Page 1

EQUIPMENT MONITORING

SYSTEM

Early Warning Noncontact Temperature Measurement System

Our Solution

n

RAYEMS

with

DataTemp® Multidrop Software

Benefits:

n

Continuous 24/7 system monitoring

n

Operational component temperature viewed safely

n

Early detection of thermal issues

n

Less waste from unexpected downtime

n

Maintenance performed when needed not when estimated

n

Reduced maintenance cost

Page 2

Condition Monitoring

The Raytek® Equipment Monitoring System

is an early warning device that provides live

temperature data to operators, allowing them

to make educated decisions regarding the

functionality of their equipment. A temperature

rise or spike on the surface of equipment

can be a leading indicator that there may be

an equipment problem. Being aware of that

temperature change means system diagnostics

can be done and service planned with no

interruption to production - saving money in

time and resources.

The Raytek® Equipment Monitoring System

is a noncontact infrared monitor that provides

a 24/7 temperature measurement of actively

powered components or operating machinery.

Temperature is displayed on its LCD control

module and/or remotely through PC-based

Raytek DataTemp® Multidrop software.

The Raytek Equipment Monitoring System

is plug and play utilizing the field proven

technology of the Raytek Compact Series MI3

sensor. The system is small in size to fit in tight,

hard-to-reach or enclosed locations. The system

monitors temperature ranges of -40˚C to 600˚C

(-40˚F to 1112˚F) and all components are IP65

rated to ensure long life in harsh environments.

Users can manually program alarm settings

through the integrated push button panel

located on the control module or easily

communicate remotely from a central location

via RS-485 and DataTemp software. For full

factory or machine control, an ASCII Protocol

will allow the system to communicate with

your own internal control network.

System Specifications

Object Temperature Range -40 to 600˚C (-40 to 1112˚F)

Optical Resolution D:S* 10:1

System Response Time* 130ms

System Accuracy* ± (1% of reading or 1˚C),

whichever is greater ± 2˚C (±4˚F)

for target temp. < 20˚C (68˚F)

System Repeatability ± 0.5% of reading or ±0.5˚C,

whichever is greater

Temperature Coefficient ± 0.05K/K or ± 0.05%/K

of reading, whichever is greater

Digital Interface USB 2.0 and RS485 standard

Alarm Relay 48 VAC, 300mA, optically isolated

Power Supply 100 to 240 VAC, 50/60 Hz,

0.15 A, 6 A internally fused

Environmental Rating IP65

EMI/EMC/ESD IEC EN61326-1 1:2006

Safety IEC EN61010-1

Sensor Head Specifications

Spectral Response 8 to 14 micron

Ambient Operating -10 to 120˚C (14 to 248˚F)

Temperature

Storage Temperature -20 to 120˚C (-4 to 248˚F)

Relative Humidity 10 to 95%, non-condensing

Construction Stainless steel

Sensing Head Cable PUR halogen free, flame retardant

insulation, 125˚C (257˚F) max. temp

Shock IEC 68-2-27 50g’s 11ms, 3 axis

Vibration 11-200Hz, 3g above 25 Hz

operating, 3 axis /68-2-6

Features:

n

DataTemp® Multidrop Software

(Windows® 7 64-bit compatible)

n

RS-485 communication for remote set up

n

Audible alarm for easy warning notification

n

IP65 (NEMA 4) rated control box

and sensors

n

Alarm output 48V/300mA

n

Compact sensor size fits in tight spaces

n

Adjustable emissivity for different

surface types

n

Adjustable sensor brackets for ease

of installation

n

Plug and Play (automatic head detection)

n

Each system comes completely wired

from the factory for quick and easy

installation

Control Box Specifications

Ambient Operating -25 to 60˚C (-13 to 140˚F)

Temperature

Storage Temperature -25 to 85˚C (-13 to 185˚F)

Construction Thermo Plastic-Halogen free,

silicone free Class II protection

* See system manual for further detailed information

Applications:

n

Electrical cabinets: bus bar connections,

circuit breakers, motor starters

n

Electrical motors: housing, bearings and gearboxes

n

Pumps: drive motors, bearings

n

Furnace controls

n

Heating elements

Page 3

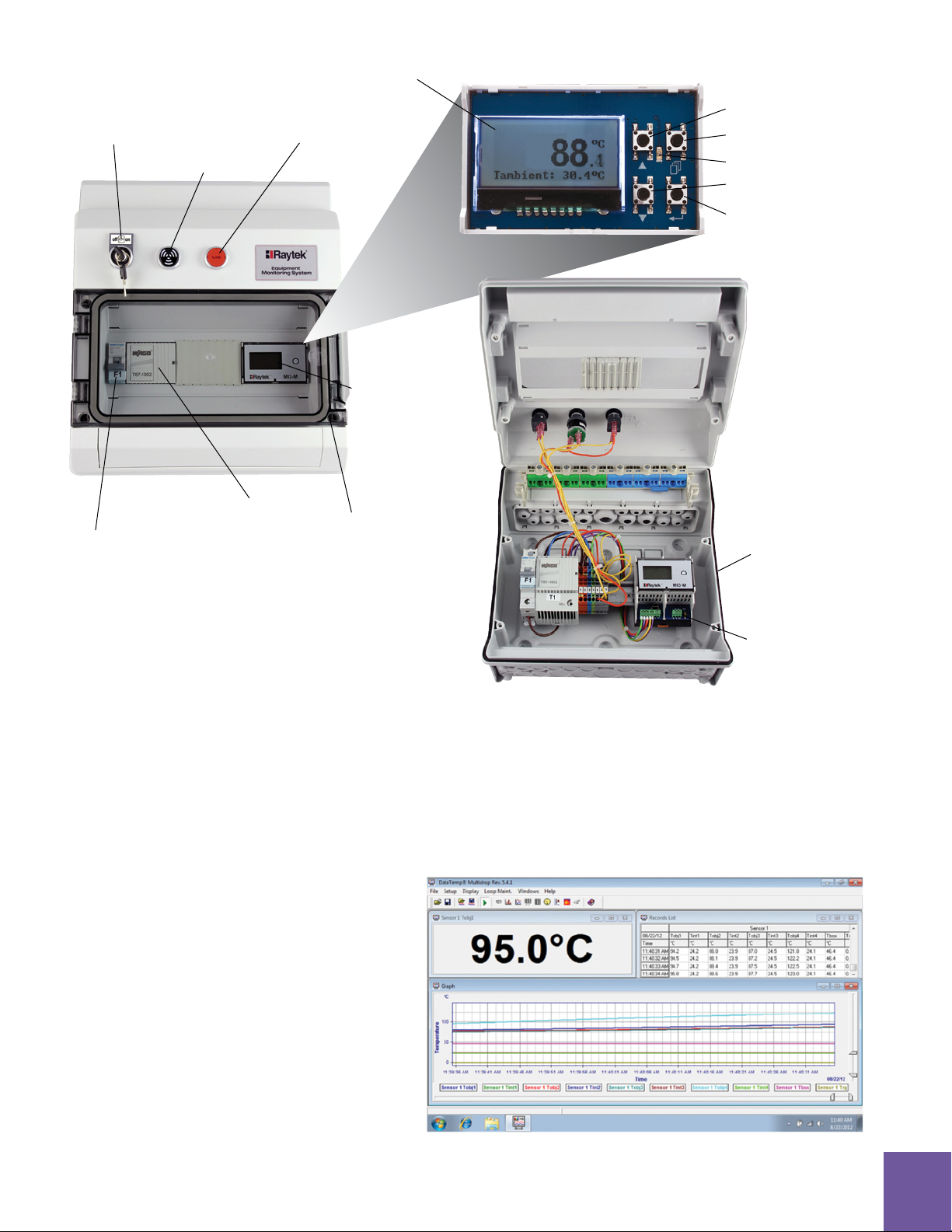

LCD Display

Manual Alarm

OFF/Reset switch

Circuit Breaker

Alarm Buzzer

Power Supply

Alarm Indicator

MI3-M Control

Module with

flip up shield

for access to

manual controls

Transparent,

lockable, sealed,

flip open door for

easy access to

control module

and circuit

breaker

Up Button

Page Button

Alarm Indicator

Down Button

Enter Button

IP65 Non-conductive

Plastic Enclosure

The Raytek Equipment Monitoring System has been

developed with operator safety in mind. Offered with

3, 4, 6 or 8 sensors, temperatures can be read by anyone

on active systems from a safe location without additional

equipment or special training.

The DataTemp Multidrop software provides simultaneous

viewing of multiple points and can be set up to monitor up

to 32 systems. This provides the ability to see temperature

and set early warning alarms on a total of 256 individual

monitor points. Early alarms provide the time needed

for further investigation or maintenance by

qualified personnel.

Software features allow operators to easily

record and store data for trend analysis,

remotely make sensor parameter adjustments

or customize screen views. Additional

capabilities allow you to change the sensor

from reading object temperature to ambient

temperature, change emissivity, and turn on or

off filters to scale the range, graph or average.

RS-485 Connection

Page 4

Part Numbers

Model

RAYEMS3

RAYEMS4

RAYEMS6

RAYEMS8

Description

3 sensor configuration consisting of MI3 LTS10 sensors with mounting brackets, 1 control box, 1 connection box,

1 power supply with circuit breaker.

4 sensor configuration consisting of MI3 LTS10 sensors with mounting brackets, 1 control box, 1 connection box,

1 power supply with circuit breaker.

6 sensor configuration consisting of MI3 LTS10 sensors with mounting brackets, 1 control box, 1 connection box,

1 power supply with circuit breaker.

8 sensor configuration consisting of MI3 LTS10 sensors with mounting brackets, 1 control box, 1 connection box,

1 power supply with circuit breaker.

Note: Each system comes pre-wired from the factory. The cable from the control box is 15m (49ft) and each sensor cable is 1m (3.3ft).

Accessories

XXXEMSACAM Sounder Beacon

Note: For further MI3 component information please use the MI3 product brochure.

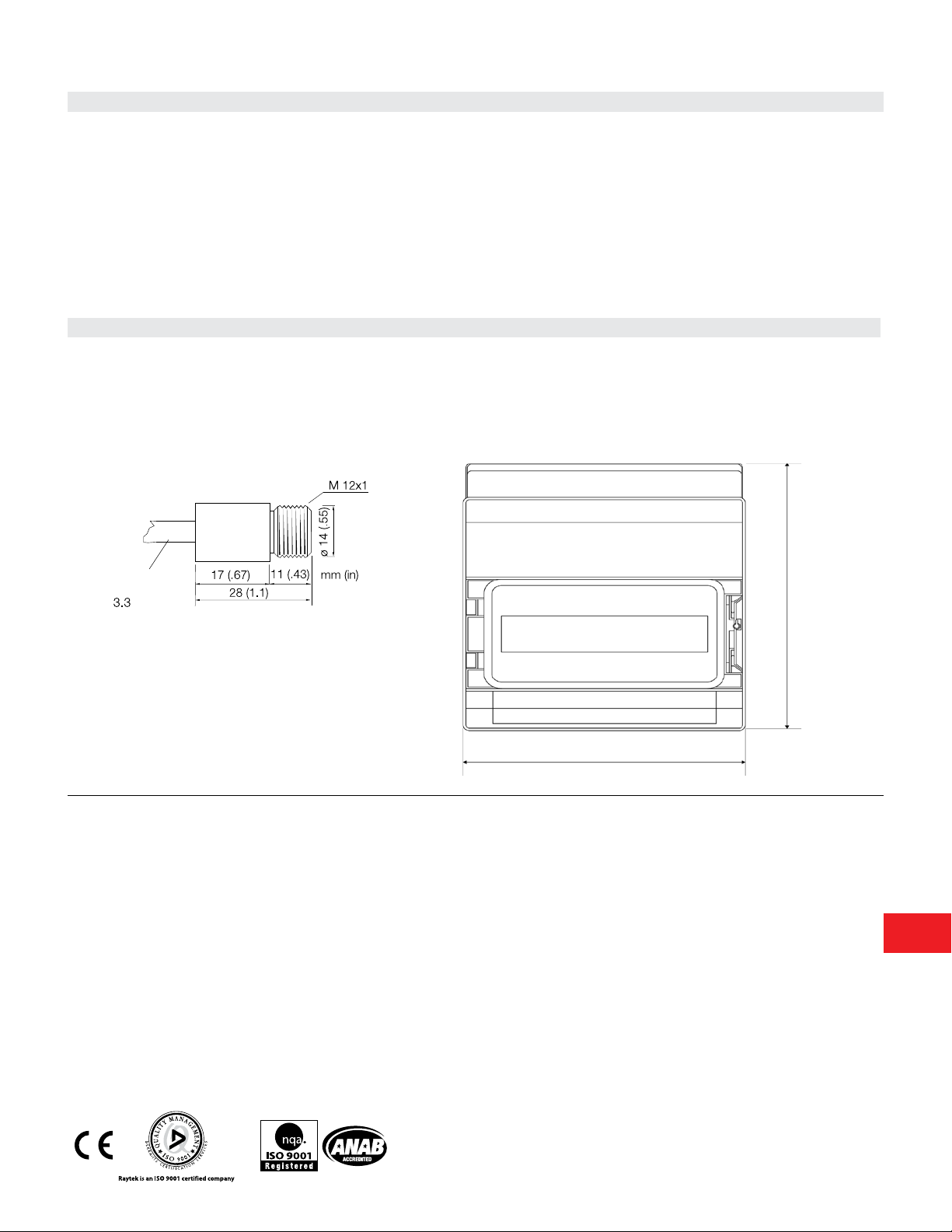

Physical Dimensions

Equipment Monitoring System Component Box

ø14 (.55)

Preinstalled cable

standard cable length

1 m (3.2 ft) Ø 5 (.2)

MI3 Sensing Head

The Worldwide Leader in Noncontact Temperature Measurement

Raytek Corporation

Worldwide Headquarters

Santa Cruz, CA USA

Tel: 1 800 227 8074 (USA and Canada, only)

1 831 458 3900

solutions@raytek.com

European Headquarters

Berlin, Germany

Tel: 49 30 4 78 00 80

raytek@raytek.de

China Headquarters

Beijing, China

Tel: 8610 6438 4691

info@raytek.com.cn

To find a Raytek office near you, please visit www.raytek.com

Worldwide Service

Raytek offers services, including repair and calibration.

For more information, contact your local office or e-mail support@raytek.com

295 (11.6)

33 (13.1)

Depth:

129 mm (5.1 in)

mm (inch)

www.raytek.com

Raytek, the Raytek logo and DataTemp are registered trademarks of Raytek Corporation.

© 2012 Raytek Corporation (4266400 Rev A ) 11/2012

Specifications subject to change without notice.

Loading...

Loading...