Page 1

B6000 Boiler Management System

Single/Multiple Boiler Control System for Precise Temperature

Management and Delivery of Hot Water.

Raypak stocking representatives are wherever

you are, in the USA, Canada and Australia,

ready to provide expert assistance in selecting,

installing and servicing Raypak equipment.

Call the Raypak home office for the nearest

Raypak representitives, or log on to

www.raypak.com.

Catalog No. 5100.11D Eff. 01-01-04 Replaces 01-01-03 Litho in U.S.A. ©1994 Raypak, Inc.

Raypak, Inc. reserves the right to make product changes or improvements at any time without notice.

FIRST IN COPPER FINNED

TUBE DESIGN.

For over 50 years

1st in Quality

1st in Reliability

1st in Service

1st in Innovation

RAYPAK CORPORATE OFFICE AND

PRINCIPAL MANUFACTURING FACILITY

2151 Eastman Avenue, Oxnard, CA 93030

(805) 278-5300 FAX (800) 872-9725

Raypak Canada Ltd

2805 Slough Street, Mississauga, Ontario, Canada L4T 1G2

(905) 677-7999 FAX (905) 677-8036

U

L

Energy Management

System

www.raypak.com

U

L

®

U

L

®

C

MODBUS

COMPATIBLE

Honeywell

Landis Staefa

and others

University of Arkansas

and

Little Rock AFB

Little Rock, AR

Moorpark College

Moorpark, CA

Crown Plaza Hotel

Los Angeles, CA

Edgefield Manor

Troutdale, OR

Governor's Mansion

Austin, TX

Sun

Microsystems

Boston, MA

Lambeau Field

Green Bay, WI

La Fonda Resort

Sante Fe, NM

Liberte Eau Claire

Condominium

Calgary, AB

W.G. Davies Building

Moose Jaw, SK

St. Vital Centre

Winnipeg, MB

Brantford Casino

Brantford, ON

Diamler-Chrysler

Kokomo, IN

Hagley Museum

Wilmington, DE

Ypsilanti Public

Schools

Ypsilanti, MI

Forensic

Sciences

Centre

To ronto, ON

Raypak B6000

Controlling all of North America

The Hot Water Management Experts™

Page 2

Efficient Flame

Modulation

A key element in

reducing energy costs

and in total system

comfort is the ability

of a boiler to precisely

meet the heating load.

Raypak not only

pioneered modulating

technology for copper

finned tube boilers,

Raypak perfected it.

Fuel input is evenly

and accurately throttled to as low as 20% of boiler full fire rate to track any load

requirement. Two Raypak modulating boilers will throttle to 10% of the full fire

rate. Wasteful short cycling is eliminated, greatly improving operating efficiency.

System Characteristics

Set Point Adjustment Range:

40 to 220˚F (-4 to 116˚C)

(Accuracy: ± 1˚)

Control Band:

Adjustable from 1 to 99

Set Point Ratio:

None to 20:1

Minimum System Temperature:

105˚F (40˚C)

Sensor:

Integrated Circuit Chip, 4000 ft.

maximum distance from control

Ambient Conditions

Control: -40 to 185˚F (-40 to 85˚C)

Sensor: -65 to 300°F (-55 to 150°C)

Humidity: To 90% non-condensing

Electrical Characteristics

Input:

• Control - 120 VAC, 0.5A; 60 Hz

• Boiler - 120 VAC, 2.0A; 60 Hz

Proportional Plus Integral Plus

Derivative Control (P+I+D)

• LED Indicator Lights

• LCD Display

• Battery: Provides minimum

5-year life

• Opto-isolators reduce feedback

potential

Dimensions:

• System Controller (module):

15-3/16”L x 12-1/2”W x 4-3/4”D

• Boiler Monitor:

17-1/2”L x 18-3/4”W x 5-1/2”D

Water Sensor:

• Fits standard 1/2” wells

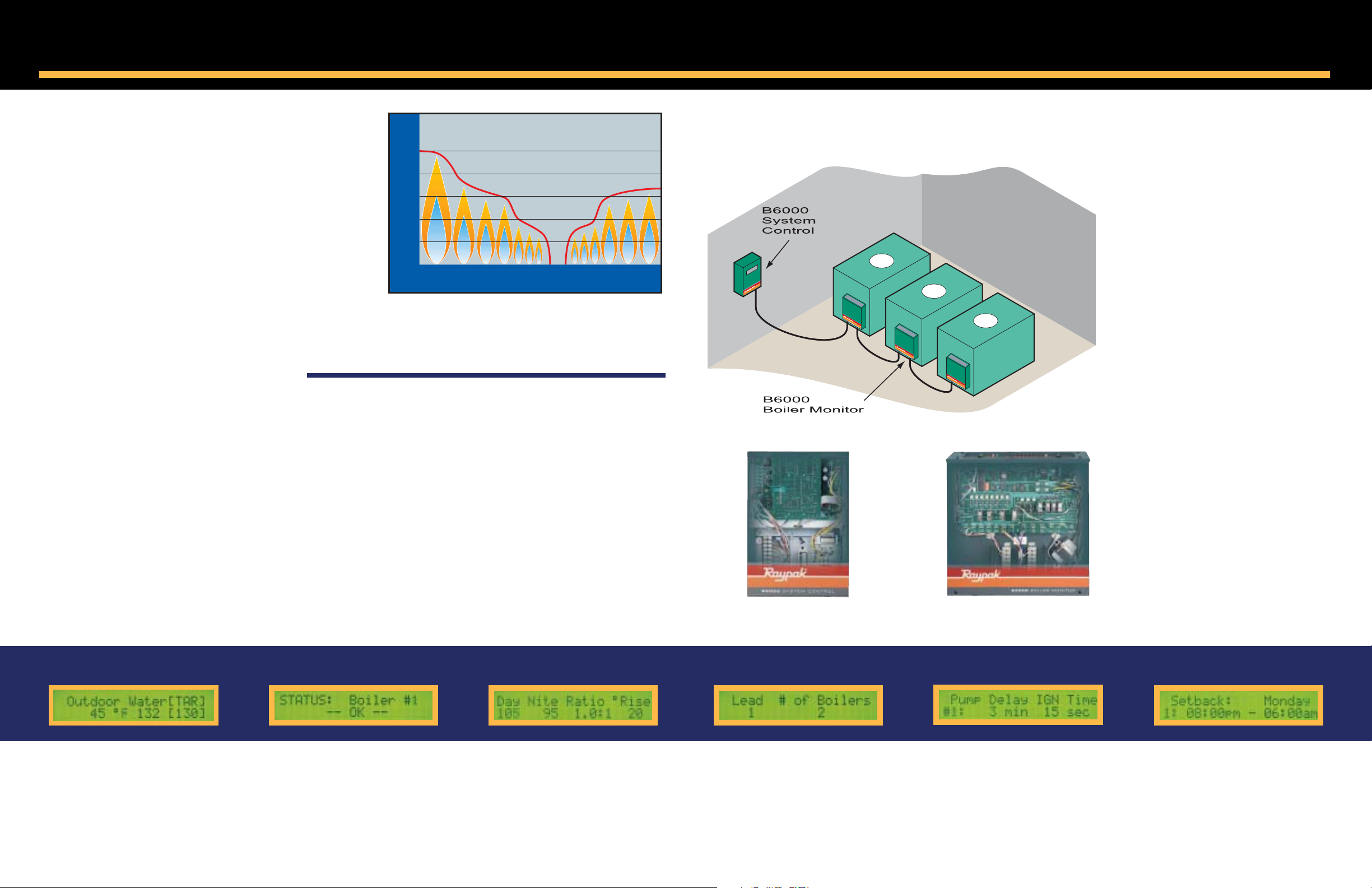

1. This status display gives the

user the current outdoor

temperature, the current water

temperature, and the calculated

target temperature.

2. This display gives the operational

status of each boiler. In the event of

a fault, its origin is displayed, a red

LED indicator light flashes, and an

alarm will sound at the System

Controller. A red LED indicator light

on the Boiler Monitor will also light

up.

3. The user can set the optimum

temperature set point, outdoor

reset ratio, throttling range, and

control band based on system

design and outdoor conditions.

4. The user selects the lead boiler in

a multi-boiler system.

Sequencing can also be

programmed automatically

with the optional Selecset™.

5. The user can select an

energy-saving pump delay of one to

ten minutes. The selectable

ignition time feature determines the

length of time the pilot will spark

without main burner ignition before

a fault condition is noted.

6. Selecset™ option allows the

operator to program setback times.

UL listed Energy Management

System

Single source responsibility – boilers

and controls

System efficiency – reduces

operating costs as much as 40%

Reduces boiler system maintenance

and service costs

Provides the ultimate in personal

comfort by precise control of water

temperature

User friendly with direct English

read-outs and easy programming

Easy to install – requires single 115

VAC connection, a three-wire

shielded communication cable to

each boiler monitor and a two-wire

shielded cable to each sensor.

Provides remote programming and

status evaluation

Diagnostic annunciation at boiler

and at remote-mounted system

control. Continuous monitoring of

up to 15 boiler operating

parameters. Audible alarm at

system control.

Controls up to 8 boilers

Applicable to all major codes

Displays temperature in Fahrenheit

or Centigrade

Default values represent standard

operating conditions for most

systems.

The B6000 system control has up to fifteen separate displays that have the capability to give system status or allow the user to program new data. Here are examples of six:

SPECIFICATIONS

FEATURES

Options

• T- 2

Metasys™ interface board allows for

seamless integration with Johnson

Controls’ energy management

system.

• T- 3

Modbus interface for use with

Honeywell™, Landis & Staefa™ and

other Modbus energy management

systems.

• T-10

Selecset™ (night setback) reduces

system temperature during up to six

off-peak periods each day. This

feature also allows for lead-lag

programming when using multiple

boilers.

The B6000 Boiler Management System is comprised of a Boiler Monitor

Module for each boiler, and one System Control Unit for each system.

System Control Boiler Monitor

• T-11

Modem option provides monitoring

and programming via telephone.

• T-12

Surge suppressor for 125V

applications

• T-13

Surge suppressor for 260V

applications

• T-14

Low-temperature control for remote

sensing such as heat pump

applications

•

•

•

•

•

•

•

•

•

•

•

•

•

%

INPUT

100

80

60

40

20

RAYPAK MODULATION

HEAVY

LOAD

MED

LOAD

LIGHT

LOADNOLOAD

LIGHT

LOAD

MED

LOAD

Loading...

Loading...