Page 1

CAT ALOG NO.: 5000.60 B

Effective: 4-09-08

Replaces: 3-15-99

T-2

Raypak B6000 Metasys™ N2

System Protocol Interface

T-2 Communications Interface

Raypak B6000 Boiler Controller

to Johnson Controls Metasys N2 Interface Card

Installation and Operating Manual

P/N 240717 Rev. 3

Page 2

TABLE OF CONTENTS

1.0 Product Specifications.........................................................................................................................3

2.0 Metasys Slave Port Functionality ......................................................................................................... 4

2.1 N2 Slave Communications .......................................................................................................4

2.1.1 Command/Replay Cycle .......................................................................................................4

2.1.2 N2 System Protocol Comands ..............................................................................................4

2.1.3 Command Error Checking ....................................................................................................5

2.1.4 Data Integrity ..........................................................................................................................5

2.2 N2 Point Layout ..................................................................................................................................5

3.0 Hardware Setup ................................................................................................................................... 6

3.1 1500 Interface Card Setup ........................................................................................................6

3.1.1 Connecting Power to the T-2 Card ........................................................................................6

3.1.2 Dip Switch Configuration .......................................................................................................6

3.1.3 1500 Jumper Configurations ................................................................................................7

3.2 B6000 Communications ....................................................................................................................7

4.0 N2 System Protocol Support ..............................................................................................................8

4.1 Attribute Commands .................................................................................................................8

4.1.1 Analog Input ...........................................................................................................................8

4.1.2 Binary Input ............................................................................................................................8

4.1.3 Analog Output.........................................................................................................................8

4.1.4 Binary Output .........................................................................................................................8

4.2 Controls Commands ..........................................................................................................................8

4.3 Device Identifier Code .........................................................................................................................8

5.0 Diagnostics ......................................................................................................................................... 9

5.1 LED Indicatiors .........................................................................................................................9

T-2 (Raypak B6000 Metasys N2 System Protocol Interface .....................................................................16

T-2 Installation and Mounting ....................................................................................................................17

Wiring 1500 - RPK .....................................................................................................................................18

B6000 System Control Board ....................................................................................................................19

Wiring: B6000 System Control To Gateway Cable ....................................................................................20

Check Your Power Source........................................................................................................................20

APPENDICES

Appendix A

Metasys Point Mapping

Appendix B

Communication cable connection diagrams

NOTE: Minimum 18 A WG , 105°C, stranded wire must be used for all low voltage (less than

30 volts) external connections to the unit. Solid conductors should not be used because they

can cause excessive tension on contact points. Install conduit as appropriate. All high voltage

wires must be the same size (105°C, stranded wire) as the ones on the unit or larger.

Page 3

1. Product Specifications

The Raypak Gateway card is a hardware product designed to be a communications front end for the Raypak

B6000 Boiler Control and Johnson Controls N2 compatible masters.

The product includes the following functionality:

Metasys N2 Slave Interface

· Binary Input, Binary Output, Analog Input and Analog Output data type commands

supported for primary control/monitoring of the B6000 operating parameters

· Supported Command/Subcommands:

0/4 : Poll Message No Acknowledge

0/5 : Poll Message with Acknowledge

0/9 : Status Update

1/1 : Read Analog Input Attributes

1/2 : Read Binary Input Attributes

1/3 : Read Analog Output Attributes

1/4 : Read Binary Output Attributes

2/1 : Write Analog Input Attributes

2/2 : Write Binary Input Attributes

2/3 : Write Analog Output Attributes

2/4 : Write Binary Output Attributes

7/2/3 : Override Analog Output

7/2/4 : Override Binary Output

F : Identify Device Type

The following commands are recognized, and acknowledged, but do not have impact on

the operation of the Gateway, and do not return any data:

0/0 : Time Update

0/8 : Warm Start

All other commands return a Bad Command Error Code

• Warning and Alarming functions preform on Analog Input and Binary Input data types

• Change of State Reponse buffering

Raypak B6000 Interface

• RS-485 electrical interface (as well as RS-232 and RS-422)

• Emulates Raypak Modem address and functionality

General Specifications

· Configuration via dip switches

Slave Address, Baud and Parity

Hardware Specifications

· 4"x5" form factor

· Two male 9-pin D shell connectors

· Slave communications port configurable for RS-232C or RS-422/485

· Communication status - Active and Fault for each port

· 9 to 30 VDC external power

3

Page 4

2.0 Metasys Slave Port Functionality

2.1 N2 Slave Communications

The Comminications Interface card supports the Johnson Controls Metasys™ N2 Protocol, as a slave, on

port 1. This capability allows the module to communicate data from the Raypak B6000 Boiler Control to

a Johnson Controls Metasys Master such as the Johnson Controls Companion™ or Metasys software.

The following discusses the functional capabilities of the card.

2.1.1 Command/Reply Cycle

Successful communications between a Slave and a Master will always consist of the following two

transactions:

Command: Message from master giving instruction to slave.

Reply: Response to command.

A slave station will respond to a master issued command in several ways.

Data Message: If the command was executed by the Slave, the response message will include the

data requested, or an acknowledgment that the command was executed.

Error Message: If the command could not be executed by the Slave, for whatever reason, an error

response message is transmitted to the master. The error response message contains an error code

indicating the cause of the error.

No Reply:If the master does not detect a reply within its time-out period, the master should retransmit the

command, before a time out error is issued. If the Slave could not decode the message or an error

occurred preventing the Slave from recognizing the message, no response will be issued.

2.1.2 N2 System Protocol Commands

The T-2 supports the commands and the data types necessary to enable control of the B6000 Controller

from an N2 master. The data types and the commands, as well as the associated addressable points are

overviewed below.

Data Types The N2 System protocol treats data as objects, with each data type having a different

structure and purpose. The data types recognized by the T-2 card are as follows:

· Binary Input (BI)

· Binary Output (BO)

· Analog Input (AI)

· Analog Output (AO)

Reading Attributes

The data objects contain attributes which describe several data points,

and some of its functionality. The contents of these attributes, including

object configuration, status, current value, and alarm/warning limits, can

be accessed with the following commands:

1/1 Read Analog Input Attributes

1/2 Read Binary Input Attributes

1/3 Read Analog Output Attributes

1/4 Read Binary Output Attributes

4

Page 5

Writing Attributes

The data object attributes can be configured by a master using the

following commands:

2/1 Write Analog Input Attributes

2/2 Write Binary Input Attributes

2/3 Write Analog Output Attributes

2/4 Write Binary Output Attributes

Controlling the B6000 Controller

Access to the control functions is made available through the Override

commands. The following commands allow the B6000 to be controlled:

7/2/3 Override Analog Output

7/2/4 Override Binary Output

Status Update

The host can issue a ‘Status Update’ command to the T-2. The response will contain device information (“1500-N2 Rev 1.0A”) as well as

current status information.

0/9 Status Update

Identify Device

When a master host first powers up, the ‘Identify Device’ command is

issued to all of the Slaves. In the case of the T-2 card, the Device Code

10 Hex is returned to the host. When the Gateway first powers up, it will

return and error code 0 in response to all commands from the host,

indicating to the host that a power up condition has occurred. The host

will respond with the “Identify Device’ command, telling the Communications Interface that the host has detected the power condition. The command code is:

2.1.3 Command Error Checking

When the Slave cannot execute a command, an error code is generated and returned to

the Master. Error codes generated at the Slave will usually be indicative of an illegal

function, an illegal address, or bad data.

2.1.4 Data Integrity

As in all good protocols, there must exist a level of data integrity checking to verify, with

some degree of assurance, the quality of the transmitted data. The N2 System protocol

supports a summation/modulus type of error checking on the address and data content of

the communication packet.

2.2 N2 Point Layout

A relationship between the N2 Point Address and the B6000 parameters has been set up to ease

control and monitoring of the unit. The relationship, by data object type, is shown in detail in

Appendix A.

F Identify Device

5

Page 6

3.0

Hardware Setup

3. 1 1500 Interface Card Setup

3.1.1 Connecting Power to the T-2 Card

The T-2 Card requires an external source of DC voltage. The DC source

voltage should be between 9V and 30V. The power is connected to TB1,

located near the two 9 pin serial port connections.

The connection to TB1 is as follows:

TB1-1 9-30 VDC (+)

TB1-2 Common (-)

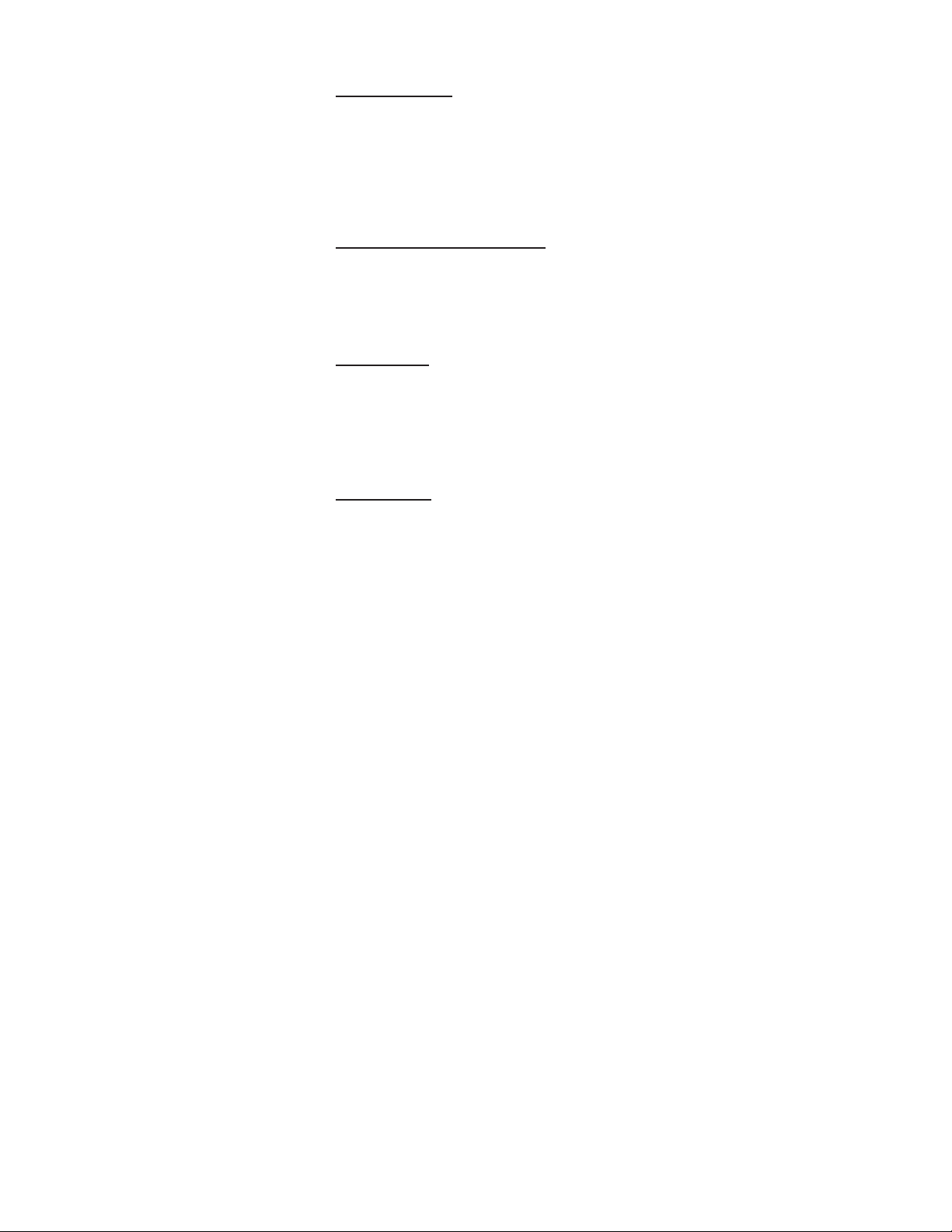

3.1.2 Dip Switch Configuration

The T-2 card is configured primarily through two sets of dip switches.

These switches are read initially on power up only.

The function of the dip switches is as follows (a value of one (1) is

registered when the switch is in the ON position):

SW 1

12345678

O

• •••••

F

F

••

↓

* Factory Settings

9600, No Parity, Address Bit 1

OFF Position: OFF Position:

ON Position: ON Position:

SW1 : Metasys Port Configuration

Switch

Position Function Positions

1 Baud Rate 3 2 1

2 Selection 000300

3 001600

4 Parity 5 4

5 Selection 0 0 None

SW 2

12345678

O

• ••••••

F

F

•

↓

0 1 0 1200

0 1 1 2400

1 0 0 4800

1019600

1 1 0 19200

1 1 1 19200

0 1 Odd

1 0 Even

1 1 Invalid

- *

- *

6 Not Used

7

8

SW2 : Metasys N2 Slave Address Configuration

Switch

Position Function Positions

1 Baud Rate 1 Address Bit 0 Value = 1

2 Address 2 Address Bit 1 Value = 2

3 Select 3 Address Bit 2 Value = 4

4 4 Address Bit 3 Value = 8

5 5 Address Bit 4 Value = 16

6 6 Address Bit 5 Value = 32

7 7 Address Bit 6 Value = 64

8 8 Address Bit 7 Value = 128

6

- *

Page 7

The parameters are defined as follows:

Baud Rate: The baud rate at which the module is to operate.

The baud rate is configured as follows:

Value Baud Rate

0 300 Baud

1 600 Baud

2 1200 Baud

3 2400 Baud

4 4800 Baud

5 9600 Baud*

6 19200 Baud

If a value outside of this range is selected,upon firing the power

up process the card’s LEDs will flash on 1/2 second intervals

until a correct address is selected. Powering down is not necessary.

Parity: The parity mode to be used by the module is defined by this word as follows:

0 No parity

1 Odd parity

2 Even parity

Metasys N2 Slave Address: Each of the separate drops off of a Johnson Controls Metasys Host must

have a different Slave address. The Slave address is selected by encoding the Slave address in a binary

form using the dip switches.

3.1.3 1500 Jumper Configurations

The 1500 Interface card has five sets of jumpers on the board. Generally, the default jumper positions will

be adequate for most applications, with JP4 and JP5 being the only jumpers that should ever need to be reviewed. For

completeness, we provide the following discussion on all of the jumper locations:

JP Discussion

1 Hardware Reset (Not used)

2 Isolated Port 2 Power

1-2 Non-Isolated (Default)

2-3 Isolated (Should not be used)

3 Isolated Port 2 Ground

1-2 Non-Isolated (Default)

2-3 Isolated (Should not be used)

4 Metasys Port (P1) Termination Resistor

1-2 Connect 120 Ohms across Rec lines

2-3 Disconnect 120 Ohms (Default)

5 Metasys Port (P1) RS-232 or RS-422/485 Select

1-2 RS-232 Select (Should not be used)

2-3 RS-422/485 Select (Default)

3.2 B6000 Communications

The B6000 Communications Interface has been hard coded to operate at the following default conditions:

Baud 9600

Parity Odd

Stop Bits 1

The 1500 Interface card emulates the modem card that is normally connected to the B6000.

7

Page 8

4.0 N2 System Protocol Support

The Raypak T-2 card supports several data read and write commands for the N2 System protocol. The

decision on which command to use is made depending on the type of data being addressed, and the level

of protocol support in the master equipment. The following sections detail the different commands supported by the module.

4.1 Attribute Commands

The T-2 Interface card supports the reading and writing to the data object attributes. Although read/

write support is available for all attributes (i.e., the card will accept, store, and respond with values

downloaded from a master), the T-2 does not use all aspects of the attribute functions. The following subsections discuss each data type, and in particular any functional aspects not supported by

the T-2.

4.1.1 Analog Input

The Analog Input data object is by far the most complicated of the objects. All aspects of

warning and alarm logic are supported by the T -2 ( i.e., the T-2 uses the low and high alarm/

warning limits to detect and trigger the object’s alarm bits).

Not supported however are the linear ranging parameters, the filter weight, and the offset.

The presumption is made that all analog input values gathered from the B6000 will come

in scaled. No scaling parameters are required from the master to support any of the

analog input values.

4.1.2 Binary Input

The Binary Input data object supports the normal state and alarm logic. The debounce and

accumulator attributes are not supported.

4.1.3 Analog Output

The Analog Output data object is used by the T-2 as a simple conduit for set points in the

B6000. No support is provided for scaling the output value, or for verifying the saturation

level of the output value. The value written from the Master is communicated to the Controller.

4.1.4 Binary Output

The Binary Output data object is implemented to respond directly to the commands received from the master. When the master sends an output command, either a bit set or

reset, the command is decoded and communicated to the Controller.

4.2 Control Commands

The 1500 card accepts control commands from a Master upon receipt of the following commands:

- Override Analog Output (Command 7/2/3)

- Override Binary Output (Command 7/2/4)

4.3 Device Identifier Code

When the T-2 receives an “Identify Yourself” command, the code 10 Hex is sent to the Master. The

10 Hex is the device ID used by Non-Johnson Controls hardware.

8

Page 9

5.0 Diagnostics

Several hardware diagnostics capabilities have been implemented using the LED indicator lights on the

front of the 1500 card. The possible conditions as indicated by the lights are:

5.1 LED Indicators

Several hardware diagnostics capabilities have been implemented using the LED indicator lights

on the front of the module. The possible conditions as indicated by the lights are:

NAME Color Status Indication

PORT Green Blinking The 1500 is receiving a valid response

ACTIVE from the Metasys Host

PORT 2 Green Blinking The 1500 is processing a B6000 command.

ACTIVE

PORT 1 Red ON The Metasys port has detected a communications

COMM error condition

ERR

PORT 2 R ed ON The 1500 card has detected a communications

FAULT error condition.

OFF The 1500 is not detecting a valid command. If the

master is transmitting, be sure all dip switches are set

correctly.

OFF Check cable connections

OFF No error conditions at this time.

OFF No error condition as at this time.

Should the configuration dip swicthes select an invalid address or an invalid baud

rate, the LED indicators will alternate in an on/off fashion on 1/2 second intervals

until correct values are selected.

9

Page 10

APPENDIX A

Metasys Point

Mapping

10

Page 11

Raypak Controller N2 Registers

Raypak Metasys Register Assignments

Analog Parm

Output Offset Description

AO1 28 Setpoint Day Setup (Desired water temp @ 70F)

AO2 29 Nitesetpoint Night Setpoing (Desired water temp @ 70F)

A O3 30 Ratio Out 1-200 = 0.1 - 20.0 in 0.1 increments

AO4 31 Throttling Delta T of all boilers in system

A O5 32 Modulating Step ( % )

A O6 3 3 Wait State Time (Sec)

A O7 34 Outdoor Cut off temperature

A O8 35 Control Band (degrees F tolerance from TAR)

A O9 36 Lead Boiler Number (1 to Number of Boilers online)

AO10 37 Number of Boilers on line

AO11 38 TP - Boiler Pump Delay (Min) Boiler #1

AO12 39 TP - Boiler Pump Delay (Min) Boiler #2

AO13 40 TP - Boiler Pump Delay (Min) Boiler #3

AO14 41 TP - Boiler Pump Delay (Min) Boiler #4

AO15 42 TP - Boiler Pump Delay (Min) Boiler #5

AO16 43 TP - Boiler Pump Delay (Min) Boiler #6

AO17 44 TP - Boiler Pump Delay (Min) Boiler #7

AO18 45 TP - Boiler Pump Delay (Min) Boiler #8

AO19 46 TS - Boiler Start Times (Sec) Boiler #1

AO20 47 TS - Ignition Time (Sec) Boiler #2

AO21 48 TS - Ignition Time (Sec) Boiler #3

AO22 49 TS - Ignition Time (Sec) Boiler #4

AO23 50 TS - Ignition Time (Sec) Boiler #5

AO24 51 TS - Ignition Time (Sec) Boiler #6

AO25 52 TS - Ignition Time (Sec) Boiler #7

AO26 53 TS - Ignition Time (Sec) Boiler #8

AO27 53 Time - Hrs

AO28 54 Time - Min

AO29 55 Time - DWK

AO30 57 Lead Change Hours

AO31 160 OC Dead band: Off T>)C, ON T<=OC-OC&B

AO32 161 Wait 1: Integral “I” Wait State Time

AO33 162 KPN : Propportional “P” Constant Numerator (0-255)

AO34 163 KPD : Propportional “P” Constant Denominator (0-255)

AO35 164 KDN : Differential “D” Constant Numerator (0-255)

AO36 165 KDD : Differential “D” Constant Denominator (0-255)

Binary Parm

Output Offset Description

BO1 16 6 Initialize B6000 by writing STAR 80h odh to unit STAR

BO2 167 Setback on/off control (0 = Off, 1 = On) - Write word value to B6000 4025h

11

Page 12

Raypak Controller N2 Registers

Raypak Metasys Register Assignments

Analog Parm

Input Offset Description

AI 1 60 Outdoor Temperature + 35

AI 2 61 Water Temperature + 35

AI 3 62 Controller Target Temp

AI 4 63 Valve Positions (0-100%) - Boiler #1

AI 5 64 Valve Positions (0-100%) - Boiler #2

AI 6 65 Valve Positions (0-100%) - Boiler #3

AI 7 66 Valve Positions (0-100%) - Boiler #4

AI 8 67 Valve Positions (0-100%) - Boiler #5

AI 9 68 Valve Positions (0-100%) - Boiler #6

AI 10 69 Valve Positions (0-100%) - Boiler #7

AI 11 70 Valve Positions (0-100%) - Boiler #8

AI 12 79 Setpoint Day Setup (Desired water temp @ 70F)

AI 1 3 80 Niteset Night Setpoing (Desired water temp @ 70F)

AI 14 8 1 Ratio Out 1-200 = 0.1 - 20.0 in 0.1 increments

AI 15 82 Throttling Delta T of all boilers in system

AI 16 83 Modulating Step ( % )

AI 17 84 W ait St ate Time (Sec)

AI 18 8 5 Outdoor Cut off temperature

AI 19 86 Control Band (degrees F tolerance from TAR)

AI 20 87 Lead Boiler Number (1 to Number of Boilers online)

AI 21 88 Number of Boilers on line

AI 22 89 TP - Boiler Pump Delay (Min) Boiler #1 -Combine w/ seconds registers

AI 23 90 TP - Boiler Pump Delay (Min) Boiler #2

AI 24 91 TP - Boiler Pump Delay (Min) Boiler #3

AI 25 92 TP - Boiler Pump Delay (Min) Boiler #4

AI 26 93 TP - Boiler Pump Delay (Min) Boiler #5

AI 27 94 TP - Boiler Pump Delay (Min) Boiler #6

AI 28 95 TP - Boiler Pump Delay (Min) Boiler #7

AI 29 96 TP - Boiler Pump Delay (Min) Boiler #8

AI 30 97 TS - Ignition Time (Sec) Boiler #1

AI 31 98 TS - Ignition Time (Sec) Boiler #2

AI 32 99 TS - Ignition Time (Sec) Boiler #3

AI 33 100 TS - Ignition Time (Sec) Boiler #4

AI 34 101 TS - Ignition Time (Sec) Boiler #5

AI 35 102 TS - Ignition Time (Sec) Boiler #6

AI 36 103 TS - Ignition Time (Sec) Boiler #7

AI 37 104 TS - Ignition Time (Sec) Boiler #8

AI 38 10 5 Time - Hrs

AI 39 106 Time - Min

AI 40 107 Time - DWK

AI 41 108 LEAD CHANGE

AI 42 109 Hrs Remaining

AI 43 1 1 1/112 Boiler Valve Up Times (Sec) #1

AI 44 113/114 Boiler Valve Up Times (Sec) # 2

AI 45 115/116 Boiler Valve Up Times (Sec) # 3

AI 46 117/118 Boiler Valve Up Times (Sec) # 4

AI 47 1 19/120 Boiler Valve Up Times (Sec) #5

AI 4 8 121/122 Boiler Valve Up Times (Sec) #6

AI 4 9 123/124 Boiler Valve Up Times (Sec) #7

AI 5 0 125/126 Boiler Valve Up Times (Sec) #8

12

Page 13

Raypak Controller N2 Registers

AI 5 1 127/128 Boiler Valve Down Times (Sec) # 1

AI 52 129/130 Boiler Valve Down Times (Sec) # 2

AI 5 3 131/132 Boiler Valve Down Times (Sec) # 3

AI 5 4 133/134 Boiler Valve Down Times (Sec) # 4

AI 5 5 135/136 Boiler Valve Down Times (Sec) # 5

AI 5 6 137/138 Boiler Valve Down Times (Sec) # 6

AI 5 7 139/140 Boiler Valve Down Times (Sec) # 7

AI 5 8 141/142 Boiler Valve Down Times (Sec) # 8

AI 59 150 OC Dead band: Off T>)C, ON T<=OC-OC- 4621h extra read registers

AI 60 151 Wait 1 : Integral “I” Wait State Time 4605h

AI 61 15 2 KPN : Proportional “P” Constant Numerator (0-25 460bh

AI 62 152 KPD: Proportional “P” Constant Denominator (0-2 460ch

AI 63 15 3 KDN : Differential “D” Constant Numerator (0-255) 460fh

AI 64 154 KDD: Differential “D” Constant Denominator (0-25 4610h

13

Page 14

Raypak Controller N2 Registers

Raypak Metasys Register Assignments

Binary Parm

Output Offset Description

Bl 1 58/0 Bit 0 = Night setback present Night Setback

Bl 2 59/0 Bit 0 = Fault Status (1=system fault) Controller LED Status

Bl 3 59/1 Bit 1 = call Out Request (1 = Yes) Controller LED Status

Bl 4 110/0 Bit 0 = Setbacl pm) 1_

Bl 5 71/0 Boiler Not On Line Boiler #1

Bl 6 /1 OK - Boiler Operation

Bl 7 /2 Low Water outoff

Bl 8 /3 Low Pressure Water

Bl 9 /4 Low Pressure Gas

Bl 10 /5 High Pressure Gas

Bl 11 /6 High Limit

Bl 12 /7 Thermostat - Operating aquastat (not fault)

Bl 13 /8 Manual Override

Bl 14 /9 Flow Switch

Bl 15 /10 No Pilot

Bl 16 72/0 Boiler Not On Line Boiler #2

Bl 17 /1 OK - Boiler Operation

Bl 18 /2 Low Water outoff

Bl 19 /3 Low Pressure Water

Bl 20 /4 Low Pressure Gas

Bl 21 /5 High Pressure Gas

Bl 22 /6 High Limit

Bl 23 /7 Thermostat - Operating aquastat (not fault)

Bl 24 /8 Manual Override

Bl 25 /9 Flow Switch

Bl 26 /10 No Pilot

B127 73/0 Boiler Not On Line Boiler #3

Bl 28 /1 OK - Boiler Operation

Bl 29 /2 Low Water outoff

Bl 30 /3 Low Pressure Water

Bl 31 /4 Low Pressure Gas

Bl 32 /5 High Pressure Gas

Bl 33 /6 High Limit

Bl 34 /7 Thermostat - Operating aquastat (not fault)

Bl 35 /8 Manual Override

Bl 36 /9 Flow Switch

Bl 37 /10 No Pilot

Bl 38 74/0 Boiler Not On Line Boiler #4

Bl 39 /1 OK - Boiler Operation

Bl 40 /2 Low Water outoff

Bl 41 /3 Low Pressure Water

Bl 42 /4 Low Pressure Gas

Bl 43 /5 High Pressure Gas

Bl 44 /6 High Limit

Bl 45 /7 Thermostat - Operating aquastat (not fault)

Bl 46 /8 Manual Override

Bl 47 /9 Flow Switch

Bl 48 /10 No Pilot

14

Page 15

Raypak Controller N2 Registers

Bl 50 75/0 Boiler Not On Line Boiler #5

Bl 51 /1 OK - Boiler Operation

Bl 52 /2 Low Water outoff

Bl 53 /3 Low Pressure Water

Bl 54 /4 Low Pressure Gas

Bl 55 /5 High Pressure Gas

Bl 56 /6 High Limit

Bl 57 /7 Thermostat - Operating aquastat (not fault)

Bl 58 /8 Manual Override

Bl 59 /9 Flow Switch

Bl 60 /10 No Pilot

Bl 61 76/0 Boiler Not On Line Boiler #6

Bl 62 /1 OK - Boiler Operation

Bl 63 /2 Low Water outoff

Bl 64 /3 Low Pressure Water

Bl 65 /4 Low Pressure Gas

Bl 66 /5 High Pressure Gas

Bl 67 /6 High Limit

Bl 68 /7 Thermostat - Operating aquastat (not fault)

Bl 69 /8 Manual Override

Bl 70 /9 Flow Switch

Bl 71 /10 No Pilot

Bl 72 77/0 Boiler Not On Line Boiler #7

Bl 73 /1 OK - Boiler Operation

Bl 74 /2 Low Water outoff

Bl 75 /3 Low Pressure Water

Bl 76 /4 Low Pressure Gas

Bl 77 /5 High Pressure Gas

Bl 78 /6 High Limit

Bl 79 /7 Thermostat - Operating aquastat (not fault)

Bl 80 /8 Manual Override

Bl 81 /9 Flow Switch

Bl 82 /10 No Pilot

Bl 83 78/0 Boiler Not On Line Boiler #8

Bl 84 /1 OK - Boiler Operation

Bl 85 /2 Low Water outoff

Bl 86 /3 Low Pressure Water

Bl 87 /4 Low Pressure Gas

Bl 88 /5 High Pressure Gas

Bl 89 /6 High Limit

Bl 90 /7 Thermostat - Operating aquastat (not fault)

Bl 91 /8 Manual Override

Bl 92 /9 Flow Switch

Bl 93 /10 No Pilot

15

Page 16

T-2 (Raypak B6000 Metasys N2 System Protocol Interface)

Contents

Quantity

T-2 1

EPROM (CPX.XNMn) in small black ESD box 1

Check packaging for damage or missing components

IMPORTANT NOTICE: These instructions are intended for the use by qualified personnel only, specifically trained

and experienced in the installation of this type of equipment and related system components. Installation and service

personnel may be required by some states to be licensed. If your state is such, be sure your contractor bears the

appropriate license. Only qualified persons shall attempt to repair this equipment.

WARNING: Improper installation, adjustment, alteration, service or maintenance may damage the equipment, create

a hazard resulting in asphyxiation, explosion, fire, electric shock, personal injury or property damage and will void the

warranty.

CAUTION: ONE SUPPLY SOURCE. TO REDUCE THE RISK OF ELECTRIC SHOCK, DISCONNECT ALL CONNECTIONS BEFORE SERVICING.

CAUTION: RISK OF ELECTRIC SHOCK. DISCONNECT SWITCH IS REQUIRED TO DE-ENERGIZE THE EQUIPMENT BEFORE SERVICING.

Thank you for selecting the Raypak B6000 Boiler Management System and the Raypak B6000 Metasys N2 System

Protocol Interface. It is our sincere hope that you will enjoy its power, ease of use and energy saving features.

Please follow the instructions carefully to insure proper installation.

FORW ARD

The Raypak Communications Interface is designed to allow the Johnson Controls Metasys System to monitor and

control the Raypak B6000 Boiler Management System.

16

Page 17

T-2 INSTALLATION AND MOUNTING

T-2 Module should be mounted on a permanent base not subject to vibrations, moisture or dust. It should be readily accessible, for

serviceability.

MECHANICAL INSTALLATION

Mount the System Protocol Interface within five (5) feet of B6000 System Control Box.

The Gateway Interface must be mounted vertically with conduit holes facing downward. Conduit holes are provided to accommodate

standard conduit fittings. Additional or larger conduit fitting that may be required should be located on the bottom of the module. Mount

the Interface with 3/8” or 1/4” hardware in four (4) places.

A Minimum of six (6) inches clearance on all sides is required and a minimum of eighteen (18) inches clearance from the front is required

for service access. The hinged side of the box is to the right and the clearance (minimum 3” from bolt hole on the right

side) should be sufficient to open the cover.

A sub-panel containing the disconnect switches and surge suppressors is required at or near the equipment locations(s).

for accessibility remove the lower interior panel, by removing the four (4) access screws.

INSTALL CONDUIT AS APPROPRIATE.

ELECTRICAL CHARACTERISTICS 120 VAC, 0.25A 60 Hz

ELECTRICAL INSTALLATION

120 VAC FEEDER CIRCUITS

Install a surge protection device sized appropriately for your installation.

Install separate disconnect means for each load. Pull in appropriately sized wire for equipment as defined by NEC

and/or local code.

It is strongly recommended that the Communications Interface B6000 System Control Module and the B6000 Boiler

Control Module be supplied from the same source power.

17

Page 18

WIRING 1500 - RPK

1. Open front door of System Protocol Interface Gateway Enclosure.

2. Remove Four Screws and the lower cover, revealing the field wiring blocks.

3. Attach wires from Johnson Controls Metasys N2 Interface Card (N2 BUSS) to the field wiring side of left

terminal block (N+, GND, N=, N- GND). Refer to diagram in this user manual.

4. Turn off power to the B6000 System Control Box.

5. Open front door of the B6000 System Control Box.

6. Remove four screws and the lower cover, revealing the field wiring blocks in lower left.

7. Run RS-485 cable (provided) to the lower left field wiring terminal in the B6000 System Control Box.

Attach wires to the upper four terminals as follows.

BLU/WHT to + ( 1)

WHT/BLU to - (2)

ORG/WHT to C OM (3)

SHIELD to G ND (4)

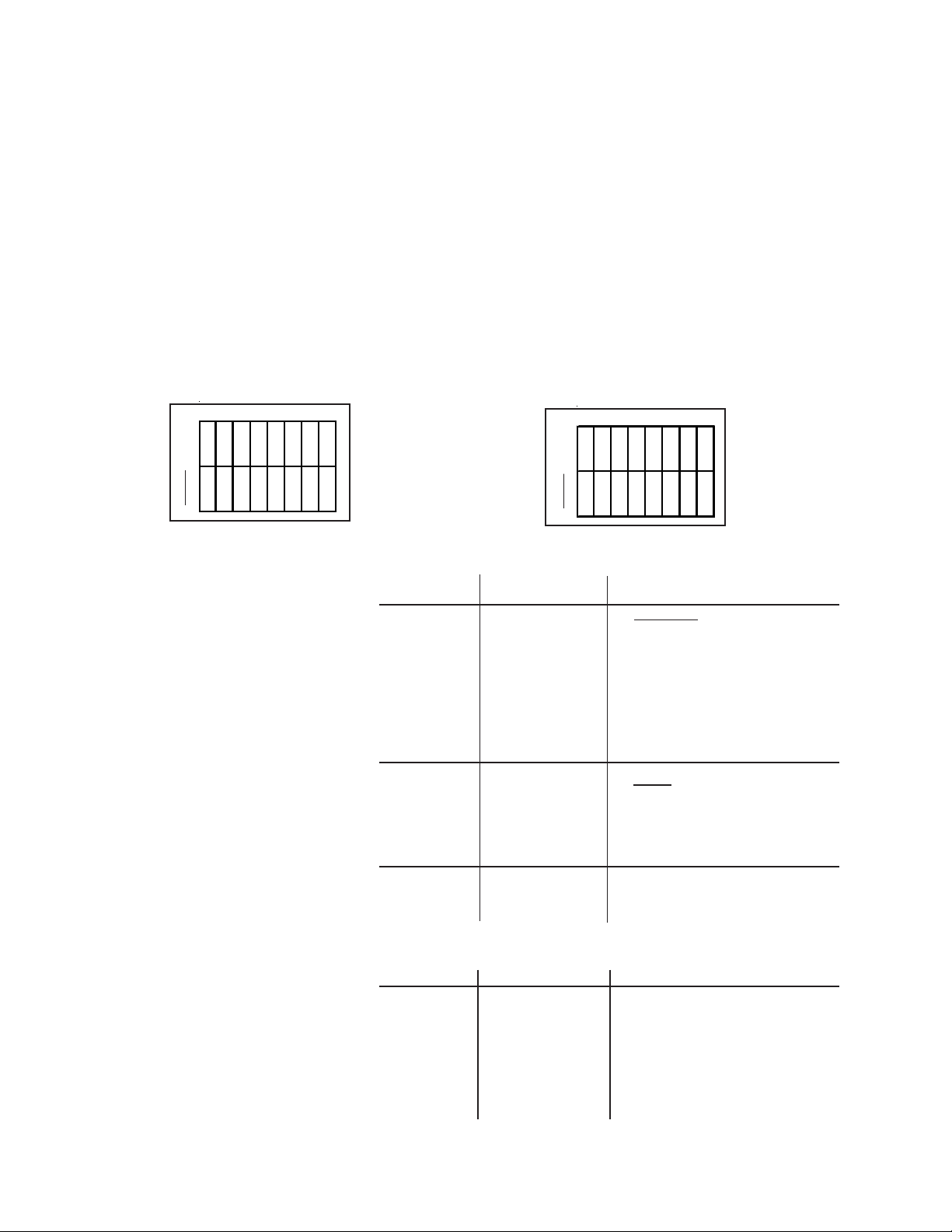

8. The EPROM (CPX.XNMn) in small black ESD box, must be installed in place of the current EPROM.

9. View the B6000 System Control Board picture on the next page. Note Location of the EPROM, U4.

10. Remove four screws holding upper panel with display screen and keypad. Carefully remove upper panel and

turn over exposing B6000 System Control board.

11. Using ESD procedures carefully remove EPROM labeled CP80NM to location U4.

12. Again using ESD procedures carefully replace with EPROM labeled CP80NM to location U4.

13. Reassemble B6000 System Control Box.

14. Turn power back on to B6000 System Control Box.

15. Connect 120 VAC (hot, Neutral, ground) to T-2 at right terminal block.

16. Reassemble.

18

Page 19

B6000 SYSTEM CONTROL BOARD

EPPROM, U4

19

Page 20

CHECK YOUR POWER SOURCE

CIRCUIT BREAKER PANEL

AC 108 Volts AC Minimum, 132 Volts MAX

AB = 108 Volts AC Minimum, 132 Volts MAX

BC = Must be less than 1.0 Volts AC

20

Page 21

APPENDIX B

Communication Cable

Connection Diagrams

21

Page 22

22

Page 23

www.raypak.com

Raypak, Inc., 2151 Eastman Avenue, Oxnard, CA 93030 (805) 278-5300 FAX (805) 278-5489

Litho in U.S. A.

Loading...

Loading...