Page 1

OPERATING AND

INSTALLATION

INSTRUCTIONS

Model B-195

GAS FIRED AUTOMATIC

INSTANTANEOUS

BOOSTER WATER

HEATER

CATALOG NO.: 3300.51I

Effective: 01-01-03

Replaces: 01-01-01

FOR YOUR SAFETY

Do not store or use gasoline or other flammable vapors and liquids or other combustible

materials in the vicinity of this or any other appliance. To do so may result in an explosion

or fire.

WARNING: Improper installation, adjustment, alteration, service or maintenance can cause

property damage, personal injury or loss of life. Refer to this manual. Installation and service

must be performed by a qualified installer, service agency or the gas supplier.

FOR YOUR SAFETY

WHAT TO DO IF YOU SMELL GAS

*Do not try to light any appliance.

*Do not touch any electrical switch; do not use any phone in your building.

*Immediately call your gas supplier from a neighbor's phone. Follow the gas supplier's

instructions.

*If you cannot reach your gas supplier, call the fire department.

This manual should be maintained in legible

condition and kept adjacent to the heater or kept

in a safe place for future reference.

Product Discontinued December 2003

NSF

P/N 240707

®

Page 2

CONTENTS

PAGE DESCRIPTION

3 1. RECEIVING EQUIPMENT

3 2. GENERAL SPECIFICATIONS AND DIMENSIONS

4 3. INSTALLATION PROCEDURES

4 - Code Requirements

4 - Combustion/Ventilation Air

5 - Venting

8 - Gas Piping

8 - Water Piping

11 - Electrical Wiring

12 4. START-UP AND OPERATION

12 - Component Location

12 - Sequence of Operation

12 - START-UP Procedures.

16 5. SERVICING UNIT

16 - Trouble Shooting Guide

- Maintenance

18 6. PARTS

19 - Illustrated Parts

20 - Parts List

23 WARRANTY

These instructions are provided to assure the proper installation, operation and maintenance

of the Raypak Booster Heater. Should questions arise regarding the specification, installation,

operation or servicing of the unit, contact the local distributor or contact the Raypak factory.

CALIFORNIA PROPOSITION 65 WARNING: This product contains chemicals known to

the State of California to cause cancer, birth defects or other reproductive harm.

2

Page 3

1. RECEIVING EQUIPMENT

On receipt of your equipment it is suggested that you visually check for external damage to the carton. If the

carton is damaged, it is suggested that a note be made on the Bill of Lading when signing for equipment. Remove

the heater from the carton and if it is damaged report the damage to the carrier immediately. Be sure that you

receive the number of packages indicated on the Bill of Lading. Claims for shortages and damages must be filed

with the carrier by consignee.

Purchased parts are subject to replacement only under the manufacturer's limited warranty. Debits for

defective replacement parts will not be accepted and defective parts will be replaced in kind only per our standard

warranties.

When ordering parts, you must specify Model and Serial Number of heater. When ordering under limited

warranty conditions, you must also specify date of installation.

Raypak recommends that this manual be reviewed thoroughly before installing your Raypak Heater. If there

are any questions which this manual does not answer, please contact your local Raypak Representative.

2. GENERAL SPECIFICATIONS

The Raypak Booster Heater is design certified and tested under the requirements of the American National

Standard, ANSI Z 21.10.3 ,and the Canadian National Standard, CAN 1-4.3-M85, and bears the National

Sanitation Foundation, NSF, seal.

The Raypak Booster Heater is an instantaneous tube type free standing unit intended for use as a supplier

of 180 Deg. F dishwasher rinse water. Inlet water temperature to the heater of 140 deg. F is required for optimum

operation of the heater.

Water enters the heat exchanger from the heater inlet water connection. The water then is circulated through

two passes of copper finned tubes, through a stainless steel tank and to the dishwasher. Water is also recirculated through a bypass system that assures the availability of the proper temperature water at the heater

outlet.

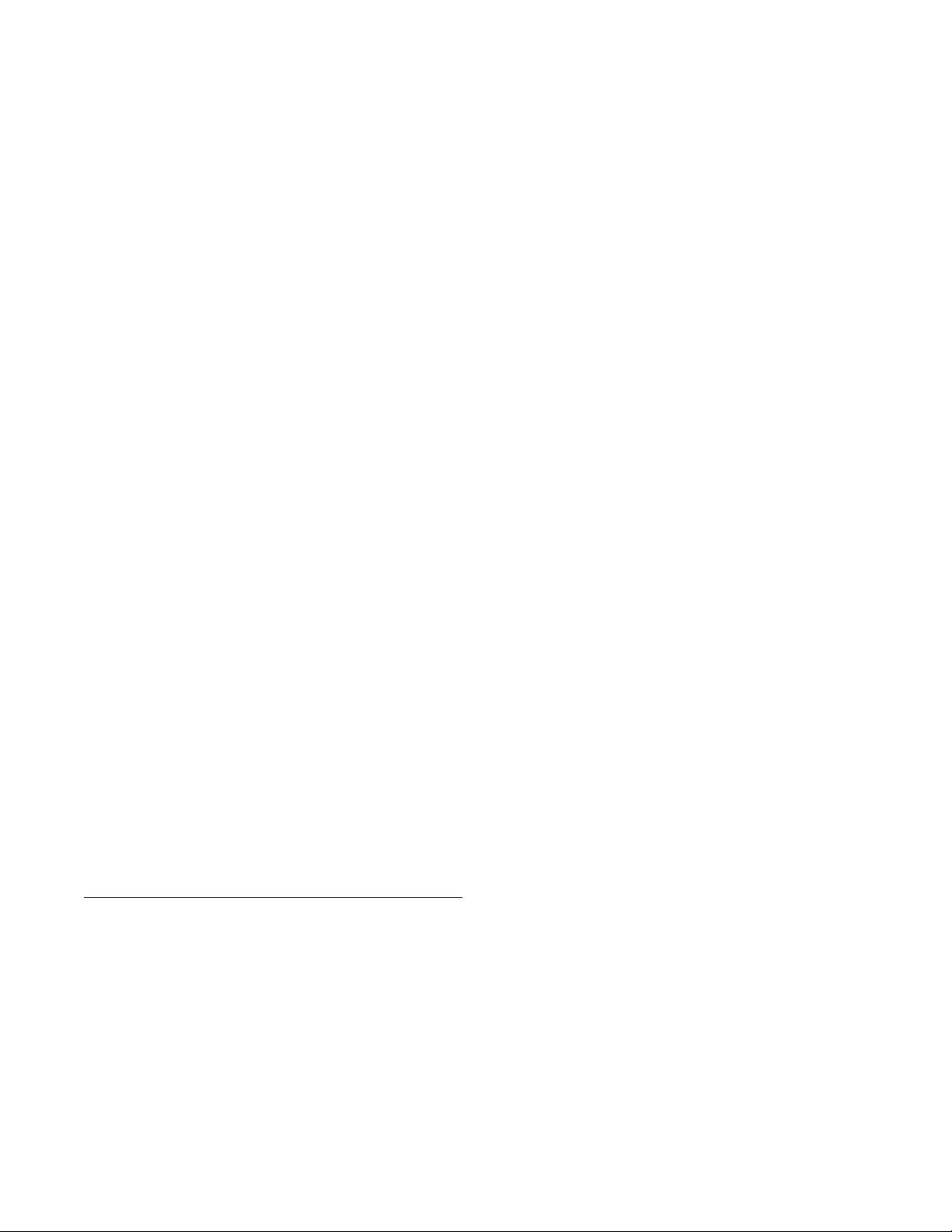

SPECIFICATIONS AND DIMENSIONS

Input GPH Delivery at Indicated Temperature Rise

Model MBH 40°F 50°F 60°F 70°F 80°F 100°F 120°F 140°F

B-195 195 490 392 327 280 245 196 163 140

Fig #9165

3

Page 4

3. INSTALLATION PROCEDURES.

CODE REQUIREMENTS

Installation must be in accordance with local codes, or in the absence of local codes with the latest edition

of the National Fuel Gas Code, ANSI Z223.1, the National Electrical Code, ANSI/NFPA 70. For Canada, CAN/

CGA B149.1 and .2, and CSA C22.2 No. 1.

LEG INSTALLATION

Four (4) legs are supplied loose within the carton for installation at the site. This will provide the required six-

inch clearance off the floor. To install the legs, raise one end of the heater just high enough to allow the legs to

be screwed into the two corners of that end. Make sure each leg is tightened securely by hand. Lower the heater

gently to minimize any undue strain on the two (2) legs. Gently raise the other end, and repeat the same procedure

for the other two (2) legs. Rotate the lower section of each leg as necessary to level the heater in place.

Booster water heater should not be located in an area where water leakage will result in damage to the area

adjacent to it or to lower floors of the structure. Where such areas cannot be avoided, it is recommended that

a suitable catch pan, adequately drained, be installed under this heater. Do not install directly on carpeting.

CLEARANCE REQUIREMENTS

Floor Top Left Right Front Back Vent

Side Side

* 0" 6" 6" Alcove 6" 1"

*Approved for installation on combustible flooring.

A front clearance of at least 24" is recommended for adequate service of burner-tray and controls.

COMBUSTION/VENTILATION AIR

B195 COMBUSTION AIR ADJUSTMENT

This model is equipped with an air adjustment screw on the combustion air blower inlet. For natural gas the

opening is factory set at about 2.12" diagonal dimension, for propane gas the opening is 1.875" diagonal

dimension, which should be the proper setting for most installations. However, field conditions including unusual

gas characteristics may create a need for adjustment to achieve optimum performance. When the combustion

air setting is proper, there will be some lifting of the flames on some areas of the burner tile under cold start

conditions. After about five minutes of operation, the flames should settle down and blue tips should become

visible on some areas and orange glow on other sections of the burner tile. Lifting of flames beyond five minutes

would indicate too much combustion air. The adjustment screw should be turned clockwise to reduce the

combustion air supply until the lifting settles down. If the blue tips disappear and the entire burner surface

becomes radiant white, it indicates that there is not enough combustion air and the adjustment screw should be

turned counterclockwise to increase the combustion air opening until the blue tips and orange glow become

visible again.

The optimum excess air will result in CO

2 levels between 8 and 8.5% for natural gas and 9.2 to 9.7% for

propane. If a flue gas analyzing equipment is available, the opening can be adjusted to achieve this CO2 level.

Or, if an inclined manometer is available, pressure measured at the combustion air switch pressure tap, can be

set at -0.35" W.C. for natural gas and -0.60" W.C. for propane by means of the adjustment screw. Pressure at

this level will result in the proper CO2 levels mentioned above.

Again, the factory setting will be adequate for most field conditions and adjustment will not normally be

required.

CAUTION: A dusty kitchen environment combined with greasy laden air will clog the combustion air blower wheel

and cause premature failure of the heater. Combustion air must not be contaminated by corrosive chemical

fumes which can severely damage the heater.

4

Page 5

Measures must be taken to prevent the entry of corrosive chemical fumes to the combustion and ventilation

air supply. Such chemicals include, but are not limited to, chlorinated and/or fluorinated hydrocarbons such as

found in refrigerants, aerosol propellants, dry-cleaning fluids, degreasers, and paint removers. Other harmful

elements may come from bleaches, air fresheners, or mastics. Vapors from these types of products can form

corrosive acid compounds when burned in a gas flame. The resulting acid condensate can damage or

substantially reduce the life of the heater. It may be necessary to provide outside air directly to the heater in order

to avoid this problem.

An adequate supply of air for proper combustion and ventilation must be provided in accordance with Sec.

5.3 of the National Fuel Gas Code, ANSI Z223.1. or applicable provisions of the local building codes.

Do not obstruct the flow of combustion and ventilation air to the heater.

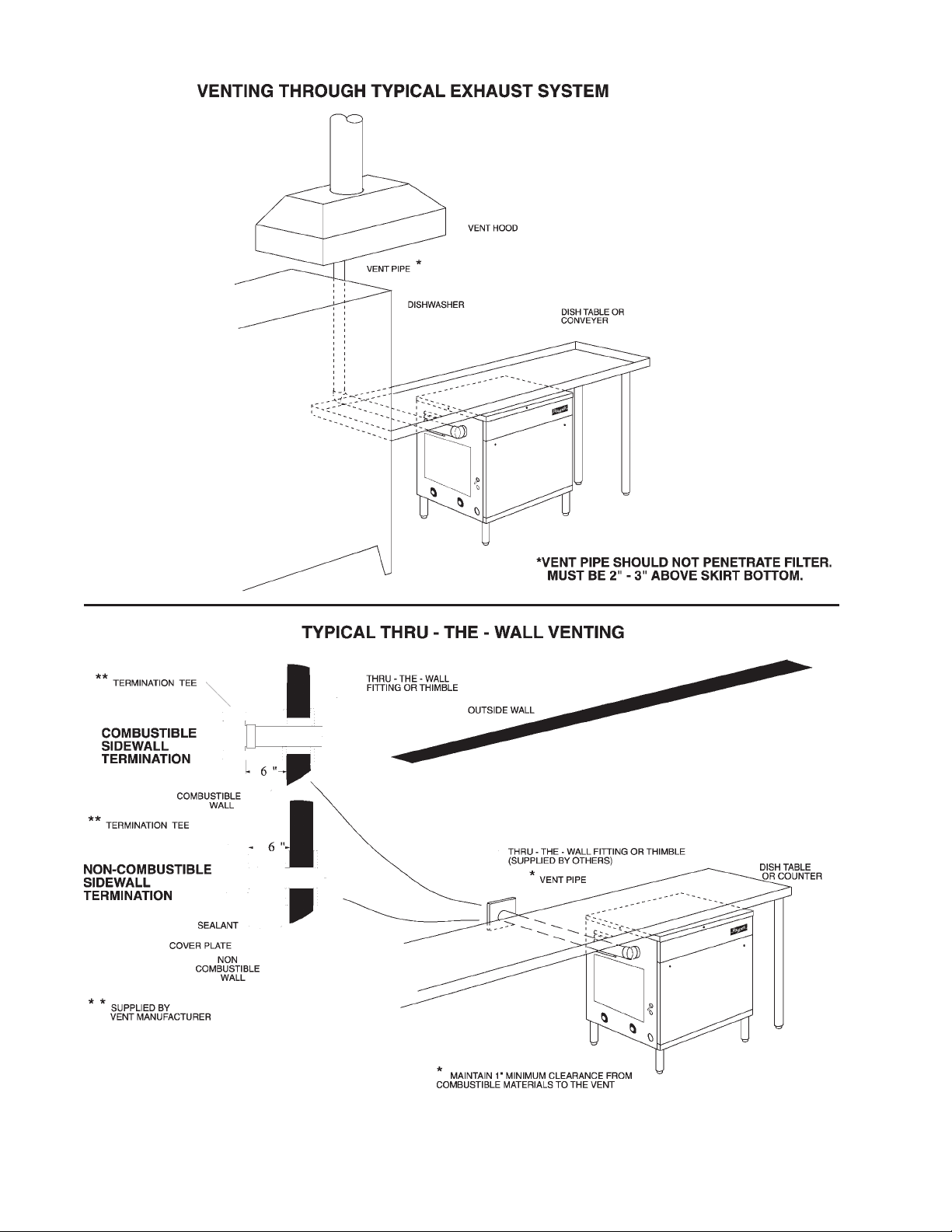

VENTING

The vent pipe must be the same size or larger than the 4" diameter outlet on the heater. The standard vent

outlet is on the right side, but this can be changed to the left side by reversing the orientation of the flue collector

box. This can be done easily in the field. Remove the top casing cover to gain access to the flue collector box.

Remove the screws along the sides of the flue collector. Disconnect the vent switch tubing from the fitting and

remove the fitting from the flue collector box. Lift the box and turn around the other direction. Remove the

stainless steel plug button and install the fitting in its place; then install the plug button where the fitting was

removed. Reconnect the vent switch tubing to the fitting. Replace and secure the flue collector box with the

screws previously removed.

The maximum flue gas temperature at the heater outlet is less than 400 degrees F. Use only the special gas

vents listed for use with Category III gas burning heaters, such as the stainless steel Saf-T Vent manufactured

by Heat-Fab, Inc. (800-772-0739), or the StaR-34 stainless steel gas vents manufactured by Flex-L International,

Inc. (800-561-1980), of the FasNSeal stainless steel gas vents manufactured by ProTech Systems, Inc. (800766-3473). A special adapter may be required. Pipe joints must be positively sealed. Follow carefully the vent

manufacturers' installation instructions.

WARNING: Provide a screen or barrier to prevent personal injury in areas where personnel contact with vent pipe

can occur; but DO NOT INSULATE the vent pipe, nor use means that will restrict thermal expansion or movement

of the vent.

5

Page 6

Applies only to exhaust hood over cooking equipment.

Fig. #8975.3

6

Page 7

All horizontal runs of the vent pipe shall have a

minimum rise of 1/4" per foot of length and should be

supported at maximum intervals of 5 feet (for Canada,

3 feet) and at each point where an elbow is used.

The gas booster heater may be vented 3 ways:

1. Through the sidewall, or the ceiling, as discussed

previously.

For horizontal venting, the total length of 4-inch

diameter pipe shall not exceed 30 feet with up to two

90° elbows and 1 termination vent. For each additional

elbow, reduce the total pipe length by 10 feet. The

minimum length, in either case, is 2 feet with two

elbows ending in a termination vent. For vertical

venting, the lengths described above should be followed, with a termination vent at the top. The minimum

length is 5 feet with up to two elbows and a termination

vent.

For sidewall venting, locate the heater as close as

possible to the wall being used. The maximum and

minimum wall thickness is determined by the wall

thimble available from the vent manufacturer. Refer to

the vent manufacturer installation instructions.

Additional requirements when venting through a

sidewall:

1. The vent terminal shall be located at least three feet

above any forced air inlet located within ten feet;

or at least four feet below, four feet horizontally

from, or one foot above any door, window, or

gravity air inlet into any building.

It shall also have a minimum horizontal clearance

of four feet from electric meters, gas meters,

regulator and relief equipment.

2. Into the exhaust system. (See illustration on page

6) Vent pipe must not penetrate filter.

When the unit is vented into the exhaust system, an

electrical inter-lock must be provided to allow the

flow of gas to the booster heater burner ONLY

when the exhaust system is energized.

3. Free vented into a room or space where other gas

fired equipment is installed, provided that one or

more of the other installed equipment is furnished

with a venting system or other approved means for

removing the vent gases so the aggregate input of

the remaining unvented equipment, including the

booster heater, does not exceed 20 BTU per hour

per cubic foot of volume. The volume of a room or

space directly connected by a doorway, archway or

other opening of comparable size that cannot be

closed, may be included in the calculations. Refer

to the National Fuel Gas Code ANSI Z223.1, NFPA

54.

2. The vent terminal shall be located not less than

seven feet above grade when it is adjacent to

public walkways.

3. The bottom of the vent terminal shall be located at

least twelve inches above grade or ground, or

normally expected snow accumulation level. The

snow level may be higher on walls exposed to

prevailing winds.

4. Avoid areas where local experience indicates that

condensate drippage may cause problems such

as above planters, patios, or over public walkways, or over an area where condensate or vapor

could create a nuisance or hazard, or could be

detrimental to the operation of regulators, relief

valves, or other equipment.

7

Page 8

GAS PIPING

The gas inlet pipe size is 1/2" NPT to the gas valve.

Provide an adequate size gas supply line. The line

should not be smaller than 1/2" NPT according to the

chart below.

MAXIMUM EQUIVALENT PIPE LENGTH (FEET)

Pipe Size

Gas 1/2" 3/4" 1"

Natural 5 30 100

Propane 70 180

Gas piping must have a sediment trap ahead of the

heater gas controls and a manual shut-off valve located outside the jacket. A manual shut-off valve is

provided loose and must be installed at the site.

The heater and its gas connection shall be leak

tested before placing the heater in operation.

Fig. # 8984

The heater and its individual shut-off valve must be

disconnected from the gas supply piping system during

any pressure testing of that system at test pressures in

excess of 1/2 psig (3.5 kPa).

The heater must be isolated from the gas supply

piping system by closing its individual manual shut-off

valve during any pressure testing of the gas supply

piping system at test pressures equal to or less than

1/2 psig (3.5 kPa).

Dissipate test pressure from the gas supply line

before re-connecting the heater and its manual shut-off

cock to the gas supply line. FAILURE TO FOLLOW

THIS PROCEDURE MAY DAMAGE THE GAS VALVE.

OVER PRESSURED GAS VALVES ARE NOT COVERED BY THE WARRANTY. The heater and its gas

connections shall be leak tested before placing the

appliance in operation. Use soapy water for leak test.

DO NOT use open flame.

NOTE: DO NOT use teflon tape on gas line pipe

threads. A flexible sealant suitable for use with Natural

and Propane gases is recommended.

GAS PRESSURE SPECIFICATIONS

Inches W.C.

Gas Min Max Manifold

Natural 4.5 10.5 3.5

Propane 11.0 14.0 10.0

The maximum inlet gas pressure must not exceed

the value shown above. The minimum gas pressure

shown is for the purposes of input adjustment.

The gas valve is provided with a pressure tap to

measure the gas pressure downstream, which is also

the manifold pressure.

WATER PIPING

The inlet and outlet water connections are 3/4 in.

NPT. A water pressure regulator is shipped loose with

the heater. Install, as needed, between the booster

heater and dishwasher lines. Adjust setting to maintain

20 PSI at the dishwasher.

Install a suitable water hammer arrester between the booster heater and dishwasher, as shown

on page 10, typical piping.

8

Page 9

A drain valve is provided in the tank for draining

water during servicing.

The temperature and pressure relief valve is easily

accessible through the front. A nipple is provided

(shipped loose with the heater) for installation in the

T & P relief valve. A drain line must be connected to

the nipple and run to a safe place of disposal.

WARNING: Failure to do so can cause water damage

or burns due to scalding if the relief valve should open.

Drain line must be as short as possible, pitch downward

from the relief valve, and have the same size as the

valve discharge connection through-out its entire length.

Refer to tag attached to T & P relief valve.

The temperature and pressure relief valve should

be manually operated at least once a year to insure that

the valve mechanism is still functional. Repair or

alteration of valve in any way is prohibited by National

Safety Standards and or local codes.

If the relief valve discharges occasionally or periodically, this may be due to thermal expansion in a

closed water supply system. Contact the water supplier or the local plumbing inspector on how to correct

this situation. DO NOT plug the relief valve or install

a shut-off valve in the discharge drain line.

The heater is equipped with a circulator to provide

the minimum water flow in the heater, and maintain a

uniform water temperature in the tank. Depending on

heater distance from the dishwasher, it may be necessary to run empty rack(s) to purge supply of line lower

than the required 180°F water temperature. For this

reason, it is best to locate heater as close as possible

to the dishwasher.

CAUTION: In severe cold weather, freezing air can be

drawn through the vent pipes to the heat exchanger

during overnight shut-down period. If there is no water

circulation or heat in the water, freezing can occur

which will damage the heat exchanger. To avoid

freezing damage, constant water circulation should be

maintained by keeping the booster heater energized

so that the circulator (pump) will run. Closing the

manual gas shut-off valve will prevent unnecessary

heating of the water. NOTE: Under this condition, the

ignition system will go into a lock-out mode. To resume

service, the heater will need to be reset by momentarily

turning the ON/OFF switch to the OFF position, and

then to the ON position.

9

Page 10

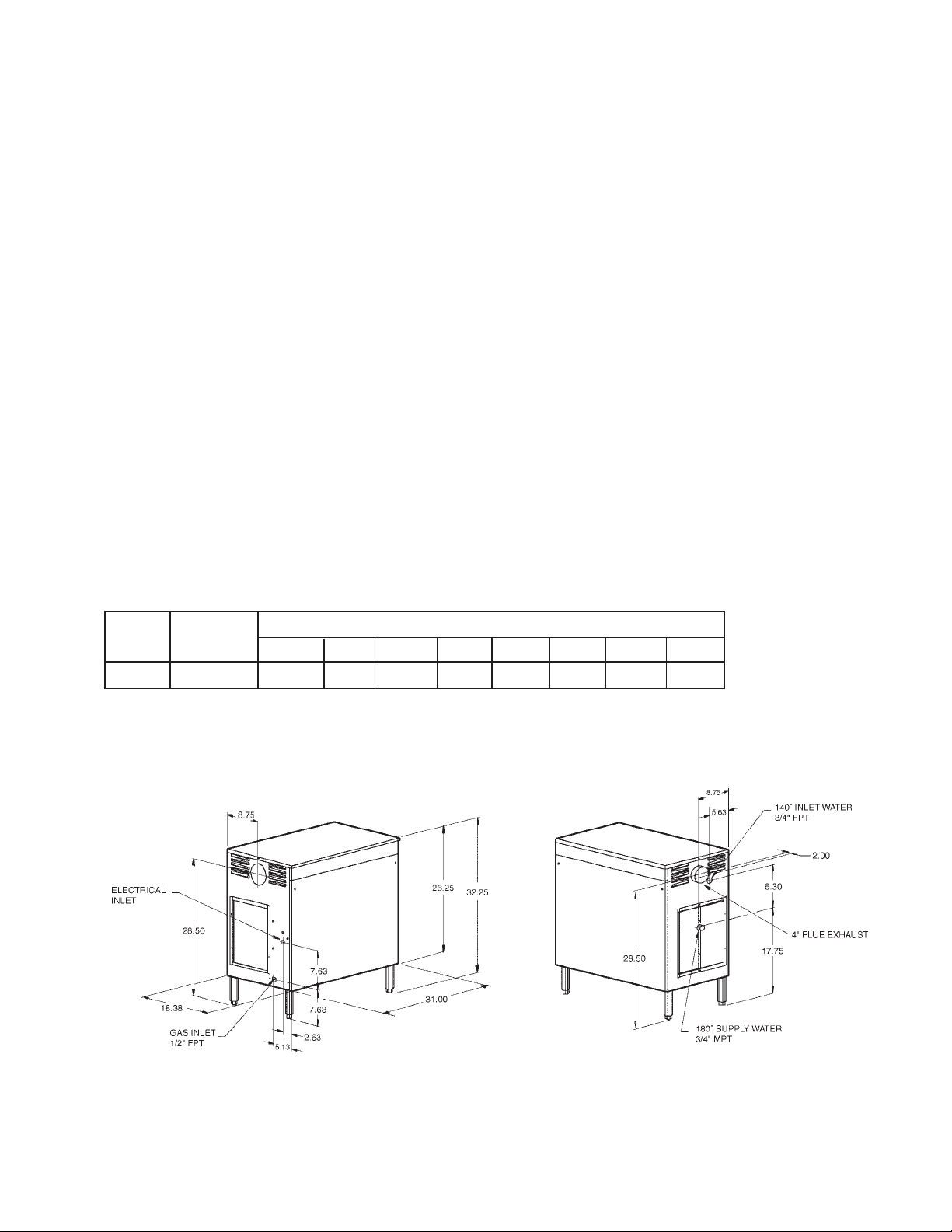

ELECTRICAL

The electrical power supply requirement for the heater is 120 volts, 60 Hz, 5.0 amps or less . Field wiring

connections and electrical grounding must comply with the local codes, or in the absence of local codes, with

the latest edition of the National Electrical Code, ANSI/NFPA 70.

NOTE: Polarity must be observed for the heater to operate properly. Consult wiring diagram. Provide a separate

fused circuit from the main electrical panel to the heater and a disconnecting means within sight of the heater.

Remove the control box cover and make the power supply connection in the field wiring compartment. The

pump and blower supplied with the heater are pre-wired and operate with the heater control system.

NOTE: If it is necessary to replace any of the original wiring it must be replaced with 105° C rated wire or its

equivalent.

10

Page 11

LADDER DIAGRAM

CONNECTION DIAGRAM

DANGER: SHOCK HAZARD

Turn off electrical power to boost heater before servicing any

component in the heater to prevent equipment damage or

personal injury.

NOTE: If it is necessary to replace any of the original wiring, it

must be replaced with 105°C rated wire or its equivalent.

11

Page 12

4. START UP AND OPERATION

COMPONENT LOCATION

SEQUENCE OF OPERATION

The booster heater is designed to maintain a temperature of 180 deg. F (82.2 Deg. C) of 490 GPH water

required for the rinse cycle of a commercial dishwasher. An inlet temperature of 140 Deg. F (60 Deg.

C) will produce optimum results.

Provided the necessary power, water, gas and

vent connections are completed, the unit is started by

the activation of the on/off switch located on the left side

panel. The blower motor and the circulator pump will

also start.

Providing the operating and safety controls includ-

ing the vent switch is closed, the ignition module will

energize the ignitor. The hot surface ignitor then heats

up, and is proven to be capable of ignition. The gas

valve is then energized. The burner will be lit and the

remote sensor will sense the flame. If the burner flame

is not sensed within four seconds the gas valve will shut

off. The ignition module will try for a total of three cycles

to prove ignition. If, after third cycle ignition is not

proven, the module will go into lockout, and a Red-LED

will start blinking. To recycle the burner, momentarily

turn the power switch to the off position and then to the

on position. When the water temperature exceeds the

setting of the operating controller, the burner will shut

off until the next call for heat. The operating limit control

is factory set at 185°F. Combustion air blower and the

circulator pump will cycle On/Off with the operating limit

controller.

START UP PROCEDURES

SECTION 1. FILLING THE SYSTEM

Fill the heater system with water purging all air. It

is recommended that the system be flushed before

putting heater into operation . This can be done by

opening the drain valve located under the stainless

steel tank.

SECTION 2. CHECKING CIRCULATOR/PUMP

Before lighting the heater, make sure the circulator

is operating properly. With the gas valve in the off

position, activate the power switch. The circulator

should start immediately. Allow the circulator to pump

the water through the system.

NOTE: The circulator motor does not require lubrication.

12

Page 13

SECTION 3. LIGHTING THE HEATER

Safety lighting and other performance criteria were

met for the burner assembly and control assembly

when the heater was tested for design certification

under the ANSI Z21.10.3 Standard

WARNING: If you do not follow these instructions

exactly, a fire or explosion may result causing property

damage, personal injury or loss of life.

A. This heater DOES NOT have a pilot. It is equipped

with a hot surface ignition device which automati-

cally lights the burner. DO

NOT attempt to light the

burner by hand.

B. Before operating smell all around the heater area

for gas. Be sure to smell next to the floor because

some gases are heavier than air and will settle on

the floor.

WHAT TO DO IF YOU SMELL GAS

4. This appliance is equipped with an ignition

device which automatically lights the burners. Do

not try to light the burners by hand.

5. Push in and move gas control lever counter

clockwise to "OFF" position.

6. Wait five (5) minutes to clear out any gas. If you

then smell gas. STOP! Follow "B" in the safety

information above on this label. If you don't smell

gas, go to next step.

7. Move gas control lever clockwise to "ON"

position.

GAS CONTROL

LEVER SHOWN

IN "OFF"

POSITION

• Do not try to light any appliance.

• Do not touch any electric switch.

• Do not use any phone in your building.

• Immediately call your gas supplier from a

neighbor's phone. Follow the gas supplier's

instructions.

• If you cannot reach your gas supplier, call the

fire department.

C. Use only your hand to push in, move or turn the gas

control knob or lever. Never use tools. If the knob

or lever will not push in, move or turn by hand, don't

try to repair it, call a qualified service technician.

Force or attempted repair may result in a fire or

explosion.

D. Do not use this heater if any part has been under

water. Immediately call a qualified service technician to inspect the heater and to replace any part of

the control system and gas control which has been

underwater.

HOT SURFACE IGNITION MODELS WITH

ROBERTSHAW GAS VALVE

1. STOP! Read the safety information.

2. Turn off all electrical power to the appliance.

3. Remove front door and control box cover.

GAS INLET

Fig. # 8934.1

8. Replace control box cover and front door.

9. Turn on all electric power to the appliance.

10. If the appliance will not operate. Follow the

instructions "To Turn Off Gas To Heater" and call

your service technician or gas supplier.

TO TURN OFF GAS TO HEATER

1. Turn off all the electric power to the heater if service

is to be performed.

2. Remove front door and control box cover.

3. Push in and move gas control lever counter

clockwise to "OFF".

CAUTION: Should overheating occur or the gas supply fails to shut off, DO NOT turn off or disconnect the

electrical supply to the pump. Instead, shut off the gas

supply at a location external to the appliance. Failure

to observe this precaution may aggravate the overheated condition resulting in possible damage to the

heater and injury to the user.

13

Page 14

SECTION 4.

TESTING THE IGNITION SAFETY SHUT-OFF

The ignition system safety shut-off must be tested by

conducting the following method of tests:

3. Remove screws on burner access panel.

4. Remove refractory block.

5. Visaully inspect burner tray panel.

6. Reverse above procedure to reinstall, checking

burner tray and seal to prevent leakage.

a) With the system power off, manually shut off the

gas supply.

b) Turn power back on, observe the igniter start to

heat up and glow bright orange.

c) After about four (4) seconds, the gas valve is

energized, then de-energizes, after the third try the

module goes into a safety lockout a few seconds later. Igniter will stop glowing and the R e d

LED on the module will start blinking.

d) Manually reopen the gas supply. No gas should be

flowing into the main burners. End of test.

e) To reset the system, momentarily shut off power

switch then turn it back on again. Igniter will start

to heat up and normal heating cycle will occur as

described in the sequence of operation on page

12.

MAINTENANCE INSTRUCTIONS

1. The water pump motor and the combustion air

blower motor are permanently lubricated and requires no other maintenance.

2. Venting system for this heater may be equipped

with high temperature plastic material rated for

operation at 480°F maximum. Check for signs of

deformation in the plastic vent pipes which will be

an indication of excessive temperature and abnormal conditions in the venting system. Refer to the

instructions supplied by the vent pipe manufacturer.

3. The burner is made of ceramic material and operates in the infrared mode. When the burner is

operating properly very little blue flame will be

visible due to the incandescent brightness of the

ceramic material. This can be observed through

the glass observation port hole.

4. Depending on the condition of the kitchen environment, the burner and blower wheel may require to

be cleaned of lint or grease-laden dust. Inspect the

burner box every six months. Refer to the Servicing Section related to burner removal.

BURNER INSPECTION/VISUAL

1. Shut-off electrical power and gas supply to the

heater.

2. Disconnect wiring to hot surface ignitor and sensor.

ADJUSTMENTS/REPLACEMENTS

OF COMPONENTS

CAUTION: Label all wires prior to disconnection when

servicing controls. Wiring errors can cause improper

and dangerous operation. Verify proper operation after

servicing.

DANGER - SHOCK HAZARD - Make sure electrical

power to the heater is disconnected to avoid potential

serious injury or damage to components.

1. Gas Valve Replacement

a) Shut off electrical power and gas supply to the

heater.

b) Remove gas piping to gas valve inlet.

c) Remove front panel and leftside access panel.

d) Disconnect flex hose gas line.

e) Disconnect wiring connections to gas valve.

f) Remove (2) screws holding gas valve.

g) Reverse above procedure to reinstall.

2. Hot Surface Ignitor Replacement

a) Shut off electrical power and gas supply to the

heater.

b) Disconnect wiring leads to the igniter by pulling

apart plastic connector plugs.

c) Remove bracket holding ignitor cylinder.

d) Reverse above procedure to reinstall.

CAUTION: Silicon carbide ignitor is fragile and brittle.

Exercise extreme care in handling the assembly to

avoid damage.

3. Ignition Module Replacement

a) Shut off electrical power to the heater.

b) Remove control cover screws and open con-

trol compartment.

c) Disconnect wiring connections to module.

d) Remove screws (2) holding module.

e) Reverse above procedure to reinstall.

4. Transformer Replacement

a) Shut off electrical power to the heater.

b) Remove control cover screws and open con-

trol compartment.

c) Disconnect wiring connections from transformer

leads.

d) Remove screws (2) holding transformer.

e) Reverse above procedure to reinstall.

14

Page 15

5. Limit Control Module

a) Shut-off electrical power to the heater.

b) Remove control cover screws and open con-

trol compartment.

c) Disconnect wiring connections to the board.

d) Carefully pull out the control board from the

nylon pin supports.

e) Reverse above procedure to reinstall.

6. Sensor Probe Replacement

a) Shut off electrical power to the heater.

b) Shut off water supply to the heater and open

drain valve to remove water to the sensor

probe level.

c) Remove front panel and control box cover.

d) Disconnect wire leads from temperature con-

trol module.

e) Remove sensor probe from the header. Use

7/16" wrench.

f) Reverse above procedure to reinstall.

7. Manual Reset High Limit Control Replacement

a) Shut off electrical power and water supply to

the heater.

b) Remove front panel and open drain valve to

remove water to the limit control level in the

tank.

c) Disconnect wiring connections to limit control.

d) Remove limit control from the tank. Use 1" hex

wrench, being careful not to break plastic body.

e) Reverse above procedure to reinstall.

8. Auto Reset High Limit Replacement

a) Shut off electrical power and water supply to

the heater.

b) Remove front panel and open drain valve to

remove water to the limit control level in the

header.

c) Disconnect wiring connections to limit control.

d) Remove limit control.

e) Reverse above steps to reinstall.

11. Combustion Air Blower Replacement

a) Shut off electrical power to heater.

b) Remove front panel and access cover on left

side of heater.

c) Remove screws (3) on blower housing mount-

ing panel.

d) Drop down blower assembly from discharge

connection.

e) Open field wiring box and disconnect blower

wiring.

f) Reverse above steps to reinstall blower.

12. Pump/Circulator Replacement

a) Shut off electrical power to the heater.

b) Shut off water supply and open drain valve to

remove water in the piping at the pump level.

c) Remove front panel and access panel on right

side of cabinet.

d) Disconnect wiring and conduit connections to

motor.

e) Remove plumbing connections to pump as-

sembly.

f) Reverse above procedure to reinstall.

13. Temperature and Pressure Relief Valve

Replacement.

a) Shut off electrical power to the heater.

b) Shut off water supply and open drain valve to

remove water in the tank to the relief valve

level.

c) Remove front panel.

d) Disconnect plumbing connections to the T & P

relief valve.

f) Reverse above procedure to reinstall.

9. Air/Vent Switch Replacement

a) Shut off electrical power to the heater.

b) Remove front panel.

c) Remove wiring connections to switch.

d) Remove screws (2) holding the switch.

e) Reverse above procedure to reinstall.

10. Remote Sensor Replacement

a) Shut off electrical power & gas supply to the

heater.

b) Remove front panel.

c) Disconneect wiring lead from sensor.

d) Remove the screws (2).

e) Reverse above procedure to reinstall.

15

Page 16

5. SERVICING UNIT

TROUBLE SHOOTING GUIDE

PROBLEM

1. On-Off switch energized. Unit

does not operate.

2. Pump/Blower NOT running.

3. Unit energized, pump and

blower running, but burner is

NOT on.

POSSIBLE CAUSE

1a. No power to heater

1b. Defective transformer

2a. Loose wire(s)

2b. Defective pump

2c. Defective blower.

3a. Limit control (operating limit)

or sensor may be defective.

SUGGESTED SOLUTION

a. Cycle the Power Switch off then on.

-Check circuit breaker and electrical

disconnect.

-Check for reversed polarity and improper ground.

-Check dishwasher vent interlock, if

applicable.

b. Check secondary voltage.

If no 24 volts, replace transformer.

2a. Check wiring connection(s)

-Check pump amperage. If pump

does not draw 0.67-0.78 amps, remove and inspect impeller.

2b. Replace cartridge or entire pump as

needed.

2c. Clean and inspect blower wheel.

-Check operation.

-Replace blower if needed

3a. If Red LED on circuit board is ON,

check for a loose sensor connection

or defective sensor. Sensor resistance readings:

60°F = 45,500± 2300 ohms

80°F = 28,000± 1300 ohms

If Yellow LED is ON , water temperature is above set point. When either

Red or Yellow LED is ON, heater will

be shut down. Check 24V, power at

OUT and COMM terminals. If no 24V

is present when Red or Yellow LED is

not ON, replace control board.

3b. Blocked vent or defective

air vent switch.

3c. Tripped or defective manual

reset limit.

16

3b. Excessive vent length or resistance

or blocked vent will open the air vent

switch. Remove blockage. If switch

stays open, replace air vent switch.

3c. Depress the Manual Reset High Limit

switch.

-Ensure Operating Limit setting is

185°F or less.

-Perform Pump Check Procedure.

(High Limit trips may be due to a

damaged pump).

-Perform Operating Limit Check

Procedure.

-If High Limit will not reset, replace

High Limit

Page 17

Continuation TROUBLE SHOOTING GUIDE

3d. Excessive vent exhaust or

defective air/vent switch.

3d. Excessive negative pressure exerted

by the exhaust system on the vent will

prevent N.O. combustion air/vent

switch from closing. Provide means to

relieve pressure and close the N.O.

switch. If combustion air/vent switch

will not close, replace switch.

4. Unit energized, pump and

blower running.

Ignitor is glowing.

Burners will not stay lighted.

3e. Ignition module or igniter

may be defective.

3f. Gas valve or the ignition

module may be defective.

4a. Improper ground

4b. Loose wiring.

4c. Remote sensor

4d. Insufficient gas pressure.

3e. Disconnect igniter leads from ignition

module. Make sure 24V is present

across ignition terminals on the ignition module during the ignition cycle.

If not, replace ignition module. Check

resistance reading across igniter

leads. If circuit is open, or reading is

greater than 30 ohms, replace the

igniter. A new igniter will measure

between 1 to 6 ohms at room temperature.

3f. During the ignition cycle, 24V should

be present at the MV1 and GND terminals for about 5 seconds. If no 24V is

measured, replace the ignition module. If 24V is present, replace the gas

valve.

4a. Check ground connections inside

control box.

4b. Check all connections and wire nuts.

4c. Check wire connection to remote sen-

sor.

4d. Check gas pressure at outlet of valve

under load, pressure should be:

3.5 in. W.C.for Natural gas

10.5 in. W. C. for Propane gas.

5 Unit does not produce

suffcient hot water

5a. Supply water temperature

too low.

5b. Dishwasher times not set

properly.

5c. Operating limit set too low.

17

5a. Ensure supply water temperature is at

least 140°F.

5b. Ensure dishwasher operates correctly.

Check rinse cycle time and inspect

spray nozzles for correct pressure

setting or damage.

5c. Adjust operating limit to minimum tem-

perature that provides 180°F rinse.

(Do not set above 185°F).

-Verify booster operates correctly, if

not, recheck all procedures listed

above.

Page 18

6. REPLACEMENT PARTS LIST

NOTE: To supply the correct part it is important that you state the model number, serial number and type of gas

when applicable.

Any part returned for replacement under standard company warranties must be properly tagged with

RAYPAK return parts tag, completely filled in with the heater Serial Number, Model Number etc., and shipped

to the Company freight prepaid.

If determined defective by the Company and within warranty, the part will be returned in kind or equivalent

substitution, freight collect. Credit will not be issued.

RAYPAK, INC.

2151 Eastman Avenue

Oxnard, CA 93030

18

Page 19

192021

Page 20

Page 21

Page 22

LIMITED PARTS WARRANTY

COMMERCIAL BOOSTER HEATER

SCOPE:

Raypak, Inc. ("Raypak") warrants to the owner that all parts of this booster heater, excluding controls and pump, will

be free from failure under normal use and service for the specified warranty periods and subject to the conditions set forth

in this Warranty. The Warranty is effective from date of original booster heater installation and satisfactory proof of the original

installation date, such as installer invoice, is required. THIS WARRANTY WILL BE VOID IF THE HEATER IS NOT

INSTALLED IN ACCORDANCE WITH LOCAL CODES AND ORDINANCES OR IF THE HEATER RATING PLATE IS

ALTERED OR REMOVED OR IF THE HEATER IS MOVED FROM ITS ORIGINAL PLACE OF INSTALLATION.

HEAT EXCHANGER WARRANTY:

• Five (5) Years. This includes only the copper and bronze waterways.

Twenty (20) Years against "Thermal Shock" (excluded, however, if caused by booster heater operating at large

•

changes exceeding 150°F between the water temperature at intake and booster heater temperature, or

operating at booster heater temperatures

TOTAL FIVE YEAR STAINLESS STEEL TANK WARRANTY:

• First Year: Raypak will replace the tank if it fails under normal use and service.

• 2nd thru 5th Year: Raypak will replace the tank if it fails under normal use and service, provided that the owner must

pay Raypak a portion of the published list price in effect at the time notice of the failure is given.

REPLACEMENT PRICE) REPLACEMENT PRICE

YEAR OF CLAIM (PERCENT OF LIST PRICE YEAR OF CLAIM (PERCENT OF LIST PRICE)

2 20% 4 60%

3 40% 5 80%

ANY OTHER PART MANUFACTURED BY RAYPAK:

One (1) Year Warranty, or eighteen (18) months from date of factory shipment based on Raypak's records,

whichever comes first.

PARTS REPLACEMENT

Under this Warranty, Raypak will furnish a replacement for any failed part. Verification of the in-warranty failure will be

made through inspection by a local recognized and certified service agency or the local Raypak representative at Raypak's

option. The replacement part will be warranted for only the unexpired portion of the original warranty. Raypak makes no

warranty whatsoever on the controls and the pump, but Raypak will apply any such warranties as may be provided to it by

the part's manufacturer.

LABOR CHARGES

Labor charges to replace any failed part during the first 90 days of this Warranty, will be paid by Raypak. Service must

be performed by a recognized and certified service agency during normal working hours. All other costs are excluded from

this warranty and are the owners responsibility.

ADDITIONAL WARRANTY EXCLUSIONS:

This Warranty does not cover failures or malfunctions resulting from:

1. Failure to properly install, operate or maintain the booster heater in accordance with our printed instructions;

2. Abuse, alteration, accident, fire, flood and the like;

3. Sediment or lime buildup, freezing or other conditions causing inadequate water circulation;

4. High velocity flow exceeding booster heater design rates;

5. Failure of connected systems devices, such as pump or controller;

6. Use of non-factory authorized accessories or other components in conjunction with the booster heaters.

7. Failure to eliminate air from, or replenish water in, the connected water system;

8. Chemical contamination of combustion air or owner's use of chemical additives to water.

TO MAKE A WARRANTY CLAIM:

Promptly notify the selling dealer, supplying model and serial numbers and description of the problem. The dealer must

then notify it's Raypak distributor for instructions regarding the claim. If the dealer is not available, contact SERVICE

MANAGER, at the address listed below. In all cases, proper authorization must first be received from Raypak before any part

is replaced. Any replaced part must be made available to Raypak in exchange for replacement.

EXCLUSIVE WARRANTY - LIMITATION OF LIABILITY:

This is the only warranty given by Raypak. No one is authorized to make any other warranties on Raypak's behalf. ALL

OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED TO THE IMPLIED WARRANTIES OF

MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE, ARE EXCLUDED. Some States do not allow

limitations on how long an implied warranty lasts, or for the exclusion or incidental or consequential damages, so the above

limitation or exclusion may not apply to you.

THIS LIMITED WARRANTY GIVES YOU SPECIFIC LEGAL RIGHTS. YOU MAY ALSO HAVE OTHER RIGHTS WHICH

VARY FROM STATE TO STATE.

The sole remedy against Raypak with respect to defective parts shall be as provided in this Warranty. It is agreed that Raypak

shall have no liability, whether under this Warranty, or in contract, tort, or otherwise, for any special, consequential, or

incidental damages.

exceeding 200°F).

RAYPAK, INC., 2151 Eastman Avenue, Oxnard, CA 93030 (805) 278-5300

23

Page 23

www.raypak.com

Raypak, Inc., 2151 Eastman Avenue, Westlake Village, CA 93030 (805) 278-5300 FAX (800) 872-9725

Raypak Canada Limited, 2805 Slough St., Mississauga, Ontario, Canada L4T 1G2 (416) 677-7999 FAX (416) 677-8036

Litho in U.S.A.

Loading...

Loading...