Page 1

IN REVIEW

UNCONTROLLED DOCUMENT IF PRINTED

INSTALLATION AND OPERATION

MANUAL

Electric Heater

MODELS

ELS 0005, ELS 0011,

ELS 0018, and ELS 0027

4000856

Tested to UL Standard 1261

FOR YOUR SAFETY: Do not store or use gasoline or other ammable vapors and

liquids or other combustible materials in the vicinity of this or any other appliance.

To do so may result in an explosion or re.

NOTE: The instructions in this manual are for the use of qualied individuals specially trained and experienced

in the installation and maintenance of this type of equipment and related system components. Installation and

service personnel are required by some states to be licensed. Persons not qualied shall not attempt to install,

service, or maintain this equipment.

This manual should be maintained in legible condition and kept adjacent to the electric heater or in a safe place

for future use.

Eective: 01-06-21

Replaces: 05-01-19

P/N 241758 Rev. 5

Page 2

IN REVIEW

UNCONTROLLED DOCUMENT IF PRINTED

TABLE OF CONTENTS

1. WARNINGS ............................................................ 3

2. WATER CHEMISTRY ............................................. 4

3. SAFETY INFORMATION ....................................... 4

4. OVERVIEW .............................................................. 4

5. BEFORE INSTALLATION ...................................... 5

6. INSTALLATION ....................................................... 5

7. WATER CONNECTION .......................................... 5

8. FREEZE PROTECTION ......................................... 6

9. ELECTRICAL CONNECTIONS ............................ 6

10. OPERATION ............................................................ 7

11. CONTROL ................................................................ 8

12. REMOTE OPERATION .......................................... 9

13. TROUBLESHOOTING ......................................... 11

14. WIRING DIAGRAMS ............................................ 12

15. ILLUSTRATED PARTS LIST ............................... 13

16. WARRANTY ..........................................................15

Revision 5 reects the following changes:

Installation text revised on page 4. Figure 2, Table B and Table C revised on page 6. Wiring Diagram revised on page 11. Illustrated

parts List added starting on page 12. Warranty added starting on page 14.

2

Page 3

1. WARNINGS

IN REVIEW

UNCONTROLLED DOCUMENT IF PRINTED

Pay Attention to these Terms

DANGER

A

WARNING

A

CAUTION

A

CAUTION

NOTE

WARNING: Do not use this heater if any part has

A

been under water. Immediately call a qualied service

technician to inspect and replace the heater.

WARNING: To minimize the possibility of improper

A

operation, serious personal injury, re, or damage to the

heater:

• Always keep the area around the heater free

of combustible materials, gasoline, and other

ammable liquids and vapors.

• Heater should never be covered or have any

blockage to the ow of fresh air to the heater.

Indicates the presence of immediate hazards which will cause severe personal injury, death or substantial

property damage if ignored.

Indicates the presence of hazards or unsafe practices which could cause severe personal injury, death or

substantial property damage if ignored.

Indicates the presence of hazards or unsafe practices which could cause minor personal injury or product or

property damage if ignored.

CAUTION used without the warning alert symbol indicates a potentially hazardous condition which could cause

minor personal injury or product or property damage if ignored.

Indicates special instructions on installation, operation, or maintenance which are important but not related to

personal injury hazards.

EFFICIENCY TESTING NOTICE: For purposes of

verifying or testing eciency ratings, the test procedure

in Title 10 APPENDIX P to Subpart B of Part 430 (Uniform

Test Method for Measuring the Energy Consumption of

Pool Heaters).

WARNING: Risk of electrical shock. More than one

A

disconnect switch may be required to de-energize the

equipment before servicing.

3

Page 4

2. WATER CHEMISTRY

IN REVIEW

UNCONTROLLED DOCUMENT IF PRINTED

CAUTION: Corrosive water voids all warranties

A

a temperature of 78°F (26°C) for competitive swimming.

However, this may be too cool for young children and the

elderly, who may require a te mperature of 80°F (27°C) or

higher.

For your health and the protection of your pool equipment,

it is essential that your water be chemically balanced. The

levels shown in Table A must be used as a guide for

balanced water.

Pool/Spa Water Chemistry

Occasional chemical shock dosing of the pool or spa

should not damage the heat exchanger providing the water

is balanced. Automatic chemical dosing devices and salt

chlorinators are usually more ecient in heated water. If

not controlled, they can lead to high chemical levels which

can damage the heat exchanger. Further advice should

be obtained from your pool or spa builder, accredited pool

shop, or chemical supplier for the correct levels for your

water.

Water Chemistry Allowable Levels

Water Temperature 68-104°F (20-40°C)

pH 7.6-7.8

Total Alkalinity (ppm) 80-120

Calcium Hardness (ppm) 200-400

Salt (ppm) 4500 Maximum

Free Chlorine (ppm)* 2-3

Total Dissolved Solids (ppm) 3000 Maximum**

*Free Chlorine MUST NOT EXCEED 5 ppm!

**In saltwater chlorinated pools, the total TDS can be as high as 6000

ppm.

Table A. Spa and Pool Water Chemistry

Automatic Chlorinators and Chemical

Feeders

All chemicals must be introduced downstream of the

heater and completely diluted into the water before being

circulated through the heater. Chlorinators must feed

downstream of the heat exchanger and have an antisiphoning device or check valve to prevent chemical backup into the heat exchanger when the pool ltration pump

is shut o.

CAUTION: High chemical concentrations from

A

feeders that are out of adjustment will cause rapid

corrosion of the heat exchanger. Such damage is not

covered under the warranty.

CAUTION: Failure of a heat exchanger due to lime

A

scale build-up on the heating surface, low pH, or other

chemical imbalance is not covered under the warranty.

3. SAFETY INFORMATION

Pool water temperatures typically range from 78°F (26°C)

to 82°F (28°C). The American Red Cross recommends

4

IMPORTANT SAFETY INSTRUCTIONS

READ AND FOLLOW ALL INSTRUCTIONS

GIVEN IN THIS MANUAL.

The water in a spa or pool should never exceed 104°F

(40°C). A water temperature in excess of 104°F (40°C)

is considered unsafe for all persons. Lower water

temperatures are recommended for extended use

(exceeding 10-15 minutes) and for young children.

Excessive water temperatures have a high potential

for causing fetal damage during the early months of

pregnancy. Pregnant or possibly pregnant women

should limit spa or pool water temperatures to 100°F

(38°C).

Before entering a spa or pool, the user should measure

the water temperature at several locations using an

accurate thermometer since the tolerance of water

temperature - regulating devices may vary as much as

much as +/- 5°F (3°C)

Alcohol, drugs or medication should not be used before

or during spa or pool use since their use may lead to

unconsciousness with the possibility of drowning.

Persons suering from obesity or with a medical history

of heart disease, low or high blood pressure, circulatory

system problems, or diabetes should consult a physician

before using a spa or pool.

Persons using medication should consult a physician

before using a spa or pool since some medication may

induce drowsiness while other medication may aect

heart rate, blood pressure and circulation.

Prolonged immersion in hot water may induce

hypothermia. Hypothermia occurs when the internal

temperature of the body reaches a level several degrees

above normal body temperature of 98.6°F (37°C).

The symptoms include dizziness, fainting, drowsiness,

lethargy and an increase in the internal temperature of the

body. The eects of hypothermia include: Unawareness

of impending hazard, failure to perceive heat, failure to

recognize the need to exit spa or pool, physical inability

to exit spa or pool, fetal damage in pregnant women and

unconsciousness resulting in a danger of drowning.

SAVE THESE INSTRUCTIONS

4. OVERVIEW

Congratulations on the purchase of the most advanced

spa/pool electrical heater in the market. To get the best

performance and savings from your new heater, it is

important to install the heater in accordance with our

instructions and the electrical, plumbing codes applicable

to your area. If you have any questions, please contact

your Authorized Dealer, or visit our website at www.raypak.

com

Page 5

IN REVIEW

UNCONTROLLED DOCUMENT IF PRINTED

5. BEFORE INSTALLATION

Please read these instructions thoroughly and completely

before installation and before use. Failure to do so could

cause property damage or serious personal injury or death

and void your warranty.

By installing this product, you acknowledge the terms of

the manufacturer's warranty and your Authorized Dealer's

return policies. The heaters that have been installed

cannot be returned. If you have any questions regarding

the warranty or product return policies, please consult your

Author ized Dealer prior to installation.

Open the box and carefully unpack the heater. Inspect all

components.

6. INSTALLATION

The heaters are designed for indoor or outdoor use. The

heater should be mounted on a level, non-combustible

surface. Heater must not be installed on carpeting. Do

NOT use the shipping crate base as an installation base.

• The heater must be mounted on a vertical position

over a ground level base or a wall.

• Secure the heater to the base with screws (not

provided).

CAUTION: Combustible materials should be kept at

A

least 24" (610 mm) away from the heater.

Recommended Clearances:

• TOP: 18" (45.7 cm)

• SIDES: 6" (15.2 cm) away from your heater and the

outlet hot water pipe.

7. WATER CONNECTION

IMPORTANT: When preparing the connections going

to heater, make sure you do not use glue or putty. Any

glue or putty going into the heater will damage the ow

sensor permanently. Prior to the nal connections to the

heater, ush all the lines to clear any debris.

NOTE: When using two-speed pumps, do not install

a gate valve on the inlet. No shuto valves are to be

installed in the piping between the spa heater outlet and

the spa. If using an in -line chlorinator, a check valve

must be used. Any chlorinator valves that can cause

return line block age will VOID the warranty.

Please follow all plumbing instructions carefully. This

product must be installed by a licensed and qualied

plumber in accordance with all applicable national, state,

pro vincial, and local plumbing codes.

• The heater must be installed after installation of the

lter.

• Models ELS 0005 and 0011 are supplied with

1-1/2" NPT inlet and outlet plumbing connections.

• Models ELS 0018 and 0027 are supplied with

2" NPT inlet and outlet plumbing connections.

• All heater models are rated operation ONLY on 240V

single-phase, 60Hz power.

• Heaters are ow activated.

• No Hartford loop is required.

After tightening both ttings at the water heater, start the

pump to allow water to run through the spa/pool heater for

at least 5-10 minutes. This process purges all the air from

the water lines and must be performed prior to turning on

the power at the heater.

CAUTION: Failure to follow this step can cause

A

permanent damage to the heating elements.

When any maintenance is performed on the spa/pool that

may introduce air into the plumbing pipes, it is important to

turn the power o to the heater and purge the air out of the

lines before allowing the heater to power up.

Dry-Firing of Elements

Dry-ring of elements is caused by water voids when power

is on. All air must be purged from the system before any

heat start-up. It is important to purge all air after cleaning

or changing a car tridge lter. The lter casing acts as an

air reservoir during this procedure, the circulation system

must be on for at least two (2) minutes before you turn

power on to this heater.

The heater must have an adequate ow of water for proper

operation. Adequate water ow removes the heat produced

by the heater and transfers the heat to the spa/pool and

prevents overheating. Low water ow usually results

from dirty lter or improperly adjusted manual bypass.

The heater is designed to run at a minimum ow rate of

15 gpm (57 lpm) and maximum of 60 gpm (227 lpm). A

manual bypass valve is needed when the ow rate exceeds

60 gpm (227 lpm). The heater will not energize elements

if the water ow is under 15 gpm (57 lpm). Once 15 gpm

(57 lpm) has been established, the heating elements will

energize 1-minute after ow is congured. This is to make

sure the tank is completely lled with water and any air in

the tank has had time to escape.

RAIN WATER RUNOFF. The heater is designed to

operate outdoors and can be exposed to rain. However,

rain water runo falling directly onto the heater from a

roof can cause damage and/or shorten the life of your

heater. Such damage will not be covered under warranty.

Install rain gutters or rain diverters on your roof if the

heater is installed in a position where contact with rain

runo may occur.

CAUTION: The heater's supporting base must be

A

high enough to keep completely free of standing water

at all times.

5

Page 6

IN REVIEW

UNCONTROLLED DOCUMENT IF PRINTED

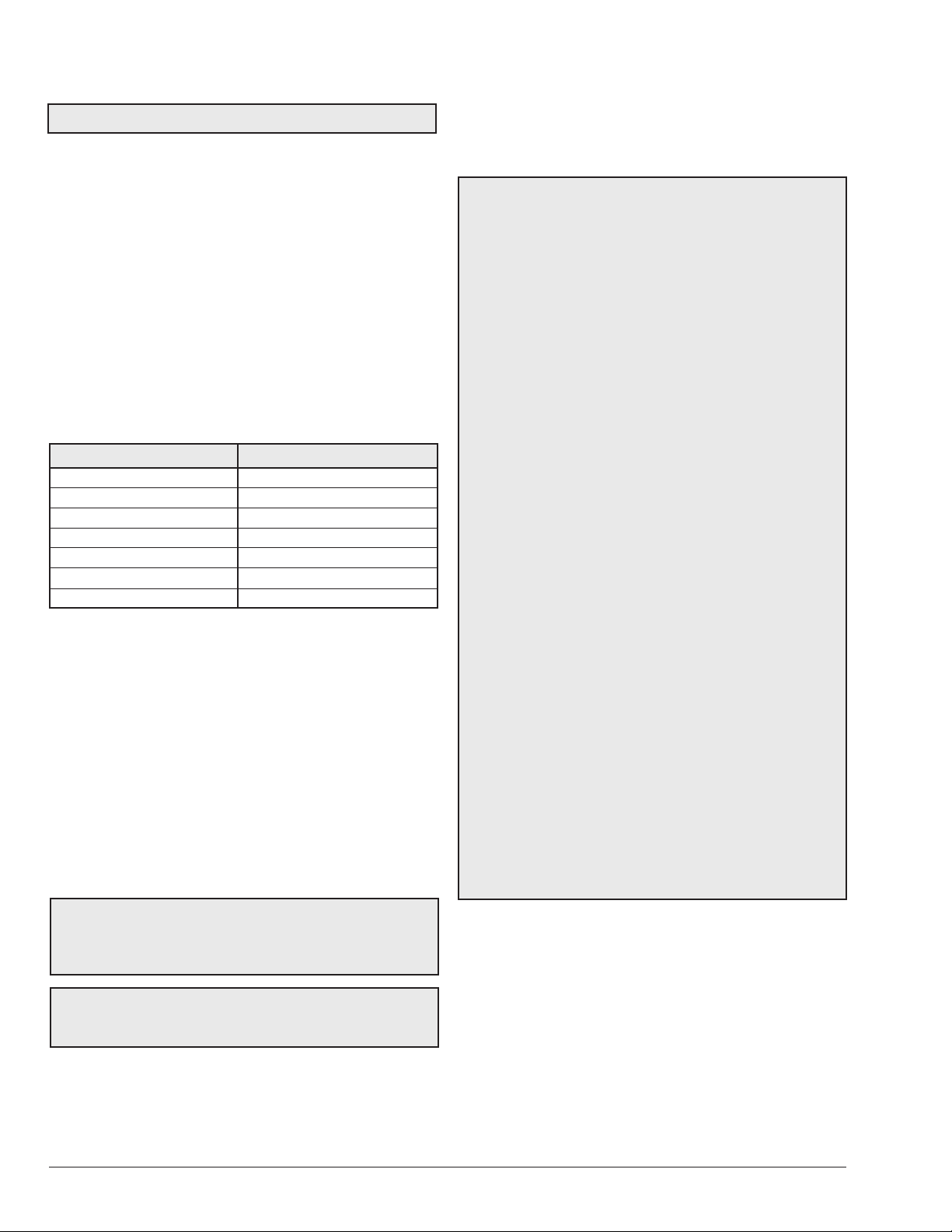

BYPASS

(CUSTOMER

INSTALLED)

DRAIN VALVE

(CUSTOMER

INSTALLED)

Figure 1. Spa/Pool Installation Diagram

GATE VALVE

8. FREEZE PROTECTION

If the heater is installed in a location subject to freezing

conditions, it is important to protect the water circuit from

freezing, just as should be done for the pump and lter.

System Drain-Down

1. Make sure the heater is disconnected or turned off.

2. With the pool pump OFF, loosen the PVC unions

supplied with the heater on both inlet and outlet pipes.

3. This should allow all of the water inside the heater to

drain out and prevent freeze damage to the heater.

9. ELECTRICAL

CONNECTIONS

WARNING: Please read these instructions

A

thoroughly and completely before installation and before

use. Failure to do so could cause property damage or

serious personal injury, or death and void your warranty.

WARNING: Risk of electrical shock. More than one

A

disconnect switch may be required to de-energize the

equipment before servicing.

This product must be installed by a licensed and qualied

electrician in accordance with Article 680 of the National

Electrical Code, NFPA 70 and with the requirements of

the authority having jurisdiction and all applicable national,

state, provincial, and local electrical codes.

As with all electrical appli ances, under no circumstances

should you attempt to install, repair or disassemble this

heater without rst shutting o all power to the heater

directly at the fuse or breaker box.

CHECK VALVE

TO SPA/POOL

FILTER

FROM SPA/POOL

WARNING: Serious bod ily injury or death could

A

occur if you ignore shutting o all power to the heater at

the fuse or breaker box.

CHLORINATOR

PUMP

F10545

All wiring (wire gauge) and circuit protection (breakers)

must comply with the U.S. National Electrical Code (NEC)

in the U.S.A., or the Canadian Electrical Code (CEC) in

Canada. Failure to do so could result in property damage

and/or personal injury, and void your warranty.

NOTE: The Canadian Electrical Code generally requires

that all supply wires and corresponding circuit protection

(breakers) used for hot water heating applications be

sized to a minimum of 125% of the maximum current

rating of the heater (see model specications below for

details).

Before installing this product, ensure that the home has

sucient electrical power available to handle the maximum

amperage load of the applicable model. All heaters have

one (1) minute time delay on start. The heater will not

energize the elements until 15 gpm (57 lpm) is established.

A separate ground conductor for each incoming circuit is

required.

CAUTION: Make sure that the electrical connections

A

are correct and all wire connec tions are tight and secure.

Make sure that the correct breaker size and wire gauge

has been used. Make sure that the heater has been

connected to a ground in accordance with applicable

codes.

6

Page 7

BREAKER

BREAKER

BREAKER

BREAKER

BREAKER

BREAKER

BREAKER

MODEL ELS 0005 MODEL ELS 0011 MODEL ELS 0018 MODEL ELS 0027

IN REVIEW

UNCONTROLLED DOCUMENT IF PRINTED

E1 E1 & E2 E1 E2 E1 E2 E3

GRND

L2 L1

GRND

L2 L1

GRND

L2 L1

L2 L1

GRND

L2 L1

L2 L1

L2 L1

30

DOUBLE

POLE

30

60

DOUBLE

POLE

60

50

DOUBLE

POLE

50

5050

DOUBLE

POLE

5050

DOUBLE

POLE

5050

DOUBLE

POLE

DOUBLE

POLE

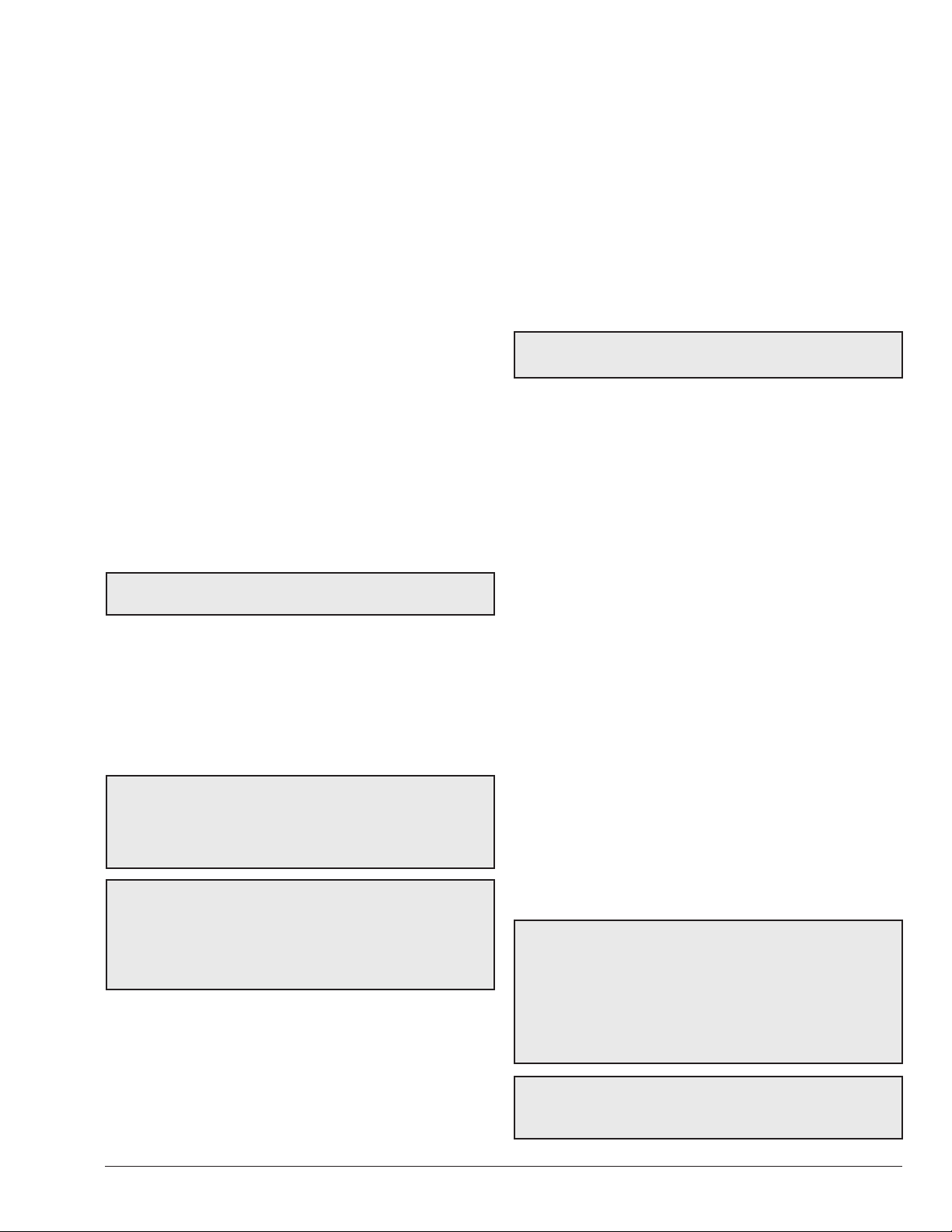

Figure 2. Wire Connection to Circuit Breakers

Properties

ELS 0005 ELS 0011 ELS 0018 ELS 0027

Models

Elements 1 2 2 3

Voltage 240 V 240 V 240 V 240 V

Frequency (HZ) 60 60 60 60

Power (kW) 5.5 11 18 27

Each Element Supply (kW) 5.5 5.5 (Qty 2) 9 (Qty 2) 9 (Qty 3)

Amp Draw per Element

(Nominal)

23 23 x 2 37.5 x 2 37.5 x 3

Total Amp Draw (Nominal) 23 46 75 112.5

Required Breaker

(min/max amps)

30/30 60/60 50/50 (Qty 2) 50/60 (Qty 3)

Electrical Service (amps) 100 150 150 200

Table B. Electrical Specication

5050

Properties

Models

ELS 0005 ELS 0011 ELS 0018 ELS 0027

Wire Gauge #10 #6 #8 #8

Wire Set 1 1 2 3

Breaker Amperage 30 60 50/50 (Qty 2) 50/60 (Qty 3)

Breaker Type Double Pole Double Pole Double Pole Double Pole

Breaker Quantity 1 1 2 3

Table C. Circuit Breaker Specication

Models ELS 0005 and 0011 display the inlet temperatures

10. OPERATION

Once the heater is installed, it can be used year-round.

The user MUST makes sure the pump is not disengaged

to allow it to run until the desired temperature setting is

reached.

The heater will function only when there is sucient ow

through it [15 gpm (57 lpm) minimum]. On the digital

control panel, press and hold the knob for ve (5) seconds

to check the ow rate in the unit.

on the GPM screen by turning the knob to the right. The

outlet temperature is displayed by turning the knob to the

left.

Models ELS 0018 and 0027 have the outlet and inlet

temperatures displayed at all times.

The unit also has a one (1) minute built-in TIME DELAY to

protect it from air in the lines and to avoid burning out the

elements as a result of it. When the unit senses sucient

water ow, it will automatically activate.

7

Page 8

11. CONTROL

IN REVIEW

UNCONTROLLED DOCUMENT IF PRINTED

Turn the control knob to set your desired temperature.

When the set tempera ture is reached the heater will go to

idle and the elements will not draw power.

NOTE: If the controls and display are active, they still

draw some power.

Digital Control Temperature Setting

The heater comes with a digital temperature control

located in the front panel that can be set from

40°-104°F (4°C-40°C) in one (1) degree increments by a

simple turn of the knob.

The heater is turned OFF by pushing the control knob

once. Hold the knob for two (2) seconds to switch from

Fahrenheit to Centigrade.

40°- 104°F 4°- 40°C

FOR CELSIUS DISPLAY:

PUSH BUTTON

FOR 2 SECONDS

TO TURN OFF

PUSH BUTTON ONCE

PRESS

2

SECONDS

40°- 104°F 4°-

FOR CELSIUS DISPLAY:

PUSH BUTTON

FOR 2 SECONDS

TO TURN OFF

PUSH BUTTON ONCE

PRESS

2

40°C

SECONDS

Figure 3. Digital Control for Models ELS 0005 and 0011 Figure 4. Digital Control for Models ELS 0018 and 0027

Code Description Action

E1 Inlet sensor has a short. Buttons do not function, no heat. Need to replace sensor.

E2 Outlet sensor has a short. Buttons do not function, no heat. Need to replace sensor.

E3 (ELS 27 only) Chamber #1 sensor short. The heater will continue to operate, continues to heat.

E4 (ELS 27 only) Chamber #2 sensor short. The heater will continue to operate, continues to heat.

E5

Remote wiring is in use. The master

external controller is not CFH.

The heater will not heat until the master control has a CFH.

Table D. Fault Codes

8

Page 9

IN REVIEW

UNCONTROLLED DOCUMENT IF PRINTED

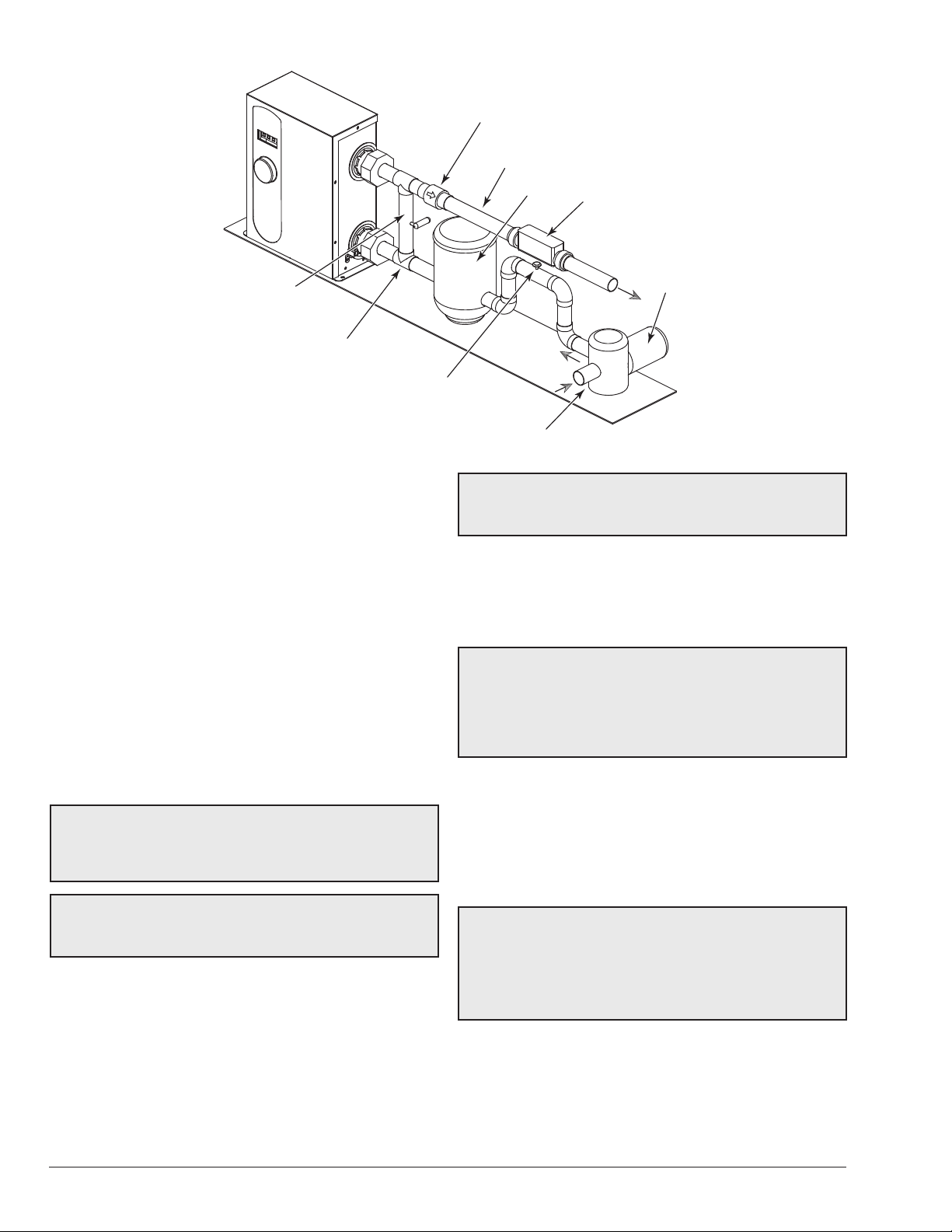

12. REMOTE OPERATION

The heaters are equipped to work with external remote

controls. The unit can be connected to either a toggle

switch or the switch contacts of a third party remote. The

remote works by either making or breaking the circuit

created by the remote wiring.

Typically, a remote does not supply power to the heater, it

only provides a switching function to turn on/o the heater.

If your remote is supplying its own voltage to the heater, it

will not work with this heater and may damage the digital

circuit board.

Remote Control Wiring

Important installation notes for remote or external wiring

conguration.

• Remote wiring must be run in a separate conduit.

• Remote wiring must not be run parallel to high voltage

lines.

• For runs of under 30 ft. (9.1 m), remote wiring

should have stranded conductors with a minimum

of 22 AWG, 600V, cable twisting 1.5" to 2.5"

(3.8 cm to 6.4 cm) lay and jacketed.

• For runs over 30 ft. (9.1 m), the conductors should

be a minimum of 20 AWG, 600V, cable twisting 1.5"

to 2.5" (3.8 cm to 6.4 cm) lay that is shielded and

jacketed.

• Maximum cable length is 200 ft. (61 m).

Remote Control (On-O)

1. Turn on power to the heater.

2. For a remote control without its own sensor, set the

desired set point, for example 102°F (39°C).

3. For a remote control with its own sensor, set the

temperature to the highest setting available on the

control on the heater. The actual set point will be

controlled by the remote control.

4. Turn off and remove power from the heater.

5. On the "Remote Interface Harness", the supplied

two wires provide power out to either a toggle

switch or the switch contacts of a third party remote.

See Figure 5.

NOTE: Code E5 is displayed on the heater digital display

when remote wiring is in use and the master external

controller is not calling for heat (CFH). The heater will

not heat until the master control is CFH.

GPM

(lpm)

15 (57) 1.6 3.6

20 (76) 2.4 5.6

25 (95) 3.6 8.2

30 (114) 5.2 11.9

35 (132) 7.5 17.3

40 (151) 8.8 20.3

45 (170) 19.2 44.4

50 (189) 22.6 52.2

60 (227) 23.2 53.7

Pressure Drop

in PSI

Pressure Drop

in ft. of Head

ADD “POOL/SPA

WHERE NECESSARY

REMOTE” SWITCH HERE

Figure 5. Supplied Wires for the Remote Interface

Harness

Table E. Pressure Drop for Models ELS 0005 and 0011

GPM

(lpm)

15 (57) 2.1 4.8

20 (76) 2.8 6.6

25 (95) 3.4 8

30 (114) 5.6 12.8

35 (132) 7.2 16.5

40 (151) 8.9 20.5

45 (170) 14.1 32.7

50 (189) 17.4 40.3

60 (227) 21.4 49.5

Table F. Pressure Drop for Models ELS 0018 and 0027

Pressure Drop

in PSI

Pressure drop

in ft. of Head

9

Page 10

IN REVIEW

UNCONTROLLED DOCUMENT IF PRINTED

150K Inlet/Outlet Sensor, All Models 10K Sensor for Model 0027 Element 3 Only

Temp ºF/ºC Resistance Ω Temp ºF/ºC Resistance Ω

32 (0) 491399.3 32 (0) 31537

41 (5) 384009.2 41 (5) 24783

50 (10) 303720 50 (10) 19587

59 (15) 242375.9 59 (15) 15568

68 (20) 191172 68 (20) 12443

77 (25) 150000 77 (25) 10000

86 (30) 122049 86 (30) 8080

95 (35) 97403.8 95 (35) 6563

104 (40) 77394 104 (40) 5359

113 (45) 61780.2 113 (45) 4398

122 (50) 49539.7 122 (50) 3628

Table G. Sensor Resistance

Models ELS 0005 and 0011

Heater Features Standard Values

Element resistance (check with at least one wire lead

disconnected from each element).

Delay in energizing elements (heater starts heating 1-minute

after powering up and sucient ow is recorded).

Turn on ow rate. 15 gpm ± 2 gpm (57 lpm ± 8 lpm)

Individual element current at max temp and max ow. 20.5 to 29.06 A

ECO trip point. 140°F (60°C)

To change temperature setting from Fahrenheit to Celsius. Press and hold the knob for 3-secs.

To display GPM. Press and hold the knob for 5-secs.

To display inlet and outlet water temperatures. On the display GPM screen, turning knob to the left shows

Models ELS 0018 and 0027

Heater Features Standard Values

Element resistance (check with at least one wire lead

disconnected from each element).

Delay in energizing elements (heater starts heating 1-minute

after powering up and sucient ow is recorded).

Turn on ow rate. 15 gpm ± 2 gpm (57 lpm ± 8 lpm)

Individual element current at max temp and max ow. 31.7 to 40.2 A

ECO trip point. 140°F (60°C)

To change temperature setting from Fahrenheit to Celsius. Press and hold the knob for 3-secs.

To display GPM. Press and hold the knob for 5-secs.

Inlet and outlet water temperatures. The inlet and outlet temperatures are displayed at all times.

Table H. E3T Electric Heater Features

9.97 to 11.6 Ω

1-minute ± 30 secs.

inlet water temperature and turning it to the left shows outlet

water temperature.

6.10 to 7.11 Ω

1-minute± 30-secs.

10

Page 11

13. TROUBLESHOOTING

IN REVIEW

UNCONTROLLED DOCUMENT IF PRINTED

Nothing happens when the

thermostat is turned on.

It takes a long time to heat the spa.

Spa does not reach temperature. Low ow Check lter, skimmer basket, pump.

Heating element continuously

burning out.

Fuses blow or circuit breaker opens.

Problem Cause Solution

1. Check lter, skimmer basket, pump.

2. If a 2-speed pump is used, turn to high speed.

Low ow

High limit has tripped Push the reset button on the limit.

Thermostat not calling for heat Turn thermostat to higher temperature.

Low input voltage Call the electric company.

Undersized heater

Heat loss from poor weather

conditions (cold, high winds)

Defective heating element Call an electrician.

High input voltage Call the electric company.

Poor water chemistry See "WATER CHEMISTRY" on page 4.

Heating element split open Over-acid condition. Watch pH, add acid slowly.

Shorted heating elements Replace element.

Undersized wire Replace eld wiring.

3. Press and hold the knob for 5-seconds. Make sure

the ow rate displayed on screen is at least 15 gpm

(57 lpm).

Calculate temperature in heat rise

°/hr. = Heater input (kw) x 410 divided by spa

gallonage (This does not take into account heat loss

due to weather).

Use an spa cover.

11

Page 12

14. WIRING DIAGRAMS

ELEMENT 2

HIGH LIMIT 1

1 3

1

2

HIGH LIMIT 2

ELEMENT 1

CPU

TRANSFORMER

VH1

VH2

HIGH LIMIT 3

ELEMENT 3

F1 —250V/1A Y1

1 3 1 2 1 2

WATER OUTLET, 150 kOhm

WATER INLET, 150 kOhm

1 3

CN5

VH5

VH6

CN8

REMOTE CONTROL WIRE

1

2

3

1 2

1 2

AC POWER SUPPLY

VH3

VH4

1 2 1 2

#1 THERMISTOR OF THE CHAMBER

#2 THERMISTOR OF THE CHAMBER

CN3

CN4

GND

GND

L1

L2

L1

L2

L1

L2

FLOW SENSOR

0027 ONLY

240VAC 1-PH 60 Hz

[SIZE 0027 ONLY]

1 3

1 3

1 21 2 1 2

WATER OUTLET,

WATER INLET,

1 3

L1

L2

GND

1 31 3

CPU

TRANSFORMER

VH1

VH2

CN1

CN2

CN4

VH3

VH4

CN8

1

2

3

REMOTE CONTROL WIRE

F1 —250V/1A

Y1

AC POWER SUPPLY

FLOW SENSOR

HIGH LIMIT 2

HIGH LIMIT 1

ELEMENT 2

ELEMENT 1

[SIZE 0011 ONLY]

150 kOhm

150 kOhm

240VAC 1-PH 60 Hz

IN REVIEW

UNCONTROLLED DOCUMENT IF PRINTED

12

Figure 6. Wiring Diagram for Models ELS 0005 and 0011

Figure 7. Wiring Diagram for Models ELS 0018 and 0027

Page 13

IN REVIEW

UNCONTROLLED DOCUMENT IF PRINTED

15. ILLUSTRATED PARTS LIST

MODELS

ELS 0005 and ELS 0011

15

1

14

12

MODELS

ELS 0018 and ELS 0027

3

5

6

4

8

7

9

10

1

15

13

11

16

12

14

2

5

7

8

6

10

9

13

4

11

16

13

Page 14

IN REVIEW

UNCONTROLLED DOCUMENT IF PRINTED

PART DESCRIPTION

1 017139F 017139F 017140F 017140F

Heating Element (Includes O-Ring)

2 N/A N/A N/A 017141F

Inlet Thermistor (Includes O-Ring)

3 017178F 017178F N/A N/A

Transformer 240V 60hZ

4 017161F 017161F 017161F 017161F

Water Sensor (Inlet & Outlet)

5 017143F 017143F 017144F(2) 017144F(3)

High Limit Manual Reset

6 017145F 017145F 017146F 017146F

Circuit Board with LED Display

7 017147F 017147F 017159F 017159F

Enclosure

8 017150F 017150F 017151F 017151F

Hall Effect Sensor

9 017152F 017152F 017160F 017160F

Terminal Block

10 017148F 017148F 017149F 017149F

11 017153F 017153F 017177F 017177F

12 017154F 017154F 017154F 017154F

13 017155F 017155F 017156F 017156F

14 017157F 017157F 017157F 017157F

15 017158F N/A 017158F N/A

16

Grounding Terminal

Triac 3-Wire

Knob

Flow Sensor

O-Rings (5)

Pipe Plug (Includes O-Ring)

Union (Set of 2) 017179F 017179F 017180F 017180F

ELS 0005 ELS 0011 ELS 0018 ELS 0027

14

Page 15

IN REVIEW

UNCONTROLLED DOCUMENT IF PRINTED

16. WARRANTY

LIMITED WARRANTY

SCOPE OF WARRANTY

Raypak, Inc. (Raypak) warrants to the original owner that the above model gas pool and spa heater (the

“Heater”) when installed in the contiguous 48 states of the United States of America with a pool or spa by

a properly licensed installer will be free from defects in materials and workmanship under normal use

and service for the Applicable Warranty Period. Under this Limited Warranty, Raypak will, at its option,

repair or furnish a replacement for any defective part of the HEATER. The repair or replacement will be

warranted for only the unexpired portion of the original Applicable Warranty Period, or the Extended

Warranty Period, as the case may be.

EFFECTIVE DATE

The Effective Date of Warranty coverage is the date of original installation if properly documented;

otherwise it is thirty (30) days after date of purchase, not to exceed one (1) year after date of

manufacture. All Applicable Warranty Periods specified in this Limited Warranty are measured from the

Effective Date.

APPLICABLE WARRANTY PERIOD – UNREGISTERED

If the HEATER is installed with a pool or spa, the Applicable Warranty Period is ninety (90) days from the

Effective Date, parts and labor, for the HEATER and component parts.

EXTENDED WARRANTY PERIOD – SERVICE PROFESSIONAL

If, within 90 days of the Effective Date, (i) the HEATER is installed

residential dwelling by a properly licensed installer (in accordance with applicable state and local laws

and regulations), and (ii) registered with Raypak (www.raypak.com) with an installation receipt attached

to such registration, then the Applicable Warranty Period is one (1) year from the Effective Date for the

HEATER and component parts, but specifically excluding the electrical heating element. The electrical

heating element will be warranted for a period of 90 days from the Effective Date. The HEATER will not

be eligible for the Extended Warranty Period if installed in a commercial application (hotel, condominium

or apartment common areas, etc.)

in a pool or spa at a single family

LABOR AND SHIPPING COSTS

This Limited Warranty covers the reasonable cost of labor for repairs or replacements covered by this

Limited Warranty, provided that said repairs or replacements are performed by a Raypak designated

service provider during the Applicable Warranty Period and Raypak has pre-authorized said repair or

replacement. This Limited Warranty does not cover any travel time or other labor costs. Furthermore,

unless applicable state law provides otherwise, this Limited Warranty does not cover any shipping costs

to and from the service provider or to or from the installation site. All of the foregoing costs and expenses

are your responsibility, unless applicable state law provides otherwise.

WARRANTY EXCLUSIONS

This Limited Warranty does NOT apply:

1. if the Heater has been moved from its original place of installation, or if the original owner no

longer owns the property where the original installation was made;

2. if the Heater is not properly installed with a pool or spa by a qualified licensed installer in

accordance with applicable local codes and ordinances, good trade practices, and the

manufacturer’s installation instructions;

3. if the rating plate(s) or serial number(s) are altered or removed;

4. if the Heater is modified in any way, or non-factory authorized accessories or other components

are used in conjunction with the Heater;

5. to damage, malfunctions or failures resulting from failure to properly install, operate or maintain

the Heater in accordance with the manufacturer’s instructions;

6. to damage, malfunctions or failures resulting from abuse, act of nature, accident, fire, flood,

freeze, lightning or the like;

7. to damage, malfunctions or failures resulting from connected system control devices;

8. to performance problems caused by improper sizing of the Heater or electric service voltage,

wiring or fusing;

15

Page 16

IN REVIEW

UNCONTROLLED DOCUMENT IF PRINTED

9. to use of any attachment, including without limitation, any energy saving device not authorized

by the manufacturer;

10. to damage, malfunctions or failures resulting from misuse or neglect, including but not limited to,

freeze-ups, operating the Heater with the cabinet door off, having flow restrictions or

obstructions between the Heater outlet and the pool/spa, electrolysis due to an improperly

installed salt chlorine generator, or not maintaining a proper chemical balance (PH level must be

between 7.4 and 7.8 and total alkalinity between 100 and 150 PPM. Total dissolved solids (TDS)

must be no greater than 3000 PPM. In salt water chlorinated pools, TDS must be no greater

than 6000 PPM).

HOW TO MAKE A WARRANTY CLAIM

You should immediately notify your dealer and provide proof of purchase model number serial number and date of

installation. Your dealer will contact Raypak for instructions regarding the claim and to determine the location of the

nearest authorized service center. If the dealer is not available, please contact Raypak warranty service at 805-278-

5300. When making a claim please be ready to supply the model number, serial number, date of original installation

and a description of the problem. Proper authorization MUST be obtained PRIOR to any repairs for the Limited

Warranty to apply. This Limited Warranty is VOID if the Heater is repaired or altered in any way by ANY

persons or agencies other than those authorized by Raypak. Raypak reserves the right at all times to inspect, or

require the return of, the defective Heater or component part and to verify warranty coverage at its factory

EXCLUSIVE WARRANTY-LIMITATION OF LIABILITY

THE LIMITED WARRANTY IS THE ONLY WARRANTY GIVEN BY RAYPAK IN CONNECTION WITH THE

HEATER AND ITS COMPONENT PARTS. NO ONE IS AUTHORIZED TO MAKE ANY OTHER WARRANTIES ON

RAYPAK’S BEHALF. ANY IMPLIED WARRANTIES, INCLUDING MERCHANTABILITY OR FITNESS FOR A

PARTICULAR PURPOSE, SHALL NOT EXTEND BEYOND THE APPLICABLE WARRANTY PERIOD SPECIFIED

ABOVE.

.

RAYPAK’S SOLE LIABILITY WITH RESPECT TO ANY DEFECT SHALL BE AS SET

FORTH IN THIS LIMITED WARRANTY. IT IS AGREED THAT RAYPAK SHALL HAVE

NO LIABILITY WHETHER UNDER THIS LIMITED WARRANTY OR IN CONTRACT,

TORT OR NEGLIGENCE OR OTHERWISE FOR CLAIMS FOR SPECIAL,

INCIDENTAL OR CONSEQUENTIAL DAMAGES (INCLUDING NO LIABILITY FOR

DAMAGE FROM WATER LEAKAGE), ALL OF WHICH ARE EXPRESSLY

EXCLUDED. SOME STATES DO NOT ALLOW LIMITATIONS ON HOW LONG AN

IMPLIED WARRANTY LASTS, OR FOR THE EXCLUSION OF INCIDENTAL OR

CONSEQUENTIAL DAMAGES, SO THE ABOVE LIMITATION OR EXCLUSION MAY

NOT APPLY TO YOU. THIS LIMITED WARRANTY GIVES YOU SPECIFIC LEGAL

RIGHTS, AND YOU MAY ALSO HAVE OTHER RIGHTS WHICH VARY FROM STATE

TO STATE.

We suggest you immediately record the model, serial number, date of original installation, receipt of purchase and

proof of installation by a qualified technician and retain this Limited Warranty Certificate in the event warranty service

is needed.

DO NOT RETURN THIS DOCUMENT TO RAYPAK. KEEP IT WITH YOUR POOL HEATER OR

BUSINESS RECORDS.

Register your product online at www.raypak.com/warranty

RAYPAK, INC., 2151 Eastman Avenue, Oxnard, CA 93030 • (805) 278-5300 FAX (800) 872-9725

Rheem Canada Ltd/Ltée. 125 Edgeware Road, Unit 1,Brampton, Ontario L6Y 0P5 CANADA

16

Page 17

ISO 9001

REGISTERED QUALITY MANAGEMENT SYSTEM

www.raypak.com

IN REVIEW

UNCONTROLLED DOCUMENT IF PRINTED

Raypak, Inc., 2151 Eastman Avenue, Oxnard, CA 93030 (805) 278-5300 Fax (805) 278-5468

Litho in U.S.A.

Loading...

Loading...