Page 1

I

DSSSqsrem

Installation

TrainingFlanual

Page 2

Foreword

This publication is intended to assist the installation technician installing the RCA brand DSS TM Digital

Satellite System. In this publication, basic installation techniques are covered for most common situations.

Included in each explanation is a suggested material and tool list. Also included is an overview of the DSS

System plus a signal flow description of the DSS receiver. This information is included to help the technician

install the system and explain its operation to their customers.

Safety Information!

DANGER Avoid Power Lines! When following the instruction in this guide to install and connect the

satellite antenna and connections, take extreme care to avoid contact with overhead power lines, lights, and

power circuits. Contact with these items may prove fatal.

Outdoor Dish Grounding: The outdoor dish used to receive satellite signals and the cable used to connect

the outdoor dish to the indoor receiving unit are required to comply with local installation codes and the

appropriate sections of the National Electrical Code (NEC), especially Article 810 and Article 820. These

codes require proper grounding of the metal structure of the outdoor dish and grounding of the connecting

cable at a point where it enters the house (or other building). The DSS System Installation Training Manual

contains instructions on how to install the system in compliance with the National Electrical Code (NEC).

If additional local installation codes apply, contact local inspection authorities.

Compliance with National Electrical and Local Codes: Before installing the Digital Satellite System,

check the electrical codes in your area.

Restrictions: Before installing the dish, check the zoning codes, covenants, and community restrictions in

your area. Some rules prohibit installing large satellite dishes, but may allow small ones. Also, there may

be restrictions in your area that limit the mounting height of dishes.

If you encounter homeowner or community restriction's, call 1-800-679-4776. Personnel at this number

can provide information that may be helpful when attempting to obtain permission to install the DSS Digital

Satellite System on the property.

* DSS and Digital Satellite System is an official trademark of DIRECTV, Inc., a unit of GM

Hughes Electronics.

Prepared by

Second Edition 9415 - First Printing

Copyright 1994

Thomson Consumer Electronics, Inc.

Trademark(s)® Registered Marca (s) Registrada(s)

Thomson Consumer Electronics, Inc.

Technical Training Department

10330 North Meridian St.

Indianapolis, Indiana 46290-1024

Page 3

Table of Contents

Overview ................................................................................................................................... 5

Technical Overview ................................................................................................................. 10

Satellites ............................................................................................................................... 12

Dish ...................................................................................................................................... 14

Receiver Circuitry ................................................................................................................ 16

Diagnostics ........................................................................................................................... 17

Site Survey ................................................................................................................................ 22

Installation ................................................................................................................................ 32

Mounting the Dish ................................................................................................................ 32

Vertical Mounting Systems .................................................................................................. 42

Panel Siding ............................................................................................................................................. 42

Lap Siding ................................................................................................................................................. 46

Brick ......................................................................................................................................................... 52

Onder Block ............................................................................................................................................. 56

Horizontal Mounting Systems .............................................................................................. 63

Deck Railing ............................................................................................................................................. 63

Roof ..........................................................................................................................................................64

SpecialMounting Systems ...................................................................................................69

PoleMount ...............................................................................................................................................69

Chimney....................................................................................................................................................72

Dish Assembly .....................................................................................................................79

AssembletheDish.....................................................................................................................................79

InstalltheLNB Cable...............................................................................................................................81

InstalltheLNB ..........................................................................................................................................86

AttachingLNB CabletoReceiver.............................................................................................................88

TelephoneCableInstallation...................................................................................................................91

InstallingtheReceiver..........................................................................................................98

System Connections..................................................................................................................................I00

AligntheDish ......................................................................................................................105

DetermineAzimuthand Elevation............................................................................................................106

AdjustElevation........................................................................................................................................I07

AdjustAzimuth..........................................................................................................................................107

AcquiringSignal.......................................................................................................................................I09

Troubleshooting ....................................................................................................................... 114

APPENDICES

A. Finding DSS Azimuth and Elevation .............................................................................. 118

B. Using a Compass ............................................................................................................. 130

C. National Electrical Code .................................................................................................. 126

D. DSS Reference Publications ............................................................................................ 129

E. RCA DSS Dish Parts List ................................................................................................ 132

Glossary .................................................................................................................................... 133

Index ....................................................................................................................................... 136

Page 4

Overview 5

Satellite Communication Basics

All comm_'cations services, from ship-to-shore communications, radio and television

to communications satellites are assigned unique bands of frequencies within the

electromagnetic spectrum in which to operate.

To receive signals from the earth successfully and relay them back again, satellites use

very high frequency radio waves operating in the microwave frequency bands--either

the C-band or KU-hand. C-band satellites generally transmit in the frequency band of

3.7 to 4.2 Gigahertz (GHz), in what is known as the Fixed Satellite Service band orFSS.

However, these are the same frequencies occupied by ground-based point-to-point

communications, making C-band satellite reception more prone to interference.

KU-band satellites may be classified into two groups: low and medium power KU-band

satellites, transmitt'mg signals in the 11.7 to 12.2 GHz FSS band; and the new high-

power KU-band satellites transmiting in the 12.2 GHz to 12.7 GHz Direct Broadcast

Satellite service (DBS) band.

Unlike C-band satellites, these newer KU-band DBS satellites have exclusive rights to

the frequencies they occupy, and therefore have no microwave interference problems.

The RCA D SS System will receive programming from high-power KU-band satellites

operating in the DBS band.

Overview

Although C-band satellites are spaced 2° apart,high power KU-band satellites are

spaced 9° apart,and transmit at 120 ormore watts of power.

Because o ftheir lower frequency and transmitting power capabilities, C-band sate llites

require a large receiving dish, anywhere from 6 to 10 feet in diameter. The higher power

of KU-band satellites enables them to broadcast to a compact 18 inch diameter dish.

Satellite System

A satellite systemis made up of three basic dements:

• An uplink facility, which beams programming signals to satellites orbiting over the

equator.

• A satellite that receives the signals and re-transmits them hack to earth.

• A receiving station including the satellite dish.

The picture and sound information originating from astudio or broadcastfacility is first

sent to an uplink site, where it is processed and combined with other signals for

transmission on microwave frequencies. Next, a large uplink dish concentrates these

outgoing mierowave signals and beams them up to a satellite located 22,247 miles

above the equator. The satellite's receiving anteuna captures the incoming signals and

sends them to a receiver for further processing. These signals, which contain the

original picture and sound information, are converted to another group of microwave

frequencies, then sent to an amplifier for transmission back to earth. This whole

receiver/transmitter package is called a transponder. The outgoing signals from the

transponder are then reflected off a transmitting antenna, which focuses the micro-

Page 5

6 Overview

waves into a beam of energy that is directed toward the earth. A satellite dish on the

ground collects the microwave energy containing the original picture and sound

information, and focuses that energy into a low noise block converter or LNB. The

LNB amplifies and converts the microwave signals to yet another lower group of

frequencies that can be sent via conventional coaxial cable to a satellite receiver-

decoder inside the user's house. The receiver tunes the individual transponders and

converts the original picture and sound information into video and audio signals that

can be seen and heard on a conventional television monitor and stereo system.

RCA DSS System

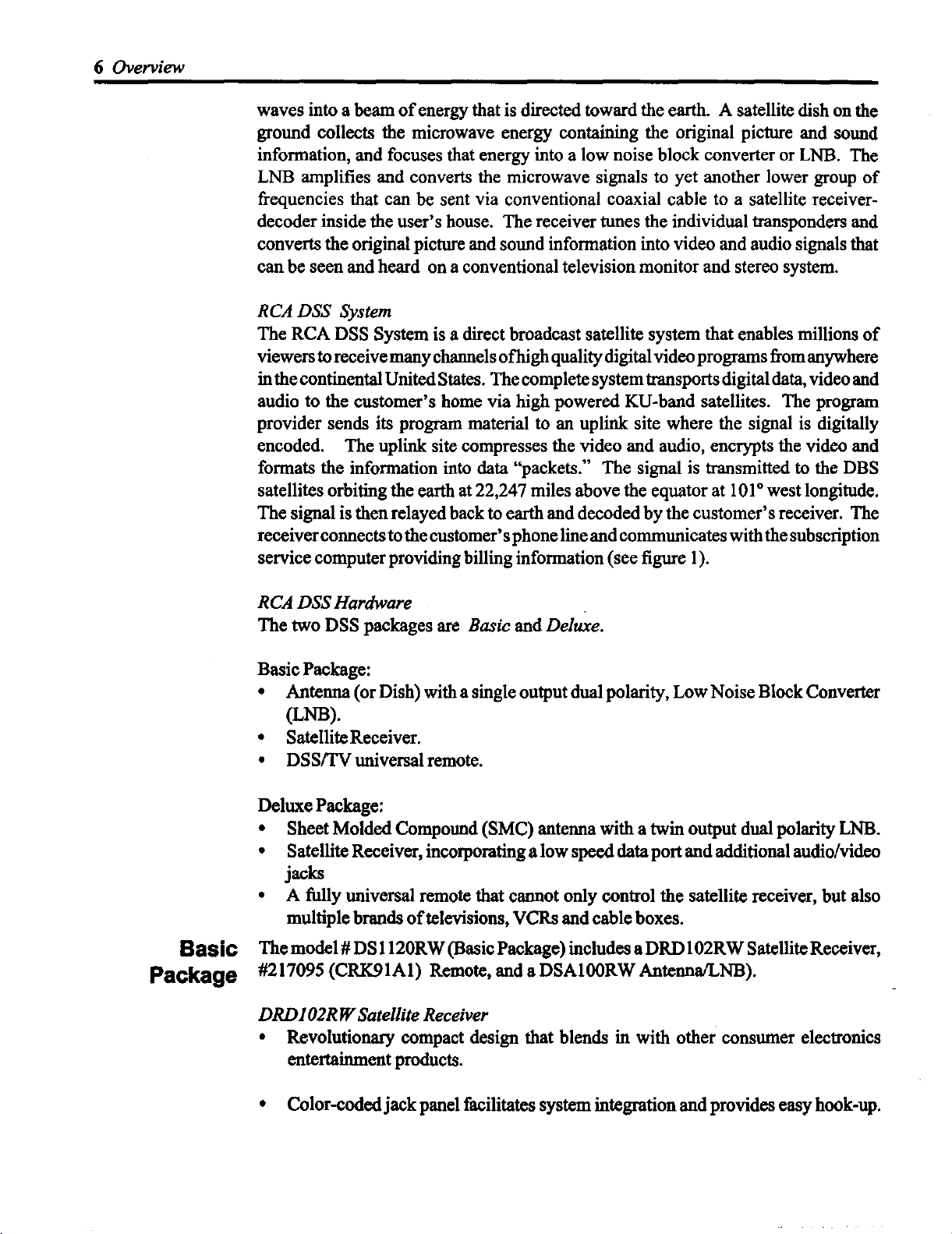

The RCA DSS System is a direct broadcast satellite system that enables millions of

viewers to receive many channels of high quality digital video programs fi,om anywhere

in the continental United States. The complete system transports digital data, video and

audio to the customer's home via high powered KU-band satellites. The program

provider sends its program material to an uplink site where the signal is digitally

encoded. The uplink site compresses the video and audio, encrypts the video and

formats the information into data "packets." The signal is transmitted to the DBS

satellites orbiting the earth at 22,247 miles above the equator at 101° west longitude.

The signal is then relayed back to earth and decoded by the customer's receiver. The

receiver connects to the customer's phone line and communicates with the subscription

service computer providing billing information (see figure 1).

Basic

Package

R CA DSS Hardware

The two DSS packages are Basic and Deluxe.

Basic Package:

• Antenna (or Dish) with a single output dual polarity, Low Noise Block Converter

(LNB).

• Satellite Receiver.

• DSS/TV universalremote.

DeluxePackage:

• SheetMoldedCompound(SMC)antenna with a twin outputdualpolarity LNB.

• SatelliteReceiver,incorporatingalowspeeddataport and additional audio/video

jacks

• A fullyuniversalremotethatcannotonly control the satellitereceiver, butalso

multiplebrandsof televisions,VCRsand cableboxes.

Themodel# DS1120RW(BasicPackage)includesaDRD102RWSatelliteReceiver,

#217095 (CRK91AI) Remote,and aDSA100RWAntenna/LNB).

DRD102R W Satellite Receiver

• Revolutionary compact design that blends in with other consumer eleca:onics

entertainment products.

• Color-coded jack panel facilitates system integration and provides easy hook-up.

Page 6

_ TELUTE #1

Overview 7

UPLINK 5ffE

PHONEUNK_IA

IRDMOO_I

DDDDD

TELEPHONE UNE

PROGRAMPRO_IOER

Figure 1, Digital Satellite @stem

Page 7

8 Overview

Connections include:

Satellite in: Provides direct connection from the satellite antenna/LNB.

In from Ant: Provides connection from an off-air antenna or cable feed.

Out to TV: Provides connection to antenna input of television.

S-VIDEO: Provides direct Y/C output to compatible televisions and VCRs.

Video, R/L Audio: Provides direct video and audio signals to television receivers,

VCRs and audio components.

Wideband Data Port: Enables reception of future services such as HDTV.

Phone: Provides connection to telephone line for program billing.

Indicators: LED on front panel that indicates "on" and blinks when there's a

message waiting.

• Local Controls: Eight buttons on the Satelfite Receiver's front panel allow full

operation of the satellite receiver, even without the remote control.

Access Card: A special card inserted into a slot on the receiver's front panel that

provides the means to track subscriber service requests and enable "turn-on" and

"turn-off" capability for subscription and pay-per-view events.

An electronic serial number unique to each card and satellite receiver enables the

Satellite Receiver to receive electronic messages from the communications center.

Messages are displayed on the television screen.

• 16x 9 widesereen formatcompatible: Processes panand scan commands fromthe

video data in a 16x 9broadcast, allowing the viewer to watch on a 4 x 3 television.

• Program Guide displays an electronically updated matrix of currentand future

programs sortedby service and time.

The system also supports specific guides, such as pay-per-view, sent by program

providers.

• Additional capabilities include the ability to display individual categories of

programming such as sports, news, movies, music, etc.

Favorite (Multiple) Channellists provideeasy selection of all orupto two favorite

groups of channels when utilizing the channel up/down buttons.

Alternate audio selection capability provides access to any of the audio channels

associated with each video channel. For example, foreign language audio may be

available for certain programs.

User Locks allow you to limit access to certain features, channels, select the rating

limit of the system and to password-protect this limit with a four-digit PIN

(Personal Identification Number).

Page 8

Additional Menus provide:

Dish positioning and adjustment.

Diagnostics.

Access to help screens.

Ability to set-up and customize operation.

Review/cancel purchases and services.

# 217095 (CRK91A1) Infrared Remote Control

• 30-button keypad.

• Ergonomicdesign.

• Provides complete satellite receiver operation.

• Large color-coded buttons are clearly identified for easy operation.

• Pre-programmed codes control the primary functions of most television brands

manufactured after 1984 utilizing infrared technology.

DSA100R W Antenna/LNB

• Small 18" parabolic reflector is lightweight and inconspicuous.

• Installation task is similar to "off-air" antenna.

• Designed to be easily mounted to the side of ahome, deck rail, roof or chirrmey that

provides an unobstructed view of the 101oWest longitude position pointing toward

Texas.

Overview 9

The model DS2430RW Deluxe Package includes a DRD203RW satellite receiver,

#217094 (CRK91B 1)remote and a DSA400RW antenna/LNB.

DRD203RW Satellite Receiver

Includes all of the features of the DRD102RW plus:

• Second pair of AN jacks on Satellite Receiver.

• Computer serial port for downloading data.

# 217094 (CRK91B1) Infrared Remote Control

Includes all of the features of the # 217095 remote with the following upgrades:

• 39-button keypad.

• Preprogrammedto controltheprimary functions ofmostmanufacturers' brands of

televisions, VCRs, laserdisc players and cable boxes utilizing infrared technology.

DSA4OOR W Antenna/LNB

Includes all of the features of the DSA200RW with the following upgrades/additions:

• Sheet molded compound (SMC) reflector-- more durable than metal.

• Antenna/LNB developed with twin outputs capable of operating two or more

compatible satellite receivers.

Deluxe

Package

Page 9

10 OverviewTechnical

Technical

Overview

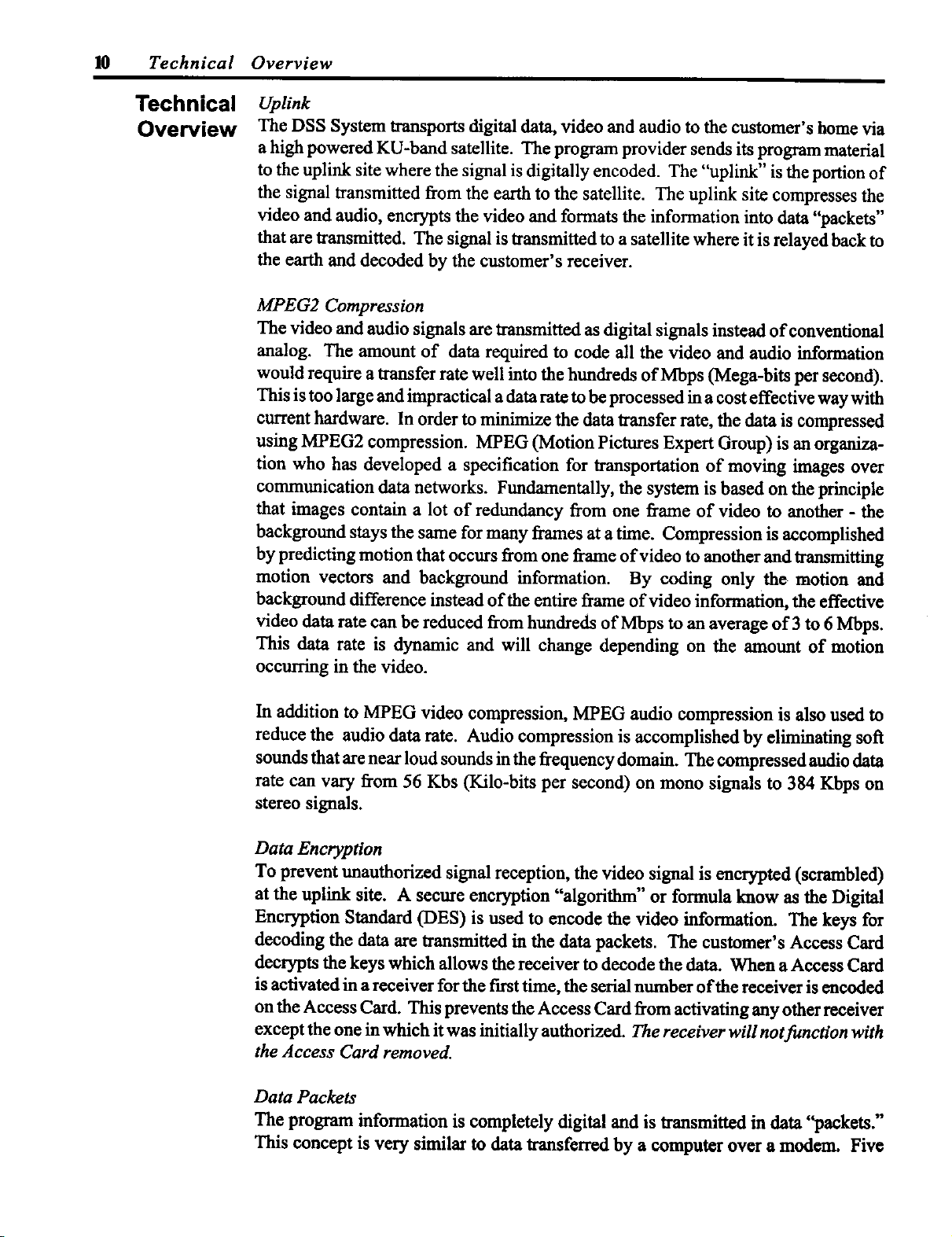

Uplink

The DSS System transports digital data, video and audio to the customer's home via

a high powered KU-band satellite. The program provider sends its program material

to the uplink site where the signal is digitally encoded. The "uplink" is the portion of

the signal transmitted from the earth to the satellite. The uplink site compresses the

video and audio, encrypts the video and formats the information into data "packets"

that are transmitted. The signal is transmitted to a satellite where it is relayed back to

the earth and decoded by the customer's receiver.

MPEG2 Compression

The video and audio signals are transmitted as digital signals instead of conventional

analog. The amount of data required to code all the video and audio information

would require a transfer rate well into the hundreds ofMbps (Mega-bits per second).

This is too large and impractical a data rate to be processed in a cost effective way with

current hardware. In order to minimize the data transfer rate, the data is compressed

using MPEG2 compression. MPEG (Motion Pictures Expert Group) is an organiza-

tion who has developed a specification for transportation of moving images over

communication data networks. Fundamentally, the system is based on the principle

that images contain a lot of redundancy from one frame of video to another - the

background stays the same for many frames at a time. Compression is accomplished

by predicting motion that occurs from one frame of video to another and transmitting

motion vectors and background information. By coding only the motion and

background difference instead of the entire frame of video information, the effective

video data rate can be reduced from hundreds of Mbps to an average of 3 to 6 Mbps.

This data rate is dynamic and will change depending on the amount of motion

occurring in the video.

In addition to MPEG video compression, MPEG audio compression is also used to

reduce the audio data rate. Audio compression is accomplished by eliminating soft

sounds that are near loud sounds in the fi'equency domain. The compressed audio data

rate can vary from 56 Kbs (Kilo-bits per second) on mono signals to 384 Kbps on

stereo signals.

Data Encryption

To prevent unauthorized signal reception, the video signal is encrypted (scrambled)

at the uplink site. A secure encryption "algorithm" or formula know as the Digital

Encryption Standard (DES) is used to encode the video information. The keys for

decoding the data are transmitted in the data packets. The customer's Access Card

decrypts the keys which allows the receiver to decode the data. When a Access Card

is activated in a receiver for the first time, the serial number of the receiver is encoded

on the Access Card. This prevents the Access Card from activating any other receiver

except the one in which it was initially authorized. The receiver will notfunction with

the Access Card removed.

Data Packets

The program information is completely digital and is transmitted in data "packets."

This concept is very similar to data transferred by a computer over a modem. Five

Page 10

Technical Overview 11

different types of data packets are Video, Audio, CA, PC compatible serial data and

Program Guide. Video and audio packets contain the visual and audio information of

the program. The CA (Conditional Access) packet contains information that is

addressed to individual receivers. This includes customer E-Mall, Access Card

activation information and which channels the receiver is authorized to decode. PC

compatible serial data packets can contain any form of data the program provider

wants to transmit, such as stock reports or software. The Program Guide maps the

channel numbers to transponders and SCID's (more on this later). It also gives the

customer TV program listing information.

Figure 2 shows a typical uplink configuration for one transponder. In the past, a single

transponder was used for a single satellite channel. With digital signals, more than one

satellite channel can be sent on the same transponder. The example shows three video

channels, five stereo audio channels (one for each video channel plus two extra for

other services such as a second language), and a PC compatible data channel. Audio

and video signals from the program provider are encoded and converted to data

packets. The configurations can vary depending on the type of programming. The

data packets are then multiplexed into serial data and sent to the transmitter.

!

Data

,t_tlosl ,.at.at..t.,

8CI0

Program

Progrul Guidw iltlkos the

cltei_nel numbers Io

trenspcmders ar,d

8C10_. It dso _S

_r PmO'm Ibtir_

PT......L

,F 3

,E 3--

licit

Figure 2, Uplink

_ €_¢waa ma_ra

_ CA _ Null Data Vldee I_11 Alldle

Page 11

12 Technical Overview

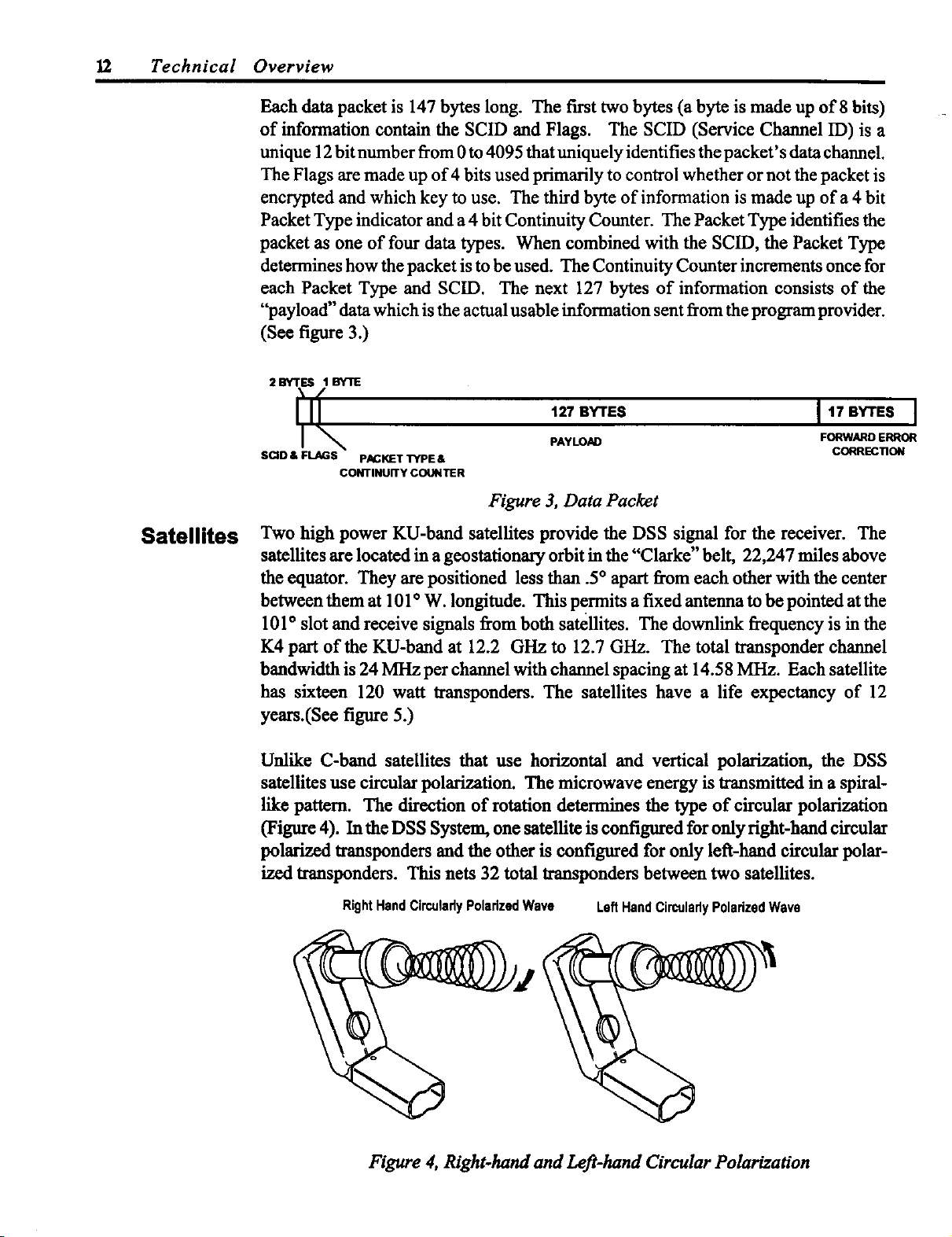

Each data packet is 147 bytes long. The firsttwo bytes (a byte is made up of 8 bits)

of information contain the SCID and Flags. The SCID (Service Channel ID) is a

unique 12bit number from0to 4095 that uniquely identifies the packet's datachannel.

The Flags are made up of 4 bits used primarily to control whether or not the packet is

encrypted and which key to use. The third byte of information is made up ofa 4 bit

Packet Type indicator and a4 bit Continuity Counter. The Packet Type identifies the

packet as one of four data types. When combined with the SCID, the PacketType

determ'mes how the packet is to be used. TheContinuity Counter increments once for

each Packet Type and SCID. The next 127 bytes of information consists of the

"payload" datawhich isthe actual usable information sentfromthe program provider.

(See figure 3.)

2 BYT_.S 1BYTE

Satellites

I I PAYLON) FORWARDERROR

SCID & FLAGS PACKETTYPE& CORRECTION

CONTINUITYCOUNTER

Figure 3, Data Packet

,=, BYTES I 17 BYTES I

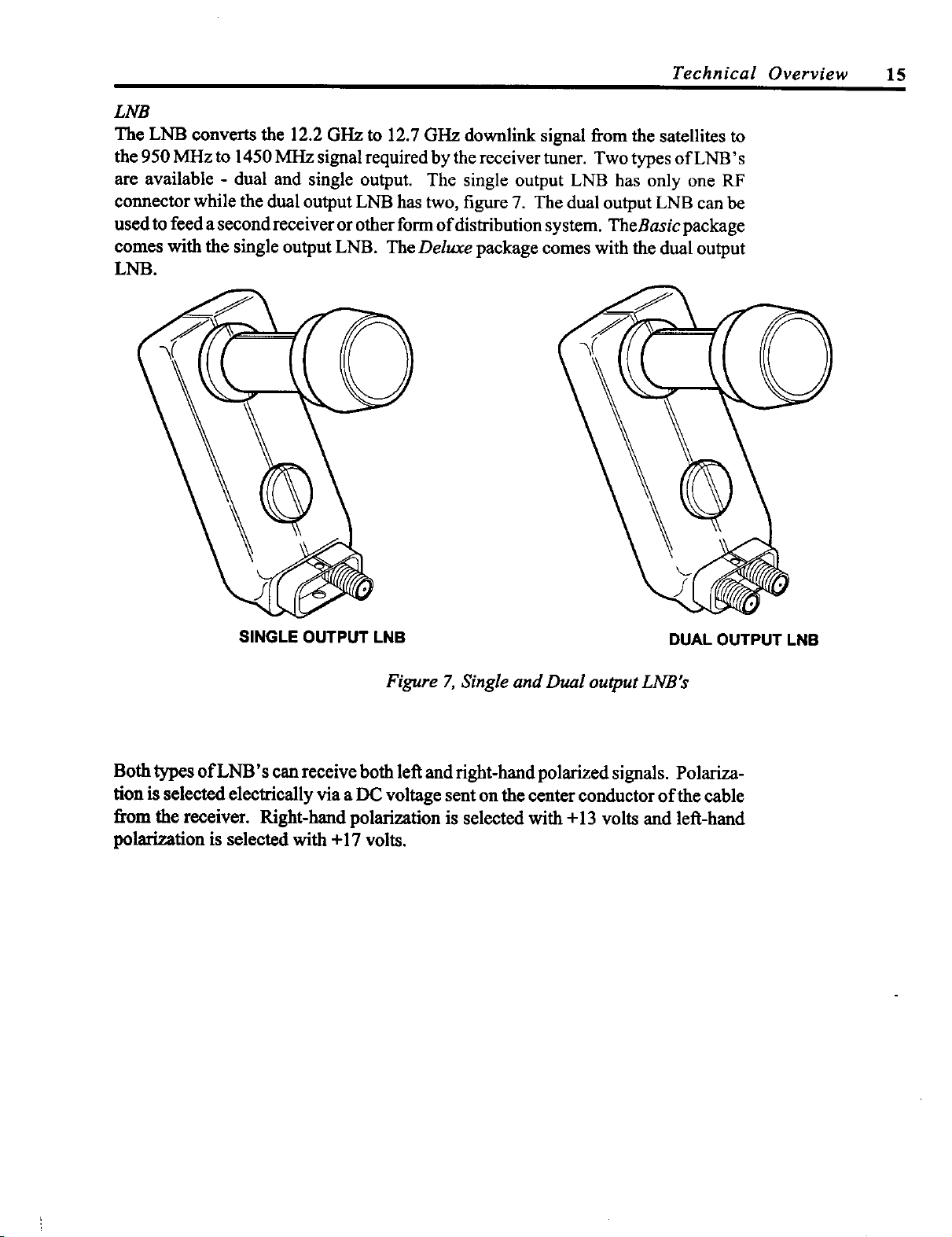

Two high power KU-band satellites provide the DSS signal for the receiver. The

satellites arelocated inageostationary orbitin the "Clarke" belt, 22,247 miles above

the equator. They are positioned less than .5° apartfrom each other with the center

between them at 101° W. longitude. This permits a fixed antenna to be pointed at the

101° slot and receive signals from both satellites. The downlink frequency is in the

K4 part of the KU-band at 12.2 GHz to 12.7 GHz. The total transponder channel

bandwidth is 24 MHz per channel with channel spacing at 14.58 MHz. Each satellite

has sixteen 120 watt transponders. The satellites have a life expectancy of 12

years.(See figure 5.)

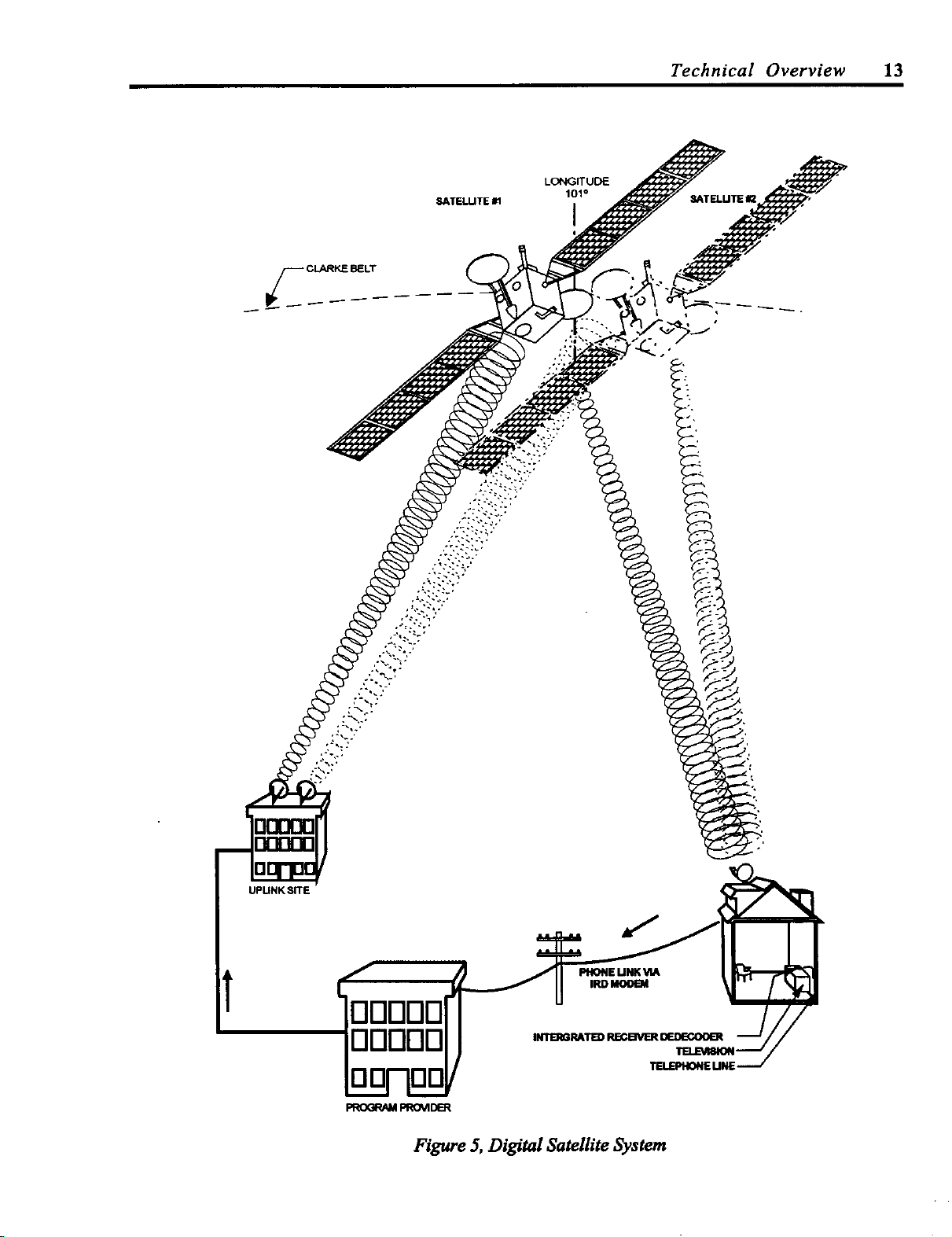

Unlike C-band satellites that use horizontal and vertical polarization, the DSS

satellites use circular polarization. The microwave energy is transmitted in a spiral-

like pattern. The direction of rotation determines the type of circular polarization

(Figure 4). In the DSS System, one satellite is configured foronly right-handcircular

polarized transponders and the other is configured for only left-hand circular polar-

ized transponders. This nets 32 total transponders between two sateliites.

RightHandCircularlyPoladzedWave LeftHandCircularlyPoladzedWave

Figure 4, Right-hand and Left-hand Circular Polarization

Page 12

LONGITUDE

101°

I

Technical Overview 13

UPHNK SITE

DDDDD

OOOOO

TELEPHONEMNE,

PROGRAMPRO_DER

Figure 5, Digital Satellite System

Page 13

14 Technical Overview

Although there areonly 16 transponders per satellite, the channel capabilities arefar

greater. Using datacompression andmultiplexing, the two satellites workingtogether

have the possibility of carrying over 150 conventional (non-HDTV) audio and video

channels via 32 transponders.

Dish

The"dish" is an 18 inch, slightly oval shaped KU-band antenna. The slight oval shape

is due to the 22.5 °offset feed of the LNB (Low Noise Block converter), figure 6. The

offset feed positions the LNB out of the way so it does not block any surface area of

the dish, preventing attenuation of the incoming microwave signal.

Figure 6, Satellite Dish

0

Page 14

Technical Overview 15

LNB

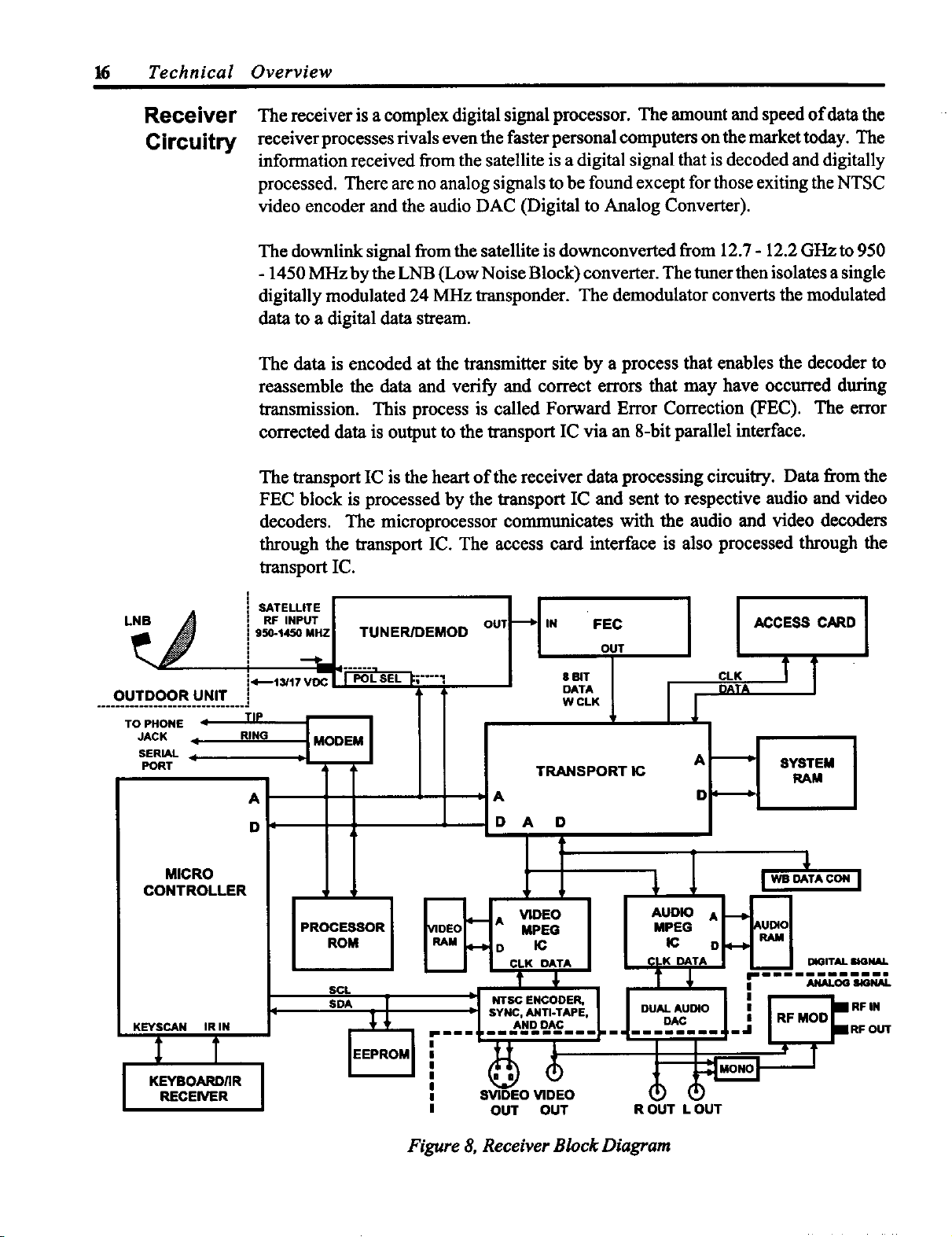

The LNB converts the 12.2 GHz to 12.7 GHz downlink signal fi'om the satellites to

the 950 MHz to 1450 MI-Iz signal required by the receiver tuner. Two types of LNB's

are available - dual and single output. The single output LNB has only one RF

connector while the dual output LNB has two, figure 7. The dual output LNB can be

used to feed a second receiver or other form of distribution system. TheBasic package

comes with the single output LNB. The Deluxe package comes with the dual output

LNB.

SINGLE OUTPUT LNB

Figure 7, Single and Dual output LNB's

DUAL OUTPUT LNB

Both types of LNB's can receive both left and fight-hand polarized signals. Polariza-

tion is selected electrically via a DC voltage sent on the center conductor of the cable

from the receiver. Right-hand polarization is selected with +13 volts and left-hand

polarization is selected with +17 volts.

Page 15

16 Technical Overview

Receiver

Circuitw

The receiver is a complex digital signal processor. The amount and speed of data the

receiver processes rivals even the faster personal computers on the market today. The

information received from the satellite is a digital signal that is decoded and digitally

processed. There are no analog signals to be found except for those exiting the NTSC

video encoder and the audio DAC (Digital to Analog Converter).

The downlink signal from the satellite is downconverted from 12.7 - 12.2 GHz to 950

- 1450 MHz by the LNB (Low Noise Block) converter. The tuner then isolates a single

digitally modulated 24 MHz transponder. The demodulator converts the modulated

data to a digital data stream.

The data is encoded at the transmitter site by a process that enables the decoder to

reassemble the data and verify and correct errors that may have occurred during

transmission. This process is called Forward ErrorCorrection (FEe). The error

corrected data is output to the transport IC via an 8-bit parallel interface.

The transport IC is the heart of the receiver data processing circuitry. Data from the

FEC block is processed by the transport IC and sent to respective audio and video

decoders. The microprocessor communicates with the audio and video decoders

through the transport IC. The access card interface is also processed through the

transport IC.

SATELLITE

LN.A ,:,:_1 TONO_MOOou,M,N'_C I I.CCE.C'_OI

21...... I I , , i

OUTDOOR UN_

................................

_D.?.o._._ T wcL./ I

TOPHONE TIP _ / T I

TO PHONE -_

...... --" ' '& -- DATA DATA /

OUT I I

/I

TRANSPORT IC

.I I I / .I. o--.I " I

"1 1 I I -I i i

L i l i ID A O

Co_CR_

CONTROLLER

,_s_,,,, I _ ...k._.o_.,.c..[I .._c...l.,I'F'°°=,,o,,

_O_/IR

I _o,_. I ' ' _ _ :1.

I _cE_,_ I w ,:,

°iII If

', I I---I k _o I I ,uo_AM......I

I PROCESSORII_oEor--I.,E. I I MPEGI P£.=."I

I Ro. I I" Ho "= I I _ °l'-'l-" I

I I I I I c.K OATA I 1 CtK_TA , _ ==,rN-..,

I sc, _ t _ T _ :".... _,_

I so* l 'I NTSGENCODER, I I I I I'_mJ_.RFI N

( B SYNC, ANTI-TAPE, DUAL AUDIO :

T IE_,,o.Ir "_ _ " _W

SVIDEO VIDEO

OUT OUT R OUT L OUT

DIGITAL _NJkl.

Figure 8, Receiver Block Diagram

Page 16

Technical Overview 17

The Access Card receives the encrypted keys for decoding a scrambled channel from

the transport IC. The Access Card deerypts the keys and stores them in a register in

the transport IC. The transport IC uses the keys to decode the data. The Access Card

also handles the tracking and billing for these services

Video data is processed by the MPEG video decoder. This IC decodes the compressed

video data and sends it to the NTSC encoder. The encoder converts the digital video

information into NTSC analog video that is output to the S-Video and standard

composite video output jacks.

Audio data is likewise decoded by the MPEG audio decoder. The decoded 16-bit

stereo audio data is sent to the dual DAC (Digital to Analog Converter) where the left

and right audio channel data are separated and converted back into stereo analog

audio. The audio is output to the left and right audio jacks and is also mixed together

to provide a mono audio source for the RF converter.

The microprocessor receives and decodes IR remote commands and front keyboard

commands. Its program software is contained in the processor ROM (Read Only

Memory). The microprocessor controls the other digital devices of the receiver via

address and data lines. It is responsible for turning on the green LED on the ON/OFF

button.

The modem connects to the customer's phone line and calls the program provider and

transmits the customers programpurchas.es for billing purposes. The modem operates

at 1200 bps and is controlled by the microprocessor. When the modem first attempts

to dial, it sends the first number as touch-tone. If the dial tone continues after the first

number, the modems switches to pulse dialing and redials the entire number. If the

dial tone stops after the first number, the modem continues to dial the rest of the

number as a touch-tone number. The modem also automatically releases the phone

line if the customer picks up another phone on the same extension.

Thereeeivercontainstwodiagnostictestmenus. ThefirsttestisacustomercontroUed Diagnostics

menu that checks the signal, tuning, phone connection and access card. The second

test menu is servicer controlled. It checks the majority of the receiver for problems.

Customer Controlled Diagnostics

The customer controlled test helps the customer during installation or any time the

receiver appears not to function properly.

Signal test:

Tuning test:

Phone test:

Access card test:

Cheeks the value of error bit number and the error rate to determine

if the antenna connections are properly installed.

Checks to insure a transponder can be tuned. Thetestis eousidered

successful and this part of the test is halted if proper tuning occurs

on 1 of the 32 transponders.

The phone test checks for dial tone and performs an internal

loopbaek test.

Sends a message to the access card and cheeks for a valid reply.

Page 17

18 Technical Overview

The response for all tests will be an "OK" display or an appropriate message

informing the customer the general area of the problem.

To enter the System Test feature:

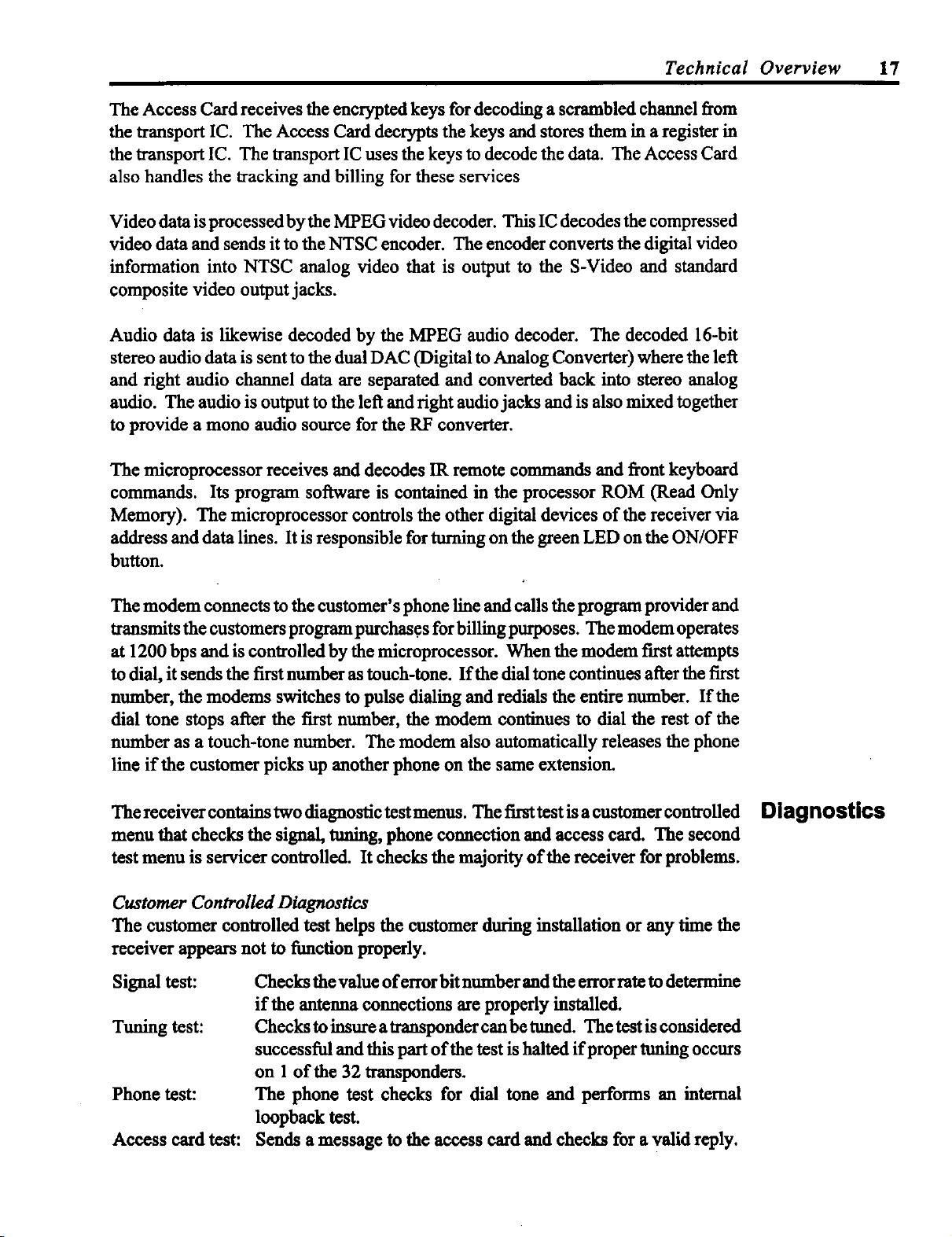

Select "Options" from the "DSS Main Menu. '"

DSS Main Menu

Fmedrl k e_l_er mP_em h m

1Pe_eu_

2Aeltadlor_l

I 4opqn

S_mlwfehJdlo

et_'W

OE5_

I 4 P_w_h_dutMp yo_ I

Figure 9, Main Menu

Select "Setup" from the "Options" menu.

_wnn_k

!

RNm

s LadL unl_ andGwld IJm

IS_p

Ol_lt

Is 8_w_DIS_

Figure 10, Options Menu

Page 18

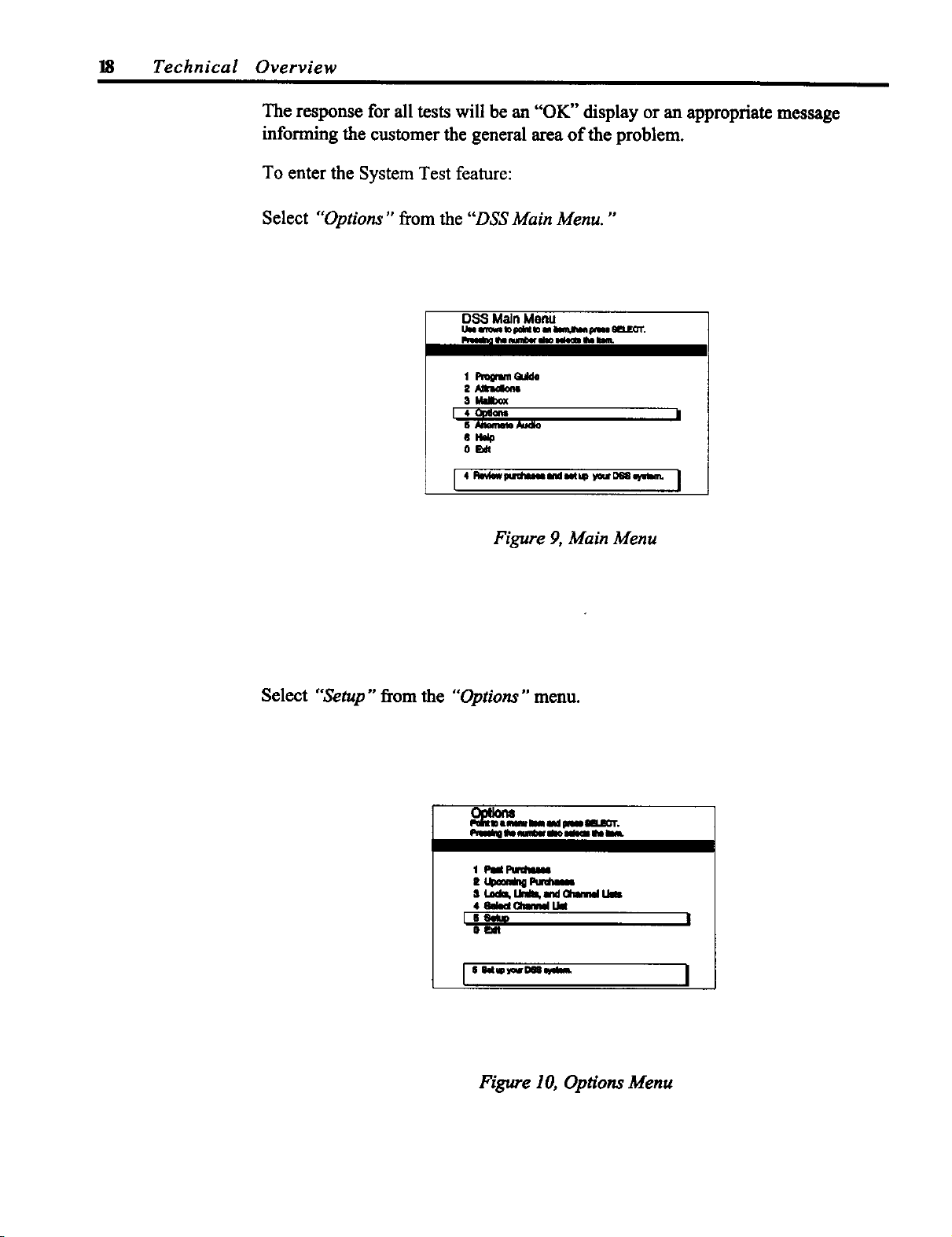

Select "'System Test" from the "Setup "'menu.

1_ Dil_ P01flllng

3 IndJl A_em C_d

4 PiO_e S_e

0Bdt

I Deim1"_dJyo_D_D_il_mm_l_. J

Figure 11, Setup Menu

Select "'Test" from the "System Test'" menu.

Technical Overview 19

_om Tost

T_ _ _ a_JGT.

_ t]mmM m _ m N lk_ MWsJ.

N_IN

Figure 12, System Test Menu

The system test results are displayed automatically wben the test is complete. The

following two screens show whether the receiver passed or failed the test. If the access

card passes the test, the access card ID number will be displayed in the window.

_Teet Results

aml imlm allJlO1".

G_t_ _14_md m

llhl:l_l:

Ohukl_omm

mcll_

G'mckm cml U

_Te_ Results

md_im IIELECT,

OK

OK

_orM_

OK

_Camk

OK

Figure 13, System Test Results

Page 19

Technical Overview

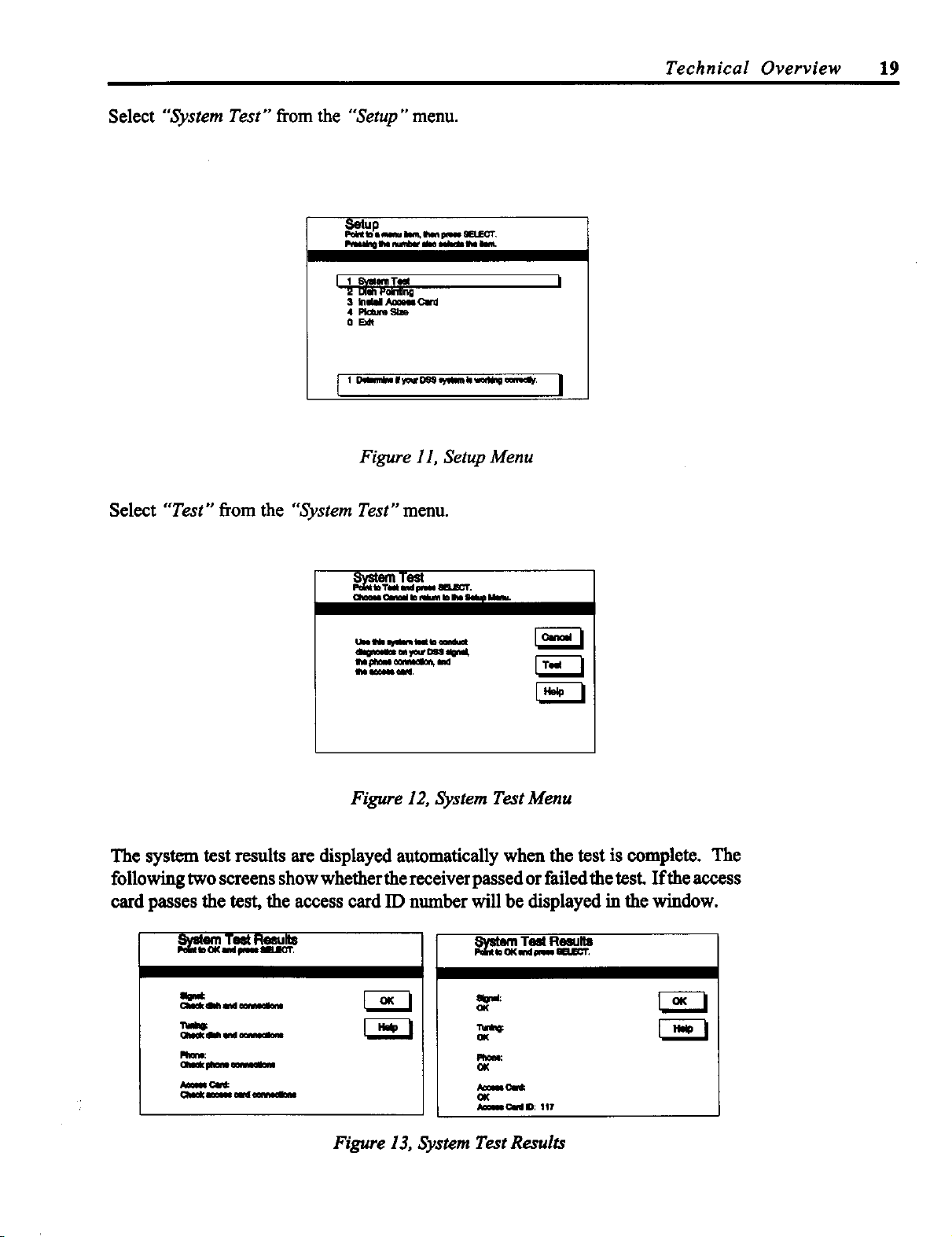

ServicerControlledDiagnostics

The servicer controlled test provides a more in-depth analysis of the receiver for

proper operation. The test pattern checks all possible connections between compo-

nents as a troubleshooting aid. The following information is provided to the servicer:

1. IRD serial number

2. Demodulator vendor & version number

3. Signal Strength

4. ROM checksum results

5. SRAM test results

6. V-Ram test results

7. Telco callback results

8. Verifier Version

9. Access Card Test & Serial Number

10. IRD ROM version

11. EEprom test results

The response for all tests will indicate the test was successful or not successful.

In addition, this menu will allow entry into the phone prefix menu so the installer can

set up a one digit phone prefix.

To Enter the Service -Test Feature:

Simultaneously press the front panel "TV/DSS" and the "DOWN" arrow button.The

following screen will appear.

$etvl_ TNt

IRD _I¢_K4FF

RDM I_1111 I

V-DramTea

VJlIWOM4 I_G0

mill1 117

iiiiiiiiii i i

i iii ii

IllamW 07m

HHIHIH

PhonoF_f_

le_em_m_F_x _m_

es_l _ ol( et_ _ gim_'T.

E3

l_st l.o_ _sra _t lo pl a _ _ lm

Figure 14, Service Test Menu

The test results are automatically displayed after the test is complete. The servicer

is given the option to exit or run the test again.

Page 20

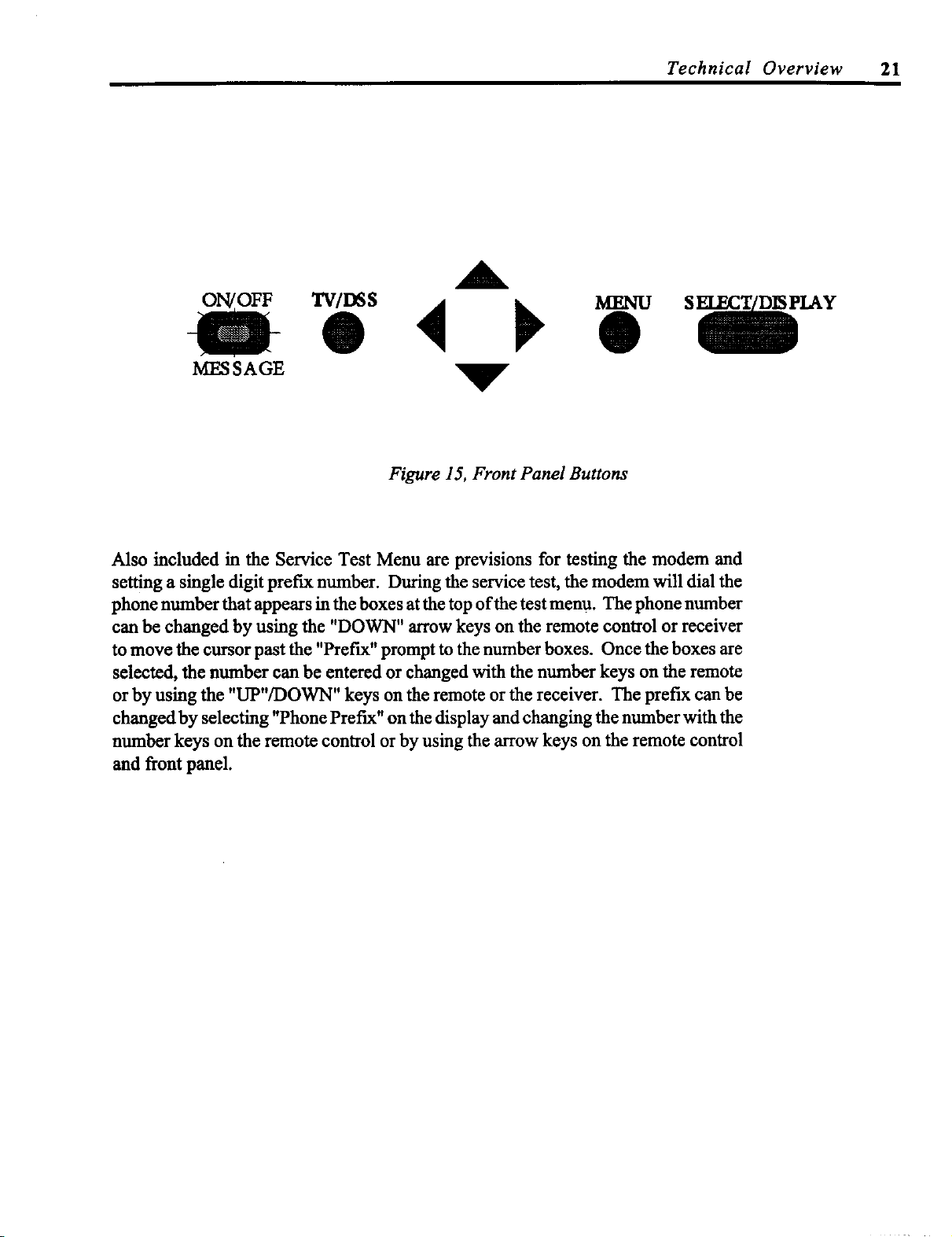

IOFF

MESSAGE

Technical Overview 21

A

Figure 15, Front Panel Buttons

Also included in the Service Test Menu are previsions for testing the modem and

setting a single digit prefix number. During the service test, the modem will dial the

phone number that appears in the boxes at the top of the test menu. The phone number

earl be changed by using the "DOWN" arrow keys on the remote control or receiver

to move the cursor past the "Prefix" prompt to the number boxes. Once the boxes are

selected, the number can be entered or changed with the number keys on the remote

or by using the "UP"/DOWN" keys on the remote or the receiver. The prefix can be

changed by selecting "Phone Prefix" on the display and changing the number with the

number keys on the remote control or by using the arrow keys on the remote control

and front panel.

Page 21

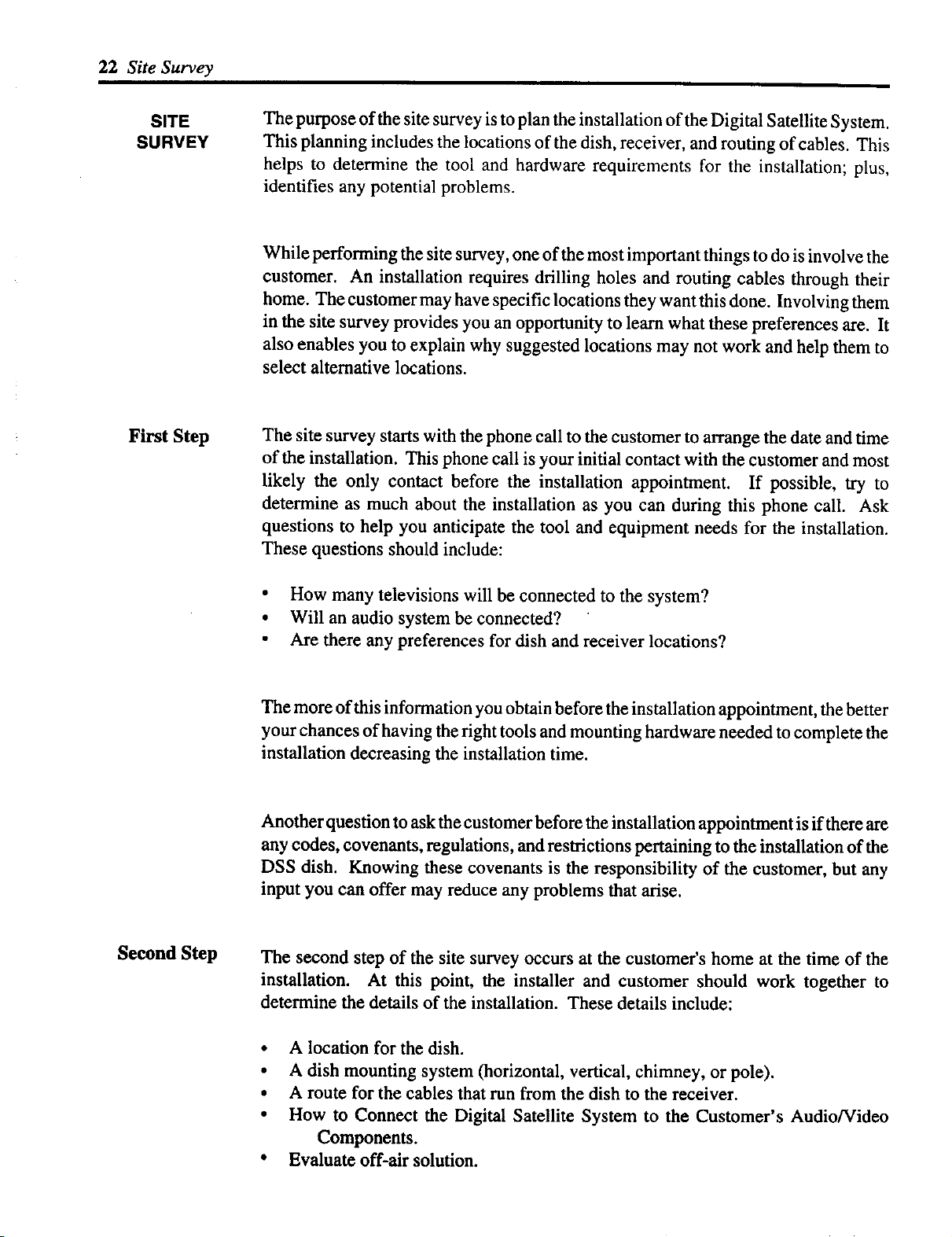

22 Site Survey

SITE

SURVEY

The purpose of the site survey is to plan the installation of the Digital Satellite System.

This planning includes the locations of the dish, receiver, and routing of cables. This

helps to determine the tool and hardware requirements for the installation; plus,

identifies any potential problems.

While performing the site survey, one of the most important things to do is involve the

customer. An installation requires drilling holes and routing cables through their

home. The customer may have specific locations they want this done. Involving them

in the site survey provides you an opportunity to learn what these preferences are. It

also enables you to explain why suggested locations may not work and help them to

select alternative locations.

First Step The site survey starts with the phone call to the customer toarrange the date and time

of the installation. This phone call is your initial contact with the customer and most

likely the only contact before the installation appointment. If possible, try to

determine as much about the installation as you can during this phone call. Ask

questions to help you anticipate the tool and equipment needs for the installation.

These questions should include:

Second Step

• How many televisions will be connected to the system?

• Will an audio system be connected?

• Are there any preferences for dish and receiver locations?

The more of this information you obtain before the installation appointment, the better

your chances of having the right tools and mounting hardware needed to complete the

installation decreasing the installation time.

Another question to ask the customer before the installation appointment is if there are

any codes, covenants, regulations, and restrictions pertaining to the installation of the

DSS dish. Knowing these covenants is the responsibility of the customer, but any

input you can offer may reduce any problems that arise.

The second step of the site survey occurs at the customer's home at the time of the

installation. At this point, the installer and customer should work together to

determine the details of the installation. These details include:

• A location for the dish.

• A dish mounting system (horizontal, vertical, chimney, or pole).

• A route for the cables that run from the dish to the receiver.

• How to Connect the Digital Satellite System to the Customer's Audio/Video

Components.

• Evaluate off-air solution.

Page 22

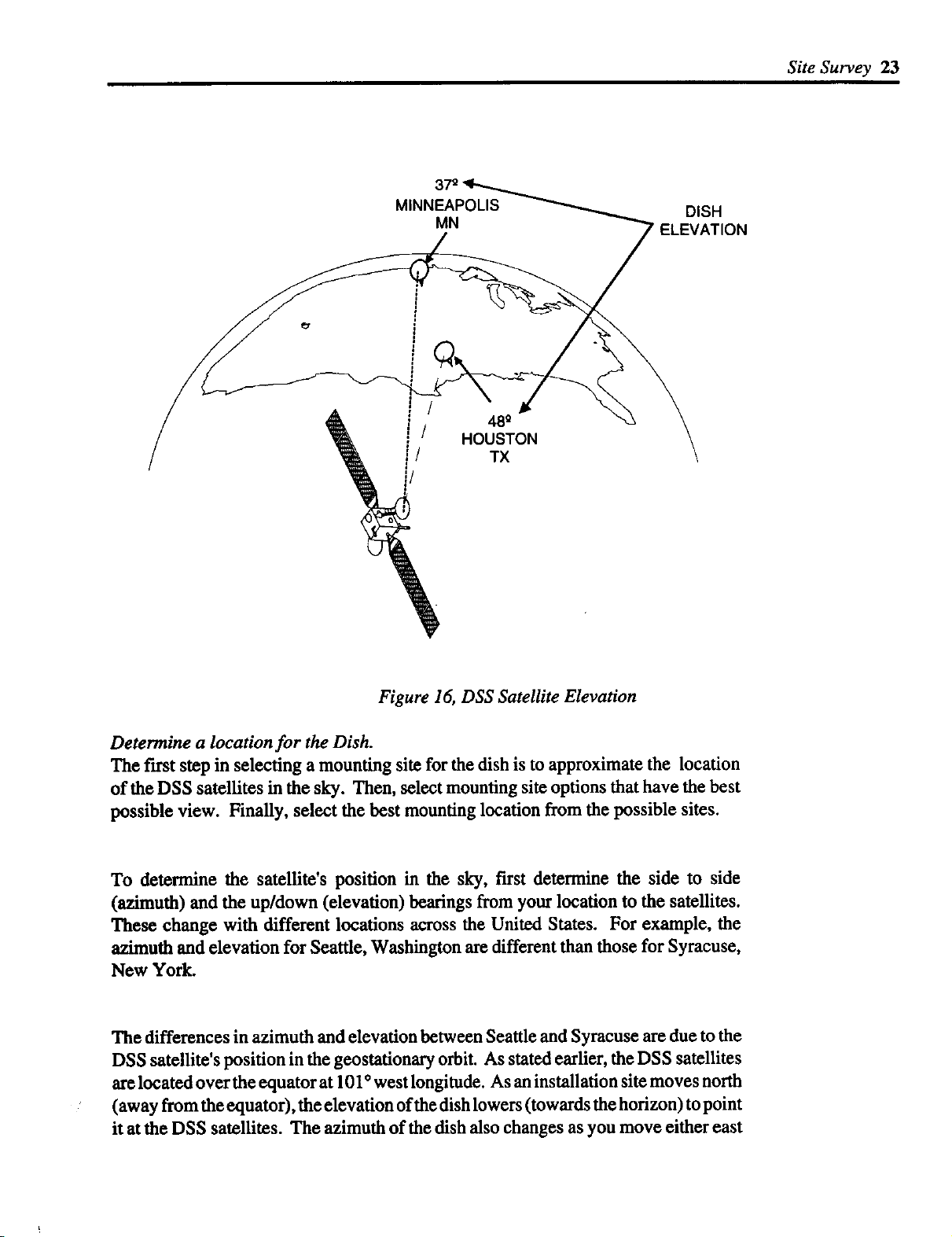

37g

MINNEAPOLIS

MN

HOUSTON

Site Survey 23

DISH

ELEVATION

48_

TX

Figure 16, DSS Satellite Elevation

Determine a location for the Dish.

The first step in selecting a mounting site for the dish is to approximate the location

of the DSS satellites in the sky. Then, select mounting site options that have the best

possible view. Finally, select the best mounting location from the possible sites.

To determine the satellite's position in the sky, first determine the side to side

(azimuth) and the up/down (elevation) bearings from your location to the satellites.

These change with different locations across the United States. For example, the

azimuth and elevation for Seattle, Washington are different than those for Syracuse,

New York.

The differences in azimuth and elevation between Seattle and Syracuse are duetothe

DSS satellite's position in the geostationary orbit. As stated earlier, the DSS satellites

are located over the equator at 10I* west longitude. As an installation site moves north

(away from the equator), the elevation of the dish lowers (towards the horizon) to point

it atthe DSS satellites. The azimuth of the dish also changes as you move either east

Page 23

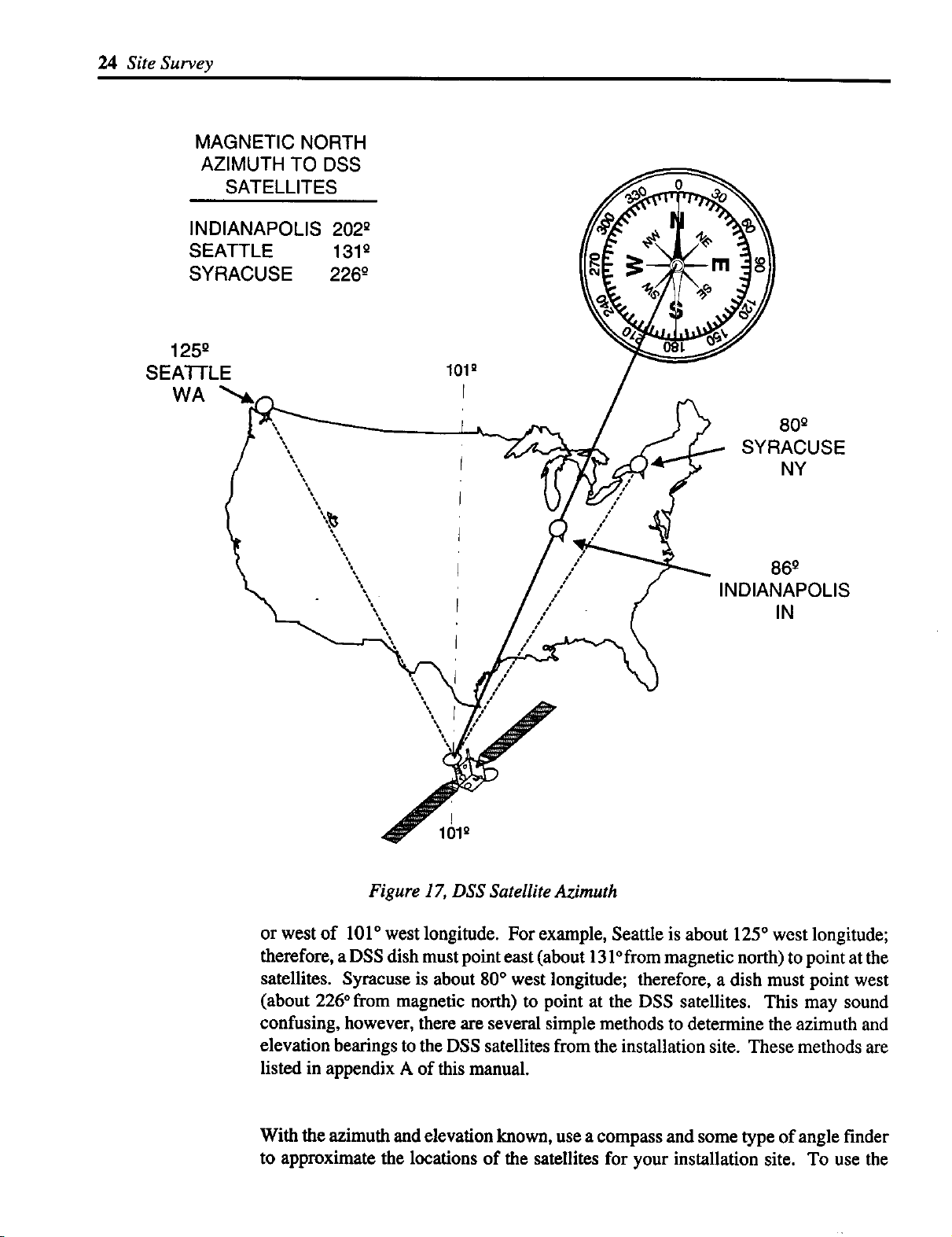

24 Site Survey

INDIANAPOLIS 202 °

SEATTLE 131o

SYRACUSE 226 g

125 °

SEATTLE

WA

MAGNETIC NORTH

AZIMUTH TO DSS

SATELLITES

101_

80 g

SYRACUSE

NY

I

0o 86g

/

/ INDIANAPOLIS

/ IN

/

101Q

Figure 17, DSS Satellite Azimuth

or west of 101 ° west longitude. For example, Seattle is about 125 ° west longitude;

therefore, a DSS dish must point east (about 131°from magnetic north) to point at the

satellites. Syracuse is about 80 ° west longitude; therefore, a dish must point west

(about 226 ° from magnetic north) to point at the DSS satellites. This may sound

confusing, however, there are several simple methods to determine the azimuth and

elevation bearings to the DSS satellites from the installation site. These methods are

listed in appendix A of this manual.

With the azimuth and elevation known, use a compass and some type of angle finder

to approximate the locations of the satellites for your installation site. To use the

Page 24

compass, first align the arrow of the compass with magnetic north. With the compass

aligned correctly, draw an imaginary line from the center of the compass to the

azimuth of the satellites. This is the general direction the dish must point. If possible,

pick a landmark in the distance that aligns with this bearing. If not, repeat this

procedure whenever confirming possible locations for the dish.

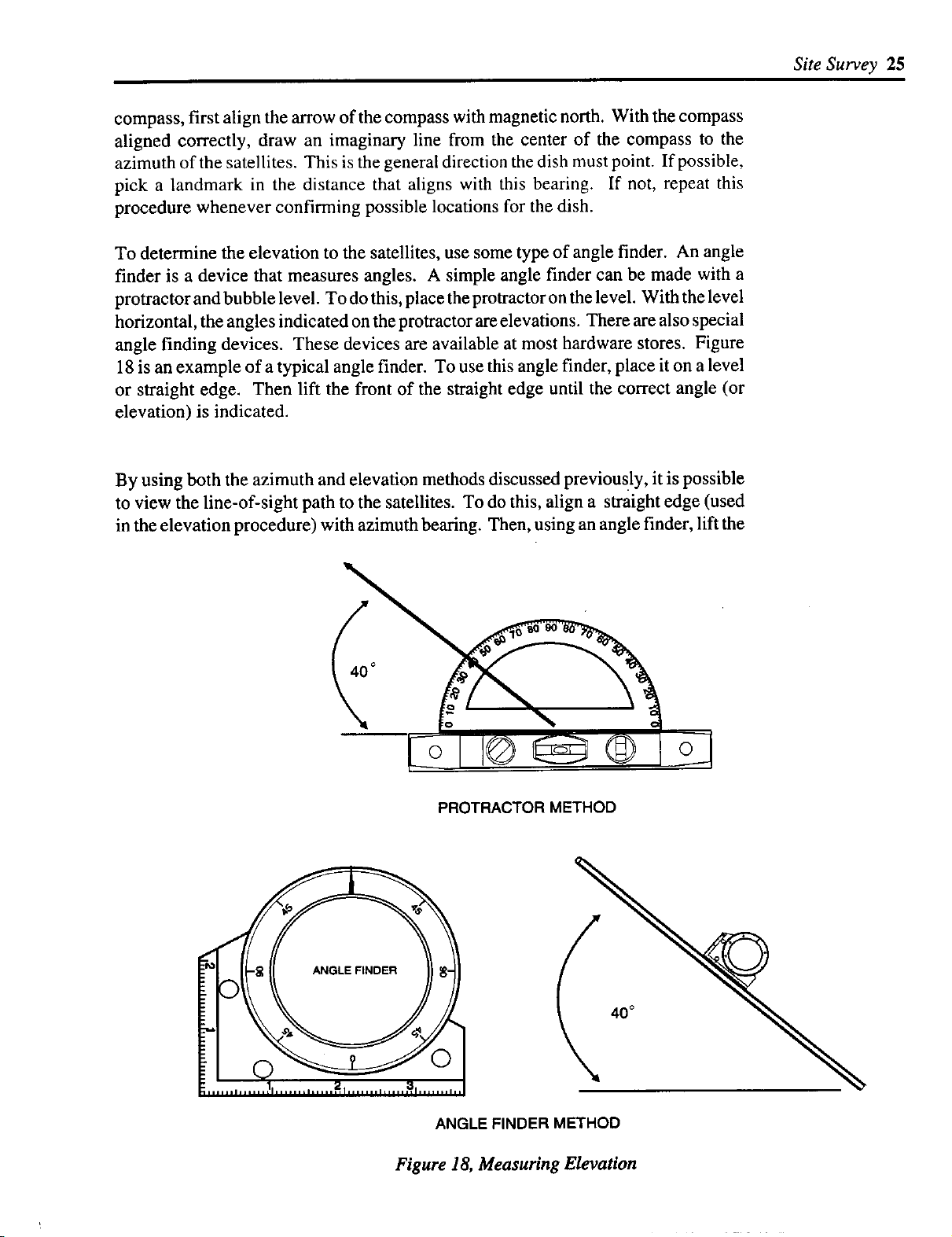

To determine the elevation to the satellites, use some type of angle finder. An angle

finder is a device that measures angles. A simple angle finder can be made with a

protractor and bubble level. To do this, place the protractor on the level. With the level

horizontal, the angles indicated on the protractor are elevations. There are also special

angle finding devices. These devices are available at most hardware stores. Figure

18 is an example of a typical angle finder. To use this angle finder, place it on a level

or straight edge. Then lift the front of the straight edge until the correct angle (or

elevation) is indicated.

By using both the azimuth and elevation methods discussed previously, it is possible

to view the line-of-sight path to the satellites. To do this, align a straight edge (used

in the elevation procedure) with azimuth bearing. Then, using an angle finder, lift the

Site Survey 25

40 °

PROTRACTOR METHOD

ANGLE FINDER METHOD

Figure 18, Measuring Elevation

Page 25

26 Site Survey

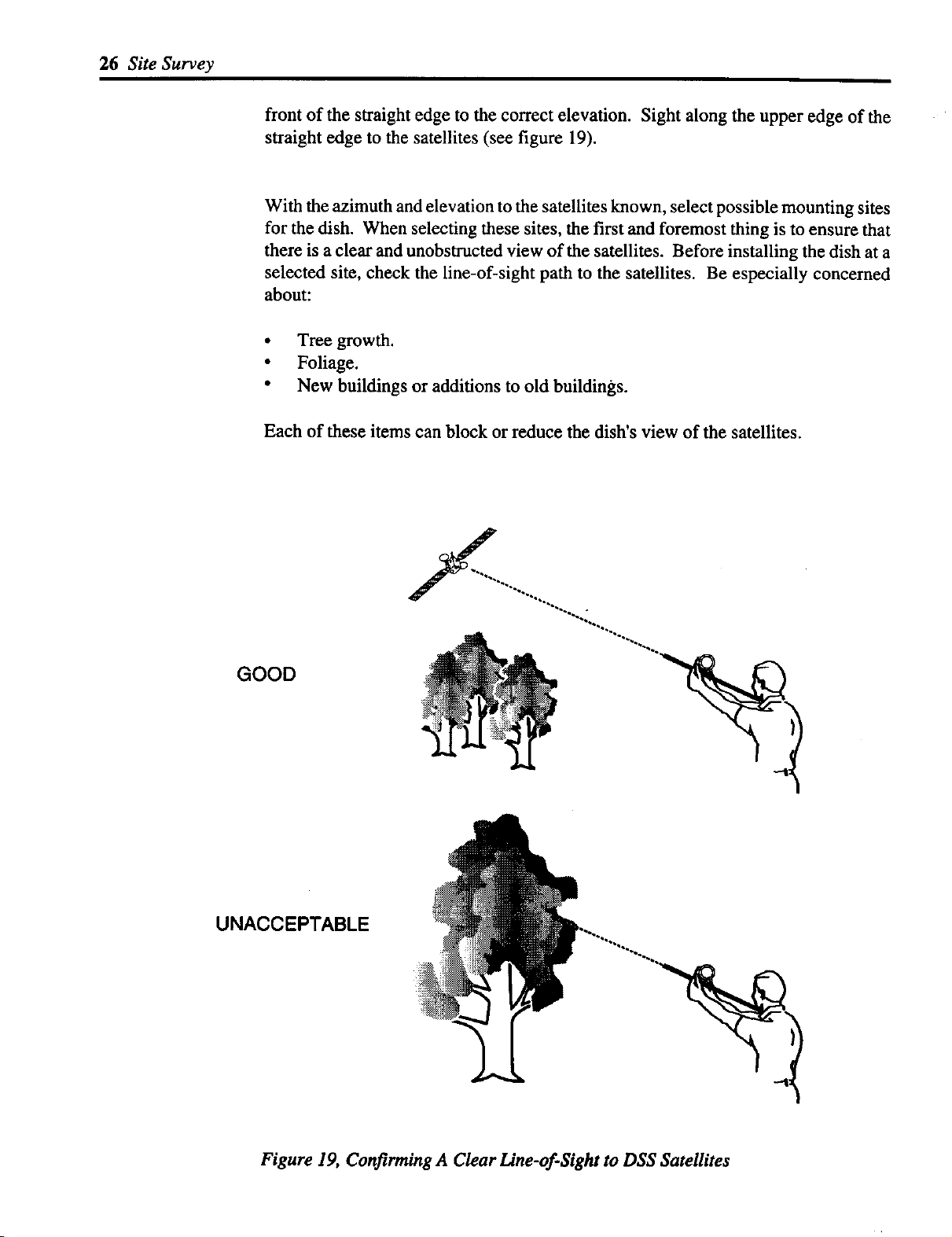

front of the straight edge to the correct elevation. Sight along the upper edge of the

straight edge to the satellites (see figure 19).

With the azimuth and elevation to the satellites known, select possible mounting sites

for the dish. When selecting these sites, the first and foremost thing is to ensure that

there is a clear and unobstructed view of the satellites. Before installing the dish at a

selected site, check the line-of-sight path to the satellites. Be especially concerned

about:

• Tree growth.

• Foliage.

• New buildings or additions to old buildings.

Each of these items can block or reduce the dish's view of the satellites.

GOOD

UNACCEPTABLE

Figure 19, Confirming A Clear One-of-Sight to DSS Satellites

Page 26

Selecting a Mounting System for the Dish

There are several different mounting systems for the DSS dish. These include

horizontal, vertical, and special. Use a horizontal mounting system for horizontal

surfaces and vertical for vertical surfaces. Special mounting systems include pole and

chimney mounts. When selecting a mounting system for the dish, consider these

items:

• Safety.

• Line-of-sight path to the satellite.

• Mounting structure.

When following these instructions, take extreme care to avoid contact with overhead

power lines, lights, and power circuits. Also, do not position the dish anywhere

contact with one of these items may occur. When digging holes, be sure and contact

the local utilities and have them locate any underground services.

How to check the line-of-sight path to the satellites from your installation site is

covered earlier in this section. For each mounting system considered, the line-of-sight

path must be checked for obstructions. If there is an obstruction, another mounting

site may need to be considered.

SiteSurvey27

Even though the DSS dish is relatively small, the surface it mounts to is very important.

This surface must be structurally sound and not have an excessive amount of

movement. A structurally sound surface can be the wall of a home, a deck rail, or a

chimney. These surfaces should withstand at least several hundred pounds of force

that the dish may place on it. This force is not constantly placed on the mounting

surface, it is only present when wind pushes on the dish. Keep these forces in mind

whenever installing a dish and selecting a mounting surface and system.

Identify a Route For the Cables that Run from the Dish to Receiver

Another important aspect of the site survey is the route of the LNB cable. This cable

connects the dish to the satellite receiver. The site survey is the opportune time to plan

the path of this cable. Also, if there are no phone jacks in the area of the receiver, plan

the installation of a telephone cable. If possible, select the shortest possible path to the

satellite receiver for each of these cables. Also try to take advantage of crawl, closet,

and attic spaces. Using these spaces to your advantage can reduce the installation time

by preventing the routing of cables through the inside of walls. The goal of any cable

installation is to keep the cables out of sight and as short as possible.

Connecting the Receiver to the Customer's Audio-Video Components

One of the last items of the installation to consider is the connection of the receiver to

the different video and audio components the customer may have. These components

can include VCR's, laser disc players, and audio systems. Explain to the customer the

best method of connecting their components to the receiver. If there are several

Page 27

28 Site Survey

possibilities, explain them to the customer pointing out the advantages and disadvan-

tages of each. If the customer is unsure of how they would like to connect the receiver,

use your experience to recommend a hookup that will work best for them.

Evaluate Off-Air Solution

Local programming is not available via the DSS satellites. If the customer does not

have an off-air (terrestrial) antenna or cable in the home, you may suggest the

installation of one. If you need assistance in selecting the best antenna for your area,

consult the DSS Accessories and Antenna Components Catalog (publication T-

8743CM).

Third Step

One of the last items to consider during the site survey is whether the different details

of the installation fall within the "basic" installation plan outlined by Thomson

Consumer Electronics. If there are components of the installation that fall outside the

"basic" installation guidelines, additional time and materials may be required. It is

important to discuss any additional charges with the customer before the installation

Thomson Consumer Electronics "basic" installation guidelines

ale:

The dish unit can be mounted on a stable structure of the dwelling - a vertical wall,

chimney, or roof, within a 100-foot cable length of the connected TV. Hardware

necessary to mount the dish must be provided by the installer and included in

"basic" installation price. This includes screws or bolts, grounding hardware, and

an occasional inexpensive Thomson-approved chimney mount.

The installer provides up to 100 feet of Thomson-approved RG-6 coaxial cable

and up to 100 feet of telephone cable.

The satellite receiver should be connected to one TV (and VCR is the VCR is

located at connected TV location).

The antenna is grounded to meet the National Electric Code (NEC) requirements.

The coax cable routed through a normal frame structure or only one layer of

masonry (brick or block).

All cables should be routed to the TV either through an exterior wall or from a

basement or crawl space.

A telephone connection should be installed at the location of the DSS receiver. An

existing phone outlet may be used if within a reasonable distance of the connected

TV and acceptable to the consumer. The installer should assume that most

installations will require a telephone cable hook-up.

Page 28

• Providing up to 20 minutes of customer education on system operation.

• Estimated time to complete a "basic" installation is 2 hours.

• The "basic" install includes travel up to 25 miles (or 25 minutes in dense metro

areas) for the installation without additional mileage charge to the consumer.

Any installation falling within these guidelines is considered a basic installation and

no additional cost is passed on to the customer. If there are aspects of the installation

that fall outside of these guidelines, additional cost can be quoted to the customer to

cover the additional expense. Some examples of items that increase the cost of an

installation are the installation of a pole mount system or using over 100 feet of cable.

Remember, these costs must be explained to the customer before the installation starts.

If the customer does not want pay the additional costs, another mounting site that falls

within the basic guidelines must be found.

Here are some installation add-ons for which a customer may be charged by the

Installer:

Site Survey 29

• The outdoor antenna unit must be mounted at significant distance from the

dwelling, requiring lengthy underground cabling.

• Multiple masonry walls or a solid concrete wall must be penetrated.

• The satellite antenna unit must be installed at a location which requires more

than 100 feet of coax cable to connect the TV and would require amplification.

• Multiple TVs are to be connected. This would probably require multiple

satellite receivers.

• An off-air (VHF-UHF) antenna is needed to capture local signals.

• Complying with state and local codes for grounding more stringent than the

National Electric Code.

• Fishing cable in the walls.

• Travel distance beyond that included with the "basic" installation.

Make certain the consumer understands the costs of any additional options before

you begin the installation work.

Page 29

30 Si_Survey

Optional accessories are items that may be required for an installation but not included

in the basic installation guidelines. Therefore, cost of these items can be passed on to

the customer. Some example of optional accessories are:

• 12' AN cables. There may be several types of cables required: stereo audio cables,

video, and S-video.

• Telephone accessories. These accessories include a telephone extension cable

and/or modular telephone connectors (in-line and T).

• Antenna system parts. Included in this category are indoor and outdoor antennas,

in-line signal amplifiers, and signal combiners.

• AC and telephone surge protectors.

The tools required to complete a basic installation include:

• Drill and bits. Depending on the installation site, it may be necessary to use

masonry bits.

• Assorted hand tools. These tools include pliers, wire cutters, hammer, flashlight,

screwdrivers, etc.. These tools should also include coax cable strippers and

crimping tools for the installation of "F' fittings on cable.

• Compass.

• Ladder. The length of this ladder must be enough to reach attics and roof tops as

required for the installation. It is recommended that a fiberglass ladder be used.

• Cleaning equipment. This equipment should be enough to clean the debris

resulting from the installation of the dish. Items in this list include a broom, dust

pan, hand held vacuum cleaner, rags, and some type of cleaner.

Once the site survey is finished and the materials gathered, the installation of the

system can begin. After reading this, it may appear as though the site survey requires

too much time to do. Once you are experienced with doing site surveys, the whole

process should not take over 15 minutes. Once the site survey is finished and the

installation starts, you'll find that the steps taken during the site survey will save you

both work and time.

Page 30

NOTES

Site Survey 31

Page 31

32 Installation

INSTALLATION The two major components of the Digital Satellite System are the dish and receiver.

These components are packed separately in the carton. The dish packaging contains

five pieces. These are the dish, LNB support arm, foot and mast assembly, LNB, and

a package that contains the nuts and bolts required to assemble the dish. The receiver

packaging contains the receiver, remote control, RF cable, and a telephone cable. The

deluxe system receiver (DRD203RW) contains the basic components listed above,

plus audio, video, and S-video cables. The dish packaging is almost the same for both

the deluxe and the basic (DS1120RW) systems. The difference between the two

antenna systems is the LNB and dish. In the deluxe system, the LNB is a dual output

while the basic system's LNB is a signal output. The dish used with the deluxe system

is made of SMC material, while the basic package includes a metal dish. Before

starting an installation, check for the presence of all pieces in the system packing.

In this section of the training manual, installation of the Digital Satellite System is

divided into four steps. Each step forms a different section of this manual. The steps

are:

1. Mounting the Dish (page 41)

2. Assembling the Dish (page 78)

3. Installing the Receiver (page 98)

4. Aligning the Dish (page 104)

Mounting the

Dish

Included in each of these sections are instructions for performing the step; plus, tool and

material lists required for the step. To see what tools are needed to do a step, go to the

section that matches your installation site. Then, look at the list of tools and materials.

To install the system, you must perform each of these steps. You may choose to perform

these steps in a different order given than that in this manual and the way you install the

system may vary. However, the goal is to install the system quickly and efficiently. The

order you perform the steps should help you do this.

This section addresses mounting the foot and mast assembly to a surface. There are

three basic mounting systems for the dish: vertical, horizontal, and special. Both the

vertical and horizontal mounting systems use the foot and mast assembly included

with the Digital Satellite System. Special mounting systems include chimney and pole

mounts. These systems require the use of hardware that is not included with the RCA

Digital Satellite System, such as a metal pole and concrete for a pole mount system and

a chimney bracket for a chimney mount system. In the explanations of the different

mounting systems, the material lists include the additional hardware needed to install

that system.

Page 32

DISH

Installation 33

\

LNB

MAST AND FOOT ASSEMBLY

HARDWARE

PACKAGE

LNB SUPPORT ARM

Figure 20, Dish Packaging

Page 33

34 Installation

Before starting the installation, there some important things to remember about

installing the system. First, never mount the dish on a surface that is not structurally

sound. Excessive movement of the mounting surface will reduce the performance of

the system. Second, whenever drilling holes in a home, follow the old rule of measure

twice and drill once. Drilling a hole in the wrong place can be difficult and costly to

repair. Finally, read and follow all the safety instructions at the start of this manual.

These warnings are for both you and your customer's safety.

Leveling Basics One of the key steps of the installation is leveling the mast. When mounting the foot

and mast on any surface, the mast must be level both horizontally and vertically. If the

mast is not level, alignment of the dish becomes difficult without the help of special

sighting equipment.

Figure 21 is the mast and foot assembly. This assembly can mount on either a horizontal

or vertical surface by adjusting the position of the mast on the foot. This is the only

adjustment on the foot. Therefore, the position of the foot on a horizontal or vertical

surface is important. Whenever positioning the foot on a nonlevel surface, orient the

foot's adjustment in the direction of the pitch. This simplifies the leveling procedure and

prevents the need of spacers to level the mast.

ADJUSTMENT

VERTICAL

Figure 21, Mast and Foot Assembly Adjustment

HORIZONTAL

Page 34

Installation 35

I

/

Figure 22, Horizontal Leveling with Bubble Level

There are two leveling procedures, one for mounting the foot on a vertical surface and

the other for a horizontal surface. Leveling procedures for special mounting systems

are provided in the specific mounting instructions given later in this manual.

The following leveling procedures gives a basic understanding of how to level the

mast for each mounting system. Abbreviated leveling instructions are also given later

in this manual in the instructions for different mounting surfaces.

Vertical Mounting System

With mounting the foot on a vertical surface, the mast is leveled horizontally (side to

side) and vertically (up and down). Use either a bubble level or plumb line with the

following procedures to level the mast.

Use the following procedure to level the mast with a bubble level.

1. Place the level on the mast as shown in figure 22. Move the bottom of the

mounting foot to center the bubble in the window of the level.

2. With apencil, draw line from the center line of tbe lower f6ot onto the waU.

This line is a reference mark that enables the foot to be restored to level

without using the level again. Before drilling the remaining holes required

to install the foot, ensure this line aligns with the center line of the

mounting foot.

Page 35

36 Installation

When horizontal leveling with a plumb line, use the following procedure:

1. Hold the string of the plumb line over the top of the mast so it hangs as shown

in figure 23.

2. Move the lower part of the foot until the plumb line aligns parallel to the side

of the mast.

3. With a pencil, draw a line from center line of the mounting foot onto the wall.

This line is a reference mark that enables the foot to be restored to level without

using the plumb line again. Before drilling the remaining holes required to install

the foot, ensure this line aligns with the center line of the mounting foot.

\

Figure 23, Horizontal Leveling with Plumb Line

r

Page 36

ADJUST

t

Figure 24, Vertical Plumbing with Bubble Level

To level the mast vertically with a bubble level, use the following procedure.

lns_l_tion 37

1. Loosen the two bolts holding the mast in position on the foot.

2. Place the level on the mast as shown in figure 24.

3. Move the mast vertically center the bubble in the window of the level.

4. Tighten the two mounting bolts securing the mast to the mounting foot.

CORRI_CT

Figure 25, Vertical Leveling with Plumb Line

Page 37

38 Installation

To level the mast vertically with a plumb line, use the following procedure:

1. Loosen the two bolts holding the mast in position on the foot..

2. Hold the string of the plumb line over the top of the mast so it hangs as shown

in figure 25.

3. Move the mast vertically until the plumb line hangs parallel with the mast.

4. Tighten the two mounting bolts securing the mast to the mounting foot.

Horizontal Mounting System

When mounting the foot on a horizontal surface, the mast must also be leveled. This

leveling is different than the leveling done for a vertical surface. Instead of leveling

in a horizontal and vertical direction as you do on vertical surfaces, horizontal surfaces

require the mast he leveled vertically in all directions. To do this requires at least two

measurements of the mast. Each measurement must be at right angles to the other

measurement (see figure 26). Both aplumb line and a bubble level will work for making

these measurements.

MEASUREMENT MEASUREMENT

1 2

Figure 26, Measuring Level Horizontal Mounting System

Page 38

The important thing in horizontal mast leveling is positioning of the foot on the

mounting surface. This is due to the one adjustment of the foot. When positioning the

foot on a horizontal surface, orient the adj u stment in the direction that has the most angle

to it. For example, if you are mounting the foot on a roof, orient the foot so the

adjustment is parallel to the pitch of the roof (see figure 27).

Insml_tion 39

Figure 27, Orient the Mounting Foot on a Horizontal Surface

Use the following procedure to level the mast on a horizontal surface:

1. With a bubble level, check the level of the mounting surface. While doing

this, check several different angles at the foot location. Mark the direction

with the most angle.

2. Position the foot on the mounting surface, aligning the foot's adjustment with

the direction marked in step one.

3. With the adjustment on the foot, level the mast (see figure 28).

Page 39

40 Installation

MOVE

ADJUSTMENT

Figure 28, Horizontal Surface Mast Leveling with Foot Adjustment

SPACERS

(IF REQUIRED)

Figure 29, Horizontal Surface Side to Side Leveling

Page 40

.

Move the bubble level (or plumb line) 90 degrees and measure. If level, double

check both measurements and secure the foot (skip steps 5 and 6). If it is not

level, continue to step 5.

,

If the side to side measurement of the mast is not level, use spacers to level

it. To use spacers, determine the side that must be raised. Then, place 5/16

washers under the foot to level the mast. Position these washers under the

mounting holes so the mounting bolts will secure them.

6, Once the side to side measurement is level, confirm the level of both

measurements and secure the foot to the surface. Always double check the

level of the mast after it is secured. If it is not level, re-adjustment may be

necessary.

Installation 41

Instructions for leveling is also given in each horizontal system installation proce-

dure.

Page 41

42 Installation/Mounting the Dish

Material List:

• 2EA. I "x3"

screws.

• 4EA /16 xlV2"Lag

screws.

• 2EA. 1-

• 4 EA. 5/is" Flat wash-

ers

Tool List:

• Drill.

• l/s" Twist drill bit.

3/16"Twist drill bit.

• Bubble level or plumb

line.

• 7/16"Box or open end

wrench.

• 3/s" Box or open end

wrench.

• Pencil.

/4 Lag

5 II

/4 Flat washers.

PANEL SIDING

__ WOOD PANEL

CENTER

HOLE

_1 I/sTuD

STUD

I

OUTSIDE/ I I NOUTSIDE

HOLES(_k I ] / HOLES

! I CENTER

HOLE

Figure 30, Panel Mounting Mast and Foot Assembly

Page 42

Installation/Mounting the Dish 43

Panel siding is typically a 4' x 8' sheet of material mounted over some type of insulating

sub layer. The thickness of these panels varies from 3/8" to 5/8". Nails secure the

panels to the frame structure of the home. Usually, the edges of panels are cut so that

lap joints form where two panels meet. This provides a relatively flat mounting

surface for the DSS dish.

Panel siding can be made of many different types of materials. These materials range

from composite materials to solid wood or plywood. Do not mount the dish to any type

of composite material. Composite materials include strand board, fiber board, and

particleboard. Acceptable siding materials include solid wood panels and plywood.

If you are unsure of the mounting material or its thickness, look at a cross sectional

view of the material by removing the cover from an exterior electrical outlet.

Due to the variety of solid wood and plywood panels used in home construction, it is

always recommended that the mounting foot be secured to one of the studs that make

up the framework of the wall.

Use the following procedure to install the foot on panel type siding:

DANGERZ

When following these instructions, take extreme care to avoid

contact with overhead power lines, lights and power circuits.

Contact with power lines, lights, and circuits may prove fatal.

Vertical

Mounting

Systems

1. Locate a wall stud close to the area selected in the site survey. To locate a stud

underneath panel siding, locate the nails securing the panel to the wall frame.

These nails are driven into the studs and usually form a track vertically on the

siding. This vertical track of nails aligns with the center of the stud and provides

an easy guide to the locations of the studs.

2x4 STUD

WOOD PANEL

/

NAIL

TRACK

Figure 31, Finding Wall Stud

Page 43

44 Installation/Mounting the Dish

2. Place the mounting foot on the panel aligning the center holes with the center

of the stud. With a pencil, mark the upper center hole of the mounting foot.

3. Remove the mounting foot and drill a 1/8" hole in the location just marked.

J

With a 114" x 3" lag screw and washer, attach the mounting foot to the wall

using the hole drilled in step three. Tighten the lag bolt until itjust holds the

mounting foot to the wall. The lower half of the mounting foot should move

slightly back and forth.

5. Horizontally level the mast using either a bubble level or a plumb line.

To horizontally level the mast, place the level or plumb line on the mast at an

perpendicular angle to the wall. If you are using a bubble level, move the

bottom of the mounting foot to center the bubble in the window of the level.

If you are using a plumb line, move the lower part of the foot until the plumb

line aligns parallel to the side of the mast. With a pencil, draw line from the

center line of the lower foot onto the wall. For details on this procedure, see the

Leveling the Dish section of this manual.

6. Using a 7/16" wrench, loosen the lower two nuts holding the mast onto the

mounting foot. With these two nuts loose, move the mast to gain access to the

lower center mounting hole.

7. Align the center mark of the mounting foot with the line drawn in the horizontal

leveling procedure.

8. Drill a 118" pilot hole in the lower center mounting hole.

9. Insert a 1/4" x 3" lag screw with washer into the lower mounting hole. At this

time tighten both top and bottom lag screws.

10. With a 3/16" bit in the drill, drill two pilot holes in opposite comers of the

mounting foot.

11. Insert 5116" x 1-1/2" lag screws with washers into the outside holes and

tighten.

Note: Inserting lag screws into these holes in the four comers of the mounting

foot is optional and only done to improve the appearance of the installation. A

minimum of two lag screws in opposite comers of the mounting foot are

Page 44

LOOSEN

Installation/Mounting the Dish 45

Figure 32, Loosening Lower Nuts

required for the installation. These screws reduce the side-to-side movement

of the dish.

12. Vertically level the dish with a bubble level or plumb line.

To do this, place the level, or plumb line, on the mast at an parallel angle to

the wall. If you have not loosened the two bolts securing the azimuth

adjustment on the mounting foot, do it now. If you are using a bubble level,

move the mast vertically to center the bubble in the windov¢ of the level. If

you are using a plumb line, hold the string of the plumb line over the top of

the mast so it hangs at a perpendicular angle to the mounting surface. Move

the mast vertically until the plumb line hangs parallel to the side of the mast.

Tighten the two mounting bolts securing the mast to the mounting foot. For

a more detailed description of this procedure, see the Leveling the Dish

section of this manual.

13. Check tightness of all bolts and proceed to the Assembling the Dish section.

Page 45

46 Installation/Mounting the Dish

Material List:

• 2 EA.I/4" x 3" Lag

SCI_WS.

• 4 EA. s/16" x IV2"

Lag screws.

• 4 EA. 5/16"Flat

washers.

• 2 EA. 1/4"Flat

washers.

LAP SIDING

_>.2x4 STUD

/

I r

Tool List:

• Drill.

• ]/s" Twist drill bit.

3 it . . .

• /16 Twist dnll bit.

• Bubble level or

plumb line.

7 Ig

• 1,6 Box or open

end wrench.

3 "

• /8 Box or open end

wrench.

• Pencil.

(Optional)

CENTER

HOLE STUD

\I I-I

/I I\

OUTSIDE \ I I / OUTSIDE

HOLES _ _ %_/ HOLES

I"° I IN, or|

I I N

I I

CENTER

HOLE

Figure 33, Mounting the Foot and Mast Assembly to a Lap Sided Wall

Page 46

Installation/Mounting theDish 47

Lap sided walls are made up of many narrow boards stacked horizontally up the wall.

Each board is lapped by the board above it. Usually, all the boards on one wall are the

same width; however, the width of lap siding material can vary from 4 to 10 inches.

Therefore, it is possible for one wall to use 5" boards and another wall to use 7" boards.

This can make finding alocation on the wall wide enough for the mounting foot difficult.

Another characteristic of lap sided walls is the siding style. Depending on this style,

the wall surface is either flat or uneven. If the surface is uneven, each board's surface

is not parallel to the vertical plane of the wall. Several common siding styles are drop,

rustic, rabbetted, bevel (also called taper), and clapboard. The wall surfaces with drop

and rustic siding styles are relatively fiat. Rabbetted, bevel, and clapboard styles have

uneven wall surfaces. Installing the dish on a wall with rustic and drop styles of siding

is the same as installing it on panel siding. If you are installing the DSS dish on one of

these siding styles, see the panel siding explanation in this manual. When installing

the system on clapboard, bevel, and rabbetted styles of siding, the mounting process

must change slightly.

DROP RUSTIC RABBEITED BEVEL

SIDING SIDING SIDING SIDING

Figure 34, Lap Siding Styles

CLAP-

BOARD

Page 47

48 Installation/Mounting the Dish

\

FACE

WIDTH

w m

-- B

\

Figure 35, Lap Siding Face Width

Another difference with the siding styles that do not have flat surfaces is the different

amount of exposed board, called the face width. For example, the face width of bevel

and taper siding styles can vary from 3-1/2" to 9". This presents a problem when

mounting the DSS foot to boards with the narrower face widths. The mounting foot

is about 7" long and mounts across aboard. When installing the foot on boards narrower

than 7", a portion of the foot will not contact the wall. This often looks unprofessional

and can reduce the strength of the installation. To install the mounting foot on siding

with a face width less than 7", a spacer can be installed with the foot in the area of the

overhang. This spacer keeps the foot securely fastened to the wall. The material used

for this spacer can be wood or plastic and must be soft enough to have holes drilled into

it. Once installed, the color of this spacer should match either the wall or mounting foot.

Page 48

Installation/Mounting the Dish 49

Lap siding can be made from many different types of materials. These materials range

from solid wood to aluminum. Do not mount the DSS Dish on any type of

aluminum or vinyl siding,. We also do not recommend mounting the system on any

type of composite material. This includes strand board, chip board, fiber board, and

particleboard. An acceptable siding material is solid wood or plywood.

There are also several types of solid wood siding sold today. This wood varies in

hardness and strength. Due to this, secure the mounting foot to one of the studs that

make up the framework of the wall.

Use the following procedure to install the mounting foot on a lap sided wall:

DANGER!

When Following these instructions, take extreme care to avoid

contact with overhead power lines, lights, and power circuits.

Contact with power lines, lights, and circuits may prove fatal.

1. Locate a wall stud close to the area selected in the site survey.

To locate a stud underneath the siding, locate the nails securing the siding to the

wall frame. These nails are driven into the studs and usually form a vertical track

on the wall. This vertical track of nails often aligns with the center of the stud

and provides an easy guide to the location of the stud.

2. Place the mounting foot on the face of a siding board aligning the center holes

of the foot with the center of the stud. With apencil, mark the upper center hole

of the mounting foot.

Note: If the foot is wider than the face of the siding board, a spacer must be

installed under the part of the foot that does not touch the siding. Tips for

installation of this spacer is given later in this section.

3. Remove the mounting foot and drill a 1/8" hole in the location just marked.

.

Use a 1/4" x 3" lag screw and washer to attach the mounting foot to the wall--

use the hole drilled in step three. Tighten the lag screw until it just holds the

mounting foot to the wall. The lower half of the mounting foot should slightly

back and forth.

Page 49

50 Installation/Mounting the Dish

5. Horizontally level the mast using either a bubble level or a plumb line.

To horizontally level the mast, place the level, or plumb line, on the mast atan

perpendicular angle to the wall. If you are using a bubble level, move the

bottom of the mounting foot to center the bubble in the window of the level.

If you are using a plumb line, move the lower part of the foot until the plumb

line hangs parallel to the side of the mast. With a pencil, draw a line from the

center line of the lower foot onto the wall. For details on this procedure, see

the leveling the dish section of this manual.