INSTALLATION & OPERATING

INSTRUCTIONS

Electric

SPA-PAK

Heater

Models

ELS 552-2 & ELS 1102-2

FOR YOUR SAFETY: Do not store or use gasoline or other flammable vapors and

liquids or other combustible materials in the vicinity of this or any other appliance. To

do so may result in an explosion or fire.

Catalog No. 6100.53V Effective: 09-01-15 Replaces: 09-28-09 P/N 240362 Rev. 23

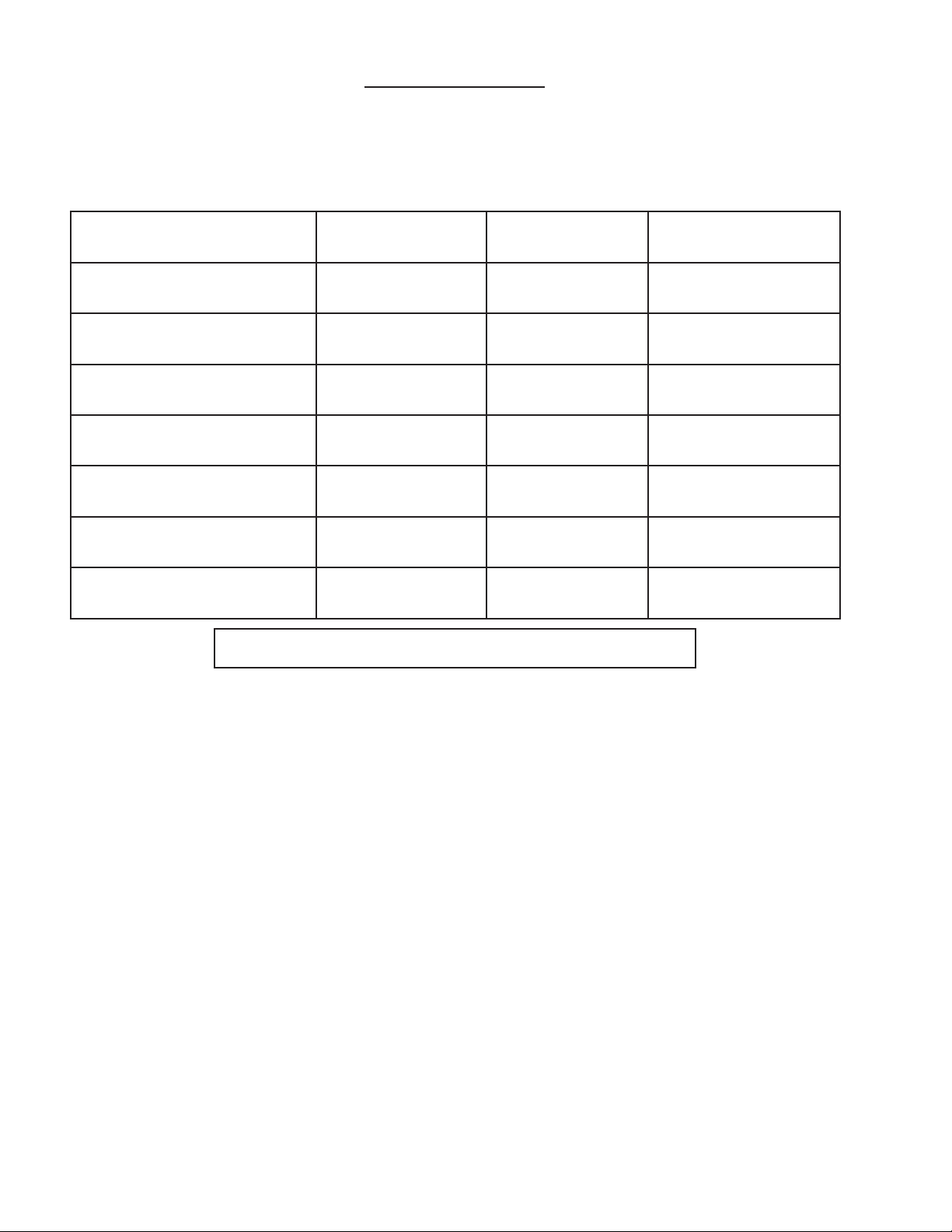

WATER CHEMISTRY

(Corrosive water voids all warranties)

For your health and the protection of your pool equipment, it is essential that your

water be chemically balanced. The following levels must be used as a guide for balanced water.

Recommended Level(s) Fiberglass Pools Fiberglass Spas

Other Pool & Spa

Types

Water Temp. (Deg. F) 68 to 88 89 to 104 68 to 104

pH 7.3 to 7.4 7.3 to 7.4 7.6 to 7.8

Total Alkalinity (PPM) 120 to 150 120 to 150 80 to 120

Calcium Hardness (PPM) 200 to 300 150 to 200 200 to 400

Salt (PPM) 4500 MAXIMUM 4500 MAXIMUM 4500 MAXIMUM

Free Chlorine (PPM)* 2 to 3 2 to 3 2 to 3

Total Dissolved Solids (PPM) 3000 MAXIMUM** 3000 MAXIMUM** 3000 MAXIMUM**

* Free Chlorine MUST NOT EXCEED 5 PPM!

** In salt water chlorinated pools, the total TDS can be as high as 6000 ppm.

• Occasional chemical shock dosing of the pool or spa water should not damage the

heater providing the water is balanced.

• Automatic chemical dosing devices and salt chlorinators are usually more efficient

in heated water, unless controlled, they can lead to excessive chlorine level which

can damage your heater, and which is not covered under warranty. A check

valve should be installed between the heater outlet and a chlorinator or other chemical dosing device.

• Further advice should be obtained from your pool or spa builder, accredited pool

shop, or chemical supplier for the correct levels for your water.

Rev. 23 reflects the following: Changes to: Water Chemistry on page 2.

2

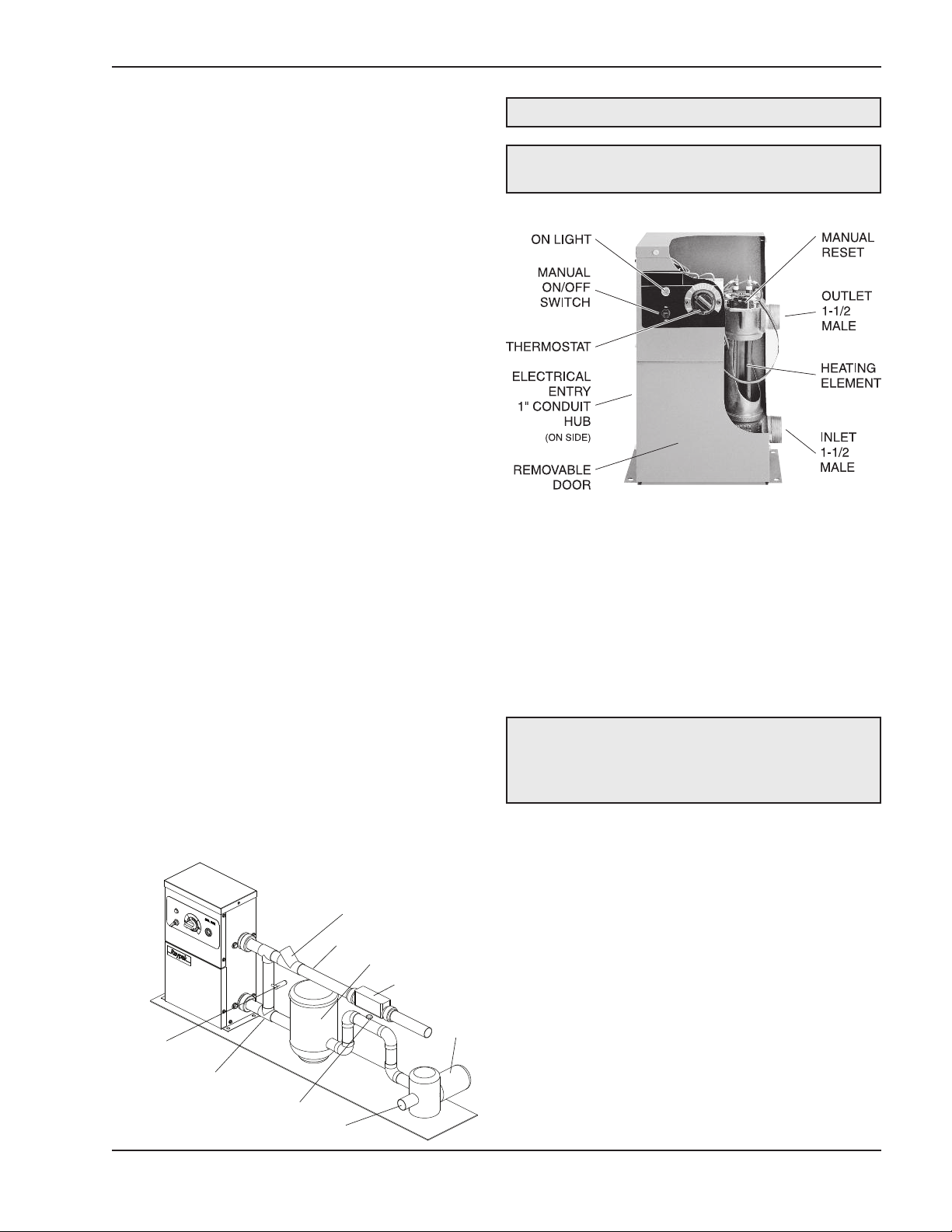

INTRODUCTION

Check Valve

To Spa

Filter

Chlorinator

Pump

Bypass

(Customer Installed)

Drain Valve

(Customer Installed)

Gate Valve

From Spa

NPT

NPT

NOTE: PVC pipe may be used.

The Spa-Pak spa Heaters have been designed to pro-

ide efficient, pollution-free, electric pool heating while

v

requiring minimal installation. The Spa-Pak consists of

a sheathed resistance element installed in a copper

tank.

This tank has a 1-1/2 NPT inlet and outlet on the side

for plumbing connections. The heater voltage is

208/240V single-phase. The control circuit passes

through a manual switch, the temperature control, and

the magnetic contactor coil. All items are pre-wired

and installed in a powder coated steel case.

It is essential that the heater be installed in accordance with the instructions given herein. Failure to do

so may cause damage to the heater and to the equipment to which it is connected, or may prevent the

heater from operating in a correct manner. The heater

is to be installed in accordance with article 680 of the

National Electrical Code ANSI/NFPA No. 70. Consult

State and local codes BEFORE installing this unit.

Where such codes have requirements beyond the

instructions given herein, the codes shall have precedence over these instructions.

Location

These heaters are listed by UL for either indoor or outdoor use. Unit must be mounted on a level base

parallel to the ground. Allow 6” clearance at sides and

18” clearance at top and front for maintenance. Secure

the unit with 5/16” mounting hardware using the holes

provided. The heater must be located where leakage

of heat exchanger or connections will not damage the

area adjacent to the heater or structure.

NOTE: When using two-speed pumps, do not install

ate valve on inlet.

g

The Spa-Pak has 1-1/2” male NPT inlet and outlet

connections at the right side of the heater. The inlet is

at the base of the heater and must be piped directly to

the filter discharge to ensure proper flow direction.

Minimum flow rate through the heater is 15 gpm, maximum is 60 gpm. If this is exceeded, an external

bypass must be added as shown. Unions should be

used on piping connections. A shut-off valve should be

included on the heater inlet to prevent draining the spa

when performing maintenance.

CAUTION: No shut-off valves are to be installed in

the piping between the heater outlet and the spa.

Any chlorinators, valves, etc., that can cause return

line blockage will void the warranty.

Water Connections

Automatic Chlorinators and

Chemical Feeders

All chemicals must be introduced and completely diluted into the spa water before being circulated through

the heater. Do not place chlorine tablets or bromine

sticks in the skimmer. High chemical concentrations

will result when the pump is not running (e.g.

overnight).

Chlorinators must feed downstream of the heater and

have an anti-siphoning device to prevent chemical

backup into the heater when the pump is shut off.

3

CAUTION: High chemical concentrates from feed-

TYPICAL COMFORTABLE

TEMPERATURE

RANGE FOR POOLS

T

YPICAL COMFORTABLE

TEMPERATURE

RANGE FOR SPAS

ers and chlorinators that are out of adjustment will

cause very rapid corrosion to the heater. Such damage is not covered under the warranty.

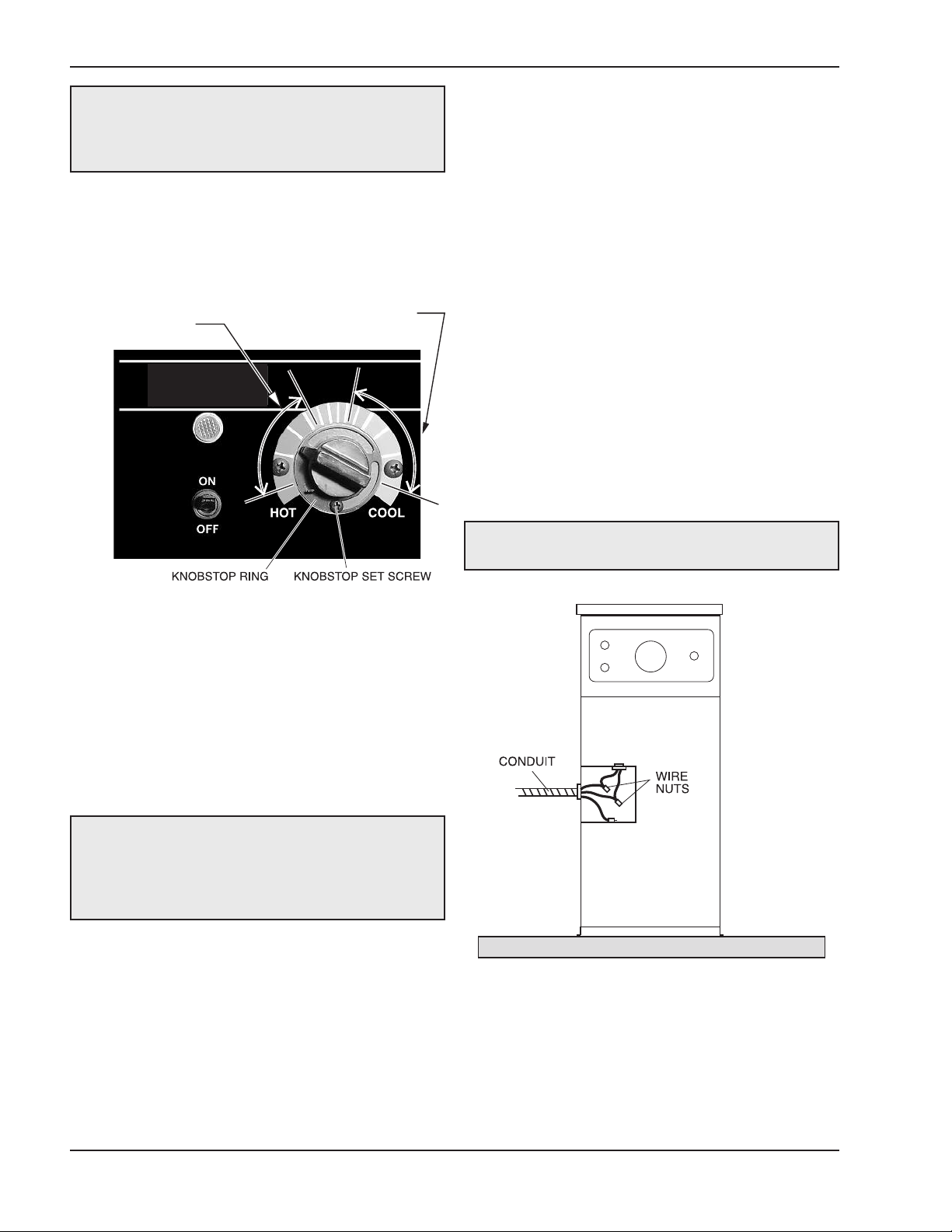

Thermostat

The heater thermostat located on the front of the unit,

may be set for any desired spa temperature.

odes. Keep wire runs as short as possible to mini-

c

mize voltage drop. Bring wires of size indicated from a

used disconnect switch (customer furnished) with an

f

amp rating of at least 125% of the amp rating shown

on the spa heater nameplate. A ground lug is provided

for connection to the supply ground. A wiring diagram

f the heater is shown at right. It is also affixed to the

o

inside front cover of the units.

Field Wiring

Heater requires three-wire service. With 240 VAC

there are two hot wires and a grounding conductor.

Even when metallic conduit is used, the grounding

conductor must be run to the supply ground.

Field wiring connections are made to the electrical

entry at the left side of the unit. A hole in the jacket is

provided for a 1” trade size conduit hub. The location

of the field wiring box is shown below. Wire nuts are

used to connect all leads except the grounding conductor, for which a pressure lug is provided.

NOTE: Heater grounding conductor shall be the

same or larger than the live power supply conductor.

Maximum Temperature Setpoint

(Knobstop Adjustment)

Adjustment to a different maximum setting is a simple

task. Loosen the small set screw on the knobstop and

rotate the knobstop ring until vertical “stop” tab is at the

desired maximum setting. Retighten the set screw.

ELECTRICAL

WARNING: The power supply circuit to this heater

shall be protected by a ground-fault circuit interrupter

(GFCI), in accordance with Art. 680 of the latest edition of the National Electrical Code (NEC). Failure to

do so could result in severe personal injury or death.

The GFCI devices shall be of the self-contained types,

circuit breaker types or the receptacle types. Feeder

ground-fault protection is not required where GFCI is

already provided in the branch circuits or receptacles

supplying power to the heater.

Electrical Disconnect

An electrical disconnect and over-current protection

device must be provided in accordance with local

Recommended Wire Sizes

for Field Connection

Use type THWN copper wire to the unit, with the AWG

wire sizes (Internal wire sizes may differ) listed in Table

A on the following page.

4

Loading...

Loading...