Raypak P-3001, P-3500, P-1468, P-1631, P-962 Installation & Operating Instructions Manual

...Page 1

INSTALLATION & OPERATING

INSTRUCTIONS

®

Raytherm

Commercial

Swimming

Pool

Heater

Models P-926 to P-1826

& P-2100 to P-4001

WARNING: If these instructions are not followed exactly, a fire or explosion may

result causing property damage, personal injury or death.

FOR YOUR SAFETY: Do not store or use gasoline or other flammable vapors and

liquids or other combustible materials in the vicinity of this or any other appliance.

To do so may result in an explosion or fire.

WHAT TO DO IF YOU SMELL GAS:

• Do not try to light any appliance.

• Do not touch any electrical switch; do not use any phone in your building.

• Immediately call your gas supplier from a neighbor’s phone. Follow the gas

supplier’s instructions.

• If you cannot reach your gas supplier, call the fire department.

Installation and service must be performed by a qualified installer, service agency or

the gas supplier.

This manual should be maintained in legible condition and kept adjacent to the heater or in another safe place for

future reference.

CATALOG NO. 6200.51T Effective: 05-15-18 Replaces: 07-01-16 P/N 240251 Rev. 21

Page 2

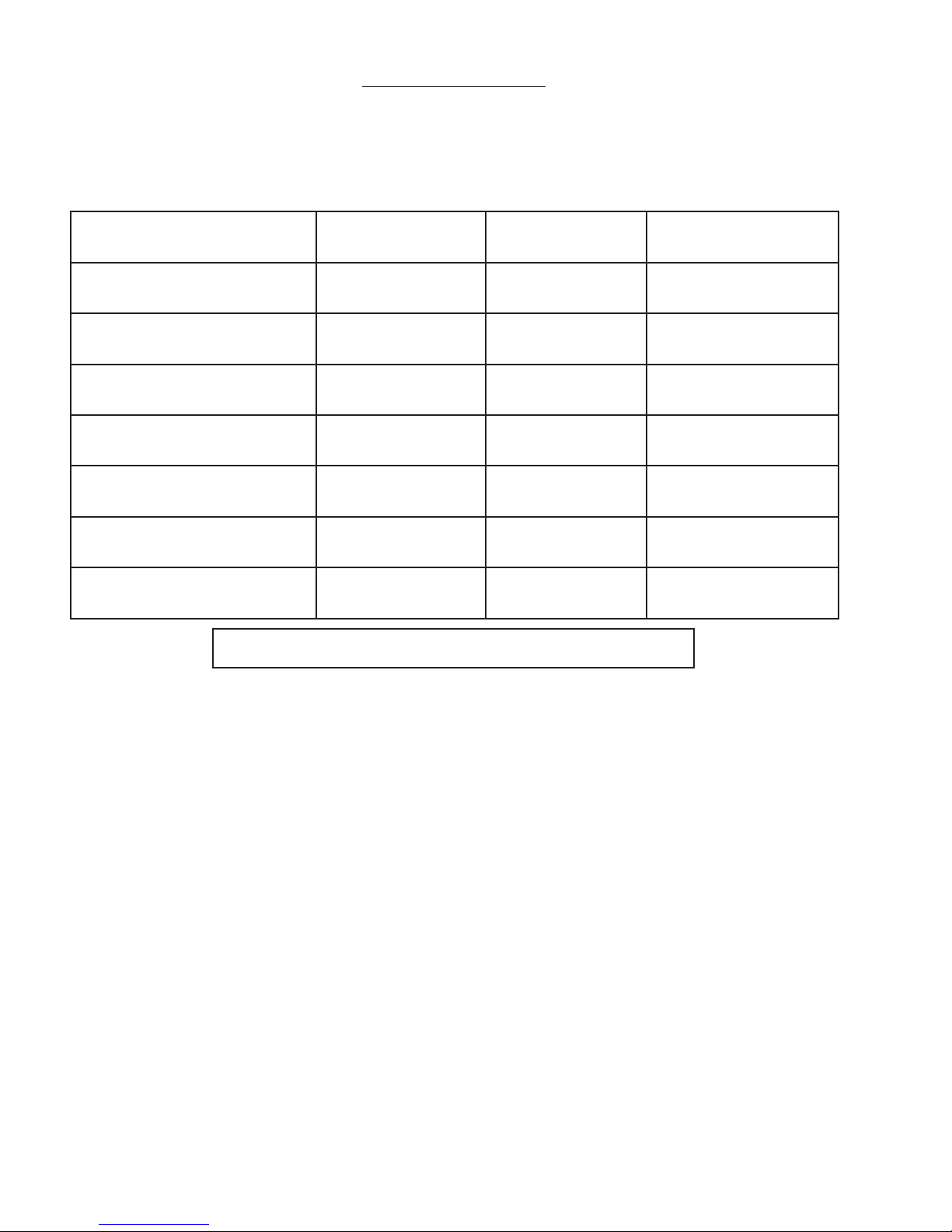

WATER CHEMISTRY

(Corrosive water voids all warranties)

For your health and the protection of your pool equipment, it is essential that your

water be chemically balanced. The following levels must be used as a guide for balanced water.

Recommended Level(s) Fiberglass Pools Fiberglass Spas

Other Pool & Spa

Types

Water Temp. (Deg. F) 68 to 88 89 to 104 68 to 104

pH 7.3 to 7.4 7.3 to 7.4 7.6 to 7.8

Total Alkalinity (PPM) 120 to 150 120 to 150 80 to 120

Calcium Hardness (PPM) 200 to 300 150 to 200 200 to 400

Salt (PPM) 6000 MAXIMUM 6000 MAXIMUM 6000 MAXIMUM

Free Chlorine (PPM)* 2 to 3 2 to 3 2 to 3

Total Dissolved Solids

(PPM)

3000 MAXIMUM 3000 MAXIMUM 3000 MAXIMUM

* Free Chlorine MUST NOT EXCEED 5 PPM!

• Occasional chemical shock dosing of the pool or spa water should not damage the

heater providing the water is balanced.

• Automatic chemical dosing devices and salt chlorinators are usually more efficient

in heated water, unless controlled, they can lead to excessive chlorine level which

can damage your heater, and which is not covered under warranty.

• Further advice should be obtained from your pool or spa builder, accredited pool

shop, or chemical supplier for the correct levels for your water.

Revision 21 reflects the following changes:

Removed California Proposition 65 on page 4.

2

Page 3

CONTENTS

WATER CHEMISTRY 2

WARNINGS 4

Pay Attention to These Terms 4

RECEIVING EQUIPMENT 5

GENERAL

SPECIFICATIONS 5

INSTALLATION 5

Code Requirements 5

Base Installation 5

Clearances 6

Combustion Air (Indoor Units Only) 6

Venting Connections 7

Gas Supply Connections 8

Water Connections 10

CONTROLS 10

Flow Switch 10

Water Pressure Switch 11

Automatic Chlorinators and Chemical

Feeders 11

Unitherm Governor Operation 11

Companion Flange Connections

(Models 926-1223) 11

Mounting the Poolstat Control with FrontMounted Loop Using Mounting Slots 12

Mounting Well into System Return Loop

Pipe - Front-Mounted Loop 14

Piping Configurations for Raytherm

Commercial Pool Heaters (926-1223) 15

Piping Configurations for Raytherm

Commercial Pool Heaters (1287-1826) 16

Piping Configurations for Raytherm

Commercial Pool Heaters (2100-4001) 17

Temperature Controls 18

External Auxiliary Bypass Valve (Where

Required) Models 926-1223 Only 18

Auxiliary Bypass Valve Adjustment 18

Electrical Wiring 19

Wiring Diagram—Models 926–1223

with UG 20

Wiring Diagram—Models 926–1826

with H-Bypass 21

Wiring Diagram—Models 2100–2500 22

Wiring Diagram—Models 3001–4001 23

SERVICING 24

General Location Of Controls 24

Temperature Control 24

Pressure Switch 24

Pressure Switch Adjustment 24

Two-Speed Pumps 25

Pilot Safety 25

START-UP PROCEDURES 25

Before Start-Up 25

Start-Up 25

After Start-Up 26

INSPECTION PROCEDURES 26

Burners 26

CONTROLS 26

SERVICING PROCEDURES 27

Tube Cleaning Procedure (Typical) 27

Heat Exchanger Reassembly 27

Burner Drawer Removal 27

Gas Valve Removal 27

Main Burner and Orifice Removal 28

Pilot Removal and Cleaning 28

Heat Exchanger Removal 28

Combustion Chamber Removal 29

Control Well Replacement 29

Tube Replacement Procedure 29

Procedure For Cleaning Flue Gas

Passageways 29

Unitherm Governor Replacement 30

MAINTENANCE AND CARE 30

Winterizing Your Heater 31

TROUBLESHOOTING 32

3

Page 4

WARNINGS

Pay Attention to These Terms

DANGER:

WARNING:

CAUTION:

NOTE:

DANGER: Make sure the gas on which the heater

will operate is the same type as that specified on the

heater rating plate.

WARNING: Should overheating occur or the gas

supply valve fail to shut, do not turn off or disconnect

the electrical supply to the heater. Instead, shut off

the gas supply at a location external to the heater.

WARNING: To minimize the possibility of improper

operation, serious personal injury, fire, or damage to

the heater:

• Always keep the area around the heater free of

combustible materials, gasoline, and other flammable liquids and vapors.

Indicates the presence of immediate hazards which will cause severe personal injury, death or substantial property damage if ignored.

Indicates the presence of hazards or unsafe practices which could cause

severe personal injury, death or substantial property damage if ignored.

Indicates the presence of hazards or unsafe practices which could cause

minor personal injury or product or property damage if ignored.

Indicates special instructions on installation, operation, or maintenance which

are important but not related to personal injury hazards.

CAUTION: Operation of this heater in lowtemperature systems requires special piping.

Harmful internal condensation will occur if the inlet

water temperature does not exceed 105°F. Warranty

claims will be denied when condensation occurs.

CAUTION: If this heater is to be installed above

radiation level, it must be provided with a low water

cut-off device at the time of heater installation.

CAUTION: If this heater is to be installed in a

negative or positive pressure equipment room, there

are special installation requirements. Consult factory

for details.

• Heater should never be covered or have any

blockage to the flow of fresh air to the heater.

WARNING: Do not use this heater if any part

has been under water. Immediately call a qualified

service technician to inspect the heater and to

replace any part of the control system and any gas

control which has been under water.

WARNING: Risk of electrical shock. More than one

disconnect switch may be required to deenergize the

equipment before servicing.

4

Page 5

RECEIVING EQUIPMENT

INSTALLATION

On receipt of the equipment, visually check for external damage to the carton or the shipping crate. If the

carton or shipping crate is damaged, make a note on

the Bill of Lading and report the damage to the Carrier

immediately. Remove the heater from the carton or

shipping crate. Do NOT use the shipping base crate

as an installation base.

On occasion, we ship some items loose. Be sure that

you receive the number of packages indicated on the

Bill of Lading. When ordering parts, you must specify

Model and Serial Number of heater. When ordering

under warranty conditions, you must also specify date

of installation.

Raypak recommends that this manual be reviewed

thoroughly before installing your Raypak Pool Heater.

If there are any questions which this manual does not

answer, please contact the factory or your local

Raypak representative.

Claims for shortages and damages must be filed with

carrier by consignee. Permission to return goods must

be factory authorized and are subject to a stocking

charge.

These instructions are intended for the use of qualified

personnel only, specifically trained and experienced in

the installation of this type of heating equipment and

related system components. Installation and service

personnel may be required by some states to be

licensed. If your state is such, be sure your contractor

bears the appropriate license. Persons not qualified

shall not attempt to fix this equipment nor attempt

repairs according to these instructions.

WARNING: Improper installation, adjustment,

alteration, service or maintenance may damage the

equipment, create a hazard resulting in asphyxiation,

explosion or fire, and will void the warranty.

Code Requirements

The heater should not be located in an area where

possible water leakage will result in damage to the

area adjacent to the appliance or to the structure.

When such locations cannot be avoided, it is recommended that a suitable drain pan, adequately drained,

be installed under the appliance. The pan must not

restrict combustion air flow.

Purchased parts are subject to replacement only

under the manufacturer’s warranty. Debits for defective replacement parts will not be accepted and will be

replaced in kind only per our standard warranties.

GENERAL

SPECIFICATIONS

Models 962, 1125, 1223, 1336, 1468, 1631, 1826 &

2100 through 4001 are specifically designed for indoor

installation ONLY. Models 926, 1083, 1178, 1287,

1414, 1571 & 1758 are specifically designed for outdoor installation ONLY. All heaters are standard with

electronic ignition for both natural and propane applications. Heaters require 120V power supply. Control

circuits operate at 24V, supplied by an internal 120V

to 24V transformer.

These heaters are design certified and tested under

the requirements of ANSI Z21.56 / CSA 4.7 American

National Standard for Gas-Fired Pool Heaters. Rated

inputs are suitable for up to 2000 feet elevation. For

elevations above 2000 feet, reduce input 4% for each

1000 feet above sea level, as high elevation reduces

combustion performance.

Installation must be in accordance with local codes, or,

in the absence of local codes, with the latest editions

of the National Fuel Gas Code (NFGC), ANSI Z223.1/

NFPA 54, and National Electrical Code (NEC), ANSI/

NFPA 70.

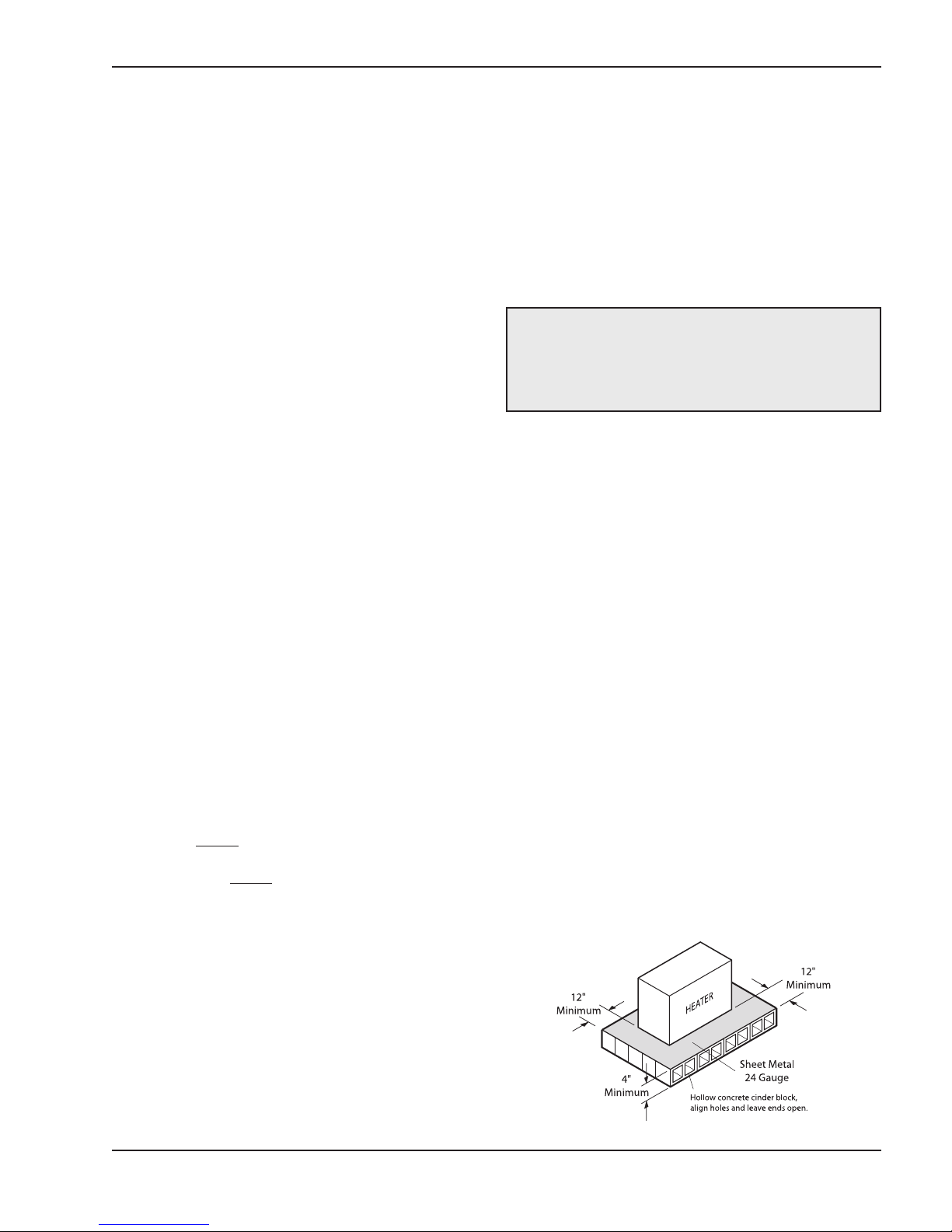

Base Installation

Do NOT use the shipping base crate as an installation

base. Heater must be mounted on a level base, such

as cement slab, cement blocks or other non-combustible surface. An optional non-combustible base

is available for Indoor Models 962 through 1826. An

alternative method for providing a base for combustible floors as illustrated below. Heaters may not be

installed on carpeting.

5

Fig. 1: Alternate Mounting Base

Page 6

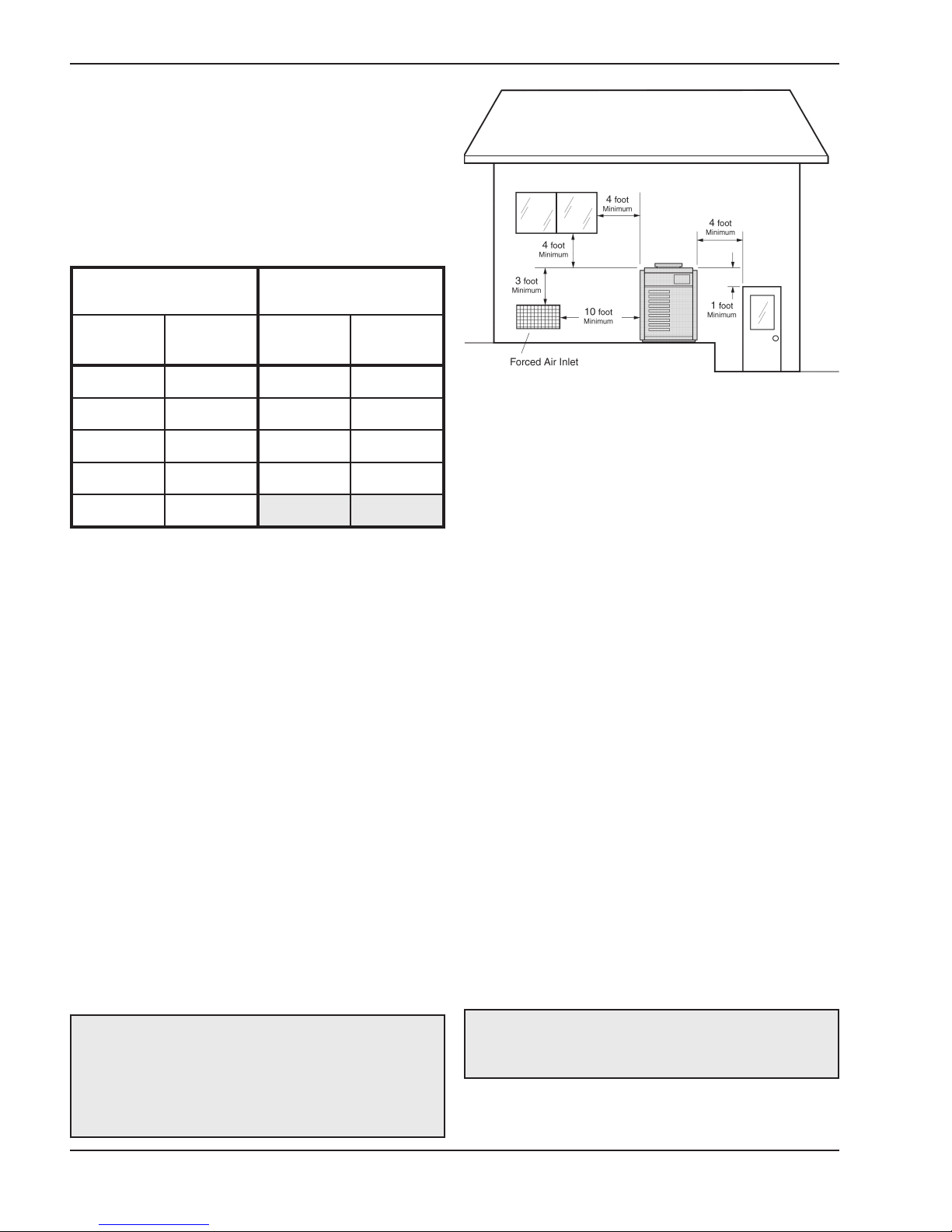

Clearances

All Heaters

For clearances from combustible surfaces, see

Table A below. A minimal vertical clearance of three

feet between the upper surface of the flue outlet to a

noncombustible material is required.

Indoor Heaters

Heater

Side

Top 24 Top 24

Back 24 Back 24

Right Side 24 Right Side 24

Left Side 24 Left Side 24

Vent* 6

*Vent includes factory supplied drafthood and does not include field

supplied vent systems above the drafthood. On Models 2100-4001

drafthood is built into heater.

For servicing provide a front clearance as shown below:

Model 926/962-758/1826 - 24”

Model 2100-4001 - 48”

Table A: Minimum Clearances from Combustible

For servicing, provide at least 24” in front of the heater

on Models 926-1826 & 48” in front of the heater on

Models 2100-4001 for burner tray removal, and at

least 18” on the right side of the heater to inspect and

delime the heat exchanger.

Clearance

(Inches)

Construction

Outdoor Heaters (926–

1758)

Heater

Side

Clearance

(Inches)

Outdoor Heaters (Models 926-1758)

Fig. 2: Minimum Distance from Openings

The point from where the flue products exit the heater

must be a minimum of four (4) feet below, four (4) feet

horizontally from or one (1) foot above any door, window or gravity inlet to a building. The top surface of

the heater shall be at least three (3) feet above any

forced air inlet, or intake ducts located within ten (10 )

feet horizontally.

High Wind Conditions

(Outdoor Units Only)

In areas where high winds are frequent, it may be necessary to locate the heater a minimum of 3’ from high

vertical walls, or install a wind break so the heater is

not in direct wind current.

Indoor Heaters

The design is certified for indoor installation when

equipped with approved drafthood. Locate the heater

as close as practical to a chimney or gas vent.

These heaters are design-certified for outdoor installation, when equipped with the approved top designated

for outdoor use. Heaters must not be installed under

an overhang of less than three (3) feet from the top of

the heater. Three (3) sides must be open in the area

under the overhang. Roof water drainage must be

diverted away from heaters installed under overhangs

with the use of gutters.

WARNING: The heater shall not be located in an

area where water sprinklers, or other devices, may

cause water to spray through the cabinet louvers

and into the heater. This could cause heavy internal

rusting or damage some electrical components, and

this would void the warranty.

Combustion Air

(Indoor Units Only)

The heater must have both combustion and ventilation air. Openings must not be obstructed. Minimum

requirements are from the National Fuel Gas Code

CAUTION: Combustion air must not be

contaminated by corrosive chemical fumes which

can cause unwarrantable damage to the heater.

6

Page 7

(ANSI Z223.1/NFPA 54).

The “two-opening” method requires:

1. Free combustion air 1 sq. in. per 1000 BTU input

within 12” of the floor.

2. Free ventilation air 1 sq. in. per 1000 BTU input

within 12” of the ceiling level.

NOTE: If the room the heater is installed in is

located against an outside wall and air openings

communicate directly with the outdoors, the openings

may be 1/4 the size specified above (ANSI Z223.1/

NFPA 54, latest edition)

Venting Connections

Drafthood (Indoor) Models 962-1826

Locate and assemble as shown in Fig. 3. Secure with

screws supplied in envelope in carton. Do not modify

the drafthood. The height of the relief openings above

pipe must have a minimum of 1/4 inch per foot rise

and should be supported at not more than five foot

intervals. Plumber’s tape, criss-crossed, will serve to

space both horizontal and vertical piping.

Gas vents supported only by the flashing and extending above the roof more than five feet should be

securely guyed or braced to withstand snow and wind

loads. We recommend use of insulated vent pipe

spacer through the roofs and walls.

For protection against rain or blockage by snow, the

vent pipe must terminate with a vent cap which complies with the local codes or, in the absence of such

codes, to the latest edition of the National Fuel Gas

Code, ANSI Z223.1/NFPA 54.

The discharge opening must be a minimum of two feet

vertically from the roof surface and at least two feet

higher than any part of the building within ten feet.

Vent stack shall be at least five feet in vertical height

above the drafthood outlet. The vent cap location shall

have a minimum clearance of 4 feet horizontally from,

and in no case above or below, unless a 4-foot horizontal distance is maintained, from electric meters,

gas meters regulators and relief equipment.

Fig. 3: Indoor Drafthood

the cabinet is critical to proper operation.

Models 2100-4001 have built-in drafthoods that must

be properly vented to the outside.

WARNING: An indoor heater requires a drafthood

that must be connected to a vent pipe and properly

vented to the outside. Failure to follow this procedure

can cause fire or fatal carbon monoxide poisoning.

Vent Piping

Vent piping the same size or larger than the drafthood

outlet is recommended, however, when the total vent

height is at least ten (10) feet (drafthood relief opening

to vent terminal), the vent pipe size may be reduced

as specified in the National Fuel Gas Code, ANSI

Z223.1/NFPA 54 - latest edition. Avoid long horizontal

runs of vent pipe and too many elbows. If installation requires horizontal or non-vertical runs, the vent

The weight of the vent stack or chimney must not rest

on heater drafthood. Support must be provided in

compliance with applicable codes. The heater top

and drafthood must be readily removable for maintenance and inspection. Vent pipe should be adequately

supported to maintain proper clearances from combustible construction.

Type “B” double-wall or equivalent vent pipe, certified

for Category I conditions, is recommended. However,

single-wall metal vent pipe may be used as specified

in the latest edition of the National Fuel Gas Code

ANSI Z223.1/NFPA 54.

10' OR LESS

2' MIN

VENT PIPE

DRAFT HOOD

HEATER

Fig. 4: Venting Clearances

VENT CAP

2' MIN

5' MIN

7

Page 8

At the time of removal of an existing heater, the fol-

TRAP

lowing steps shall be followed with each appliance

remaining connected to the common venting system

placed in operation, while the other appliances remaining connected to the common venting system are not

in operation.

(a) Seal any unused openings in the common venting

system.

(b) Visually inspect the venting system for proper

size and horizontal pitch and determine there is

no blockage or restriction, leakage, corrosion and

other deficiencies which could cause an unsafe

condition.

(c) Insofar as is practical, close all building doors and

windows and all doors between the space in which

the appliances remaining connected to the common venting system are located and other spaces

of the building. Turn on clothes dryers and any

appliance not connected to the common venting

system. Turn on any exhaust fans, such as range

hoods and bathroom exhausts, so they will operate at maximum speed. Do not operate a summer

exhaust fan. Close fireplace dampers.

(d) Place in operation the appliance being inspected.

Follow the lighting instructions. Adjust thermostat

so appliance will operate continuously.

(e) Test for spillage at the drafthood relief opening

after 5 minutes of main burner operation. Use the

flame of a match or candle, or smoke from a cigarette, cigar or pipe.

(f) After it has been determined that each appliance

remaining connected to the common venting system properly vents when tested as outlined above,

return doors, windows, exhaust fans, fireplace

dampers and any other gas burning appliance to

their previous conditions of use.

(g) Any improper operation of the common venting

system should be corrected so the installation

conforms with the latest edition of the National

Fuel Gas Code, ANSI Z223.1/NFPA 54. When

re-sizing any portion of the common venting

system, the common venting system should be

re-sized to approach the minimum size as determined using the appropriate tables in the National

Fuel Gas Code, ANSI Z223.1/NFPA 54.

For special venting applications that require reduced

vent sizes or through-the-wall venting, the optional D

Series Power Vent can be used. Consult the factory or

your local Raypak representative.

8

Gas Supply Connections

Per NFGC requirements, gas piping must have a

sediment trap ahead of the heater gas controls, and a

manual shut-off valve located outside the heater jacket. All gas piping should be tested after installation in

accordance with local codes.

MANUAL

SHUT-OFF

VALV E

SEDIMENT

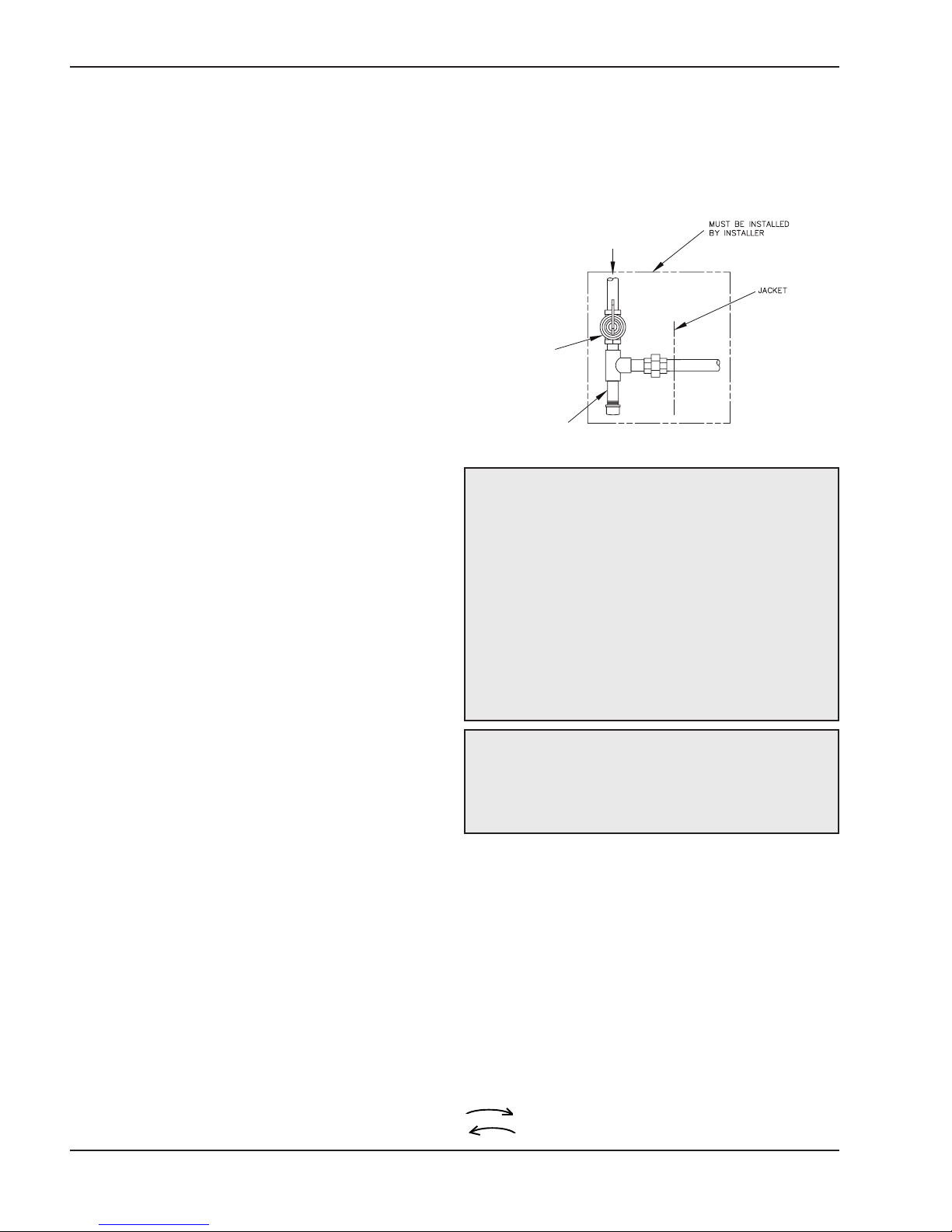

Fig. 5: Gas Piping

CAUTION: The heater and its manual shut-off

valve must be disconnected from the gas supply

during any pressure testing of that system at

test pressures in excess of 1/2 psig (3.45 KPA).

Dissipate test pressure in the gas supply line before

reconnecting the heater and its manual shut-off

valve to gas supply line. FAILURE TO FOLLOW

THIS PROCEDURE MAY DAMAGE THE GAS

VALVE. OVER PRESSURIZED GAS VALVES ARE

NOT COVERED BY WARRANTY. The heater and

its gas connections shall be leak tested before

placing the appliance in operation. Use soapy water

for leak test. DO NOT use open flame.

CAUTION: Do not use Teflon tape on gas line

pipe thread. A pipe compound rated for use with

natural and propane gases is recommended. Apply

sparingly only on male pipe ends, leaving the two

end threads bare.

A minimum of 7 in. WC and a maximum of 10.5 in. WC

upstream pressure under load, and no load conditions

must be provided for natural gas or a minimum of 11

in. WC and a maximum of 13 in. WC for propane gas.

Gas Pressure Regulator

The gas pressure regulator is preset and sealed at 4

in. WC for natural gas, and 11 in. WC for propane gas.

Between the gas valve and the burners is a 1/8” pipe

plug. The pressure at this point, taken with a manometer, should be about 3.7 in. WC natural gas and 10.5 in.

WC propane gas. If an adjustment is needed, remove

seal and turn adjustment screw clockwise

, to increase pressure or counter-clockwise

, to decrease pressure.

Page 9

AT HEATER

MANUAL

SHUTOFF

VALV E

GAS PRESSURE

TEST UPSTREAM

GAS PRESSURE

TEST AT GAS

VALV E

GAS PRESSURE TEST

MANOMETER

Fig. 6: Gas Pressure Test Points

Venting of Diaphragm Gas

Components

Code. Under NO circumstances shall bleed lines terminate in the gas utilization equipment flue or exhaust

system.

Heaters with gastrain components that have diaphragms in their construction are supplied with a bleed

line connection that must be connected to the outside

atmosphere as required by the National Fuel Gas

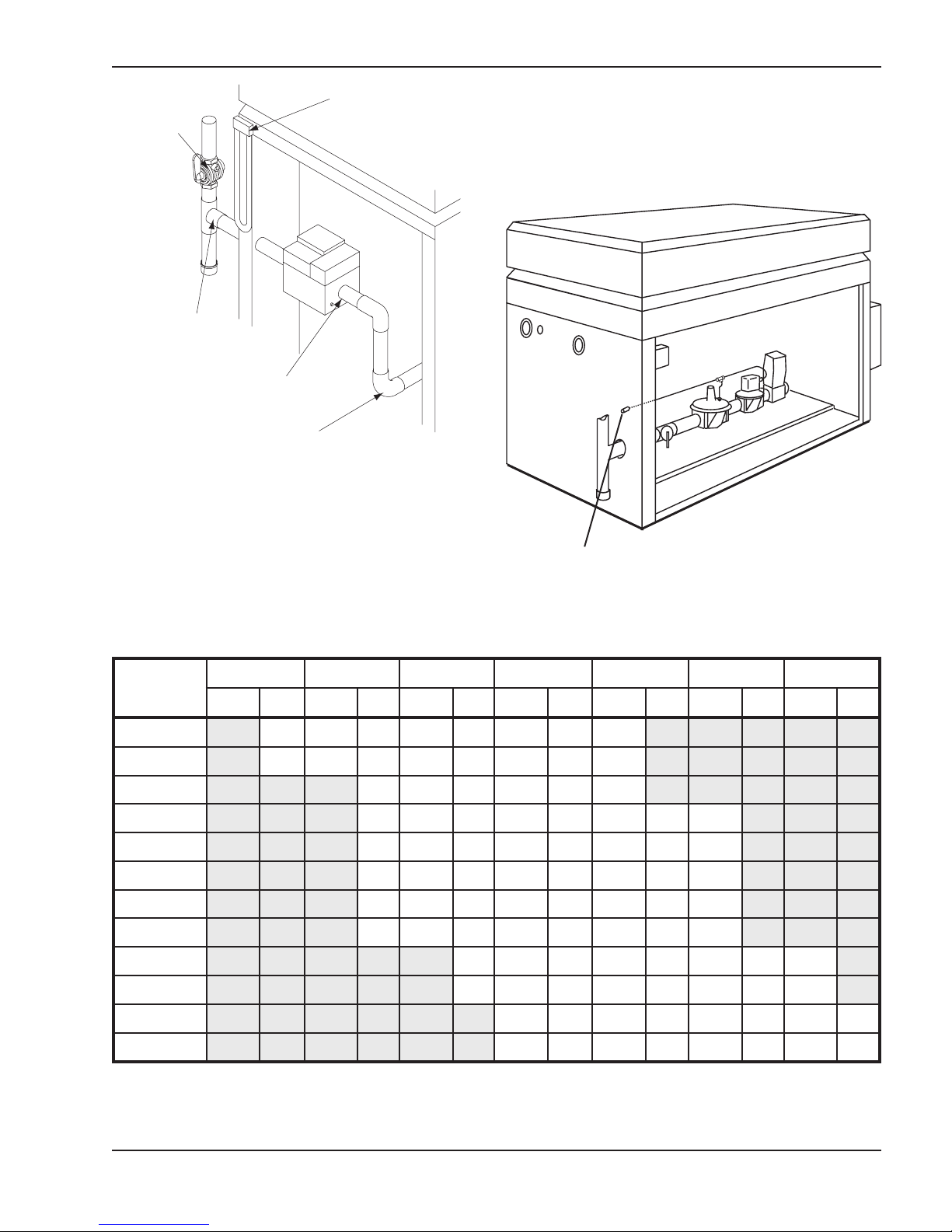

Model

No.

1” 1-1/4” 1-1/2” 2” 2-1/2” 3” 4”

N P N P N P N P N P N P N P

Bleed Line

Connection

Fig. 7: Bleed Line Connection

926/962 15 20 45 45 110 150 360 400

1083/1125 10 15 35 35 80 120 300 300

1178/1223 25 25 60 85 220 200

1287/1336 25 20 55 75 180 170 325 560

1414/1468 20 15 45 65 150 165 300 500

1571/1631 15 15 35 50 20 125 250 400

1758/1826 15 10 30 40 100 100 225 340

2100 10 10 25 30 80 75 175 260

2500 15 20 55 55 135 160 400 600

3001 10 15 35 40 85 120 250 500

3500 10 30 30 45 80 200 400 600

4001 5 20 25 35 65 160 300 400

Natural Gas, 1000 BTU/FT3 .60 Specific Gravity @ 0.5 in. WC Pressure Drop

Propane Gas, 2500 BTU/FT3 1.53 Specific Gravity @ 0.6 in. WC Pressure Drop

Table B: Maximum Equivalent Pipe Length

9

Page 10

Water Connections

Location

Models 926-1223 With UG

The heater requires water flow and positive pressure

to fire and operate properly. It must therefore be

installed downstream of the discharge side of the filter

pump. A typical installation is plumbed as follows:

1. The inlet side of the filter is plumbed directly to the

discharge side of the filter pump;

2. The outlet side of the filter is then plumbed to the

inlet of the heater; and

3. The outlet of the heater is plumbed to the return

line to the pool or spa. The pump, filter and heater

are thus plumbed in series.

the low temperature piping. A fireman switch included

in the time clock may be used for this purpose with

instructions not to override this sequence manually.

See wiring diagram section for electrical hookup location of the fireman switch in the electrical circuit.

NOTE: If piping is used into the heater, this piping

(copper) must be anchored or screwed into the

flange (metal) if operating pressures above 30 PSI

are encountered.

All Models With H-Bypass or CWR

These heaters must be installed using primary/secondary piping. For multiple-heater installations, use

reverse-return logic to ensure equal duty cycles. Flow

in the main line must be at least 120% of the heater

flow. See pages 16-17.

CONTROLS

Heater must be located so that any water leaks will not

damage the structure of adjacent area. Hightemperature plastic pipe (CPVC) may be connected

directly into the heater, if local codes permit and if

controls operate the pump for at least fifteen minutes

after the heater is turned off.

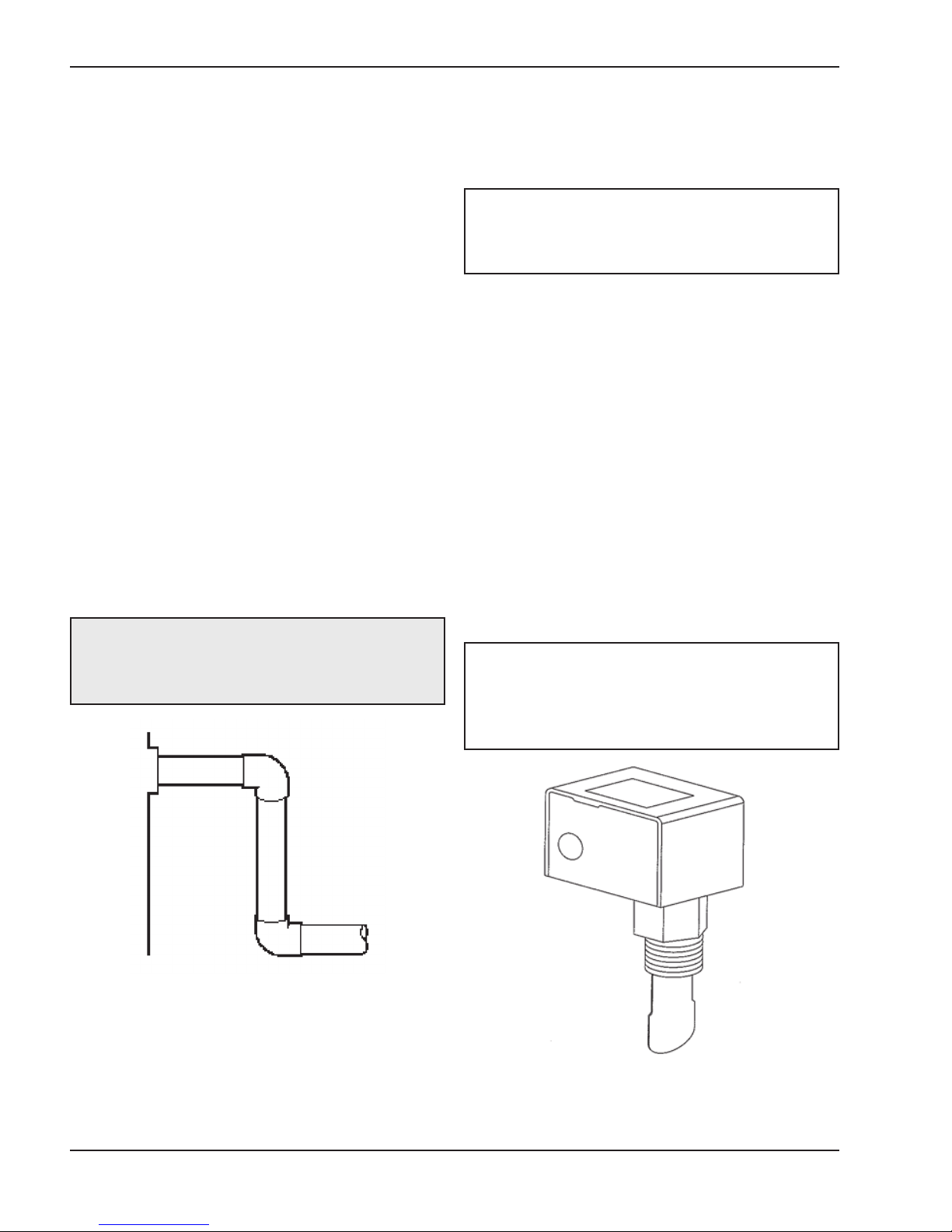

CAUTION: NEVER install PVC directly into heater.

Four feet of copper or high temperature pipe and

two elbows are required between the heater and the

PVC connections. See Fig. 8 below.

Flow Switch

This dual purpose control shuts off the boiler in the

case of a pump failure or low water condition. It is

mounted and wired in series to the main gas valve.

Standard on all units except on UG models.

NOTE: Flow switch will not operate if flow is less

than:

Models 926-1223 60 gpm

Models 1287-1826 85 gpm

Models 2100-4001 180 gpm

Fig. 8: Plumbing

When local codes permit the use of less than four feet

of high-temperature piping or two elbows, provisions

should be made to always shut the heater off a minimum of 15 minutes prior to pump shutdown in order

to carry away residual heat and prevent damage to

Fig. 9: Flow Switch

10

Page 11

Water Pressure Switch

Unitherm Governor Operation

On Models 926-1223 built with a Unitherm Governor

(UG), a water pressure switch is provided in the heater

instead of a flow switch, to shut down the gas valves in

the event the water supply to the heater is interrupted.

It is very important to verify that the switch electrically

opens and shuts off the gas valve when water flow to

the heater is interrupted.

Otherwise, rapid and severe damage to the heater

will likely occur. (The water pressure switch should

be checked and adjusted for proper operation by a

qualified service person at the time of installation and

periodically checked thereafter. Refer to pressure

switch servicing instructions on page 24).

WARNING: Operation of the heater without water

circulation will cause rapid and severe damage to

the heater.

Automatic Chlorinators and

Chemical Feeders

All chemicals must be introduced and completely diluted into the pool or spa water before being circulated

through the heater. Do not place chlorine tablets or

bromine sticks in the skimmer. High chemical concentrations will result when the pump is not running (eg,

overnight).

Chlorinators must feed downstream of the heater and

have an anti-siphoning device to prevent chemical

backup into the heater when the pump is shut off.

NOTE: High chemical concentrates from feeders

and chlorinators that are out of adjustment will

cause very rapid corrosion to the heat exchanger in

the heater. Such damage is not covered under the

warranty.

The patented Unitherm Governor (UG) is a thermostatic mixing valve specifically designed to maintain

constant heater internal temperature between 105°

and 115°F despite continually changing flow rates from

the filter and changing pool temperatures. This narrow

range is needed to prevent damaging condensation on

the burners which will occur if the heater runs for any

length of time with an inlet temperature below 105°F.

It is also needed to inhibit scale formation in the tubes

by maintaining temperatures well below accelerated

scaling temperatures.

The Unitherm Governor is the default configuration on

models 926 through 1223. Where installed, it is built

into the inlet/outlet header. The larger sizes, models

1287 through 4001, do not have a UG option. Instead,

they have an externally-mounted bypass pump that is

designed to maintain the water entering the heater at

the proper temperature to prevent condensation and

scale. Thermometers are provided on the inlet and

outlet to the heater.

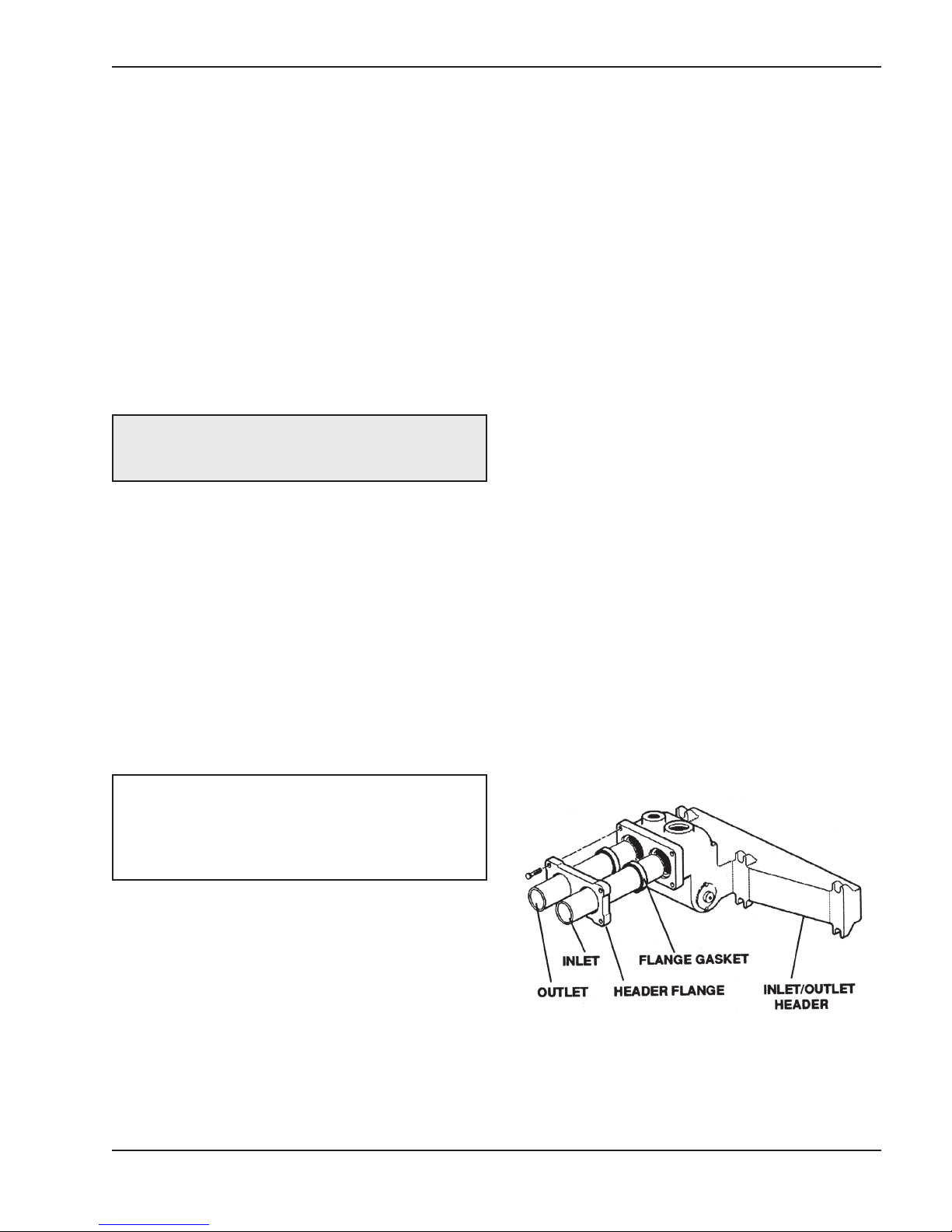

Companion Flange

Connections

(Models 926-1223 with UG)

DO NOT use petroleum base assembly fluids (such as

Petroleum Jelly or Lubricating Oil). If assembly lube is

required use a silicone base such as Armoral etc.

The inlet/outlet header flange accepts a 2” copper

tube as a slip connection directly into the header.

The flange is also threaded for a 2 NPT copper male

adapter.

Fig. 10: Companion Flange Connections

(Models 926–1223 with UG)

11

Page 12

Fig. 11: Companion Flange Connections

2"

Ball

Pump

(Models 926/962–1287/1336 with H-Bypass)

3"

3"

Outlet

Inlet

Raypak recommends the installation of an air bleed

vent at a suitable location (usually the highest point in

the plumbing) to remove air from the piping system.

These units should be available at your local wholesale supplier. Raypak does not provide this item.

CAUTION: Power to the heater should be

interlocked with the main system pump to make

sure the heater does not fire without the main

system pump in operation. Improper flow control can

damage the heater. Uncontrolled flow (too high) or

restricted flow (too low) can seriously affect heater

operation. Follow these instructions to make sure

your heater is properly installed.

Slip

Valve

Inlet/Outlet

Header

Fig. 12: Companion Flange Connections

(Models 2100–4001)

Model No.

926–1223

with UG

Connection

Size

2” FPT 60 100

Minimum

gpm

Maximum

1287–1826 2-1/2” FPT

Refer to Table D

2100–4001 3” FPT

Table C: Water Connections

Model No.

Loop* Flow Rates

(gpm)

Heater Flow

Rates (gpm)

1287/1336 30–50 85

1414/1468 35–55 85

1571/1631 40–65 85

1758/1826 45–70 85

2100 50–80 180

2500 60–95 180

2 H.P.

gpm

Models with H-bypass are equipped with an external

pump and bypass arrangement that blends outlet

water with the inlet to increase the inlet water temperature, thereby reducing the likelihood of condensation

forming on the heat exchanger. The pump also serves

to circulate water through the heater from the main

system piping. Adjust the bypass to maintain 105ºF

inlet.

To complete the installation of the pool heater, the

poolstat needs to be installed in the main return water

line. This will ensure that the heater will be energized

at the right time. If the main water line is too far away

from the heater and the capillary bulb will not reach it,

locate the poolstat adjacent to the main line and run

wires back to the heater. Follow the instructions listed

below to install the poolstat.

Mounting the Poolstat Control

with Front-Mounted Loop

Using Mounting Slots

For heater models:

1287, 1336, 1414, 1468, 1571, 1631, 1758, 1826,

2100, 2500, 3001, 3500, 4001.

NOTE: For more detail on piping, refer to the

diagrams on pages 15, 16 & 17.

1. Remove the poolstat control cover by removing

the two cover screws at the top. See Fig. 13 & 14.

3001 75–115 180

3500 90–135 180

4001 100–150 180

*Loop is secondary piping to heater from main system.

Table D: Flow Rates

12

Page 13

Fig. 13: Poolstat Control

Fig. 14: Control Cover

3. Remove either the left or right “knock-out” for wiring on the poolstat control as shown in Fig. 17.

Fig. 17: Remove Knockout

4. Attach appropriate conduit and connectors to the

poolstat control.

5. Attach wires to the poolstat wire terminals. See

2. Lace metal strapping or clamps, (NOT PROVIDED)

through the ¾” slots on the cover and fasten

securely to pipe as shown in Fig. 15 & 16. Do not

over-tighten clamps.

Fig. 15: Hose Clamp Slots

Fig. 18: Attach Wires

Fig. 18.

6. Install poolstat control to the cover and fasten

cover screws.

7. Poolstat should be mounted level as shown in Fig.

Fig. 16: Insert Clamps

Fig. 19: Mount Level

19.

13

Page 14

Mounting Well into System

Return Loop Pipe - FrontMounted Loop

1. Locate and mark an area on the main system

NOTE: For more detail on piping configurations for

large systems, refer to the diagrams on pages 15,

16 & 17.

return loop pipe where the well is always exposed

to the water circulating back from the pool. See

Fig. 20.

2. Shut off water and drain any water from the pipe

HEATER

Fig. 22: Installation with Weld O Lets

NOTE: The drawings and instructions above show

only one of several acceptable ways of installing

the dry well into main system loop. The use of

saddle clamps and “Weld O Lets” (shown in Fig.

22) are acceptable. Follow clamp manufacturer’s

instructions.

To adjust the temperature:

1. Both isolation valves must be fully open.

Fig. 20: Installation Location

as necessary.

3. Drill a 23/32” diameter hole (½” NPT) into the pipe

as shown in Fig. 21.

Fig. 21: Drill Hole in Pipe for Dry Well

4. Using a ½” NPT tap and appropriate handle,

thread the tap into the pipe.

5. Apply pipe dope as necessary to male threads

of well and insert into threaded hole. Do not

over-tighten well.

2. Adjust Bypass Valve “A” 1/2 open and Balancing

Valve “B” fully open. (See piping configuration

page 15, 16 & 17)

3. Fire your Raypak pool heater and adjust Bypass

Valve “A” to obtain a heater inlet temperature

approximately 105°F. Turning Valve A in the open

direction will raise the heater inlet temperature

and closing Valve “A” will lower the heater inlet

temperature.

CAUTION: The inlet water temperature must

be kept above 105°F. Changes in system flow or

valve position may require re-adjustment of the flow

settings. Check the heater bypass settings after

making adjustments. Failure to maintain an inlet

temperature above 105°F may result in damage to

the heater. Failure to comply with this instruction

voids the warranty.

4. If the heater inlet temperature remains less than

100°F and Valve “A” is fully open, leave Valve “A”

fully open and throttle Valve “B” until the heater

inlet temperature rises above 105°F.

5. The resultant heater outlet temperature should be

in the range of 120-130°F.

14

Page 15

6. As the pool temperature rises to the desired tem-

Models 0926 thru 1223 with UG

perature as controlled by the Pool aquastat, small

adjustments to valves “A” and “B” will be required

for optimum performance. Heater temperatures

should be checked regularly to prevent heater

condensation. The heater inlet temperature can

be higher than 105°F without heater damage but

operating at less than 105°F inlet can cause damage from condensation.

NOTE: Consult factory if target temperatures cannot

be achieved.

Piping Configurations for Raytherm Commercial Pool Heaters

INTERNAL DIVERTING

BYPASS SYSTEM (UG)

4 PIPE

DIAMETERS

MAX.

15

Page 16

Models 926-1826 with H-Bypass

ISOLATION VALVES FOR SERVICE

Piping Configurations for Raytherm Commercial Pool Heaters

4 PIPE

DIAMETERS

MAX.

4 PIPE

DIAMETERS

MAX.

TI

To

4 PIPE

DIAMETERS

MAX.

BLENDED WATER TEMPERATURE

(THERMOMETER AT HEATER INLET)

HEATER OUTLET TEMPERATURE

THERMOMETER

Tc

HEATER THERMOSTAT

RECOMMENDED FIELD INSTALLED

16

Page 17

ISOLATION VALVES FOR SERVICE

Models 2100 thru 4001 with H-Bypass

Piping Configurations for Raytherm Commercial Pool Heaters

4 PIPE

DIAMETERS

MAX.

4 PIPE

DIAMETERS

MAX.

TI

To

4 PIPE

DIAMETERS

MAX.

BLENDED WATER TEMPERATURE

(THERMOMETER AT HEATER INLET)

HEATER OUTLET TEMPERATURE

THERMOMETER

Tc

HEATER THERMOSTAT

RECOMMENDED FIELD INSTALLED

17

Page 18

External Auxiliary Bypass

Valve (Where Required)

926-1223 Models Only

An auxiliary bypass valve should be used when flow

rates exceed 100 gpm (usually a high performance

pump size larger than two HP will exceed this flow

rate). This valve is required to complement the function of the automatic bypass valve, particularly when

starting the heater in winter or early spring when the

spa or pool temperature is below 55°F. It also serves

to eliminate needless pressure drop through the heater and accompanying reduction in the flow rate to the

spa jets, etc.

Bypass Valve

Open Position

Fig. 24: Manual Bypass Valve on UG models

Closed Position

Fig. 23: Auxiliary Bypass Valve

Auxiliary Bypass Valve

Adjustment

To set bypass: With clean filter, adjustment is made by

feeling the inlet and outlet pipes at the heater. Outlet

pipes should be slightly warmer than inlet and comfortable to the touch. If pipe is hot, close bypass; if cold,

open bypass.

NOTE: Do not use a gate valve as an auxiliary

bypass valve on any heaters.

Models 926-1223 with UG

The heater is also equipped with a manual bypass

built into the header. This is in addition to the automatic bypass valve. This may be used with flow rates up

to 100 gpm and adjusted as below.

NOTE: Sooting or liming caused by improper

bypass adjustment voids the warranty.

NOTE: To avoid water damage or scalding due to

valve operation, drain pipe must be connected to

valve outlet and run to a safe place of discharge.

Drain pipe must be the same size as the valve

discharge connection throughout its entire length

and must pitch downward from the valve. No shut-off

valve shall be installed between the relief valve and

the drain line. Valve lever should be tripped at least

once a year to ensure that waterways are clear.

Temperature Controls

High Limits

The pool heater is equipped with two high limits. Both

high limits, the non-adjustable auto reset high limit and

adjustable manual reset high limit are attached to the

outlet side of the in/out header.

Poolstat

The pool heater is equipped with a poolstat that is

attached to the inlet side of the in/out header to control

the pool temperature.

18

Page 19

Low Water Cutoff

Automatically shuts down burner whenever water

level drops below probe. A 3 to 5 second time delay

prevents premature lockout due to temporary conditions such as power failure or air pockets. Standard

on Cal Code heaters.

Fig. 25: Low Water Cutoff

High & Low Gas Pressure Switches

Pressure switches sense either high or low gas pressure and automatically shut down burners if abnormal

pressures exist. Standard on Models 3001-4001.

CAUTION: Label all wires prior to disconnection

when servicing controls. Wiring errors can cause

improper and dangerous operation. Verify proper

operation after servicing.

NOTE: If it is necessary to replace any of the

original wiring, it must be replaced with 105° C wire

or its equivalent.

NOTE: Models 2100-4001 require 240VAC power

to the pump.

Electronic Ignition

The intermittent ignition device conserves energy by

automatically extinguishing the pilot when desired

temperature is reached. When additional heat is needed, the pilot re-ignites electrically, eliminating the fuel

costs of maintaining a constant pilot. To ensure safe

operation, the gas valve cannot open until the pilot

relights and is confirmed.

Heater must be electrically grounded and bonded

Without Lockout With Lockout

Model

N P N P

926–1826 Standard N/A Optional Standard

2100–4001 N/A N/A Standard Standard

Fig. 26: High/Low Gas Pressure Switch

Electrical Wiring

DANGER - SHOCK HAZARD - Make sure

electrical power to the heater is disconnected to avoid

potential serious injury or damage to components.

Table E: Lockout Availability

in accordance with local codes, or, in the absence

of local codes, with the latest edition of the National

Electrical Code, ANSI/NFPA 70.

The heater draws less than 1 amp - not including the pump power - when operating on either

120VAC or 240VAC power.

Fig. 27: Ignition Module

19

Page 20

Wiring Diagram—Models 926–1223 with UG

20

Page 21

Wiring Diagram—Models 926–1826 with H-Bypass

21

Page 22

Wiring Diagram—Models 2100–2500

22

Page 23

Wiring Diagram—Models 3001–4001

23

Page 24

SERVICING

Temperature Control

General Location Of Controls

Models 926-1223 with UG

Fig. 28: General Location of Controls

(Models 926-1223 with UG)

Models 2100-4001

Inlet/Outlet

Header w/Bypass

Pump

The pool water temperature is controlled by the

poolstat. The heater water temperature high limit is

controlled by the manual reset high limit.

Pressure Switch

The pressure switch on a unit equipped with a

Unitherm Governor ensures that the heater operates

only when the filter pump is in operation. It is factory

set at 1.75 PSI for deck level installations. When the

heater is located below the level of the spa or pool,

it may be necessary to reset the pressure switch to

compensate for the no-flow static head. See Fig. 31.

If it is necessary to reset the pressure switch, we recommend the following procedure.

Pressure Switch Adjustment

1. Make sure the pool filter is clean before adjusting

the switch.

2. Set the heater control to the OFF mode.

3. Turn the filter pump on and confirm that the pressure switch is closed (use a multimeter to check).

If the pressure switch fails to close, either the

switch setting is too high or the filter pump is not

supplying enough pressure.

Electrical

Connection

Main Burner

Gas ValveManual On/Off Valve

Fig. 29: General Location of Controls

(Models 2100-4001)

4. Turn the heater ON.

5. Manually turn the pressure adjustment knob clockwise (see Fig. 30) until the heater shuts off. (A flat

screw driver may be necessary if knob is too tight).

6. Slowly turn the adjustment knob counter-clockwise until the heater calls for heat again.

7. Turn an additional 1/2 turn counter-clockwise.

8. While the heater is running, check the adjustment

by turning the pump off and on several times. The

burners should shut off immediately when the

pump is turned off. If it does not, repeat the above

steps until proper operation is observed.

24

Page 25

A

DJUSTMENT KNOB

Fig. 30: Pressure Switch Adjustment

5’ Max

START-UP

PROCEDURES

Before Start-Up

Burners

Clean main burners and air louvers of dust, lint and

debris. Keep heater area clear and free from combustibles, flammable liquids, and chemicals. Do not

obstruct the flow of combustion and ventilating air.

Water

Water must be flowing through the heater.

Start-Up

5’ Max

CAUTION: Propane gas is heavier than air and

sinks to the ground. Exercise extreme care in lighting

heater in confined areas.

Fig. 31: Heat Exchanger Height Above/Below Pool

NOTE: If heater is installed outside of the limits

shown, a flow switch must be used in place of the

pressure switch when mounted and wired adjacent

to the heater.

Two-Speed Pumps

In some cases, the flow on the low speed is insufficient

to operate the heater. This is apparent when the pressure switch cannot be further adjusted or if the heater

makes banging noises. In these cases, the pump must

be run at high speed when heating the water.

CAUTION: Do not operate a UG-equipped heater

without properly-adjusted pressure switch.

Pilot Safety

Lighting Instructions

1. Close all gas valves. Turn off electric power supply

wait 5 minutes.

2. Open manual pilot valve. Turn on electric power,

pilot is automatically lighted.

3. Open main gas valve.

4. Set temperature controls to desired temperature.

To Shut Down

Close all manual gas valves. Turn off electric power.

The heater employs a pilot safety which closes the

main gas valve within 8/10ths of a second whenever

the pilot flame is interrupted. Pilot flame is automatically lit when the device is powered. Unit performs its own

safety check and opens the main valve only after the

pilot is proven to be lit.

25

Page 26

After Start-Up

INSPECTION

Pilot System Checkout Procedure

1. Turn on power to the ignition systems and turn gas

supply off.

2. Check ignition module as follows:

a. Set the poolstat above pool water temperature

to turn heater on.

b. Watch for continuous spark at the pilot burner.

c. Time the spark operation. Time must be within

the lockout timing period (15 or 90 seconds).

d. Turn poolstat down to turn off heater and wait

60 seconds on lockout models before beginning step 3.

3. Turn on gas supply.

4. Set poolstat above pool water temperature to turn

on heater.

5. Systems should start as follows:

PROCEDURES

Burners

Clean main burners and air louvers of dust, lint and

debris. Keep heater area clear and free from combustibles and flammable liquids. Do not obstruct the flow

of combustion and ventilating air. Make visual check of

burner and pilot flame. Yellow flame indicates

clogging of air openings. Lifting or blowing flame indicates high gas pressure. Low flame indicates low gas

pressure.

Fig. 32: Main Burner Flame

a. Spark will turn on and pilot gas valve will open

at once. Pilot burner should ignite after gas

reaches the pilot burner.

b. Spark ignition should cut off when pilot flame

is established.

c. Main gas valve should open and main burner

should ignite after gas reaches the burner

port.

Fig. 33: Pilot Burner Flame

Feel inlet and outlet pipes. Outlet should be only slightly warmer than inlet. It should not be hot.

WARNING: Should overheating occur or the gas

supply fails to shut off, turn off the manual gas

control to the appliance.

CONTROLS

Check all controls to see that they are operational. To

check electric safety turn off main burner. Observe

pilot burner when shutting off pilot gas. Ignition spark

should go on. Main gas valve will also drop out.

26

Page 27

SERVICING

Burner Drawer Removal

PROCEDURES

Tube Cleaning Procedure

(Typical)

Establish a regular inspection schedule, the frequency

depending on the local water condition and severity of

service. Do not let the tubes clog up solidly. Clean out

deposits over 1/16” in thickness.

Although the illustration shows the mechanical cleaning procedure of a small heater, it is typical of all sizes.

The heater may be cleaned from the return header

side as shown, without breaking pipe connections. It is

preferable, however, to remove both headers for better

visibility through the tubes and to be sure the ground

up lime dust does not get into the system.

Note that you do not remove the top pan or the heat

exchanger, generally.

After reaming, mount the wire brush in lieu of the

auger and clean out the debris remaining in the tubes.

Another method is to remove the heat exchanger,

ream tubes and immerse heat exchanger in non-inhibited de-scale solvent.

1. Shut off power and gas supply to the pool heater.

Disconnect union(s) and pilot tubing, then loosen

and remove burner-hold down screws.

2. Disconnect wires at gas valve and slide burner

drawer out.

Gas Valve Removal

1. Shut off gas supply to the pool heater. Remove

gas piping to gas valve inlet.

2. Disconnect wires, pilot tubing and bleed line, if

required.

3. Turn vertical gas pipe from manifold slightly and

unscrew gas valve.

4. Reverse above procedure to re-install.

RAYPAK TUBE CLEANING KIT

Extension Pieces (5) Auger with Carbide Tip Wire Brush

Fig. 34: Tube Cleaning Kit

Fig. 35: Tube Cleaning Procedure

27

Page 28

Main Burner and Orifice

Removal

1. Remove screws and burner hold down bracket.

NOTE: If the heat exchanger is sooted badly, the

burner hold-down bracket and spacer can become

distorted from direct flame impingement and this

usually necessitates replacement of these parts.

Heat Exchanger Reassembly

1. Heat exchanger header O-rings should be replaced

with new ones.

2. Install inlet-outlet and return water headers and

install header retainer nuts and torque nuts evenly.

2. Lift burners from slotted spacer and slide from

orifices. Clean with a wire brush.

3. Orifices usually do not need to be replaced. To

clean, run either copper wire or wood through orifice. Do not enlarge hole. To remove orifice, use a

socket wrench and remove the manifold. DO NOT

overtighten when reinstalling.

Pilot Removal and Cleaning

1. Disconnect pilot tubing at pilot and sensor/igniter

wire. Remove screws holding pilot bracket to burner drawer.

2. Remove pilot and bracket, clean pilot of debris,

small bugs, etc., with wire or small brush.

3. Replace pilot, pilot tubing, sensor ignition wires

and check for leaks.

Heat Exchanger Removal

1. Shut water, gas and electricity off, close valves,

relieve pressure and remove relief valve. Remove

side inspection panels.

2. Remove top holding screws.

3. Install the four (4) corner clips between tube

sheets and refractory. Replace “V” baffles.

4. Install thermostat sensing bulbs in header wells

and replace bulb retaining clips.

5. Install inlet and return pipes in water headers

using pipe thread sealant.

6. Install water pressure relief valve, flow switch, and

low water cutoff devices if so equipped.

7. Open water supply and return shutoff valves. Fill

heater and water piping system with water. Check

heater and piping system for leaks at full line pressure. Run system circulating pump for a minimum

of 1/2 hour with heater shutoff.

8. Shut down entire system and vent all radiation

units and high points in system piping. Check all

strainers for debris.

9. Install flue collector, jacket top and inspection panels. Install top holding screws. Install draft diverter

and vent piping if so equipped.

10. If gas piping was disconnected, reconnect gas

piping system and check for leakage using a soap

solution.

3. Remove draft diverter, lift and remove top and flue

collector on stack type models. Remove inspection panels.

4. Loosen bolts and disconnect flange nuts on inlet/

outlet header, loosen union(s) at gas pipe, and

slide heater away from piping until studs clear the

heater.

5. Remove heat exchanger corner brackets.

6. Remove combustion chamber clips at the four

corners of the heat exchanger.

7. Lift heat exchanger straight up using caution not to

damage refractory.

11. Double check electrical circuits, grounding connections and pump with wiring diagram supplied

with heater.

12. Check for correct water pressure and water level

in the system. Make sure that system pump operates immediately on the call for heat. The system

is ready for operation.

28

Page 29

Combustion Chamber Removal

To remove the combustion chamber you must first

have removed the heat exchanger. Unbolt metal

combustion chamber retainer from top and remove

combustion chamber panels individually.

Fig. 36: Refractory Panels—Top View

Control Well Replacement

canopy and flue collector off (on models 926-1826,

remove the canopy hold-down brackets). Remove “V”

baffles over tube(s) to be replaced. If no pipe unions

have been provided, use the header as a union,

remove the flange nuts off the inlet-outlet header,

break gas connection and slide heater away from

piping, allowing room to work. Pull wedge clips out

of control wells and remove sensing bulbs. Remove

flange nuts from the return header and remove header. Lift heat exchanger straight up and out.

Heat exchanger header o-rings must be replaced with

new ones. The tube may be cut out with a hack-saw or

hammer and chisel adjacent to both tube sheets, leaving stubs in the tube sheets. Then proceed to collapse

stubs in the tube sheets with a chisel or screwdriver.

Use caution not to cut into the tube sheet. Replacement

tubes will have the fins stripped off longer on one end.

The long end is inserted into the opening of the tube

sheet first; then the short end is fitted through the

opposite tube sheet. If the tube ends become dented

or bent, straighten at least four (4) inches back from

the tube end by means of a tapered punch.

Remove top, sensing bulb and clip. Collapse well

tube at the open end and with a chisel, push through

into the header, and remove the well through header.

Insert a new well and roll into place. If a roller is not

available, solder the well in place with silver solder.

Fig. 37: Immersion Well

Tube Replacement Procedure

On Raypak tube replacement may be affected without

rolling, as a temporary means of repair, provided there

are two or more tubes rolled into act as stays on left

and right sides. The “O” rings should provide a seal up

to 125 PSI working pressure. Use a 3/8” heavy duty

reversible drill motor or larger, to power the tube roller.

If a reversible drill is not available, after rolling the tube

in, remove the drill motor and wrench out the roller. A

tube roller is available from the factory.

Insert tube roller into tube opening up to stop against

tube, then push center rod in until roller is tight. Be

careful to keep replacement tube squared up 1/8” outside each tube sheet. A loose tube will sometimes pull

toward the roller. Attach drill motor to tube roller, holding it straight and level. Proceed to expand tube until

the tool begins to grab. At this point, 1/2” to 1” should

be exposed on the tool shank. Reverse drill motor

or wrench out by hand. Care should be exercised to

avoid applying excessive torque during rolling operation and to avoid thinning out any part of the tube wall

excessively over .015”. Use same procedure at the

opposite end of the tube.

Apply line pressure test, and re-roll, if necessary,

before replacing canopy.

Procedure For Cleaning Flue

Gas Passageways

Soot can clog areas behind fins and cause eventual

tube failure. Any sign of soot at base of burners or

around outer jacket indicates a need for cleaning.

1. Lift off drafthood and flue collector by removing

bolts and screws.

2. Remove “V” baffles from heat exchanger.

Shut gas and power off to the unit, close the system

off and drain the pool heater. Remove draft diverter.

Remove the access panels and jacket top. Lift the

3. Remove burner tray.

4. Take garden hose and wash heat exchanger,

29

Page 30

making sure soot is removed from between fins.

(Avoid excessive water against refractory).

5. Reassemble; when heater is fired, some steam will

form from wet refractory. This is normal.

MAINTENANCE AND

CARE

To be followed one month after initial start-up and then

quarterly.

NOTE: In extreme cases it may be necessary to

remove the heat exchanger completely for cleaning.

The simplest method is steam cleaning at a local car

wash. DO NOT WIRE BRUSH!

CAUTION: Soot is combustible, so exercise

extreme care.

Unitherm Governor

Replacement

1. Shut off water, gas and electricity, close valves,

relieve pressure.

2. Drain heat exchanger.

3. Remove Unitherm Governor.

1. Inspect top of heater and draft-hood for soot, and

open fuel gas passageways.

2. Clean main burners and pilot burner of dust and

lint.

CAUTION: Soot may be combustible. Wet completely when cleaning.

3. Inspect and operate all controls and gas valve.

4. Make visual check of burner and pilot flame.

Flame pattern on main burner and pilot is indicated on page 26. Yellow flame means restriction

of air openings. Lifting or blowing flame indicates

high gas pressure. Low flame means low gas

pressure.

5. Clean room air intake openings to ensure adequate flow of combustion and ventilation air.

6. Remove header opposite inlet pipes when cleaning and inspect internal tubes for scale deposits.

If scale does not form within first quarterly inspection, then inspect annually thereafter.

Fig. 38: Unitherm Governor—Models 926–1223

To test operation of Unitherm Governor, place in hot

water (110°F or higher) and watch for movement

against spring. If no movement, replace.

CAUTION: Combustion air must not be

contaminated by corrosive chemical fumes which

can damage the heater and void the warranty.

7. Keep heater air clear and free from combustible

materials and other flammable and corrosive

vapors and liquids.

8. Keep moving parts lubricated.

9. Manual operation of pressure/temperature relief

valve at least once a year.

30

Page 31

Winterizing Your Heater

When heaters installed outdoors in freezing climate

areas are to be shut down for the winter, please

observe the following step-by-step procedure:

1. Remove the drain plug or open the drain cock

located on the inlet-outlet header. On larger

heaters with external Unitherm Governor(s) and

piping, locate plug at low point of Governor piping,

or break connections and rotate inlet fittings 180

degrees to face downward. Turn off manual main

gas and main gas shut off.

2. On units equipped with a UG (models 926-1223),

locate the pressure switch. Disconnect the compression fittings on both ends of the 1/8” copper

tube and allow the tube to drain. Remove the “heat

exchanger inspection panels” on the right side of

the heater to gain access to the fitting on the return

header. Remove the return header to ensure that

no water remains in the heat exchanger.

31

Page 32

IMPORTANT NOTICE

*Usually occurs on initial start-up

TROUBLESHOOTING

These instructions are primarily intended for the use of qualified personnel specifically trained and experienced

in the installation of this type of heating equipment and related system components. Installation and service

personnel may be required by some states to be licensed. Persons not qualified shall not attempt to install this

equipment nor attempt repairs according to these instructions.

MECHANICAL (FOR QUALIFIED SERVICE PERSONNEL ONLY)

PROBLEM

Harmonics, or whining noise

Heater going on and off

continously

Liming or scale forming on

heat exchanger

Sooting

CAUSE

U.G. Inoperative……………………

*Debris or restriction in system……

*Debris in gas line…………………..

Low flow……………………………...

Dirty filter……………………………

Low water level in pool..……………

External bypass setting out of

adjustment…………………………..

*Pressure switch out of

adjustment…………………………..

Pool water…………………………....

High flow rates…………………….....

U.G. Inoperative……………………..

*Air starvation………………………..

*Improper venting…………………....

*Insects or debris clogging

burner intake ports…………………..

SOLUTION

Check movement by putting in hot

water (110°F or higher). If no movement, replace.

Locate the restriction and remove.

Flush system and clean.

Remove debris or blow out gas line.

Scale forming in heat exchanger clean heat exchanger and check

pool pH and total alkalinity.

Backwash filter.

Raise water level.

Adjust bypass

Adjust pressure switch

Recommended pH should be between 7.3 and 7.8 total alkalinity 100150 PPM maximum. Hardness -150400 PPM maximum. (see page 2)

Reduce by adding manual bypass

valve and adjust by putting thermometer in header (1/4" NPT) drain

opening. Set bypass so thermometer reads between 105° and 110°F.

Check movement by putting in hot

water (110°F or higher). If no movement, replace.

Refer to installation instructions.

Follow recommended installation

instructions.

Clean burners

Pilot outage

Yellow lazy flame

Low gas pressure…………………....

Restricted pilot……………………....

Weak pilot generator………………..

Low gas pressure…………………....

*Insects or debris clogging

burner intake ports…………………..

32

Adjust gas pressure.

Clean pilot.

Replace pilot.

Adjust gas pressure.

Clean burners.

Page 33

Outer jacket very hot

(paint blistered)

*Broken refractory caused by

heat

no

when

water

main-

cor-

Limin

Leaking at well.

Leaking

Gasket brittle and leaking(overheated)

Takes long time to heat pool

or spa

shipping damage or improper

combustion…………………………..

Excessive sooting of heat

exchanger…………………………...

Calculate temperature in °F/hr……...

Filter not running long enough……....

Dirty filter……………………………..

Gas line or meter under-

sized………..................................

Replace refractory panels.

Determine cause of sooting &

correct.

Heat rise (°F/hr.) =

Htr.output

Pool gallonage x 8.33

or refer to heater sizing chart.

This does not take into account

loss due to weather.

Reset time clock.

Clean filter.

Refer to installation instructions.

g

at heat exchanger.

Bypassing too much water………....

Inspect bypass for movement, if

movement, replace.

U/G not functioning……………….....

Replace if no movement

heated.

Overacid…………………………......

Replace well and maintain

chemistry properly.

Overacid……………………………...

Replace heat exchanger and

tain chemistry properly.

.

Heater running after pump

shuts off……………………………...

Refractory damage………………….

Sooted heater………………………..

See pressure switch adjustment.

Replace refractory.

Determine cause of sooting and

rect.

*Usually occurs on initial start-up

33

Page 34

ENDS

ELECTRICAL (ELECTRONIC IGNITION IID) IID

Intermittent Pilot System

TROUBLESHOOTING HONEYWELL S8600

WARNING: HIGH VOLTAGE. For qualified

technicians ONLY.

NOTE: Some heaters may be equipped with an

ignition module that shuts off pilot gas if the pilot fails

to light. To reset, interrupt power to the heater.

START

TURN GAS SUPPLY OFF.

TURN THERMOSTAT

(CONTROLLER) TO CALL

FOR HEAT

POWER TO MODULE

(24 V NOMINAL)

YES

SPARK ACROSS

IGNITER/SENSOR GAP

YES

TURN GAS SUPPLY ON

PILOT BURNER LIGHTS?

YES

SPARK STOPS WHEN

PILOT IS LIT?

YES

NOTE: Before troubleshooting, familiarize yourself with the start-up and checkout

procedure.

Check line voltage power, low voltage transformer, limit controller, thermostat

NO

(controller) and wiring.

Pull ignition lead and check spark at module.

NO

Spark Okay?

YES

• Check ignition cable, ground wiring, ceramic insulator and gap, and correct.

• Check boot of the ignition cable for signs of melting or buckling. Take protective

action to shield cable and boot from excessive temperatures.

• Check that all manual gas valves are open, supply tubing and pressures are

NO

good, and pilot burner orifice is not blocked.

• Check electrical connections between module and pilot operator on gas control.

• Check for 24 Vac across PV-MV/PV terminals on module. If voltage is okay,

replace gas control; if not, replace module.

NOTE: If S8600H goes into lockout, reset system by removing power for at least

60 seconds. Lockout is used on Pro. models.

• Check continuity of ignition cable and ground wire.

NO

• Clean flame rod.

• Check electrical connections between flame rod and module.

• Check for cracked ceramic flame rod insulator.

• Check that pilot flame covers flame rod and is steady and blue.

• Adjust pilot flame.

• If problem persists, replace module.

• Check for 24 Vac across MV-MV/PV terminals. If no voltage, replace module.

MAIN BURNER LIGHTS?

YES

SYSTEM RUNS UNTIL

CALL FOR HEAT ENDS?

YES

CALL FOR HEAT ENDS

SYSTEM SHUTS OFF?

YES

TROUBLESHOOTING

NO

• Check electrical connections between module and gas control. If okay, replace

gas valve or gas control operator, i.e. pilot gas valve, flow switch etc.

NOTE: IF S8600H goes into lockout, reset system.

NO

• Check continuity of ignition cable and ground wire.

NOTE: If ground is poor or erratic, shutdowns may occur occasionally even though

operation is normal at the time of checkout.

• Check that pilot flame covers flame rod and is steady and blue.

• If checks are okay, replace module.

• Check for proper thermostat (controller) operation.

NO

• Remove MV lead at module; if valve closes, recheck temperature controller and

wiring; if not, replace gas valve.

Repeat procedure until trouble free operation is obtained.

34

Page 35

35

Page 36

www.raypak.com

Raypak, Inc., 2151 Eastman Avenue, Oxnard, CA 93030 (805) 278-5300 Fax (805) 278-5468

Litho in U.S.A.

36

Loading...

Loading...