RCA CTC203 Diagram

THOMSON TECHNICAL TRAINING

THOMSON TECHNICAL TRAINING

1999 ctc203 TRAINING

FOREWORD

This publication is intended to aid the technician in servicing the CTC203 television

chassis. It will explain the theory of operation, highlighting new and different circuits

associated with the digitally controlled chassis. The manual covers power supplies,

horizontal and vertical deflection, tuner, video signal processing, and audio signal

processing theory of operation along with practical troubleshooting tips and suggestions.

It is designed to assist the technician to become more familiar with chassis operation,

increase confidence and improve overall efficiency in servicing the product.

Note: This publication is intended to be used only as a training aid. It is not meant to

replace service data. TCE Electronic Service Information for these instruments contains

specific information about parts, safety and alignment procedures and must be consulted

before performing any service. The information in this manual is as accurate as possible

at the time of publication. Circuit designs and drawings are subject to change without

notice.

SAFETY INFORMATION CAUTION

Safety information is contained in the appropriate Thomson Consumer Electronics Service

Data. All product safety requirements must be complied with prior to returning the

instrument to the consumer. Servicers who defeat safety features or fail to perform safety

checks may be liable for any resulting damages and may expose themselves and others to

possible injury.

All integrated circuits, all surface mounted devices, and many other

semiconductors are electrostatically sensitive and therefore require

special handling techniques.

dbx® is a registered trademark of Carillon Electronics Corporation.

DirecTV® is a registered trademark of DirecTV, Inc., a unit of Hughes Electronics Corp.

Guide Plus+® is a registered trademark of Gemstar Development Corporation.

SRS®, the SRS symbol and Sound Retrieval System® are registered trademarks

of SRS Labs, Inc.

First Edition 9929 - First Printing

Copyright 1999 Thomson Consumer Electronics, Inc.

Trademark(s)® Registered Marca(s) Registrada(s)

Printed in U.S.A.

Prepared by

Thomson Consumer Electronics, Inc.

Technical Training Department

PO Box 1976

Indianapolis, Indiana 46206 U.S.A.

®

Contents

Chassis Description ............................................................................................................ 5

CRK76 Remote Control ............................................................................................................................... 9

Power Supply Overview .................................................................................................. 10

Standby Supply Overview ........................................................................................................................... 12

Digital Latches ............................................................................................................................................ 13

Control Latch Review ................................................................................................................................14

Latch Circuit ............................................................................................................................................... 15

Main Supply Block Diagram .......................................................................................... 16

AC Input and Degaussing ......................................................................................................................... 17

Main Supply Operation .............................................................................................................................. 19

Run Supplies ............................................................................................................................................... 27

Scan Derived Supplies ............................................................................................................................... 28

Deflection Overview ......................................................................................................... 30

Horizontal Output ...................................................................................................................................... 34

XRP ............................................................................................................................................................. 40

Horizontal Scan Derived Supply Generation ........................................................................................... 41

Vertical Scan Overview .............................................................................................................................. 42

System Control ................................................................................................................. 50

T4-Chip Power Control .............................................................................................................................. 57

Main Power Supply On/Off Control ......................................................................................................... 57

Batten Down the Hatches .......................................................................................................................... 58

V-Chip ......................................................................................................................................................... 67

Service Menu .............................................................................................................................................. 69

Error Codes .................................................................................................................... ............................72

Tuner.................................................................................................................................. 76

Instruments with GEMSTAR.................................................................................................................... 86

IF Circuit ........................................................................................................................... 92

F2PIP ................................................................................................................................. 94

Analog Switches .........................................................................................................................................96

Main Signal Processing.............................................................................................................................96

Burst Lock Clock........................................................................................................................................96

Video Input Switching ................................................................................................................................ 98

Video Processing ............................................................................................................. 100

CRT Drivers .................................................................................................................... 108

CTC203 Video Module .................................................................................................. 112

T4-Chip U12101 ............................................................................................................. 114

T-Chip Overview ....................................................................................................................................... 114

CRT Management.......................................................................................................... 116

Deflection Processing .............................................................................................................................. 116

Video Processing ...................................................................................................................................... 116

Analog Comb Module.................................................................................................... 118

Composite Video Switch ........................................................................................................................... 119

Analog Comb............................................................................................................................................ 119

S-Video Switch..........................................................................................................................................120

Input Jacks ............................................................................................................................................... 120

Output Jacks.............................................................................................................................................121

Power Supplies ......................................................................................................................................... 121

Audio................................................................................................................................ 122

Stereo/SAP Decoder ................................................................................................................................. 123

Stereo/SAP Switch .................................................................................................................................... 124

DBX...........................................................................................................................................................124

GEMSTAR ...................................................................................................................... 128

Operation ..................................................................................................................................................131

Diagnostic Test .........................................................................................................................................134

Troubleshooting ....................................................................................................................................... 136

Chipper Check™ Overview.......................................................................................... 138

Chipper Check™ Hardware....................................................................................................................139

Chipper Check™ Software ...................................................................................................................... 140

“Dead Set” Troubleshooting with Chipper Check™.............................................................................140

Further Reading ....................................................................................................................................... 145

4 Overview

INTRODUCTION

The CTC203 series chassis is Thomson Consumer Electronics latest core-line chassis. Consumer

operation and majority of features of the CTC203 series chassis are very similar to previous ProScan,

RCA and GE chassis. Menu structures will be recognizable to any previous TCE product user.

Although there are differences, the component designations on the CTC203 series chassis are similar

to designations on previous chassis. Most components are labeled on the circuit board. To save space

the first numbers from the schematic may be dropped off. Q14100 may become Q100 or Q4100.

However, it will probably be located in the 14000 series component area. In TCE Service Literature,

2 number components (R16) are generally located on the top of the circuit board, while 3 number

components (C523) are located on the bottom of the chassis.

It is important for the technician to understand the difference between switching transistors and

amplifiers. When switching transistors are "On", they have a very low emitter-collector voltage drop,

typically 0.12.1 volts. Transistor amplifiers are normally biased "On" at all times and while the

base-emitter voltage drop will be similar, (very close to 0.6 volts), the emitter-collector voltage drop

can be from around 1 volt up to the power supply voltage.

Although this Training Manual makes every effort to follow the service data template for component

location and identification, always consult the Basic Service Data (ESI) for up-to-date information.

The component type (transistor, resistor, capacitor...etc.) is designated by the way the component is

labeled in both Training and Service Data material.

CTC203 training material will include nomenclature that differs somewhat from previous manuals.

To designate individual pin assignments of an IC, the following will be shown;

U13101-5 designates IC U13101, pin 5.

Q14608-B indicates the base lead of transistor device Q14608.

Q14601-G indicates the gate of MOSFET device Q14601.

Power supply voltages and labels will be used whenever possible. +5Vr identifies the positive 5 volt

run supply. There are various classes of power supply indicators for the CTC203. They should be

self-explanatory to experienced technicians, but may differ slightly from designation used in TCE

Electronic Service Data. The common designations are:

l s - Standby

l r - Run

l Reg B+, which can be standby or run

l t - Tuner

Pay attention to which power supply is being referred to and confusion will be avoided. A standby

supply may also provide run current.

The CTC203 uses "Hot" and "Cold" grounds. Training material and service data will continue to

differentiate between the two using for hot ground and for cold. Always use an isolation

transformer when performing service on the CTC203 chassis.

Overview 5

Chassis Description

The CTC203 chassis will be used in a variety of models and screen sizes. Important additions include

a Gemstar Program Guide (Guide Plus+), V-Chip, on-board tuner, and a system control section that

can be connected to Chipper Check. It also has a number of chassis configurations that give the

chassis comb filter and S-Video capabilities. Active pincushion can also be switched in and out to

accommodate large picture tubes.

While the CTC203 is versatile, most major circuits are not new, but refinements of existing designs

modified to work together in the CTC203 chassis. For example, the switch mode power supply is

very similar to that of Thomsons MM101 chassis, the tuner section is close to the CTC175/6/7

chassis family, and system control will look and operate much like the CTC197 chassis. Keep in

mind there will be differences in symbol numbers and values of some components will change, but the

basic design is the same.

The CTC203 is expected to be a "workhorse" chassis, possibly replacing all CTC176/177/186/187

product. A commercial version (to support hospital, lodging, and educational markets) is also

planned.

6 Overview

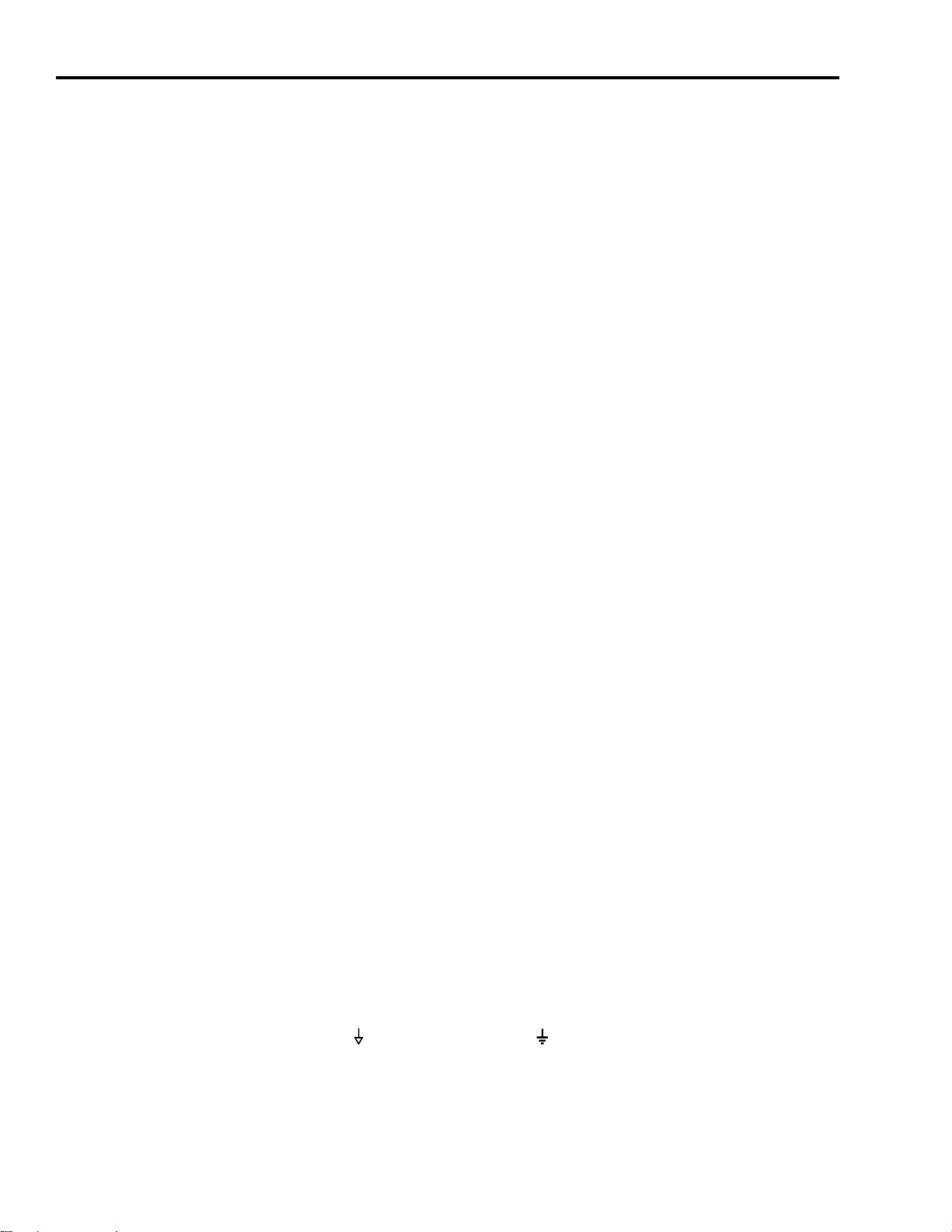

Figure 1-1, CTC203 Chassis Layout

This CTC203 Technical Training Manual will break the chassis into several major

areas. Those areas are:

Main Power Supply

Scan Generated Power Supply

Horizontal Deflection

Vertical Deflection

System Control

Tuner

IF

F2PIP

Following the main discussions are several appendices which include pinouts of the

major IC's, overall block diagrams of System Control, Video Switching and Audio

Switching, a glossary of new and old terms used with the CTC203 and TCE chassis

in general and circuit board/component interconnect diagrams.

Video Module

Video Processing

Analog Comb Filter

CRT Management

Audio

GEMSTAR

Chipper Check

Overview 7

VIDEO

VCR

CONTROL

AUDIO

RL/MONO

IN

RL/MONO

OUT

S-VIDEO

F

S

CABLE/

ANTENNA

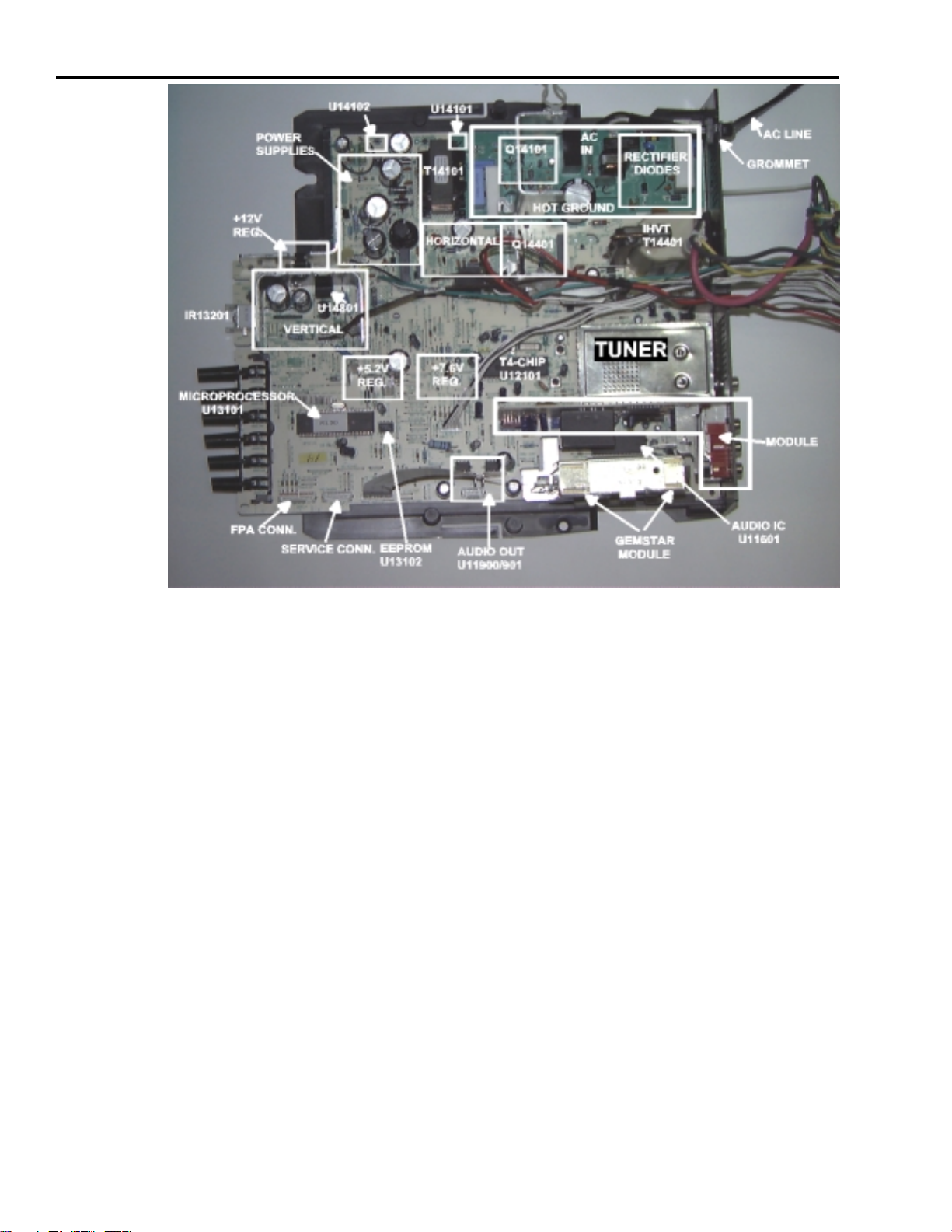

Figure 1-2, CTC203 Rear Panel

Rear Jack Panel

The CTC203 rear jack panel consists of three versions. One, shown above has

audio/video input and audio output jacks (5J). One has only audio/video inputs (3J)

and another has no audio/video input or output jacks (0J). All models have an RF

cable/antenna connecter and the VCR Control connection.

AC

LINE

CORD

The VCR Control connector enables the Guide Plus software to control a VCR or

Cable Box to either automatically tune to the selected Guide Plus channel or begin

recording a show selected in the Guide Plus menu.

Five jack (5J) models also have an S-Video input. If an active S-Video signal is

detected, the video input will automatically switch to the S-Video source.

The screen and focus adjustments are accessible from the rear panel without removing

the back of the set.

The Guide Plus+ software has a special learning/demo mode available to the

consumer. Most sets contain a pin inserted into the VCR CONTROL jack on

the rear panel of the set automatically enabling this mode. The pin activates

the mode every time the set is turned on. Although the set immediately

enters the demo mode it can be taken out via on-screen menu selection.

However, as long as the pin is the rear panel jack, the set will not receive channels

above VHF 13 whether the demo mode is active or inactive. The set must be

turned off, the pin removed and the set turned back on for normal operation to

return.

TECH

TIP

8 Overview

CH CTRL

SAT-CABLE

LED

SOUND

WHO-INPUT

SWAP

PIP

CH CTRL

RESET

Figure 1-3, CRK76E1 Remote Control

CRK76 Remote Control

Although similar to previous remote controls, the CRK76 remote for the CTC203 has a

few added capabilities. Carried over are the "navigation" buttons located in the middle

of the remote. Instead of using "Channel Up", "Channel Down", "Volume Up" and

"Volume Down" to navigate through the on screen menu structure, these navigation

buttons will be used. The user will point using these buttons, then press "OK" to select

the desired instruction. They are also essential to the use of the Guide Plus+ menu

system.

The CRK76 series used in the CTC203 is also a "universal" remote capable of controlling

current equipment such as VCR's, Cable Boxes, and Satellite Receivers from most

major consumer electronics manufacturers. In addition, the remote may be programmed

to control RCA and RCA Dimensia audio equipment and RCA, GE and PROSCAN

DVD players.

Remote Control Operation

Normal remote functions will not be discussed. These functions have not changed over

the last several remote control models. The following text explains new buttons and

their functions.

Overview 9

LED: Indicates the remote is in "Learning" mode when programming the remote to be

used with other equipment.

SOUND: With one press brings the user directly to the audio processor menu.

Guide: Accesses the Guide Plus+ menu. When the remote is programmed to control

the SAT-CABLE equipment, accesses any available on-screen menus for those devices.

GO BACK: Returns the user to the previous channel selection, or if in MENU, returns

to the previous menu selection.

WHO-INPUT: Toggles through all available input sources.

SAT-CABLE: Places the remote in control of a compatible satellite receiver or cable

box. If Auto-tuning is enabled, also will turn on the TV and select the correct input to

display.

Some buttons and functions are not available on every model equipped with a CTC203

chassis. For instance, on models without PIP, the bottom four buttons on the remote

will not be present. Some models of the remote do not include back lighting and on

some models only the volume and channel buttons illuminate. Always consult the

latest ESI for the correct remote part number for a particular chassis prior to ordering

a replacement.

10 Power Supply

SERVICING

PRECAUTION!

Variable

IsoTap

AC Vol tag e Out

with 120VACIn

Monitor

ADD

Most ground connections on the CTC203 series chassis are

cold, ( ), indicating they are isolated from the AC line.

However, there are many "Hot" connections, ( ), meaning

direct connection to the AC line. The AC input and primary

side of the power supply circuitry are examples.

Always use an isolation transformer

and consult service data when performing service on this

chassis and other chassis in this family!

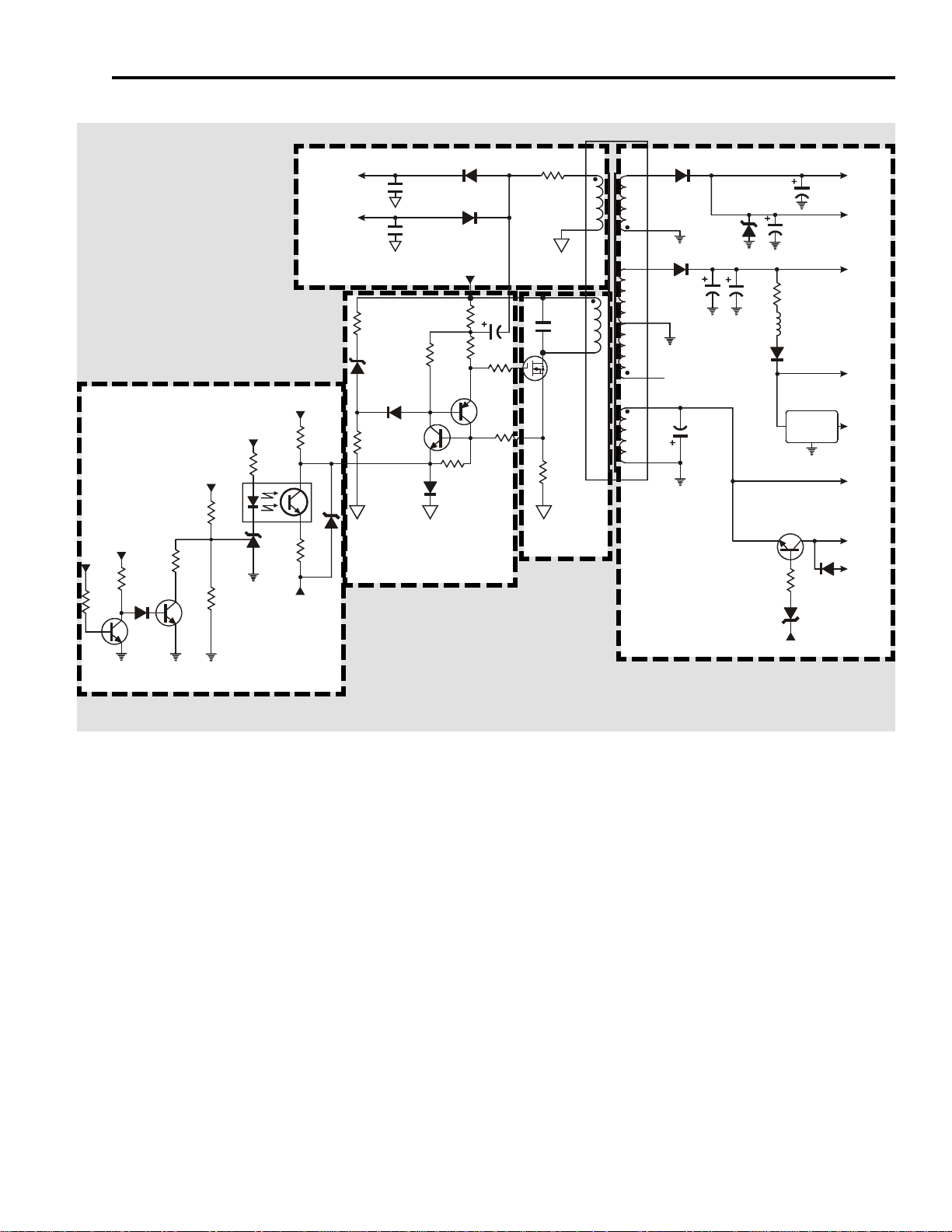

Power Supply Overview

There are three power supplies providing power to the CTC203. All derive power

from Raw B+ and/or Regulated B+. They are:

•Standby

•Run (Switched)

•Scan Derived (High Voltages)

Due to higher power requirements of the CTC203, the power supply takes a new

approach to meet the higher loads. Primarily, the main supply operates in "forward"

conduction mode, delivering power to the secondary transformer windings during

power transistor "on" time when the magnetic fields are expanding, rather than

during "off" time when the fields are collapsing.

All standby supplies also ramp up to supply the current demands of the chassis

during run operation. Derivations of the main supply also provide current for the

scan derived and the switched supplies.

There are three modes of operation for the main supply but only two for the switched

and scan derived supplies. They are:

•Standby

•Data Acquisition

•Run

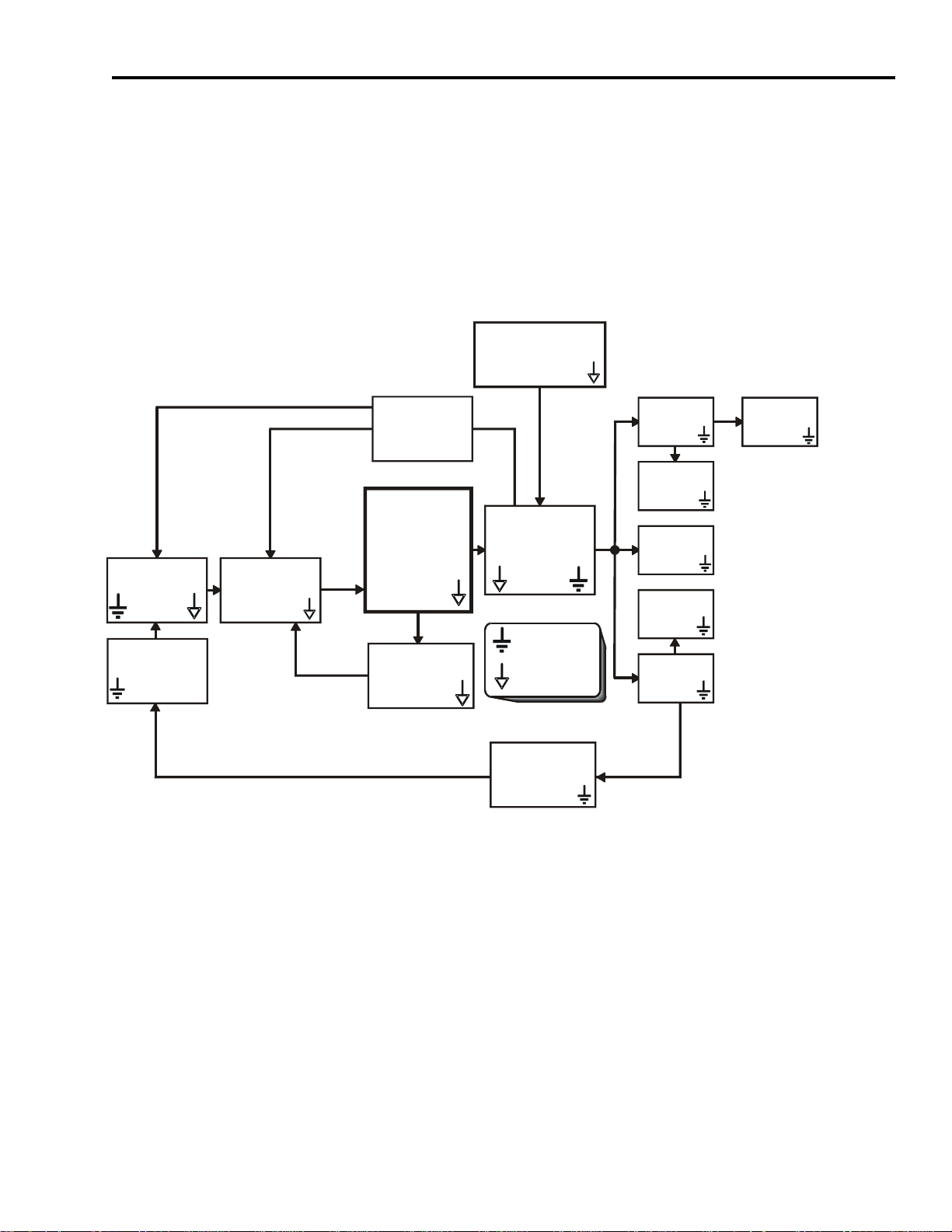

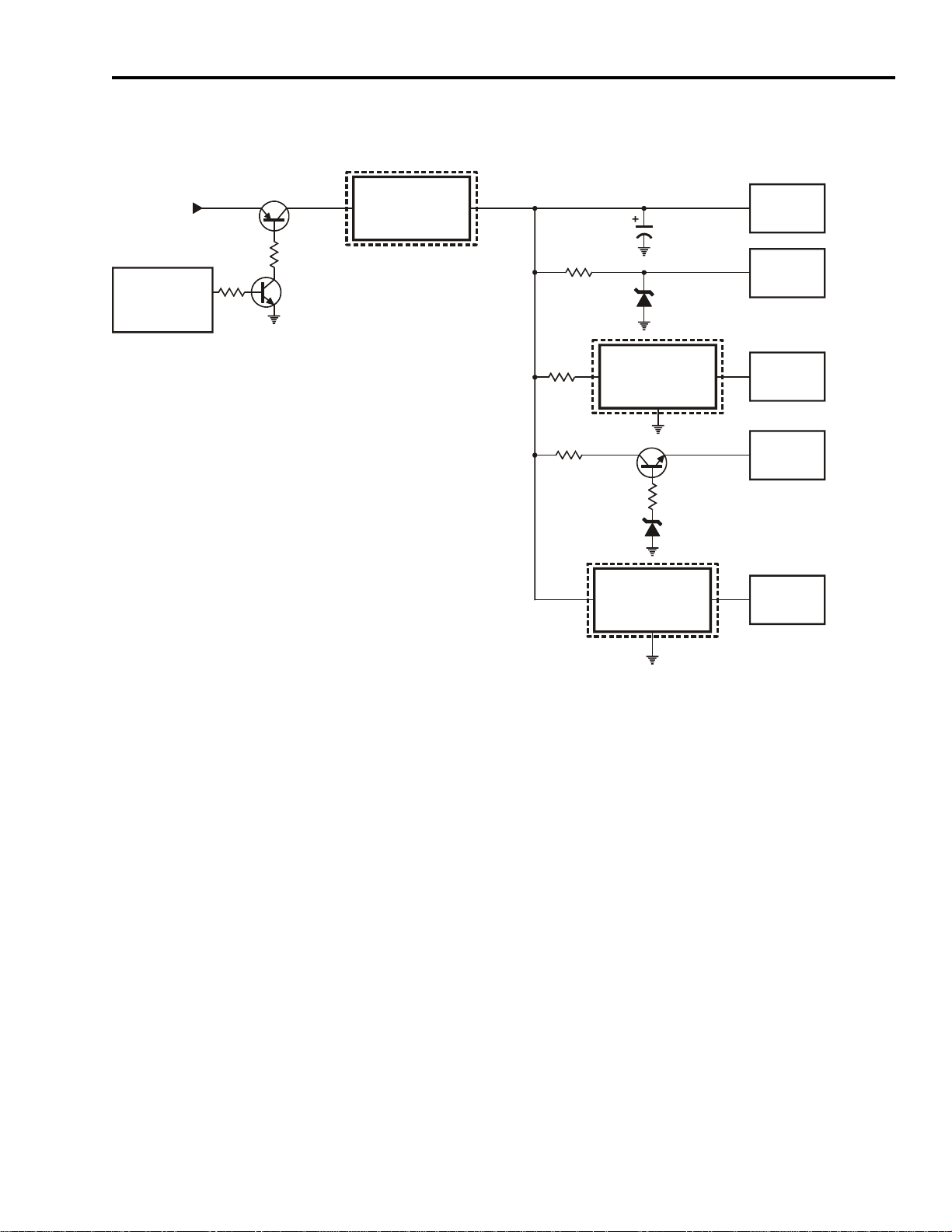

The main power circuits supply many different voltages to the CTC203 chassis.

Figure 2-1 is a block diagram showing the voltages generated and their derivations

from the main power. Notice all standby voltages are derived from Raw B+.

However, differing from most previous chassis', the main supply generates all low

voltages required during Run, Standby and Data Acquisition modes of operation.

All voltages, except the switched and scan derived, are available any time the AC is

connected to the line. Mainly, they supply the microprocessor, infrared remote

control detection and tuning circuitry during standby. All other voltages are derived

from the main supply and switched on during run or data acquisition modes.

The main supply generates voltages for normal operation of all other circuits and

components. In addition, many of the supplies are used to generate the remainder of

the low and high voltages required by the chassis.

The Technical Training Manual will discuss the power supplies in this order; Main,

Switched (SW) and Scan Derived.

Raw B+

Power Supply 11

OPTO-ISOLATOR

U14101

PRECISION

REGULATOR

U14102

BIAS

SUPPLIES

OUTPUT

POWER

TRANSFORMER

T14101

Cold Ground

Hot Ground

Reg B+

Feedback

CONTROL

LATCH

Q14102/103

POWER

OUTPUT

Q14101

OVER-CURRENT

OVER-VOLTAGE

R14108

Figure 2-1, CTC203 Main Power Supply Block Diagram

+16Vr

+5.2Vs

-12Vr

+33Vs

Reg B+

+7.6Vr

12 Power Supply

Standby Supply Overview

The standby supply is a new class of high power, ZVS (Zero Voltage Switching)

supply developed to minimize switching losses and radiated noise. A return to

discrete devices lowered parts count and decreased circuit board space utilization.

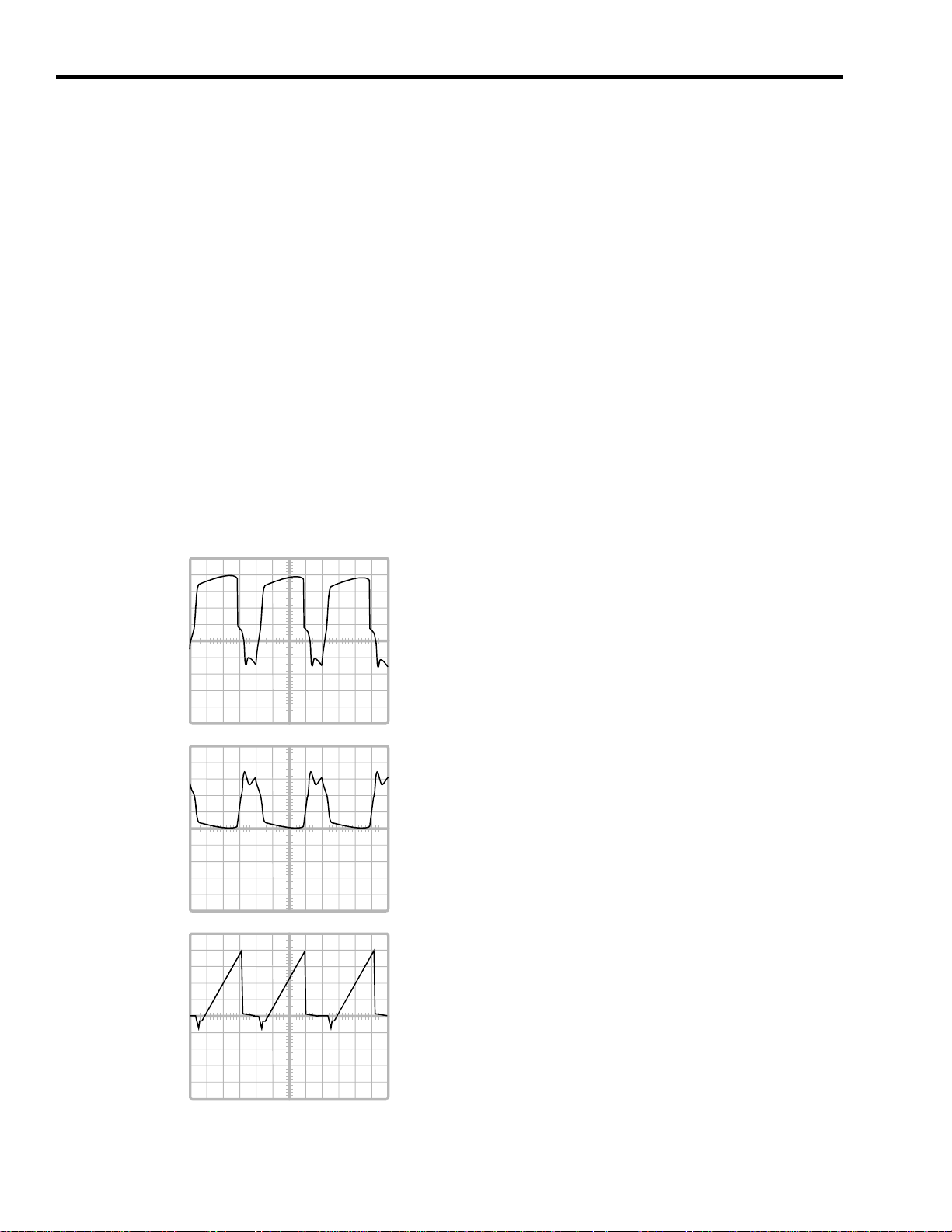

ZVS refers to the ability of the supply causing the voltage across the principal power

output device, to reduce to near zero before the device is switched on. Yet it has a

slow enough time lag to allow the device to switch off completely before any

appreciable voltage is present across the device. This can better be illustrated in

Figure 2-2.

Note that the first two waveforms are voltages, while the third is current. The

MOSFET begins conducting current when the gate voltage reaches the proper turn

on point. From that time, output current rises linearly due to the inductance of the

output transformer. However, notice that once the gate voltage goes high, the drain

voltage decreases almost to zero volts. This eliminates much of the heat dissipation

normally required of an output device.

Q14101

Gate Voltage

Q14101

Drain Voltage

By reducing the switching losses to almost

zero, the efficiency of the power supply is

greatly increased and the limiting of the

switching voltages causes a substantial

reduction of switching noise.

Also note that by utilizing the resonant

recapture of energy stored in the leakage

inductance of the output transformer, neither

a snubber nor a clamp is required, leading to

improved efficiency and lower parts count.

Q14101

Drain Current

Figure 2-2, Power Supply Output Device Waveforms

Power Supply 13

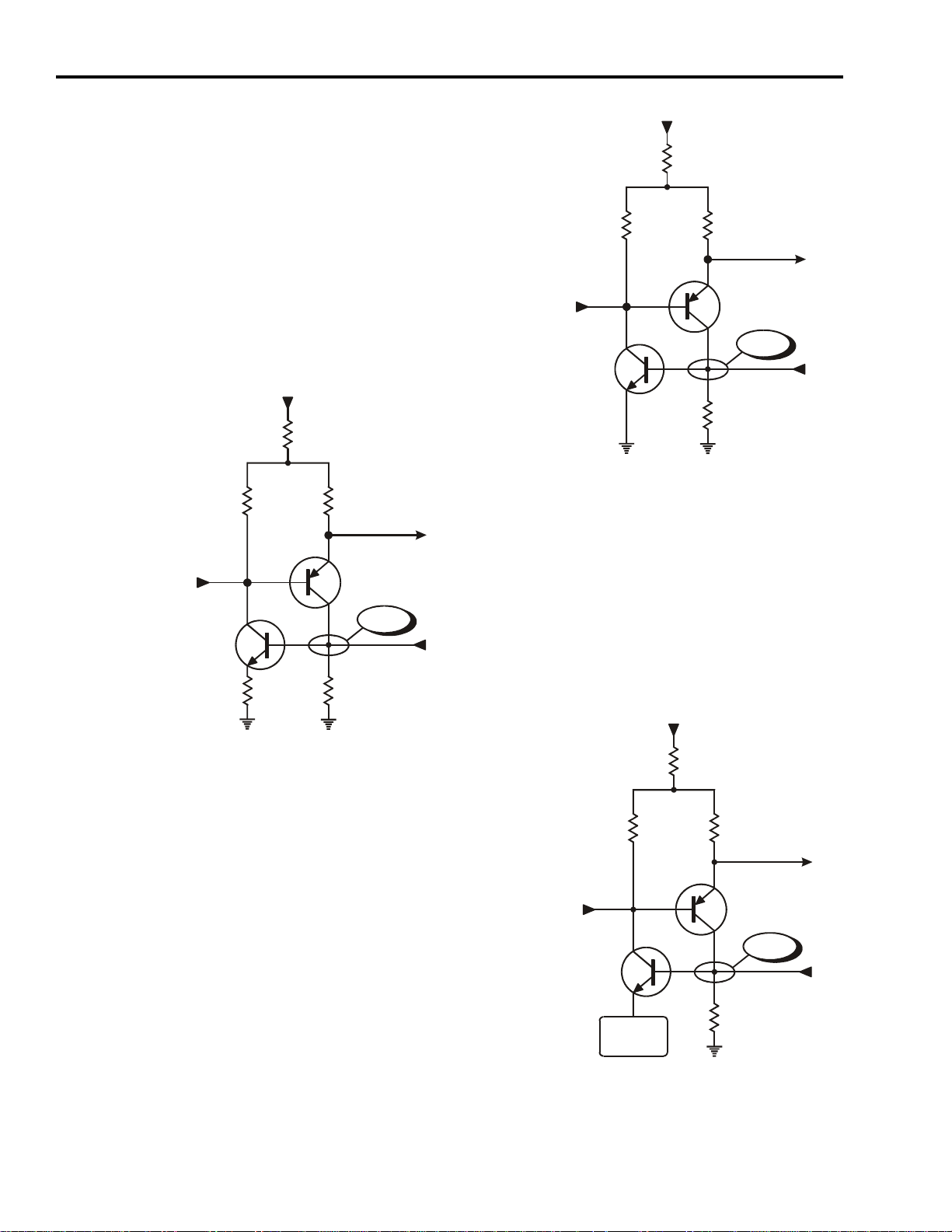

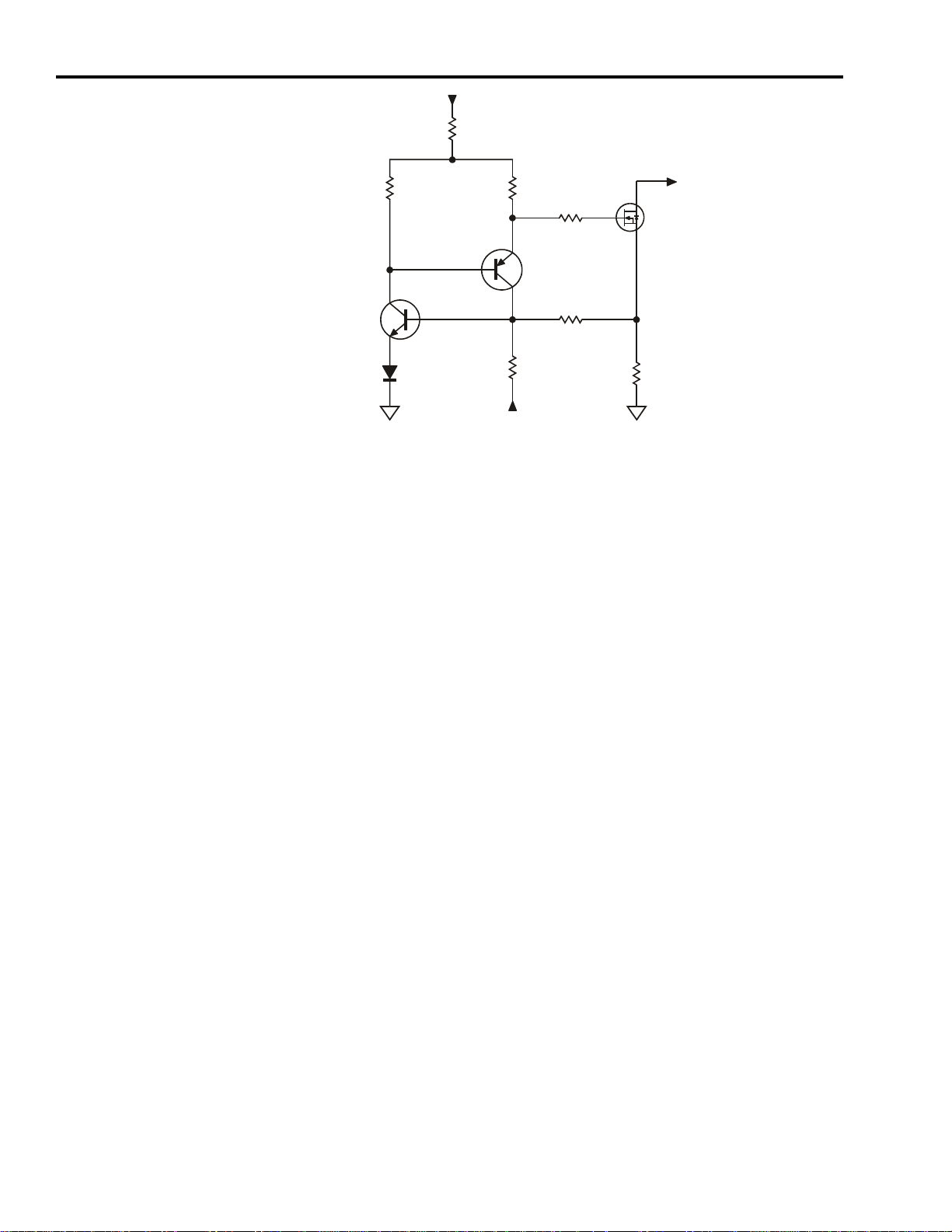

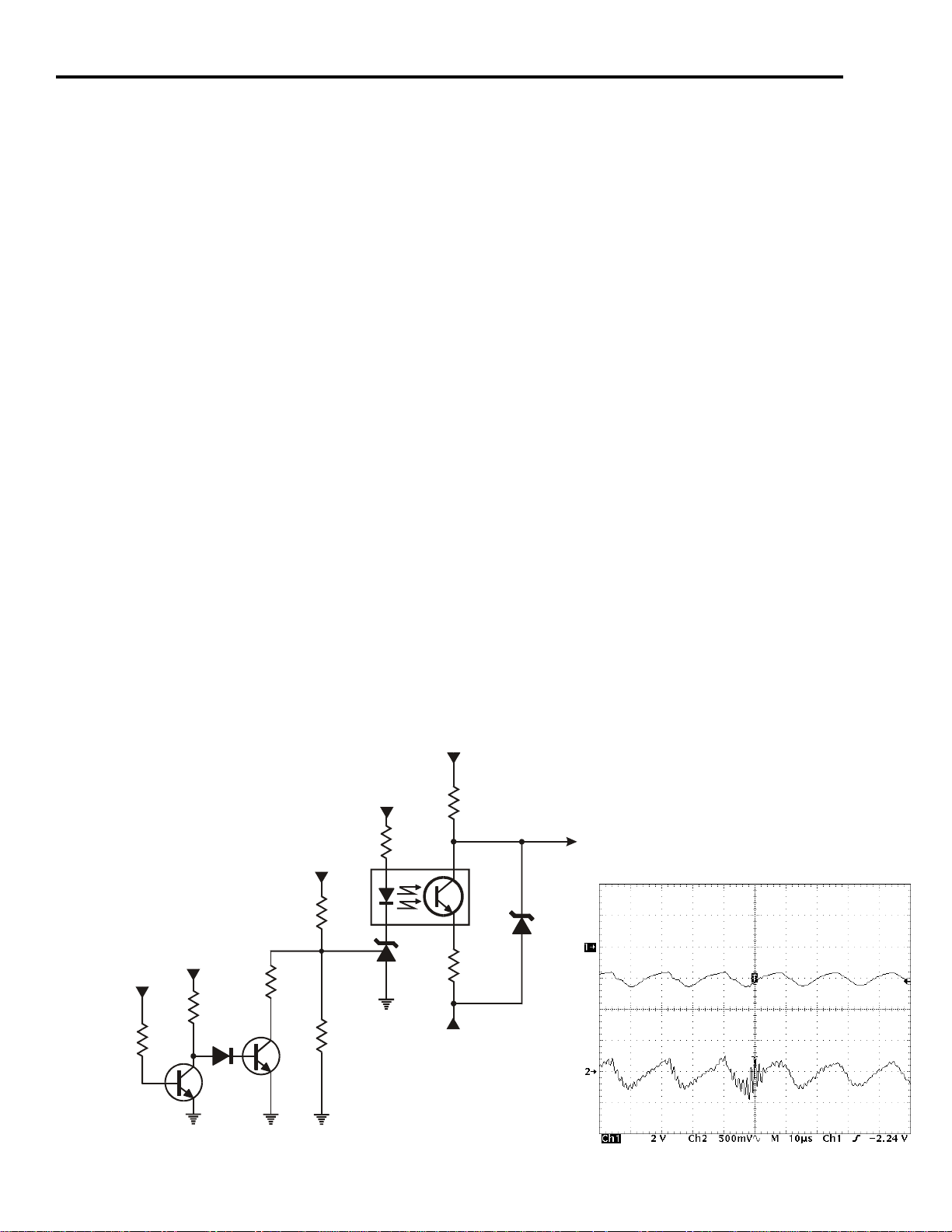

Digital Latches

Before wading deeper into the CTC203 power supply, the technician should become

familiar with the control circuitry used to turn the power output devices on and off. It will

be common to various ZVS supplies used throughout this and other TCE chassis'.

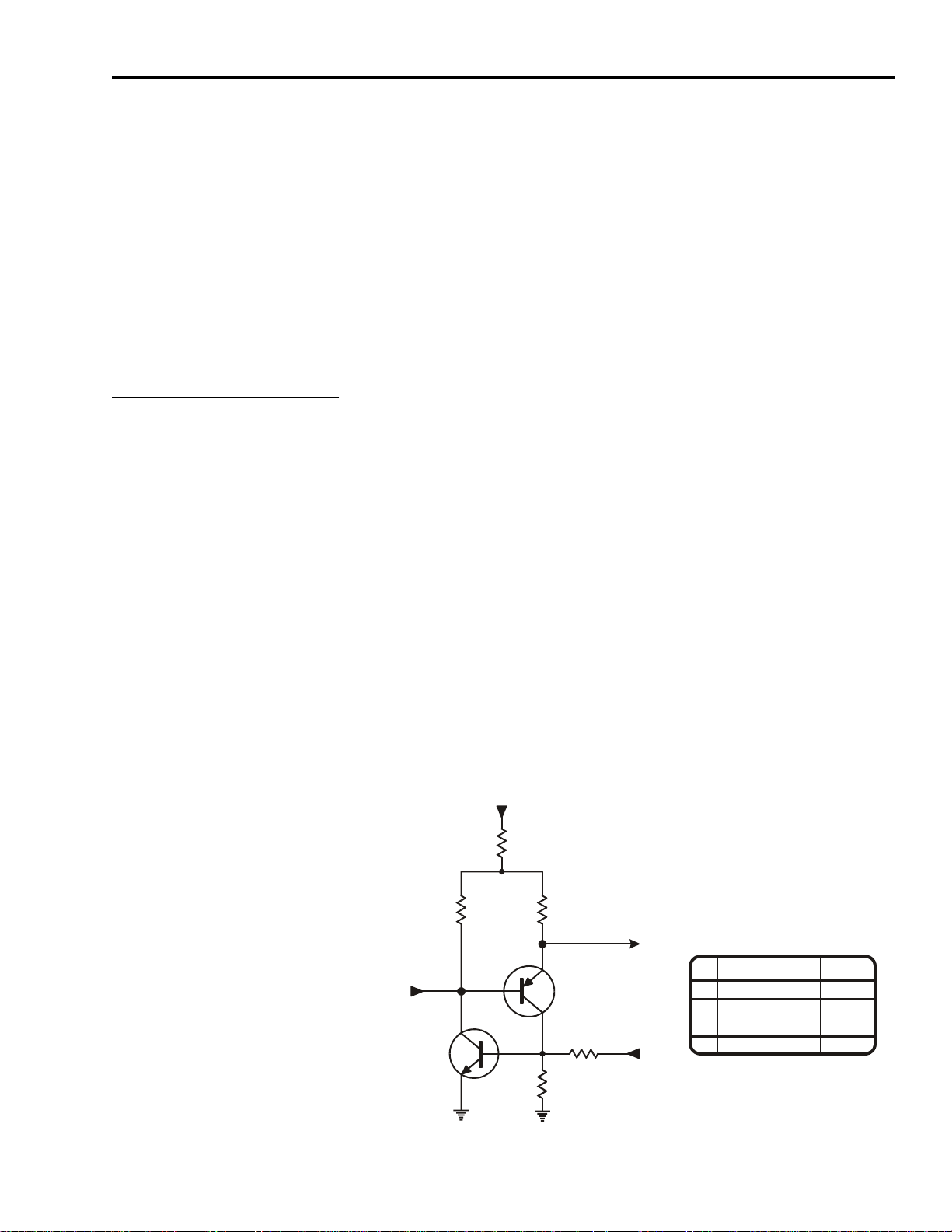

The control switches act similar to an SCR, but with a few variations. Figure 2-3 shows a

truth table and simplified schematic representaion of the power supply control latch shown

in Figure 2-4. Again, while the other ZVS supplies may have slight variations, the basic

concept and operation is the same.

Q1 and Q2 form the basic latch circuit. Both are switching transistors that saturate when

tripped on. In this case an NPN and PNP are used to force the desired results on the output.

The latch is controlled by placing or removing voltages on either base while sufficient

voltage is present on Q2-E to set the latch. Keep in mind

B+ will supply drive to the output

when the latches are off!!! The latch REMOVES the output. Any time the truth table

shows a low (0) condition, output is removed.

In condition A, both IN1 and IN2 are low (0). A low in Q2-B turns it on providing a current

path from B+ through R5, R2, Q2-E/C and R3 to ground. Sufficient bias is developed

across R3 to turn Q1 on, setting the latch. Now, regardless of what happens on IN1, the

latch is set. The combined voltage drop on R3 and Q2-E/C places Q2-E at a very low

voltage, shutting the output off.

If IN2 goes high (1) as in condition B, there will be no effect on the output. The high on

IN2 would turn Q1 on, but since it is already on the result is no change in the output state.

In condition D, both inputs are high. A high on Q1-B turns it on. When it turns on it

saturates, bringing Q2-B low, turning it on. When it turns on the latch is again set and the

output goes low.

Condition C is the most difficult to understand because it relies on the input voltages being

different before the latch is tripped. If IN1 is high, the latch state is dependant upon IN2 for

its output state. If IN2 is low, the output is high. If IN2 is high, the output is low.

However, if the latch is set

(tripped) Q2 saturates and holds

B+

Q1 on even with IN1 high. What

has to happen before the latch

will trip off is the loss of bias on

R5

680K

Q1-B.

As IN2 decreases it begins to

divert current flow away from

R3 and its voltage drop also

begins to decrease. The voltage

on Q1-B will eventually drop low

enough for it to shut off. If IN1

is still high Q2-B is now high

and it also shuts off. This

removes both Q1 and Q2 from

R1

1000

Q2

IN 1

Q1

R3

3300

R2

1000

R4

1000

Out

IN 2

IN1 IN2 O UT

A

00 0

B

01 0

C

11 0

D

011

the circuit and B+ now supplies

the output voltage.

Figure 2-3, Digital Latch & Truth Table

14 Power Supply

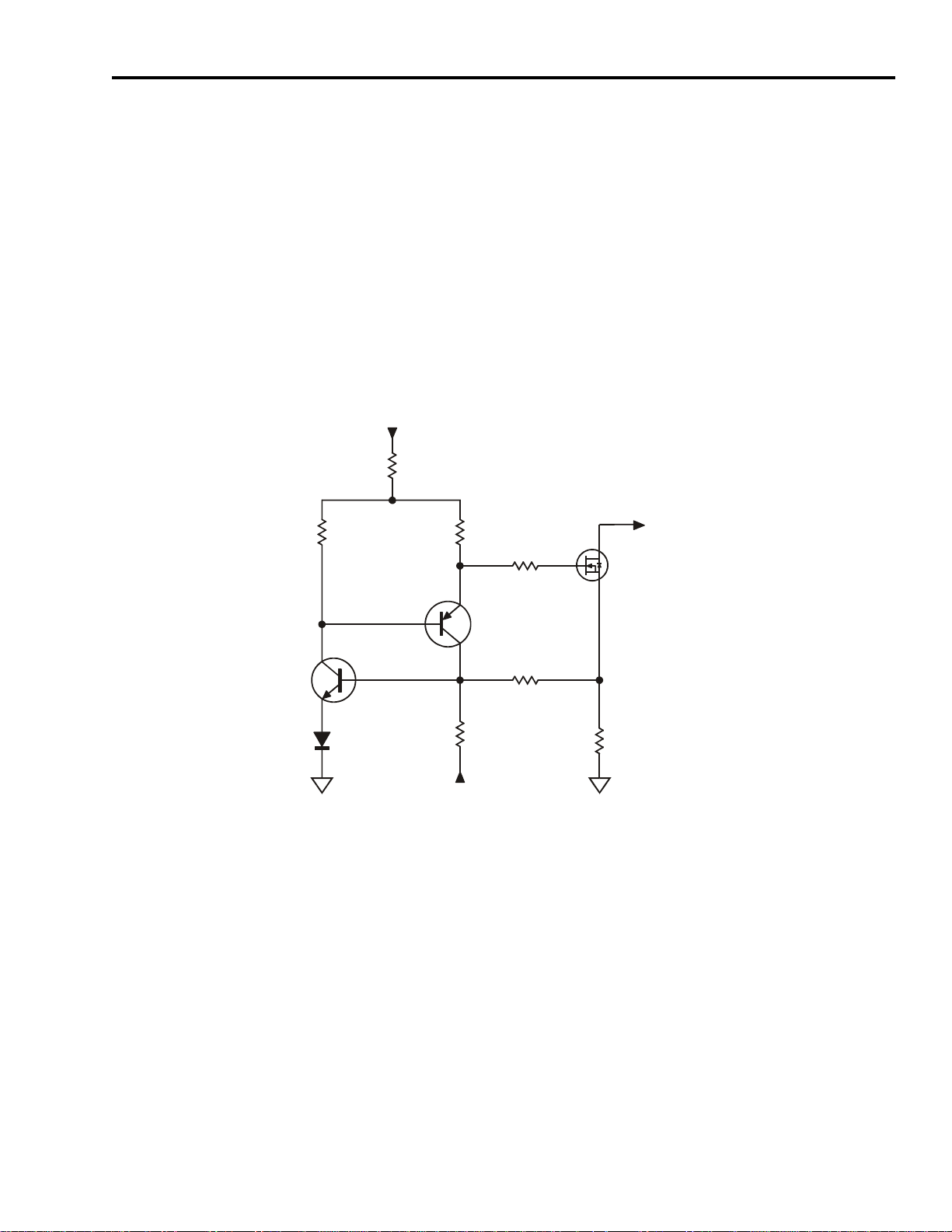

Control Latch Review

Now that the digital latch operation is

understood, it needs to be shown how it is used

to regulate the CTC203 power supply. Using

the simplified digital latch schematic from the

previous page, when IN1 is high, IN2 may be

used to control the output. When IN2 is high,

the output is low. When IN2 is low, the output

is high. In Figure 2-4A, Q1-E is grounded.

Normal PN junction drop of a transistor dictates

that a bias of at least +0.6V must be placed on

Q1-B to turn it on.

B+

R5

680K

R1

1000

Q2

IN 1

Q1

R2

1000

+1.0V

Out

IN 2

In Figure 2-4B a resistor (R5) has been placed

in the emitter circuit of Q1. The resistance of

R5 reduces the amount of current through the

PN junction of Q1E/B with the same voltage

on Q1-B. Thus, to increase current high

enough to turn on Q1, Q1-B voltage must

R5

1000

R3

3300

increase. In this case to about +1.0V.

B+

R5

680K

R1

1000

Q2

IN 1

Q1

R3

3300

R2

1000

+0.6V

Figure 2-4A, Digital Latch Normal

B+

Out

IN 2

Figure 2-4B

In Figure 2-4C Q1-E is connected to a

negative 5V supply. The current to turn

the PN junction of Q1 on remains the same.

Now the voltage on Q1-B need only be

0.6V higher than Q1-E, or about -4.4V.

In this manner, the voltage that triggers Q1

may be varied and used to control the output

of the latch. By understandby this circuit,

the regulation and protection of the power

supply may be more fully understood.

IN 1

R1

1000

Supply

Q2

Q1

-5V

Figure 2-4C

R5

680K

R2

1000

Out

-4.4V

IN 2

R3

3300

Latch Circuit

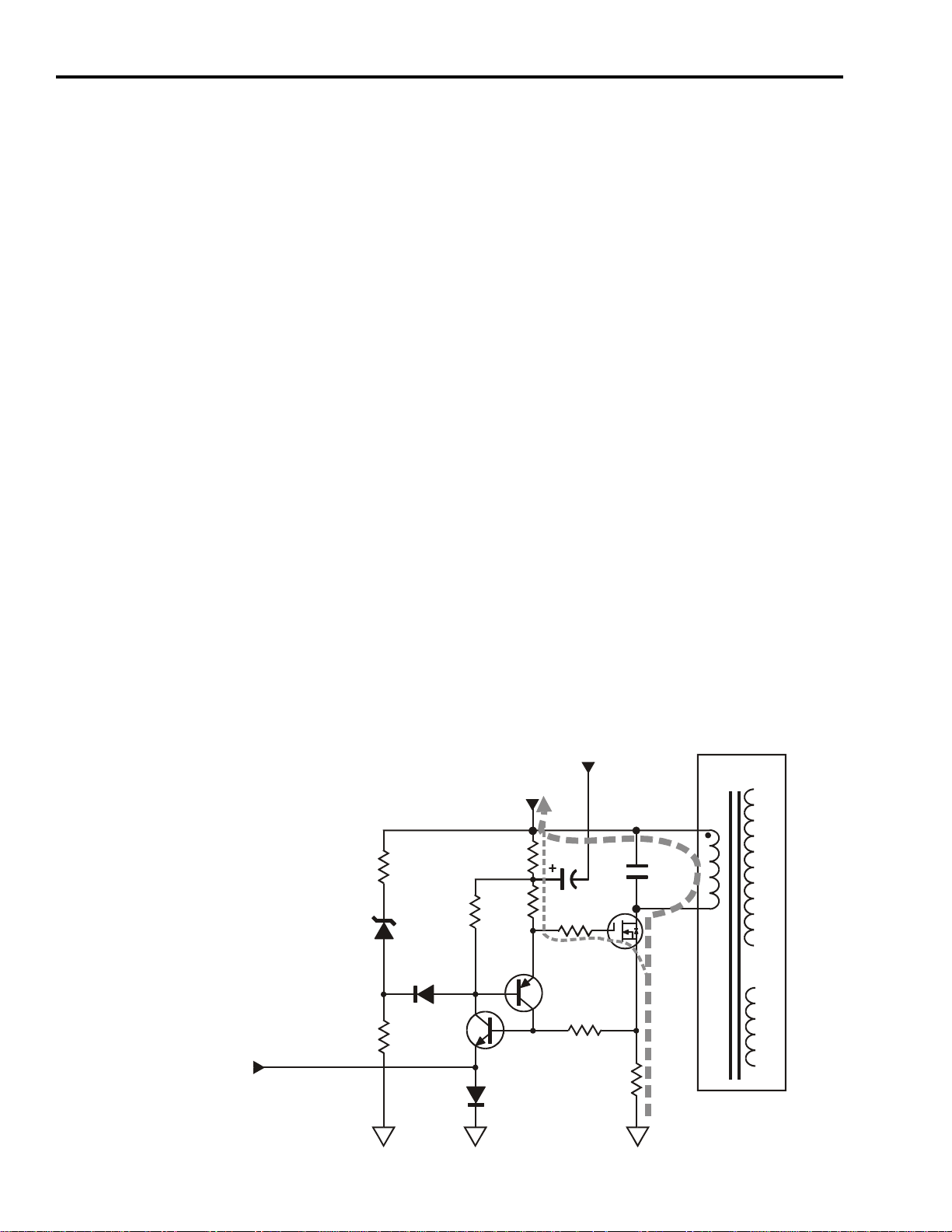

Figure 2-5 is the control latch for the CTC203 power supply. It is not much different

from the simplified schematic in Figure 2-3, however there are some additional

circuits that will need to be discussed later.

When power is first applied to the chassis, Raw B+ is available on the "IN1" line at

the junction of Q14103-C and Q14102-B. Since there is no bias difference from

Q14102B-E, it is off and the latch is off. Raw B+ now supplies gate drive to the

output device Q14101-G, turning it on providing output transformer current. At this

time, "IN1" is high, IN2 is low and the latch is off, allowing gate drive.

As current builds in the output device, a voltage is developed accross R14108.

When this voltage increases enough, it will bias Q14103 on, which also turns on

Q14102, setting the latch. A current path now exists between Raw B+, R14103,

R14106, Q14102-C/E, R14110 and a negative bias voltage developed from the

output transformer.

R14104

3300

Raw B+

R14103

1Meg

R14106

1000

OUT

R14107

43

To Output

Transformer

T14101

Q14101

Power Supply 15

Q14102

IN1

Q14103

R14109

750

IN2

R14110

CR14105

22K

Positive Bias

Supply

Figure 2-5, Power Supply Control Latch

Once the latch is set, Q14102-E voltage and output drive is removed and the output

device, Q14101 shuts off. With output current dropping, the corresponding voltage

drop across R14108 begins to decrease along with the negative bias supply. At some

point the voltage at Q14103-B drops low enough to allow it to turn off. When it

does, bias is removed from Q14102-B and it shuts off. When it shuts off, gate drive

is again allowed to turn the output device, Q14101 on and output current begins to

build once more.

As the power supply circuits develop, it will be seen that by either varying the bias

voltage on Q14103-B while maintaining the voltage on Q14103-E, or varying the

bias on Q14103-E, while maintaining the voltage on Q14103-B, the on/off time of

the latch can be controlled precisely. Controlling the latch means output current is

also controlled. The off time of the latch is reasonbly constant. It is the "on" time of

the output that controls the supply voltages.

R14108

0.1

3W

16 Power Supply

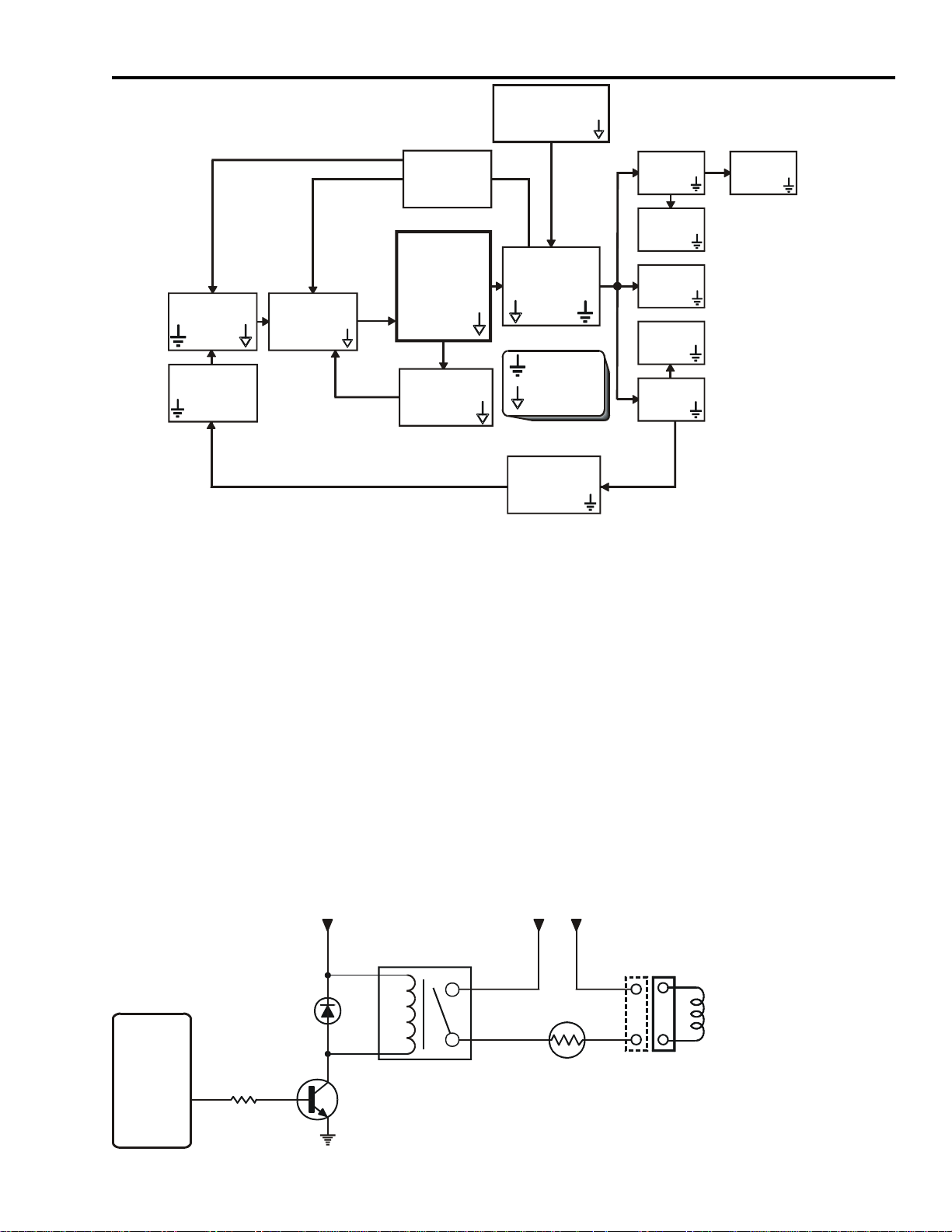

Main Supply Block Diagram

The Main Supply distributes power to all devices that need to remain "alive" when

the chassis is "off". In addition, it must retain enough power to keep the

microprocessor active during a power failure event long enough to exercise the

"batten down the hatches" routine leading to a graceful shutdown of the chassis

before power disappears completely. ("Batten" is a software routine which stores

off all customer settings and chassis alignments to the EEPROM. This enables the

set to start normally after a catastrophic power failure.)

The voltages available during standby operation are:

•-12 volts

•+5.2 volts

•+7.6 volts

•+16 volts

•+33 volts

•Reg B+

The supply converts raw B+ from the incoming AC line into the various DC supplies

required by the CTC203. There is a "Data Acquisition" mode requiring greater

current supply demands from the supply than normally needed during standby, but

less than is needed during full run operation. For instance, during a TVGuide+

download, there is no reason for the set to display a picture, however, the tuner must

be active to receive the signal. This requires more current from Reg B+ from which

the +33V supply is derived.

Since the forward conduction mode is used, the driver current is proportional to the

supply current and higher frequencies (70-90 kHz) may be used for greater efficiency.

The standby supply may be broken into several sections according to Figure 2-5.

The Latch circuit (discussed previously) consists of Q14102 and Q14103. They

control the off/on time of the output device, Q14101.

Current in the output power transformer, T14101, transferred to the secondary, is

used to generate the various supplies from Raw B+ provided by the main rectifier

from incoming AC.

The regulator, U14102 and opto-isolator, U14101 provide regulation of the +16Vs

supply and isolation between the cold ground run supplies and the hot ground

generator circuit components.

Overcurrent and overvoltage protection of the output device is provided by resistor

R14108 in series with Q14101.

Raw B+

Power Supply 17

OPTO-ISOLATOR

U14101

PRECISION

REGULATOR

U14102

CONTROL

LATCH

Q14102/103

BIAS

SUPPLIES

POWER

OUTPUT

Q14101

OVER-CURRENT

OVER-VOLTAGE

R14108

OUTPUT

POWER

TRANSFORMER

T14101

Cold Ground

Hot Ground

Reg B+

Feedback

+16Vr

+5.2Vs

-12Vr

+33Vs

Reg B+

+7.6Vr

Figure 2-6, CTC203 Main Supply Block Diagram (Standby Voltages)

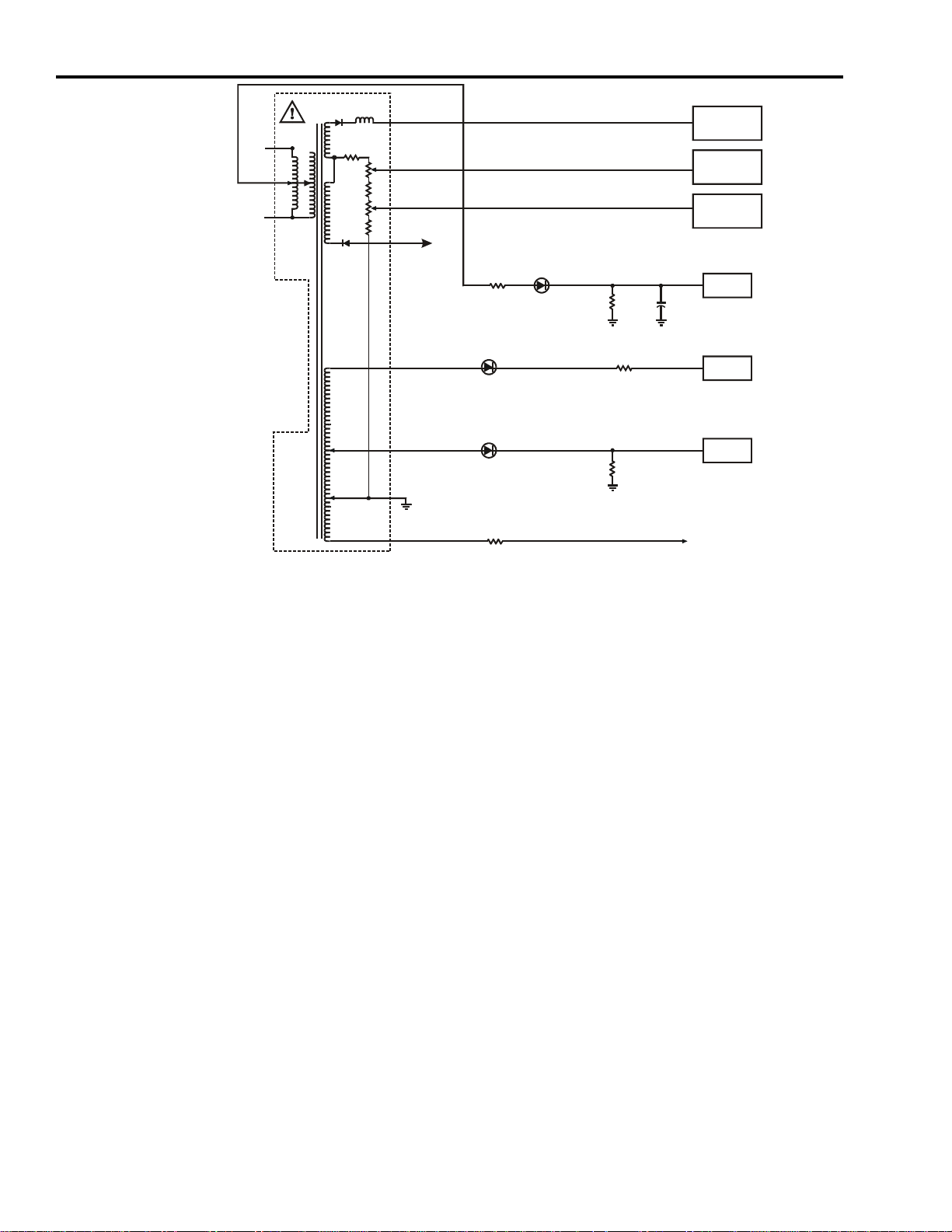

AC Input and Degaussing

Raw AC is connected using protection (F14200) and filtering/smoothing components

to assure spikes and unexpected surges do not cause catastrophic failure.

Degaussing may only be done when the +12V run supply is active. System Control

sends a high out during startup turning on Q14201. As long as the +12Vr supply is

up, relay K14201 is turned on activating the contacts on pins 3 & 4. Current from the

AC line is now routed to the degaussing coil. Degaussing occurs as long as thermal

resistor RT14250 allows. It provides an exponential decay of current to the degaussing

coil. Degauss current must be allowed to decay before the relay stops all degauss

coil current to allow proper degaussing, otherwise color non-uniformity will result.

When System Control removes the active deguass signal, Q14201 shuts off, removing

drive current from the relay coil, breaking the contacts and removing AC power

from the degaussing coil. The degaussing cycle is then complete.

Figure 2-7, Degaussing

From Incoming

AC Line

RT14201

DEGAUSSING

COIL

J14203

U13101

SYSTEM

CONTROL

45

Degauss: High

R14206

1000

CR14250

+12VrSW

Q14201

1

2

K14201

4

3

18 Power Supply

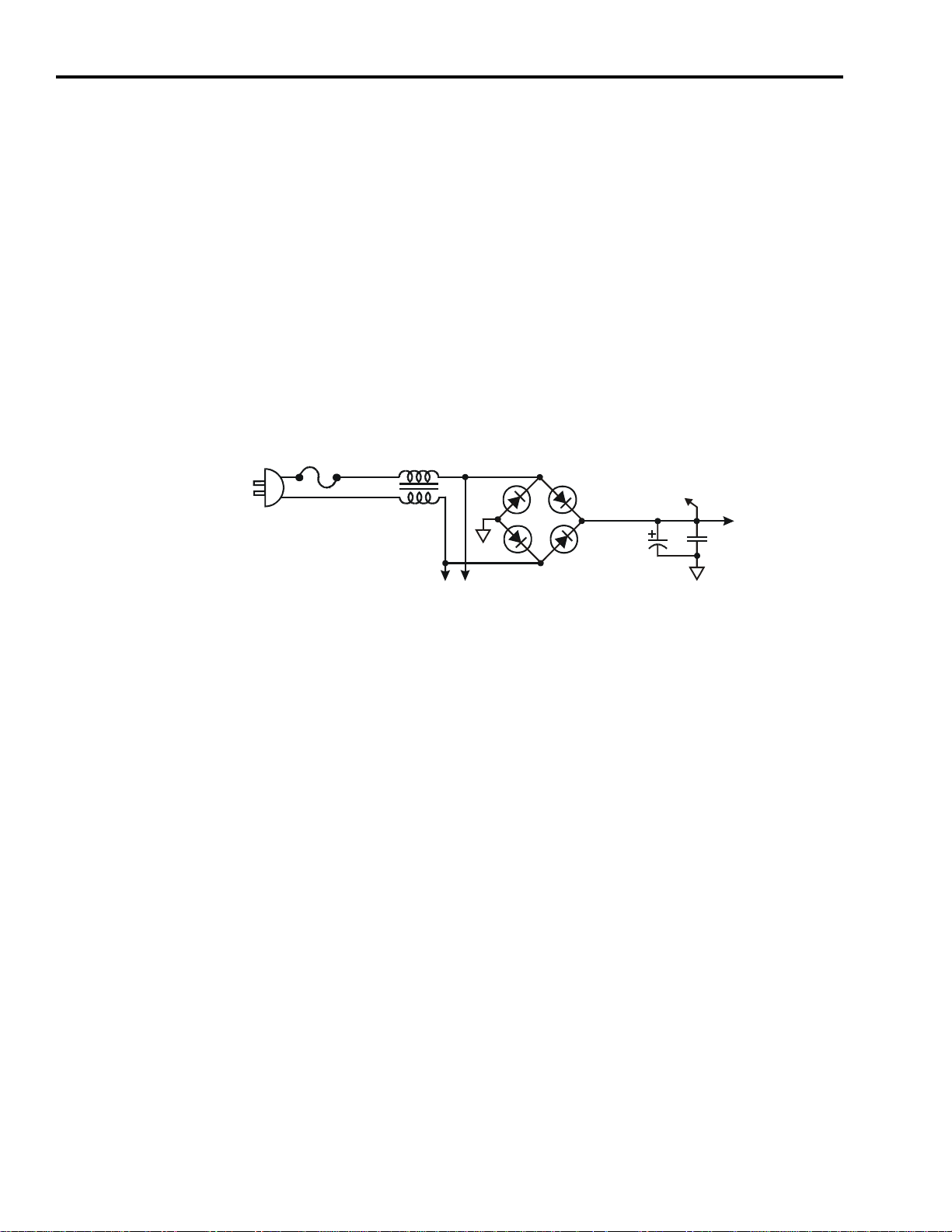

Raw B+

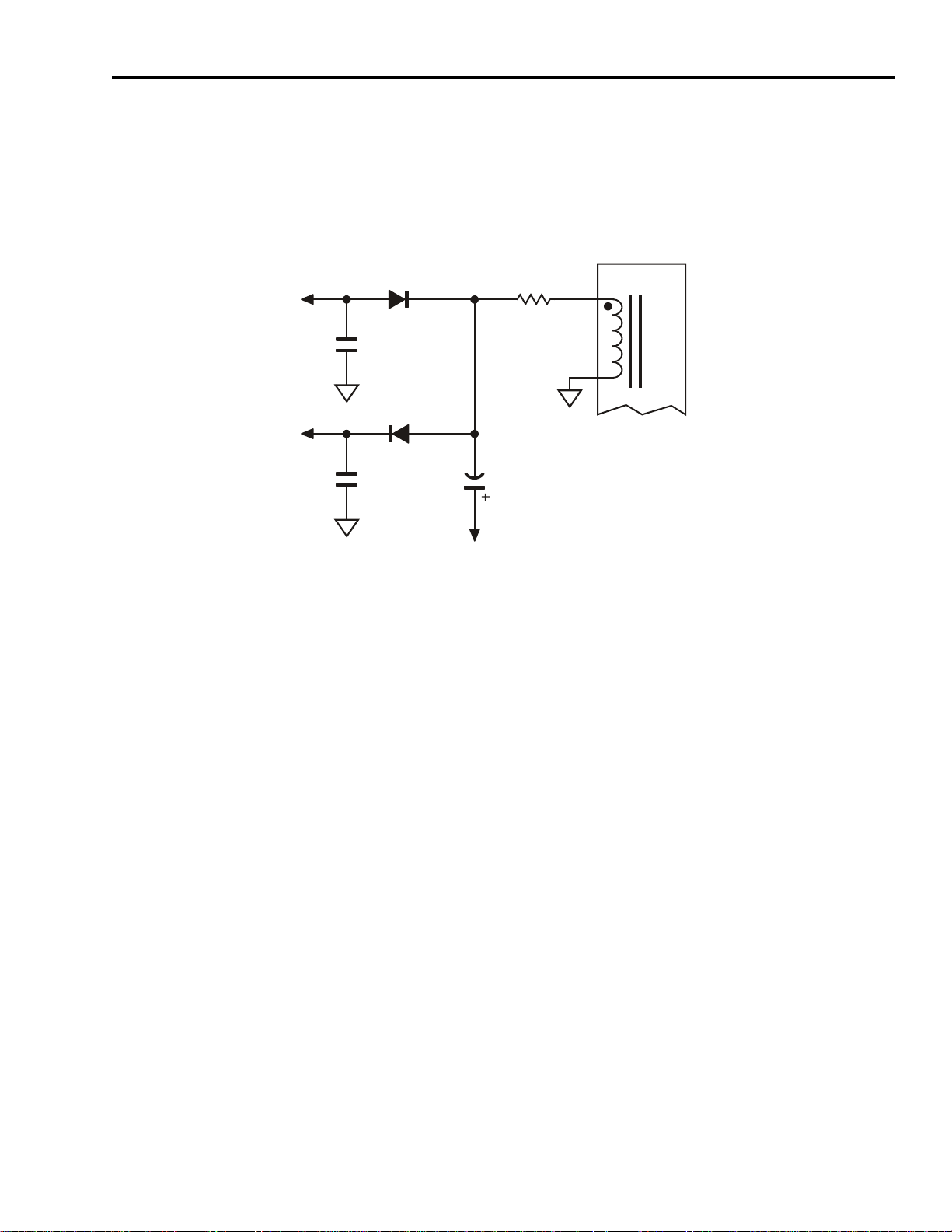

Incoming AC (95 - 135 VAC) is input through an LCI (Line Conducted Interference)

filter consisting mainly of T14201 and several filter capacitors. Raw B+ is generated

from the incoming AC by a discrete bridge rectifier circuit consisting of CR14201,

CR14202, CR14203 and CR14204. Main power supply input voltage is 95-135

VAC to provide a Raw B+ voltage of about +156V depending upon the chassis

version. Generally, larger screen sizes will require higher raw B+.

F14201

120VAC

5A

T14201

To DeGauss

Circuit

CR14201CR14202

TP14210

Raw B+

C14205

680uF

CR14203CR14204

156VDC

C14206

0.012

Figure 2-8, AC Input

Power Supply 19

+13Vr

R14128

680K

+16Vs

R14127

10K

CR14111

Q14107

R14115

143K

R14126

37.4K

Q14106

RegB+Vs

R14116

2000

+16Vs

R14113

1300

U14101

U14102

R14112

680

Pos Hot

Bias Supply

Neg Hot

Bias Supply

CR14101

Pos Hot

Bias Supply

R141111

Neg Hot

Bias Supply

Bias Supplies

C14104

0.047

C14108

0.047

R14101

47K

R14104

CR14102

R14102

6800

3300

Q14103

CR14105

10K

47V

CR14117

16V

Control

CR14103

CR14104

R14103

1Meg

R14106

2000

R14110

22K

RAW B+

C14101

2.2uF

R14107

43

Q14102

R14109

750

R14105

10

C14108

1100

1.6KV

Q14101

R14108

0.1

3W

Drive

3

8

9

5

T14101

C14122

33uF

C14114

3.3uF

L14102

R11513

4700

CR11504

18V

Output

C14122

33uF

R14124

3.3

2W

CR14110

U14103

+5.2V

Reg

Q11501

CR11505

+12VrSW

Reg B+

+33Vs

+16Vs

+7.6Vs

+5.2Vs

-12Vs

-12Vr

-12V

Fil

CR14106

16

CR14108

C14121

3.3uF

CR14107

C14116

47uF

33V

14

15

13

NC

10

11

12

Feedback/Regulation

Figure 2-9, Main Power Supply

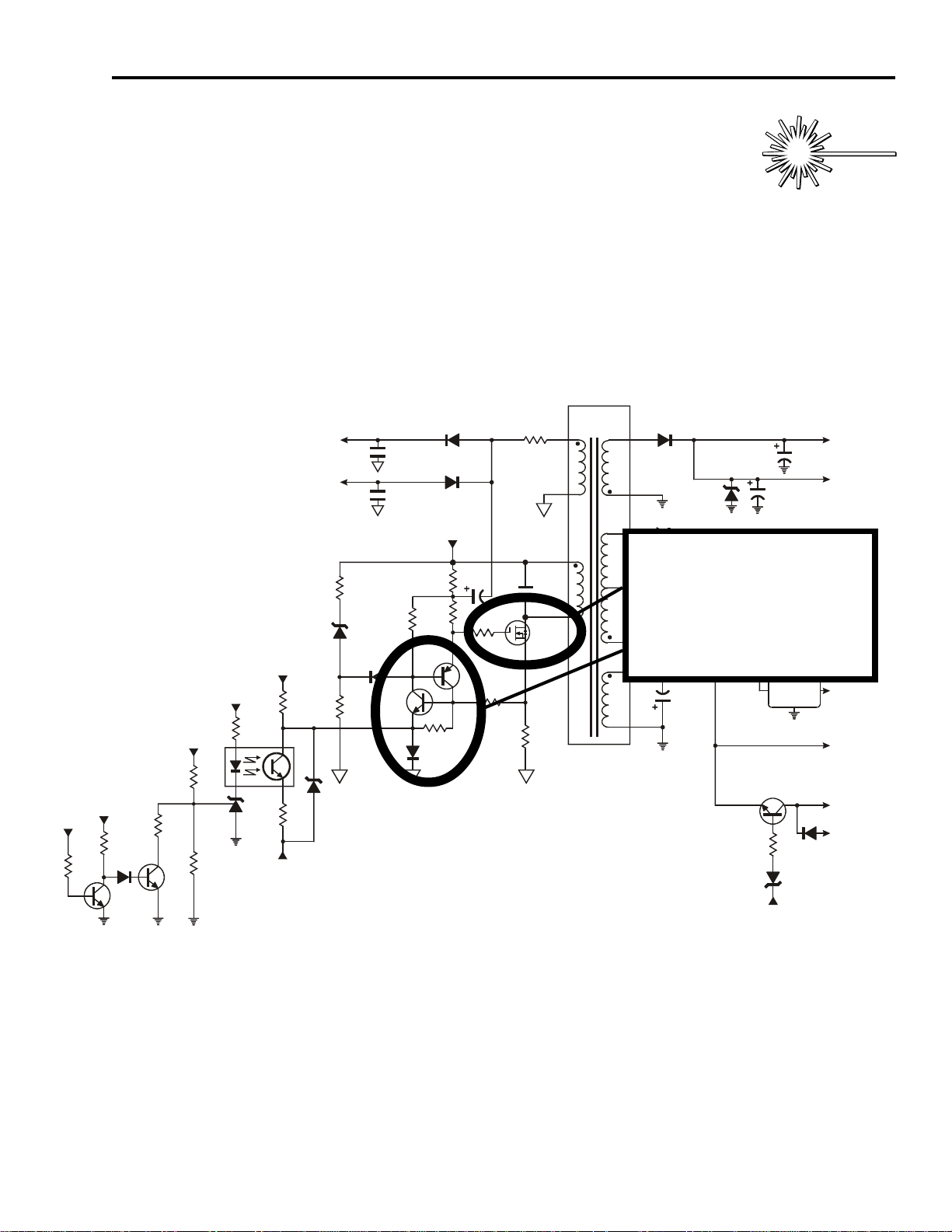

Main Supply Operation

To simplify the understanding of the standby supply (shown in Figure 2-9), it will be

broken down into smaller blocks. These blocks operate somewhat independently,

but ultimately must all function together for proper operation of the supply.

The sections are:

Output

Drive

Control

Feedback/Regulation

Bias Supplies

20 Power Supply

Standby Supply Startup

A voltage divider network from Raw B+ consisting of R14103 and R14107 provides

the initial positive gate voltage for output MOSFET Q14101 to begin conduction. As

current begins to flow in the output transformer T14101, winding 3/8, feedback current

is induced to windings 1/2. This winding provides several bias voltages to the supply

drivers and feedback circuit, but initially is used to increase the gate voltage, using

C14101 to couple the transformer to the gate. The voltage at pin 9 is increasing in a

positive direction as current increases in the primary. This rising voltage eventually

causes the output, Q14101, to saturate, beginning the first cycle of operation.

As current through Q14101 increases, the voltage drop across current sense resistor

R14108 increases until a threshold is reached. (This threshold is discussed in the

control latch section.) At the time the threshold is reached, the regenerative switch

(latch circuit) consisting of Q14102/Q14103 turns on, removing gate drive from output

device Q14101.

Current flow through Q14101 drops quickly to zero and energy stored in the transformer

primary winding is transferred to C14108 which charges with the negative potential at

Q14101-D. This rising voltage appears across the secondary winding.

When the secondary side of the transformer conducts, the energy stored in the primary

of T14101 is delivered to the secondary supply capacitors and the load. After the

secondary diodes stop conducting, energy still contained in C14108 drives the drain

voltage of Q14101 toward zero. When the drain voltage attempts to go below zero, an

internal diode clamps it near ground.

Now the voltage of T14101 drive winding, 5/9, goes positive and if the latch circuit

allows it, will turn on Q14101 and the next cycle begins. Once the initial startup pulse

from Raw B+ starts the cycle, this bias supply takes over and continues to supply gate

drive to the output device.

Bias Supply

from T14101

From

Regulator

Circuits

CR14101

47V

R14102

6800

R14101

47K

R14104

CR14102

Q14103

CR14105

3300

RAW B+

R14103

1Meg

R14106

2000

Windings 9/5

C14101

2.2uF

R14107

43

Q14102

R14109

750

C14108

1100

1.6KV

Q14101

R14108

0.1

3W

Part of

T14101

3

8

Figure 2-10, Power Device Start up Current Flow

RAW B+

C14101

2.2uF

R14107

43

R14108

0.1

3W

Bias Supply

Windings

C14108

1100

1.6KV

Q14101

9

5

3

8

T14101

Power Supply 21

CR14106

16

C14122

33uF

C14114

3.3uF

L14102

R11513

4700

CR11504

18V

C14122

33uF

R14124

CR14110

Q11501

3.3

2W

U14103

+5.2V

Reg

CR14108

C14121

3.3uF

CR14107

C14116

47uF

33V

14

15

13

NC

10

11

12

Reg B+

+33Vs

+16Vs

+7.6Vs

+5.2Vs

-12Vs

-12Vr

-12V

Fil

Figure 2-11, Main Supply Output

+12VrSW

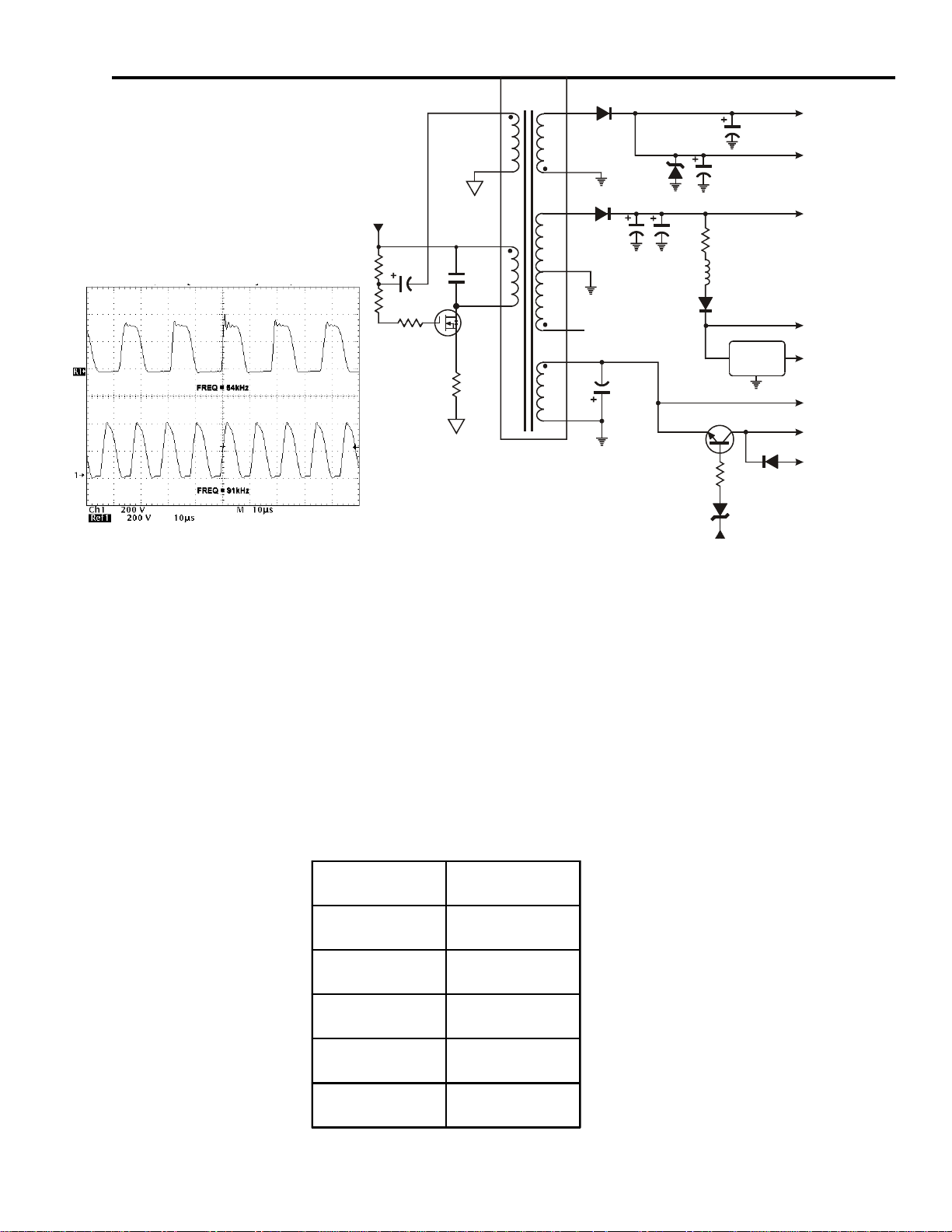

Output

Q14101 provides all transformer primary winding drive current. It is a power mosfet

which conducts current from source to drain when the gate voltage is high. Once on,

gate voltage must be reduced to around zero or the drain-source current path must be

interrupted to stop output current. During conduction, current flows from common

(hot) through R14108, Q14101 and T14101 primary winding to Raw B+. C14108 is

used to "tune" the resonant frequency of the primary for better power transfer.

Normally this frequency is around 90kHz during standby and 40-60kHz during run

operation. Figure 2-11 shows the driver and output voltages and a waveform

comparing Q14101-D outputs in standby and run mode. As current flows through

the primary, flux lines induce current flow into secondary windings 5/9, 11/12,

13/15 and 14/16. Typical AC voltages generated from the windings are shown in

Figure 2-12.

T14101 Pin# AC Voltage

3/8 400 p-p

5/9 15 p-p

11/12 26 p-p

13/15 35 p-p

14/16 250 p-p

Figure 2-12, Typical Secondary Winding Voltages

22 Power Supply

R14104

3300

IN1

Raw B+

Q14103

R14103

1Meg

R14106

1000

OUT

IN2

Q14102

R14107

43

R14109

750

To Output

Transformer

T14101

Q14101

CR14105

R14110

22K

Positive Bias

Supply

R14108

0.1

3W

Figure 2-13, Main Supply Output Drive Control

Standby Supply Drive

To assist the understanding of the control circuit, this discussion will not take the

positive bias supply in consideration at this time. Operation of the control circuit

will be identical.

At initial startup, R14103 provides the gate voltage to turn Q14101 on, providing

primary current. As Q14101 begins to conduct, primary winding current increases,

increasing voltage across the winding and inducing current flow to all secondary

windings. Q14101 quickly saturates.

R14108 monitors the primary winding current, which is also the current through the

output device, Q14101. As this current increases, the corresponding voltage drop

across R14108 increases. When it reaches a voltage high enough to turn Q14103 on,

the latch "sets" stopping drive to the output, Q14101. It does this do to a current path

from common through CR14105, Q14103-E/B, Q14102, R14106 the gate drive

being developed by C14101 and T14101 windings 5/9. Q14102 emitter drops to a

low voltage, shutting the output device Q14101 off. This cuts current flow to the

primary of T14101. Without drain current, drain voltage now increases due to back

EMF across the transformer windings. The secondary diodes conduct and power is

delivered to the loads. C14108 helps shape the waveform, limiting conduction time

as Q14101 shuts off and drain voltage is driven to zero.

Two things are now happening. First, with Q14101 now off, primary current flow

begins to decrease. Second, with current flow in the primary and output stopped, the

voltage across R14108 now decreases below the bias point of Q14103 and it shuts

off, shutting off Q14102. The bias supply developed from T14101-5/9 and C14101

now supplies gate drive and the output, Q14101 turns back on. The process now

begins again.

Bias Supplies

There are two supplies generated during standby supply operation used to internally

bias the control and regulation components of the supply. Both cycles of the

transformer waveform are utilized to provide a positive and negative supply voltage.

These voltages vary with respect to the current flow in the primary winding of

T14101 but should normally be within the 5 to 10 volt range, positive and negative

respectively. An unrectified pulse is used as the initial gate pulse to saturate the

output device.

Negative Supply

Source

(app -5 to -15V)

CR14104

C14066

0.047uF

R14601

100

T14101

9

5

Power Supply 23

Positive Supply

Source

(app +5 to +15V)

CR14105

C14103

0.047uF

C14101

2.2uF

To Q14101-G

Figure 2-14, Bias Supplies

Standby Supply Control

Without some form of regulation, the power supply will quickly reach a nominal

output voltage using the control circuit in Figure 2-13. Figure 2-15 again shows the

control circuitry, but adding regulation to keep the output voltages from the secondary

of the supply within design limits. Load variations are constant and there is the

problem of loads outside the normal expected variations to deal with. The main

supply is required to provide standby and run power to some circuits, further

complicating load demands.

All this means that the supply must be regulated and protected against overload

conditions. An opto-isolator protects the "hot" primary side of the supply from the

"cold" secondary side and is also used for regulation.

Referring back to Figure 2-13, it may be seen that by varying the on/off time of the

latch, Q14102 and Q14103, output current can also be varied. For instance, the trip

voltage required to turn Q14103 on with diode CR14105 in its emitter circuit is

about +1.2V. This assumes a PN junction IR drop of 0.6V for the diode and 0.6V for

the emitter-base junction of the transistor. If a second diode were placed in series

with CR14105, the trip voltage would now be +1.8V. (Of course, with the added IR

drop of R14109, the voltage would need to be greater.) If CR14105 were removed,

the trip voltage now would be lower by 0.6V or about +0.6V.

Now it can be seen that regulating the output current by varying IN2 is a matter of

either increasing the voltage on Q14103-B, or lowering the voltage on Q14103-E.

Either method achieves the same results. This technique may be used to provide

regulation of output current.

24 Power Supply

Main Power Supply Regulation

To provide regulation of the control latch which in turn varies the secondary

voltages, a regulation circuit is used. Since the regulator is monitoring secondary

voltages which use "cold" ground, and manipulating circuits on the primary or "hot"

side of the power supply transformer, the regulator must also provide isolation.

Initially, a bias voltage is set up on Q14103-B by a voltage divider network between

the positive and negative bias supplies. R14112, the output of U14101 and R14111

make up this network. Since the supplies are constantly changing do to primary

current, they are difficult to measure, however when operating normally the nominal

voltage on Q14103-B is very close to zero.

A feedback voltage, Reg B+, is used to monitor the secondary voltages generated by

the main supply. If Reg B+ increases such that the junction of R14115 & R14116

rises above +2.5 volts, the internal impedance of U14102 (See the Tech Tip on this

new device) decreases. Increased current through the device turns on

opto-isolator, U14101 harder and the output impedance of this device decreases.

This output is in the voltage divider network between the negative and positive bias

supplies. As the impedance decreases, the voltage on Q14103-E goes more negative.

It now takes less voltage on Q14603-B to trip the control latch to the "ON"

condition. Remember that when the latch is on, gate drive is removed from the

output device, Q14101, and output current stops. Secondary supply voltages begin

to drop.

R14128

680K

+13Vr

The waveform shows voltage levels on the emitter of U14101 (Top) and the collector

(Bottom). The emitter is essentially the negative supply ripple. The DC level is

about -11V. The internal impedance of the output section is increasing and decreasing

at such a rate that under normal load levels it fluctates closely around 0V.

Pos Hot

Bias Supply

+16Vs

R14127

10K

CR14111

Q14107

R14115

143K

R14126

37.4K

Q14106

+16Vs

R14113

1300

Reg B+

U14101

U14102

R14116

2000

R14111

10K

R14112

680

Neg Hot

Bias Supply

To Control

Q14103-E

CR14117

16V

Figure 2-15, Standby Supply Regulation

Power Supply 25

When Reg B+ drops sufficiently, the junction of R14115 & R14116 drops below

+2.5V. Now the internal impedance of U14102 increases. As it increases, the output

section of the opto-isolator, U14101 is driven less and its impedance also increases.

The voltage on the collector of U14101 now goes towards the positive supply. This

voltage is also on Q14103-E. It now takes more voltage on Q14103-B to turn the

control latch off. Gate drive is allowed on the output, Q14101 and primary winding

current is again available in T14101. As current in the primary increases, voltage in the

secondaries also increases and the cycle repeats.

If a failure occurs in the regulation circuits such that the output of U14101 opens, the

positive hot supply is placed on Q14103-E. Output current is now stopped only by the

overvoltage/overcurrent protection provided by R14108, which is acting as a current

monitor for the output device.

If the failure mode shorts U14101 output or places it in a low impedance mode, the

negative hot supply, only limited by R14112 appears on U14101-C and thus Q14103-E.

It now takes very little output current to trip the latch and remove output drive. All

supplies will be reduced and not maintain any regulation.

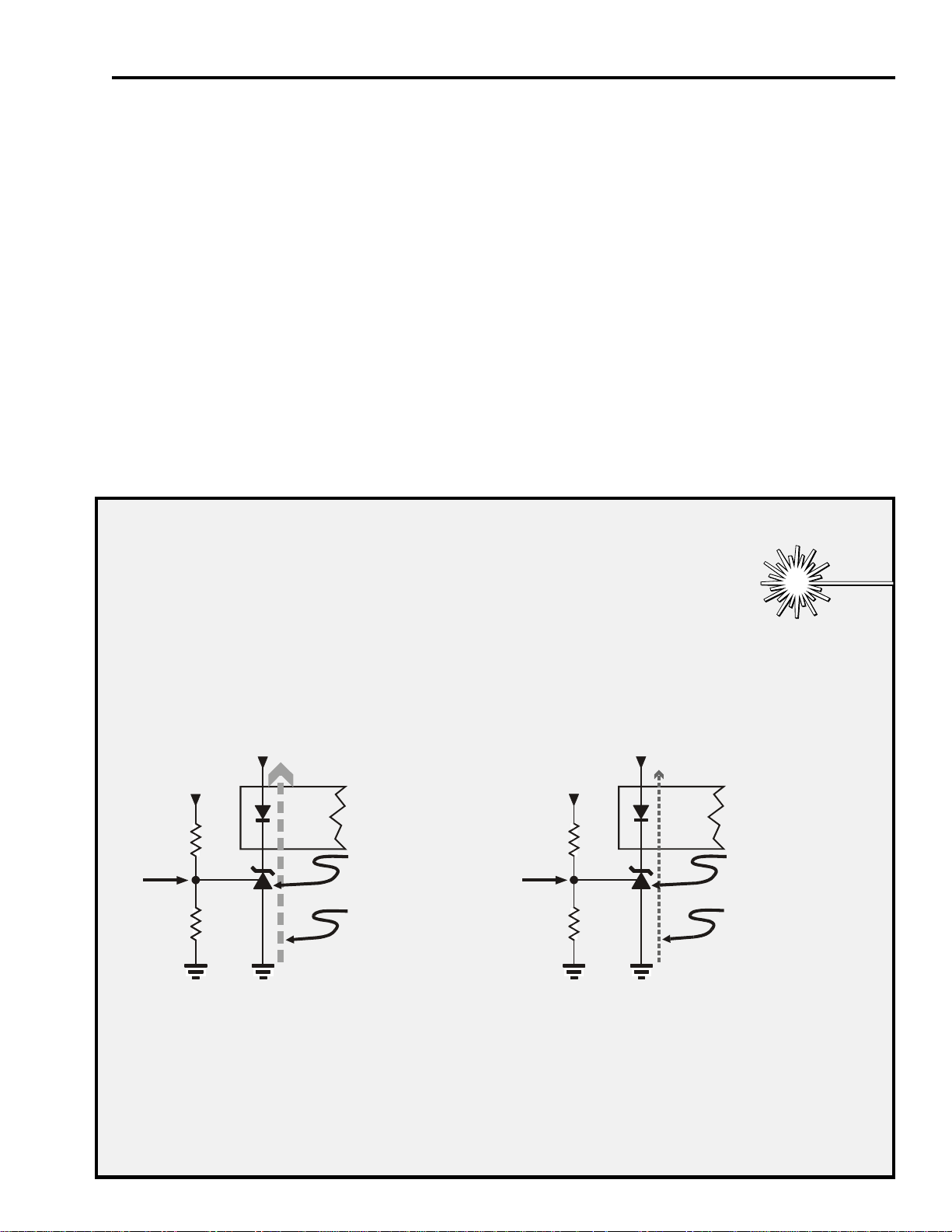

Precision Shunt Regulator

The three terminal precision shunt regulators used throughout the various supplies

of the CTC203 are unique devices. They may be thought of as "gated" zener

diodes, or infinite gain operational amplifiers with a reference voltage tied to the

negative input. In both cases, for the CTC203 chassis, 2.5V is the reference

voltage.

Figure A shows the regulator when the reference voltage on pin 1 is above 2.5V. The

regulator conducts, its internal impedance decreases, and current through the device

increases.

>2.5

R14115

143K

0.1%

R14116

2000

0.1%

Reg B+

U14102

+16Vs

1

3

2

U14101

Decreased

Internal

Impedance

Increased

Current Flow

Reg B+

R14115

143K

0.1%

<2.5

R14116

2000

0.1%

U14102

+16Vs

1

3

2

U14101

Increased

Internal

Impedance

Decreasing

Current Flow

TECH

TIP

Figure A Figure B

Figure B shows the regulator when the reference voltage on pin 1 is less than 2.5V. The

internal impedance of the regulator increases and current flow through the device

decreases.

In both cases, the current through the regulator directly drives the LED side of the

opto-isolator. As this current increases, the output impedance of the opto decreases.

As current decreases, the output impedance increases.

26 Power Supply

Run Mode

In order to supply the different current demands between standby and run modes, the

main supply monitors the +13Vr supply generated from scan. If the supply is

running, Q14107 is on, turning off Q14106. This removes R14126 from the

regulator circuit and supply operates normally.

When scan is lost, the +13Vr supply is removed turning off Q14107. This turns on

Q14106 placing R14126 in parallel with the second regulator network resistor

R14116. This effectively lowers the resistance of the pair. It takes less Reg B+

voltage to trip the latch and current in the output transformer is decreased.

Pos Hot

Bias Supply

R14128

680K

+13Vr

+16Vs

R14127

10K

CR14111

Q14107

R14115

143K

R14126

37.4K

Q14106

+16Vs

R14113

1300

Reg B+

U14101

U14102

R14116

2000

R14111

10K

R14112

680

Neg Hot

Bias Supply

To Control

Q14103-E

CR14117

16V

Figure 2-16, Run Mode

For instance, during normal operation, only R14116 and R14115 are in the feedback

voltage divider. If Reg B+ increases, the sample voltage at the gate of U14102

increases, output current decreases and Reg B+ begins to fall. If it falls such that the

voltage divider drops below the expected voltage level, output current is increased to

raise Reg B+.

When the set is in standby mode, the load on the secondary supply is greatly reduced

and Reg B+ tends to increase beyond the supplies ability to properly regulate it. By

placing R14126 in parallel with R14116 Reg B+ can go considerably higher than its

design while the sample voltage at U14102 remains the same.

The result is Reg B+ is allowed to be higher than normal by a fixed percentage based

on the parallel resistance of R14126 & R14116. That same percentage applies to the

remainder of the secondary voltages, but since the percentage is small, their regulation

will not be greatly affected. Reg B+ is not used during standby so it may be allowed

to float considerably above its required voltage. In effect, the parallel resistance

raises the target voltage (Reg B+) being regulated.

Power Supply 27

+16Vs

ON\OFF

From Micro

U13101-19

RUN: High

Standby: Low

R14121

1000

Q14104

R14123

470

1W

Q14105

U14104

1

+12V REG

3

2

R14156

51

1/2W

R14151

8.2

1W

R14157

1/2W

12

75

R14159

3

C14118

10uF

CR14116

9.1

U14150

+7.6V REG

3

Q14115

47

CR14115

U18101

+3.3V REG

1

5.6

2

+12Vr

+9Vr

+7.6Vr

+5Vr

+3.3Vr

Figure 2-17, Run Supplies

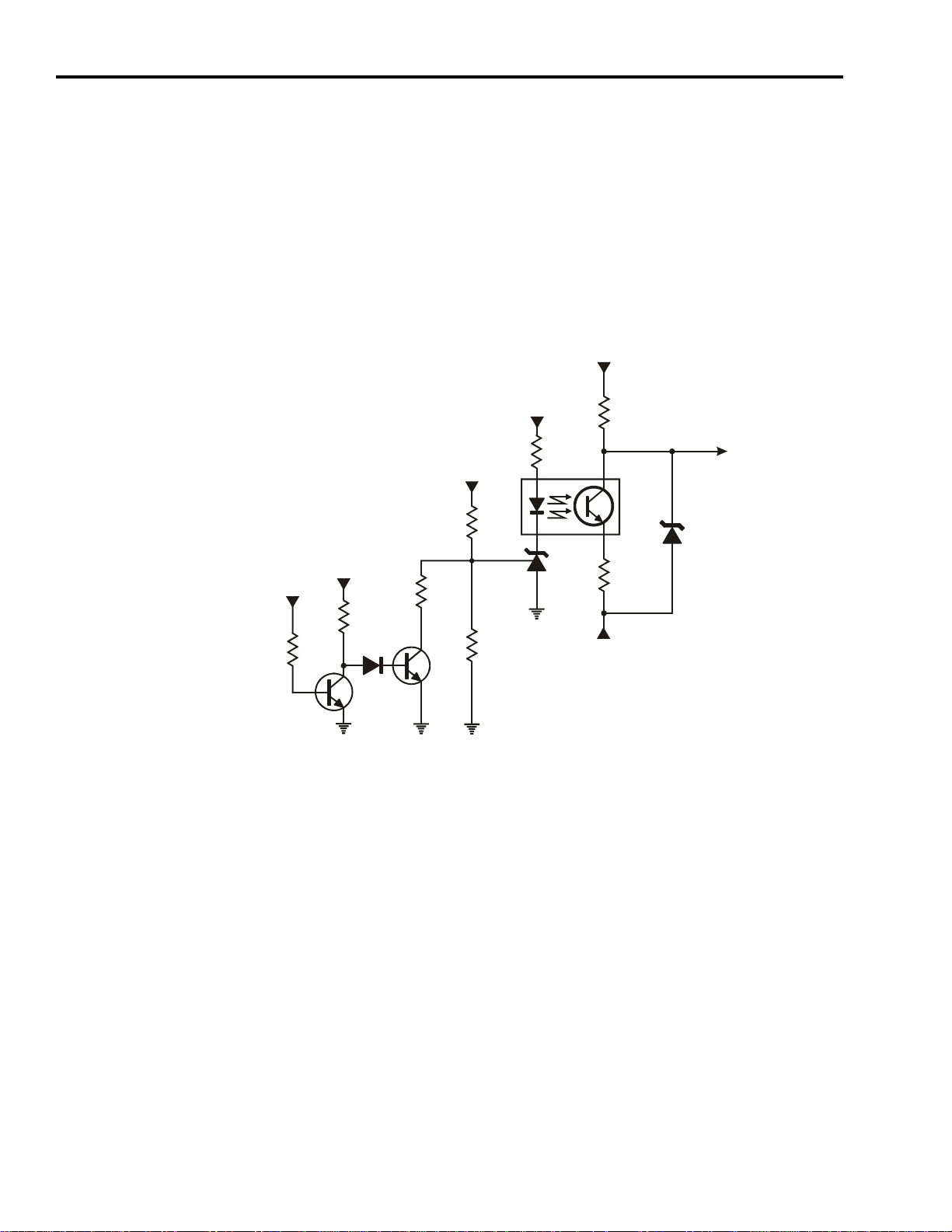

Run Supplies

There are several supplies generated from the main supply but only required during

run operation. They are shown in figure 2-17. To turn them on and off System

Control sends a high to Q14105-B turning it on. That turns Q14104 on passing the

+16Vs supply to the input of the main +12V regulator. The output of the regulator

then feeds +12V directly to the circuits or feeds other regulators.

28 Power Supply

T14401

10

6

2

FOCUS

SCREEN

4

To Beam

Limiter

9

8

5

7

R14701

10

1/2W 20%

CR14701

CR14704

R14703

0.88(0.82)

3W

CR14702

R14702

130K

1/2W

R14509

300

2W

10%

C14703

47uF

250V

R14508

1.0

2W 10%

FILAMENT

High Voltage

+

TO

CRT ANODE

TO

CRT FOCUS

GRID

TO

CRT SCREEN

GRID

+200Vr

+23Vr

+13Vr

TO

CRT

Figure 2-18, Scan Derived Supplies

Scan Derived Supplies

Several other sources of power must also be generated by the CTC203. They are

derived from the scan circuits in a traditional way. Horizontal scan operation will be

covered later.

Two low voltage supplies are generated; +23V and +13V. An AC filament supply

for the CRT is taken from the same winding.

The CRT drivers require a higher voltage than can be generated by the normal

supply. It is generated here and is about +200V. It is slightly unique as it is derived

from the primary windings of the horizontal output transformer, not the secondary.

The remainder of the scan derived supplies are used to power and control the CRT.

They are the anode, focus grid and the screen grid supply.

When output MOSFET Q14101 fails, it is a good idea to replace the latch transistors,

Q14102 & Q14103. Unexpected excessive current may damage these transistors

and other components in the immediate area.

Power Supply 29

TECH

TIP

+13Vr

R14128

680K

+16Vs

R14127

10K

CR14111

Q14107

R14115

143K

R14126

37.4K

Q14106

RegB+Vs

R14116

2000

+16Vs

R14113

1300

U14101

U14102

R14112

Bias Supply

Bias Supply

Pos Hot

Bias Supply

R141111

680

Neg Hot

Bias Supply

Pos Hot

Neg Hot

CR14101

47V

10K

CR14117

16V

R14101

47K

CR14102

R14102

6800

C14104

R14104

3300

Q14103

CR14105

0.047

C14108

0.047

CR14103

CR14104

R14103

1Meg

R14106

2000

R14110

22K

RAW B+

C14101

2.2uF

R14107

43

Q14102

R14109

750

R14105

10

C14108

1100

1.6KV

Q14101

R14108

0.1

3W

3

8

9

5

T14101

CR14106

16

C14122

33uF

C14114

3.3uF

L14102

C14122

33uF

R14124

3.3

2W

14

15

13

CR14107

33V

CR14108

C14121

3.3uF

Replace all on any

Reg B+

+33Vs

+16Vs

Output Device

R11513

4700

CR11504

18V

CR14110

U14103

Q11501

+12VrSW

+5.2V

Reg

CR11505

+7.6Vs

+5.2Vs

-12Vs

-12Vr

-12V

Fil

C14116

47uF

Failure

NC

10

11

12

Figure 2-19, Main Power Supply (Repeated)

30 Deflection

Deflection Overview

The CTC203 deflection circuits are very similar to previous TCE core line chassis.

Some models will have pin-corrected yokes, while others use an active pincushion

correction circuit. XRP is the same as previous chassis and other CRT control and

protection is also similar.

The horizontal deflection system has two primary functions in the CTC203 chassis.

First, it supplies the current for the horizontal yoke coils providing energy necessary

to move the electron beam horizontally across the face of the picture tube. Second,

it provides a number of voltage supplies needed for operation of the CRT and

deflection.

Horizontal yoke current is provided by a circuit consisting of a switch (HOT), the

primary inductance of the Integrated High Voltage Transformer (IHVT), a retrace

capacitor, trace capacitor (S-Shaping capacitor), and the horizontal yoke coils.

Voltage supplies provided by the horizontal deflection system are derived from

secondary and tertiary windings on the IHVT. The supplies are used by the video

amplifier (kine drivers), tuner, CRT, and the vertical amplifier.

Low level signal processing circuits for the horizontal deflection system are contained

in the T4-Chip. These include the horizontal sync separator and a two-loop horizontal

AFPC system. The T4-Chip allows bus control of several parameters associated

with the horizontal deflection system. These include horizontal drive pulse width,

AFC Gain, Sync Kill, and ON/OFF.

Enabling or disabling the horizontal drive signal from the T4-Chip determines

whether the chassis operates in the Standby or Run mode. In the Standby mode, no

IHVT-derived supplies are present reducing standby power requirements.

The vertical deflection circuit in the CTC203 is a linear amplifier DC coupled to the

vertical yoke coils. The circuit is similar to the CTC197 vertical circuitry. The

vertical ramp is generated in the T4-Chip. Vertical size, bias, S-Correction, and

linearity adjustments are done in the T4-Chip via the IIC bus. Timing information

for the ramp generator is derived from a digital vertical countdown circuit, resulting

in excellent interlace performance. The vertical output stage includes an integrated

circuit containing the power amplifier, vertical flyback generator, and thermal

protection.

Loading...

Loading...