CTC175/176/177/186/187

Supplemental Training Manual

VERTICAL

TO

E8

RED BIAS

<21-B>

TO

E7

GRN BIAS

E5003

E5007

TP50

RED OUTP UT

194V

THO MSO N TECHNIC AL TRAINING

This training manual is a supplement to the CTC175/176/177 technical training manual (T-CTC175/

6/7-1). It contains additional information regarding system control circuit changes in later production

CTC175/76/77 chassis, new CTC186/87 circuits and an in-depth description of the tuner-onboard circuitry with troubleshooting strategies. This publication also contains "Tech Tips" from the

field on commonly encountered problems and their solutions. Using this manual in conjunction with

the CTC175/176/177 technical training manual and service data will enable the field technician to

repair these chassis more effectively and efficiently.

FOREWORD

Note: This publication is intended to be used only as a training aid. It is not intended to replace service

data. Thomson Consumer Electronics Service Data for these instruments contains specific

information about parts, safety and alignment procedures and must be consulted before performing

any service. The information in this publication is as accurate as possible at the time of publication.

Circuit designs and drawings are subject to change without notice.

SAFETY INFORMATION CAUTION

Safety information is contained in the appropriate Thomson Consumer Electronics Service Data. All

product safety requirements must be compiled with prior to returning the instrument to the consumer.

Servicers who defeat safety features or fail to perform safety checks may be liable for any resulting

damages and may expose themselves and others to possible injury.

All integrated circuits, all surface mounted devices, and many other semiconductors are electrostatically sensitive and therefore require special handling

techniques.

Prepared by

Thomson Consumer Electronics, Inc.

Technical Training Department

10330 North Meridian Street, Indianapolis, Indiana 46290-1024

U.S.A.

Table of Contents

CTC186/87 .................................................................................... 1

System Control .............................................................................. 4

MicroProcessoer Pinout .......................................................................................5

Comb Filter.................................................................................... 6

Troubleshooting .................................................................................................................................6

Stereo Decoder ..............................................................................7

dbx Alignments ..................................................................................................................................8

Inductor /Capacitor (LC) Basics .................................................... 14

Varactor Diode ................................................................................................................................15

Basic Tuner....................................................................................16

Oscillator / Mixer / IF Bandpass........................................................................................................ 17

PLL / Frequency Synthesizer............................................................................................................. 17

CTC176/77/86/87 Tuner ................................................................ 18

Single Tuned Filter ........................................................................................................................... 21

RF Amplifier.................................................................................................................................... 23

Double Tuned Filter.......................................................................................................................... 23

OSC., Mixer, PLL ...........................................................................................................................26

IF Amp ........................................................................................................................................... 29

Tuner Alignment ............................................................................................................................... 30

Troubleshooting ...............................................................................................................................31

Tuner Voltage Charts........................................................................................................................ 33

Tech Tips ..................................................................................... 41

Page 3

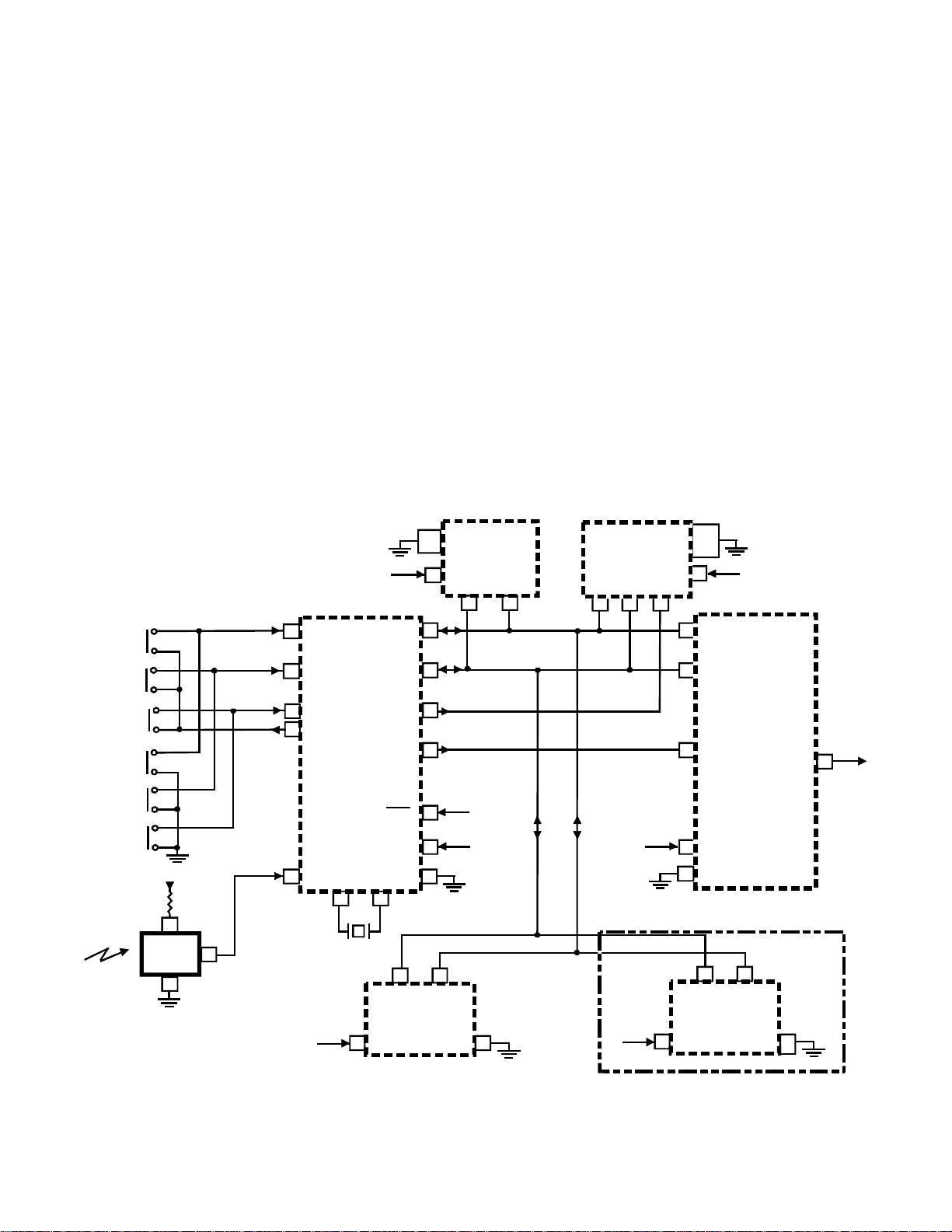

The CTC186/87 chassis is virtually the same as the CTC176/77 with the addition of a

dbx Stereo Decoder / Comb filter board. For complete descriptions of the common

circuitry, refer to the CTC175/176/177 Technical Training Manual (publication number

T-CTC175/6/7/-1).

CTC186/87

Later production CTC175/176/177 chassis have a different microprocessor (U3101).

These chassis can be identified with a “2” after the alpha suffix on the bar code label.

For example, a CTC177AA chassis that had the new version microprocessor would be

labeled CTC177AA2. This is extremely important because the pinouts are not the same.

In other words, they are NOT interchangeable. The CTC186/87 also supports this

newer version microprocessor.

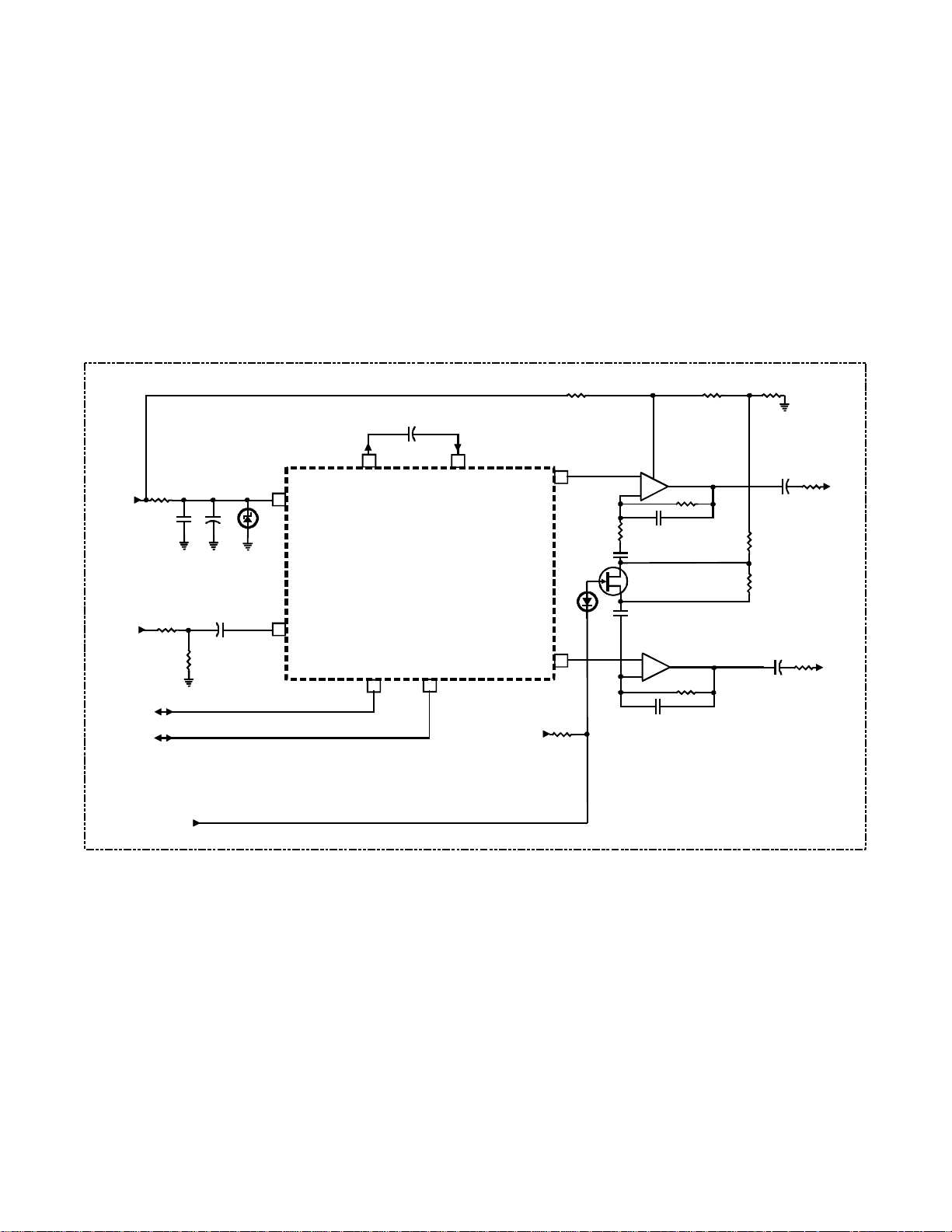

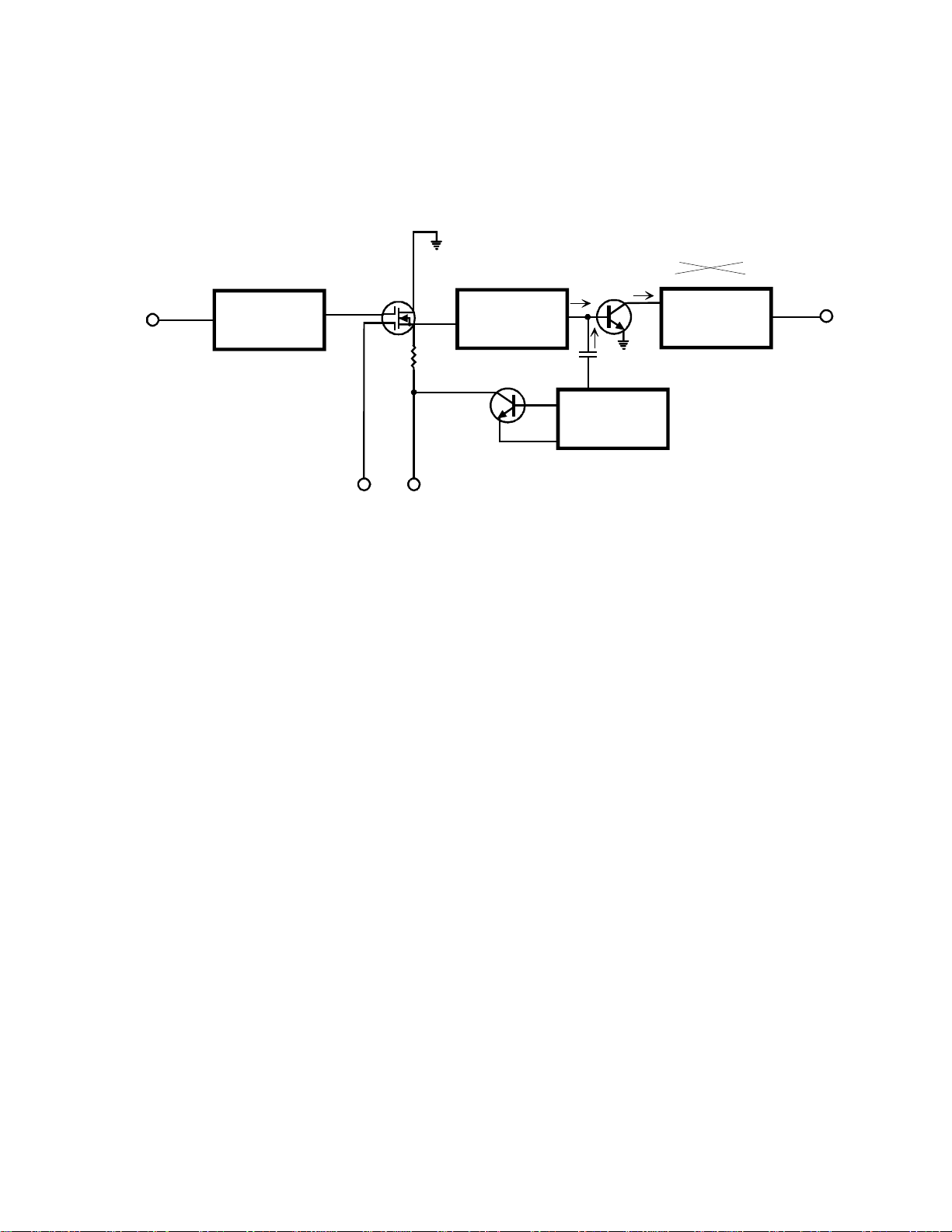

The use of the bus controlled stereo decoder (U1600) and the new Thomson ST-9

microprocessor (U3101), changes the system control block diagram slightly to accommodate the different parts. The differences are pin-out changes on the microprocessor

and the addition of U1600, figure 1. With the exception of these changes, the system

control circuit is functionally the same as the CTC177 (see the System Control section

of the CTC177 training manual).

POWER

VOL. UP

VOL. DN.

CH. UP

1,2, 3

GND

U3201

4,7

5V

KS1

6

KS2

7

KS3

8

KD1

5

T-CHIP DATA

TUNER CLOCK

T-CHIP CLOCK

TUNER DATA

U3101

µ

P

PIP

ENABLE

T-CHIP

ENABLE

8

19

20

12

14

EEPROM

VDD

DATA

5

CLO CK

6

DATA

20 21

U2901

D-PIP

CLOC K

GND

VDD

ENABLE

22

39

54

53

52

System Control

3,5

15, 16

40, 41

5V

DATA

CLOCK

U1001

T-CHIP

ENABLE

HORZ.

OUT

24

CH. DN.

MENU

5V

2

IR3401

3

5V

2

RESET

VDD

21

OSC

OSC

GND 56

1

OUT

36 37

1

Y3101

22

IN

4

DATA

CLOCK

5V

5

U7401

5V

TUNER PLL

VCC

10

GND

13

7.6 V

STBY

9V

CTC186/87 ONLY

22

STEREO DEC OD ER

VCC

15

BUS

GND

1

DATA

U1600

2

CLOC K

GND

3,4,

17

Figure 1, System Control Block Diagram

Page 4

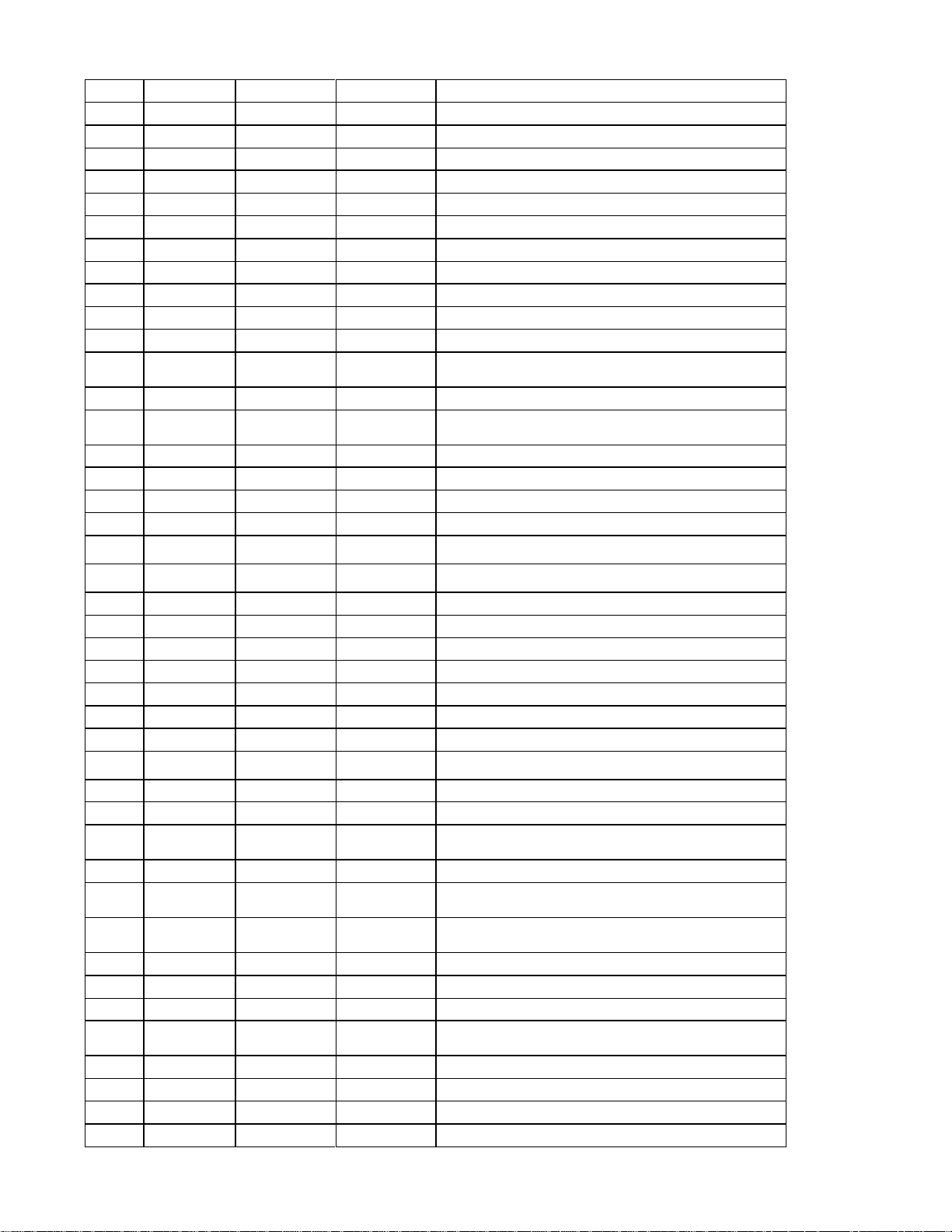

U3101 - Thomson ST-9 SYSTEM CONTROL MICROPROCESSOR

PIN NO. NAME VOLTAGE

1 IR IN 4.5

2 RESET 5

3 NC 4 DEGAUSS 0

5 KD1 0

6 KS1 4.7

7 KS2 4.7

8 KS3 4.7

9 DATA OUT 0.3

10 ATE ENABLE 0

11 CC VIDEO 2

12 PIP ENABLE 4.7 >20M

13 NC -

14 T-CHIP ENBL 4.6 >20M

15 BLUE OSD 0

16 GRN OSD 0

17 RED OSD 0

18 FSW 0

19

20

T-CHIP DATA

TUNER/ST CLK

T-CHIP CLK

TUNER/ST DATA

4.5

4.7 >200K Serial communication - data/clock

21 VDD 4.7

22 VSS 0

23 PLL FILTER 2.6

24 PLL BIAS 2.2

25 PLL VCC 4.7

26 H 0.7

27 V 0.2

28

EXP S T SW

ST / MONO

11 / 0 36K Expanded stereo, NWS-gain and mono /stereo control line.

29 SPK MUTE 0

30 TONE 0 / 5

31

SCLOCK/FM

ON/OFF

0 >20M

32 ST SENSE 0 / 5

33 RF SEC * VARIES >20M

34 RF PRI * VARIES >20M

35 SINGLE TUN * VARIES

36 OSC OUT 2.3

37 OSC IN 2.3

38 TUN SYNC 2.3 >20M

39 FM TUN * VARIES

40 IF DEFEAT 0

41 STBY SW 42 DATA IN 4.8

IN CKT. RES.

>300K

>200K

>20M

>20M

>200K

>200K

>200K

>20M

10K

>50K

-

1K

1K

1K

2K

>20M

>20M

0

>20M

6K

>20M

8K

1.8K

>100K

>100K

>20M

>20M

>20M

>20M

>20M

>20M

>20M

>200K

Serial communication line used to control data between

the micro. and PIP.

Serial comm. line used to control communication between

the micro and T-Chip.

Fast switch - controls OSD and video switching in T-chip.

Serial clock for DBX stereo decoder. FM on control for

commercial TV.

PWM output - Controls the secondary of the double tuned

filter in the tuner.

PWM output - Controls the primary of the double tuned

filter in the tuner.

PWM output - Controls the single tuned filter in the tuner.

Sync input to detect the presence of an active channel

when tuning.

Input to detect an active FM station on commercial TV.

Page 5

DESCRIPTION

IR input signal from remote control.

Micro reset - active LO.

-

Activates degaussing relay.

Keyboard drive line.

Keyboard scan input.

Keyboard scan input.

Keyboard scan input.

Data out for commercial television.

Used for factory testing.

Closed caption video input.

-

Blue OSD output.

Green OSD output.

Red OSD output.

Serial communication - data/clock.

Power supply input for microprocessor.

Ground for microprocessor.

PLL filter network.

PLL bias resistor Connection.

Power supply for PLL.

Horizontal timing input for OSD.

Vertical timing input for OSD.

Goes HI to mute speakers.

Goes HI for low tone and LO for high tone.

Stereo Detect line for non-DBX stereo sets.

8MHz crystal connection.

8MHz crystal connection.

Output to defeat IF circuit via AGC.

-

Data input for commercial television.

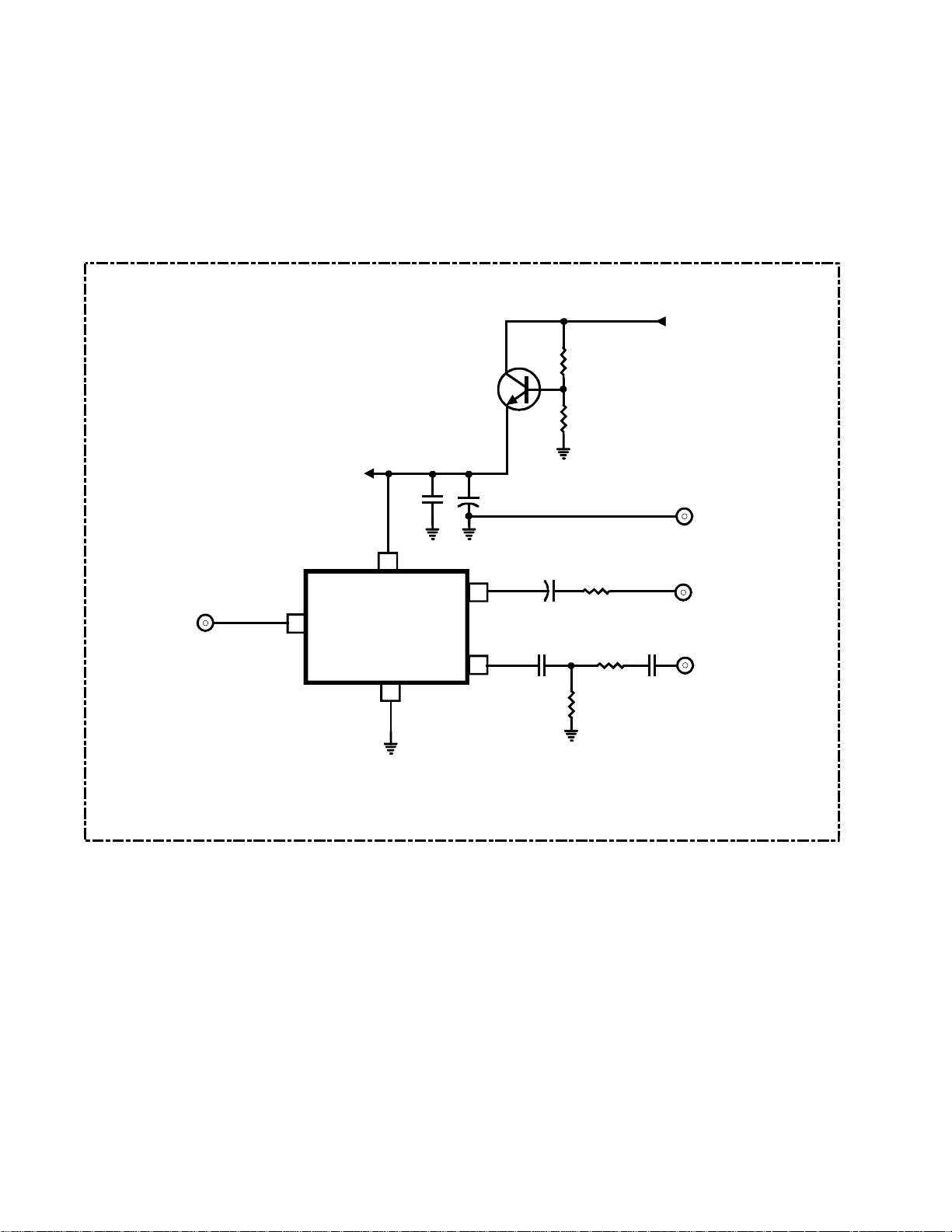

This board contains an analog comb filter that is used to separate luminance and chrominance. Composite video is routed from the main board from E2601 and applied to the

input at pin 2 of the comb filter IC (FL2651). Luma is output at pin 5 and chroma is

output at pin 3. These signals are sent back to the main board at E2602 and E2603

where they are input to the T-Chip (U1001), figure 2. Refer to the luminance and

chrominance processing section of the CTC177 training manual for signal processing on

the main board.

+12V

Q2651

+9V

+

Comb Filter

E2505

GND

1

5

E2601

VIDEO IN

2

FL2651

3

4

STEREO DECODER / COMB FILTER PCB

Figure 2, Comb Filter

1. Check for composite video at E2601. If there is no video present, the problem is on

the main board and not the comb filter. If video is present, go to the next step.

2. Check for luma and chroma out at E2602 and E2603. If luma and chroma are

present, the comb filter is working correctly. If they are not present, go to the next

step.

E260 2

LUM A OUT

E260 3

CHROMA OU T

Troubleshooting

3. Check for 9 volts at pin 1 of the comb filter (FL2651). If the voltage is present,

suspect a defective FL2651. If the voltage is missing, check Q2651 and its associated components.

Page 6

Stereo Decoder

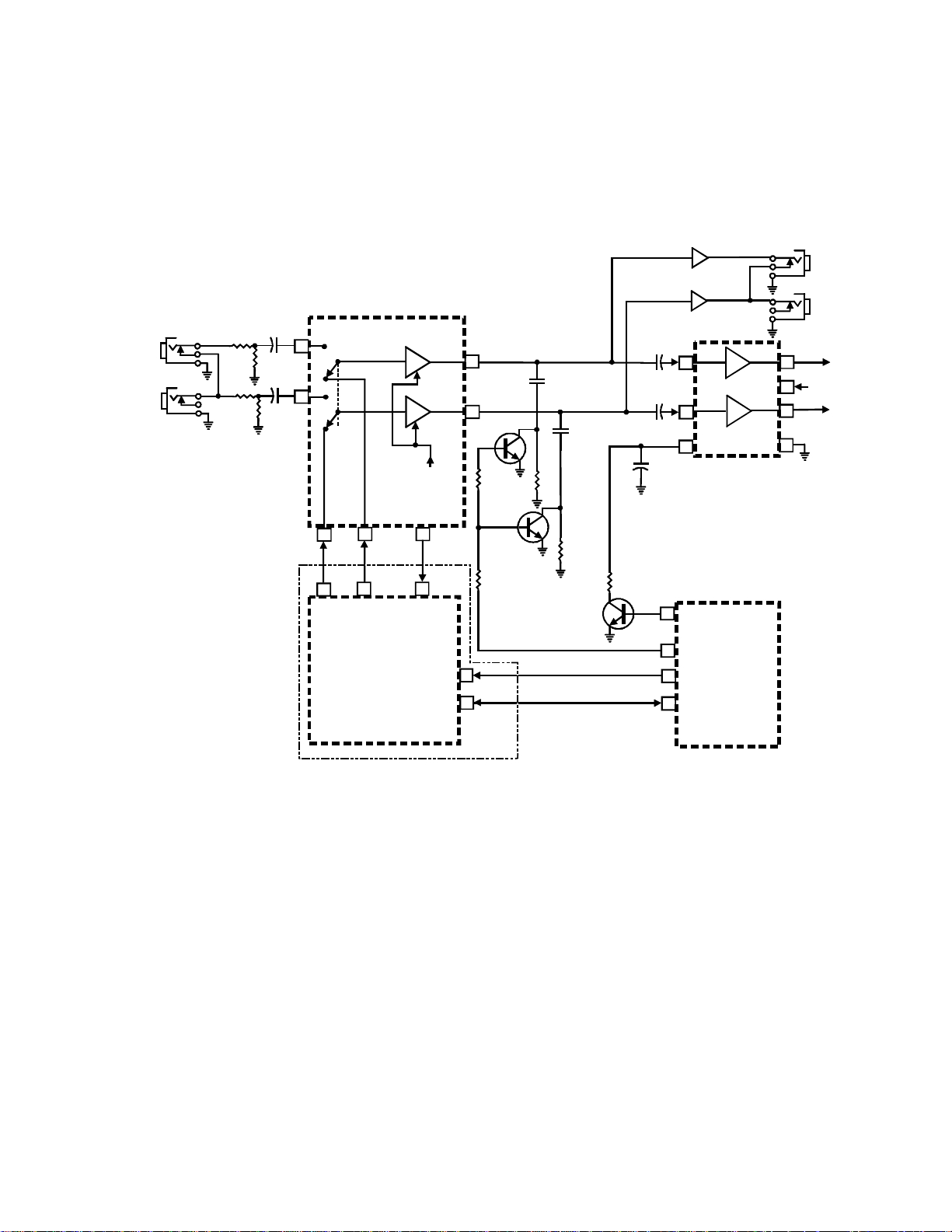

The stereo decoder (U1600) receives wideband audio from the main board and decodes left and right audio information. Wideband audio enters the board at JS107

(figure 3) and is capacitively coupled to U1600 pin 11. Decoded left and right signals

are output at pins 29 and 28 respectively. U1601 buffers the left and right output and

provides the expanded stereo feature in conjunction with Q1601. When the expanded

stereo line (JS112) goes LO, Q1601 turns on and cross-mixes the left and right channel

information to produce a perceived increase in stereo separation. Pins 1 and 7 of U1601

output the left and right signals respectively that are capacitively coupled back to the

main board via JS105 and JS106.

+12V

JS103

WBA

JS107

SCLK

JS111

SDATA

JS110

EXP. STEREO

JS112

+

CR1600

9.1V

+

15

11

VCC

WBA IN

8 7

MAIN

OUT

MAIN

IN

U1600

STEREO DECODER

2 1

STEREO DECODER / COMB FILTER PCB

L OUT

R OUT

+12V

29

CR1601

28

U1601

3

2

Q1601

U1601

5

6

8

+

1

-

+

7

-

+

+

LEFT

JS105

RIGHT

JS106

Figure 3, DBX Stereo Decoder

Page 7

U1600 is digitally controlled over the I2C bus. Analog lines that were used in the

CTC177 for stereo sense and stereo select (see the Audio Processing section of the

CTC177 training manual) are no longer used. Instead, communications between U1600

and the television’s microprocessor are carried out over the serial bus, figure 4.

U1001

T-CHIP

AMP

AMP

BUS

CTL

VOL ./M UTE

BUS CTL

WB AUDIO

OUT

L INR IN

4

5

3

60

C1912

59

Q1901

C1913

R1912

Q1902

+

5

+

1

+

3

AUX LEFT

AUDIO INPUT

AUX RIGHT

AUDIO INPUT

+

7

+

8

AMP

AMP

U1901

8

9

10

6

LEFT HI-FI

OUT

R / MO NO

HI-FI

OUT

LEFT

26V

RIGHT

Q1903

MUTE

R1913

29

30

20

19

29

28

R OUT

TV

AUDIO

L OUT

11

WB AUDIO

IN

U1600

ST EREO

DECODE R

STEREO DECODER / COMBFILTER PCB

SCLK

SDATA

1

2

Figure 4, Audio Circuit Block Diagram

The CXA 1734S Stereo/SAP Mpx IC registers are accessed via the IIC Bus. All

necessary bus controls are contained in the SERVICE MENU.

Signal Description Summary

ALIGNMENT INPUT SIGNAL DESCRIPTIONMEASUREMENT

WBA Input;JS107

#25 ATT 100 Hz, 424 mv rms JS106 (RIGHT OUT)

#26 STVCO Open WBA or short AC to gnd. JS106 (RIGHT OUT)

#27 SAPVCO 78,670 Hz (5 x fH), 255 mv rms Observe OSD * (star)

#28 STLPF 9.4 KHz, 1.04 v rms Observe OSD STEREO”

#29 SAPBPF 88 KHz, 206 mv rms Observe OSD * (star)

#30 WBSEP Stereo, LEFT only, 300 Hz w/ pilotJS106 (RIGHT OUT)

#31 SPECSEP Stereo, LEFT only, 3KHz, w/ pilot JS106 (RIGHT OUT)

SPEAKR

MUTE

TONE

SCLK

SDATA

U310 1

SYSCON

dbx Alignments

Page 8

NOTES:

• All replacement stereo IC’s must be aligned according to this procedure.

• All Stereo/SAP alignments must be performed in the sequence shown. Several

alignments are coarse alignments for ones that follow.

• When the set starts up, the dbx Stereo IC will be aligned with IIC alignment data

which is stored in EEPROM memory from the previous IC that was installed in the

set. In most cases, stereo and SAP will be detected, but the stereo and SAP vco

free-running frequencies will not be properly aligned. Neither will stereo separation

nor the various internal filters be optimized. The full alignment procedure must be

performed to make sure the IC performs within specification.

• A modulator or other signal source with video must be connected to the tuner, and

the set tuned to the appropriate channel in order to detect stereo. Stereo and SAP

alignments cannot be performed with VIDEO IN selected (channel 00).

Alignment Preparation

Make sure that the EXPANDED STEREO function is turned off, otherwise the output

amplitudes will be in error. Also, STEREO SEPARATION alignments will be impossible.

Access the SERVICE MENU for the dbx IC as follows:

1. Press and hold the MENU button, then while holding MENU press the ON button,

followed by the VOLUME + button. This accesses the GENERAL SERVICE

MENU display.

2. Release all buttons.

3. Increment VALUE (V) number to 76 by pressing and holding the VOLUME UP

button.

4. Increment PARAMETER (P) number to 13 by pressing and holding the CHANNEL

UP button.

5. Increment V number to 77 with VOLUME UP button.

6. Increment P number to 25 with CHANNEL UP button. This is the first alignment

parameter.

Page 9

Perform the alignments in the following sequence.

Attenuator (ATT = Parameter # 25)

DAC range = 0 to 15.

All following alignments depend on the correct setting of this alignment.

1. Unsolder and lift the bottom end of R1609 from the circuit board. This is the

Wideband Audio input (WBA) to the CXA1734 stereo IC.

2. Connect an audio generator to the unsoldered end of R609 (WBA). Adjust the

generator output for 100 Hz, 424 mv rms, +/- 10 mv at module pin #7, WBA. This

corresponds to a full 25KHz carrier deviation mono audio signal from the sound IF.

3. Connect an AC voltmeter to module JS106, RIGHT CHANNEL OUTPUT. This is

also the bottom end of R612. (Do not use the top end, or oscillations may result.)

Adjust the ATT DAC using the volume control button. Set the DAC for an output

level as close to 489 mv rms as possible. Each DAC step will change the output

level by about 25 mv.

4. Observe on an oscilloscope that the audio output at module pins #5 (LEFT) and #6

(RIGHT) are clean and undistorted.

5. Observe that the rms amplitude of both pins #5 and #6 are within 20 mvrms of each

other.

6. If the final DAC alignment value is not within the range of 7 - 11, check to make

sure that the signal amplitude is proper. (Do not use 1KHz, because the internal deemphasis filter will cause an amplitude error.)

STEREO VCO free running frequency. (STVCO = Parameter # 26)

DAC range = 0 to 63.

This alignment is also a course adjustment for the next alignment.

1. Remove the audio generator connection from the bottom end of R1609. False

STVCO frequency will be generated if WBA is not open, as VCO tries to lock to

noise or other frequency.

2. Connect a frequency counter to module JS106, RIGHT OUT. (4 x fH vco is

automatically routed to JS106 when in P#26.)

3. Adjust DAC while monitoring frequency. Set DAC for frequency = 62,936 Hz +/200Hz. (4 x fH). The frequency increment for each DAC step is approximately 300

Hz.

Page 10

SAPVCO free running frequency. (SAPVCO = Parameter # 27)

DAC range = 0 to 15.

This is not a direct frequency measurement. It uses the internal status registers of

the stereo IC to indicate PLL lock. The previous alignment (STVCO) is a coarse

adjust for this alignment.

1. Adjust audio generator for 78.67 KHz, 254 mv rms (559 Vp-p), +/- 10 mv. (5 x

fH SAP subcarrier, equivalent to 15 KHz carrier deviation) at WBA input.

2. Set SAPVCO DAC to step # 0. Observe TV screen. No star (*) should be

present.

3. Increment DAC once per second or slower until * becomes present. Record this

DAC setting. (A flashing * is OK. Usually, one more DAC increment will stop the

flashing.)

4. Set DAC to step # 15. Observe that no * is present. Decrement DAC until * once

again becomes present. Record this DAC setting.

5. Average the DAC settings from steps (c) and (d). Set DAC to this averaged value.

This is the proper alignment value for SAPVCO. Setting will usually be 1 - 14. If

not, verify that previous step was done properly.

STEREO LOWPASS FILTER (STLPF = Parameter # 28)

DAC range = 0 to 63.

This alignment is also a course adjustment for the next alignment.

1. Adjust audio generator for 9.4 KHz, 1.04 vrms (1.47 Vp-p) at WBA input.

2. Set STLPF DAC to step # 0. Observe TV screen. No “STEREO” indicator

should be present.

3. Increment DAC once per second or slower until “STEREO” indicator becomes

present. Record this DAC setting. (It is OK for the “STEREO” indicator to flash.

Usually, one more DAC increment will stop the flashing.)

4. Set DAC to step # 63. Observe that no “STEREO” indicator is present. Decrement DAC until “STEREO” indicator once again becomes present. Record this

DAC setting.

5. Average the DAC settings from steps (c) and (d). Set DAC to this averaged value.

This is the proper alignment value for STLPF.

Page 11

SAP BANDPASS FILTER (SAPBPF = Parameter # 29)

DAC range = 0 to 15.

1. Adjust audio generator for 88 KHz, 220 mv rms, +/- 10 mv.

2. Set SAPBPF DAC to step # 0. Observe TV screen. No * should be present.

3. Increment DAC once per second or slower until * becomes present. Record this

DAC setting.

4. Set DAC to step # 15. Observe that no * is present. Decrement DAC until * once

again becomes present. Record this DAC setting.

5. Average the DAC settings from steps (c) and (d). Set DAC to this averaged value.

This is the proper alignment value for SAPBPF.

WIDEBAND SEPARATION (WBSEP = Parameter # 30)

DAC range = 0 to 63.

This alignment is for the dbx WIDEBAND detector

1. Set stereo generator for STEREO LEFT CHANNEL ONLY SIGNAL, 300 Hz.

2. Connect AC rms voltmeter to module JS106, RIGHT CHANNEL OUT.

3. Set WBSEP DAC to step # 31 (DAC midpoint).

4. Start incrementing WBSEP DAC (or decrementing, as necessary) while observing

voltmeter reading. Find DAC setting which produces a minimum voltmeter reading

(null setting). Record this DAC setting. The exact null setting will typically be

difficult to determine, because the null range is rather broad.

5. Measure module JS105, LEFT CHANNEL OUT, and check for at least 20 dB

separation between LEFT and RIGHT.

6. This alignment will be repeated after doing the next alignment, because of some

interaction between the WBSEP and SPECSEP DAC’s.

Page 12

SPECTRAL SEPARATION (SPECSEP = Parameter # 31)

DAC range = 0 to 63.

This alignment is for the dbx SPECTRAL detector

1. Set stereo generator for STEREO LEFT CHANNEL ONLY SIGNAL, 3KHz.

Note:If the MTS generator being used is not capable of generating a 3KHz signal,

the alignment cannot be performed. If this is the case, set the DAC to the nominal

default of 35.

2. Connect AC rms voltmeter to module JS106, RIGHT CHANNEL OUT.

3. Set SPECSEP DAC to step # 31 (DAC midpoint).

4. Start incrementing SPECSEP DAC (or decrementing, as necessary) while observing

voltmeter reading. Find DAC setting which produces a minimum voltmeter reading

(null setting). Record this DAC setting. The exact null setting will typically be

difficult to determine, because the null range is rather broad. Do the best you can.

5. Measure module JS105, LEFT CHANNEL OUT, and check for at least 20 dB

separation between LEFT and RIGHT.

Page 13

A television tuner receives (or selectively tunes) a 6MHz bandwidth RF (Radio Fre-

N

quency) carrier that contains audio and video information and converts it to a common IF

signal (Intermediate Frequency). The IF signal is demodulated by the television into its

audio and video components. All tuners work on the principle of a tuned circuit whose

resonant frequency determines what channel is tuned. By changing the tuned circuits’

resonant frequency, different RF carriers (channels) are selected. Before discussing the

different sections that comprise the tuner’s circuitry, it is appropriate to review certain

fundamental concepts of inductors, capacitors and varactors. These components play a

major role in all tuned circuits.

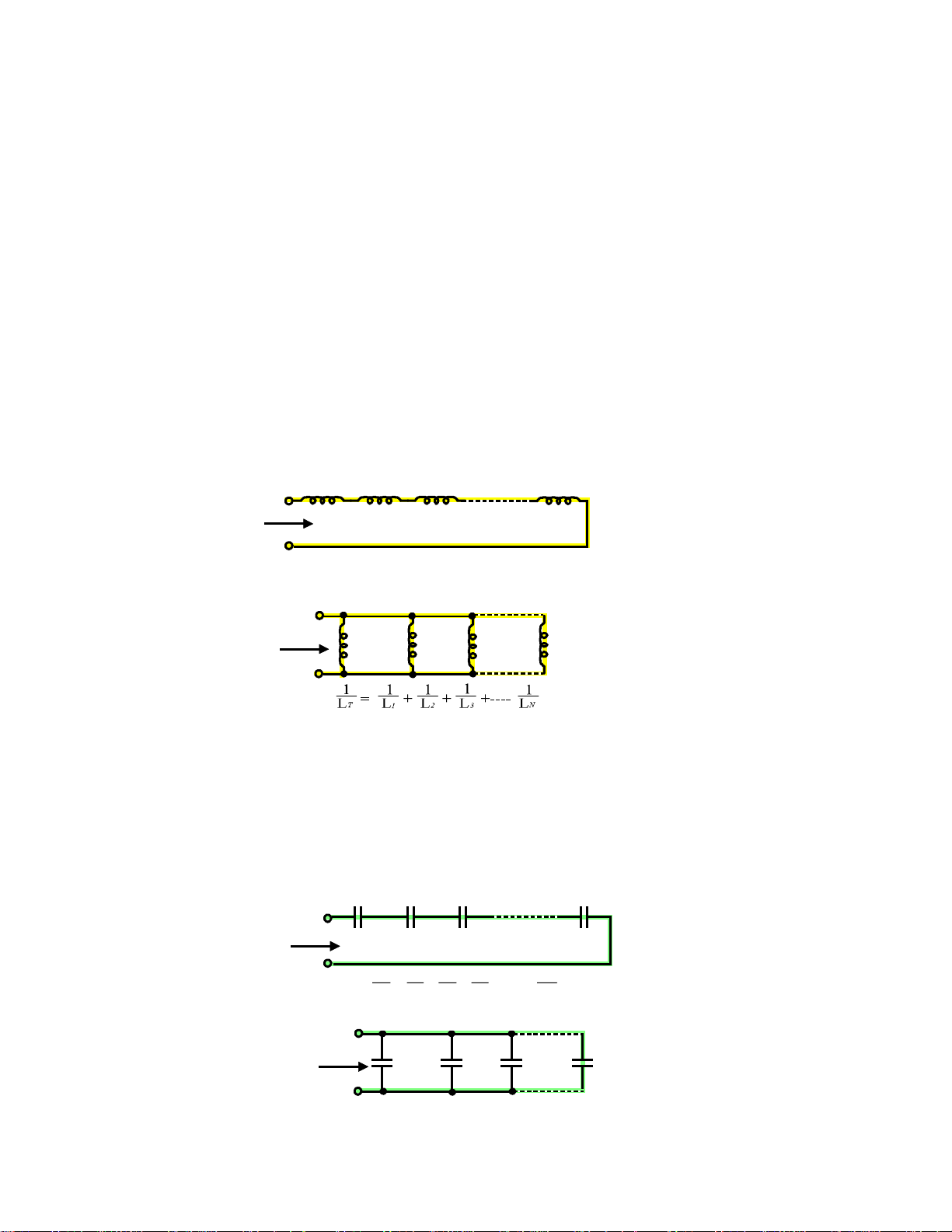

Inductors

Remember, an inductor is simply a coil of wire. The ability of a coil to oppose a change

in current is a measure of the inductance L of the coil. Inductance is measured in henries

(H). For inductors in series, the total inductance is found in the same manner as resistors

in series, figure 5. Likewise, the total inductance of inductors in parallel is found in the

same manner as resistors in parallel, figure 5. The main idea to remember here is inductors added in parallel reduce the total inductance and inductors added in series in-

crease the total inductance.

Inductor /

Capacitor

(LC) Basics

1

T

L

L

T

L

2

L

3

L

LT = L1+L2+L3+- -- -L

1

L

2

L

N

3 L

L

N

L

N

Figure 5, Inductors in Series and Parallel

Capacitors

Capacitors are components that are made up of two parallel conducting plates separated

by an insulating material. A capacitor stores a charge on its plates. The storage capacity

C is measured in Farads (F). The farad is generally too large a unit for most tuner

applications so the pico farad (pF) 10

-12

F is used. Total capacitance is calculated in

the opposite manner as inductance, figure 6. Capacitors in parallel increase total

capacitance and capacitors in series decrease total capacitance.

C T

C

1

C

C

2

3

C

N

1 1 1 1 1

= + + + − − −

1 2 3

T

C C C C C

T

C

C

1

CT = C1+ C2+ C3+ --- - C

C

2

N

C

3

N

C

Figure 6, Capacitors in Series and Parallel

Page 14

These two fundamental concepts are essential to understanding and troubleshooting tuner

circuits. The circuit in figure 7 is a simple parallel resonant band-pass filter circuit, similar

to what would be found in a tuner. The frequency is determined by relationship as

shown. The main point here is decreasing the capacitance and/or inductance will

raise the resonant frequency. Increasing the capacitance and/or inductance will

lower the resonant frequency.

Vi

+

L

-

+

C

Vo

-

Vi

fp

f

1

fp

=

π

2

Figure 7, Band-pass Filter

Varactor Diode

One of the major components that is found in an electronic tuner is the varactor diode.

The varactor acts like a voltage variable capacitor. An increase in reverse bias across

the diode causes the capacitance to decrease. Conversely, a decrease in reverse bias

causes its capacitance to increase. This allows the resonant frequency of a tuned

circuits to be change by applying a tuning voltage, figure 8.

LC

SIGNAL

SOURCE

TUNING VOLTAGE

SOURCE

Figure 8, Basic Varactor Tuning Circuit

Page 15

Input Filter

A tuner is composed of the basic elements shown in figure 9. The front end of a tuner

has a filter network that filters out unwanted FM and IF frequencies that may be present.

It also contains a singled tuned filter that tunes the frequency of the desired channel and

inputs this signal to the RF amplifier.

Basic Tuner

ANTENNA

INPUT FILTER

RF AMP

CHANNEL 6

PIX = 83.25MHz

RF BANDPASS

OSCILLATOR

B+AGC

83.25MHz S 129MHz =

MIXER

129 MHz

OSC. NETWORK

SUM 212.25MHz

IF BANDPASS

Figure 9, Basic Tuner

RF Amplifier

The RF amplifiers in the tuners we will be concerned with use dual gate depletion type

MOS FET’s (Metal Oxide Semiconductor Field Effect Transistors). These transistors

are very high impedance (in the mega ohms) voltage controlled devices that function

very much like vacuum tubes. The N-channel depletion type MOSFET’s are normally

“on” without any type of gate bias. When a negative voltage is applied to the gate with

respect to the source, drain current flow is reduced or pinched off entirely if the reverse

bias is sufficient. Conversely, a positive voltage on the gate with respect to the source

will increase drain current flow to a point. Dual gate MOS FET’s have two gates both

of which affect drain current. In RF amplifier configurations, the RF signal is input on

Gate 1 and the AGC (Automatic Gain Control) voltage is applied to Gate 2. As the

AGC voltage rises, more drain current is produced increasing the output of the respective RF stage. As the AGC voltage decreases, the output of the RF stage decreases.

These fundamental principles are important when troubleshooting.

DIFF. 45.7 5MHz

IF PIX = 45.75MHz

IF

RF Bandpass

The RF bandpass is a double-tuned filter that receives the amplified signal from the RF

amplifier and re-tunes it. This performs “sharp” tuning of the RF signal to obtain greater

selectivity. It also performs some impedance matching to the latter stages of the tuner.

Page 16

Oscillator / Mixer / IF Bandpass

E

The oscillator network comprises the local oscillator with its control circuitry. The

oscillator generates a signal that is beat or heterodyned against the incoming RF signal.

This is done to obtain the IF picture frequency of 45.75MHz. To accomplish this, the

oscillator frequency is set 45.75MHz higher than the incoming RF signal. The two

signals are “beat” or heterodyned together in the mixer stage. Using channel 6 as an

example, the picture frequency of 83.25 MHz is heterodyned with an oscillator frequency of 129MHz. This produces a sum signal of 212.25MHz and a difference signal

of 45.75MHz. The IF bandpass extracts the difference signal which produces the

channel’s video carrier at 45.75 MHz, the chroma carrier at 42.17MHz and the audio

carrier at 41.25MHz. Changing the local oscillator frequency accordingly allows all

channels to produce the same IF frequencies.

PLL / Frequency Synthesizer

The local oscillator frequency must change over a wide range to convert the many

channels to the IF frequency. The local oscillator in modern electronic tuners, and more

importantly the tuner in the CTC175/76/77/86/87 chassis, uses a frequency synthesizer

to control the oscillator. A frequency synthesizer is made up of a PLL (Phase Lock

Loop) and a programmable divider circuit.

A basic PLL block diagram is shown in figure 10. A voltage controlled oscillator (VCO)

sends a frequency sample back to a comparator. The comparator compares the sample

frequency of the oscillator to a reference signal derived from a crystal controlled oscillator. When the oscillator is off the frequency, the comparator generates an error voltage

that corrects the oscillator. The VCO will stay locked to the reference oscillator.

FREQUENCY

SAMPLE

VOLTAGE

CONTROLLED

OSCILLATOR

FREQUENC Y

COMPARATOR

REFER ENCE

FREQUENCY

CRYSTAL

CONTROLLED

OSCILLATOR

Figure 10, Basic Phase Locked Loop (PLL)

Page 17

DC VOLTAG

Adding a programmable divider to the PLL enables the oscillator to be locked at differ-

CTC176/77/86/87

E

ent frequencies. Division logic, usually supplied by a microprocessor, sets a divide ratio

in the frequency divider. The divided down frequency is compared against the reference

frequency. The comparator generates a correction voltage to keep the oscillator locked

to the desired frequency, figure 11. By changing the frequency divider, the PLL is able

to “synthesize” different frequencies.

VOLTAGE

CONTROLLED

OSCILLA TOR

FREQUENCY

COMPARATOR

REFERENCE

FREQUENCY

CRYSTAL

CONTROLLED

OSCILLATOR

DIVISION

LOGIC

FREQUENCY

SAMPLE

FREQUENCY

DIVIDER

(÷N)

FREQUENCY

SAMPLE

÷

N

DC VOLTA G

The CTC176/177/186/87 chassis supports a new concept in tuner design. The tuner is

built on the main board instead of being a separate assembly. This change will require

the technician to repair the tuner instead of replacing it. Although repairing the tuner may

be new for some, it is no different than working on other discrete sections of the TV.

Figure 11, Frequency Synthesizer

Tuner

Page 18

The tuner on board is digitally aligned. The television microprocessor adds offset voltage

T

to the single tuned and primary and secondary of the double tuned circuits. This allows

the three stages of the tuner to be independently adjusted to optimize circuit performance

for each channel. This improves the tuners overall response on cable systems as well as

off-air signals, figure 12.

LOW PASS

FILTER/SUMMING

U3201

EEPROM

SINGLE

TUNED FILTER

ST. P WM

BAND

SW

U7501

PRI. P WM

RF

AMP

BAND

SW

U3101

P

DOUB LE

TUNED FILTER

PRI. SEC.

BT BTBT

BAND

SW

SEC. PWM

BAND

SW

MIX ER

LO

BT

IIC BUS

FROM

P

IF FI LTER

U7401

TUNER

PLL

IF

OU

BAND

SW

Figure 12, CTC176/77/86/87

When a channel is selected, U3101 sends clock and data information to U7401 telling it

what band and frequency to synthesize. The output of pins 1 and 14 of U7401 sets up

the tuning voltage for the local oscillator (VT/LO) and the VREF tuning voltage. The

VT/LO tuning voltage adjusts the frequency of the local oscillator to produce the IF

frequency of the desired channel. A sample of the local oscillator's frequency is fed back

to U7401 pin 11 to serve as feedback for the phase lock loop (digital AFT information is

also fed to U3101 from U1001 over the serial bus which in turn adjusts U7401). The

band switching voltages from U7401 pins 8 and 9 tell the filters what band to tune. At

the same time, the VREF tuning voltage is summed with D/A voltages from U3101 and

sent to the single and double tuned filters to tune the desired channel’s RF carrier, figure

12. The D/A levels are set via digitally stored alignment data.

Page 19

W

R

ANT

U/V SPLIT

B3 ST.

FM & IF

TRAPS

INTERFACE CIRCUIT

RESPONSE

30

RF

TUNING

VOLTAGE

0

LO TUNING

VOLTAGE

Q7101

UHF

AMP

R7101

R7109

AGC

B1/B2

V ST.

VHF

AMP

Q7102

BS1

R7520

R7519

8 14 7

V ST. V PR I. V SEC.

U7501

INTERFACE C IRCUITRY

D/A STEP 63

D/A STEP 0

30

LO

TUNING

VOLTAGE

B3 DOUBLE TUNED

V PRI.

BV/U

RF

BV/U

B1/B2 DOUBLE TUNED

V PRI. V SEC.

BS1

VREF

3

V SEC.

R7518

BV/U

7

VHF/UHF

12

10

1ST IF

FILT ER

5

3

4

8+ 12V

U3101

D/A SEC.

34

5

12

35

36

10

D/A PRI.

D/A ST.

SYSTEM

CONTROL

UHF

M IXER

VHF

MIXER

U7301

OSC./M IX

15

16

AMP

OSC.

IF

UHF

VHF

OSC.

BS 1

CLOCK

DATA

B3 OSC

16

TANK

2ND IF

1

FILT ER

FM SAW

OUT PUT

9

B1/B2

OSC TANK

8

BS 1

5

U7401

TUN ER

4

65

VREF

U3201

EEPROM

RESISTIVE

DIVIDER

+ 5V

PLL

10

BV/U

9

fLO

SAW

AMP

11

1

14

R7301

fLO

fLO

BV/U

fLO

VT/LO

VT/LO

VT/LO

SPLIT

VT

TO SA

FILTE

TO FM

SIP

VT/LO

+33V

Figure 13, Tuning Circuit Block Diagram

The alignment data for the channels is stored in U3201, the EEPROM, and is used by

U3101, the microprocessor, during channel selection, figure 13. Pins 34, 35 and 36 of

U3101 output a PWM (pulse width modulated) signal that is low pass filtered and

summed in U7501 with the VREF (voltage reference) from the PLL circuitry. These

voltages control the secondary and primary of the double and the single tuned filters

respectively. The actual voltage to the filters is a function of the tuning voltage from the

local oscillator plus a correction voltage from the D/A’s of U3101.

U7501 forms the interface circuit that low pass filters the PWM signal from U3101 and

sums it with the VREF tuning voltage. The interface circuit response is shown on figure

13. The higher the tuning voltage, the more offset voltage range from the D/A’s. This is

necessary because varactor diodes require more voltage across them to get the same

change in capacitance at higher tuning voltages than at lower tuning voltages.

Page 20

RF from the antenna connector is passed through a trap network to remove any FM or

F

F

IF signals that might have been picked up by the antenna. The filtered RF is then tuned

by the single tuned filter. The circuit shown in figure 14 is the VHF single tuned filter.

The VHF low band channels (2 - 6) span frequencies from approximately 54MHz to

88MHz. The VHF high band channels (7- 13) and the midband cable channels (A - I)

span frequencies from approximately 120MHz to 212MHz. There is an approximate

32MHz gap between the VHF high and low bands that makes it impractical for a single

varactor circuit to tune. Therefore, inductors are added to the circuit with switching

diodes to cover this range of frequencies.

RF

IN

FM/IF

TRAP

C7140

C7142

L7108

C7110

CR7112 CR7105

R7112

R7138

BS1

L7115

C7134

PCBL1

L7107 CR7106

CR7107

L7106

R7114

C7137

SINGLE_TUNED

C7113

TO R

AMP

R7113

Figure 14, CTC175/76/77/86/87 VHF Single Tuned Filter

In the case of VHF low band channels, BS1 is set to approximately -14.5 volts. This

reverse biases CR7112 and CR7105. The inductors that make up the tuned circuit are

L7108, L7115, L7107 and L7106, figure 15. The inductors are tuned by the

SINGLE_TUNED voltage applied to varactors CR7106 and CR7107. This voltage is

affected by the digital alignments but is normally around 0 volts for channel 2 and around

5 volts for channels 6.

RF

IN

FM/IF

TRAP

C7140

C7142

L7108

C7110

CR7112 CR7105

R7112

R7138

BS1

L7115

C7134

PCBL1

L7107 CR7106

CR7107

L7106

R7114

C7137

SINGLE_TUNED

C7113

TO R

AMP

R7113

Figure 15, Single Tuned Filter (BS1 = -14.5V)

Page 21

In the case of VHF high band channels, BS1 is set to approximately +11.5 volts. This

F

turns on CR7112 and CR7105. With CR7112 turned on, L7108 is shunted, removing it

from the circuit. CR7105 connects PCBL1 to the circuit in parallel with L7106. This

switching action reduces the total inductance allowing the higher frequencies to be tuned

by CR7106 and CR7107, figure 16. The SINGLE_TUNED voltage will vary from

approximately 0 to +30 volts depending on the band and channel being tuned. The

higher the voltage, the higher the frequency being tuned.

L7107 CR7106

CR7107

L7106

R7114

C7137

SINGLE_TUNED

RF

IN

FM/IF

TRAP

C7140

C7142

L7108

C7110

CR7112 CR7105

R7112

R7138

BS1

L7115

C7134

PCBL1

Figure 16, Single Tuned Filter (BS1 = +11.5)

The BS1 line is switched positive (approximately +11.5) for cable channels 7- 13,

and 18 - 125. The BS1 line is switched negative (approximately -14.5) on cable

channels 2 - 6, and 14 - 17.

C7113

TO R

AMP

R7113

TECH

TIP

The UHF single tuned filter is analogous to the VHF circuit with one exception. The

frequencies tuned by the UHF circuitry are contiguous (no large gaps like VHF) so

inductor switching is not performed.

Page 22

The tuned “channel” from the single tuned filter is sent to the RF amplifier (Q7102) G1

T

through C7113. The ACG voltage is applied to G2, figure 17. The higher the AGC

voltage the higher the gain of the RF stage. Q7403 and Q7404 make up the VHF/UHF

switch. When a VHF channel is selected, the switch is turned on providing a ground

path for the source of Q7102. When the UHF RF circuitry is used, the BV/U switch is

turned off, removing the ground path from Q7102’s source, turning off the VHF stage

RF amplifier. The amplified RF signal is output and coupled to the double tuned filter via

C7118. The UHF RF amplifier is the same configuration as the VHF circuit.

+12V

RF FROM

SINGLE TUNED

FILTER

C7113

C7116

D

VHF RF

S

L7109

Q7102

AMP.

+12V

C7130

R7123

G1

G2

C7117

R7119

RF

AGC

Figure 17, VHF RF Amplifier

C7118

RF

OU

R7121

R7121

BV/U SWITCH

Q7403, Q7404

The double tuned filter re-tunes the RF signal to obtain greater selectivity or “sharp”

tuning and provides impedance matching. The primary is tuned by CR7108 which is

controlled by the RF_PRI line. This control voltage is derived from the PLL circuit and

is summed with the digital alignment offset voltage. When the BS voltage is approximately -14.5 volts, the tuned circuit is composed CR7108, L7111 and L7112, figure

18. When the BS1 line is +11.5, CR7109 is forward biased, shunting L7112 by connecting the low side of L7111 to ground through C7125, figure 19.

Page 23

R7108

C7145

C7119

C7122

R7128

RF FROM

Q7102

RF_PRI

C7118

R7135

R7151

R7108

C7125

CR7109

R7125

C7112

CR7108

L7111

L7112

M

M

R7127

Figure 18, Double Tuned Filter

C7145

C7119

CR7111

L7113

L7114

CR7113

CR7110

R7149

C7122

C7126

C7144

R7128

R7136

C7318

R7134

RF TO

MIXER/OSC.

U7301

RF_SEC

BS

RF FROM

Q7102

RF_PRI

C7118

R7135

CR7111

L7113

L7114

R7127

R7151

C7125

CR7109

R7125

C7112

CR7108

L7111

L7112

M

M

Figure 19, Double Tuned Filter (BS1 = -14.5V)

CR7113

CR7110

R7149

C7126

C7144

R7136

C7318

R7134

RF TO

MIXER/OSC.

U7301

RF_SEC

BS

Page 24

TECH

TIP

The secondary is tuned in a similar manner. The RF_SEC voltage, derived from the PLL

circuit and summed with digital alignment offset voltage, is applied to the cathodes of

CR7111 and CR7113. When the BS line is set to approximately -14.5, L7113 is in

series with L7114. They are tuned by CR7111 and CR7113. When the BS1 line is set

to approximately +11.5 volts, CR7110 is forward biased, shunting L7114 by connecting

the low side of L7113 to ground through C7126, figure 20.

The UHF double tuned circuit is analogous to the VHF circuit except there is no band

switching. This eliminates the need for additional inductors and switching diodes, making

the UHF circuit somewhat simpler than its VHF counterpart.

The BS1 line is switched positive (approximately +11.5V) for cable channels 713, and 18 - 125. The BS line is switched negative (approximately -14.5) on cable

channels 2 - 6, and 14 - 17.

RF FROM

Q7102

RF_PRI

C7118

R7135

C7145

R7108

C7125

R7151

CR7109

R7125

C7112

C7119

CR7108

L7111

L7112

M

M

CR7111

L7113

L7114

R7127

Figure 20, Double Tuned Filter (BS1 = +11.5V)

C7122

CR7113

CR7110

R7149

R7128

C7126

C7144

R7136

C7318

R7134

RF TO

MIXER/OSC.

U7301

RF_SEC

BS

Page 25

The oscillator and mixer are contained in U7301. UHF and VHF signals from their

T

respective double tuned filters are input to pin 4 for VHF, and pins 10 and 12 for UHF.

The mixer and oscillator circuit for UHF is functionally the same as VHF.

As mentioned previously, the mixer circuit beats the RF frequency with the local oscillator to obtain the IF frequency. The tank circuit for the VHF oscillator is located off

U7301 pins 9 and 11. The tuned circuitry off these pins is tuned by varactor diodes

CR7305 and CR7302. These diodes are tuned so the oscillator is set 45.75MHz above

the RF carrier.

U7401 contains the PLL for the tuner. It decodes I2C bus information from the microprocessor and sets up the tuning voltage for the different RF stages and the local oscillator. Pin 8 is the BS1 (Band Select) line for the VHF RF stages and the VHF local

oscillator tank circuit. The VHF tank circuit has two modes of operation.

Pin 8 is set HI for cable channels 2 - 6, and 14 - 17. This turns off Q7402 allowing the

emitter to be pulled low by the -12 volt supply. This keeps CR7303 reversed biased

preventing it from affecting the VHF oscillator tank circuitry, figure 21.

OSC.,

Mixer, PLL

C7306

L7302

VHF IN

UHF_HI IN

UHF_LO IN

C7304

CLOC K

C7318

C7322

DATA

R7317

C7305

Y7401

4MHz

PCBL2

C7604

L7301

C7301

C7302

VHF /UHF

+ 5V

PCBL3

4

1

3

5

12

10

fLO_BV/U

2

3

5

4

U7301

OSC./MIX

VHF

MIXER

IF

AMP

UHF

MIXER

7

9

BV/U

U7401

TUNER

PLL

10

8

fLO

VHF

OSC.

UHF

OSC.

BS1

R7601

C7416

C7406

R7602

C7315

R7605

Q7601

SAW

AMP

R7604

+12V

R7305

R7314

C7311

C7312

C7310

C7308

C7402

C7309

L7303

+33V

R7403

R7402

Q7401

C7319

CR7305

R7311

C7320

R7301

CR7301

R7407

R7401

R7310

R7408

C7314

C7323

CR7302

BS1 = HI

R7307

R7306

L7306

R7315

C7413

+33V

R7411

C7414

L7304

R7415

C7415

+12V

Q7402

VREF

C7325

R7416

R7412

L7305

+12V

CR7303

R7313

R7417

-12V

R7304

11

9

+12V

R7312

R7316

8

R7303

14

CR7304

R7302

15

C7307

16

13

C7316

11

C7403

1

R7404

14

R7602

+12V

C7605

L7601

R7603

R7606

C7603

C7321

OU

IF

Figure 21, Local Oscillator (U7401-8 = HI)

Page 26

Pin 8 is set LO for cable channels 7- 13, and 18 - 125. This turns on Q7402 causing

T

its emitter to go to +12 volts. This forward biases CR7303 which shunts L7305 and

C7323 out of circuit by connecting C7315 (1000 pF) in parallel. This raises the frequency of the tank circuit for the higher VHF channels, figure 22.

C7306

L7302

VHF IN

UHF_HI IN

UHF_LO IN

C7304

CLOC K

C7318

C7322

DATA

R7317

C7305

Y7401

4MHz

PCBL2

C7604

L7301

C7301

C7302

VHF /UHF

+ 5V

PCBL3

4

1

3

5

12

10

fLO_BV/U

2

3

5

4

U7301

OSC./MIX

VHF

MIXER

IF

AMP

UHF

MIXER

7

9

BV/U

U7401

TUNER

PLL

10

8

fLO

VHF

OSC.

UHF

OSC.

BS1

R7304

11

9

+12V

+12V

R7305

R7314

C7311

C7312

R7312

C7319

CR7305

R7311

C7314

CR7302

L7304

C7323

CR7303

L7305

R7313

R7601

R7602

C7315

R7605

Q7601

SAW

AMP

R7604

BS1 = LO

R7316

8

R7303

14

CR7304

R7302

15

C7307

16

13

C7316

11

C7403

1

R7404

14

C7310

C7308

C7402

C7309

L7303

+33V

R7403

R7402

Q7401

C7320

R7301

CR7301

R7310

R7407

R7401

R7408

R7307

R7306

L7306

R7315

+33V

C7413

R7411

C7414

R7415

C7415

+12V

Q7402

VREF

C7325

R7416

R7412

+12V

-12V

R7417

C7416

C7406

R7602

+12V

C7605

L7601

R7603

R7606

C7603

C7321

OU

IF

Figure 22, Local Oscillator (U7401-8 = LO)

The variable tuning of the local oscillator is controlled by a DC voltage generated by the

PLL’s loop filter off pins 1 and 14 of U7401. The reference oscillator is generated by

the 4 MHz crystal on U7401 pins 2 and 3. The frequency of the local oscillator (fLO) is

sampled at U7410 pin 11, divided down and compared against an internal reference

frequency. Pins 1 and 14 output pulses (not readily seen on an oscilloscope) that are

low-pass filtered and used to sink current through Q7401 to lower the tuning voltage at

its collector. As Q7401 conducts less, the +33V pull-up supply pulls the tuning voltage

higher. The tuning voltage is split and sent to two places.

Page 27

First, part of the tuning voltage is sent to R7401 and R7408 where it is divided to form

T

the VREF signal. This is sent to the interface circuitry (U7501) where it is summed with

digital alignment offset voltages. The summed voltages are used to control the single

tuned filter and the primary and secondary of the double tuned filter, figure 23.

Second, the tuning voltage is sent to the VHF and UHF local oscillator tank circuits

where it tunes the respective varactor diodes.

C7306

L7302

VHF IN

UHF_HI IN

UHF_LO IN

C7304

CLOCK

C7318

C7322

DATA

R7317

C7305

Y7401

4MHz

PCBL2

C7604

L7301

C7301

C7302

VHF/UHF

+ 5V

4

1

3

5

12

10

PCBL3

2

3

5

4

U7301

OSC ./MIX

VHF

MIXER

IF

AMP

UHF

MIXER

fLO_BV/U

7

9

BV/U

U7401

TUNER

PLL

10

8

fLO

VHF

OSC.

UHF

OSC.

BS1

R7601

C7416

C7406

R7602

C7315

R7605

Q7601

SAW

AMP

R7604

+12V

R7305

R7314

C7311

C7312

C7310

C7308

C7402

C7309

L7303

+33V

R7403

R7402

Q7401

C7319

CR7305

R7311

C7320

R7301

CR7301

R7310

R7407

R7401

R7408

C7314

R7307

R7306

L7306

R7315

CR7302

+33V

C7413

R7411

C7414

L7304

C7323

R7415

C7415

+12V

Q7402

VREF

C7325

R7416

R7412

L7305

+12V

-12V

CR7303

R7313

R7417

R7304

11

9

+12V

R7312

R7316

8

R7303

14

CR7304

R7302

15

C7307

16

13

C7316

11

C7403

1

R7404

14

R7602

+12V

C7605

L7601

R7603

R7606

C7603

C7321

OU

IF

Figure 23, Local Oscillator Tank Circuit Tuning

Page 28

After the RF signal is mixed with the local oscillator, the 1st IF filter off of U7301 pins 3

T

and 5 helps to remove the “sum” signal and leave the “difference” signal of 45.75MHz

for the IF video carrier. The signal is amplified and output at pin 1 where is passes

through the second IF filter composed of L7302, C7306 and R7317. Finally, the

resulting IF signal is amplified by the SAW amp (Q7601) which provides the necessary

gain to overcome the attenuation of the SAW filter in the IF stage, figure 24.

C7306

L7302

VHF IN

UHF_HI IN

UHF_LO IN

C7304

CLOCK

DATA

C7318

C7322

R7317

C7305

Y7401

4MHz

PCBL2

C7604

L7301

C7301

C7302

VHF/UHF

+ 5V

PCBL3

4

1

3

5

12

10

fLO_BV/U

2

3

5

4

U7301

OSC./MIX

VHF

MIXER

IF

AMP

UHF

MIXER

7

9

BV/U

U7401

TUNER

PLL

10

8

fLO

VHF

OSC.

UHF

OSC.

BS1

R7601

C7416

C7406

R7602

C7315

R7605

Q7601

SAW

AMP

R7604

+12V

R7305

R7314

C7311

C7312

C7310

C7308

C7402

C7309

L7303

+33V

R7403

R7402

Q7401

C7319

CR7305

R7311

C7320

R7301

CR7301

R7310

R7407

R7401

R7408

C7314

R7307

R7306

L7306

R7315

+33V

CR7302

C7413

R7411

L7304

C7323

C7414

R7415

C7415

+12V

Q7402

VREF

C7325

R7416

R7412

L7305

+12V

-12V

CR7303

R7313

R7417

R7304

11

9

+12V

R7312

R7316

8

R7303

14

CR7304

R7302

15

C7307

16

13

C7316

11

C7403

1

R7404

14

R7602

+12V

C7605

L7601

R7603

R7606

C7603

C7321

OU

IF

Figure 24, IF Amplifier

Page 29

The tuner D/A’s are aligned on 19 “data channels” that span all the frequencies to be

tuned (see figure 25). Linear interpolation is used to determine the correct setting of the

D/A’s on channels that fall between the “data channels”. This greatly reduces the

number of alignments and saves space in the EEPROM. The “data channels” are aligned

via the service menu described in the System Control section of this manual.

There are three alignments for each data channel: Single Tuned, Double Tuned Primary

and Double Tuned Secondary. Because changing the setting on one channel will affect

the linear interpolation curve, all channels must be aligned if any parameter is changed.

The alignment must be performed with the top and bottom tuner covers in place with the

bottom shield soldered.

1. Monitor IF AGC voltage at pin 14 of the T-Chip, U1001.

2. Adjust each parameter for minimum AGC voltage on each step while attenuating

the test signal appropriately.

Note: The Double Tuned Secondary and Primary adjusments may have little effect

initially. After adjusting the Single Tuned filter for the lowest AGC voltage, go

back and re-adjust the Secondary and Primary before going on to the next alignment channel.

Tuner Alignment

TECH

TIP

Figure 25, 19 Data Channels

Page 30

To properly align the tuner, an RF generator capable of producing varibly attenuated,

FCC frequencies up to cable channel 125 must be used. Off-air signals from an antenna

or cable will not do. Because RF generators are often quite expensive, Thomson has

developed an inexpensive alternative: the TAG001.

The TAG001 (Tuner Alignment Generator) operates off an external +5VDC supply and

modulates composite audio and video signals on cables channels 2 through 125. Video

IF also can be selected by entering 00. The generator is controlled by a standard RCA

or GE remote control. A standard coaxial cable connects the television to the

TAG001’s 75 ohm “F” connector. The output level can be controlled with the built-in

attenuator switches.

The TAG001 has been designed to not only be an effective tuner alignment generator,

but a versatile tool for servicing all brands of television, VCR and MATV (Master

Antenna Television) systems. To order a TAG001 contact:

Thomson Consumer Electronics

10003 Bunsen Way

Louisville, KY 40299

Phone: (502) 491-8110

Troubleshooting the tuner is best accomplished with a digital multimeter. By making

voltage and resistance checks, tuner failures can be isolated in a reasonable amount of

time. Certain precautions should, however, be observed. Always put the shields back

on after servicing and solder them if they were unsoldered. Make sure none of the coils

in the tuner are moved or in any way repositioned (this will prevent making painstaking

coil alignments later). Solder connections should be clean and smooth. Do not use

more solder than is necessary.

If any of the varactor diodes are replaced in either the VHF circuits (CR106,

CR107, CR108, CR111, CR113 CR302 and CR305) or UHF circuits (CR101,

CR102, CR103, CR114, CR301 and CR304), all the diodes in the respective

circuit must be changed. The replacement diodes are matched for capacitance

characteristics and come as a set. If these guidelines are not followed, the

tuner will not function correctly. The stock number for the diode kit containing

the matched diodes is 215494.

Page 31

One Band Inoperative

If the tuner will tune channels on all bands but one, limit troubleshooting to the band

specific circuitry. Obviously, if one band is functional, U7501, U3101, U3201, U7401

and at least part of U7301 are working properly.

1. Check the plus and minus 12 volt supplies.

2. Check the biasing on the respective RF amplifier MOSFET(Q7101-UHF, Q7102-

VHF).

3. If the problem is only VHF low (2- 6) or VHF hi (7 -13), make sure the band

switching voltage from the collector of Q7402 turns on (or off) CR7112, CR7105,

CR7109, and CR7110.

Picture Present But Not Good

1. Check the AGC voltage

2. Check all the supply voltages to the tuner: +5V, +12V, -12V and +33V.

3. Check single tuned, primary and secondary tuning voltages (see voltage chart).

DIGITAL

4. Check for the correct voltages on U7501 (see voltage chart).

5. Check for the correct EEPROM values by trying to improve one channel by realign-

ing the D/A’s (make sure to record the original value in order to restore it if alignment

does not fix the problem).

6. Go to number 9 on the “No Tuning” symptom below.

No Tuning

1. Verify channel numbers change on the screen. If the OSD does not respond to

channel change commands, the problem lies in the system control circuit and not in

the tuner.

2. Check all the supply voltages to the tuner: +5V, +12V, -12V and +33V.

3. Check for the correct band switching voltage on pins 8 and 9 of U7401, pin 7 of

U7301, the collector of Q7402 and the collectors of Q7403 and Q7404 (see

voltage chart).

4. Check the tuning voltage on the collector of Q7401 (compare to Q7401 Collector

Voltage Chart). Note: If the tuning voltage is stuck HI or LO, there is a prob-

lem in the PLL loop. Check for a 4MHz oscillator signal on Y7401. Depending

on the loading of the oscilloscope, it should be around 1Vpp with a X10 probe.

The tuning voltage can be manually controlled by connecting a 100K potentiometer from the collector of Q7401 to ground after shorting its base to emitter,

turning it off.

Page 32

DIGITAL

5. Check the LO voltage at R7301. The voltage should increase as channels go up in

number and decrease and channels come down in number. If the voltage is missing,

check the path between R7401 and R7301. Also check for a leaky or shorted

CR7301, 2, 4 & 5.

6. Check the single tuned, primary and secondary varactor diode tuning voltages (see

voltage chart on page 35).

7. Check band switch logic (BS1) on Q7402 (see voltage chart).

8. Check B V/U logic on Q7403 and Q7404 (see voltage chart ).

9. Check the RF AGC. Check the AGC line components: R2313, R2314, R2315,

C2306 and R7130 (see service data schematic). Attenuate service modulator

output. RF AGC voltage should increase.

10. Check the MOSFET bias on Q7101 and Q7102 (see voltage chart).

11. Check IF output, Q7601 and associated components.

U7301

Pin Lo V Chan. Hi V Chan. UHF Chan.

No. 2 6 7 13 14 40 69

1. 5.43V 5.42V 5.38V 5.38V 5.30V 5.22V 5.30V

2. 2.93V 2.98V 2.95V 2.95V 3.18V 3.16V 3.18V

3. 7.80V 7.81V 7.75V 7.69V 7.56V 7.51V 7.56V

4. 2.99V 2.99V 2.96V 2.97V 3.18V 3.16V 3.18V

5. 7.82V 7.81V 7.75V 7.71V 7.56V 7.51V 7.56V

6. 0V 0V 0V 0V 0V 0V 0V

7. 3.06V 3.06V 3.04V 3.01V 0V 0V 0V

8. 9.06V 9.03V 8.97V 8.89V 8.84V 8.80V 8.84V

9. 3.02V 3.02V 2.98V 2.98V 3.36V 3.33V 3.36V

10. 3.25V 3.25V 3.22V 3.19V 2.88V 2.87V 2.88V

11. 4.94V 5.00V 5.06V 5.02V 9.62V 9.58V 9.62V

12. 3.25V 3.23V 3.22V 3.19V 2.87V 2.87V 2.88V

13. 0V 0V 0V 0V 0V 0V 0V

14 .9.05V 9.04V 8.97V 8.90V 5.43V 5.39V 5.46V

15. 3.43V 3.43V 3.40V 3.37V 2.88V 2.84V 2.88V

16. 3.44V 3.43V 3.40V 3.38V 2.89V 2.89V 2.89V

Note: Voltages shown are typical voltages only. Voltages will vary from set to set

because of alignment differences.

Page 33

U7401

Pin Lo V Hi V UHF

No.

1. 1.75V 2.11V 1.72V

2. 2.11V 2.11V 2.11V

3. 2.11V 2.11V 2.11V

4. 4.78V 4.78V 4.78V

5. 4.71V 4.71V 4.71V

6. 0V 0V 0V

7. 1.32V 1.32V 1.34V

8. 11.5V 0V 0V

9. 7.41V 7.41V 0V

10. 4.85V 4.85V 4.85V

11. 2.30V 2.30V 2.30V

12. 2.30V 2.30V 2.30V

13. 0V 0V 0V

14. 0.60V 0.60V 0.60V

U7501

Pin Lo V Hi V UHF

No. 2 6 7 13 14 40 69

1. 1.36V 1.96V 1.58V 1.93V 1.74V 2.90V 4.84V

2. 1.36V 1.96V 1.58V 1.93V 1.74V 2.90V 4.84V

3. 1.35V 1.95V 1.57V 1.92V 1.73V 2.89V 4.83V

4. 33.0V 33.0V 33.0V 33.0V 33.0V 33.0V 33.0V

5. 1.06V 1.74V 1.47V 1.87V 1.46V 2.53V 4.08V

6. 1.06V 1.74V 1.47V 1.87V 1.46V 2.54V 4.09V

7. 1.06V 6.05V 4.09V 7.03V 3.95V 11.8V 23.2V

8. 0.68V 4.57V 3.46V 6.19V 4.41V 12.3V 24.0V

9. 1.01V 1.54V 1.39V 1.76V 1.52V 2.60V 4.19V

10. 1.01V 1.54V 1.39V 1.76V 1.52V 2.60V 4.19V

11. 0V 0V 0V 0V 0V 0V 0V

12. 1.05V 1.75V 1.36V 1.72V 1.44V 2.51V 4.15V

13.1.05V 1.75V 1.36V 1.72V 1.44V 2.51V 4.15V

14.1.01V 6.10V 3.24V 5.92V 3.78V 11.6V 23.6V

Page 34

DIGITAL

Q7101

Lo V Hi V UHF

2 7 14

G1 0V 0V 4.84V

G2 5.03V 6.54V 7.19V

D 0.16V 0.20V 11.3V

S 0.19V 0.17V 4.83V

Q7102

2 7 14

G1 4.64V 4.58V 4.61V

G2 5.32V 6.85V 7.19V

D 11.3V 11.2V 11.4V

S 4.08V 4.20V 11.3V

Tuner

Voltage Charts

Cable Signal

U7301

Pin Band 1 Band 2 Band 3

No. 2 17 18 50 51 75 99

1. 5.44V 5.40V 5.41V 5.40V 5.30V 5.28V 5.48V

2. 2.99V 2.96V 2.96V 2.96V 3.18V 3.17V 3.00V

3. 7.80V 7.78V 7.77V 7.75V 7.57V 7.57V 7.89V

4. 2.99V 2.96V 2.96V 2.96V 3.18V 3.17V 3.00V

5. 7.82V 7.78V 7.77V 7.77V 7.57V 7.57V 7.89V

6. 0V 0V 0V 0V 0V 0V 0V

7. 3.06V 3.04V 3.05V 3.05V 0V 0V 3.08V

8. 9.02V 9.01V 8.98V 9 00V 8.84V 8.83V 9.14V

9. 3.01V 3.01V 2.98V 2.98V 3.36V 3.35V 3.01V

10. 3.26V 3.23V 3.22V 3.23V 2.88V 2.88V 3.28V

11. 4.96V 5.04V 5.07V 5.16V 9.62V 9.60V 5.14V

12. 3.26V 3.23V 3.22V 3.23V 2.88V 2.87V 3.28V

13. 0V 0V 0V 0V 0V 0V 0V

14. 9.05V 9.00V 8.98V 9.00V 5.43V 5.42V 9.13V

15. 3.43V 3.41V 3.42V 3.41V 2.88V 2.87V 3.46V

16. 3.41V 3.41V 3.41V 3.41V 2.87V 2.89V 3.47V

Note: Voltages shown are typical voltages only. Voltages will vary from set to set

because of alignment differences.

Page 35

U7401

Pin Band 1Band 2Band 3

No. 2 18 51

1. 1.74V 1.74V 1.74V

2. 2.11V 2.11V 2.11V

3. 2.11V 2.11V 2.11V

4. 4.78V 4.78V 4.78V

5. 4.71V 4.71V 4.71V

6. 0V 0V 0V

7. NC NC NC

8. 11.5V 0V 0V

9. 7.47V 7.42V 0V

10. 4.85V 4.85V 4.85V

11. 2.31V 2.31V 2.31V

12. 2.31V 2.31V 2.31V

13. 0V 0V 0V

14. 0.60V 0.60V 0.60V

DIGITAL

U7501

Pin Band 1 Band 2 Band 3

No. 2 17 18 50 51 75 99

1. 1.36V 4.63V 1.30V 5.52V 1.20V 2.21V 2.86V

2. 1.36V 4.63V 1.30V 5.52V 1.20V 2.21V 2.86V

3. 1.36V 4.63V 1.30V 5.52V 1.20V 2.21V 2.86V

4. 33.0V 33.0V 33.0V 33.0V 33.0V 33.0V 33.0V

5. 1.06V 3.62V 1.16V 4.68V 0.99V 1.90V 2.54V

6. 1.06V 3.62V 1.16V 4.68V 0.99V 1.90V 2.54V

7. 1.07V 19.8V 1.78V 27.6V 0.54V 7.20V 11.9V

8. 0.69V 24.2V 1.30V 25.3V 0.86V 7.63V 12.5V

9. 1.01V 4.22V 1.10V 4.38V 1.01V 1.96V 2.62V

10. 1.01V 4.22V 1.09V 4.38V 1.04V 1.96V 2.62V

11. 0V 0V 0V 0V 0V 0V 0V

12. 1.06V 4.36V 1.07V 4.76V 0.99V 1.86V 2.66V

13. 1.06V 4.36V 1.07V 4.76V 0.99V 1.86V 2.66V

14. 1.02V 25.2V 1.12V 28.1V 0.54V 6.91V 12.7V

Page 36

Q7101

Band 1 Band 2 Band 3

2 18 51

G1 0V 0V 4.82V

G2 5.05V 4.17V 7.19V

D 0V 0.10V 11.3V

S 0.10V 0.10V 4.83V

Q7401 Collector

CABLE

CHANNEL

VOLTAGE

2 1.6

6 5

Q7102

G1 4.59V 4.65V 4.61V

G2 5.44V 4.50V 7.20V

D 11.3V 11.2V 11.1V

S 4.08V 3.71V 11.0V

Q7401

E 0V 0V 0V

B 0.60V 0.60V 0.60V

C 2.05V 1.65V 1.00V

Q7402

E 11.3V 11.4V 11.4V

B 11.4V 10.6V 10.6V

C -14.5V 11.2V 11.2V

Q7403

E 0V 0V 0V

B 0.71V 0.71V 0V

C 0.11V 0.11V 11.3V

14 12.7

17 22.7

18 1.8

13 5.6

34 10.8

37 12.7

48 26.2

50 31

51 0.7

57 2

63 3.8

76 8

83 10.1

93 12.6

110 15.9

117 18.3

Q7404

E 11.4V 11.4V 11.4V

B 11.0V 11.0V 10.7V

C 0.11V 0.11V 11.3V

Note: Voltages shown are typical voltages only. Voltages will vary from set to set

because of alignment differences.

125 23.5

Page 37

Varactor Diode Tuning Voltage Chart

CABLE

CHANNEL

2 0.69 1 1.1

6 4.37 5.7 6.3

14 14.92 14.5 14.9

17 26 25.5 23.5

18 1.6 1.3 1.9

13 5.7 5.5 6.7

34 11 10.5 12.8

37 12.8 12.2 14.7

48 22.8 23.1 26.2

50 24.1 24.3 26.6

51 0.6 0.64 0.69

CR7106, CR7107 CR7108 CR7111

CR7101, CR7114 CR7102 CR7103

57 1.7 1.81 1.98

63 3.06 3.28 3.68

76 6.88 7.09 7.76

83 8.92 9.08 9.83

93 11.45 11.63 12.3

110 14.43 14.73 15.61

117 16.54 17 18.2

125 19.6 21.6 26.5

Note: Voltages are approximate cathode voltages only and will vary

from set to set. This chart is supplied as a basic guide for typical

voltages on the alignment channels. DO NOT USE THESE

VOLTAGES AS A BASIS FOR TUNER ALIGNMENT.

Page 38

Q7401

20

E

C

B

21

B

C

E

22

23

E

C

B

E

C

B

CR7103

CR7111

CR7102

CR7108

SD

Q7102

G2 G1

CR7109

Q7101

G2

SD

G1

25

CR7106

CR7107

CR7114

CR7101

26 24

K

J

I

H

G

F

E

Figure 26, Components - Tuner Bottom

Page 39

Figure 27, Components - Tuner Top

Page 40

Tech Tips

The following repair information is based on information received from the field. The

symptoms along with their respective solutions are not all inclusive, but will aid in repairing commonly encountered problems.

Dead Set -

Power Supply

Dead Set -

System

Control

POWER

VOL. UP

VOL. DN.

CH. UP

1. R4101 open at U4101 pin 4 (CTC176/77/86/87).

2. Corrupted EEPROM.

3. Immediate U4101 failure caused by an open R4129 or trace open at pin 5, or a

short on the secondary of T4101.

1. Make sure the standby power supplies are working. (12, 7.6 & 5)

2. Check for horizontal drive pulses out of pin 24 of U1001 when the power button is

pressed. If the pulses are there even momentarily, system control is working and the

problem is in the deflection circuits. If the pulses do not appear, check the 7.6 volt

standby voltage on pin 22 of U1001. If the supply is not present on pin 22,

unsolder the pin and see if the supply comes up on the pad. If it does, U1001 is

defective. If it does not, trace the supply back to its source. If 7.6 volts is present

on U1001 pin 22 in circuit, go to the next step.

1,2,3

GND

U3201

4,7

5V

KS1

6

KS2

7

KS3

8

KD1

5

T-CHIP DATA

TUNER CLOCK

T-CHIP CLOCK

TUNER DATA

U3101

µ

P

PIP

ENABLE

T-CHIP

ENABLE

8

15

16

12

14

EEPROM

VDD

DATA CLOCK

5 6

U2901

D-PIP

DATA CLOCK ENABLE

20 21

GND

VDD

22

3,5

15,16

40,41

39 5V

DATA

54

CLOCK

53

ENABLE

52

U1001

T-CHIP

HORZ.

OUT

24

CH. DN.

MENU

5V

2

IR3401

3

5V

1

RESET

7.6 V

5

STBY

GND

13

56

22

BUS

GND

5V

5V

10

4

DATA CLOCK

U7401

TUNER PLL

VCC

VDD

20

OSC

OSC

GND

3

OUT

41 42

1

Y3101

21

IN

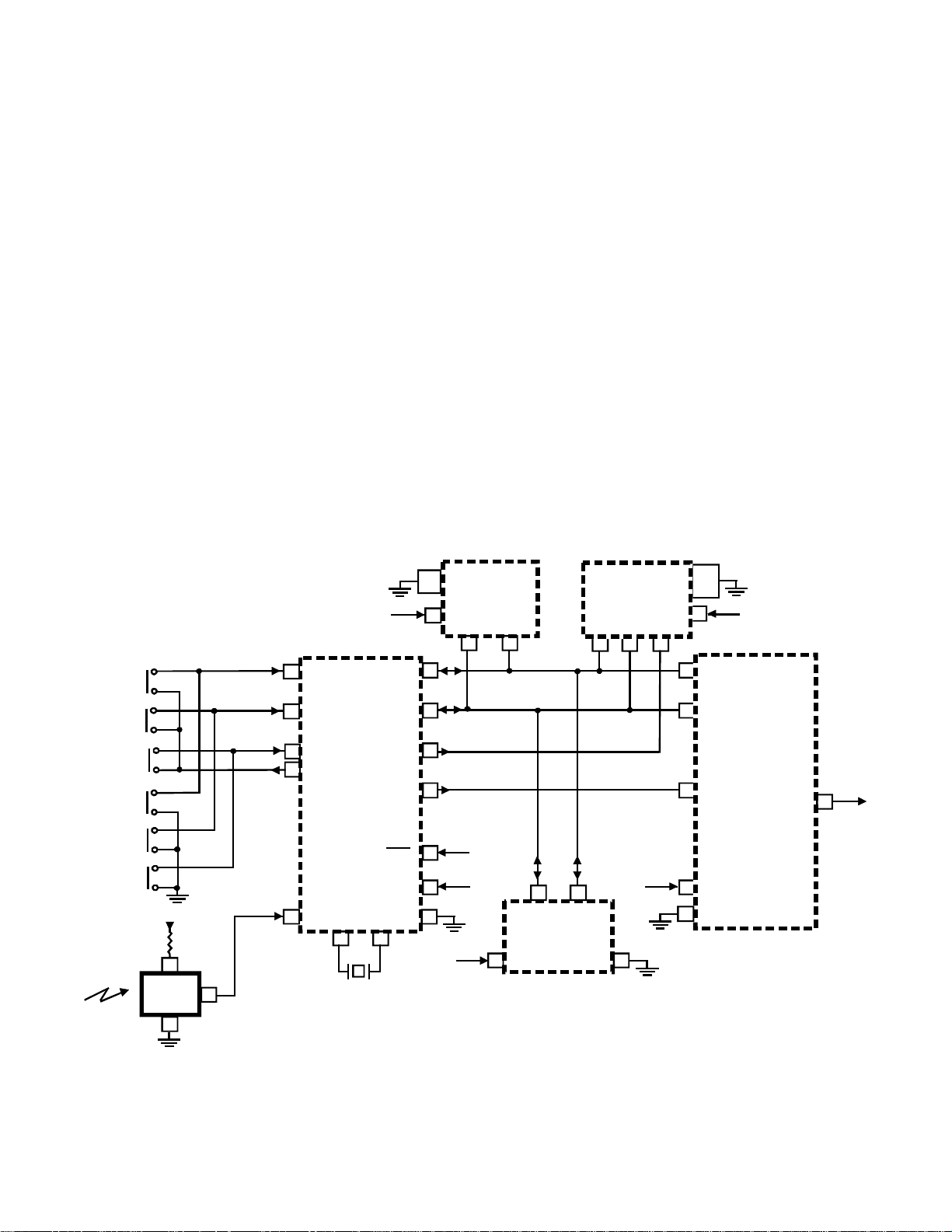

Figure 28, CTC175/76/77 System Control Block Diagram

Page 41

Note: ( ) refers to the pins on the Thomson ST-9 microprocessor used on late

production CTC175/76/77 chassis and the CTC186/87 chassis.

3. Check for standby 5 volts on pin 20 (21) of U3101. If it is missing, check the

power supply. If present, go to the next step.

4. Check the reset pin 1 (2) of U3101 for 5 volts. If it is low or missing, check the

reset circuit. If it is, go to the next step.

5. Check pins 41 (36) and 42 (37) of U3101 for a 5 Vpp oscillator. If the signal is not

5 Vpp, check Y3101 and its peripheral components. If the signal is completely

absent, suspect U3101 or Y3101. If the 8 MHz signal is present, go to the next

step.

POWER

VOL. UP

VOL. DN.

CH. UP

CH. DN.

MENU

5V

2

IR3401

3

22

GND

VDD

54

53

52

22

3,5

15,16

40,41

39

DATA

CLOC K

ENABLE

BUS

GND

5V

U1001

T-CHIP

HORZ.

OUT

24

1,2,3

GND

U3201

4,7

EEPROM

5V

KS1

6

KS2

7

KS3

8

KD1

5

1

T-CHIP DATA

TUNER CLOCK

T-C HIP CLOCK

TUN ER DATA

U3101

µ

P

OSC

OUT

PIP

ENABLE

T-CHIP

ENABLE

RESET

VDD

OSC

GND 56

IN

19

20

12

14

21

22

VDD

8

DATA

CLO CK

5

6

5V

2

5V

DATA

20 21

U2901

D-PIP

CLOC K

7.6 V

STBY

ENABLE

36 37

5V

Y3101

TUNER PLL

VCC

10

4

DATA

U7401

5

CLOCK

GND

13

9V

DATA

STEREO DEC ODER

VCC

15

1

CLOC K

U1600

2

3,4,

GND

17

1

CTC186/87 ONLY

Figure 29, System, Control Block Diagram (late production)

Page 42

TECH

TIP

6. Monitor pins 14, 15 (19) and 16 (20) of U3101. There should be no data activity

in the standby mode. When the power button is pressed, 5 Vpp data pulses should

appear. If no pulses appear when the power button is pressed, unsolder pins 20, 21

and 22 of U2901 and pins 4 and 5 of U7401. Now re-check U3101 pins 14, 15

(19) and 16 (20). If data activity returns, suspect a defect in U2901’s or U7401’s

circuit areas. If data activity does not return, go to the next step.

7. Unsolder pins 14, 15 (19) and 16 (20) on U3101 and check for constant 5 Vpp

data pulses in the standby mode on those pins.

Note: When U3101 is initialized, it checks to see if U3201 is present. Under normal

conditions, it immediately finds U3201 and ceases data activity . With the enable,

data and clock lines disconnected, U3101 continues to send out data activity looking

for U3201. This is normal and indicates U3101 is working.

If no data activity is seen on U3101 pins 14, 15 (19) and 16 (20) with the pins out of

circuit, U3101 is probably defective. If data activity is present, reconnect the pins

and go to the next step.

TECH

TIP

8. Having confirmed data activity on pins 14, 15 (19) and 16 (20) of U3101 out of

circuit, disconnect pins 5 and 6 of U3201. Check for data activity in the standby

mode on the circuit board foil side of U3201 pins 5 and 6. If data activity is present

on the foil pads for those pins with the IC out of circuit, U3201 is defective.

Do not throw away the original U3201 until the problem is absolutely confirmed. If

U3201 turns out not to be the problem, putting the old IC back in will prevent a

complete chassis alignment from having to be performed.

If no data activity is seen on the circuit board with U3201 out of circuit, connect the

IC and go to the next step.

9. Unsolder pins 52, 53 and 54 on U1001. Check to see if the data pulses are present

on the foil that leads to the pins. If data pulses are present on the circuit board foil,

U1001 is most likely defective. If no data pulses appear on circuit board foil side of

U1001 pins 52, 53 and 54, suspect an open connection or resistor, or possibly a

leaky capacitor on the data bus.

10. Once the problem is isolated and repaired, do not forget to re-connect U2901,

U7401 and any other parts that may have been unsoldered during troubleshooting.

Audio -

Low/No

Audio -

Buzz

Check the speaker mute logic HI at U3101 pin 29. Replace the EEPROM (U3202)

when HI. The EEPROM data has been corrupted.

Change C4129 from 10µF to 100µF (194366) in the CTC176/77 chassis.

Page 43

Bad connection on the system control and tuner shield tabs.

Front Panel Phantom

Operation

Check for slightly insufficient 5V STBY supply voltage. If low, suspect leaky CR4104

(5.6V zener) in the base circuits of Q4103 and Q4105.

Check for above normal DC voltage and/or noise at U1001 pin 18. Suspect defective

C4501 or C4503.

No On-screen

Display

Vertical

Deflection Non-linear

Page 44

Loading...

Loading...