Raypa AE-28, AE, AE-75, AE-110, AE-150 Instruction manual

R.ESPINAR S.L. AEi/01

R.ESPINAR, S.L.

INSTRUCTION MANUAL

FOR USE AND MAINTENANCE

AUTOCLAVES FOR STERILIZATION

“MICROPROCESSOR CONTROLLED

WITH DRY AND PREVACUUM”

Models: AE-28 DRY

AE-75 DRY

AE-110 DRY

AE-150 DRY

1/22

R.ESPINAR S.L. AEi/01

This manual has been written for safety reasons, read the instructions

carefully before installing and /or using this apparatus.

If this apparatus should be sold or transferred, ensure that this manual is

given to the new owner, for the correct use and installation.

This manual should be kept by the apparatus for in case of doubt in its use

and for maintenance reasons.

INDEX

Description .................................................................................................……......…......... page 3

Rear view .................................................................................................................…......... page 3

Characteristics and microprocessor functions ........................... .............................….......... page 4

Technical specifications ........................................................................................................ page 5

Characteristics .................................................................................................................... page 6

Accessories .................................................................................................…........................ page 6

Installation ..........................................................................................….............................. page 7

Connection to the mains ......................................................................…............................. page 7

Changing voltage ................................................................................…............................... page 8

Programming mode ...........................................................................…................................ page 9

Alphanumeric display functions ............................................................................................. page 9

Program introduction ..........................................................................…............................... page 10

Time and date adjust ............................................................................................................ page 11

Programming of printer connection ....................................................................................... page 11

SOLID/LIQUID Modes .......................................................................................................... page 11

Start up ................................................................................................................................ page 12

Filling of the condensation tank ............................................................................................ page 12

Shut down of the autoclave ................................................................................................... page 15

Loading the autoclave ....................................................……………….................................. page 15

Printer mode ....................................................................................................................... page 16

Protected programs (info.) ................................................................................................. page 18

Warning messages .....................................……................................................................... page 18

Failure massages ...….......................................................................................................... page 19

Repairs and spare parts .........................................................................................…......... page 21

Guarantee ......................................................................................................................... page 21

Conformity declaration “CE” .............................................................................................. page 22

2/22

R.ESPINAR S.L. AEi/01

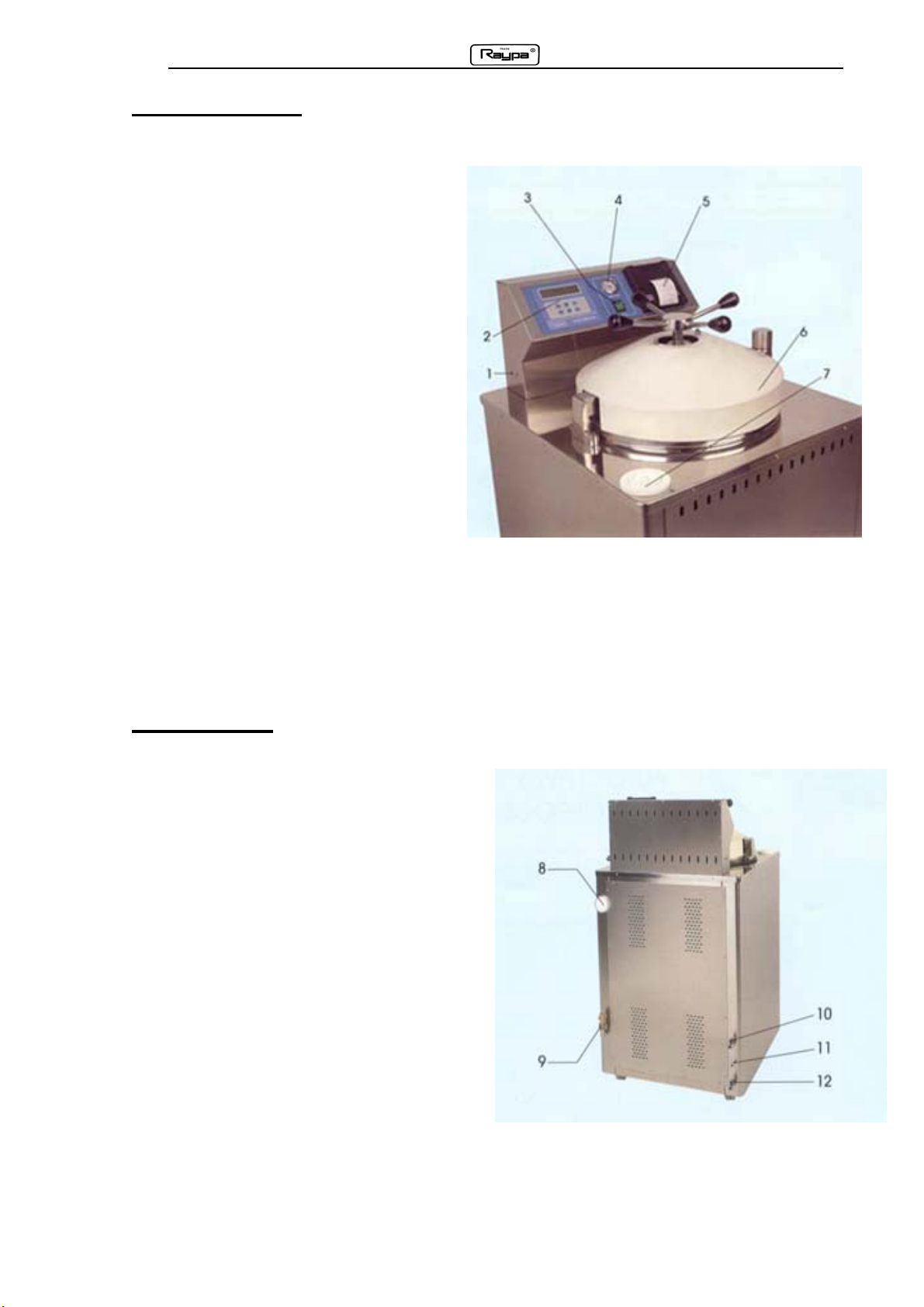

DESCRIPTION

1.- Interface outlet RS-232.

2.- Microprocessor.

3.- Mains switch.

4.- Mano-vacuometre.

5.- Thermal printer of continuous sheet.

6.- Thermal protector of the cover.

7.- Filling of the condensed water tank.

REAR VIEW

8.- Ventilation bacteriological filter.

9.- Safety valve.

10.- Condensed water tank empty valve.

11.- Condensed tank outlet.

12.- Valve for autoclave chamber empty.

3/22

R.ESPINAR S.L. AEi/01

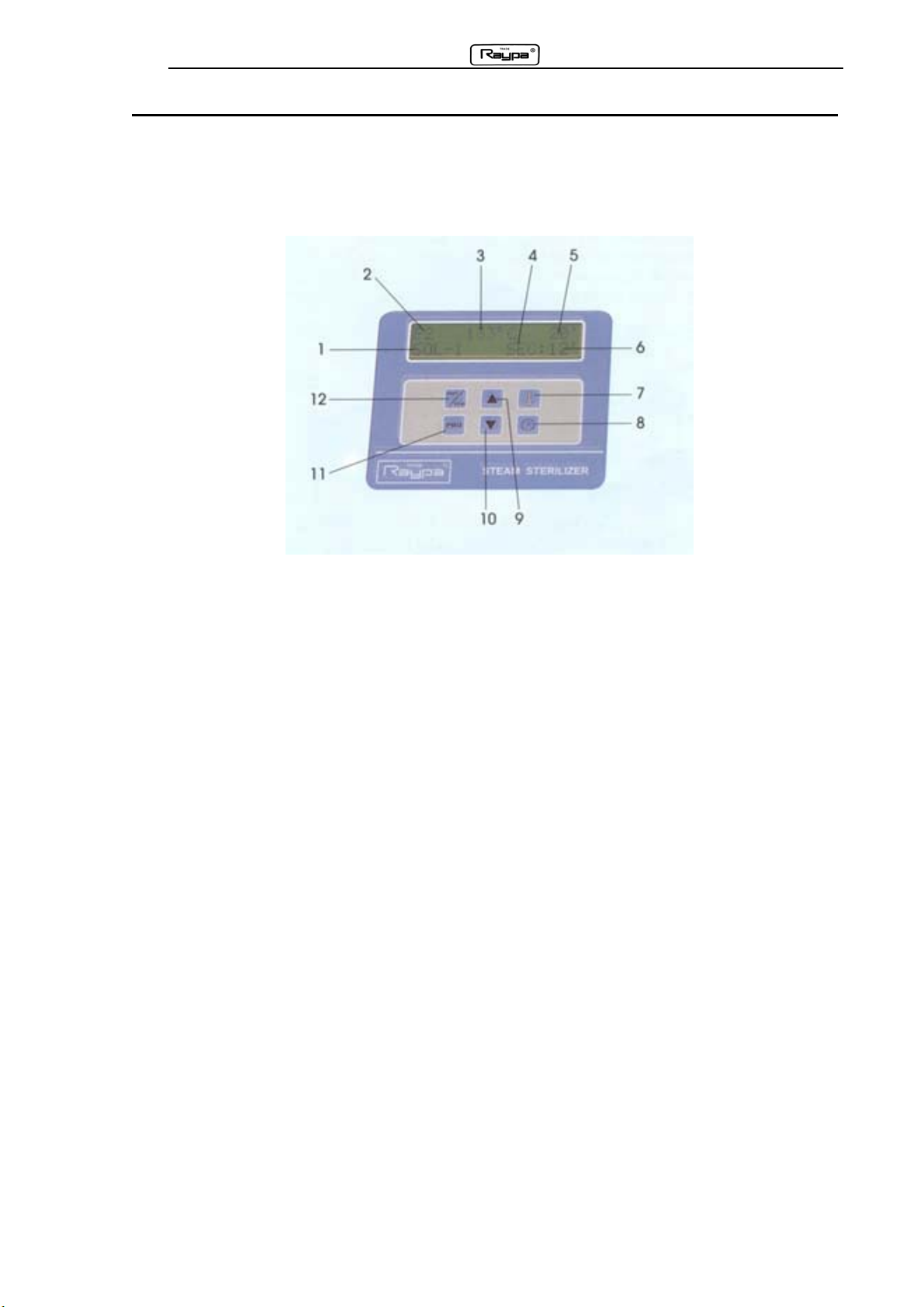

MICROPROCESSOR FUNCTIONS AND CHARACTERISTICS

DESCRIPTION

1.- Operation mode: SOLIDS/LIQUIDS.

2.- Number of the program.

3.- Sterilization temperature.

4.- Final drying.

5.- Sterilization time.

6.- Dry time.

7.- Switch for sterilization temperature selection. (TEMPERATURE)

This switch is used during a sterilization program edition to select and edit the figures.

8.- Switch for sterilization time selection. (CLOCK)

This switch is used during the edition of a sterilization program to select and edit different

figures.

Time of sterilization.

Type of sterilization.

Dry time.

Date/Hour.

9.- Increase switch.

In program mode it is used to increase the value of the parameter in edition.

Out of program it is also used to select a program.

10.- Decrease switch.

4/22

R.ESPINAR S.L. AEi/01

In program mode it is used to decrease the value of the parameter in edition.

Out of program it is also used to select a program.

11.- Programming switch. (PRO)

While pressing this switch during 2 seconds you can access to the edition of the program.

During the process of sterilization will shoe the program while pressing.

12.- Start/Stop switch.

This switch is used to run or to stop the sterilization program selected.

To stop the sterilization cycle it must be pressed the START/STOP switch during 2

seconds. If this operation is made, in the final onform will appear the message “STOP”

instead of the message “STERILIZATION OK”.

TECHNICAL SPECIFICATION

Apparatus: Steam sterilization autoclave

Sterilization temperature: From 105ºC to 139ºC.

Max. pressure: 2,5 bar

Voltage: 220 V single-phase (for AE-28 DRY and AE-75 DRY)

220 V or 380 V triple phase + N (for AE-110 DRY and

AE-150 DRY)

Frequency: 50/60 Hz

Consume: 2.000 W (Model AE-28 DRY)

3.000 W (Model AE-75 DRY)

4.500 W (Model AE-110 DRY)

6.000 W (Model AE-150 DRY)

Sterilization time: from 3 to 120 minutes.

Final Drying: Selectable: (DRY/NOT DRY)

Drying time: From 0/3 to 60 minutes.

Data printing: Manual.

Printing cadence: Every 120 seconds.

Printer connection: Interface RS-232

5/22

R.ESPINAR S.L. AEi/01

CHARACTERISTICS

Tank, rotary seal and lid made of stainless steel AISI 316.

Exterior metallic and top surface made of AISI-304 stainless steel.

Seal of silicone.

Automatic air purge evacuation by initial pre-vacuum.

Distilled water tank , with maximum and minimum water levels.

Drying system with dry heat and vacuum pump.

Automatic water filled in the sterilization chamber.

Over-temperature and over-pressure safety devices, safety presostate and safety

valve.

ACCESSORIES

ACCESSORIES THAT MUST BE INSTALLED AT THE FACTORY:

Code Ref. Description

90131400 PT-2 Heart probe PT-100, hermetic with flexible wire of silicone to

introduce it into the liquids or bags to sterilize at a real time and

temperature, not depending on the volume or capacity of the

material to sterilize.

90131300 IT Thermal printer of continuous sheet, that prints the number of

the program, number of cycle, temperature, time and date of

every sterilization.

Other accessories:

Code Ref. Description

90130228 CI-28 Perforated stainless steel basket AISI-316 of Ø280x200mm for

AES-28. (2 per autoclave)

90130375 CI-75 Perforated stainless steel basket AISI-316 of Ø380x260mm for

AES-75 and for AES-110. (2 per autoclave AES-75 and 3 per

AES-110)

90130450 CI-150 Perforated stainless steel basket AISI-316 of Ø475x360mm for

AES-150. (2 per autoclave)

90130628 CCI-28 Non-perforated stainless steel basket AISI-316 of Ø280x200mm

for AES-28. (2 per autoclave)

6/22

R.ESPINAR S.L. AEi/01

Code Ref. Description

90130775 CCI-75 Non-perforated stainless steel basket AISI-316 of Ø380x260mm

for AES-75 and AES-110. (2 per autoclave AES-75 and 3 per

AES-110)

90130850 CCI-150 Non-perforated stainless steel basket AISI-316 of Ø475x360mm

for AES-150. (2 per autoclave)

90130740 CEP-7040 Pippete sterilize cylinder of Ø70x400mm

90131340 CEP-1340 Pippete sterilize cylinder of Ø130x400mm

90131326 CEP-1326 Petri capsules sterilize cylinder of Ø130x260mm

90131347 CEP-1347 Petri capsules sterilize cylinder of Ø130x400mm

90131428 SRA-1 Height adjustable support with shelves for AE/AES-28

90131475 SRA-2 Height adjustable support with shelves for AE/AES-75

90131510 SRA-3 Height adjustable support with shelves for AE/AES-110

90131550 SRA-4 Height adjustable support with shelves for AE/AES-150

All accessories must be installed in factory

INSTALLATION

Install the apparatus on a stable and solid surface.

Don’t install the autoclave in areas where there is danger of fire or explosion.

Don’t block or cover the rear ventilation grid.

Connect a flexible tube to the rear outlet (11) for drainage.

CONNECTION TO THE MAINS

There is the characteristics plate situated at the rear, indicating the voltage and power.

Check to make sure that your electrical installations have the same conditions.

The plug of the oven is a SCHUKO with central and lateral connection, for security

reasons the oven must be installed to ground.

The triphasic autoclaves (AE-110 DRY and AE-150 DRY) have a normalized plug of 16A,

3 poles, neutral and ground.

The autoclaves are equipped from the factory to be connected at 380V+N and ground, but

they can be changed into triphasic 220V and ground following the instructions given in

CHANGE OF VOLTAGE.

CHANGING VOLTAGE

7/22

Loading...

Loading...