RCA CTC 175176, CTC177186 Service Manual

CTC175/176/177/186/187

Supplemental Training Manual

VERTICAL

TO

E8

RED BIAS

<21-B>

TO

E7

GRN BIAS

E5003

E5007

TP50

RED OUTP UT

194V

THO MSO N TECHNIC AL TRAINING

This training manual is a supplement to the CTC175/176/177 technical training manual (T-CTC175/

6/7-1). It contains additional information regarding system control circuit changes in later production

CTC175/76/77 chassis, new CTC186/87 circuits and an in-depth description of the tuner-onboard circuitry with troubleshooting strategies. This publication also contains "Tech Tips" from the

field on commonly encountered problems and their solutions. Using this manual in conjunction with

the CTC175/176/177 technical training manual and service data will enable the field technician to

repair these chassis more effectively and efficiently.

FOREWORD

Note: This publication is intended to be used only as a training aid. It is not intended to replace service

data. Thomson Consumer Electronics Service Data for these instruments contains specific

information about parts, safety and alignment procedures and must be consulted before performing

any service. The information in this publication is as accurate as possible at the time of publication.

Circuit designs and drawings are subject to change without notice.

SAFETY INFORMATION CAUTION

Safety information is contained in the appropriate Thomson Consumer Electronics Service Data. All

product safety requirements must be compiled with prior to returning the instrument to the consumer.

Servicers who defeat safety features or fail to perform safety checks may be liable for any resulting

damages and may expose themselves and others to possible injury.

All integrated circuits, all surface mounted devices, and many other semiconductors are electrostatically sensitive and therefore require special handling

techniques.

Prepared by

Thomson Consumer Electronics, Inc.

Technical Training Department

10330 North Meridian Street, Indianapolis, Indiana 46290-1024

U.S.A.

Table of Contents

CTC186/87 .................................................................................... 1

System Control .............................................................................. 4

MicroProcessoer Pinout .......................................................................................5

Comb Filter.................................................................................... 6

Troubleshooting .................................................................................................................................6

Stereo Decoder ..............................................................................7

dbx Alignments ..................................................................................................................................8

Inductor /Capacitor (LC) Basics .................................................... 14

Varactor Diode ................................................................................................................................15

Basic Tuner....................................................................................16

Oscillator / Mixer / IF Bandpass........................................................................................................ 17

PLL / Frequency Synthesizer............................................................................................................. 17

CTC176/77/86/87 Tuner ................................................................ 18

Single Tuned Filter ........................................................................................................................... 21

RF Amplifier.................................................................................................................................... 23

Double Tuned Filter.......................................................................................................................... 23

OSC., Mixer, PLL ...........................................................................................................................26

IF Amp ........................................................................................................................................... 29

Tuner Alignment ............................................................................................................................... 30

Troubleshooting ...............................................................................................................................31

Tuner Voltage Charts........................................................................................................................ 33

Tech Tips ..................................................................................... 41

Page 3

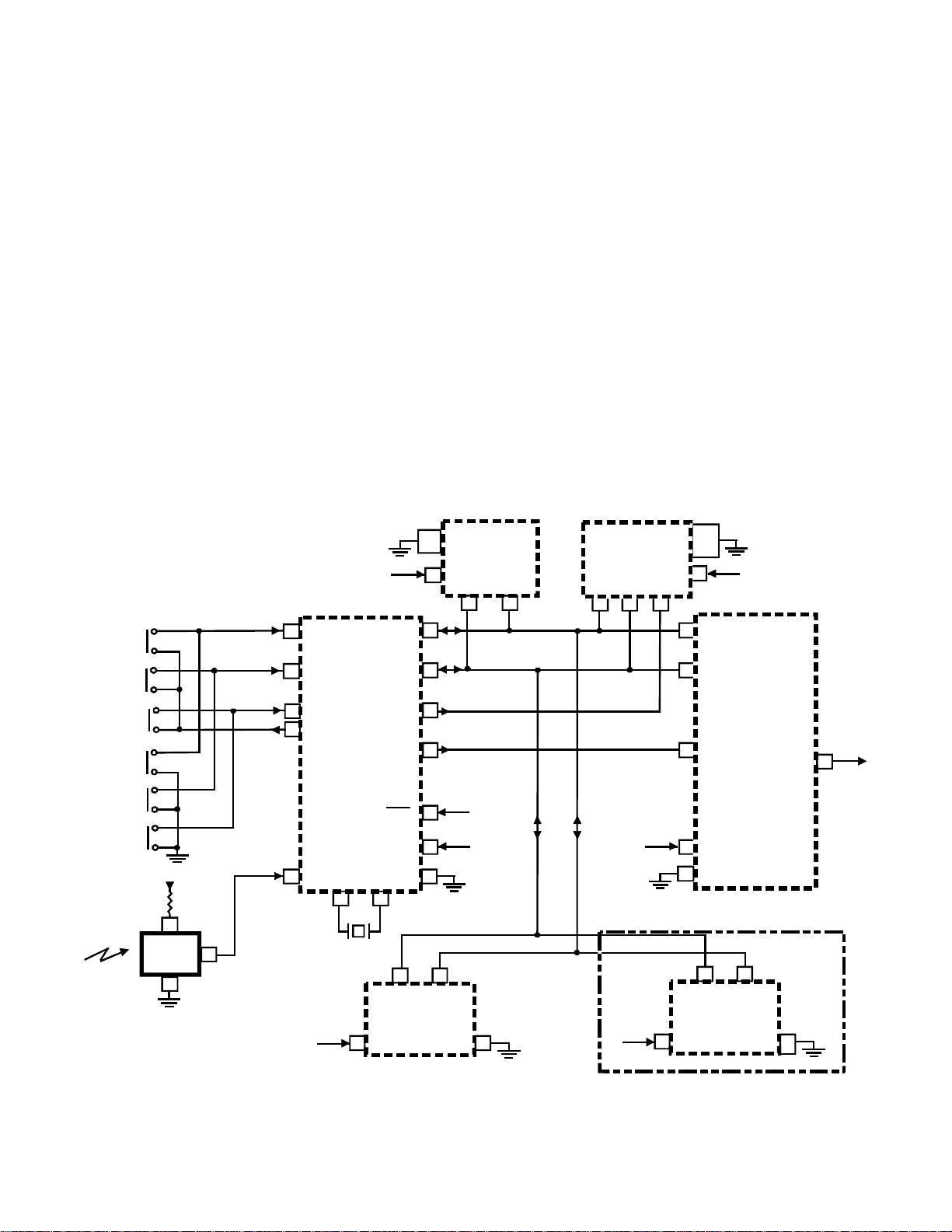

The CTC186/87 chassis is virtually the same as the CTC176/77 with the addition of a

dbx Stereo Decoder / Comb filter board. For complete descriptions of the common

circuitry, refer to the CTC175/176/177 Technical Training Manual (publication number

T-CTC175/6/7/-1).

CTC186/87

Later production CTC175/176/177 chassis have a different microprocessor (U3101).

These chassis can be identified with a “2” after the alpha suffix on the bar code label.

For example, a CTC177AA chassis that had the new version microprocessor would be

labeled CTC177AA2. This is extremely important because the pinouts are not the same.

In other words, they are NOT interchangeable. The CTC186/87 also supports this

newer version microprocessor.

The use of the bus controlled stereo decoder (U1600) and the new Thomson ST-9

microprocessor (U3101), changes the system control block diagram slightly to accommodate the different parts. The differences are pin-out changes on the microprocessor

and the addition of U1600, figure 1. With the exception of these changes, the system

control circuit is functionally the same as the CTC177 (see the System Control section

of the CTC177 training manual).

POWER

VOL. UP

VOL. DN.

CH. UP

1,2, 3

GND

U3201

4,7

5V

KS1

6

KS2

7

KS3

8

KD1

5

T-CHIP DATA

TUNER CLOCK

T-CHIP CLOCK

TUNER DATA

U3101

µ

P

PIP

ENABLE

T-CHIP

ENABLE

8

19

20

12

14

EEPROM

VDD

DATA

5

CLO CK

6

DATA

20 21

U2901

D-PIP

CLOC K

GND

VDD

ENABLE

22

39

54

53

52

System Control

3,5

15, 16

40, 41

5V

DATA

CLOCK

U1001

T-CHIP

ENABLE

HORZ.

OUT

24

CH. DN.

MENU

5V

2

IR3401

3

5V

2

RESET

VDD

21

OSC

OSC

GND 56

1

OUT

36 37

1

Y3101

22

IN

4

DATA

CLOCK

5V

5

U7401

5V

TUNER PLL

VCC

10

GND

13

7.6 V

STBY

9V

CTC186/87 ONLY

22

STEREO DEC OD ER

VCC

15

BUS

GND

1

DATA

U1600

2

CLOC K

GND

3,4,

17

Figure 1, System Control Block Diagram

Page 4

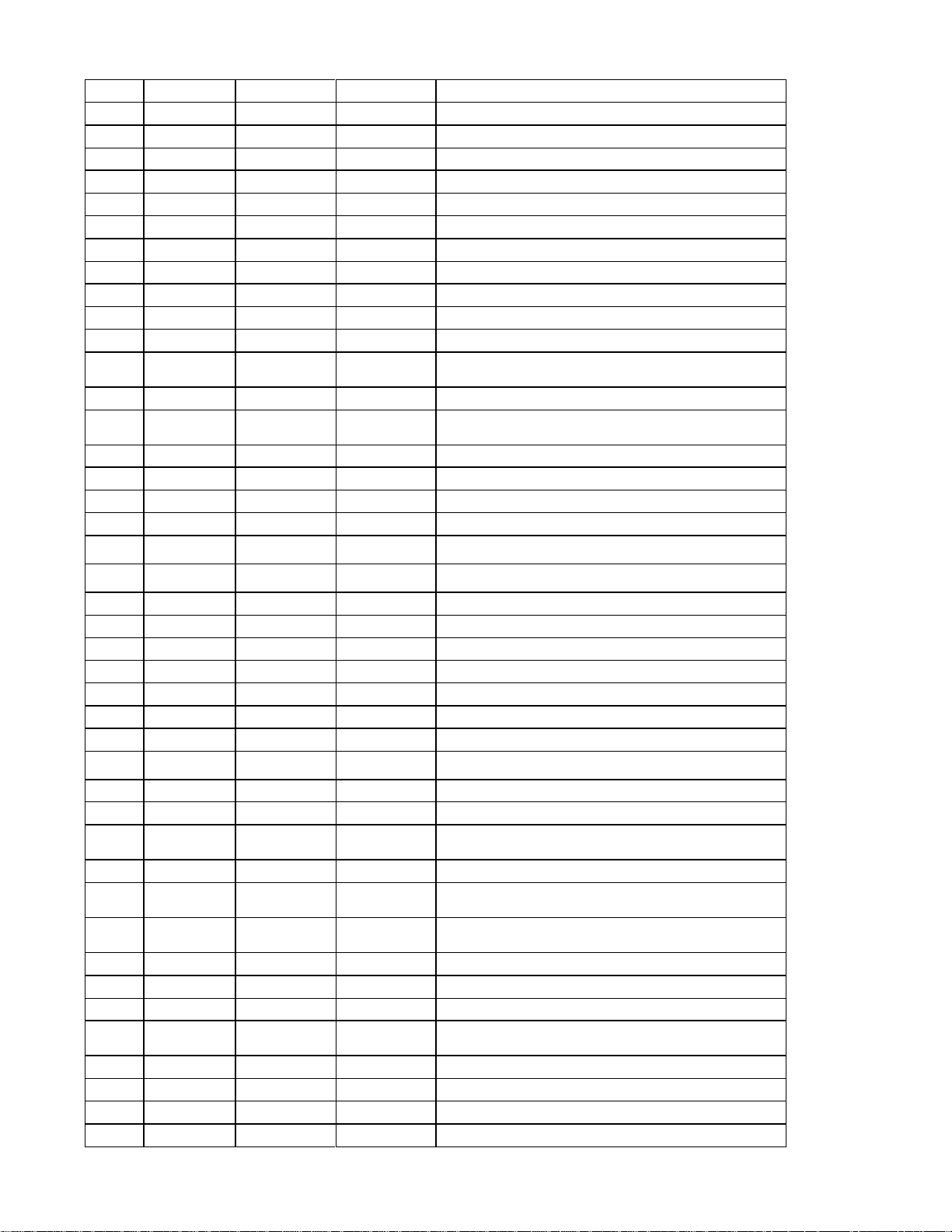

U3101 - Thomson ST-9 SYSTEM CONTROL MICROPROCESSOR

PIN NO. NAME VOLTAGE

1 IR IN 4.5

2 RESET 5

3 NC 4 DEGAUSS 0

5 KD1 0

6 KS1 4.7

7 KS2 4.7

8 KS3 4.7

9 DATA OUT 0.3

10 ATE ENABLE 0

11 CC VIDEO 2

12 PIP ENABLE 4.7 >20M

13 NC -

14 T-CHIP ENBL 4.6 >20M

15 BLUE OSD 0

16 GRN OSD 0

17 RED OSD 0

18 FSW 0

19

20

T-CHIP DATA

TUNER/ST CLK

T-CHIP CLK

TUNER/ST DATA

4.5

4.7 >200K Serial communication - data/clock

21 VDD 4.7

22 VSS 0

23 PLL FILTER 2.6

24 PLL BIAS 2.2

25 PLL VCC 4.7

26 H 0.7

27 V 0.2

28

EXP S T SW

ST / MONO

11 / 0 36K Expanded stereo, NWS-gain and mono /stereo control line.

29 SPK MUTE 0

30 TONE 0 / 5

31

SCLOCK/FM

ON/OFF

0 >20M

32 ST SENSE 0 / 5

33 RF SEC * VARIES >20M

34 RF PRI * VARIES >20M

35 SINGLE TUN * VARIES

36 OSC OUT 2.3

37 OSC IN 2.3

38 TUN SYNC 2.3 >20M

39 FM TUN * VARIES

40 IF DEFEAT 0

41 STBY SW 42 DATA IN 4.8

IN CKT. RES.

>300K

>200K

>20M

>20M

>200K

>200K

>200K

>20M

10K

>50K

-

1K

1K

1K

2K

>20M

>20M

0

>20M

6K

>20M

8K

1.8K

>100K

>100K

>20M

>20M

>20M

>20M

>20M

>20M

>20M

>200K

Serial communication line used to control data between

the micro. and PIP.

Serial comm. line used to control communication between

the micro and T-Chip.

Fast switch - controls OSD and video switching in T-chip.

Serial clock for DBX stereo decoder. FM on control for

commercial TV.

PWM output - Controls the secondary of the double tuned

filter in the tuner.

PWM output - Controls the primary of the double tuned

filter in the tuner.

PWM output - Controls the single tuned filter in the tuner.

Sync input to detect the presence of an active channel

when tuning.

Input to detect an active FM station on commercial TV.

Page 5

DESCRIPTION

IR input signal from remote control.

Micro reset - active LO.

-

Activates degaussing relay.

Keyboard drive line.

Keyboard scan input.

Keyboard scan input.

Keyboard scan input.

Data out for commercial television.

Used for factory testing.

Closed caption video input.

-

Blue OSD output.

Green OSD output.

Red OSD output.

Serial communication - data/clock.

Power supply input for microprocessor.

Ground for microprocessor.

PLL filter network.

PLL bias resistor Connection.

Power supply for PLL.

Horizontal timing input for OSD.

Vertical timing input for OSD.

Goes HI to mute speakers.

Goes HI for low tone and LO for high tone.

Stereo Detect line for non-DBX stereo sets.

8MHz crystal connection.

8MHz crystal connection.

Output to defeat IF circuit via AGC.

-

Data input for commercial television.

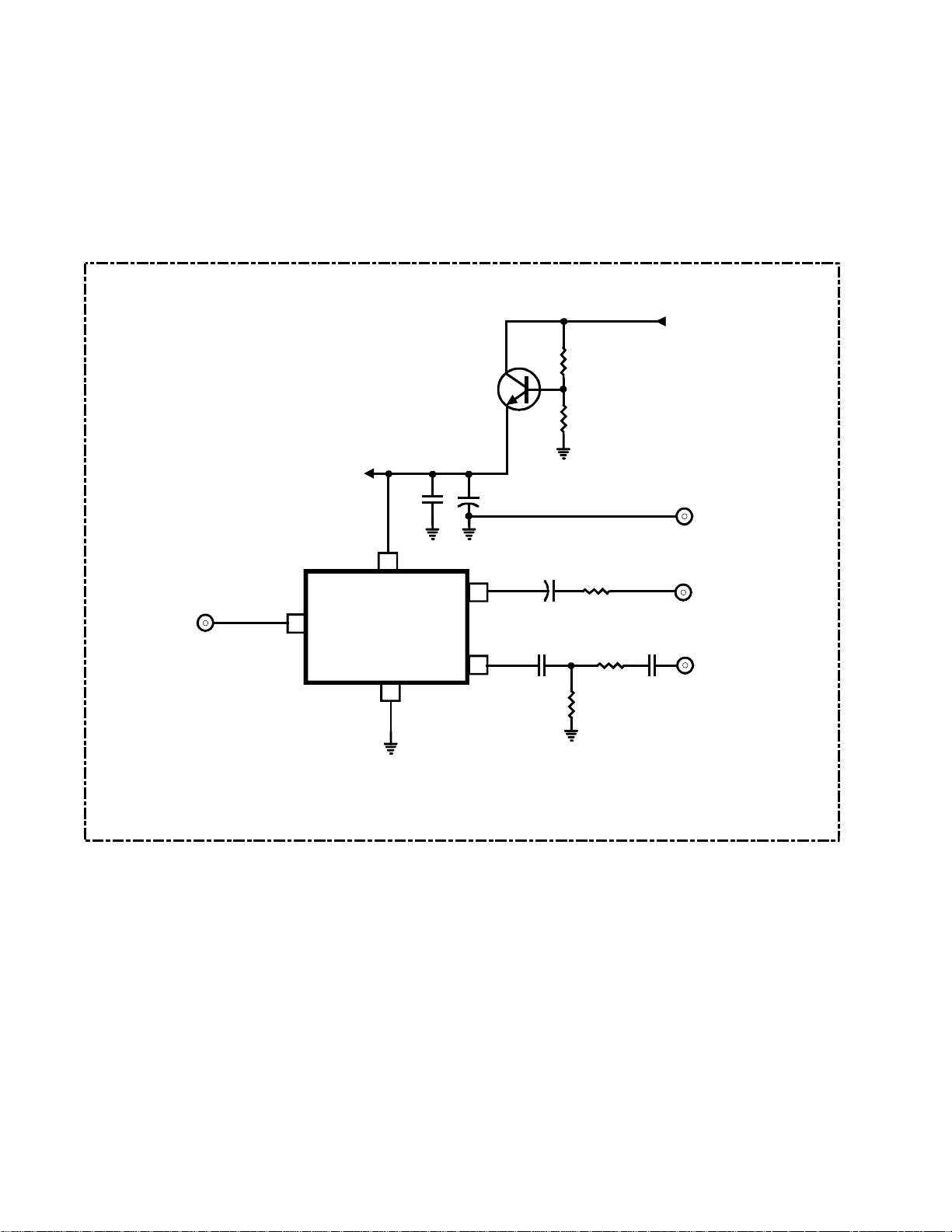

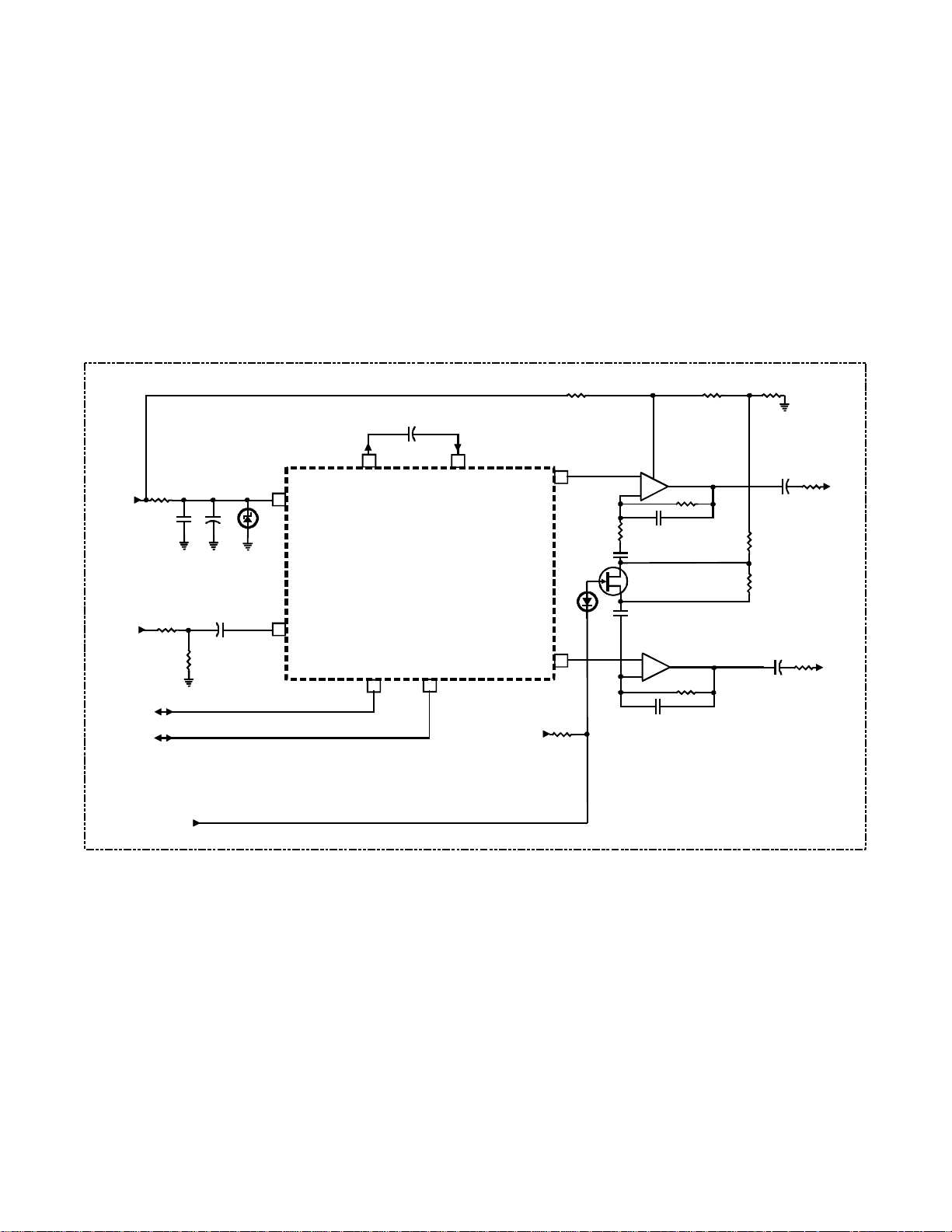

This board contains an analog comb filter that is used to separate luminance and chrominance. Composite video is routed from the main board from E2601 and applied to the

input at pin 2 of the comb filter IC (FL2651). Luma is output at pin 5 and chroma is

output at pin 3. These signals are sent back to the main board at E2602 and E2603

where they are input to the T-Chip (U1001), figure 2. Refer to the luminance and

chrominance processing section of the CTC177 training manual for signal processing on

the main board.

+12V

Q2651

+9V

+

Comb Filter

E2505

GND

1

5

E2601

VIDEO IN

2

FL2651

3

4

STEREO DECODER / COMB FILTER PCB

Figure 2, Comb Filter

1. Check for composite video at E2601. If there is no video present, the problem is on

the main board and not the comb filter. If video is present, go to the next step.

2. Check for luma and chroma out at E2602 and E2603. If luma and chroma are

present, the comb filter is working correctly. If they are not present, go to the next

step.

E260 2

LUM A OUT

E260 3

CHROMA OU T

Troubleshooting

3. Check for 9 volts at pin 1 of the comb filter (FL2651). If the voltage is present,

suspect a defective FL2651. If the voltage is missing, check Q2651 and its associated components.

Page 6

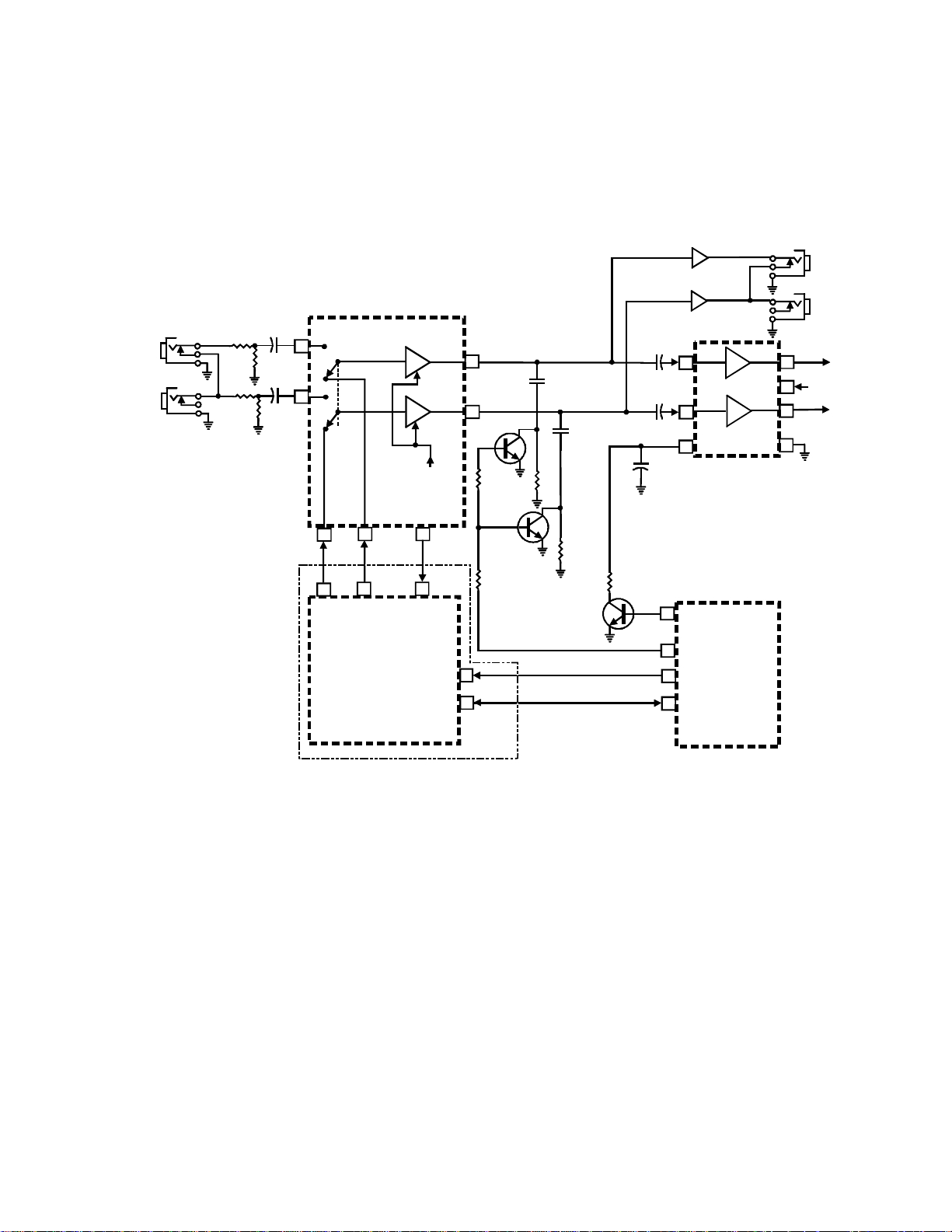

Stereo Decoder

The stereo decoder (U1600) receives wideband audio from the main board and decodes left and right audio information. Wideband audio enters the board at JS107

(figure 3) and is capacitively coupled to U1600 pin 11. Decoded left and right signals

are output at pins 29 and 28 respectively. U1601 buffers the left and right output and

provides the expanded stereo feature in conjunction with Q1601. When the expanded

stereo line (JS112) goes LO, Q1601 turns on and cross-mixes the left and right channel

information to produce a perceived increase in stereo separation. Pins 1 and 7 of U1601

output the left and right signals respectively that are capacitively coupled back to the

main board via JS105 and JS106.

+12V

JS103

WBA

JS107

SCLK

JS111

SDATA

JS110

EXP. STEREO

JS112

+

CR1600

9.1V

+

15

11

VCC

WBA IN

8 7

MAIN

OUT

MAIN

IN

U1600

STEREO DECODER

2 1

STEREO DECODER / COMB FILTER PCB

L OUT

R OUT

+12V

29

CR1601

28

U1601

3

2

Q1601

U1601

5

6

8

+

1

-

+

7

-

+

+

LEFT

JS105

RIGHT

JS106

Figure 3, DBX Stereo Decoder

Page 7

U1600 is digitally controlled over the I2C bus. Analog lines that were used in the

CTC177 for stereo sense and stereo select (see the Audio Processing section of the

CTC177 training manual) are no longer used. Instead, communications between U1600

and the television’s microprocessor are carried out over the serial bus, figure 4.

U1001

T-CHIP

AMP

AMP

BUS

CTL

VOL ./M UTE

BUS CTL

WB AUDIO

OUT

L INR IN

4

5

3

60

C1912

59

Q1901

C1913

R1912

Q1902

+

5

+

1

+

3

AUX LEFT

AUDIO INPUT

AUX RIGHT

AUDIO INPUT

+

7

+

8

AMP

AMP

U1901

8

9

10

6

LEFT HI-FI

OUT

R / MO NO

HI-FI

OUT

LEFT

26V

RIGHT

Q1903

MUTE

R1913

29

30

20

19

29

28

R OUT

TV

AUDIO

L OUT

11

WB AUDIO

IN

U1600

ST EREO

DECODE R

STEREO DECODER / COMBFILTER PCB

SCLK

SDATA

1

2

Figure 4, Audio Circuit Block Diagram

The CXA 1734S Stereo/SAP Mpx IC registers are accessed via the IIC Bus. All

necessary bus controls are contained in the SERVICE MENU.

Signal Description Summary

ALIGNMENT INPUT SIGNAL DESCRIPTIONMEASUREMENT

WBA Input;JS107

#25 ATT 100 Hz, 424 mv rms JS106 (RIGHT OUT)

#26 STVCO Open WBA or short AC to gnd. JS106 (RIGHT OUT)

#27 SAPVCO 78,670 Hz (5 x fH), 255 mv rms Observe OSD * (star)

#28 STLPF 9.4 KHz, 1.04 v rms Observe OSD STEREO”

#29 SAPBPF 88 KHz, 206 mv rms Observe OSD * (star)

#30 WBSEP Stereo, LEFT only, 300 Hz w/ pilotJS106 (RIGHT OUT)

#31 SPECSEP Stereo, LEFT only, 3KHz, w/ pilot JS106 (RIGHT OUT)

SPEAKR

MUTE

TONE

SCLK

SDATA

U310 1

SYSCON

dbx Alignments

Page 8

NOTES:

• All replacement stereo IC’s must be aligned according to this procedure.

• All Stereo/SAP alignments must be performed in the sequence shown. Several

alignments are coarse alignments for ones that follow.

• When the set starts up, the dbx Stereo IC will be aligned with IIC alignment data

which is stored in EEPROM memory from the previous IC that was installed in the

set. In most cases, stereo and SAP will be detected, but the stereo and SAP vco

free-running frequencies will not be properly aligned. Neither will stereo separation

nor the various internal filters be optimized. The full alignment procedure must be

performed to make sure the IC performs within specification.

• A modulator or other signal source with video must be connected to the tuner, and

the set tuned to the appropriate channel in order to detect stereo. Stereo and SAP

alignments cannot be performed with VIDEO IN selected (channel 00).

Alignment Preparation

Make sure that the EXPANDED STEREO function is turned off, otherwise the output

amplitudes will be in error. Also, STEREO SEPARATION alignments will be impossible.

Access the SERVICE MENU for the dbx IC as follows:

1. Press and hold the MENU button, then while holding MENU press the ON button,

followed by the VOLUME + button. This accesses the GENERAL SERVICE

MENU display.

2. Release all buttons.

3. Increment VALUE (V) number to 76 by pressing and holding the VOLUME UP

button.

4. Increment PARAMETER (P) number to 13 by pressing and holding the CHANNEL

UP button.

5. Increment V number to 77 with VOLUME UP button.

6. Increment P number to 25 with CHANNEL UP button. This is the first alignment

parameter.

Page 9

Perform the alignments in the following sequence.

Attenuator (ATT = Parameter # 25)

DAC range = 0 to 15.

All following alignments depend on the correct setting of this alignment.

1. Unsolder and lift the bottom end of R1609 from the circuit board. This is the

Wideband Audio input (WBA) to the CXA1734 stereo IC.

2. Connect an audio generator to the unsoldered end of R609 (WBA). Adjust the

generator output for 100 Hz, 424 mv rms, +/- 10 mv at module pin #7, WBA. This

corresponds to a full 25KHz carrier deviation mono audio signal from the sound IF.

3. Connect an AC voltmeter to module JS106, RIGHT CHANNEL OUTPUT. This is

also the bottom end of R612. (Do not use the top end, or oscillations may result.)

Adjust the ATT DAC using the volume control button. Set the DAC for an output

level as close to 489 mv rms as possible. Each DAC step will change the output

level by about 25 mv.

4. Observe on an oscilloscope that the audio output at module pins #5 (LEFT) and #6

(RIGHT) are clean and undistorted.

5. Observe that the rms amplitude of both pins #5 and #6 are within 20 mvrms of each

other.

6. If the final DAC alignment value is not within the range of 7 - 11, check to make

sure that the signal amplitude is proper. (Do not use 1KHz, because the internal deemphasis filter will cause an amplitude error.)

STEREO VCO free running frequency. (STVCO = Parameter # 26)

DAC range = 0 to 63.

This alignment is also a course adjustment for the next alignment.

1. Remove the audio generator connection from the bottom end of R1609. False

STVCO frequency will be generated if WBA is not open, as VCO tries to lock to

noise or other frequency.

2. Connect a frequency counter to module JS106, RIGHT OUT. (4 x fH vco is

automatically routed to JS106 when in P#26.)

3. Adjust DAC while monitoring frequency. Set DAC for frequency = 62,936 Hz +/200Hz. (4 x fH). The frequency increment for each DAC step is approximately 300

Hz.

Page 10

SAPVCO free running frequency. (SAPVCO = Parameter # 27)

DAC range = 0 to 15.

This is not a direct frequency measurement. It uses the internal status registers of

the stereo IC to indicate PLL lock. The previous alignment (STVCO) is a coarse

adjust for this alignment.

1. Adjust audio generator for 78.67 KHz, 254 mv rms (559 Vp-p), +/- 10 mv. (5 x

fH SAP subcarrier, equivalent to 15 KHz carrier deviation) at WBA input.

2. Set SAPVCO DAC to step # 0. Observe TV screen. No star (*) should be

present.

3. Increment DAC once per second or slower until * becomes present. Record this

DAC setting. (A flashing * is OK. Usually, one more DAC increment will stop the

flashing.)

4. Set DAC to step # 15. Observe that no * is present. Decrement DAC until * once

again becomes present. Record this DAC setting.

5. Average the DAC settings from steps (c) and (d). Set DAC to this averaged value.

This is the proper alignment value for SAPVCO. Setting will usually be 1 - 14. If

not, verify that previous step was done properly.

STEREO LOWPASS FILTER (STLPF = Parameter # 28)

DAC range = 0 to 63.

This alignment is also a course adjustment for the next alignment.

1. Adjust audio generator for 9.4 KHz, 1.04 vrms (1.47 Vp-p) at WBA input.

2. Set STLPF DAC to step # 0. Observe TV screen. No “STEREO” indicator

should be present.

3. Increment DAC once per second or slower until “STEREO” indicator becomes

present. Record this DAC setting. (It is OK for the “STEREO” indicator to flash.

Usually, one more DAC increment will stop the flashing.)

4. Set DAC to step # 63. Observe that no “STEREO” indicator is present. Decrement DAC until “STEREO” indicator once again becomes present. Record this

DAC setting.

5. Average the DAC settings from steps (c) and (d). Set DAC to this averaged value.

This is the proper alignment value for STLPF.

Page 11

SAP BANDPASS FILTER (SAPBPF = Parameter # 29)

DAC range = 0 to 15.

1. Adjust audio generator for 88 KHz, 220 mv rms, +/- 10 mv.

2. Set SAPBPF DAC to step # 0. Observe TV screen. No * should be present.

3. Increment DAC once per second or slower until * becomes present. Record this

DAC setting.

4. Set DAC to step # 15. Observe that no * is present. Decrement DAC until * once

again becomes present. Record this DAC setting.

5. Average the DAC settings from steps (c) and (d). Set DAC to this averaged value.

This is the proper alignment value for SAPBPF.

WIDEBAND SEPARATION (WBSEP = Parameter # 30)

DAC range = 0 to 63.

This alignment is for the dbx WIDEBAND detector

1. Set stereo generator for STEREO LEFT CHANNEL ONLY SIGNAL, 300 Hz.

2. Connect AC rms voltmeter to module JS106, RIGHT CHANNEL OUT.

3. Set WBSEP DAC to step # 31 (DAC midpoint).

4. Start incrementing WBSEP DAC (or decrementing, as necessary) while observing

voltmeter reading. Find DAC setting which produces a minimum voltmeter reading

(null setting). Record this DAC setting. The exact null setting will typically be

difficult to determine, because the null range is rather broad.

5. Measure module JS105, LEFT CHANNEL OUT, and check for at least 20 dB

separation between LEFT and RIGHT.

6. This alignment will be repeated after doing the next alignment, because of some

interaction between the WBSEP and SPECSEP DAC’s.

Page 12

SPECTRAL SEPARATION (SPECSEP = Parameter # 31)

DAC range = 0 to 63.

This alignment is for the dbx SPECTRAL detector

1. Set stereo generator for STEREO LEFT CHANNEL ONLY SIGNAL, 3KHz.

Note:If the MTS generator being used is not capable of generating a 3KHz signal,

the alignment cannot be performed. If this is the case, set the DAC to the nominal

default of 35.

2. Connect AC rms voltmeter to module JS106, RIGHT CHANNEL OUT.

3. Set SPECSEP DAC to step # 31 (DAC midpoint).

4. Start incrementing SPECSEP DAC (or decrementing, as necessary) while observing

voltmeter reading. Find DAC setting which produces a minimum voltmeter reading

(null setting). Record this DAC setting. The exact null setting will typically be

difficult to determine, because the null range is rather broad. Do the best you can.

5. Measure module JS105, LEFT CHANNEL OUT, and check for at least 20 dB

separation between LEFT and RIGHT.

Page 13

A television tuner receives (or selectively tunes) a 6MHz bandwidth RF (Radio Fre-

N

quency) carrier that contains audio and video information and converts it to a common IF

signal (Intermediate Frequency). The IF signal is demodulated by the television into its

audio and video components. All tuners work on the principle of a tuned circuit whose

resonant frequency determines what channel is tuned. By changing the tuned circuits’

resonant frequency, different RF carriers (channels) are selected. Before discussing the

different sections that comprise the tuner’s circuitry, it is appropriate to review certain

fundamental concepts of inductors, capacitors and varactors. These components play a

major role in all tuned circuits.

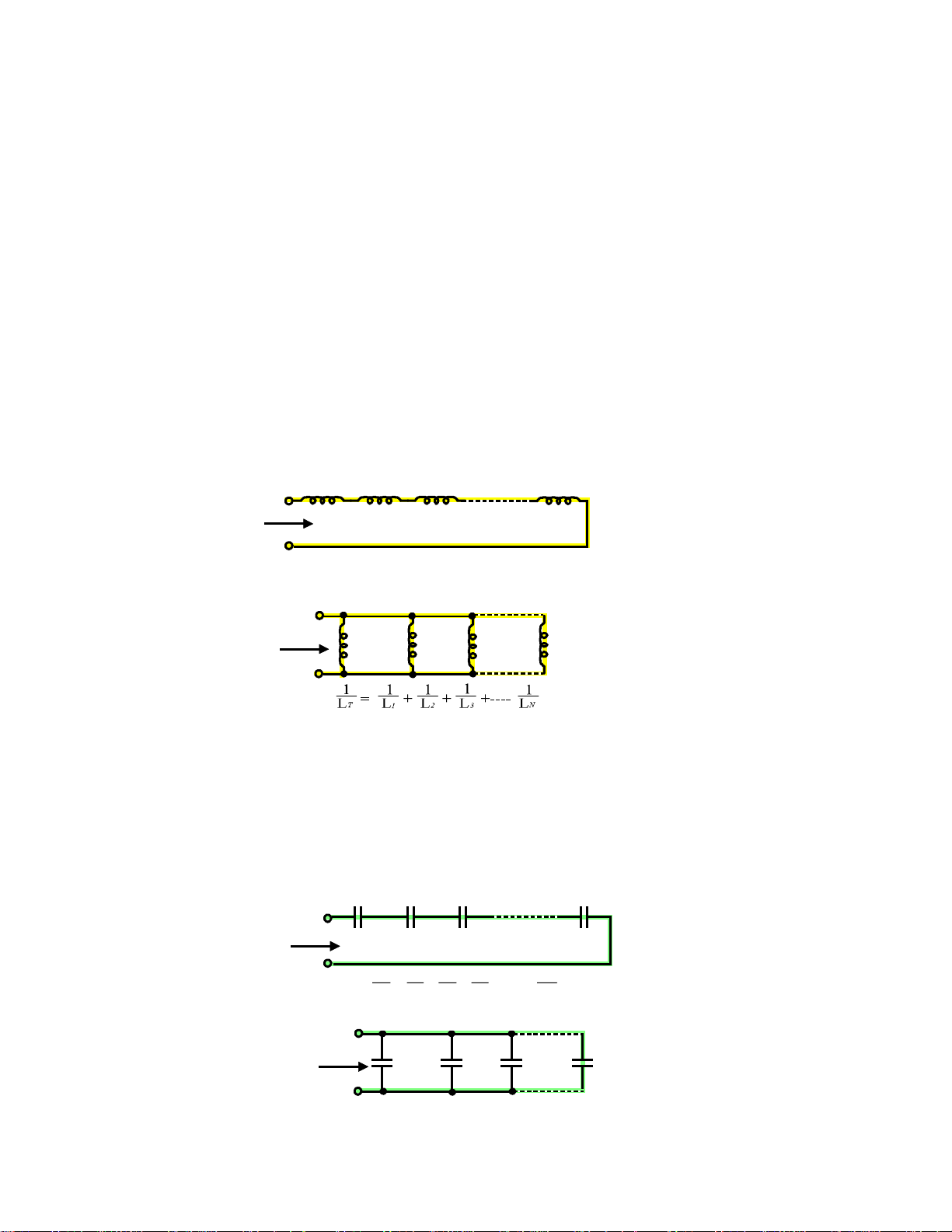

Inductors

Remember, an inductor is simply a coil of wire. The ability of a coil to oppose a change

in current is a measure of the inductance L of the coil. Inductance is measured in henries

(H). For inductors in series, the total inductance is found in the same manner as resistors

in series, figure 5. Likewise, the total inductance of inductors in parallel is found in the

same manner as resistors in parallel, figure 5. The main idea to remember here is inductors added in parallel reduce the total inductance and inductors added in series in-

crease the total inductance.

Inductor /

Capacitor

(LC) Basics

1

T

L

L

T

L

2

L

3

L

LT = L1+L2+L3+- -- -L

1

L

2

L

N

3 L

L

N

L

N

Figure 5, Inductors in Series and Parallel

Capacitors

Capacitors are components that are made up of two parallel conducting plates separated

by an insulating material. A capacitor stores a charge on its plates. The storage capacity

C is measured in Farads (F). The farad is generally too large a unit for most tuner

applications so the pico farad (pF) 10

-12

F is used. Total capacitance is calculated in

the opposite manner as inductance, figure 6. Capacitors in parallel increase total

capacitance and capacitors in series decrease total capacitance.

C T

C

1

C

C

2

3

C

N

1 1 1 1 1

= + + + − − −

1 2 3

T

C C C C C

T

C

C

1

CT = C1+ C2+ C3+ --- - C

C

2

N

C

3

N

C

Figure 6, Capacitors in Series and Parallel

Page 14

Loading...

Loading...