (it must be set to On).

• Check to make sure clock is set to the correct time.

BLANK SCREEN OR BLACK BOX APPEARS ON THE SCREEN

• "1"ryanother channel.

• Press RESET, in case the picture controls are set too low.

• Captioning may be turned on. Check the Closed-Caption Display control

panel in the Channel menu.

NO SOUND, PICTURE OKAY

• Maybe sound is muted. Try pressing volume up button to restore sound.

NO PICTURE, NO SOUND BUT POWER LIGHT IS ON

• Maybe cable/air function is in wrong position.

• Maybe a vacant channel is tuned,

• If watching VCR, make sure TV is tuned to channel 3 or 4- same as CH3/4

switch on VCR. Also check to make sure TVNCR switch on VCR is in

correct position.

SOUND OKAY, PICTURE POOR

• Check antenna connections.

• Try adjusting sharpness function to improve weak signals.

Page 18

You can clean the TV as required, using a soft cloth or the dusting attachment

for your vacuum cleaner. Be sure to occasionally vacuum the ventilation slots

in the cabinet to help assure adequate ventilation.

To clean the TV screen, use a diluted soap and water mixture and a soft cloth.

Do not use furniture polish on the TV cabinet or screen.

While cleaning do not allow liquid to run down the screen and inside

the TV. Also, avoid placing drinks or vases with water on top of the

TV. This could increase the risk of fire or shock hazard or damage to

the TV.

Caution: If fixed (non-moving) images are left on the screen for long |

perio,_ls, they may be permanently imprinted on the screen. Such images

_include network Iogos, phone numbers, and video games. Extended

f viewing of channels displaying these images should be avoided.

m _IMB m

CREATING A GREENER FUTURE

At Thomson Consumer Electronics we are dedicated to the preservation

of our natural heritage and to a healthy and safe way of life for current and

future generations. This is a global effort which encompasses every

THOMSON facility throughout the world.

We believe that clean air, clean water, a protected earth, and healthy people

are not only practical and desirable goals, but achievable ones as well. Our

Corporate Environmental, Health and Safety Charter acknowledges our

commitment to protect these precious assets and provides a challenging

vision and guideline for conducting our business. Below are a few

examples of Thomson's achievements in our efforts to preserve our natural

resources.

Page 19

,_,_ _ ll==_dlUUUe Wc'ts{e

_ually diverting it from landfills.

)mson treats millions of

rods of waste water sludge

_ually and renders it

_hazardous.

,mson recycles over 50 million

rids of nonhazardous material

ually that otherwise would

s been treated as trash, an

rail recow31"y rate of 50%.

mson globally recycles

ions of pounds of broken

ure tube _;llass through both

rnal and external processes

,Jally.

based paints at many locations

resulting in an 80% reduction in

toxic air emissions for equivalent

material used.

Thomson has eliminated the use

of ozone depleting substances at

television manufacturing facilities

around the world.

Thomson is collecting and

returning over 1.5 million pounds

of air pollution control dust to the

glass making process annually.

Thomson has launched worldwide

energy savings programs which

contribute to global efforts to

reduce air emissions from

electrical generating facilities.

I IlOIII;:;(J[I recovers over 2 million

pounds of fine glass particles from

process water each year and

recycles them back into its glass

furnaces.

Thomson's state-of-the-art waste

water treatment plants filter out

over 26 million pounds of solids

from process water each year.

Thomson's US glass factory

recycles 2,500 gallons of water per

minute and cleans 2.6 million

gallons of water per day.

Thomson is researching new

processes and is developing new

manufacturing equipment and

technologies to further reduce

large volume water usa.

mson has also increased its usage of recycled materials for packaging of our products. For

-nple, in the U.S. and Mexico our television plants use recycled content in our television cartons

instruction booklets. The inks used for the print on cartons and instruction booklets issoy based

nontoxic. For a free brochure regarding Thomson's Environmental Health and Safety Programs,

eto Thomson Consumer Electronics 10330 N. Meridian, Indianapolis, IN 46290, attention

ronmenlLalPrograms: INH340.

Loading...

Loading...