Raypak ELS 552-2, ELS 1102-2, Spa-Pak ELS 552-2, Spa-Pak ELS 1102-2 Installation & Operating Instructions Manual

Page 1

INSTALLATION & OPERATING

INSTRUCTIONS

Electric

SPA-PAK

Heater

Models

ELS 552-2 & ELS 1102-2

FOR YOUR SAFETY: Do not store or use gasoline or other flammable vapors and

liquids or other combustible materials in the vicinity of this or any other appliance. To

do so may result in an explosion or fire.

Catalog No. 6100.53U Effective: 09-28-09 Replaces: 11-11-08 P/N 240362 Rev. 22

Page 2

WATER CHEMISTRY

For your health and the protection of your pool equip-

ent, it is essential that your water be chemically

m

balanced. The following levels must be used as a

guide for balanced water.

Occasional chemical shock dosing of the pool or spa

should not damage the heater providing the water is

balanced.

Automatic chemical dosing devices and salt chlorinators are usually more efficient in heater water, unless

controlled, they can lead to excessive chlorine level

which can damage your heater.

CAUTION: Corrosive water voids all warranties.

Recommended

Level(s)

Water Temperature 68-88°F (20-31°C) 89-104°F (31-40°C) 68-104°F (20-40°C)

pH 7.3-7.4 7.3-7.4 7.6-7.8

Total Alkalinity (ppm) 120-150 120-150 80-120

Calcium Hardness (ppm) 200-300 150-200 200-400

Salt (ppm) 6000 Maximum 6000 Maximum 6000 Maximum

Free Chlorine (ppm)* 2-3 2-3 2-3

Total Dissolved Solids

(ppm)

*Free Chlorine MUST NOT EXCEED 5 ppm!

Fiberglass Pools Fiberglass Spas

3000 Maximum 3000 Maximum 3000 Maximum

Further advice should be obtained from your pool or

spa builder, accredited pool shop, or chemical supplier for the correct levels for your water.

Other Pool and Spa

Types

Rev. 22 reflects the following: Changes to: The C-UL Listed Mark on page 1.

2

Page 3

INTRODUCTION

Check Valve

To Spa

Filter

Chlorinator

Pump

Bypass

(Customer Installed)

Drain Valve

(Customer Installed)

Gate Valve

From Spa

NOTE: PVC pipe may be used.

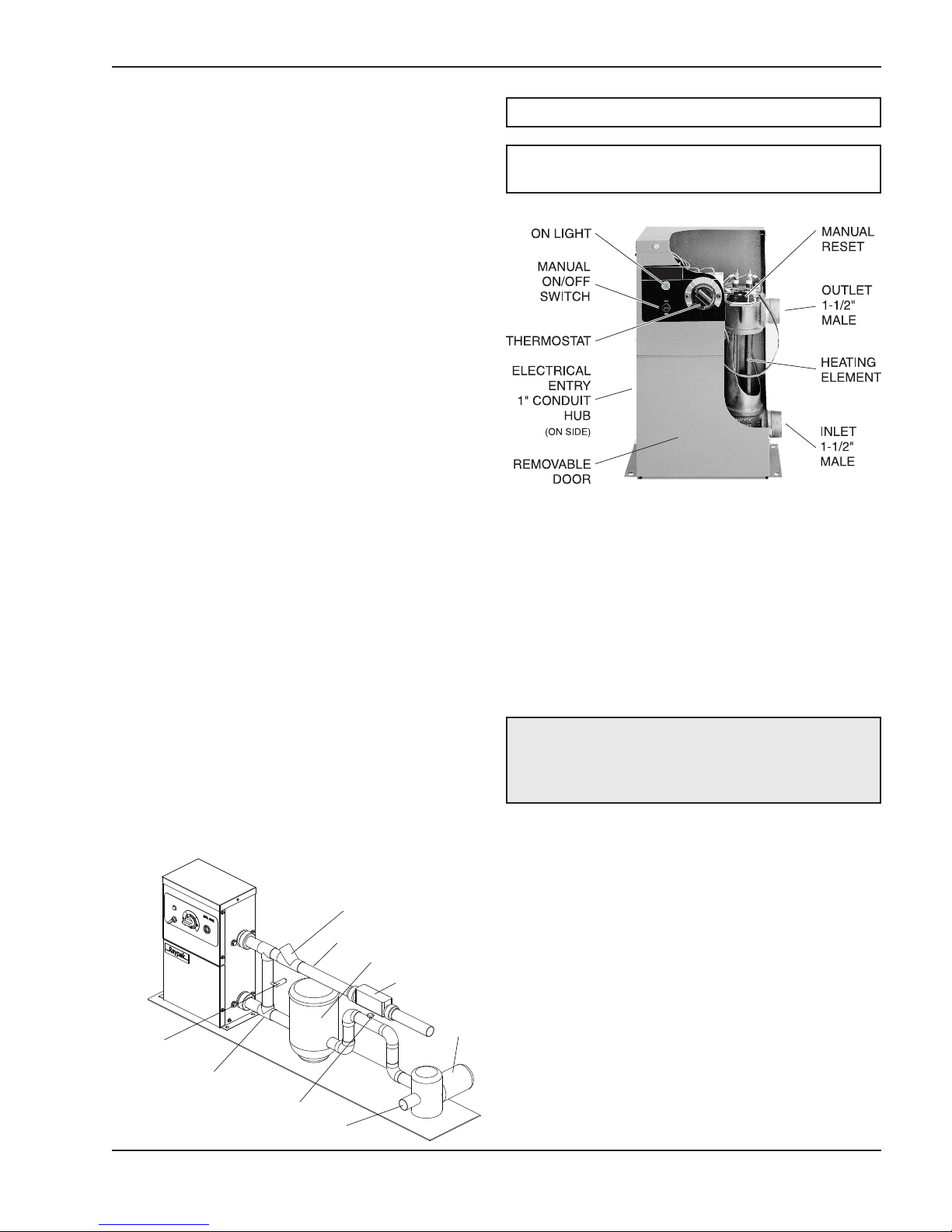

The Spa-Pak spa Heaters have been designed to pro-

ide efficient, pollution-free, electric pool heating while

v

requiring minimal installation. The Spa-Pak consists of

a sheathed resistance element installed in a copper

tank.

This tank has a 1-1/2” inlet and outlet on the side for

plumbing connections. The heater voltage is 208/240V

single-phase. The control circuit passes through a

manual switch, the temperature control, and the magnetic contactor coil. All items are pre-wired and

installed in a baked enamel steel case.

It is essential that the heater be installed in accordance with the instructions given herein. Failure to do

so may cause damage to the heater and to the equipment to which it is connected, or may prevent the

heater from operating in a correct manner. The heater

is to be installed in accordance with article 680 of the

National Electrical Code ANSI/NFPA No. 70. Consult

State and local codes BEFORE installing this unit.

Where such codes have requirements beyond the

instructions given herein, the codes shall have precedence over these instructions.

Location

These heaters are listed by UL for either indoor or outdoor use. Unit must be mounted on a level base

parallel to the ground. Allow 6” clearance at sides and

18” clearance at top and front for maintenance. Secure

the unit with 5/16” mounting hardware using the holes

provided. The heater must be located where leakage

of heat exchanger or connections will not damage the

area adjacent to the heater or structure.

NOTE: When using two speed pumps, do not install

ate valve on inlet.

g

The Spa-Pak has 1-1/2” male NPT inlet and outlet

connections at the right side of the heater. The inlet is

at the base of the heater and must be piped directly to

the filter discharge to ensure proper flow direction.

Minimum flow rate through the heater is 15 gpm, maximum is 60 gpm. If this is exceeded, an external

bypass must be added as shown. Unions should be

used on piping connections. A shut-off valve should be

included on the heater inlet to prevent draining the spa

when performing maintenance.

CAUTION: No shut-off valves are to be installed in

the piping between the heater outlet and the spa.

Any chlorinators, valves, etc., that can cause return

line blockage will void the warranty.

Water Connections

Automatic Chlorinators and

Chemical Feeders

All chemicals must be introduced and completely diluted into the spa water before being circulated through

the heater. Do not place chlorine tablets or bromine

sticks in the skimmer. High chemical concentrations

will result when the pump is not running (e.g.

overnight).

Chlorinators must feed downstream of the heater and

have an anti-siphoning device to prevent chemical

backup into the heater when the pump is shut off.

3

Page 4

CAUTION: High chemical concentrates from feed-

TYPICAL COMFORTABLE

TEMPERATURE

RANGE FOR POOLS

T

YPICAL COMFORTABLE

TEMPERATURE

RANGE FOR SPAS

ers and chlorinators that are out of adjustment will

cause very rapid corrosion to the heater. Such damage is not covered under the warranty.

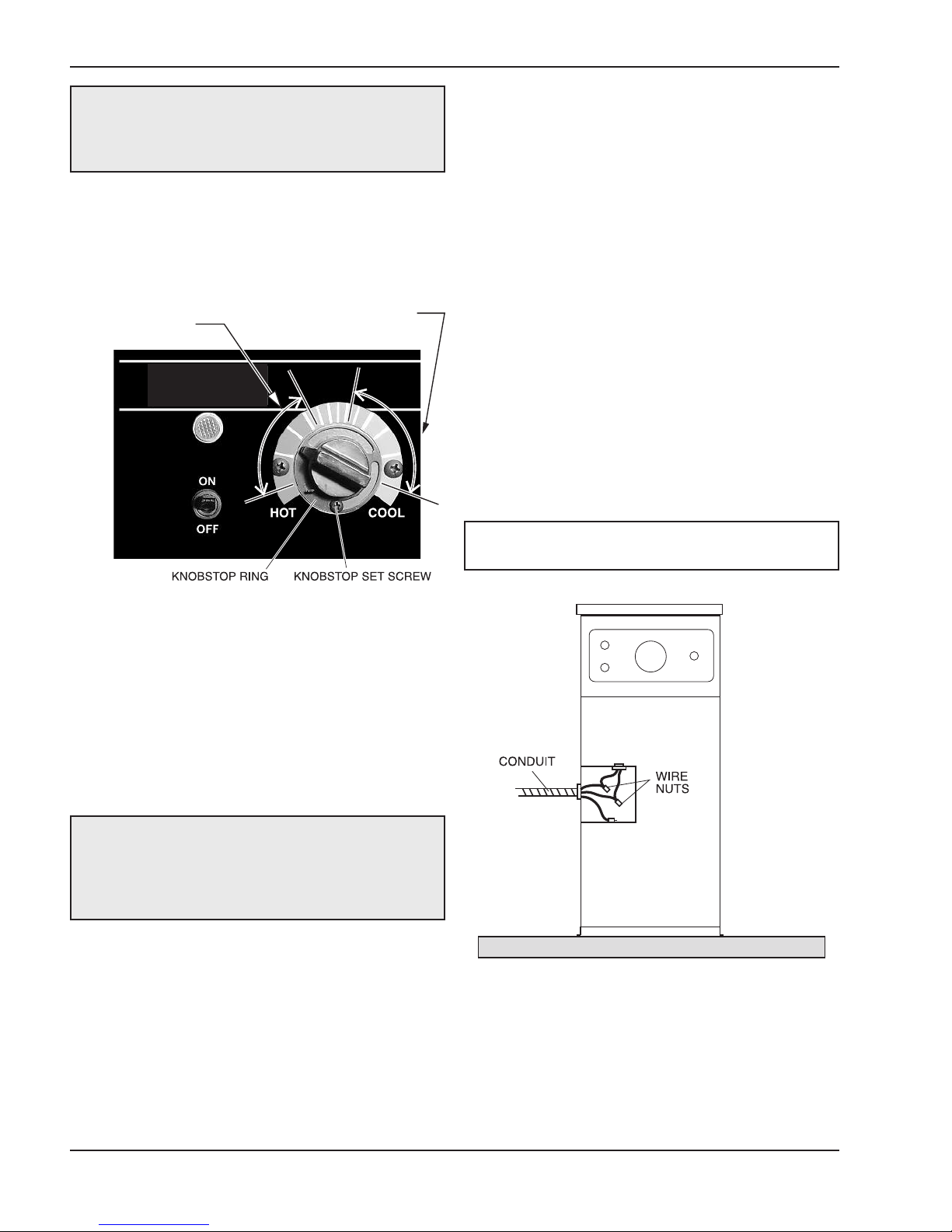

Thermostat

The heater thermostat located on the front of the unit,

may be set for any desired spa temperature.

odes. Keep wire runs as short as possible to mini-

c

mize voltage drop. Bring wires of size indicated from a

used disconnect switch (customer furnished) with an

f

amp rating of at least 125% of the amp rating shown

on the spa heater nameplate. A ground lug is provided

for connection to the supply ground. A wiring diagram

f the heater is shown at right. It is also affixed to the

o

inside front cover of the units.

Field Wiring

Heater requires three-wire service. With 240 VAC

there are two hot wires and a grounding conductor.

Even when metallic conduit is used, the grounding

conductor must be run to the supply ground.

Field wiring connections are made to the electrical

entry at the left side of the unit. A hole in the jacket is

provided for a 1” trade size conduit hub. The location

of the field wiring box is shown below. Wire nuts are

used to connect all leads except the grounding conductor, for which a pressure lug is provided.

NOTE: Heater grounding conductor shall be the

same or larger than the live power supply conductor.

Maximum Temperature Setpoint

(Knobstop Adjustment)

Adjustment to a different maximum setting is a simple

task. Loosen the small set screw on the knobstop and

rotate the knobstop ring until vertical “stop” tab is at the

desired maximum setting. Retighten the set screw.

ELECTRICAL

WARNING: The power supply circuit to this heater

shall be protected by a ground-fault circuit interrupter

(GFCI), in accordance with Art. 680 of the latest edition of the National Electrical Code (NEC). Failure to

do so could result in severe personal injury or death.

The GFCI devices shall be of the self-contained types,

circuit breaker types or the receptacle types. Feeder

ground-fault protection is not required where GFCI is

already provided in the branch circuits or receptacles

supplying power to the heater.

Electrical Disconnect

An electrical disconnect and over-current protection

device must be provided in accordance with local

Recommended Wire Sizes

for Field Connection

Use type THWN copper wire to the unit, with the AWG

wire sizes (Internal wire sizes may differ) listed in Table

A on the following page.

4

Page 5

ire Size

L1 L2

MODEL

ELS 552-2

ONLY

W

Model Amp Draw Conduit Size

(including

round)

g

Disconnect (amps)

ELS 1102-2 46 1” 6 60

ELS 552-2 23 *1/2” 10 30

*Use a reducer bushing.

Table A: Wire Sizes for Field Connection

LADDER DIAGRAM

Size of Fused

SCHEMATIC DIAGRAM

5

Page 6

Controls

IMPORTANT SAFETY

Spa-Pak spa heaters have integral thermostats and

ontactors. They are also equipped with a high tem-

c

perature limit thermostat which will open the circuit

utting off power to the heating element in the event of

c

excessive water temperature. This high limit thermostat is factory set at 140°F. A pressure switch is utilized

to ensure water flow through the heater before the unit

will function.

NOTE: The filter must be kept clean so the flow rate

will be maintained above 15 gpm. Failure to do so

will cause the pressure switch to drop out, and the

heater will become inoperative.

OPERATION

Preliminary

MAKE SURE THAT POWER TO THE UNIT IS OFF.

Remove any tools or other foreign objects from the

inside of the unit. Replace the removable lower panel.

Place temperature control in the off position. Check

tightness of electrical screw terminals.

Filling

INSTRUCTIONS

CAUTION: Elevated water temperature can be

hazardous.

The U.S. Consumer Product Safety Commission recommends the following guidelines. When using this

electrical equipment, basic safety precautions should

always be followed, including the following:

1. READ AND FOLLOW ALL INSTRUCTIONS.

2. To reduce the risk of injury:

a. The water in a pool or tub should never

exceed 104°F (40°C). A water temperature in

excess of 104°F is considered unsafe for all

persons. Lower water temperatures are recommended for extended use (exceeding 10 –

15 minutes) and for young children.

b. Since excessive water temperatures have a

high potential for causing fetal damage during

the early months of pregnancy, pregnant or

possibly pregnant women should limit pool or

tub water temperatures to 100°F (38°C).

Open all valves in the inlet piping and fill the system

with water. Turn on the filter pump and purge all air

from the system. On in-ground spa installations it may

be necessary to prime the pump. Check the unit and

all piping connections for leaks.

Start-up

FILTER PUMP MUST BE ON FOR THE HEATER TO

OPERATE. Turn on the main power to the unit, then

set the temperature control to the desired position and

turn the switch to the “ON” position to place the heater

in operation. Shut pump off and on to be certain that

heater shuts off when pump is off.

A thermal cutout prevents the unit from overheating.

Should overheating occur, the control circuit may be

made operational by depressing the manual reset button through the grommet on the front panel. This will

be possible only after the unit has cooled down for

several minutes.

c. Before entering a pool or tub, the user should

measure the water temperature at several

occupant locations using an accurate thermometer since the tolerance of water

temperature-regulating devices may vary as

much as ±5°F (±3°C).

d. Alcohol, drugs, or medication should not be

used before or during pool or tub use since

their use may lead to unconsciousness with

the possibility of drowning.

e. Persons suffering from obesity or with a med-

ical history of heart disease, low or high blood

pressure, circulatory system problems, or diabetes should consult a physician before using

a pool or tub.

f. Persons using medication should consult a

physician before using a pool or tub since

some medication may induce drowsiness

while other medication may affect heart rate,

blood pressure, and circulation.

6

Page 7

WARNING: The use of alcohol, drugs, or medication can greatly increase the risk of fatal

hyperthermia in pools and tubs.

NOTE: Hyperthermia occurs when the internal temperature of the body reaches a level several degrees

above the normal body temperature of 98.6°F

(37°C). The symptoms of hyperthermia include dizziness, fainting, drowsiness, lethargy, and an increase

in the internal temperature of the body. The effects of

hyperthermia include (1) unawareness of impending

hazard, (2) failure to perceive heat, (3) failure to recognize the need to exit pool or tub, (4) physical

inability to exit pool or tub, (5) fetal damage in pregnant women, and (6) unconsciousness resulting in a

danger of drowning.

3. A green terminal (or wire connector marked "G",

"GR", "GROUND" or "GROUNDING") is provided

within the control box. To reduce the risk of electric

shock, connect this terminal or connector to the

grounding terminal of the electric service or supply

panel with a continuous copper wire in accordance

with the Canadian Electrical Code, Part I.

4. This product shall be protected by a Class A

ground fault circuit interrupter (GFCI).

MAINTENANCE

ARNING: ONLY QUALIFIED PERSONNEL

W

SHOULD ATTEMPT MAINTENANCE ON THIS

QUIPMENT (N.E.C. ARTICLE 100-1971) (MAIN-

E

TENANCE MUST BE DONE WITH MAIN

DISCONNECT OPEN).

Spa Water Chemistry

Chemical imbalance can cause severe damage to

your heater and associated equipment. Maintain your

water chemistry according to the chart on page 8. If

the mineral content and dissolved solids in the water

become too high, scale forms inside the heat exchanger tubes, reducing heater efficiency and also

damaging the heater. If the pH drops below 7.2, the

heater will be severely damaged. This will result in corrosion of the heat exchanger. Heat exchanger

damage resulting from chemical imbalance is not

covered by the warranty.

Element Inspection and

Replacement

The element assembly head is removed as follows:

5. SAVE THESE INSTRUCTIONS.

Pressure Switch Adjustment

Pressure switch is normally factory set for universal

spa applications. Heater must not be installed more

than five feet above water level or five feet below. If the

heater is installed below the spa level or if a two speed

filter pump is used it is necessary to reset the pressure

switch as follows:

1. With pump and heater on, turn adjustment knob

clockwise until a click is heard.

2. Turn adjustment knob counter clockwise 1/4 turn.

3. Turn pump off and on several times. Heater should

shut off immediately. If it does not, repeat steps

above until proper adjustment is made.

Shut Down

Turn off electrical power to heater at main disconnect

when draining spa.

1. Turn off electrical power to heater at the main disconnect and turn off water supply line.

2. Drain the heater.

3. Remove access panel.

4. Disconnect all wires to terminals of elements.

5. Remove four bolts holding element in place.

6. Remove element assembly.

7. Replace element assembly and gasket using

reverse procedure.

Removing the Aquastat

1. Turn off electrical power to heater at main disconnect.

2. Remove screw holding aquastat to mounting

plate.

3. Disconnect wires from aquastat and control knob.

7

Page 8

. Remove retainer clip at bulb and remove capillary

4

bulb.

5. Remove aquastat, using extreme care to see that

he capillary tube is not kinked or broken. (Never

t

use anything but fingers to bend capillary tubing).

Removing the Magnetic

Contactor

1. Turn off electric power to heater at main disconect.

n

Removing the High Limit

1. Turn off electrical power to heater at main disconnect.

2. Disconnect wires from high limit.

3. Remove screws holding high limit to tank.

Removing the Pressure Switch

1. Turn off electrical power to heater at main disconnect.

2. Drain heater.

3. Disconnect pressure switch leads.

4. Unscrew pressure switch.

2. Remove wires from contactor.

3. Remove screw holding contactor to cabinet.

Winterizing

Damage will occur if water is allowed to freeze inside

the heater. Normally the heater will drain when the spa

is drained. If the heater is positioned lower than the

spa a drain valve must be added at the heater inlet.

The water must be drained from the heater and the

main disconnect switch shut off.

Filter

CAUTION: Do not allow filter to become clogged to

the extent that cycling of the pressure switch occurs.

This can result in accelerated wear of the magnetic

contactor. Contactor damage caused by dirty filter is

not covered by warranty.

8

Page 9

TROUBLESHOOTING

Problem Cause Solution

Nothing happens when the thermostat is turned on

It takes a long time to heat the spa Low input voltage…………………..

Low flow..........................................

High limit.........................................

Thermostat not calling for heat.......

Undersized heater……...................

Heat loss from poor weather con-

ditions (cold, high winds)……….....

Defective heating element………...

1. Check filter, skimmer basket,

pump.

2. If a 2-speed pump is used, turn

to high speed. If heater operates, adjust pressure switch for

low speed operation.

Push reset button.

Turn thermostat to higher temperature.

Call electric company.

Calculate temperature in Heat rise

°/hr.= Heater input (kw) x 410 divided by spa gallonage (This does not

take into account heat loss due to

weather).

Use spa cover.

Call electrician. Check resistance/

element bundle:

240V 11 kw = 5.0 to 5.8 OHMS

240V 5.5 kw = 10.0 to 11.6 OHMS

Spa does not reach temperature Mis-adjusted knob-stop……………

Low flow……………………………..

Heating element continuously

burning out

Continuous shutdown of manual

reset high limit

Fuses blow or circuit breaker

opens

Contactor hum Circuit breaker or fuses too small..

Contactor chatter Low flow…………………………….. Check filter skimmer basket and

High input voltage………………….

Poor water chemistry......................

Heating element split open………..

Mis-adjusted or defective pressure

switch…………………….................

Shorted heating elements………....

Undersized wire…………………….

Contactor contacts dirty or worn….

(NOTE: Some hum is normal)

Re-adjust knob-stop.

Check filter, skimmer basket,

pump.

Call electric company.

See Water Chemistry on page 11.

Over-acid condition. Watch pH,

add acid slowly.

Replace pressure switch.

Replace element.

Replace wire.

Replace.

Replace contactor.

pump.

9

Page 10

8

12

9

PART DESCRIPTION ELS 552-2 ELS 1102-2

F208100F108100tnemelE1

2 Element Gasket (Not Shown) 800164 800164

3

Element Tube Assy. 001805F 001808F

F780400F780400lleWrosneS4

5 Well Retaining Clip 300203 300203

6Pressure Switch 062237B 062237B

F118100F118100timiLhgiH7

8Contactor/Wire Kit 001813F 001813F

9Thermostat Control 003346F 003346F

167056167056hctiwSelggoT01

F218100F218100thgiLrotacidnI11

F588600F588600bonK21

F688600F688600potsbonK31

516009516009etalPlaiD41

15 Wire Kit (Complete) N/A N/A

A/NA/NpoTtekcaJ61

A/NA/NlenaPtnorFreppU71

A/NA/NlenaPtnorFrewoL81

10

Page 11

11

Page 12

www.raypak.com

Raypak, Inc., 2151 Eastman Avenue, Oxnard, CA 93030 (805) 278-5300 Fax (805) 278-5468

Litho in U.S.A.

Loading...

Loading...