Page 1

How to use this Manual

To get

the full functionality of this manual we

recommend to use Adobe®Acrobat

Reader®5 or higher.

It is availabe at:

http://www.adobe.com

Once you have open this manual in

Acrobat Reader choose the tab “Bookmark” at the left to see the Table of

Contents.

These headlines are linked with the

corresponding chapters of the manual.

Just click on a headline to see the

chapter in the main window.

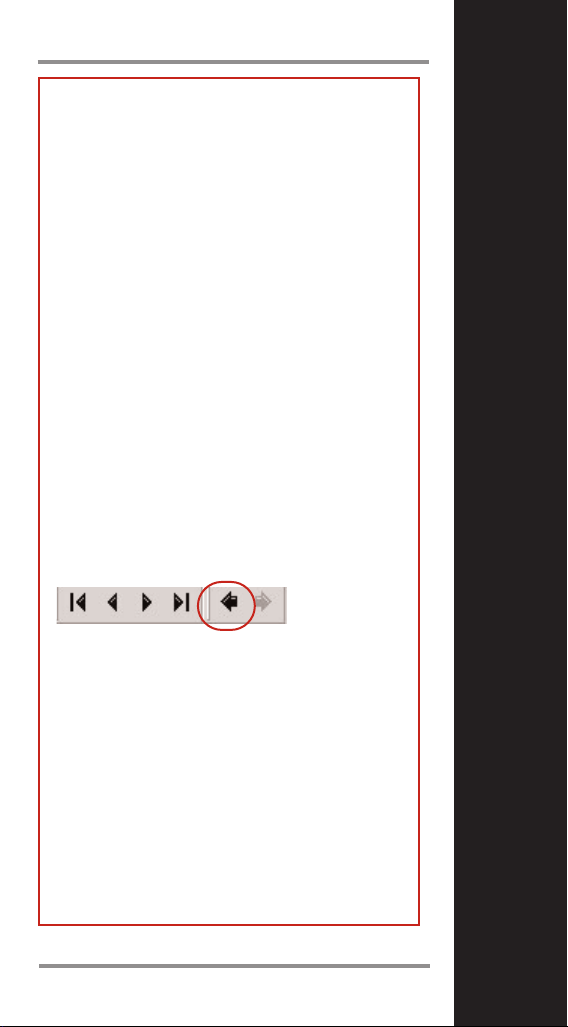

Sometimes you’ll find phrases in the

text marked red. These will guide you

to additional information. To go back to

the manual use this arrow button in the

upper bar of Acrobat Reader.

1

Page 2

3

2

Basic Mode

This chapter is dedicated

to explore the unit and the

software and to get familar with its basic functions.

It helps to get first results

fast and easy.

It explains the software

installation and how to use

the unit with factory defaults.

Please take a bit time and

follow up carefully.

Once you feel trained

enough go to the

“Expert Mode” to find out

what else this unit can do for

you.

Page 3

5

Before Starting

4

Requirements

To use the unit and the software you need a

Windows compatible PC with a minimal configuration:

• 200 Mhz processor (400 Mhz recommended)

• CD/DVD drive

• USB 1.1 - port

• 15 MByte free diskspace on the hard drive

The software works with

Windows

®

98, ME, XP and 2000.

Note! With a fresh set of batteries, the unit can

store photographs for up to 2,000 hours.

However, we recommend that you download

photographs soon after you have taken them.

To avoid the loss of photos you should change

the batteries within two minutes after the unit

has shut down completly.

Page 4

6

7

Signs and Icons in the Manual

Introduction

We hope that you enjoy using your photographic

infrared thermometer!

It measures the amount of infrared energy emitted by a target object, and calculates the

temperature of that object´s surface. In addition,

it takes a photo of the measured spot highlighted by a bright laser circle. In a few easy steps

you can create reports that incorporate the

photo of the target and also the temperature,

location, date/time, and a description - all this

can be customized by using the software

delivered with the unit.

Your unit includes:

-A digital camera synchronized with the

temperature measurement

-True Spot laser Sighting

- Nameable locations

- Adjustable emissivity

- High/Low alarm

- Data logger

- ...and a lot more!

Features

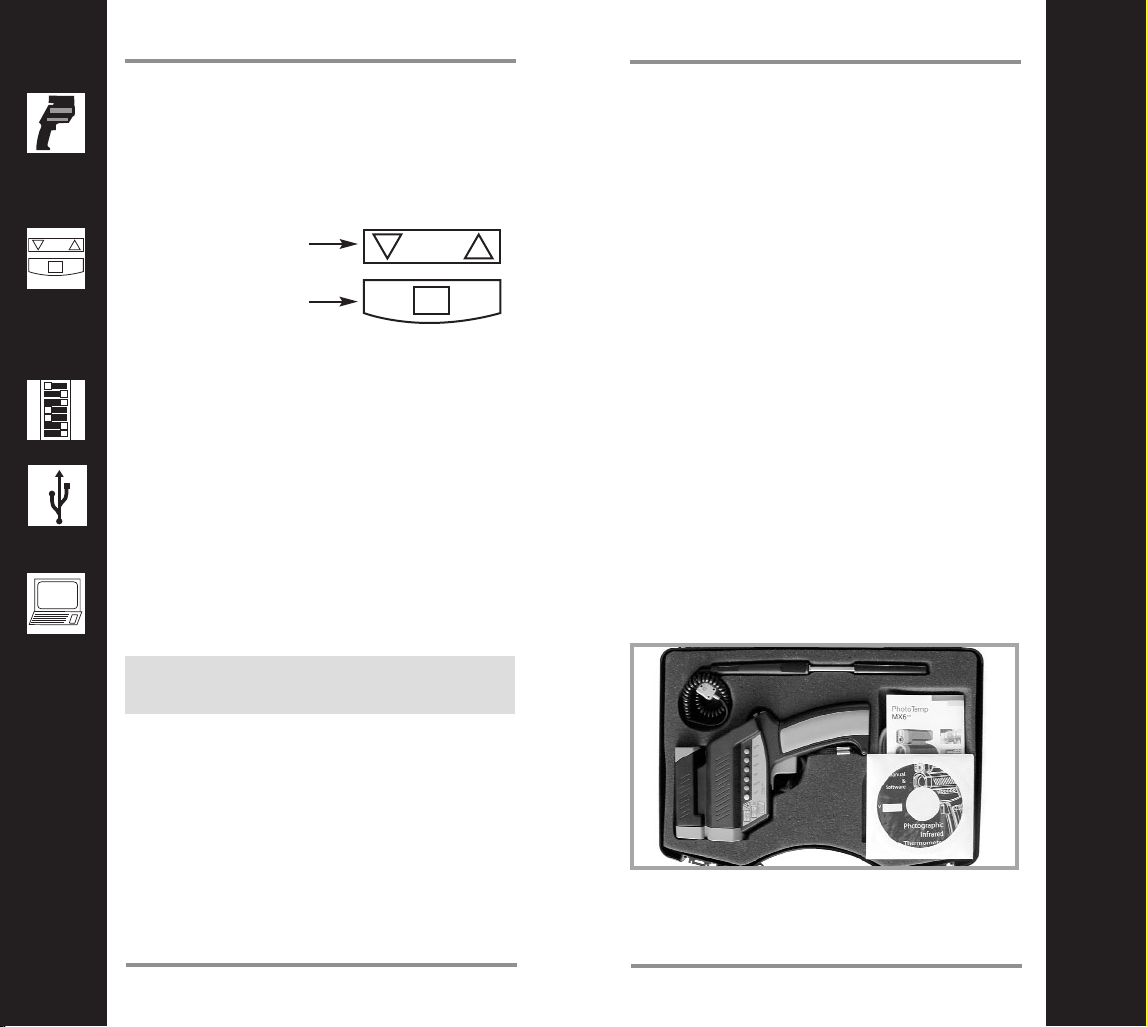

Delivery Content

If you see this icon, use the unit to follow the

steps described.

If you see this icon, you should have started

your PC and the companion Software delivered

with your unit.

If you see this icon, the unit is connected

to the PC.

Software descriptions appear in a grey textbox

This icon shows that

you can adjust values

with these buttons on

the unit.

To store these values

press the ENTER button on the unit.

This icon shows that there are additional options

related to the DIP-switch settings.

The unit • Thermocouple Type K probe • Windows-based software on CD • USB cable • Two

AA batteries • Manual on CD • Quick start

Page 5

8

9

Configuration of the PC

Installing the software

Hardware Setup

Connect the unit to the PC via USB.

New hardware will be found. You have to

install three different device drivers - two

for USB ports and one for the USB camera.

A device driver is software needed by your

PC to communicate with the unit. You will

be asked three times to install a driver.

Note! During driver installation, a message

window could appear, indicating that a particular driver is not supported or authorized by

Microsoft. Please ignore this message and continue with the installation.

The Windows Hardware Assistant will guide

you through the installation process. If you are

asked where to look for the drivers, choose

CD-ROM.

In most cases Windows will find the drivers

automatically. It could happen, that Windows

asks for the file STV680u.dll. This file is located

in the drivers folder on the CD.

Software Setup

1. Insert the CD into your CD drive.

2. Double click on setup.exe.

3. Follow the instructions, shown on the

screen.

4. Launch the software.

The software is now ready to use.

Plese read the following information first and

configure language, time, and date if

necessary.

This configuration can be repeated at any time.

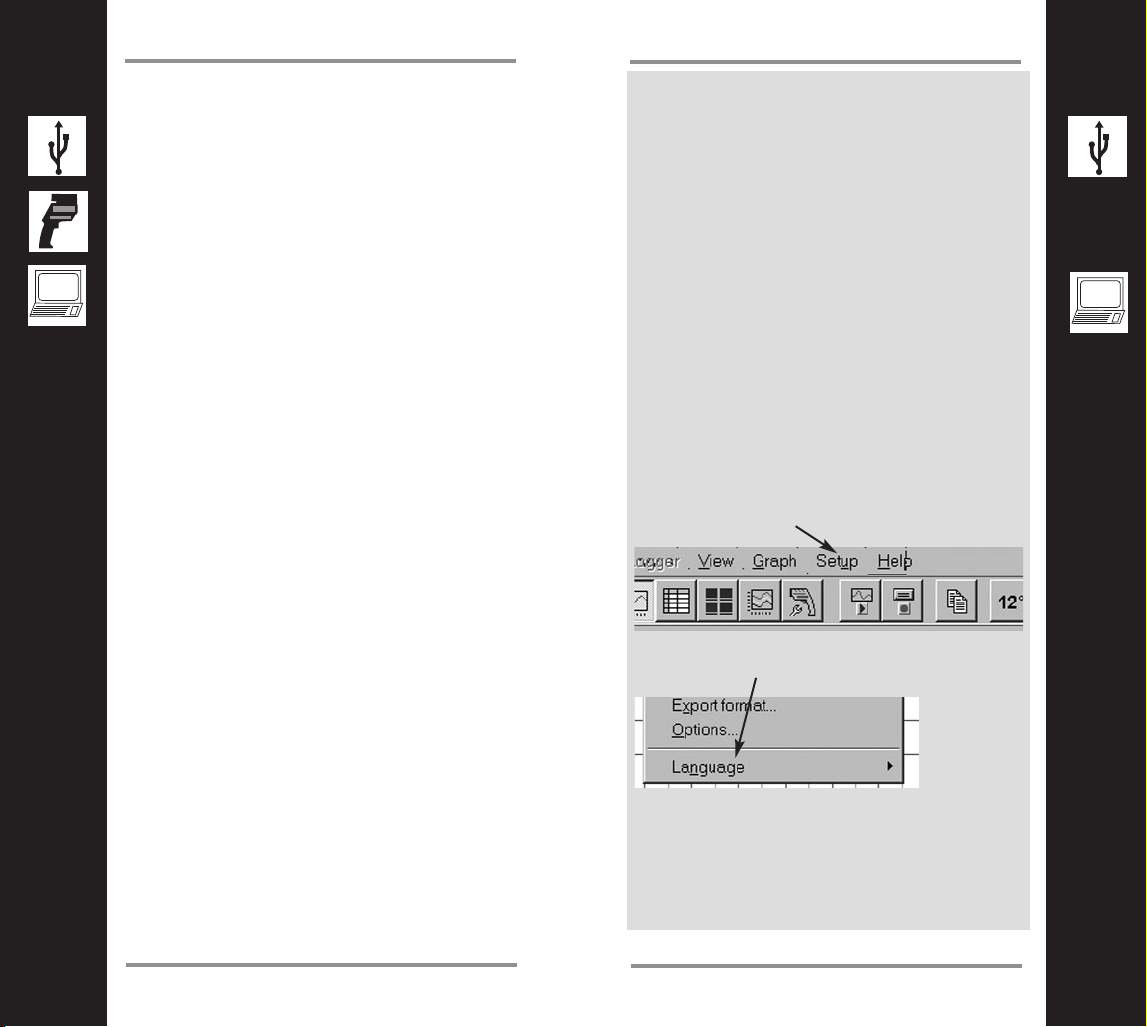

Software Language

To choose one of the available languages of the

software, go to “Setup”.

Click on “Language” in the Pull Down menu.

Then make your selection.

Page 6

11

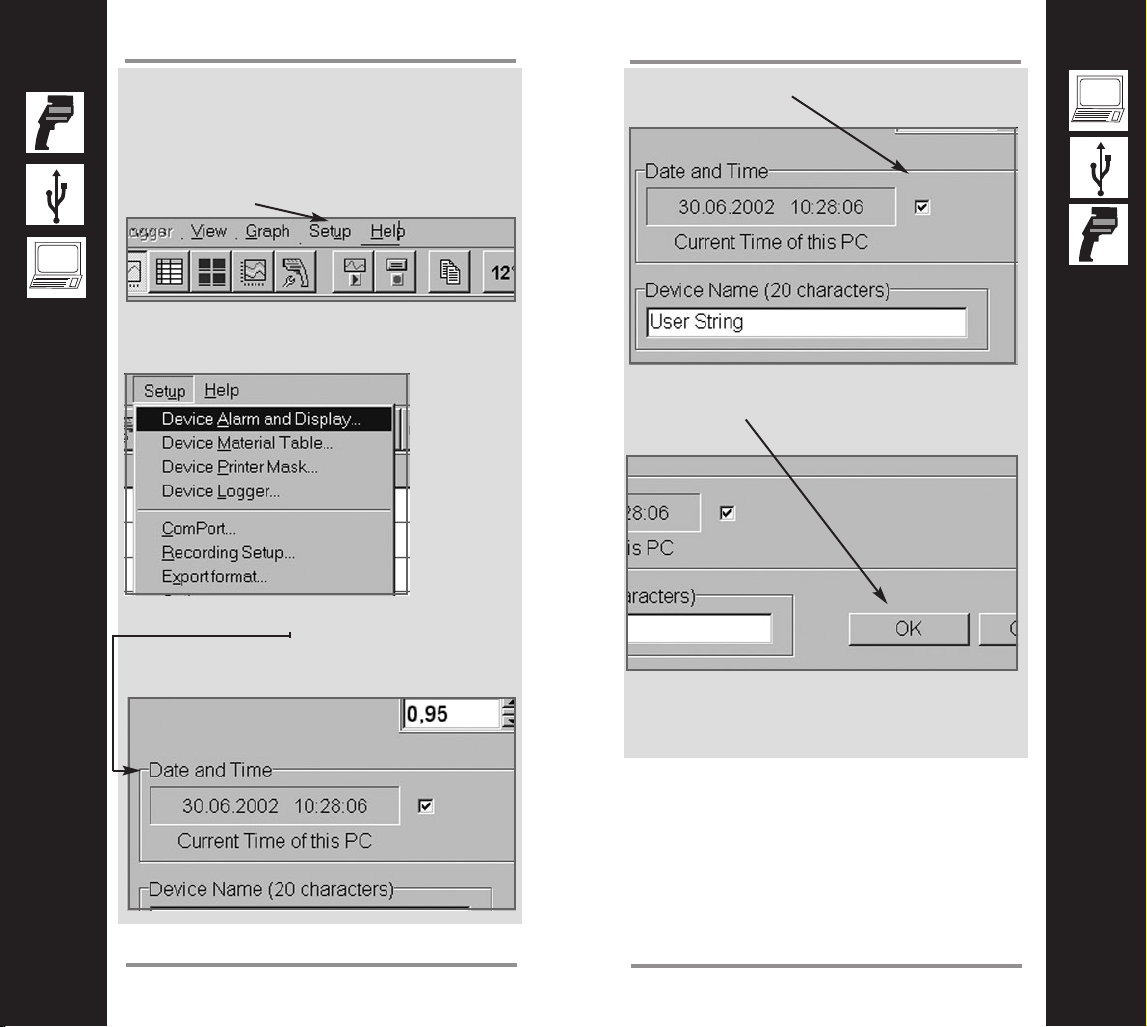

Configure Date and Time

10

Configure Date and Time

Set Date and Time of the unit

To get the right date and time stamp in your

picture, proceed with the following steps:

1. Choose “Setup” in the software’s menu bar.

2. Go to “Device Alarm and Display”

3. Look for “Date and Time” and verify that the

correct values are shown (these values

depend on your computer system settings)

4. Enable the checkbox to the right of the values.

5. Click on “OK”.

6. Disconnect the unit from the PC.

Page 7

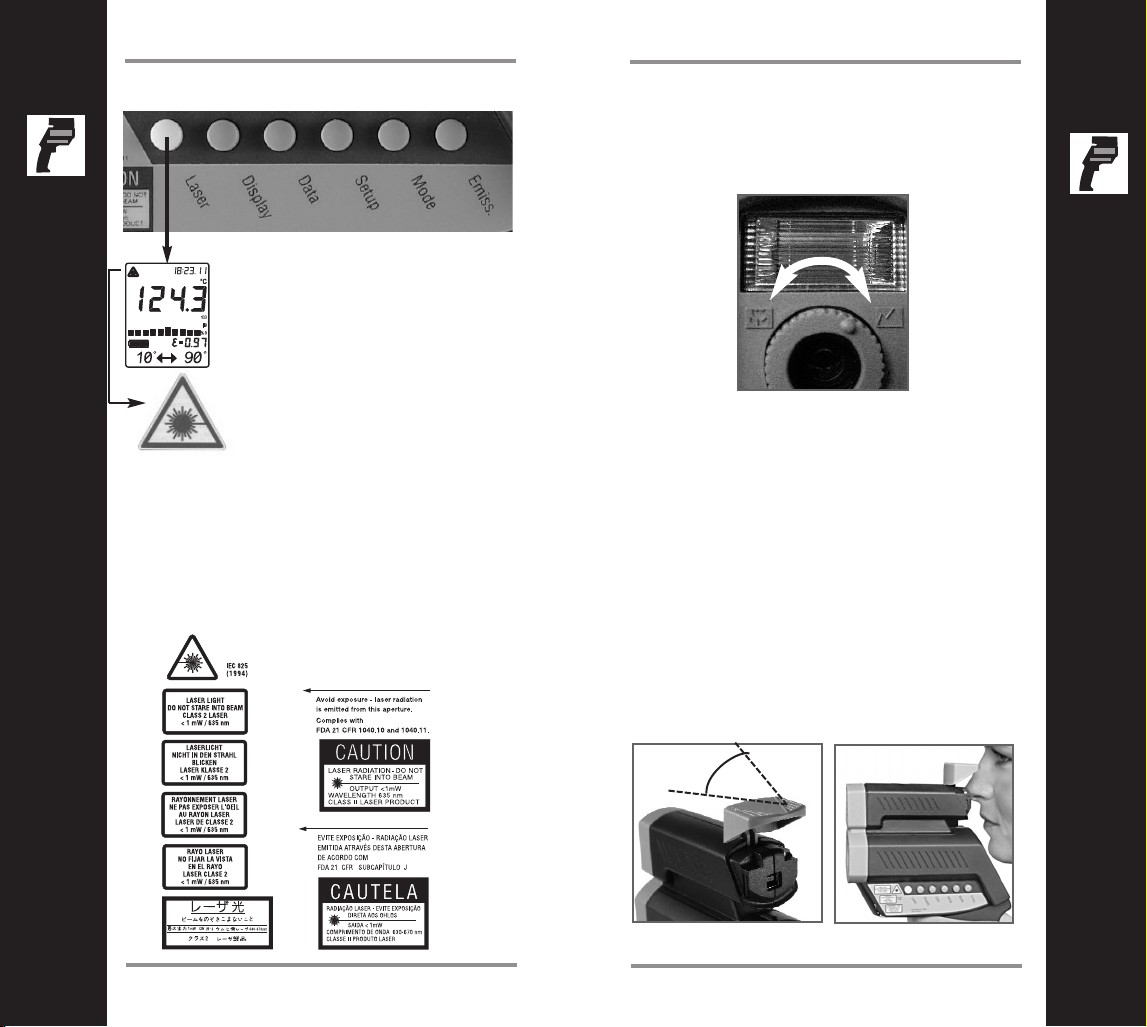

13

Basic Mode

12

Simply turn the lens focus ring depending on

the distance of your target.

How to focus the camera

Between

0.2 m

(8 in) and

0.3 m

(12 in.)

adjust the

lens to the

flower

symbol.

Between

0.5 m (19 in)

and infinity

adjust the

lens to the

mountain

symbol.

This is a simple aid to understanding the

camera’s field of view. The opening angle of the

lens is approximately 40°.

Rotate the cap up to a horizontal position and

look over it, as shown below. The embossed

triangle will show you the approximate width of

the photo.

The view finder guide

Laser ON and OFF

laser ON

symbol

The laser circle shows the

spot size that includes the

measured target. To turn

the laser On or Off, press

the LASER button when

the trigger is pulled.

A laser symbol appears

when the laser is on. The

laser automatically turns

off if you release

the trigger.

CAUTION!

Do not stare into beam!

Avoid indirect exposure via reflective materials!

Laser Warning Label

Basic Mode

40°

Between 0.25 m

(10 in.) and 0.6 m

(23 in.) adjust the

lens in the middle of

both symbols

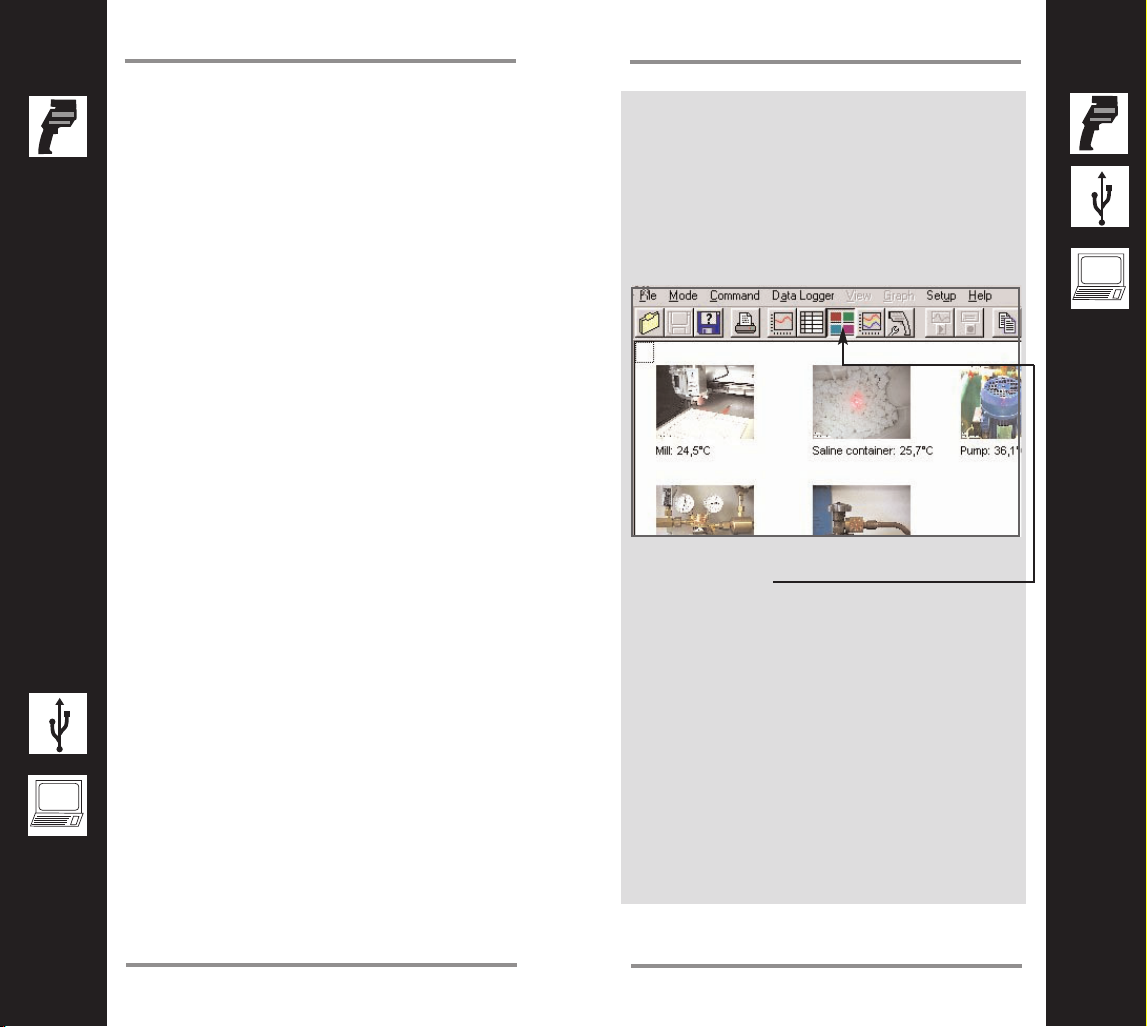

Page 8

15

Basic Mode

14

Basic Mode

1. To switch on the unit, pull the trigger.

2. Press the “Enter” button to activate the

camera while the display is active.

3. First the word “LOG” flashes and then the

camera icon appears.

The unit is ready to use now! It is preset to

take 26 pictures!

4. Pull the trigger and hold it. The laser circle

shows where you are measuring.

5. Aim at the target. Be sure that the laser

circle is inside the target.

6. Gently release the trigger to record the

photo and the temperature. Successful

recording of picture and temperature is indicated by two short beeps and a green

shining LED above the display. The next

location will be shown on the display.

Caution:

If you hear a longer beep and the LED

above the display is shining red, look at the

display. If you see “Use Flash!” and a flash

symbol, repeat your last measurement. A

small green LED above the camera icon

signals: “Flash has charged”. The flash will

now fire automatically.

7. For the next measurement repeat points

5 and 6.

8. Once you have taken all your photos,

connect the unit to the PC via USB.

9. Start the software on your PC. After a few

seconds, the data download begins. Click on

“OK” if a message about logger file and unit

configuration incompatibility appears. Click

on “Yes” if you are asked to download all

images

10. See your pictures and data as a thumbnail

collection.

11. If this doesn’t happen automatically, toggle

to this button.

Page 9

16

17

Basic Mode

Basic Mode

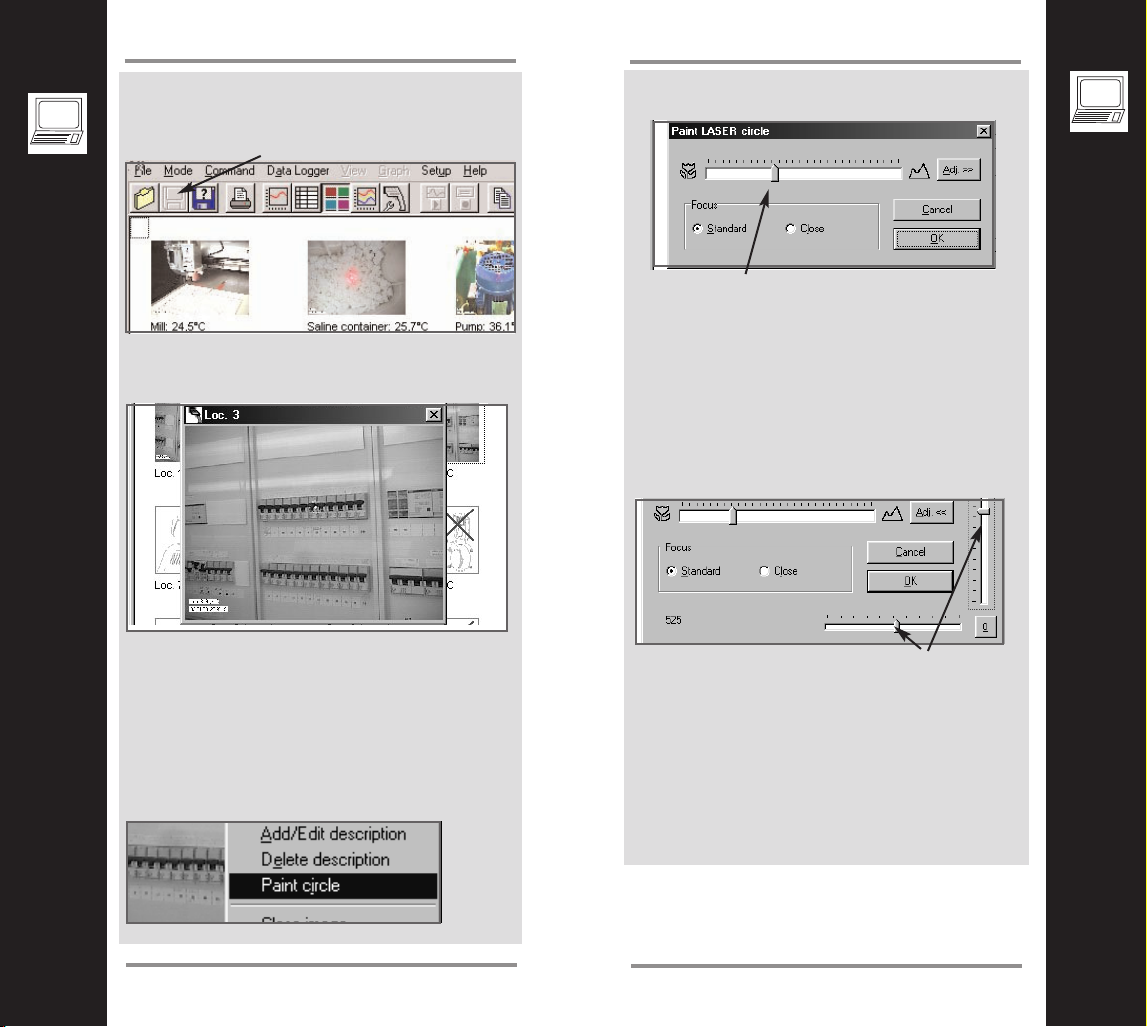

Once you have downloaded all data from the

unit to the PC, save the data as library.lgg file.

To edit a picture, click on it once with the left

mouse button. It will be enlarged.

Now you are able to add discriptions to the

photo or to insert a drawing of the laser circle.

This may be necessary, if the ambient light was

too bright while taking the photo and the laser

circle is hard to see.

Right clicking on the photo will open a menu,

where you can choose what you want to do.

Additional software features

If you choose “Paint circle” the following window

appears.

With the distance slider you could adjust the

size of the laser circle drawing corresponding to

the original size of the real laser circle.

NOTE: This feature will only work properly, if

you have adjusted once the circle drawing

to the camera with the following procedure:

Ta ke a photo - enlarge it in the software - draw

a laser circle - adjust the size with the distance

slider as shown above - adjust the place of the

circle by using “Adj.” and then these sliders.

The drawing will be stored within the photo. The

same happens with the description function.

With the “Copy image” function you can create

a report easily by pasting the photo into a programme of your choice.

“Print Image” starts the printers dialog of your

standard printer. Now you can print out a single

photo.

Page 10

19

18

Expert Mode

Expert Mode

This chapter is dedicated

to the advanced user and

based on the

“Basic Mode” part of this

manual.

We recommend to going

through this part step by

step to get the most benefit

out of the unit.

For additional information

contact the manufacturer or

refer to its website.

(See back page of the cover

of the printed manual.)

In the “Basic Mode” chapter you have seen how

easy it is to use this unit and to store photos

and data.

A special file has been created automatically by

the unit, based on the factory defaults. This file

is called “Logger” and has the extension “lgg”.

Under special circumstances it may happen,

that the factory default settings don’t match your

needs. In that case, it is possible to customize

the factory default logger file.

You may wish, for instance, to name the locations where you want to measure or to add different emissivity values or special materials.

Additionally it may necessary to add more than

just temperature, location, date and time information to the photos.

All this is possible and explained in the next

few pages

Page 11

21

Expert Mode

20

Expert Mode

How to create a logger file?

Note! The following operation will

change the current settings in the

unit!

Configure an inspection table using the menu

SETUP/DEVICE LOGGER. The following screen

display will appear.

Continue by setting the desired number of the

inspection points to be measured in the table at

the lower right. In our example it is 5. Choose

the desired image resolution. “High” means a

resolution of 640x480 pixels, “Low” is

320x240 pixels.

Please note! In both modes you could configuere up tp 100 positions. If you have chosen

“High” the maximum number of photos is 26.

In the “Low” resolution mode, you can take

more than 100 photos. The camera memorycan store up to 106 photos. This could be helpful, if you want to repeat a photo at a previous

position.

Next, enter the name of the location and insert

the related material from the material table by

clicking here. For a known emissivity enter the

value in the column EMS. In the column “Image”

you could enable or disable taking a photo by

checking the appropriate box

The material names are stored in a material

table file. This can be customized. See chapter

“How to create a material table?”

Save this logger file with a new name by

clicking on the “Save as” button. With a click on

“OK” transfer the table to the unit.

Now go to the Logger view by clicking here and

open the file you have just saved

Page 12

23

Expert Mode

22

Expert Mode

Examples

Disconnect the unit from the PC and begin your

inspection.

Once the inspection has been done, transfer

data and photos to the PC. Connect the unit via

USB to the computer, while the software is running. The data transfer begins automatically

when the message “Connected” appears.

Now you can set up which data fields should be

inserted in the photos after you have taken

them. All columns you choose here will be included in the final photo.You can’t delete any information from the photo itself. To open the sub-

menu simply right click into the table

With the following dialog choose and order the

columns.

Note! The more data you insert in the photo the

more these data will hide the picture. Especially

if your working in the low resolution mode, we

recommend to choose only a few columns.

See the examples!

Many columns

chosen

Fewer columns

chosen

Page 13

Ta ke your photos and data as described above

and save them by pressing disc buttoninto the

same file as before.

The number of inspections is shown in the bot-

tom line of the window

To see changes of the temperature over time,

you can create a routing graph.

This feature is very useful to monitor measurement points over time and identify problematic

trends.

For instance, in electrical panels, it is difficult to

find out that something is outside the normal

temperature range, especially if the panel has

live voltage. If you monitor the panel over time,

you find out, where the problems are, before

they become dangerous.

Go to

and then open the logger file you have just

created.

25

Expert Mode

24

Expert Mode

The photos and data appear in a thumbnail preview. To see the table click here.

With a right click into the table you open a sub

menu.

By choosing “Columns” you can add or delete

columns to show all the data you have saved.

Save the data. This will delete the unit’s

memory and the unit is now ready for the next

inspection.

Page 14

27

Expert mode

26

The result.will look as follows:

The routing graph

Expert Mode

The following dialog appears:

Now select in the curves menu up to five

objects measured and set up their appearance

in the graph.

Then choose the time frame of the measurement.

Page 15

29

28

Expert Mode

How to create or edit a material table?

This function enables you to easily create

customized material / emissivity tables that

meet your requirements.You can then transfer

the table, online, to your thermometer. Proceed

as follows:

Choose the item DEVICE MATERIAL TABLE

from the menu SETUP.

The following screen display appears.

Creating a New Material Table

The cursor is located in the first line under the

entry MATERIAL. Enter the name of the first

material here. In the same line enter the associated emissivity under EMS. To access the

other fields, use the keyboard or the mouse and

fill in the complete table. Now save the table by

clicking the button SAVE TO FILE. In the subsequent window (see next page) enter the file

name; the file suffix "mat" is automatically

appended.

Save the file in a directory on the drive of your

choice. We recommend the directory name

"Material."

Default Material Table

For your convenience we have provided a selection of 30 common materials. To access these,

simply click FACTORY DEFAULT with the primary mouse button or choose a material table

in the language you need by selecting

LOAD FROM FILE.

A complete table will appear as shown above.

By clicking OK you transfer this table to the unit.

Editing an Existing Material Table

Just as easily you can edit a material table. To

call up the table, choose the function LOAD

FROM FILE in the editing window.

By selecting and overwriting, you can modify the

list as you prefer and then save it again.

Page 16

31

Expert Mode

30

Expert Mode

Temperature Monitoring mode

Using the software, the unit can monitor

temperature and take photos automatically.

This happens when the temperature exceeds

the preset values for high or low alarm.

Proceed as follows:

Install the unit on a tripod.

Adjust the measurement direction with the help

of the live video window of the software.

Then go to “Setup” menu in the software and

choose “Device Alarm and Display...”

Choose the alarm values for which you want

the unit to take a photo when exceeded. If

necessary, choose the material of the target or

emissivity value.

Then click “OK”.

Now go to “Recording setup” in the setup

menu.Mark when the snapshot should be taken

- at high alarm or low alarm.

The “min. interval(s)” setting means that the unit

only checks after this interval for the alarm values exceeded.

A photo will only be taken if an alarm is newly

exceeded.

The snapshots will be taken in the measurement and recording mode.

But you can only save the data for later documentation in the recording mode.

The “Max. number of images” is limited only by

hard disk space. The file size of a low resolution

photo is approxomate 30 kB and for high resolution 60 kB.

The live video window appears in both modes.

Please do not close it. Otherwise the snapshot

mode will not work.

To resize the live video window, simple click the

right mouse button and choose another size.

When you press the recording or measuring

button again to stop the process, you will be

prompted for a file in which to save the

temperature data.

Page 17

33

32

Expert Mode

After taking the snapshot, you can see the

photos by clicking on the square markers in the

graph.

Page 18

34

35

Appendix A - Unit functions

Appendix A - Unit functions

Selecting a function

1. To switch on the unit pull and release

the trigger.

2. While the display is active, push the button

of the desired function.

3. Many of the functions are adjustable by

using the Up and Down keys.

For storing, press ENTER.

1

2

3

The DIP switches

Some functions of the unit be changed by using

the DIP switches. These switches are located in

the Battery compartement of the unit.

ON

Sets the unit into continuous measuring mode

Switches between

degrees Celsius and

Fahrenheit

Switches acoustic

signals On or Off

Switches the backlight of

the display On or Off

Sets the unit’s values to

default, if On

If On, the function

buttons are blocked

If On, the laser will flash

when temperature values exceed alarm

If On, photoflash is

activated

Auto = automatic flash use

All = every photo is taken

with flash

Time or Date will be

displayed

Thermocouple settings refer to the

corresponding

chapter

ON

Lock

°C/°F

Buzzer

Backlight

Set Default

Ltd. Access

Laserflash

Photoflash

Auto/All

Time/Date

NTC/TC

TC-J/TC-K

Page 19

37

Appendix A - Unit functions

36

Appendix A - Unit functions

The Data button

Press Data once to activate the log

mode of the thermometer and the

camera. With the right logger file

configuration, you can store

temperature values and photos.

The configuration of the logger file

is performed by the companion

software.

By pressing the Data button twice, one of the

following four displays appears.

“RCL” is displayed for the recall mode.

A photo and

a temperature value

have been

stored at this

Logger position.

Only a

temperature

value has

been stored

at this logger

position.

Camera is

active at this

logger position. Nothing

has been

stored.

Camera is

inactive at

this logger

position.

Nothing has

been stored.

The Display button

The last ten measurements are

shown in the bar graph on the

unit’s display. Auto Range of the

bar graph is automatically defined

by the measured maximum and

minimum value. Manual Range

(Man Range) is user defined.

CYCLE allows the adjustment of

the display interval of the bar

graph.

Press Display once to see how

many photos are already taken.

This sets up the BEGIN value for

the graphic display of the bar

graph. The graphic display shows

the temperature as a picture.

This sets up the END value for the

graphic display of the bar graph.

Page 20

39

Appendix A - Unit functions

38

Appendix A - Unit functions

The Setup button - HiAL, LoAL, Time...

High alarm (HiAl)

generates an audible and visual

(flashing LED and laser) alarm if

the temperature is above the

setpoint.

Low alarm (LoAl) generates an

audible and visual (flashing LED

and laser) alarm if the

temperature is below the setpoint.

This function is used with a selected

emissivity to add or subtract an offset

value (±10°C/±18°F) to the temperature

value.

The OFFSET feature allows the

temperature values for several units to be

matched, correcting for the allowed

temperature tolerance difference between

units. The OFFSET function can also be

used to increase the accuracy for a narrow

temperature range.

Change the time using the Up and Down

keys.Then press ENTER for each time

segment to activate this time setting. The

segment flashes whilst being set. The

time is stored within the data logger.

Change the date using the Up and Down

keys.Then press ENTER for each date segment to activate this date setting. The segment flashes while being set. The date is

stored within the data logger.

...Date, Offset, Clear Images

This feature deletes all

photos from the unit’s

memory.

“Clear Image Press

Enter” is shown as a run-

ning string in the bottom

line of the display

BE CAREFUL if you use

this function. The pictures

cannot be restored.

Back to the

Setup Button

The configuration of the alarm values can

also be performed by the companion

software.

Page 21

41

Appendix A - Unit functions

40

Appendix A - Unit functions

The Mode button - MINMAX, Material, MAX...

...MIN, DIF, AVG,

To activate the MAX mode, press

MODE until the MAX symbol

appears . The measured maximum

temperature is displayed as long

as the trigger is pulled or locked

on. The real time temperature is

shown in the lower part of the display (NORM).

To show which specific material

has been choosen for the specific

location, press MODE until the

name appears in the bottom line.

If “Free” appears, you can change

the emissivity settings by using

the Emiss. button, when not in

LOG mode. See chapter The

Emiss. button!

To show the minimum and maximum temperature values during a

measurement at the bottom of the

display, press MODE until the two

values appear.

To activate the MIN mode, press

MODE until the MIN symbol

appears. The measured minimum

temperature is displayed as long

as the trigger is pulled or locked

on.The real time temperature is

shown in the lower part of the display (NORM)

To activate the DIF mode, press

MODE until the DIF symbol

appears. The difference between

the measured max and min temperatures is displayed as long as

the trigger is pulled or locked on.

The real time temperature is

shown in the lower part of the display (NORM).

To activate the AVG mode, press

MODE until the AVG symbol

appears. The average value of

measured temperatures is diplayed

as long as the trigger is pulled or

locked on. The real time

temperature is shown in the lower

part of the display (NORM).

Next page

Page 22

43

Appendix A - Unit functions

42

Appendix A - Unit functions

s

ON

Open the battery compartment and set the switches

ON or Off according to the

desired probe type.

NTC - thermistor

TC - thermocouple

Thermocouple type J

Thermocouple type K

Connect the probe to the input.

The input is located at the bottom of the handle behind the

rubber cover.

Press MODE, until the desired

probe symbol (TC-K shown

here) appears. The probe

temperature is shown in the

lower part of the display. The

real time infrared temperature is

shown in the main display.

The Mode button - Thermocouple Settings

back to

Mode

button

The Emiss. button

To choose the emissivity of a material, press EMISS.

The display shows a material

name, an emissivity value, and the

calculated temperature value. To

choose another material, use the

Up and Down keys.

Press ENTER to activate this setting.

To adjust the emissivity value,

press EMISS., when not in LOG

mode. Use the Up and Down keys

to select “Free“ (“F

ree” will have a

flashing underline).

Press EMISS again. “Free” is not

underlined, and the emissivity icon

flashes. Use the Up and Down keys

to adjust. Press ENTER (D) to activate this setting.

ON

Lock

°C/°F

Buzzer

Backlight

Set Default

Ltd. Acces

Laserflash

Photoflash

Auto/All

Time/Date

NTC/TC

TC-J/TC-K

Page 23

45

Appendix B

44

Appendix B

To adjust the unit’s emissivity value for a

material with unknown emissivity, plug in the

probe.

Pull the unit’s trigger. Place the measuring

tip of the probe on the area to be measured.

Wait for the reading to stabilize.

Note the indicated probe temperature reading.

Release the trigger.

Pull the trigger again. Measure the same area

using infrared measurement.

Press the emissivity button. Use the Up and

Down keys to select the material name “Free”

which will be shown in the display. Press the

emissivity button again until the emissivity sign

flashes. Use the arrow keys to change the

emissivity value until the temperature matches

the probe’s reading.

The amount of infrared energy radiated by an

object depends on its emissivity and its

temperature.

The emissivity depends on the material and its

surface characteristics.

Note: For more accurate readings, adjust the

emissivity value for the type of material being

measured.

Emissivity explained

Unknown Emissivity Value

Reflected energy

Emitted energy

Tr ansmitted energy

Target

EMISSIVITY

Page 24

47

Appendix B

46

Appendix B

The measured spot size depends on the

distance between the object you are measuring

and the infrared thermometer.

The relationship between distance and spot size

is 60:1 at the focus point.

The D:S in the far field (>33ft/10m) is 35:1.

The measured spot size depends on the distance

between the object you are measuring and the

infrared thermometer. The relationship between distance and spot size is 50:1 at the focus point.

The D:S in the far field is 12:1.

The best distance between sensor and object is from

10 cm (4“) up to 50 cm (20“).

Optical Resolution (Infrared Themometer)

Standard Focus Model

Optical Resolution (Infrared Thermometer)

Close Focus Model

STANDARD MODEL

Optical Chart

DISTANCE: SENSOR TO OBJECT (IN)

0

30

20

36

46

48

0.76 IN @ 46 IN

SPOT DIA. (IN)

1.0

0.9

0.87

23

24

24

250

100

500

0

SPOT DIA. (mm)

DISTANCE: SENSOR TO OBJECT (mm)

FOCUS POINT D:S = 60:1 FAR FIELD D:S = 35:1

1.2

0.82

0.81

19.8

29.0

19 mm @ 1150 mm

1000

60

1500

1.51

84

72

1.85

44.0

2000

58.0

108

100

2.3

2500

120

2.9

2.5

72.0

3000

CLOSE FOCUS MODEL

Optical Chart

DISTANCE: SENSOR TO OBJECT (IN)

0

6

7.9

2

SPOT DIA. (IN)

1

0.9

0.75

18,7

22

25

0

50

SPOT DIA. (mm)

DISTANCE: SENSOR TO OBJECT (mm)

FOCUS POINT D:S = 50:1 FAR FIELD D:S = 12:1

9.8

4

0.24 IN @ 11.8 IN

0.62

0.49

0.37

9,2

12,3

15,5

6 mm @ 300 mm

150

100

200

250

20

0.93

Close Focus

23

500

40

2.81

70

1000

Page 25

49

Appendix B

48

Appendix B

Aluminum* 0.30

Asbestos 0.95

Asphalt 0.95

Basalt 0.70

Brass* 0.50

Brick 0.90

Carbon 0.85

Ceramic 0.95

Concrete 0.95

Copper* 0.95

Dirt 0.94

Frozen food 0.90

Hot food 0.93

Glass (plate) 0.85

Ice 0.98

Iron* 0.70

Lead* 0.50

Limestone 0.98

Oil 0.94

Paint 0.93

Paper 0.95

Plastic** 0.95

Rubber 0.95

Sand 0.90

Skin 0.98

Snow 0.90

Steel* 0.80

Te xtiles 0.94

Water 0.93

Wood*** 0.94

*oxidized

** opaque, over 20 mils

***natural

Table of emissivity values of common materials

The DIP-switches are located in the battery

compartment (8). In the beginning we recommend you use the default DIP-switch settings.

DIP switch settings - Factory Defaults

Factory Defaults

DIP-Switch Settings

ON

Lock

°C/°F

Buzzer

Backlight

Set Default

Ltd. Access

Laserflash

Photoflash

Auto/All

Time/Date

NTC/TC

TC-J/TC-K

Celsius setting shown

ON

Lock

°C/°F

Buzzer

Backlight

Set Default

Ltd. Access

Laserflash

Photoflash

Auto/All

Time/Date

NTC/TC

TC-J/TC-K

Fahrenheit setting shown

Page 26

51

Troubleshooting

50

Troubleshooting

Symptom

Display Code Problem Action

Camera cannot Driver installation Open

send photos failed Harware Manager on

to the PC the PC to fix it

-O- Target temperature is over Select target

-U- or under range within unit’s specs

EEPROM-Err EEPROM error Contact Factory

CalAreaErr calibration errors Contact Factory

ProbCalEr

Flash needs Battery is low Replace Batteries

too long to

charge or does not

charge at all

Blank display Battery is dead Replace Batteries

Laser won’t Low or dead battery Replace Batteries

work

Ambient above 45°C (113°F) Operate unit in

45°C (113°F)

ambient or below

Display “ON” Display locked “ON” Disconnect the unit

from the PC

Photos lost Batteries changed before Wait for shutdown

shutdown or too long to end. Change

after removing old ones batteries within two

minutes of removing

old ones

PC displays “logger The setup in the unit and Click “OK”. Either save

file does not match in the PC software do not the current data to a

device logger setup” match new file name or find

the correct *.lgg file,

open it in “Setup

Device Logger”, save,

and redownload the

data with the “Data

Logger/Load Device

Data Logger”

Sometimes a long beep and the red LED above

the display shines to indicate a problem, check

your display to find out which problem has

occured.

Symptom

Display Code Problem Action

Photo quality Light is sufficient for photo Use Photoflash

diminished with without flash always on (Dip switch

available light. “Auto/All”set to “All”

(Abrupt transitions or provide more

between color shades) ambient light.

Connection of unit Wrong com port selected Select correct com

to PC software or correct com port in use. or disconnect other

does not happen device from correct

when software started com port

No picture in More than one video Right mouse click

“Live” mode source is installed on the “Live” mode

window window. Choose

correct “Video source”

in the menu.

Unit indicates The light is too bright for Go to next location

“Use flash” in a photo or reduce brightness.

bright light

Unit leaves LOG The last position has been used If for the data and

after a photo and to record photo and data. photos required, then

data recorded. push Enter button and

use arrow keys to

re-record a position.

Photo Mem! All memory for storing photos 1. Download existing

has been used. photos and data and

clear memory.

- or -

2. If you don’t mind

losing photos

in the unit, you can go

to Setup in the unit,

push the button until

“Clear photo” appears

in the display and

press Enter.

Page 27

52

53

Maintenance

Lens Cleaning:

Blow off loose particles using clean

compressed air.

Brush remaining

debris away with a

camel’s hair brush.

Wipe the surface

with a moist cotton

swab. The swab

may be moistened

with water or a water based glass cleaner.

NOTE: DO NOT use solvents to clean the plastic lens.

Cleaning the Housing: To clean the

exterior housing,

use soap and water

or a mild commercial cleaner. Wipe

with a damp

sponge or soft rag.

Page 28

55

CE Confirmity

54

Important Hints

Avoid static electricity, arc welders, and induction

heaters. Keep away from very strong EMF

(electromagnetic fields).

WARNING: DO NOT touch live voltage with

contact probe.

Manufacturer,

Address

Made in Germany: Month, Year

Model: XXXXXXX

Serial: 000000-0000-0000

Power Requirements 3 V

SERIAL NUMBER LABEL

Avoid abrupt changes in temperature. If this

occurs, allow 40 minutes for thermal stabilization before use to prevent the possibility of

inaccurate temperature readings.

Thermal Shock

This instrument conforms to the following

standards:

EMC: - EN 61326-1

Safety: - EN 61010-1:1993 / A2:1995

- EN 60825-1:1994

This product herewith complies with the

requirements of the EMC Directive

89/336/EEC and the Low Voltage

Directive 73/23/EEC.

This instrument conforms to the Standards

of the European Community.

Certification

The temperature sources used to calibrate this

instrument are traceable to the U.S. National

Institute of Standards and Technology (NIST)

and the Deutscher Kalibrierdienst (DKD). Calibration certificates are available as an option from

the manufacturer.

Don’t leave the

unit on or near

objects of high

temperature.

Page 29

57

56

Secifications (Camera)

Secifications (Thermometer)

Factory defaults

Default Range

Emissivity/Gain 0.95 0.10 to 1.50

in steps of 0.01

Emissivity Table Free 30 materials

Mode normal

Hi Alarm

Standard model 900°C (1600°F) -30 to 900°C

(-25 to 1600°F)

Sub Zero model 500°C (932°F) -50 to 500°C

(-58 to 932°F)

Lo Alarm

Standard model -30°C (-25°F) -30 to 900°C

(-25 to 1600°F)

Sub Zero model -50°C (-58°F) -50 to 500°C

(-58 to 932°F)

Offset Adjust 0°C (0°F) -10 to 10°C

(-18 to 18°F)

Graphic Display Auto Range Auto Range

/ Man Range

Cycle Time 0.2 sec 0.1 sec to 300 sec

Data logger 26 points 100 points max.

pre-set with emissivity 0.95

adjustable only via Software

Temp. Range (Standard Model) - 30 to 900°C (- 25 to 1600°F)

Temp. Range (Sub Zero Model) - 50 to 500°C (-58 to 932°F)

Display Resolution 0.1°C (0.2°F)

Accuracy (Infrared, Standard Model) ± 0.75% of reading or

at 25°C (77°F) ambient temperature ± 0.75°C (± 1,5°F), whichever is greater

±2°C (± 4°F) for targets below -5°C (23°F)

Accuracy (Infrared, Sub Zero Model) ± 1% of reading or ± 1°C (2°F),

at 25°C (77°F) ambient temperature whichever is greater for targets between

- 5 to 500°C (23 to 932°F), ± 1.5°C (3°F)

for targets between -30 to -5°C (-22 to 23°F)

and ± 2°C (4°F) for targets beween

-50 to -30°C (-58 to - 22°F)

Ambient derating < 0.05K/K or < 0.05%/K,

whichever is greater at

+ 25°C (77°F) ± 25°C (± 45°F)

Optical Resolution 60:1 (19mm spot size at 1.15m.)

(Standard Focus) (0.75in. spot size at 3.8 feet)

Optical Resolution 50:1( 6mm spot size at 0.3m.)

(Close Focus) (0.24in. spot size at 0.98 feet)

Accuracy ± 2°C or ± 0.75%,

(Thermocouple K & J) whichever is greater

Accuracy

(Thermistor)

-30 to 0°C (-22 to 32°F) ± 0.6°C

0to 70°C (32 to 158°F) ± 0.4°C

70 to 100°C (158 to 212°F) ± 1°C

100 to 120°C (212 to 248°F) ± 1.5°C

Repeatability ± 0.5% of reading or ± 0.5°C (1°F),

(Infrared) whichever is greater,

±1°C (± 2°F) for targets

below -5°C (23°F)

Response Time (95%) 250 mSec

Hot Spot Detection (30%) 85 mSec

Spectral Range 8 to 14 µm

Ambient Operating Range 0 to 50°C (32 to 122°F)

Storage Temperature -20 to 50°C (-4 to 122°F) without batteries

Relative Humidity 10 to 95% at 30°C (86°F), non condensing

Analog output 1 mV/°C(°F)

Digital Output USB 1.1

Power 2 x 1.5 V Alkaline Type AA

Battery Life (continuous use) 8 hrs (13 hrs with photo mode off)

Dimensions 240 x 170 x 50 mm (7.9 x 6.7 x 2 inches)

Tripod Mount 1/4”-20 UNC

Maximum Picture Number 26

640x480 Pixels (VGA)

Maximum Picture Number 100

320x240 Pixels (1/4 VGA)

Recharge Time for Flash app. 5 sec

Useful Flash Range

Standard Focus 0.5 to 2m (19 to 79 in.)

Close Focus 0.2 to 1m ( 8 to 40 in)

Camera Lens 6 mm (approx. equal to

42 mm on

a 35 mm camera)

Focal Points 200 mm (8 in.)(Close-up)

Infinity (Far Distance)

Light Sensitivity 6 lux

Shutter Speed variabel, max. 1/15 sec

Data Interface USB 1.1

Image File Format JPEG

Page 30

To open the battery compartment, press gently

on the top part of the handle to release the

catch and pivot the grip as shown in the figure

on the cover of the printed manual. Position the

batteries [two alkaline R6 (AA, UM3)], as shown

on the housing. (See coverpage of the printed

manual)

Caution:

Wait for unit Auto Shut down before battery

change! You will see the message “Shut down”

for a few seconds (max. 30 sec) on the display

after the unit is used in LOG mode.

Download stored photos and data and remove

batteries when you are not using the unit for a

longer time!

If the battery life icon shows two or less illumi-

nated segments, be ready to replace the

batteries since you are setting close to the end

of battery life.

58

Batteries

Loading...

Loading...