Page 1

TM

B6000

BOILER

MANAGEMENT

SYSTEM

Catalog No.: 5000.51J

Effective: 10-14-05

Replaces: 06-15-03

SYSTEM CONTROL BOILER MONITOR

Installation and Operating Manual

Part No. 240564

Page 2

is a registered trademark of UnderWriters Laboratories Inc. ®

is a registered trademark of UnderWriters Laboratories-Canada Inc.®

______________________________________________________________________________________

Before operating this product, please read these instructions completely.

Page 2

Page 3

B6000 BOILER MANAGEMENT SYSTEM (BMS)

Contents

Equipment Quantity

B6000 System Control 1

B6000 Boiler Monitor, Installed on Boiler(s) As Ordered

Outdoor Temperature Sensor Assy. (064140) 1

Water Temperature Sensor Assy. (064139) 1

Optional Equipment As Ordered

Check packaging for damage or missing components.

IMPORT ANT NOTICE: These instructions are intended for the use by qualified personnel only,

specifically trained and experienced in the installation of this type of equipment and related system

components. Installation and service personnel may be required by some states to be licensed. If your state

is such, be sure your contractor bears the appropriate license. Only qualified persons shall attempt to repair

this equipment. Repair must be according to these instructions.

WARNING: Improper installation, adjustment, alteration, service or maintenance may damage the

equipment, create a hazard resulting in asphyxiation, explosion, fire, electric shock, personal injury or property

damage and will void the warranty.

CAUTION: MORE THAN ONE (1) SUPPLY SOURCE. THIS CONTROL HAS THE POTENTIAL TO BE

CONNECTED TO MORE THAN ONE (1) ELECTRICAL SUPPLY SOURCE. TO REDUCE THE RISK OF

ELECTRIC SHOCK, DISCONNECT ALL CONNECTIONS BEFORE SERVICING.

CAUTION: RISK OF ELECTRIC SHOCK. MORE THAN ONE (1) DISCONNECT SWITCH MAY BE

REQUIRED TO DE-ENERGIZE THE EQUIPMENT BEFORE SERVICING.

PLEASE REGISTER

Before proceeding any further, please take a moment to complete the enclosed user registration form and

mail to Raypak, Inc., 2151 Eastman Avenue, Oxnard, CA 93030.

Page 3

Page 4

TABLE OF CONTENTS

PAGE

Contents 3

Getting Started 5

Foreword 5

Installation and Mounting 7

Mechanical Installation 7

Electrical Installation 8

Check Your Power Source 8

Air Temperature Sensor 9

Water Temperature Sensor 10

Important Configuration Note 12

Wiring - Air and Water Sensors 12

Communication (RS485) Wiring 13

Wiring: Power Source to Control and Boiler Modules 14

Power Test 15

Boiler Monitor Select Switch 16

Boiler Monitor Communications Jumper W1 17

Optional Boiler Monitor Control 18

Field Wiring - Single Boiler 18

Field Wiring - Multiple Boilers 19

Installation Verification Procedure 20

System Control/Display Familiarization 21

Power Up - Boiler Monitor 22

Power Up - System Control Module 23

Displays 23

Important (Start Alternate) 35

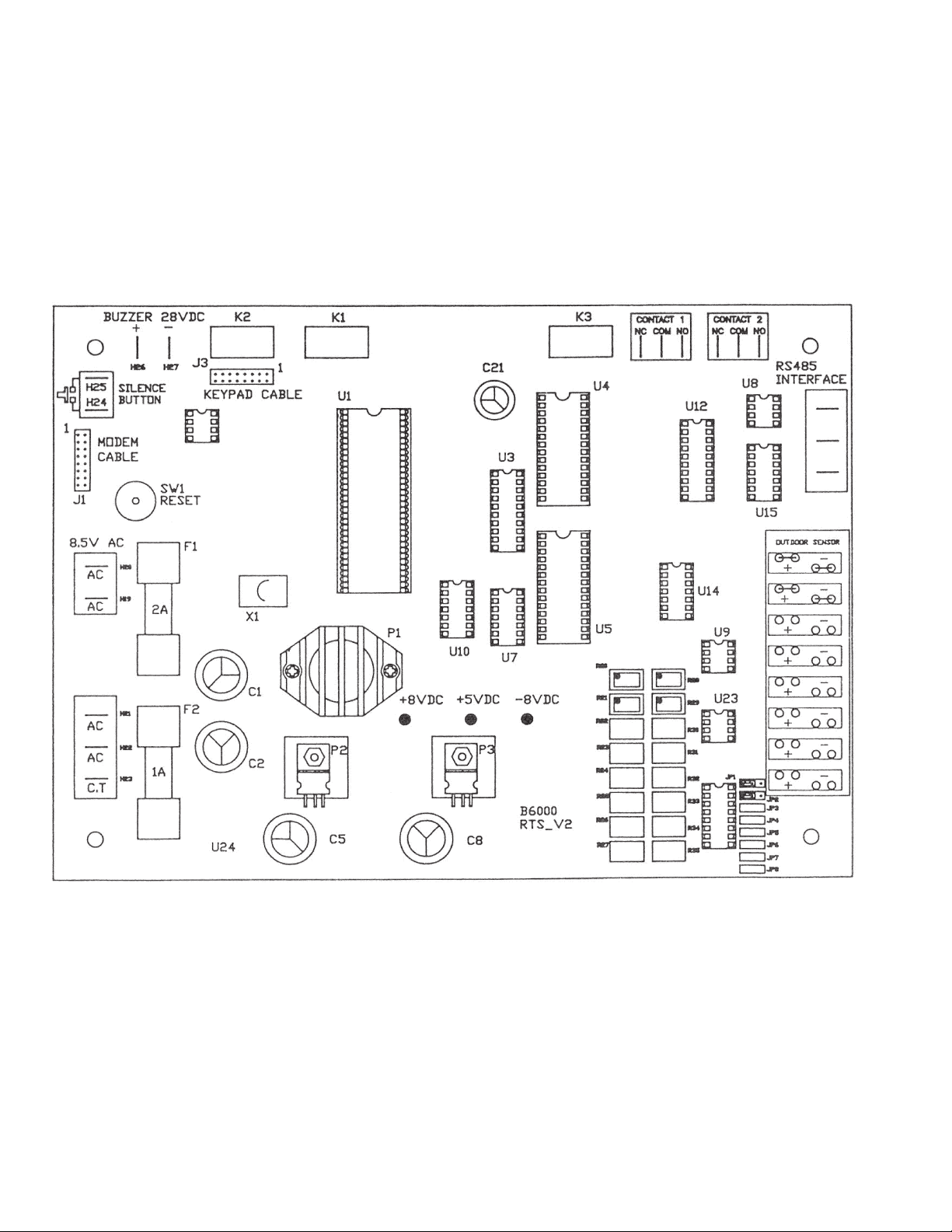

System Control Box 39

System Control Board Pictorial 40

Replacement Parts List 42

Boiler Monitor Control Box 44

System Settings 46

Troubleshooting Guide 47

Page 4

Page 5

Thank you for selecting the Raypak B6000 Boiler Management System (BMS). It is our sincere hope that

you will enjoy its power, ease of use and energy saving features.

GETTING STARTED

To learn about the B6000 BMS, simply install it and start using it. The following steps will outline the

things you will need for installation and to prepare it for use.

FOREWORD

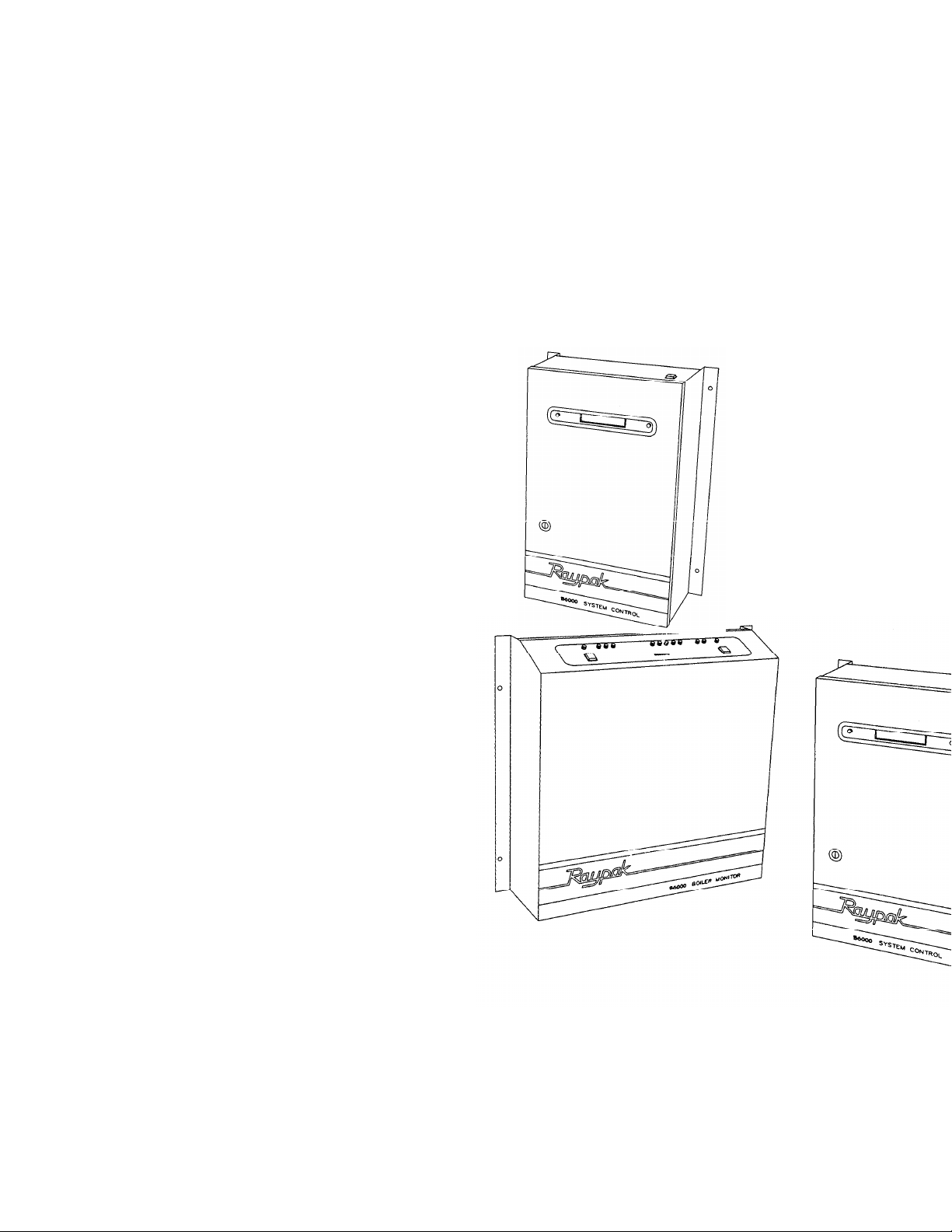

The B6000 Boiler Management System is comprised of a Boiler Monitor for each

boiler, one System Control for each system, an Outdoor Air Temperature Sensor and

a Water Temperature Sensor. The system is a microprocessor-based energy manage-

ment hot water control system that controls single or multiple boiler installations used for

hydronic heating and/or domestic hot water supply.

The B6000 BMS is designed to provide the ultimate in personal comfort, efficiency and

operation. The system requires minimal attention after initial setup. The system control to

boiler can be separated by up to 2000 feet. It is capable of being monitored from a remote

location, with an optional modem package and a Personal Computer (PC) equipped with

a modem. The Raypak Boiler Management System minimizes boiler operator attendance

and increases system reliability and cost effectiveness.

The System Control Module has

• A screen that displays the different operating characteristics of the system.

• A green light, to the left of the screen, that indicates normal system operating conditions.

• A red light, to the right of the screen, that flashes when a fault occurs.

• An alarm buzzer with a silencing switch. If the buzzer is silenced the red light will continue

to flash until the diagnosed fault is corrected.

• Buttons which are used to monitor and program the selectable system features.

• On board relays designed to control primary system pumps, combustion vent louvers

and/or other boiler accessories.

Page 5

Page 6

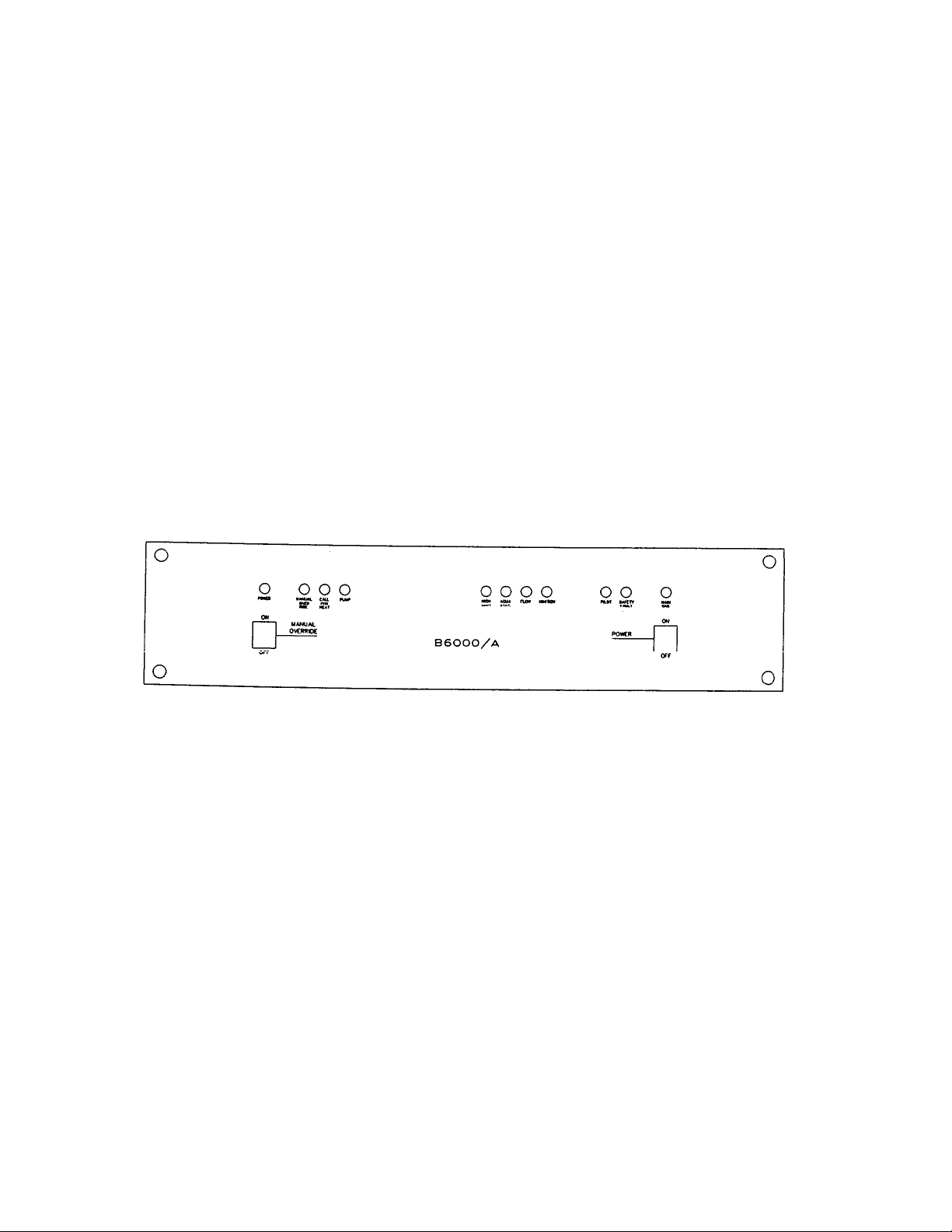

Each Boiler Monitor Module contains

• The boiler on-off power switch.

• The boiler manual override switch, which allows the boiler to operate independently

in the event of asystem control failure.

• Standard indicator lights:

"Power On" - green, indicates the boiler is powered.

"Manual Override" - red, indicates boiler is in manual override mode.

"Call for Heat" - amber, indicates there is a call for heat.

"Pump" - green, indicates pump circuit is energized.

"High Limit" - red, indicates boiler is off on high limit.

"Aqua Stat" or "Thermostat" - red, indicates boiler is off on operating control (may not

appear on all models).

"Flow" - red, indicates boiler fault - no flow.

"Ignition" - red, indicates ignition failure.

"Pilot" - yellow or amber, indicates pilot is lit.

"Safety Fault" - red, indicates fault in safety valve or safety circuit.

"Main Gas" - green, indicates modulating valve is energized.

• Boiler identification dip switch.

B6000/A Illustrated

Page 6

Page 7

INST ALLA TION AND MOUNTING

The System Control module should be mounted on a permanent base not subject to

vibrations, moisture or dust. It should be mounted with the display screen at a convenient

height for reading and for access to the alarm silence button located on the top of the cabinet.

Dimensions & Weight

Boiler Monitor System Control

18-3/4" W 12-1/2" W

5-1/2" D 4-3/4" D

17-1/2" L 15-3/16" L

21-1/4 lbs. 20 lbs.

MECHANICAL INSTALLATION

Install the B6000 System Control Module at a convenient place within 2000 feet of the

boiler(s). The B6000 System Control Module must be mounted vertically with conduit holes

facing downward. Conduit holes are provided to accommodate standard conduit fittings.

Additional or larger conduit fittings that may be required should be located on the bottom of

the module.

Mount the B6000 System Control with 3/8" or 1/4" hardware in four (4) places.

A minimum of six (6) inches clearance on all sides is required and a minimum of eighteen

(18) inches clearance from the front is required for service access. The hinged side of the

box is to the right and the clearance (minimum 3" from bolt hole on the right side) should be

sufficient to open the cover.

Page 7

Page 8

A sub-panel containing the disconnect switches and surge suppressors is required at or

near the equipment location(s).

For accessibility remove the lower interior panel, by removing the four (4) access screws.

INSTALL CONDUIT AS APPROPRIATE.

NOTE: Shielded cable, Belden #8132 or #9842 or equivalent, must be used to connect the

sensors to the System Control Module.

DIMENSIONS AND WEIGHT

System Control Module 19 1/2 lbs Boiler Monitor Module 21 1/4 lbs

15 3/16 L 17 1/2 L

12 1/2 W 18 3/4 W

4 3/4 D 5 1/2 D

ELECTRICAL CHARACTERISTICS

Control Module - 120 VAC, 0.5A; 60 Hz

Boiler Monitor Module - 120 VAC, 2.0A; 60 Hz

ELECTRICAL INSTALLATION

115 VAC FEEDER CIRCUITS

Install surge protection device(s) sized appropriately for your installation.

Install separate disconnect means for each load. Pull in appropriately sized wire for

equipment as defined by NEC and/or local code. All primary wiring will be 125% of minimum

rating.

It is strongly recommended that the System Control Module and the Boiler Control Module

be supplied from the same source power.

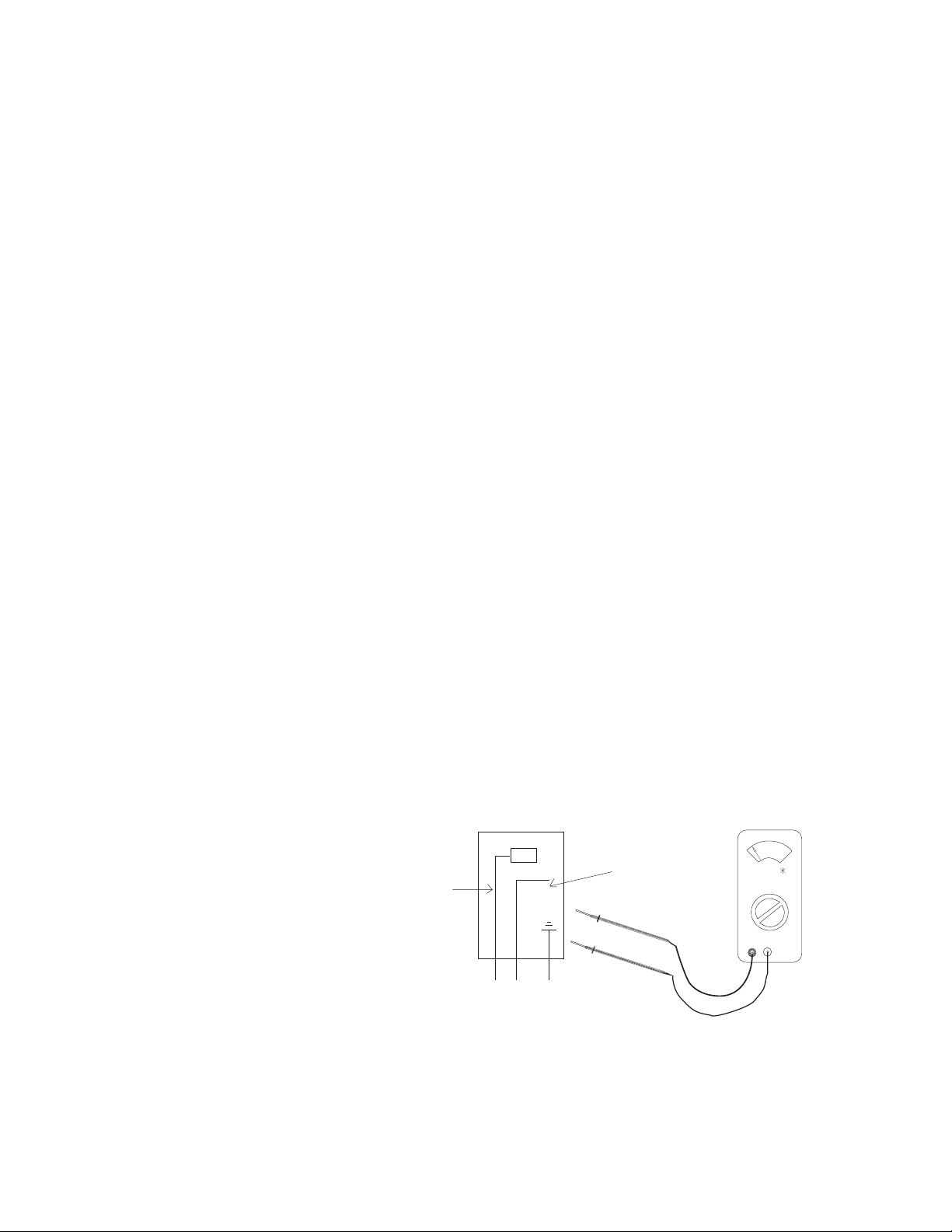

CHECK YOUR POWER SOURCE

Using a volt-ohm meter, check the following

voltages at the circuit breaker

Hot

BLACK

CB

WHITE

GROUND

A

B

Neutral (Return)

GREEN

C

VOM

PIDOMA

AC = 108 Volts AC Minimum, 132 Volts MAX

Hot to Ground

AB = 108 Volts AC Minimum, 132 Volts MAX

Hot to Neutral

BC = Must be less than 1.0 Volts AC

Neutral to Ground

Page 8

Page 9

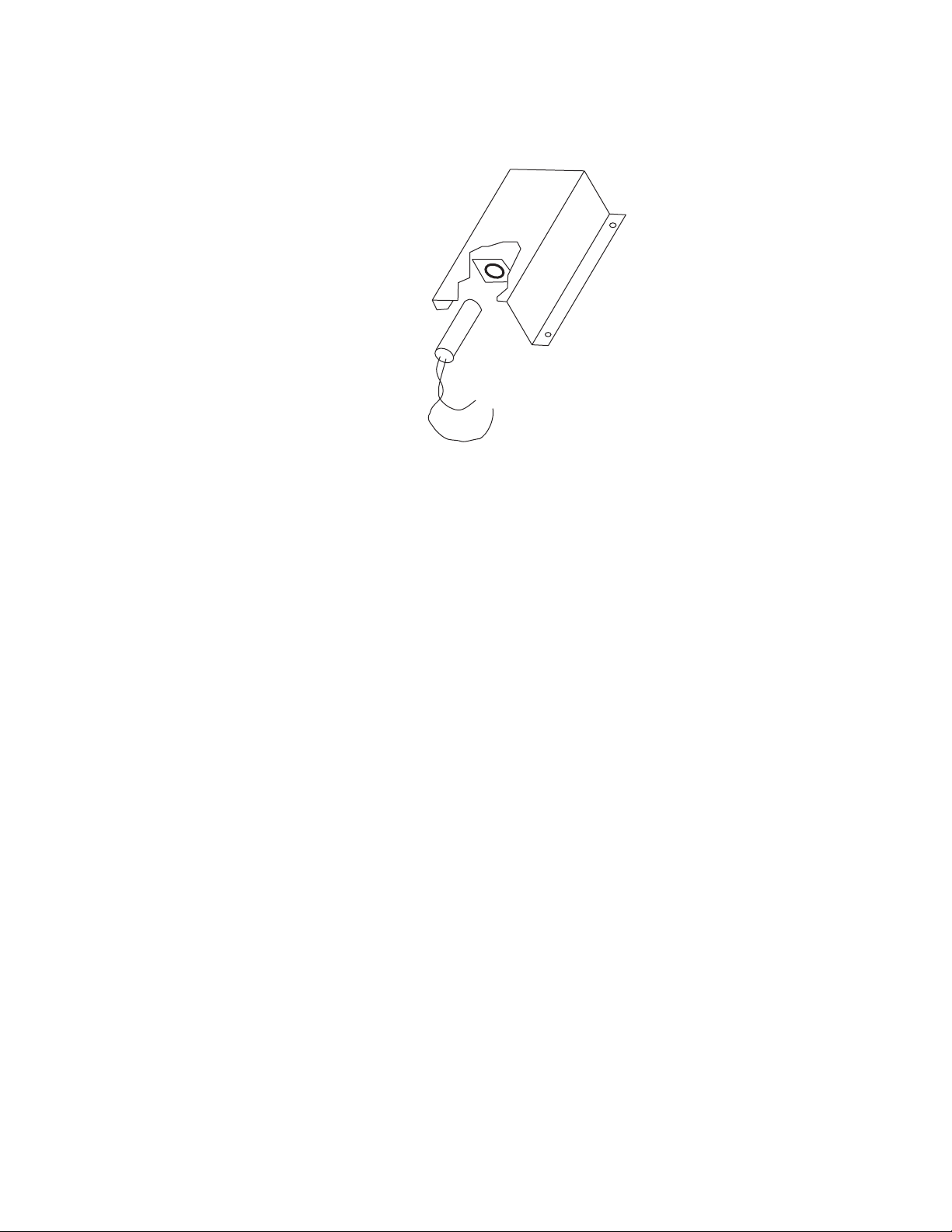

AIR TEMPERATURE SENSOR

• INSTALLATION

TYPICAL AIR TEMPERATURE SENSOR

Air Temperature Sensor Installation Notes:

Fig. #9040

• Locate on coldest side of building, usually (North or West) side.

• Install the sensor in a shaded area, out of direct sunlight.

• Locate no higher than 2/3 way up side of building or between 2nd and 3rd floor if building

is more than 3 stories tall.

• Shielded cable length not to exceed 4000 feet.

• Do not locate under an overhang, near wall corners, near drafts from stacks, air

moving devices, windows, doors, or balconies.

• Assure cable length does not exceed 4000 ft. Use larger gauge (Belden #9842)

cable if run is in excess of 100 ft.

• Install in conduit with no other wiring.

• Observe proper wire colors. Sensor is polarity sensitive.

Page 9

Page 10

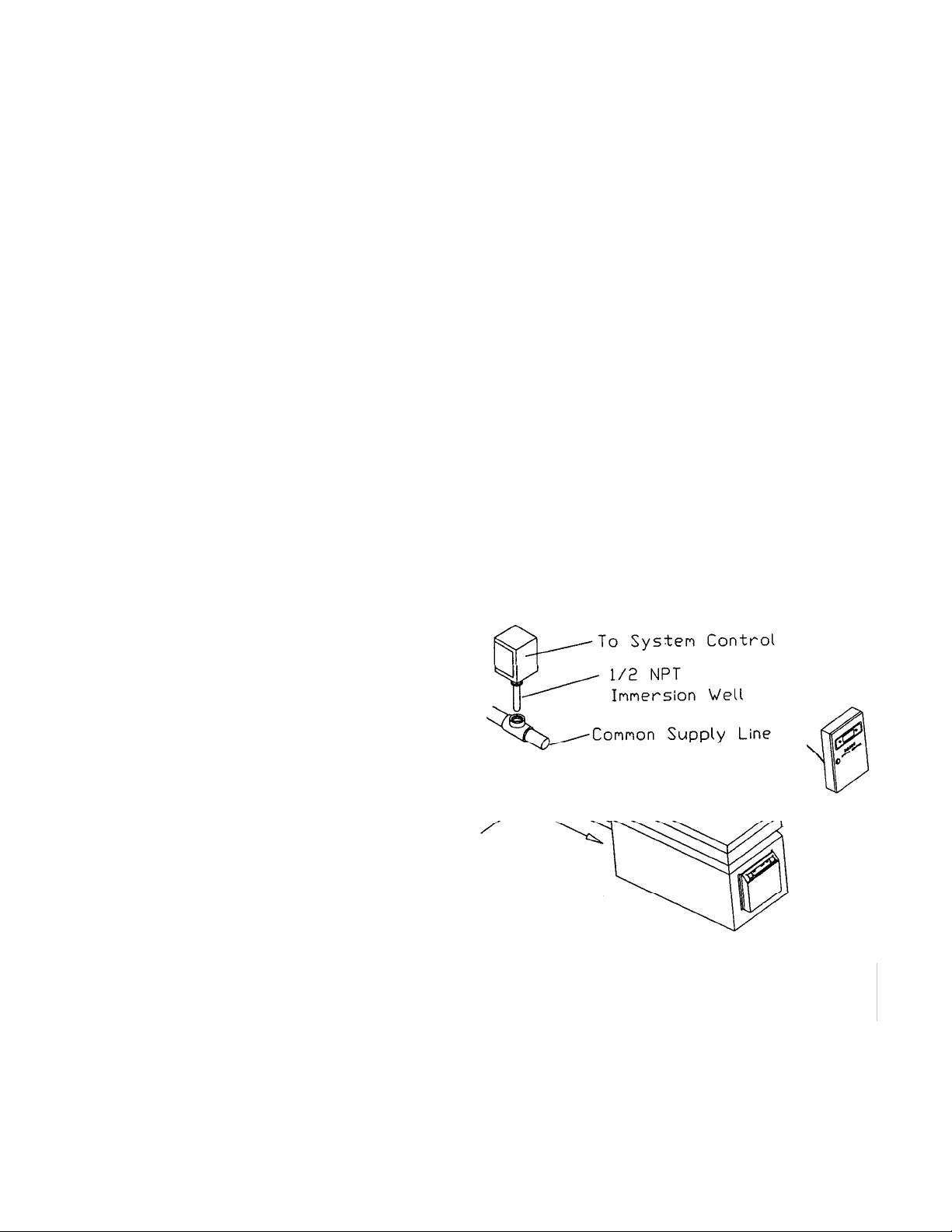

WATER TEMPERATURE SENSOR

• INSTALLATION

The water sensor

should be installed

in the system supply.

Return

Single Boiler

Supply

Multiple Boilers

Water Sensor

TYPICAL WATER SENSOR

Water Temperature Sensor Installation Notes:

• Locate sensor in system piping within a minimum of three (3) feet or prior to the first

take off connection, on the downstream side of the System Supply Loop.

• Assure cable length does not exceed 4000 ft. Use larger gauge (Belden #9842) wire

if run is in excess of 100 ft.

• Install in conduit with no other wiring.

• Observe proper wire colors. Sensor is ploarity sensitive.

Page 10

Page 11

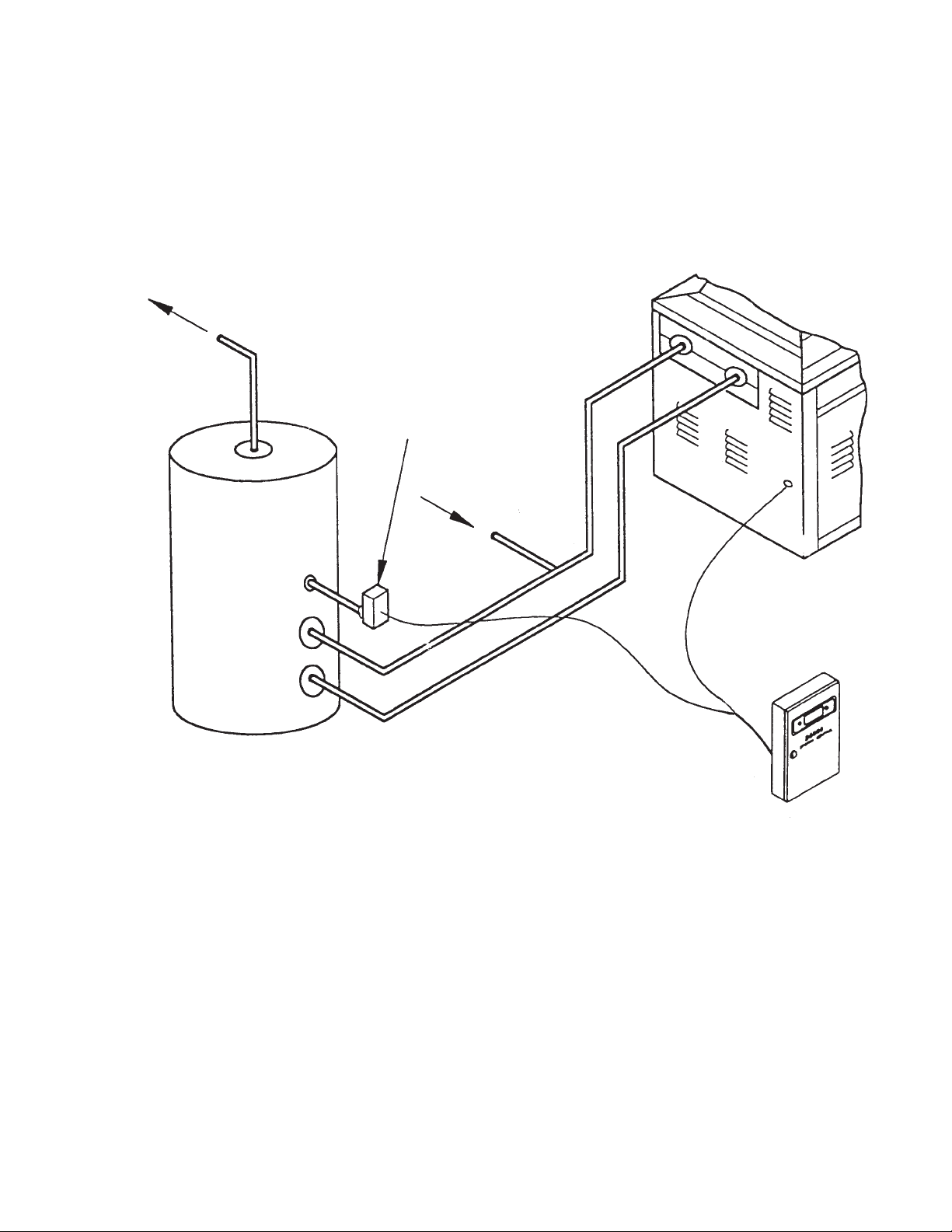

WATER TEMPERATURE SENSOR INSTALLATION (Domestic Hot Water Supply)

HOT

WATER

SUPPLY

STORAGE

TANK

IMMERSION WELL

WATER SENSOR

1/2 NPT

COLD

WATER

OUTLET

INLET

BOILER

INLET

OUTLET

B6000

SIMPLIFIED DIAGRAM OF TYPICAL PIPING

(PIPING LAYOUT MAY VARY PER SPECIFIC APPLICATION)

AIR TEMPERATURE SENSOR MUST BE INSTALLED ACROSS AIR TEMPERATURE

SENSOR CONTACTS. THE SENSOR IS NOT ACTIVATED AND CAN BE LEFT

STORED IN B6000 ENCLOSURE.

Page 11

Page 12

IMPORTANT

Configuration Note:

If your System Control Module is supplied with a single Field Wiring

Teminal Strip use "Alternate" wiring. (See page 36-38)

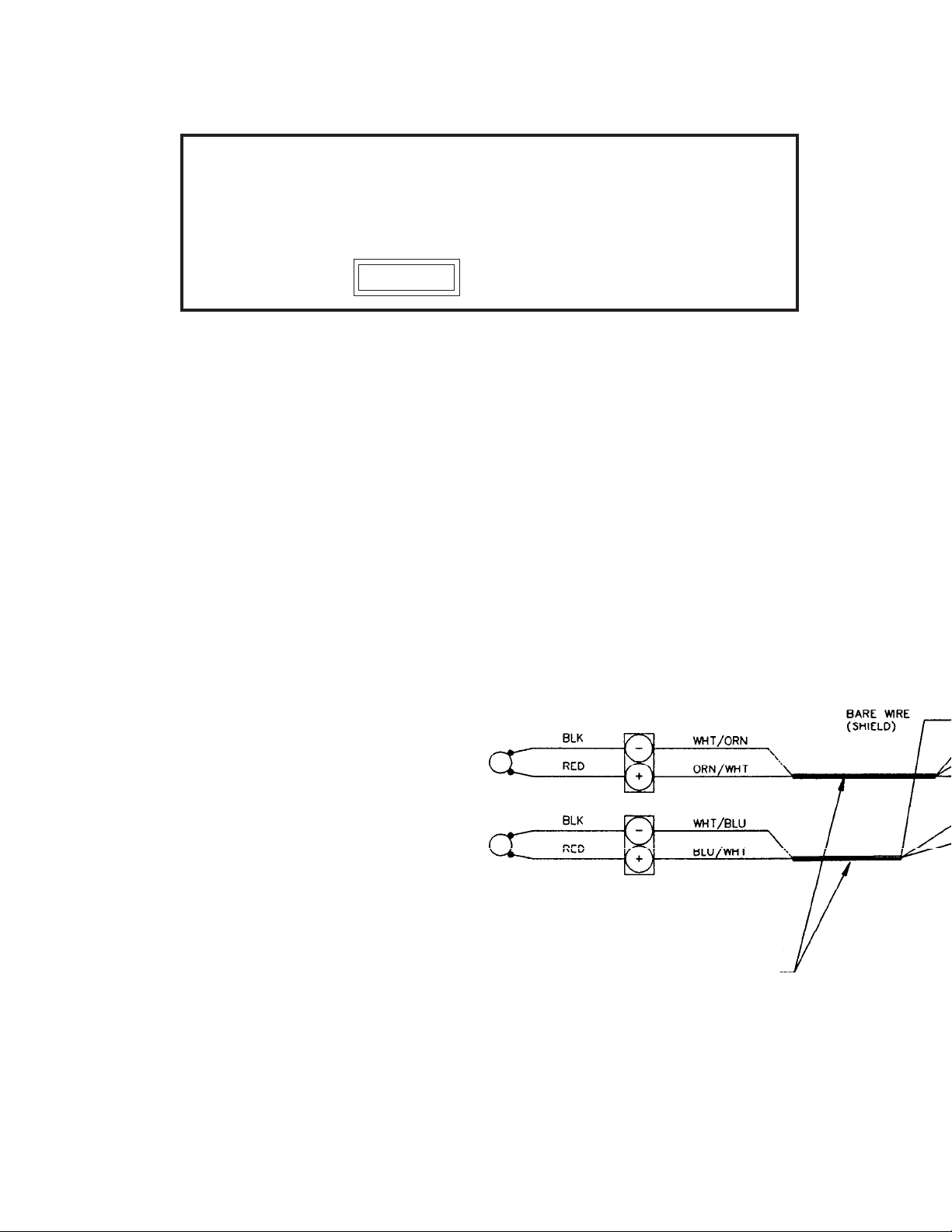

WIRING - AIR AND WATER SENSORS

TO THE SYSTEM CONTROL MODULE

WATER

SENSOR

OUTDOOR

SENSOR

SYSTEM CONTROL

TERMINAL TB 2

BELDEN #8132

OR BELDEN #9842

NOTE: Tighten terminal strip

clamping screws 20 lbs - In

(2.26N.m) Breakage from over

torquing is not covered under

warranty.

Use copper conductors only.

Page 12

For supply connections use

wires sized on the basis of 60°C

Ampacity and rated Min. 90°C

(194°F).

Page 13

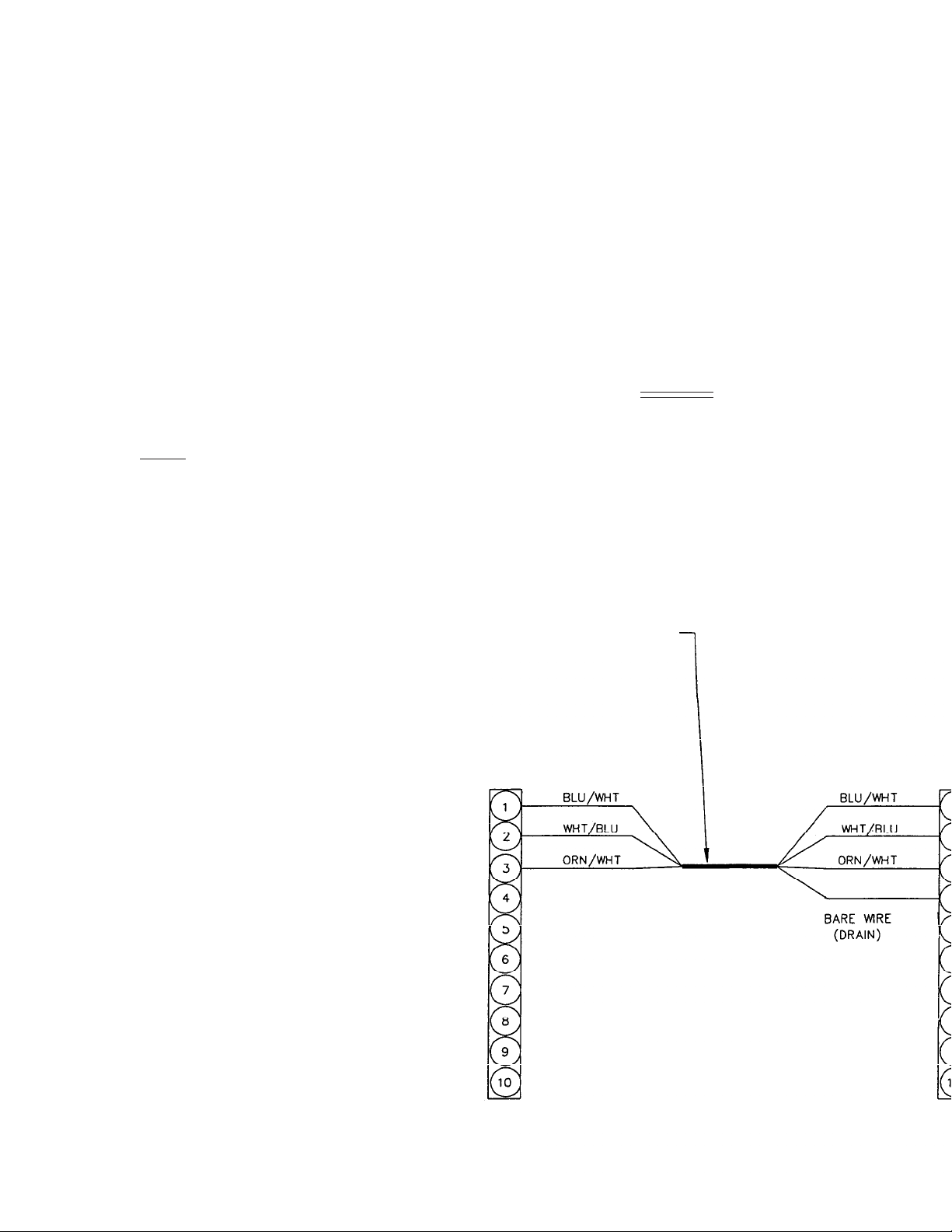

COMMUNICATION (RS 485) WIRING

System Control

Boiler Monitor

• Use Belden #9842 Cable Or Equivalent (See Note). Polarity must be observed. Make

use of wire color coding to ensure proper polarity.

• The shielding foil wrapper - bare wire (drain) - MUST be grounded.

Grounding is done at the System Control Module only. DO NOT ground at Boiler

Monitor.

•

Note: Equivalent shielded cable must be suitable for RS 485 communication

applications; must have 100-140 ohm impedance; and less than 30 picofarad per foot

capacitance.

• Install in conduit with no other wiring.

BELDEN #9842

NOTE: Tighten terminal strip

clamping screws 20 lbs - In

(2.26N.m) Breakage from over

torquing is not covered under

warranty.

Use copper conductors only.

For supply connections use

wires sized on the basis of 60°C

Ampacity and rated Min. 90°C

(194°F).

BOILER MONITOR SYSTEM CONTROL

TERMINAL TB 3 TERMINAL TB2

RS 485 Communications Cable Schematic

Page 13

Page 14

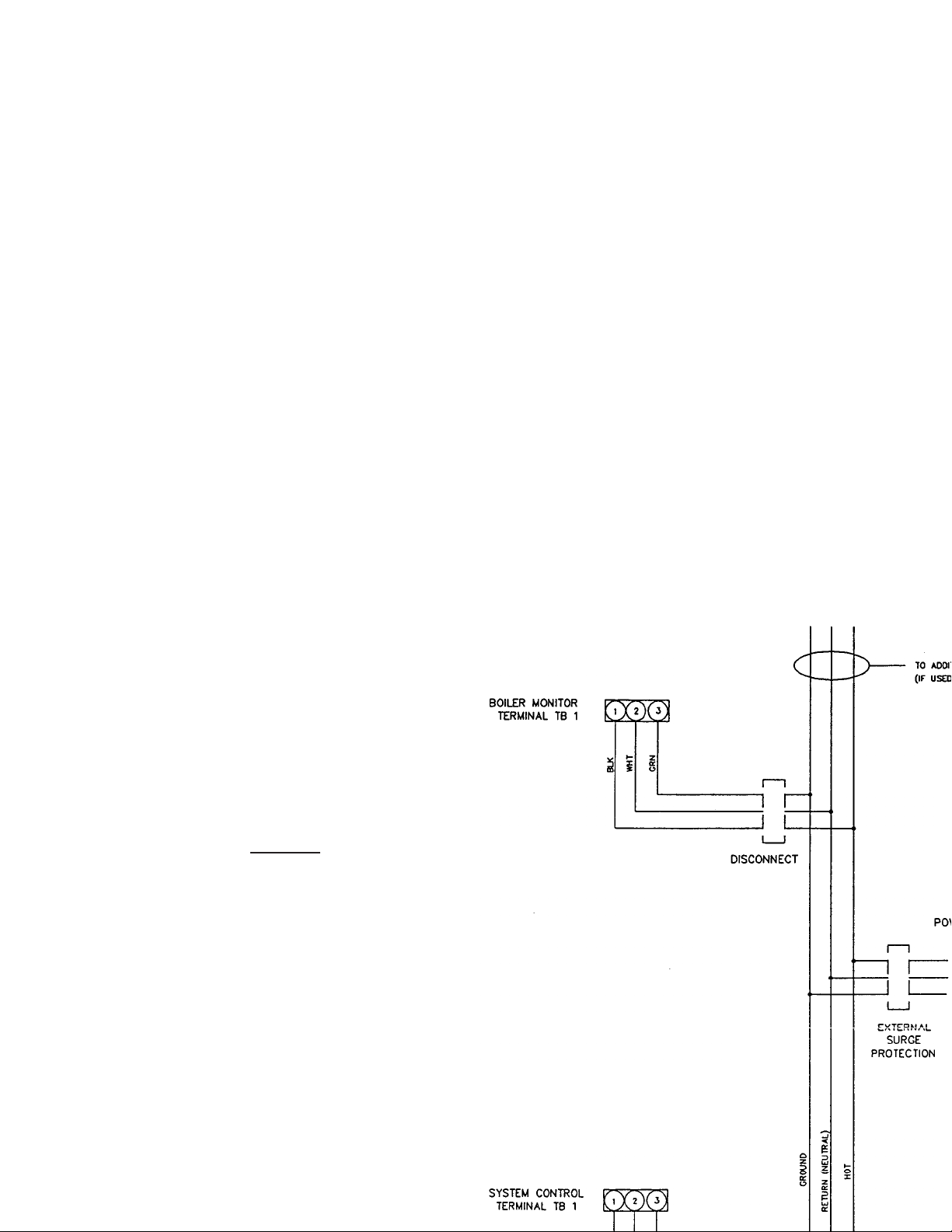

WIRING:WIRING:

WIRING:

WIRING:WIRING:

ules.ules.

ules.

ules.ules.

P P

P

P P

oo

ww

er Sourer Sour

o

w

er Sour

oo

ww

er Sourer Sour

ce to System Contrce to System Contr

ce to System Contr

ce to System Contrce to System Contr

ol and Boiler Mod-ol and Boiler Mod-

ol and Boiler Mod-

ol and Boiler Mod-ol and Boiler Mod-

NOTE: Tighten terminal strip

clamping screws 20 lbs - In

(2.26N.m) Breakage from over

torquing is not covered under

warranty.

Dia. #9

• Observe proper Polarity.

• Observe proper wire colors.

• Provide external surge suppressor capable of maintaining system integrity.

• Provide overload protection and disconnect means as required by code and for

equipment serviceability.

• Conduit can not be used as the ground. (Must be "WIRED" ground).

• Very Important: Grounding electrode conductor - shall be used to connect the

equipment grounding conductors, the equipment enclosures, and where the system

is grounded, the grounded service conductor to the grounding electrode.

Page 14

Use copper conductors only.

For supply connections use

wires sized on the basis of 60°C

Ampacity and rated Min. 90°C

(194°F).

Page 15

POWER TEST

CHECK POWER

Utilizing a Volt-Ohm-Meter (VOM) monitor the following on the "System Control Module"

and "Boiler Monitor(s)" for proper voltage levels.

POWER TEST TABLE

Module Test Points Indication

System Control TB1-1- TB1-2 108 VAC to 132 VAC

System Control TB1-1- TB1-3 108 VAC to 132 VAC

System Control TB1-2- TB1-3 LESS THAN 1 VAC

System Control TB1-1 - I 108 VAC to 132 VAC

System Control TB1-2 - I LESS THAN 1 VAC

System Control TB1-3 - I LESS THAN 0.5 VAC

Module Test Points Indication

Boiler Monitor TB1-1- TB1-2 108 VAC to 132 VAC

Boiler Monitor TB1-1- TB1-3 108 VAC to 132 VAC

Boiler Monitor TB2-2- TB2-3 LESS THAN 1 VAC

Boiler Monitor TB1 -1 - I 108 VAC to 132 VAC

Boiler Monitor TB2 -2 - I LESS THAN 1 VAC

Boiler Monitor TB3 -3 - I LESS THAN 0.5 VAC

FROM: BOILER MONITOR to SYSTEM CONTROL

Boiler Monitor System Control Indication

TB1 - 1 TB1 - 1 LESS THAN 0.5 VAC

TB1 - 2 TB1 - 2 LESS THAN 0.5 VAC

TB1 - 3 TB1 - 3 LESS THAN 0.5 VAC

TB1 - 2 TB1 - 3 LESS THAN 0.5 VAC

Page 15

Page 16

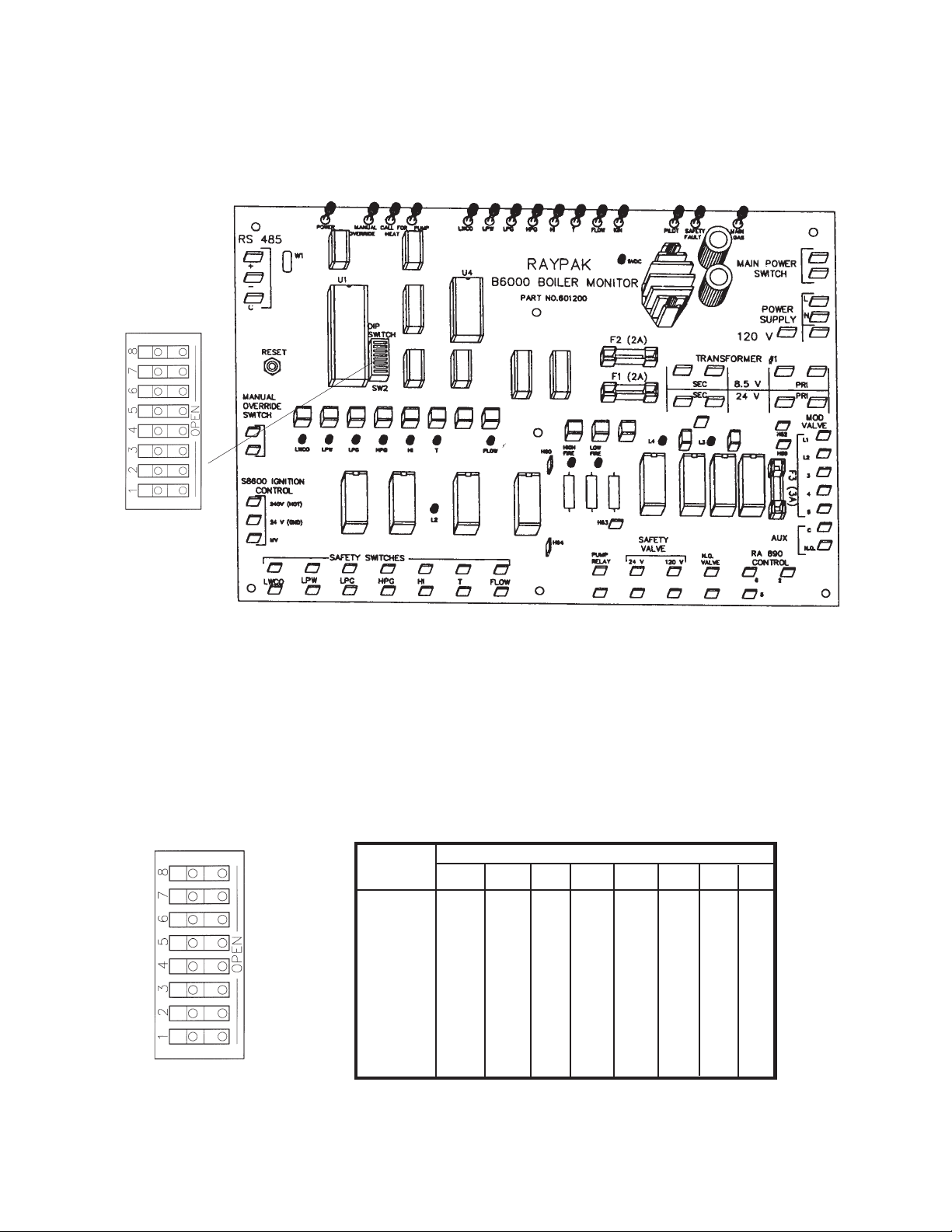

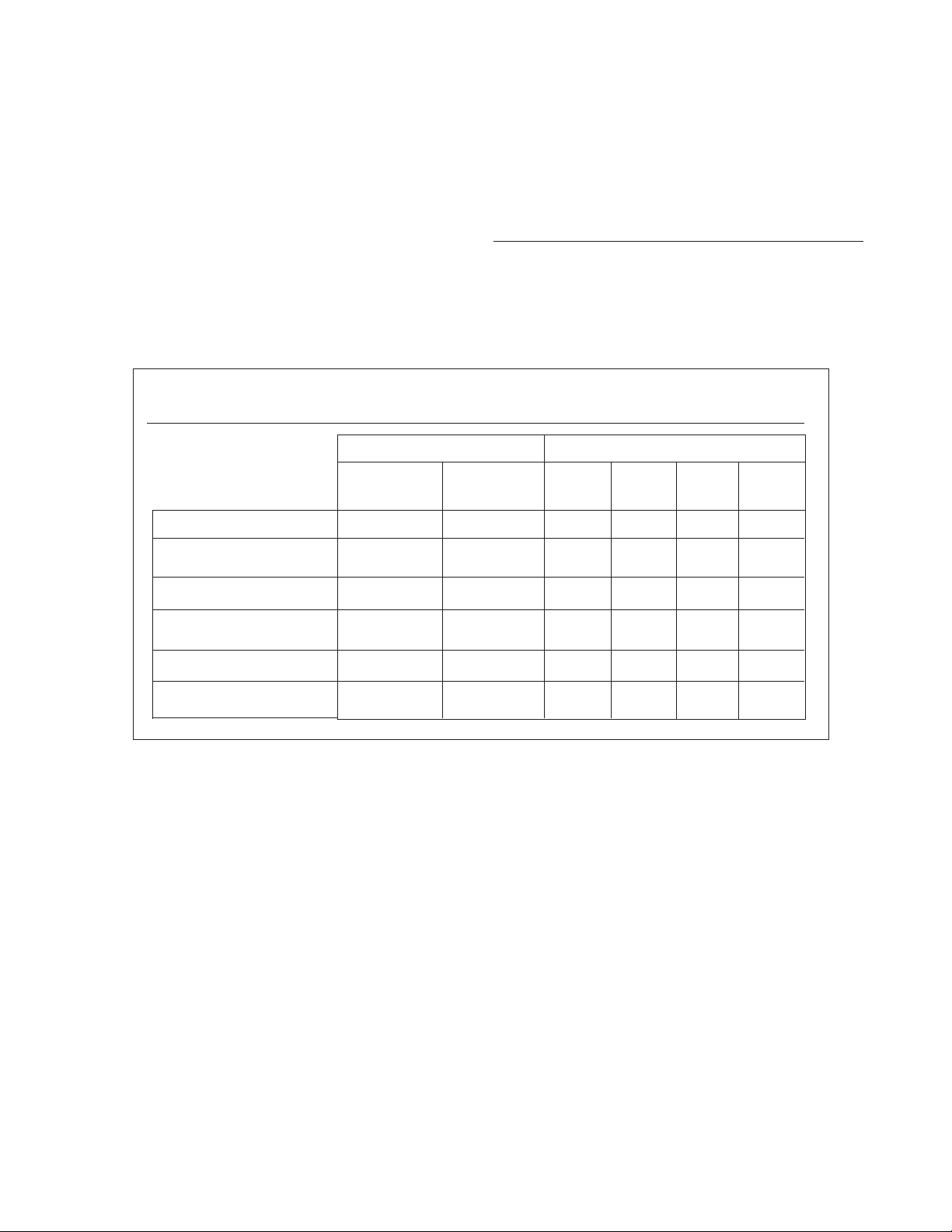

IMPORTANT: The Boiler Monitor control board has a series of dip switches which identify the boiler(s) (SW2). It is required that the switches be set as shown in the switch

position table shown below.

BOILER MONITOR CARD PICTORIAL

BOILER MONITOR SELECT SWITCH

SWITCH POSITION

BOILER NUMBER

SWITCH 1234 5678

8 OOOO OOOO

7 OOOO OOOO

6 OOOO OOOO

5 OOOO OOOO

4 OOOO OOOO

3 OOOO XXXX

2 O O X X O O X X

1 O X O X O X O X

SWITCH O = Open X = Closed

Page 16

Page 17

BOILER MONITOR COMMUNICATIONS JUMPER W1

• Located in the upper left hand corner of the "LAST" Boiler Monitor board.

• NOTE: The jumper indicates to the System Controller logic that the "Last" wired

boiler has been communicated with over the RS485 BUSS Link.

• Definition: The "LAST" wired boiler is physically wired with the greatest wire

length from the "System Control" or is the last wired boiler for a single or multiple

boiler installation.

• On a single boiler make sure the W1 Jumper has been installed.

W1

BOILER MONITOR CARD PICTORIAL

On boiler systems the jumper (W1) MUST BE installed on the "Last" wired boiler. This

is located on the Boiler Monitor board in the upper left hand corner, adjacent to the

RS485 terminals.

On Multiple boiler systems the W1 jumper must be removed from all Boiler Monitor

boards except on the "Last" wired boiler.

For normal boiler operation the dip switch settings can be utilized to define any of the

boilers as #1 thru # (maximum), independent of the "Last" wired boiler position.

Page 17

Page 18

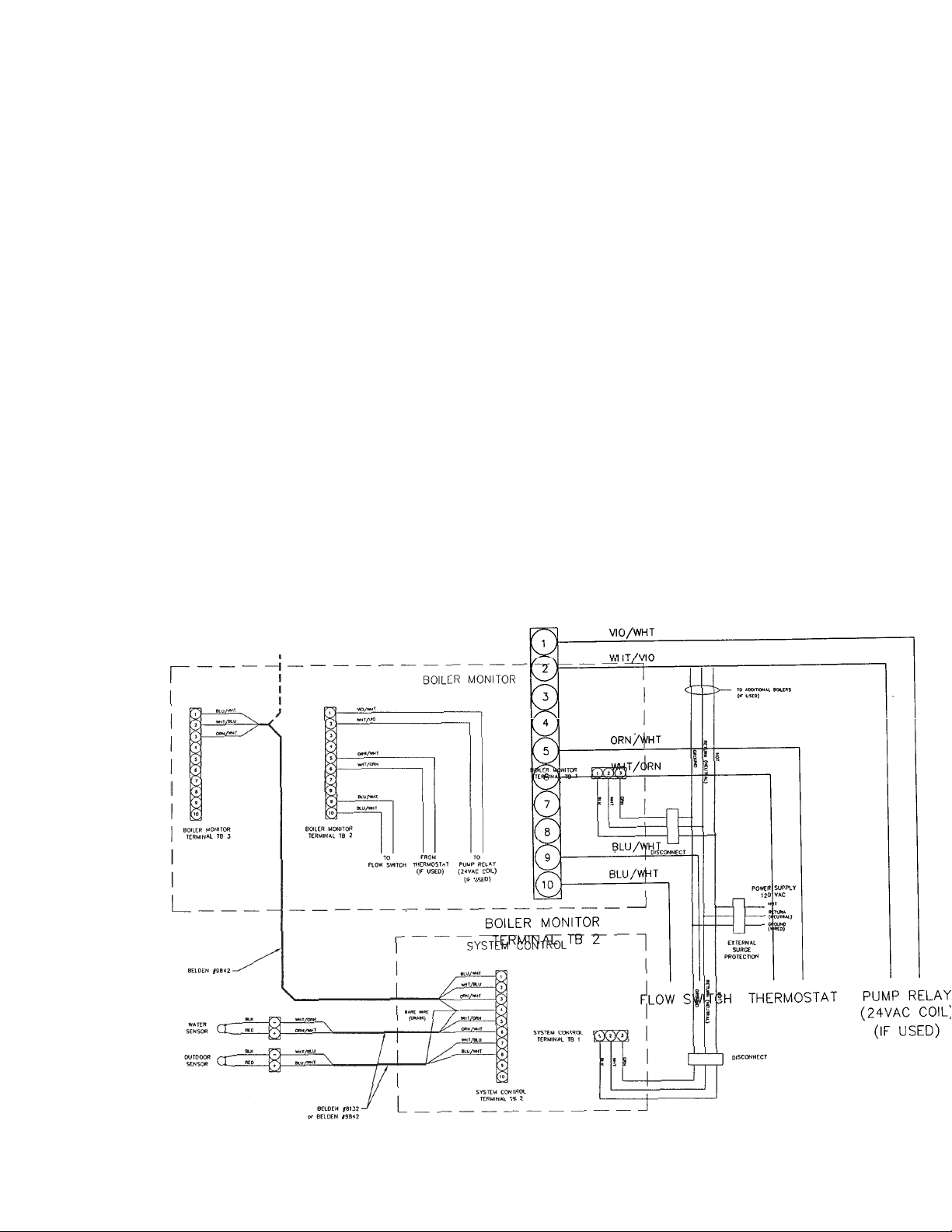

OPTIONAL BOILER MONITOR

• Wiring

• Contact Authorized Raypak representative for other wiring options

NOTE: Tighten terminal strip

clamping screws 20 lbs - In

(2.26N.m) Breakage from over

torquing is not covered under

warranty.

Use copper conductors only.

For supply connections use

wires sized on the basis of 60°C

Ampacity and rated Min. 90°C

(194°F).

Dia. #2

Field Wiring - Single Boiler

Dia. #7

Page 18

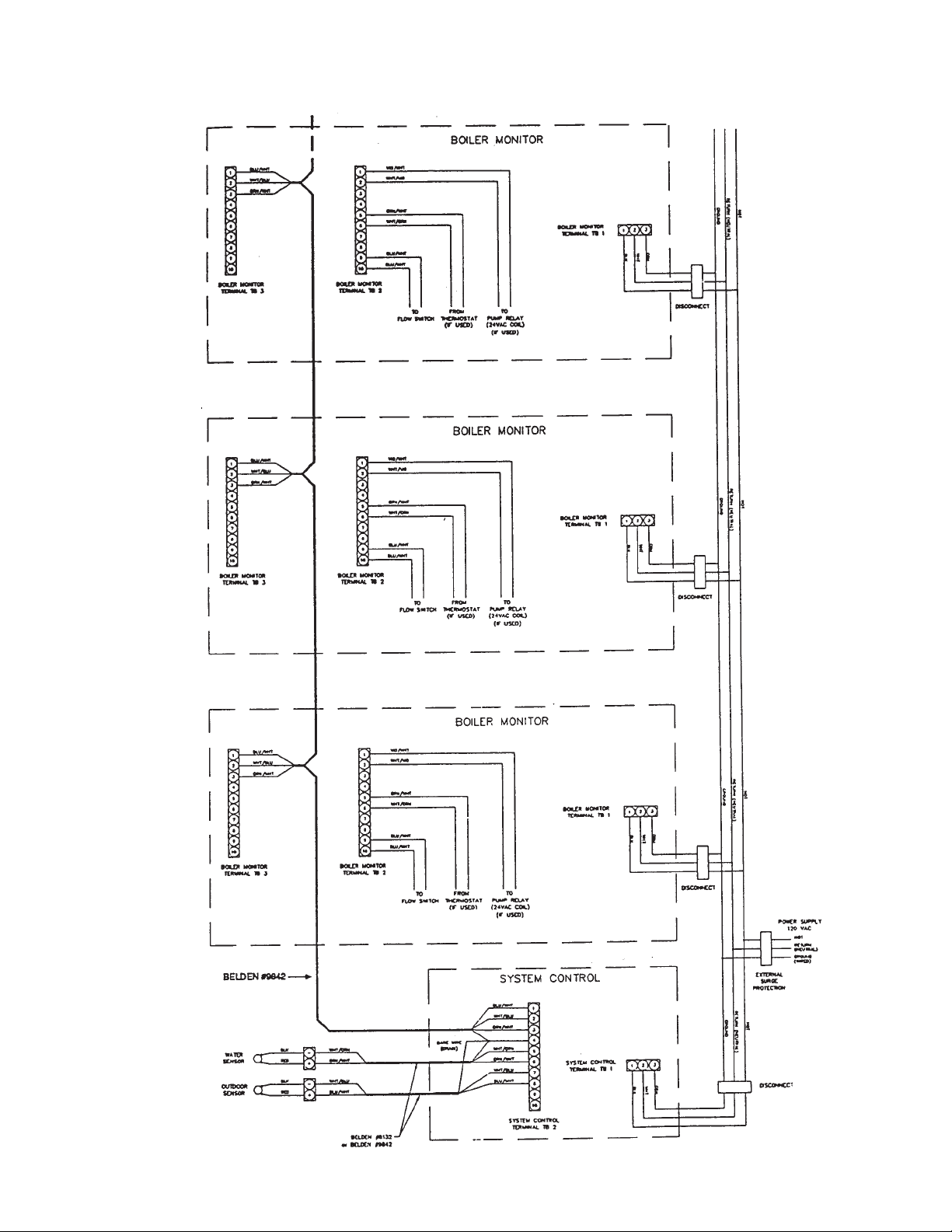

Page 19

Field Wiring - Multiple Boilers

Dia. #7

Page 19

Page 20

INSTALLA TION VERIFICATION PROCEDURE

REGISTER

Before proceeding any further, please verify that the user registration form has been

completed and mailed (reference: Registration Card ).

MECHANICAL INSTALLATION

Verify installation has been completed (reference: Mechanical Installation ).

AIR TEMPERATURE SENSOR

Verify installation parameters have been met (reference: Air Temperature Sensor).

WATER TEMPERATURE SENSOR

Verify installation parameters have been met (reference: Water Temperature Sensor).

Verify System Control/Boiler Monitor power wiring connections.

Verify Torque Requirements.

Verify Air Temperature Sensor wiring, must be Belden #8132, #9842 or equivalent.

Verify Water Temperature Sensor wiring, must be Belden #8132, #9842 or equivalent.

Verify Power Test has been completed successfully.

Verify RS485 Communications Cable, must be Belden #9842 or equivalent.

Verify Boiler Monitor Select Switch (SW2) settings.

Verify Installation/Removal of Boiler Monitor Communications Jumper(s) [W1].

Verify Optional Boiler Monitor Control Wiring.

MODEM (Optional)

Perform and/or verify modem installation and hook-up per Raypak Add/On Options

P/N 240596 and B6000 BMS Optional Modem Software Documentation P/N 240595.

Page 20

Page 21

SYSTEM CONTROL/DISPLA Y F AMILIARIZATION

The System is set up by using the selector buttons and the displays on the System Control

module.

There are ten or more displays. Each display provides information regarding the system

operating parameters and system component status. Some displays provide information

only, such as current outdoor temperature, system temperature, etc..

Selectable data is identified by flashing characters.

The selector buttons are:

"MENU" - which when pressed will change displays.

"SELECT" - moves the cursor - flashing character - to the next selection in a display.

"+" - moves a value to a higher reading (e.g. Display shows flashing boiler #1. Pushing

"+" will change display to boiler #2).

"–" - moves a value to a lower position (e.g. Display shows flashing boiler #2. Pushing

"–" will change display to boiler #1).

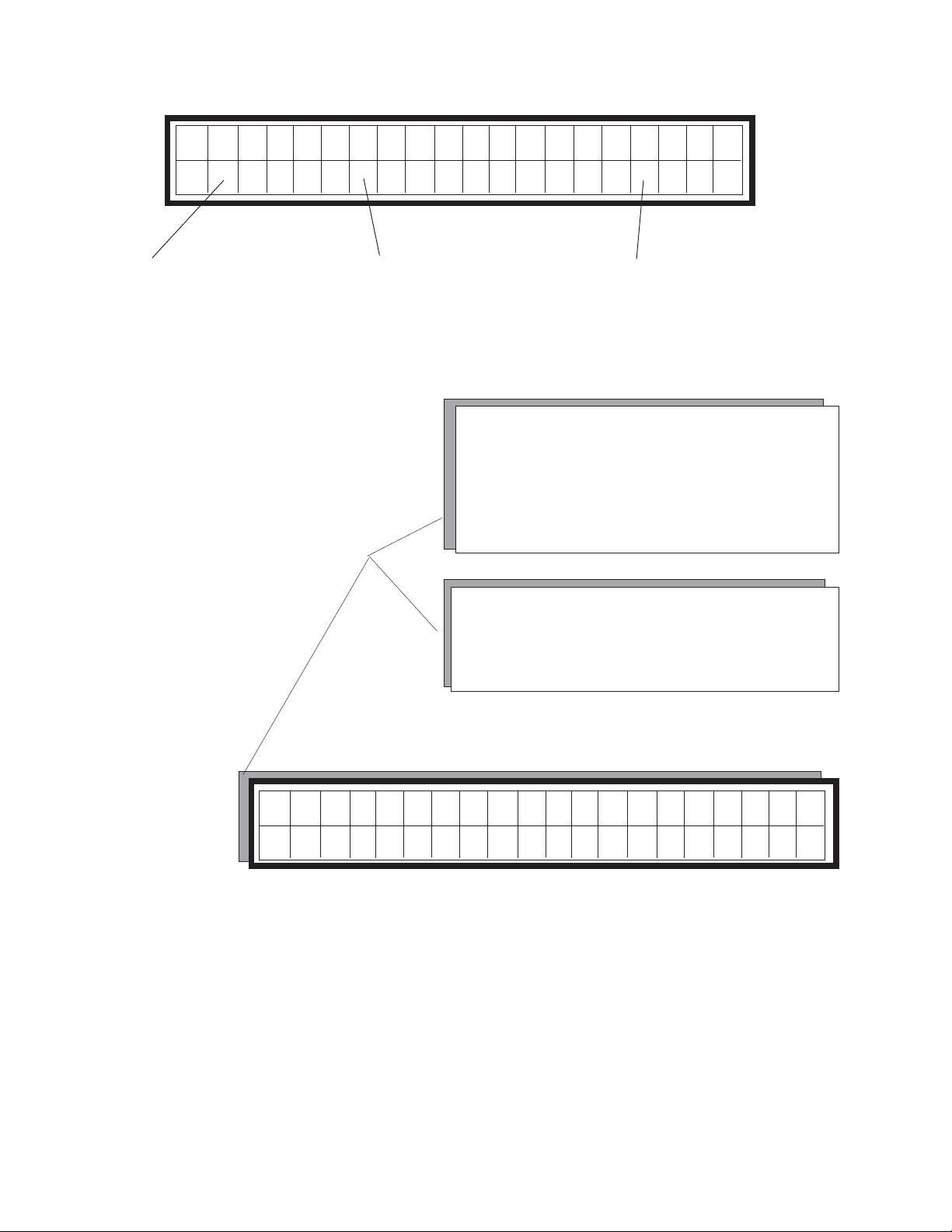

EDITING B6000 DISPLAYS LOCATION

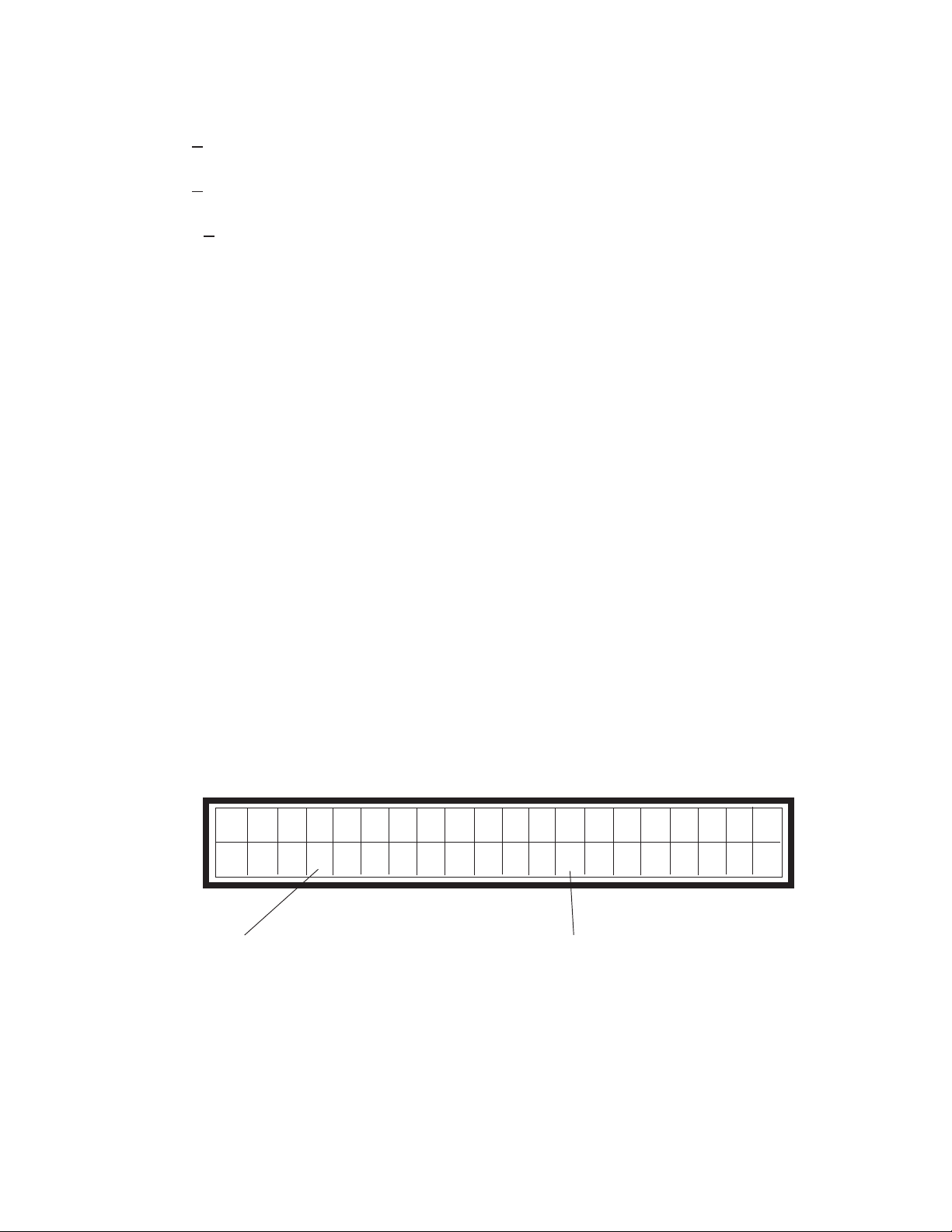

The B6000 BMS has a forty (40) character screen that displays status and memory contents.

Selectable Parameters on the B6000 Monitor Screen are as follows:

Selectable Parameters Range Value

Change to Fahrenheit (F) or Celsius (C). Default (After Initialization)

Maximum Water Temp 70 - 235 Degrees…………180

Set 40 - 220 Degrees…………100

Day Temperature 40 - 220 Degrees…………100

Nite 40 - 220 Degrees………… 90

Ratio None - 20:1 Numeric…………1.0:1

° Rise 1 - 99 Degrees………… 20

Step 1s,2s, 5 - 100 Percentile……… 20

O/C (Outdoor Cutoff) 35 - 199 Degrees………… 65

O/Cdb (O/C dead band) 1 - 9 Degrees………… 4

CBand (Control Band) 1 - 9 Degrees………… 3

Lead 1 - 8 Numeric………… 1

Change Hours 0 - 225 Numeric…………100

Pump Delay * 0 - 20 Minutes………… 3

Ign Time* 15 - 100 Seconds………… 30

*Indicates multiple entries

When the B6000 BMS is equipped with a night setback feature, [ WHEN INITIALIZED],

NITE SETBACK defaults to OFF.

Page 21

Page 22

NOTE: Nite setback feature must be set at the B6000 BMS Control Panel to "ON". This results

in display change that shows NITE rather than DAY. The BMS can change "SETBACK TIMES"

up to six selections for each of the seven days.

WARNING WARNING WARNING WARNING WARNING WARNING

When the initialize control selection is set to "Y" and "SELECT" button is pushed, the B6000

BMS resets all of the SELECTABLE PARAMETERS on this screen to DEFAULT values.

Nite Setback (NSB), Lead Lag is set to "OFF" (If option installed).

POWER-UP

Boiler Monitor

a. Energize by pushing Power Switch to "ON" position. The following indicator lights will

be lit: - Power On

The following indicator lights will be lit if the boiler is performing the valve calibration cycle.

- Call for Heat

- Pump

- Pilot

b. Boiler will start provided there are no "faults" after the System Control module has

been energized.

VX. XXXX I ni t i al i z e?

N

Version # of Software Flashing (N,Y)

System Control Module

a. Energize the system control module.

- The screen should show the System Temperature (Display #1)

b. Press the "MENU" button until the screen shows the Initialize screen .

c. Press "+" or "–" button to change the cursor to "Y".

d. Press "Select" button.

- This will initialize the control memory to the default values.

Page 22

Page 23

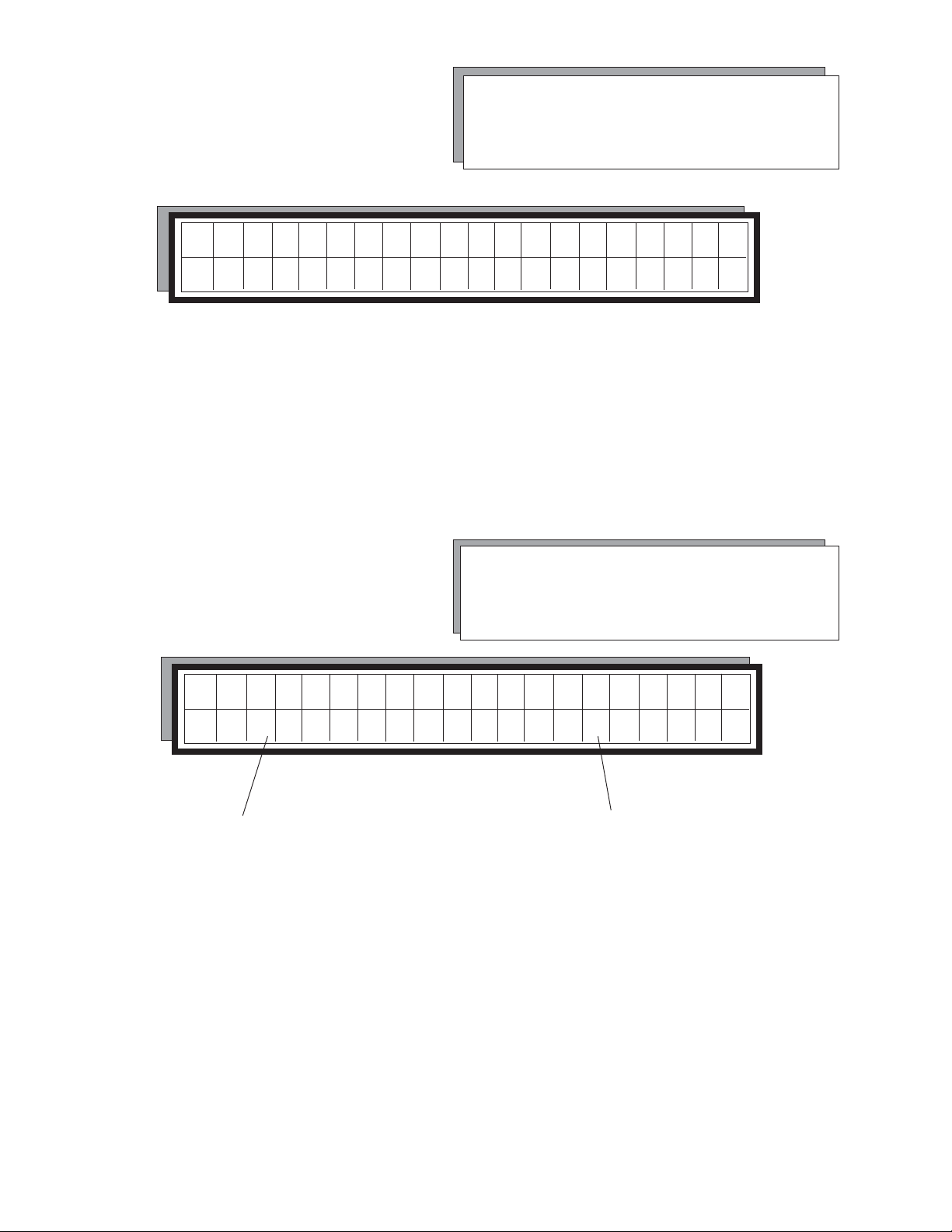

DISPLAYS

System Temperatures * Indicates selectable item

Program the System Control Module to meet the design conditions of the installation.

Return to System Temperature Display by pressing the "MENU" button until screen appears

as below.

Out door Wat er [ TAR]

XXX ° F XXX [ XXX]

Current Outdoor Air Current System Target Temperature

Temperature Water Temperature System Design

Temperature

Selectable °F or °C

Default is °F

INFORMATION ONLY

This is the first screen displayed when system is energized. After system is set up this

display should be used. °F or °C is selectable by pressing "+" or "–".

Provides: - Outdoor temperature – actual

- System Water temperature – actual

- Target Temperature, which is the desired system temperature.

Press MENU button

Boiler Valve

Firing Rates

Valve Position

X

Displays "H"

if over Hi Limit,

"M" if over MAX

#X: XXX%

Indicates Boiler being monitored Provides valve firing position

On multiple boiler installations press "+" or "–"

to view position of other boiler firing rates.

INFORMATION ONLY

- Provides firing valve position for each boiler.

- Multiple boilers - press SELECT button to determine status of each boiler.

Press MENU button

Page 23

Page 24

Boiler Status

STATUS: Boi l e r #X

-- OK --

Operating status of boiler *Boiler

Ok or Fault Indicator Pushing "+" or "-" buttons will show

status of other boiler(s) in system

READOUT

Readout

OK - boiler operation normal

FAULT indications: MAX TEMP - Target exceeds Max Temp -Not a fault-

THERMOSTAT - Operating aquastat - Not a fault LWCO - low water cutoff - when supplied

LO PRES WTR - Low pressure water - when supplied

LO PRES GAS - Low pressure gas - when supplied

HIGH PRES GAS -High pressure gas

HIGH LIMIT FLOW SWITCH - Flow switch

NO PILOT MANUAL OVERRIDE - Boiler in emergency or manual operation

• When a fault is indicated, the red light, to the right of the display, flashes and the alarm

buzzer sounds. The light continues to flash after alarm is silenced and until the fault is

corrected.

• When fault is corrected display will read "OK"

• Should communication between the system control module and the boiler monitor

module(s) be disrupted, the display will show "BOILER NOT ON-LINE".

• To display status of other boilers press the (+) or (–) buttons on multiple boiler installations.

Page 24

Page 25

GREEN RED AMBER GREEN RED

Power Manual Call Pump Low

System Control On Over- f or On Water

Display ride Heat Cutoff

OK x x x

System operating normally

LWCO x xxx

Low water in boiler

LOW PRES WATER x x x

Water Pressure t oo low

LO PRESS GAS x x x

Gas pressure below setting

HIGH PRESS GAS x x x

Gas pressure on manifold too high

HIGH LIMIT x x x

Boiler temp excess high limit

THERMOSTAT OFF x x x

Boiler off on aquastat

FLOW SWITCH x x x

Flow through boiler insufficient

NO PILOT x x x

Pilot light failed to start

BOILER NOT ON-LINE x x x

Communication lost

x = Light On

PUMP light used only when Economaster programmed.

If a boiler should lose communication with the System Controller, BOILER NOT ONLI

Page 25

N

Page 26

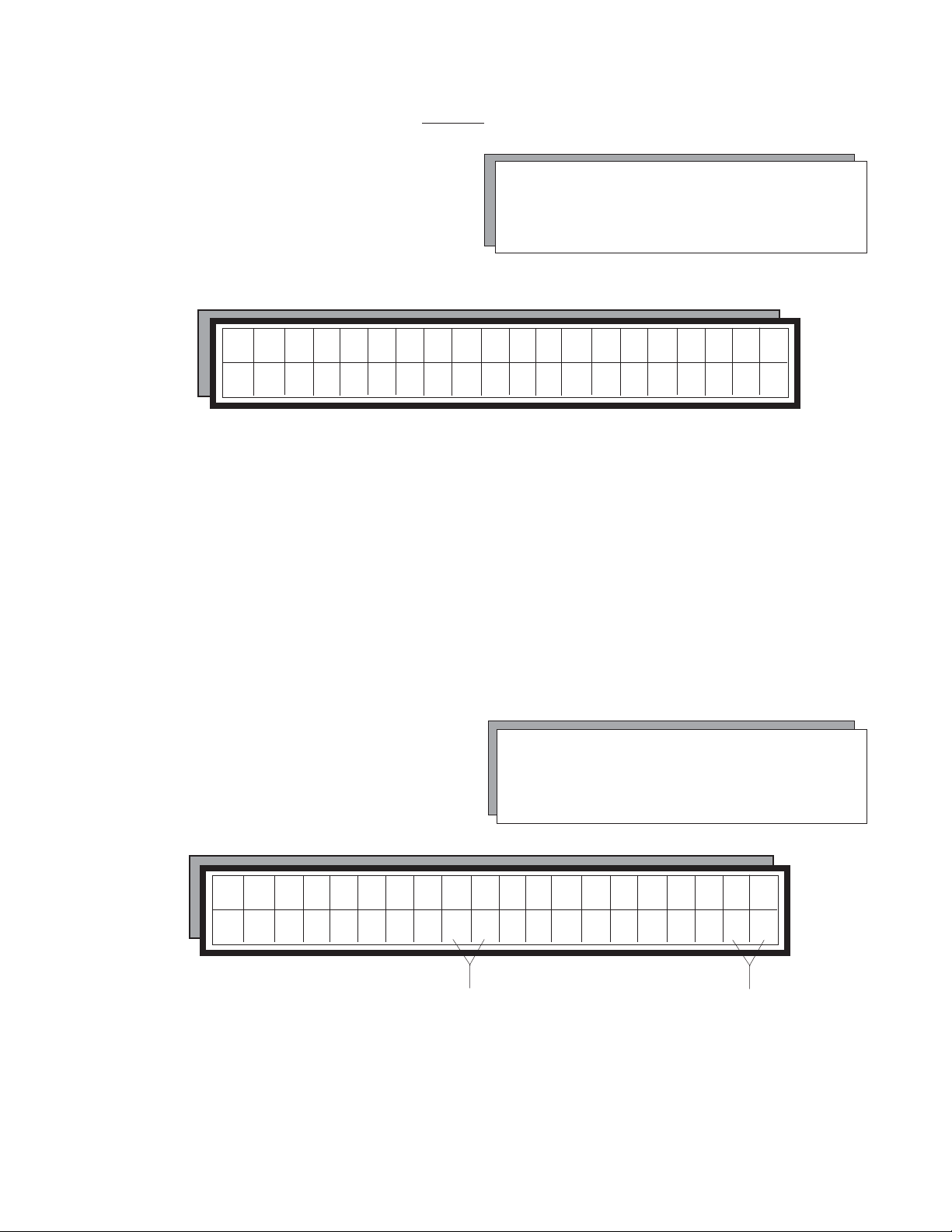

Primary Control Parameters

Set Ratio °Rise

*System water temperature *RESET RATIO * Rise is the temperature rise in

desired at outdoor Ratio of outdoor temperature system when all boilers are at full

temperature of 70°. to water system temperature. rate. (ÐT of system) Range 1 -99

Range 40 - 200 Range: 0.0:1 to 20: and "None" Default value is 20°F

Default value 100°. for constant water temperature

for constant water temperature

(TAR T - Set Point). Default value is 1.0:1.

LEAD LAG, NIGHT SET BACK

* System water temperature desired

at outdoor temperature of 70°.

NOTE"S"

This "shadow box" indicates the display

for "Lead Lag, Nite Setaback" feature.

Default value 100° (Day).

Default value 90°F (Nite).

LEAD LAG, NIGHT SET BACK

Primary Control Parameters

DayNiteRatio °R ise

XXX XX X .X: X XX

Day Value is used as the set point

when setback is OFF; Nite value,

when setback is ON.

– Sets up boiler and system,

SET –Sets desired water temperature @ 70°F - minimum design

Range 40 -220 (Day), 40 - 220 (Night)

Default value is 100° (Day); 90°F (Nite)

To increase PUSH [+] button to required temperature - suggested setting is 110°F.

Page 26

Page 27

PUSH SELECT

RATIO – Sets the desired change in system water temperature increases as the outdoor

temperature decreases. The reset ratio is expressed as follows:

2:1 for every 2 degree change in outdoor temperature the sytem temperature will change

1 degree.

Temperature °F

e.g: Set = 135°F Ratio Outdoor System

2:1 60 140

40 150

20 160

Suggested Guidelines

Typical Reset Ratio Setpoint at Design Temp:

Temp@ Temp@

RADIATION Design Cond 70°F 40°F 20°F 0°F -20°F

Standing 190 105 0.3:1 0.6:1 0.8:1 1.1:1

Convection or

Baseboard 200 105 0.3:1 0.5:1 0.7:1 0.9:1

Fan Coil - Heating 190 105 0.3:1 0.6:1 0.8:1 1.1:1

Fan Coil - Heat & Cool 140 105 0.9:1 1.4:1 2.0:1 2.6:1

Radiant Floor 120 105 2.0:1 3.3:1 4.7:1 6.0:1

Radiant Ceiling 120 105 2.0:1 3.3:1 4.7:1 6.0:1

SUGGESTED GUIDELINES

The selection of the correct ratio is dependent on the initial temperature and the desired system

water temperature setpoint and the design temperature conditions.

The reset ratio and setpoint must be selected so that the controller will raise the system water

temperature from the initial setpoint – suggested 110°F – to the maximum temperature required

when the outdoor temperature drops from 70°F to the design temperature.

PUSH SELECT

Design temperature rise of the system related to the boiler. Default value 20°F.

Page 27

Page 28

Secondary Control Parameters

St ep O / C O / C db Cb and

XX% XXX X °F X

*Step

Increment of firing

valve opening.

Range 1s, 2s 5-100

Default value 20%.

*O/C

Maximum outdoor

temperature that heat is

desired, set at 70°,

Range 35° to 199°.

Default value is 65.

*O/Cdb,

Outdoor cutoff

deadband is the

number of degrees

below O/C where

O/C reset occurs.

Range 1-9

Default value is 4°F.

Page 28

*C Band is a range of

temperature above and

below the target

temperature.

Range 1-9

Default value is 3°F.

Page 29

*STEP

Enter desired valve firing increments. Recommended setting is between 5% and 20% for

Modulating Boiler.

Or

Enter 1S If Gas Valve is an On-Off or Single Stage

Or

Enter 2S

Enter 20%

control of a single system control module.

*O/C

Enter desired outdoor cutoff temperature, usually 70°F, depending on geographical location.

When outdoor temperature exceeds desired setting, target temperature will show "O/C".

Note: Boiler will restart when outdoor temperature drops below O/CF Tep - O/C db.

*O/Cdb

Enter desired outdoor cutoff dead band, which is the number of degrees below O/C where

O/C resets, usually 1F.

If Gas Valve is 2 Stage Firing

Or

If the control boilers include modulating and 2 stage or single stage boilers under

*C Band

Enter desired Control Band, determines when boiler will fire below target temperature and

shut off above target temperature, usually 1°F.

NOTE: The above settings are recommended at initial installation. For maximum

performance and system efficiency these settings should be modified, as required, to meet

such parameters as system capacity, location and usage.

NOTE: Contact factory for recommended settings if this is a special application ie. Heat

pump applications.

Lead Boiler Select

Le a d # of Bo i l e rs

XX

*Indicates boiler designated as "Lead". *Indicates number of boilers being used.

Used when there are multiple boilers. Set number (#) of boilers to match actual installation.

Readout lists lead boiler. To change lead boiler PRESS [+] or [–] button until desired boiler

is displayed. In the event of a fault in the designated lead boiler the next boiler, numerically,

becomes the lead boiler.

Boiler being monitored is displayed. If multiple boilers, push [+] or [–] to select the desired

boiler.

Page 29

Page 30

LEAD LAG, NIGHT SET BACK

Automatic Lead Lag

Lead C hange hr s . XX X

Hour s Remai ni ng XXX

*Lead Change Hours

Designated lead boiler will change when remaining hours reaches 0.

Range 0-225 hrs. Default value is 100 hrs.

If set at 0 hours lead will not change.

Hours remaining will automatically total.

Enter the desired number of hours of lead boiler operation before change. Hours remaining is automatically calculated. Designated lead boiler will change as soon as

remaining hours run out. Set at 0 hours and lead will not change.

STANDARD

BOILER PARAMETERS LEAD LAG, NIGHT SET BACK

Boiler Parameters

Pump D el ay I G N T i me

#X: XX m i n XXX s ec

*Pump delay selectable from 0 to 20 *Ignition time sets the duration to monitor

minutes. Range 0-20. Default value 3 mins. Ignition prior to lock out. Range 15-100.

Default value 30 secs.

PUSH SELECT

PUMP DELAY

Enter time desired for boiler pump operation, if one is installed and wired to boiler monitor. If there is no pump or a continuous running pump, ignore.

PUSH SELECT

IGN TIME

Display shows time of monitoring the ignition prior to main flame. Default timing is 30

seconds.

Note: On multiple boilers, a time must be entered for each boiler.

Page 30

Page 31

Night Setback

"OFF" indicates the system is in the Normal or design operating mode. "ON" indicated

the system is operating in a programmed night setback mode.

NOTE"S"

This "shadow box" indicates the display

for "Lead Lag, Nite Setaback" feature.

LEAD LAG, NIGHT SET BACK

Automatic Lead Lag

* XX: XXPM **Mond a y

S et back: ***OFF

*Set Time of day

** Day of Week

*** On or Off

This screen shows the time and day of the week. Default values:

Monday for the day, and "OFF" for Setback.

Enter the current time.

PUSH SELECT Until day flashes.

Enter day of the week.

Setback status can be manually changed from "OFF" to "ON", or vice versa, provided the

setback times have been cleared, otherwise the timer will override the manually selected status

of setback. Push [+] or [–] to setback mode to "on" or "off".

LEAD LAG, NIGHT SET BACK

Setback Times

S et back: *Mond a y

1: * XX: XX - XX: X X

am or pm

This screen shows the Setback "ON" and "OFF" times for each day.

There are six (6) "ON" and six (6) "OFF" times per day, as indicated

by the number on the left.

Page 31

am or pm

Page 32

Set Back Example:

Period SETBACK SETBACK

1 xx:xx 05:00 am Monday

2 10:00 pm xx:xx Monday

1 xx:xx 05:00 am Tuesday

2 10:00 pm xx:xx Tuesday

1 xx:xx 05:00 am Wednesday

2 10:00 pm xx:xx Wednesday

1 xx:xx 05:00 am Thursday

2 10:00 pm xx:xx Thursday

1 xx:xx 05:00 am Friday

2 10:00 pm xx:xx Friday

1 xx:xx xx:xx Saturday

2 xx:xx xx:xx Saturday

"ON" "OFF" DAY

1 xx:xx xx:xx Sunday

2 xx:xx xx:xx Sunday

The above example will set back temp weekends and 10:00 pm to 5:00 am weekdays. Each

day can have up to six (6) separate setbacks.

When no time is entered (indicated by xx:xx) the setback time in effect from the previous time

period will continue on to the next period, which means, when the night setback is "ON" the

system water temperature for nighttime use will be maintained until the next "OFF" entry is

reached.

Page 32

Page 33

Boiler Valve Timing

Boiler Valve Timing

Information only

Va lv e T im in g

#X: XXu XXd sec .

u= UP Boiler Number Displays in seconds real time opening and closing

d = DOWN of modulating gas valve from closed (0%) to full open (100%)

This display shows the time (secs) required for the gas valve to open and close. If "u"

display is from 12 to 26 and "d" is less than "u" and between 4 and 18 the gas valve

requires no adjustment. This timing is not operator changeable on the screen display.

Proportional Integral

Derivative Operator

Manual Action (PIDOMA) A.Proportional Integral Derivative

Operator Manual Action

A Pconst W a it D con s t

X/XXX/X

*Pconst is the proportional ratio

which causes the boiler to step up

or down, faster or slower (overshoot or undershoot) and finally

end up offset from desired temperature. Default is 1/3.

*Pconst

Proportional ratio which causes the boiler to step up or down, faster or slower.

*WAIT

Wait as time controller hesitates before acting on a temperature change.

*Dconst

Derivative ratio speeds or slows boiler response compensating for overshoot and undershoot.

*Wait is the time controller waits

until it acts on a temperature

change. Default value is 5 seconds.

*Dconst is the derivative ratio

which tells the system how first to

react to differing changes in water

temperature. Default is 3/1.

Page 33

Page 34

Proportional Integral

Derivative Operator

Manual Action (PIDOMA) B.Proportional Integral Derivative

Operator Manual Action

B Pconst W a it D con s t

X/XXX/X

*Pconst is the proportional ratio

which causes the boiler to step up

or down, faster or slower (overshoot or undershoot) and finally

end up offset from desired temperature. Default is 1/3.

*Pconst

Proportional ratio which causes the boiler to step up or down, faster or slower.

*WAIT

Wait as time controller hesitates before acting on a temperature change.

*Dconst

Derivative ratio speeds or slows boiler response compensating for overshoot and undershoot.

*Wait is the time controller waits

until it acts on a temperature

change. Default value is 5 seconds.

*Dconst is the derivative ratio

which tells the system how first to

react to differing changes in water

temperature. Default is 3/1.

ALL BOILERS ON/OFF

Al l Boi l er s on/ of f

XX above/ XX bel ow

Range 1 to 99. Default valve 20° F.

This Display Indicates:

The temperature above or below target at which the control will turn off or on all the boilers.

TARGET MIN/MAX AND HI LIM

Target Mi n/ Max: Hi Li m

XXX/ XXX XXX

Min Default 105, range 0 to 220°F Hi Lim shows the maximum obtainable water

Max Default 180, range 0 to 220°F temperature.

Hi Lim Default 200, range 0 to 220°F Hi Lim can not be lower than the target XXX/

Max.

Note: All of the values interact and are

depedent upon each other.

Page 34

Page 35

tandard

Initialize

LEAD LAG, NIGHT SET BACK

Initialize

VX . XXXX I ni t i al i z e?

Y - Yes

N - No

Y

Version # of software.

* This will initialize all previous selectable values to default values. Should not be

used unless operator wants to reprogram new values. Should be used at Start-up

to clear the control memory.

This should be by-passed, if controls have been initialized as the first step.

Standard

Utility Service LEAD LAG, NIGHT SET BACK

Utility Service

Temp: XXX ( XXX ) m :x

XXX%XXX%XXX%XXX%XXX%

Displays controller operating mode,

changes continously from 1 to 5.

Displays Firing Rate of each Boiler Displays System Target Temperature

Displays Actual System Temperature

Information Only.

Displays the system operating conditions and the firing rate of each boiler up to total of (5).

Page 35

Page 36

IMPORTANT

START "ALTERNATE" If your system module(s) are supplied with a single

Field Wiring Terminal Strip use this method for wiring.

WIRING - AIR AND WATER SENSORS

To The System Control Module

WATER

SENSOR

OUTDOOR

SENSOR

BARE WIRE

(SHIELD/

BELDEN #8132

or BELDEN #9842

DRAIN)

TO:

SINGLEPOINT

GROUND

(SPG)

AIR/WATER TEMPERATURE SENSOR SCHEMATIC

FIELD WIRING

TERMINAL STRIP

Dia. #10

Page 36

Page 37

"ALTERNATE" Continued

COMMUNICATION (RS 485) WIRING

From: System Control Module

To: Boiler Module

• Shielded communications cable - Belden #9842 must be used.

Polarity must be observed. Make use of wire color coding to ensure polarity.

• The shielding [foil wrapper - bare wire (drain)] MUST be grounded.

Grounding is done at the (System Control) only. DO NOT ground at boiler monitor.

• Note: Equivalent shielded cable must be suitable for RS 485 communication applications;

must have 100-140 ohm impedance; and less than 30 picofarad per foot capacitance.

• Install in conduit with no other wiring.

SYSTEM CONTROL

RS 485 Communications Cable Schematic

Page 37

TERMINAL

Dia. #11

Page 38

WIRING: Power Source to Control and Boiler Modules

• Observe Polarity very important.

• Observe wire colors

• Provide external surge suppressor

capable of maintaining system integrity.

• Provide overload protection and disconnect means as required by code and for

equipment serviceability.

• Conduit can NOT be used as ground.

* Must be "WIRED" Ground.

Page 38

Dia. #12

Page 39

"ALTERNATE"

POWER TEST

CHECK POWER

Utilizing a Volt-Ohm-Meter (VOM) monitor the following on the "System Control" and "Boiler

Monitor(s)" for proper voltage levels. Check at the Terminal Block (TB).

POWER TEST TABLE

SYSTEM CONTROL INDICATION

From: To:

TB pin 1 TB pin 2 108 VAC to 132 VAC

BOILER MONITOR(S) INDICATION

From: To:

TB pin 1 TB pin 2 108 VAC to 132 VAC

TB pin 1 SPG 108 VAC to 132 VAC

TB pin 2 SPG less than 1 VAC

BOILER SYSTEM

MONITOR(S) CONTROL INDICATION

From: To:

TB pin 1 TB pin 1 Less than 0.5 VAC

TB pin 2 TB pin 2 Less than 0.5 VAC

SPG SPG Less than 0.5 VAC

TB pin 2 SPG Less than 0.5 VAC

TB pin 1 SPG 108 VAC to 132 VAC

TB pin 2 SPG less than 1 VAC

END – – – – – – – – "ALTERNATE" Return to: "Boiler Monitor Select Switch"

(See page 20.)

Page 39

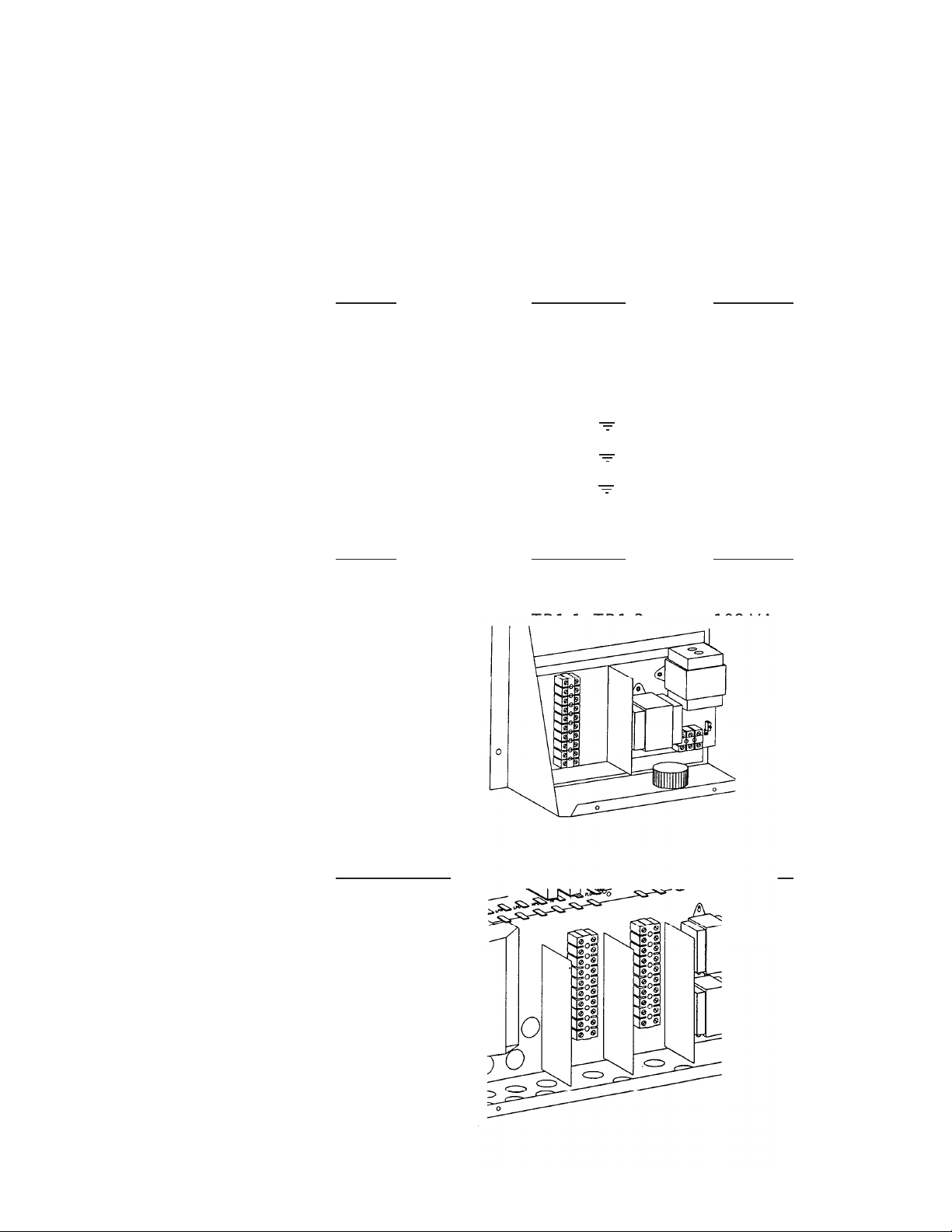

Page 40

Page 40

Fig. # 9458

Page 41

Page 41

Fig. # 9459

Page 42

SYSTEM CONTROL BOARD

Page 42

Fig. # 9460

Page 43

Replacement Parts List

New

Part

#

CP10.0_ _ _

CP10.0N _ _

CP10.0NMn

90FI

90EI

900D

Page 43

Page 44

Replacement Parts List

Page 44

Page 45

Located in place of

ignition control on

C2 boilers only.

Fig. # 9461

BOILER MONITOR CONTROL BOX

Page 45

Page 46

Replacement Parts List

CALL OUT B 6000 SYSTEM PART NO.

Boiler Monitor Control Box

B-1 Control PC Board 004795F

B-2 Power/Manual or Override Switch 650745

B-3 Transformer, 120/8.5 VAC C.T. 064921

B-4 Transformer, 120/24 VAC C.T. 650495

B-5 Transformer, 120/24 VAC (C2 Units only) 650495

B-6 Ignition Control with Lockout 004818B

F1 & F2 Fuse, AGC 2, 250V, 2A 650896F

F3 Fuse, AGC3, 250V, 3A 650523

K-1, K-2, K-3, K-4 Relay, 5 VDC, SPDT 650846F

K-7, K-8 Relay, 24 VAC, DPDT 650849F

K-6 Relay, 120 VAC, SPDT 650848F

K-5 Relay, 24 VAC, SPDT 650847F

K-1, K-2, K-3,

K-4, K-5, K-6 Relay, Socket SPDT 650851F

K-7, K-8 Relay, Socket DPDT 650850F

U4 EPROM BVx.x 601194

Page 46

Page 47

B6000 BOILER MANAGEMENT SYSTEM START-UP DATA

SYSTEM SETTINGS ENTERED ON DATE:_____________________________________

Temperature Scale

°F or °C

Standard

Set _____ Deg. Ratio _____ : 1 Rise _____ Deg.

System Water Temp. @ Oc Reset Ratio-Outdoor: System Design Temp. Diff.

Default Value 100°F (38°C) Default Value: 1.0:1 Default Value: 20°F (7°C)

Select Set Optional

Day _____ Deg. Nite_____ Deg. Ratio _____:1 Rise _____ Deg.

System Temps @ Oc Reset Ratio System Design Temp. Rise

Default Value Default Value: Default Value: Default Value:

100°F (38°C) 90°F (32°C) 1 .0:1 20°F (7°C)

Universal

Step _____ % O/C_____Deg. O/Cdb _____Deg. C Band _____ Deg.

Valve Opening Outdorr Cutoff Outdoor Cutoff Control Band

Default Value: Default Value: Deadband Default Value:

5% 65 degs. Default Value: 4 Deg 3 Deg.

Lead _____ # of Boilers _____

Indicates Lead Boiler Number of Boilers in system.

Select Set Optional

Lead Change hrs. _____

Lead boiler will change after selected no. of hours.

Universal

Pump Delay _____ Min. Ign Time _____ Sec.

Delay off pump timing. Ignition lockout timing.

Default Value: 3 min. Default value: 15 seconds.

Select Set Option

____________ __________ ____________________ _______________

Time of Day AM or PM Day of Week Set-back- Off or On

Default Value: Monday Default Value: Off

Period 123456

Set-Back On Off On Off On Off On Off On Off On Off

Monday ___ ___ ___ ___ ___ ___ ___ ___ ___ ___ ___ ___

Tuesday ___ ___ ___ ___ ___ ___ ___ ___ ___ ___ ___ ___

Wednesday ___ ___ ___ ___ ___ ___ ___ ___ ___ ___ ___ ___

Thursday ___ ___ ___ ___ ___ ___ ___ ___ ___ ___ ___ ___

Friday ___ ___ ___ ___ ___ ___ ___ ___ ___ ___ ___ ___

Saturday ___ ___ ___ ___ ___ ___ ___ ___ ___ ___ ___ ___

Sunday ___ ___ ___ ___ ___ ___ ___ ___ ___ ___ ___ ___

Proportional Integral Derivative

____________________ ____________________ ____________________

Pconst Wait (Integral) Derivative

V___________________ Version # of Software

Page 47

Page 48

Troubleshooting Guide

The procedures outlined below assume that the initial

installation / turn on / power up procedures have been

completed and that the B6000 was operational. This

guide is a basic instruction to determine if an authorized

Raypak representative should be contacted.

Symptom

No Display.

* Nite set-back time display no

longer correct.

* Nite set-back not working

properly.

* Time display does not maintain

proper time.

Possible Cause

No Primary power.

Time display accidentally

Re-Programmed.

Nite set-back turned off.

Clock times not set.

System ground not adequate.

Line noise.

Internal battery weak.

Prolonged power outage.

If you follow the instructions in this manual and have

difficulty operating the B6000, locate the SYMPTOM in

the left column below. Check the corresponding POS-

SIBLE CAUSE and CORRECTIVE ACTION Column to

locate and remedy the problem.

Corrective Action

Check power connections to units.

Check surge protection devices.

Check disconnects, check

grounds.

Check power switches.

Initialize system.

Program Nite set-back feature.

Initialize system.

Initialize system and / or

contact authorized Raypak

Representative for further instructions.

System not working automatically.

Display shows incorrect number of

boilers.

Scrambled control display.

Boiler does not function properly

after power outage.

Boiler "Not on Line" displayed.

Outdoor and water temp.

readings Incorrect (-35°F).

Displayed parameters

do not make sense.

System Faults indicators do not

make sense.

Boiler monitor has Manual Mode

selected

Inadequate grounds.

Line noise

Power outages.

Power outages.

Internal battery weak.

Line noise.

System ground not adequate.

Primary power at boiler not

connected.

Inadequate ground

Line noise.

Power outage.

Power outage.

Power outage.

Select Automatic mode on Boiler

Monitor.

Check primary power - check

wired ground.

Rework as necessary.

Initialize system.

Initialize system.

Initialize system.

Initialize system.

Initialize system.

Initialize system.

Initialize system.

* With Nite Set-Back option only.

Page 48

Page 49

Trouble Shooting Guide-Continued

Symptom

Boiler # x

"Not on Line" Displayed

Outdoor Temp. Sensor readings

are high.

Sensor reading 220°F.

Sensor reading - 35°F.

Low water cut-off alarm.

Possible Cause

Boiler not powered.

Outdoor sensor not mounted

correctly.

Sensor wiring shorted

Sensor wiring open.

Excessive circuit loading of pump

contacts by user supplied system

pump.

Low water level in boiler

Corrective Action

Check primary power.

Correct as necessary.

Check communication cable,

check (surge) ground Remove /

Replace (R/R) as necessary.

Initialize system.

Refer to installation manual

mounting instructions. Possible

relocation for sensor.

Check sensor wiring for damage.

R/R as necessary.

Initialize system.

R/R as necessary

Initialize system.

Check power.

Check pump contactor / relay

R/R as necessary.

Replace F1 fusing.

Check main water supply

Power lamp off on Boiler Monitor.

Pump not running.

Off at flow switch.

Off on High Limit.

Fuse F1 blown.

Excessive circuit loading of pump

contacts by user supplied system

pump.

Circuit breaker tripped.

Excessive circuit loading of pump

contacts by user supplied system

pump.

Pump going off on thermal overload circuit breaker tripped

Paddle damaged or missing.

Pump off on thermal overload.

Low limit settings.

Intermittent power or pump

failure.

Replace F1 fusing.

Remove Relay-K1 to isolate circuit

loading.

R/R as necessary.

Reset circuit breaker.

Replace F1 fusing.

Check pump.

Reset circuit breaker

Check paddle on flow switch.

Check pump, contact or relay.

Replace F1 fusing.

Check and correct settings.

Meter amperage on pump.

R/R as needed.

Page 49

Page 50

LIMITED WARRANTY

B6000, Y-Series, E-4 & Accessories

SCOPE OF WARRANTY :

Raypak, Inc. ("Raypak") warrants to the original owner the Control System to be free from defects in materials and workmanship

under normal use and service for the applicable warranty period. In accordance with the terms of this Limited Warranty, RAYPAK will

furnish a replacement or repair, at our option, any defective part which fails in normal use and service during the applicable warranty period.

The replacement or repair will be warranted for only the unexpired portion of the original Warranty Period.

APPLICABLE WARRANTY PERIOD

The effective date of warranty coverage is the date of original installation, of the Control System, by a qualified electrician or by a

RAYPAK authorized service technician. The Applicable Warranty Period is one (1) year from the effective date.

WARRANTY EXCLUSIONS

This Limited Warranty does not apply:

1. if the control system is not properly installed by a qualified technician in accordance with manufacture's installation

instructions, applicable codes, ordinances and good trade practices,

2. to damage or malfunctions resulting from failure to properly install, operate or maintain the system in accordance

with the manufacture's instructions;

3. if the rating plate(s) or serial number(s) are altered, defaced or removed;

4. if the System is modified in any way or used with any non-factory authorized accessories or components;

5. to damage or failure from abuse, accident, act of nature, fire, flood, freezing or the like;

6. to accessories, rubber or plastic parts, light bulbs or glass parts;

7. if the System is moved from its original installation site; or if the original owner no longer owns the site or the System.

LABOR AND SHIPPING COSTS

This Limited Warranty does not cover labor costs for service, removal or reinstallation of any part nor shipping charges to or from

RAYPAK'S designated repair center or to or from the installation site. All such costs are your responsibility.

HOW TO MAKE A WARRANTY CLAIM

To make a warranty claim, promptly ship (postage prepaid) or carry the defective part to a designated RAYPAK Service Dealer or

Service Station in the United States, supplying proof of purchase and date of installation and the model and serial numbers. If you cannot

locate a dealer, contact RAYPAK'S Service Department at the address/telephone listed below. Raypak reserves the right at all times to

inspect the claimed defect and verify warranty coverage at its factory.

EXCLUSIVE WARRANTY - LIMITATION OF LIABILITY

This is the only warranty given by RAYPAK. No one is authorized to make any other warranties on Raypak's behalf. ANY IMPLIED

WARRANTIES, INCLUDING MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE, SHALL NOT EXTEND

BEYOND THE APPLICABLE WARRANTY PERIOD SPECIFIED ABOVE. RAYPAK'S SOLE LIABILITY WITH RESPECT TO

ANY DEFECT SHALL BE AS SET FORTH IN THIS LIMITED WARRANTY. ANY CLAIMS FOR INCIDENTAL OR

CONSEQUENTIAL DAMAGES (INCLUDING DAMAGE FROM WATER LEAKAGE) ARE EXCLUDED. Some states do not allow

limitations on how long an implied warranty lasts, or for the exclusion of incidental or consequential damages, so the above limitation or

exclusion may not apply to you.

THIS LIMITED WARRANTY GIVES YOU SPECIFIC LEGAL RIGHTS, AND YOU MAY ALSO HAVE OTHER RIGHTS

WHICH VARY FROM STATE TO STATE.

We suggest you immediately complete the information below and retain this Limited Warranty Certificate in case warranty service

is needed.

RAYPAK, INC. SERVICE DEPARTMENT

2151 Eastman Avenue, Oxnard, California 93030

Telephone: (805) 278-5300 FAX (805) 278-5468

The following information must be provided when you write or call:

________________________________________________ _______________________________________________

Original Owner Daytime Telephone Number

__________________________________________________________________________________________________

Complete Mailing Address

________________________________________________ _______________________________________________

City State Zip Code Installation Site

________________________________________________ _______________________________________________

Model Number Contractor/Installer

________________________________________________ _______________________________________________

Date of Installation Serial Number

Raypak, Inc., 2151 Eastman Ave, Oxnard, CA 93030 (805) 278-5300 FAX (805) 278-5468 Litho in U.S.A.

Page 51

www.raypak.com

Design and specifications subject to change without notice.

U

®

This symbol on the nameplate means the product is listed by Underwriters

L

Laboratories, Inc. ®

Raypak, Inc., 2151 Eastman Avenue, Oxnard, CA 93030 • (805) 278-5300 • FAX (800) 872-9725

Litho in U.S.A.

Loading...

Loading...