Page 1

THE R MA L E R T®C I

™

C OMPAC T INFR A R E D

S E N S OR

OP E R ATO R ’ S G U IDE

T WO Y EA R LI M IT ED WA RR A N T Y

R aytek warr ants thi s prod uct to be free f rom d efects i n materi al and

wor k man shi p u nder nor mal u se an d s erv ice f or a per iod of two

year s f rom date of p urchase except as herein after pr ovi ded. T his

warr anty extend s on ly to the ori gin al pur chaser ( a pu rch ase fr om

R ay tek or R aytek ’ s l icensed di str ibutors is an ori ginal p urch ase).

This w arranty shall not appl y to fu ses or batteries. Factory calibr ation is wa rr anted for a peri od of one year. T he war ran ty shal l not

appl y to any prod uct w hich has been subject to m is use, neglect,

accident, or abnor ma l con ditions of op erati on or stor age. Should

R ay tek be u nabl e to repair or r eplace th e product withi n a reason able am ount of time, p urchas er’s exclu sive remedy shall be a refu nd

of the pur chase pri ce upon retu rn of th e prod uct.

In the event of fail ure of a produ ct covered by this war ranty, R aytek

wi ll r epair th e ins tru ment w hen it is retur ned by the pu rchaser,

frei ght prepai d, to a n author ized Servi ce Facil ity w ithi n the appl icable w arran ty peri od, pr ovided Ray tek’ s exami nation d iscloses to its

satis facti on that the pr odu ct w as defectiv e. R ay tek m ay, at its

option, repla ce the produ ct in l ieu of repair. W ith regar d to any covered p rodu ct r eturn ed w i thin the ap pli cable wa rr anty period ,

repai rs or replacem ent wi ll be m ade w ithout cha rge and w ith return

frei ght pa id by R ay tek, u nless the f ail ur e w as ca used by mi sus e,

neglect, a ccident, or abnorma l condi tions of operation or storage, in

wh ich case r epairs wil l be bil led at a reasonable cost. I n such a case,

an esti mate wi ll be su bmitted before w ork is started, if requested.

T HE F OR EG O IN G WA R RA N T Y I S I N L IE U OF AL L OT H E R WA RR A N T IE S, E XPR E S SE D O R IM PL IE D, I N C L U D I N G BU T N OT

L IM IT E D T O A NY I MP LI ED WA R RA N T Y O F M ER CH A N TA BIL IT Y, FI TN E SS, O R A D EQ UA C Y F OR AN Y PA RT IC U LA R PU RP OSE

OR US E . R AY TE K SH A LL N O T B E L IA BLE FO R A NY SPE CI A L,

IN CID EN TA L O R CO N SEQ UE N TI A L D A MA GE S, W HE TH ER IN

C ON TR AC T, TO RT, OR OT H E RW ISE .

Rev K

11/ 2009

56800-1

R aytek, the Ray tek L ogo, and Therm alert are regis tered tr ademark s and

C I is a tr ademark of R aytek C orporation

© C opyri ght 1996-2000 by Ray tek C orpor ation

C I

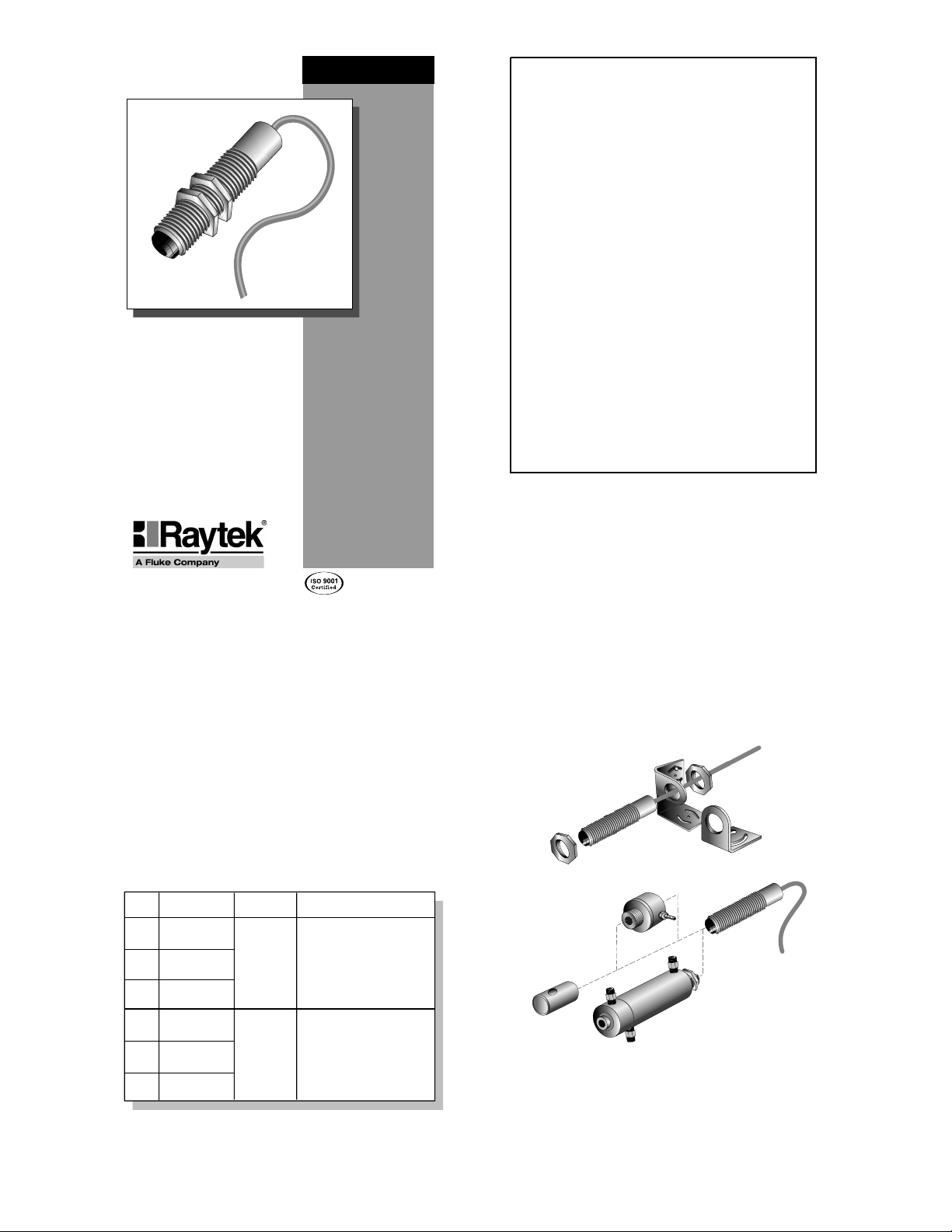

A full r ange of accessor ies for v ar ious applications and

industrial environm ents are av ailable ( see F igure 1).

A ccessories may be ordered at any time and added

on-si te. A lso avail able is a J- or K -type thermocouple

connection k it and extensi on cables.

T H ER M AL ER T C I

The T hermalert®C I™C ompact Infr ared Sensor series

of onli ne instruments are noncontact infr ared temperature measur ement sy stems. T hey are d esigned to measure accurately and repeatably the am ount of heat energy emi tted from an object and to conv ert that energy

into a measu rable electrical signal.

E ach mod el (see Table 1) comes with a 1 m (3 ft) cable

and tw o mounting nuts and is designed for easy integrati on into standard 4-wir e sy stems. T here are J or K

thermocouple output models or 10 mV / °C vol tage output mod els if your appli cation i s suscepti ble to noise or

requi res a long cable run. T he electronics are protected

by a r ugged N E M A 4 stainless steel housing.

2

1

A CC ES S OR I ES

Table 1: M odels

Fi gure 1: A ccessories and O ptions

THERMALERT SERIES

Mod el Ou tput Ac cu rac y

J The rmocouple

C I1A

K The rmocouple

C I2A

Vo ltage

C I3A

J The rmocouple

C I1B

K The rmocouple

C I2B

Vo ltage

C I3B

Ov era ll

Te mp. R ang e

0 to 350û C

(32 to 662 û F )

30 to 500û C

(86 to 932 ûF )

0 to 115 û C (3 2 to 24 0û F )

la rger of ±2% or ±3û C (±6 û F )

116 to 225 û C (2 41 to 4 40û F)

large r of ± 5% or ± 6û C (±1 0û F )

226 to 350 û C (4 41 to 6 62û F)

>±5%

100 to 5 00û C (21 2 to 932 û F )

la rger of ±2% or ±3û C (±6 û F )

30 to 99û C (8 6 to 21 1û F)

large r of ± 5% or ± 6û C (±1 0û F )

Adjus table mounting

brack et ac ces sory

F ixed

Mounting nuts

(2 supplied)

S ens or

Air purge colla r

ac ces sory

R ight angle mirror

ac ces sory

Air/Wa ter-cooled housing

mounting brac ket

ac ces sory

S ens or

with integrated a ir purge

(fac tory insta lled option)

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 2

OPTIONS

Options for various applications and environments

are available. Options are factory installed and must

be ordered with base model units. These include the

following:

• NIST traceable certification

• Air/Water-cooled housing (comes with integrated

air purging and high temperature cable)

• High temperature cable–260°C (500°F) maximum

ambient temperature (comes standard with

air/water-cooled housing option)

• Longer 3 m (10 ft) standard cable

3

SPECIFICATIONS

Table 2 (below and continued on Page 4) lists the sensor’s optical, thermal, operational, electrical, environmental, and physical specifications.

Continued on next page

Table 2: Specifications

4

Table 2 (continued): Specifications

65

Optical Chart

Figure 2 shows you how to read the optical chart. The

optical chart (Figure 3) indicates the nominal target

spot diameter at any given distance from the sensing

head and assumes 90% energy.

Figure 2: How to Read the Optical Chart

INSTALLATION

The installation process consists of the following:

• Preparation

• Mechanical Installation

• Electrical Installation

The most important part of the installation process is

preparation. Please read the following section thoroughly before proceeding with the mechanical and

electrical installations.

Preparation

Distance and Spot Size—The size of the area (spot

size) you wish to measure determines the distance

between the sensor and the target (see Figure 3 for distances and spot sizes). The spot size must not be larger than the target. Mount the sensor so the measured

spot is the same or smaller than the target. Figure 4 is

an overview of proper sensor placement.

Figure 4: Proper Sensor Placement

Figure 3: Optical Chart

Optical Resolution

Spectral Response Range

Thermal

Measurement range

Detecting element

Accuracy

Repeatability

Temperature coefficient

Operational

Temperature resolution

Emissivity

Response time

Warm-up period

4:1

90% energy

@

7–18 µm

See Table 1

Thermopile

See Table 1

±1% of reading

0.2˚ C per ˚C (0.2˚ F per ˚F)

< 0.5˚ C (1˚ F)

Fixed at 0.95

350 mSec (95% response)

< 1 minute

Electrical

Power supply voltage

Maximum current draw

Ripple

Output impedance

Minimum load impedance

Outputs

Environmental

Sensing head rating

EMI

Conducted noise immunity

Relative humidity

Storage temp. range

Thermal shock

Ambient operating range

air cooling

water cooling

water cooling/high temp cable

Physical

Dimensions

Weight

Material

Cable–Standard

Maximum ambient temperature

Material (type & color)

Cable length

Gauge

Cable–High Temperature

Maximum ambient temperature

Material (type & color)

Cable length

Gauge

12 – 24 VDC @20 mA

≤ 10 mA

≤ 2.5%

50 ohms

50K ohms

J or K thermocouple,

10mV/˚C Linear Voltage

IP 65, NEMA 4

IEC 801-4, Level 1

10 to 95%, non-condensing

-30 to 85˚ C (-22 to 185˚ F)

Max error of 5˚ C (for ∆T=25˚)

stabilization time=20 mins.

0 to 70˚ C (32 to 160˚ F)

0 to 94˚ C (32 to 200˚ F)

0 to 105˚ C (32 to 220˚ F)

0 to 260˚ C (32 to 500˚ F)

19 mm dia x 87 mm L

(0.75 in dia x 3.4 in L)

130 g (4.5 oz)

Stainless steel

105˚ C (220˚ F)

PVC, grey

1 m (3 ft)

AWG 24 (J, K t/c cable)

AWG 22 (10mV/˚C cable)

260˚ C (500˚ F)

Teflon, black

1 m (3 ft)

AWG 24

Target spot size

at focus point

Diameter of target

spot size in millimeters

Focus Point D:S = Distance to spot divided by spot diameter at the focus point

Far Field D:S = Ratio at distances greater than 10x the focus distance

Diameter of target

spot size in inches

Distance from sensor to

object in millimeters or meters

Distance from sensor

to object in inches or feet

GoodBest Incorrect

Sensor

Target greater

than spot size

Target equal

to spot size

Background

Target smaller

than spot size

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 3

Ambient Temperature—The sensing head is designed

to operate in ambient temperatures from 0 to 70°C (32

to 160°F). For ambient temperatures above 70°C

(160°F), a factory installed air/water-cooled housing

option is available that allows operation in ambient

conditions up to 260°C (500°F) with water cooling.

The air/water-cooled housing option comes with a

high-temperature cable and integrated air purging.

Atmospheric Quality—Smoke, fumes, dust, and other

contaminants can coat the lens and cause erroneous

temperature readings. We recommend using the air

purge collar accessory in these types of environments

to keep the lens clean. (The air/water-cooled housing

comes with integrated air purging.)

Electrical Interference—To minimize electrical or electromagnetic interference or “noise,” mount the sensor

away from motors producing large step load changes.

Wiring—Before installing, be sure to check the distance between the sensor and the monitoring/controlling device. If necessary, extension cables are available

as accessories.

Power—Have available a 12–24 VDC, 10 mA, power

supply.

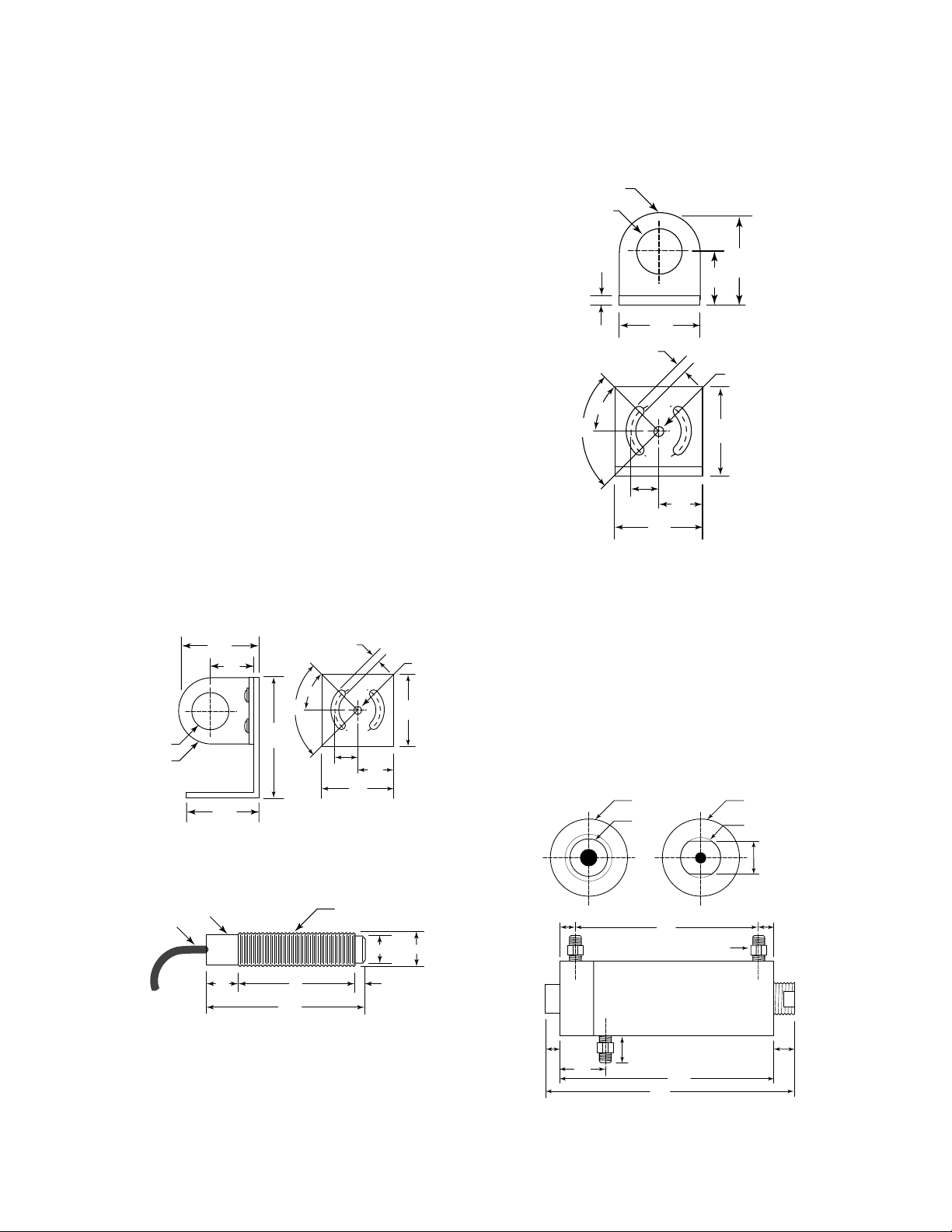

Mechanical Installation

All sensors come with a 1 m (3 ft) cable and 2 mounting nuts. You can mount the sensor in brackets or

cutouts of your own design, or you can use the fixed

and adjustable mounting bracket accessories. Figures

5 through 7 show the mounting bracket accessories’

and sensor’s dimensions.

8

7

Figure 5: Fixed Mounting Bracket

Air/Water-cooled Housing with integrated air purge—

The air/water-cooled housing option (Figure 8) allows

the sensor to withstand ambient temperatures up to

260° C (500° F) with water cooling and the high-temperature cable. (The high-temp cable is standard when the

housing is ordered as an option.) It has 1/8” NPT fittings for water and air. Water temperature should be

15-30° C (60-86° F) for best performance. Chilled water

below 10° C (50° F) is not recommended. Without the

high-temperature cable, the sensor can withstand ambient

temperatures only up to 105° C (220° F) with water cooling.

9 10

Figure 8: Air/Water-cooled Housing

Figure 6: Adjustable Mounting Bracket

Figure 7: Sensor

Full R

∅19 (.76)

38

(1.5)

(.75)

22

(.875)

∅5 (.196)

38

(1.5)

19

mm (inches)

2X 90˚

1.5

(.06)

2X 45˚

(.196)

2X 13

(2X .5)

38

(1.5)

5

38

(1.5)

∅19 (.76)

Full R

41

(1.625)

(1.5)

38

(.875)

22

2X 90˚

59

(2.31)

2X 45˚

(.196)

2X 13

(2X .5)

5

1 m (3 ft)

PVC Cable

∅4 (.17)

∅17 (.67)

(.75)

19

(3.5)

(2.48)

89

63

3/4"–16UNF 2A

M18 x 1 (if ordered metric)

19

(.75)

38

(1.5)

mm (inches)

∅14 (.56) ∅19 (.75)

(.27)

mm (inches)

∅5 (.196)

(1.5)

38

∅38 (1.5)

∅20 (0.8)

~ 25

(~ 1)

Rear View

96

(3.79)

1/8" NPT fittings (3)

118

(4.63)

137

(5.38)

Front View

10

(0.39)

7

6

(0.25)

25

(1)

∅38 (1.5)

3/4"–16UNF 2A

13

flats

(0.5)

(0.45)

~ 13

(~ 0.5)

mm (inches)

12

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 4

11

Air Purge Collar—The air purge collar accessory

(Figure 9) is used to keep dust, moisture, and other

contaminants away from the lens. It must be screwed

in fully. Air flows into the 10/32” fitting and out the

front aperture. Clean or “instrument” air is recommended. The air purge collar accessory is not needed with

the air/water-cooled housing.

Figure 9: Air Purge Collar

Table 3: Recommended Water and Air

12

Right Angle Mirror—The right angle mirror accessory

(Figure 10) allows a perpendicular view of a target. It

may be used when space is limited or when you need

to avoid excessive radiation to the sensor. This can be

mounted either on the end of the sensor or on the air

purge collar, but not on the air/water-cooled housing.

Note: When using the right angle mirror, a small

amount of energy emitted by the source is lost, which

results in a lower than actual temperature reading. To

compute the corrected temperature, use this formula:

T = 1.035T

m – .035Tamb

where T=corrected temperature, Tm=temperature reading with mirror, and Tamb=ambient temperature. All

temperatures are in either °C or °F.

Figure 10: Right Angle Mirror

13

WARNING

Incorrect wiring will cause severe, per-

manent damage to the sensor.

Pay close attention to the wiring diagram in

Figure 11, and match your sensor to the appropriate output type in Table 4 or 5. Wire accordingly.

DO NOT CONFUSE OUTPUT WIRES WITH

POWER SUPPLY WIRES.

Electrical Installation

Sensor to Electronics Cable—The sensor to electron-

ics cable is a 1m (3 ft), 4-wire, PVC cable. One end is

attached, at the factory, to the sensor head. The

other end has two pairs of wires and a bare shield

(ground) wire (see Figure 11).

The unlabeled pair of wires is for connecting to a

controller or chart recorder or for attaching to a thermocouple plug (for connecting to a thermocouple

meter). DO NOT CONNECT TO APOWER

SOURCE.

The second pair of wires, with the label, is for connecting to a power source.

14

Figure 11: Wiring Configuration

Table 4: Standard Cable Wiring

Wiring—Wire the electronics cable using Figure 11 and

Table 4 or 5 (for high temp cables) as a guide. USE

ONLY THE OUTPUT TYPE OF YOUR SENSOR.

WIRING TO THE WRONG OUTPUT WILL DAMAGE THE SENSOR. Note in Figure 11 that the num-

bers refer to the wire numbers in Table 4 or 5, which

shows proper wiring connections based on insulation

color coding.

Inside threads M18 x 1

(if ordered with metric threaded sensor)

3/4" – 16UNF 2A

35

(1.36)

(0.42)

11

(0.84)

9

(0.37)

21

31

(1.21)

mm (inches)

∅19 (0.75)

10/32" threads

∅35

(1.38)

~ 25

(~ 1)

(2.38)

61

Recommended

Cooling water supply

Temperature

Flow rate

Pressure drop

Cooling air supply

Temperature

Flow rate

Pressure drop

Air purge air supply

Temperature

Flow rate

Pressure drop

(across unit only)

(across unit only)

(across unit only)

15–30˚ C (60–86˚ F)

1.89 liters per min (0.5 gpm)

< 0.69 bar (10 psi)

< 30˚ C (< 86˚ F)

70.8 liters per minute (2.5 SCFM)

< 0.34 bar (5 psi)

< 30˚ C (< 86˚ F)

11.33 liters per minute (0.4 SCFM)

< 0.34 bar (5 psi)

∅20 (.8)

3/4"–16 UNF 2B

82

13

(.5)

20

(.8)

31

(1.25)

mm (inches)

NOTE LABEL

(ON POWER

SUPPLY WIRES ONLY)

Wire Numbers

(Refer to Table 4 or 5)

12 – 24 VDC Red (+)

1

2

3

4

5 (Shield)

J-type

Thermocouple

K-type

Thermocouple

10mV/˚C

Voltage

Output

Power

Supply

–

Output

Power

Supply

–

Output

Power

Supply

–

Wire

Number

1

2

3

4

5

1

2

3

4

5

1

2

3

4

5

White

Red (white stripe)

Red (yellow stripe)

Yellow

Bare

Yellow

Red (yellow stripe)

Red (white stripe)

White

Bare

White

Green

Red

Black

Bare

FunctionWire ColorOutput Label

Signal + (Iron)

Signal – (Constantan)

Power Supply +

Power Supply –

Shield Ground

Signal + (Chromel)

Signal – (Alumel)

Power Supply +

Power Supply –

Shield Ground

Signal +

Signal Ground

Power Supply +

Power Supply –

Shield Ground

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 5

E xten sion C ables—E xtension cables are avail able as

accessories. A lso av ailable is a thermocouple connection kit.

M A I N T EN A N CE A N D

T R O UB L ES H O O T I N G

If your sensor i s not perf ormi ng as it shou ld, tr y to

match the symptom in Table 6 to its probable cause. I f

the table does not help, call us at one of the phone

num bers listed on the last page.

Our custom er service representatives ar e al w ays at

your d isposal for appli cation assi stance, cali bration,

repai r, and solutions to specific questi ons or problems.

C ontact our Service D epartment before returning any

equipment to us. In many cases, problems can be

solv ed ov er the telephone.

I M PO RT AN T

Be aware of the foll ow ing when using the sensor:

If the sensor is exposed to significant changes in

ambient temperature (hot to cold or col d to hot),

all ow 20 mi nu tes f or the temperature to stabili ze

before tak ing or recording measurements.

Do not operate the sensor near large electri cal or

magnetic fields (e.g., around ar c w elders or i nduction heaters). E lectro-M agnetic I nterference (E MI)

can cause measurement errors.

C onnectors or w ires must be connected only to the

appr opr iate i nput jacks or terminals.

16

15

O PE R AT I ON

Once the sensor is in position and you hav e m ade sure

that the appropriate pow er, air, w ater, and cable connections ar e secure, the system is r eady for continuous

operation.

To operate, complete the fol lowing si mple steps:

1. Turn on the power supply.

2. Turn on the m eter, chart recorder, or controller.

3. R ead/ monitor the temperature.

WA R N IN G

I f usi ng the ai r /water-cool ed hous i ng, do not

leave i t in a heated envi ronm ent w i th the

coolant turned of f . D amage to th e s ensor and to

the hou sing can occur.

Table 5: H igh Temperature C able W ir ing

17

S ymp tom

No output

E rroneous Temp.

E rroneous Temp.

E rroneous Temp.

P ro ba ble C aus e

No power to se nsor

Incorre ct wire

conne ction

Fa ulty s ensor cable

F ield of view

obstruc tion

S olu tion

C heck the power

supply

C heck wire c olor

codes and reconne ct

Verify cable continuity

R emove obstruction

L ens C leani ng—K eep the lens clean at al l times. Blow

off loose par ticles (if not using the air purge accessory)

with clean com pressed air, then carefu lly wi pe sur face

with moist cotten swab (w ater or w ater-based glass

cleaner ). D O N O T use sol vents.

Table 6: Troubleshooting

Wi re

Nu mber

J -type

The rmocouple

K -type

The rmocouple

10mV /ûC

Volta ge

Output

P ower

S upply

Output

P ower

S upply

Output

P ower

S upply

1

White

2

R ed ( white s tripe)

3

R ed

4

Y ellow

5

Ð

Ð

Ð

B are

1

Y ellow

2

R ed

3

R ed ( white s tripe)

4

White

5

B are

1

R ed

2

Y ellow

3

R ed ( white s tripe)

4

White

5

B are

F unc tionWi re C olo rOu tput L abe l

S ignal + (Iron)

S ignal Ð ( Cons tantan)

P ower S upply +

P ower S upply Ð

S hield G round

S ignal + (C hromel)

S ignal Ð ( Alumel)

P ower S upply +

P ower S upply Ð

S hield G round

S ignal +

S ignal G round

P ower S upply +

P ower S upply Ð

S hield G round

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Loading...

Loading...