Page 1

SmartPilot

S1000 Autopilot

Installation Guide

Document Number: 87040-5

Date: March 2007

Page 2

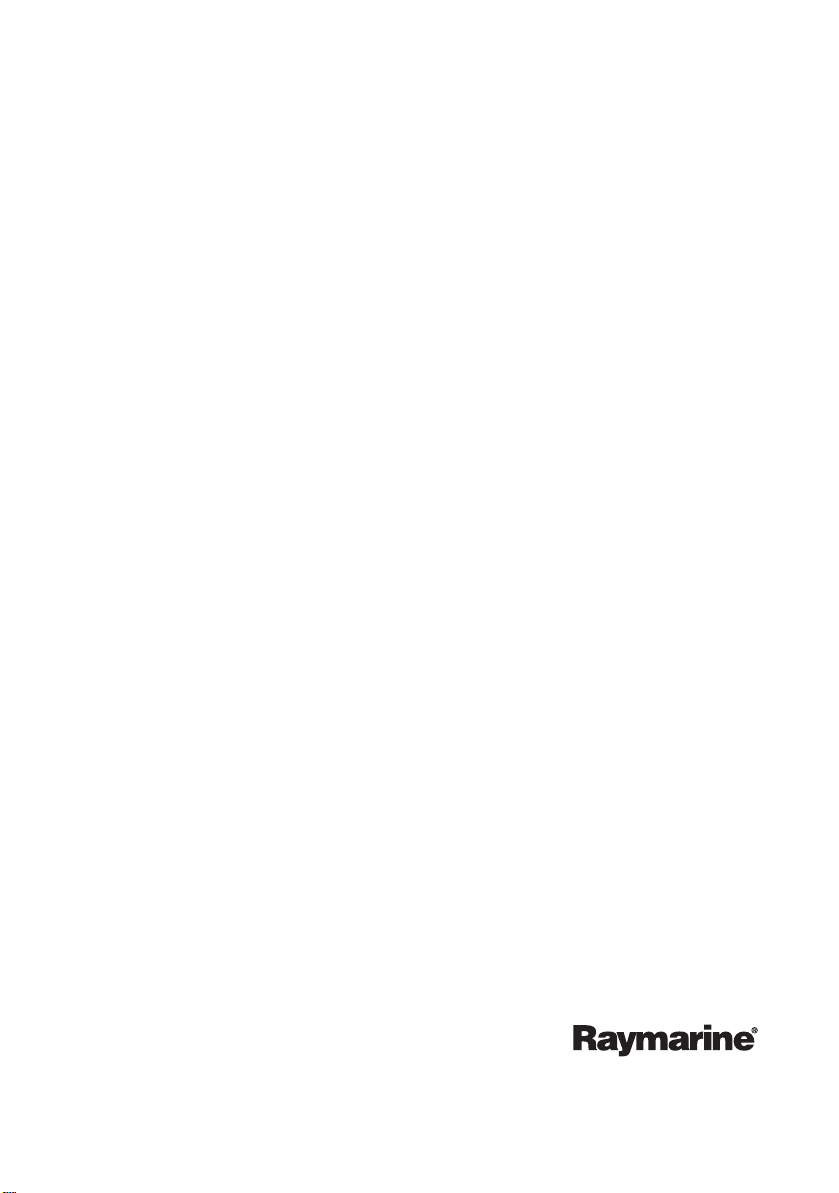

Welcome to the Raymarine S1000 Autopilot

Congratulations on having bought a Raymarine S1000 Autopilot. This state-of-the-art

product is specifically designed to be easily integrated with your boat’s steering system, and

enable you to automatically control the steering.

S1000 Autopilot System

Existing hydraulic steering system

S100 Remote

S100 REMOTE

MODE

PILOT

STANDBY

Course

computer

GPS input

The S1000 requires

GPS data (SeaTalk or

NMEA compatible),

to operate correctly

Pump control

Autopilot

pump

Alarm signal

Safety

alarm

The S1000 Autopilot is intended for use in:

• HC5345, HC5347, HC5348, and HC5358 SeaStar steering systems.

• Systems with HC4600, HC4645, HC4647, HC4648, and HC4658, BayStar steering rams.

• Systems with Hynautic K6 steering rams.

SeaTalk® is a Registered Trademark of Ray marine

SeaStar® is a Reg istered Trad emark of Telef lex Incor porated

BayStar is a Trademark of Teleflex Incorporated

®

is a Registered Trademark of the National Marine Electronics Assocociation

NMEA

All other trademar ks used in this document are ackn owledged.

© Copyri ght Raymarine UK Lim ited 2006

D7501-1

Page 3

S1000 Autopilot Installation Guide 1

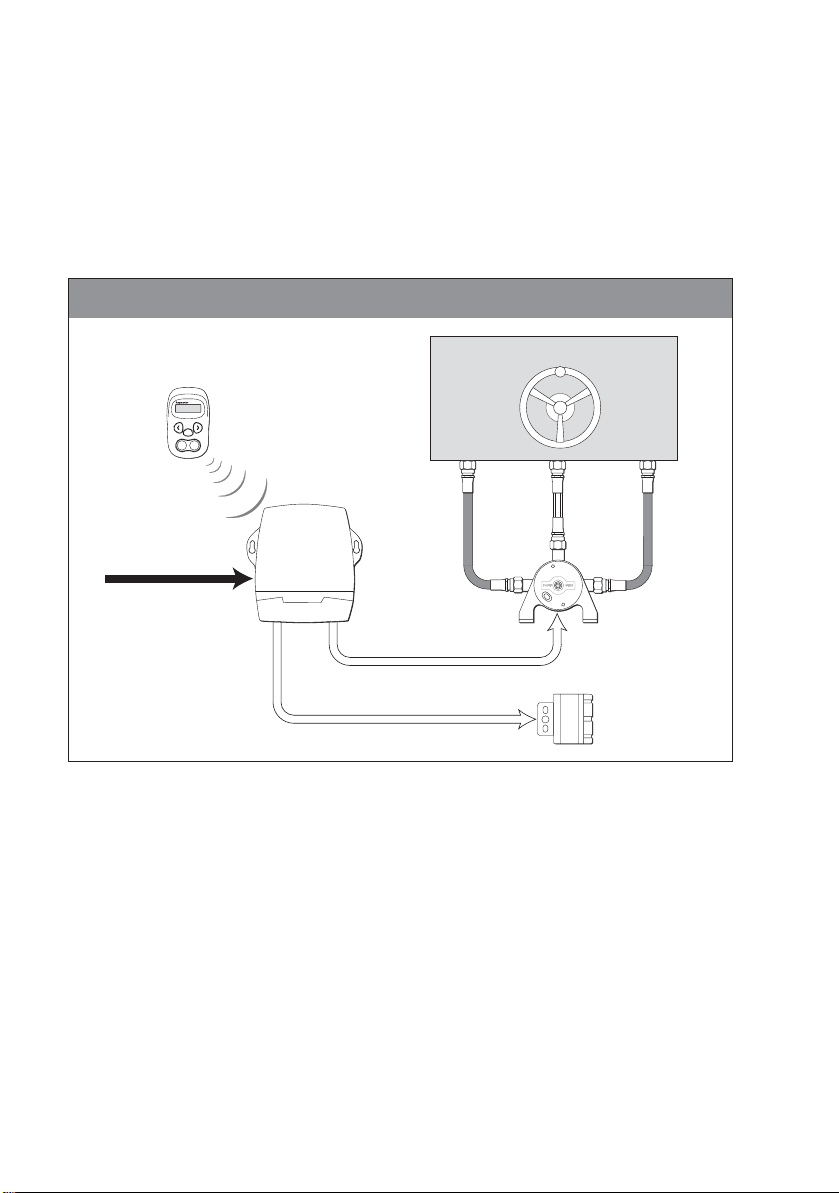

Installation overview

Connect the autopilot pump

1.

to your existing steering system.

Page 9

Bleed the steering system.

2.

Page 12

Secure the autopilot pump.

3.

Page 16

Fit the course computer.

4.

Page 17

Fit miscellaneous items

5.

Page 18

Make electrical connections

6.

Page 21

Carry out post installation checks

7.

Page 28

S100 Remote

In-line

power switch Safety alarm

D7583-1

Page 4

2 S1000 Autopilot Installation Guide

This guide

Before starting to install your S1000 Autopilot, please take time to read this guide. In particular, please take note of the safety and electromagnetic compatibility (EMC) information at the

end of this guide.

WARNING:

This product must be installed and operated in accordance with the

Raymarine instructions provided. Failure to observe this could

result in personal injury, damage to the boat and/or poor product

performance.

The installation procedures are described in a rational sequence, but because of variations in

boat design, space available etc, you may need to adapt the sequence to suit your particular

circumstances.

Before you start fitting your S1000 Autopilot, we recommend you:

• Unpack your S1000 Autopilot and check that all parts are present.

• Plan your S1000 Autopilot installation so that you fit the components in the best possible

locations.

Important note

The S1000 Autopilot must receive position information from a suitable GPS in

order to function correctly. GPS systems compatible with SeaTalk or NMEA or

both, are suitable. If you need advice as to which GPS to use, please contact

your Raymarine dealer.

Page 5

S1000 Autopilot Installation Guide 3

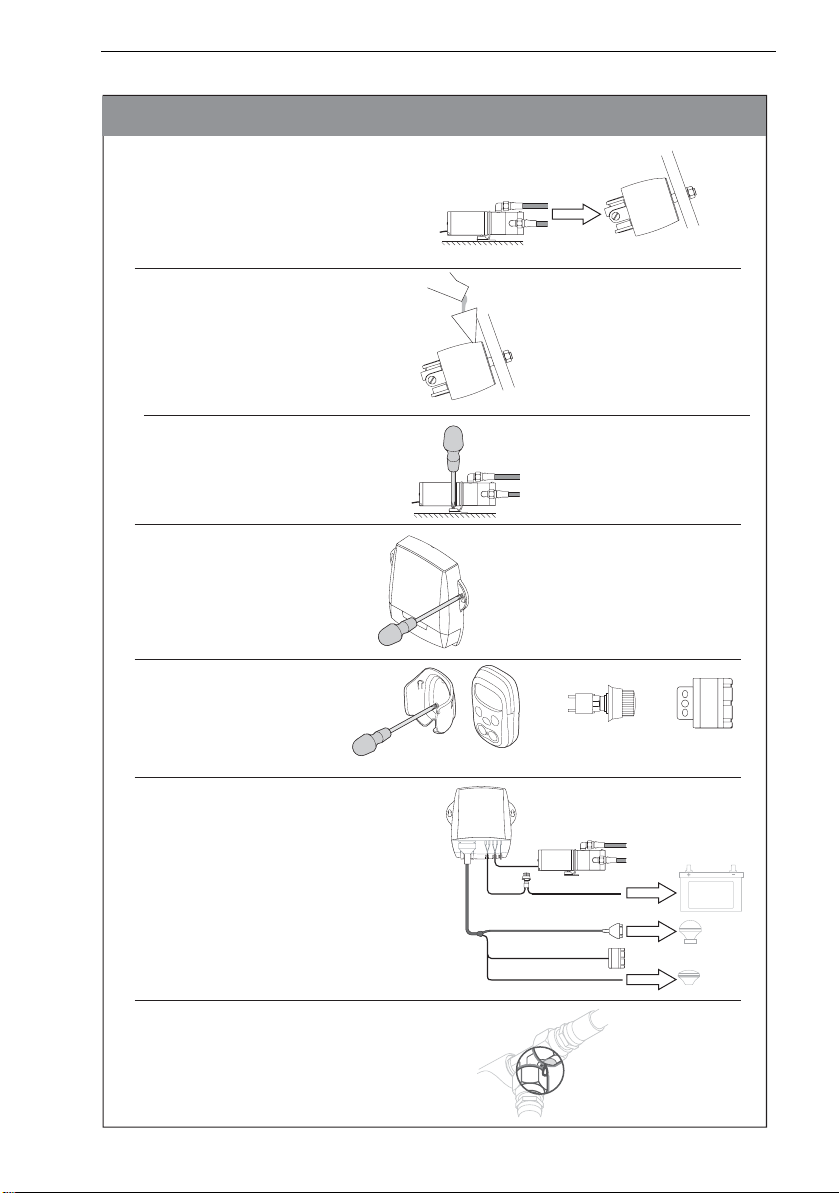

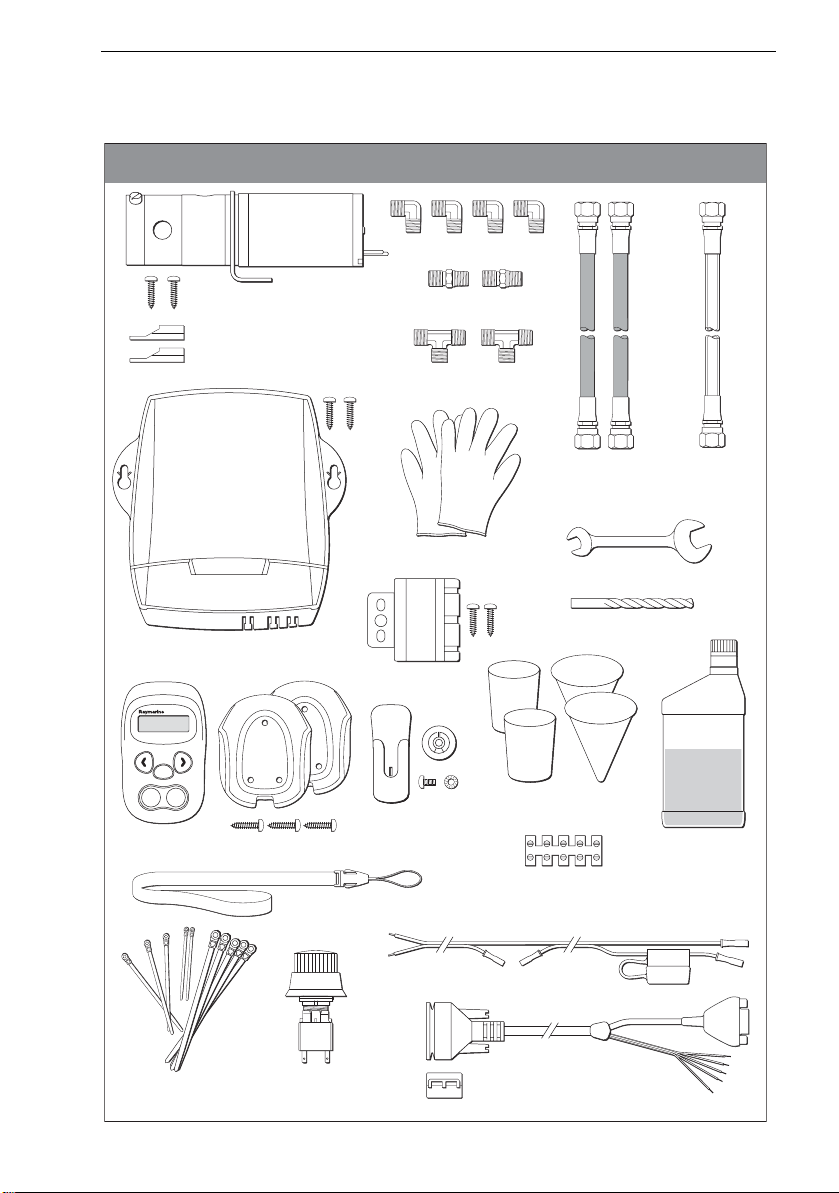

What you need

Parts supplied

Elbow fitting, x 4

Autopilot Pump

Anti-vibration mounts x 2

Course Computer

S100 REMOTE

MODE

PILOT

STANDBY

S100 Remote & 2 x cradles

Lanyard

Straight fitting x 2

'T' fitting x 2

Nitrile gloves

Safety alarm

Belt clip assembly

High pressure

steering hoses

(x 2)

Wrench 12 mm AF x 19 mm AF

Drill 3.4 mm

Drain cups

Fill cups

Connector block

Low pressure

transparent

bleeding hose

1 pint (0.5 liter)

hydraulic fluid

Miscellaneous

cable ties

In-line power

switch

Power cable

Data cable

Ferrite

D7330-2

Page 6

4 S1000 Autopilot Installation Guide

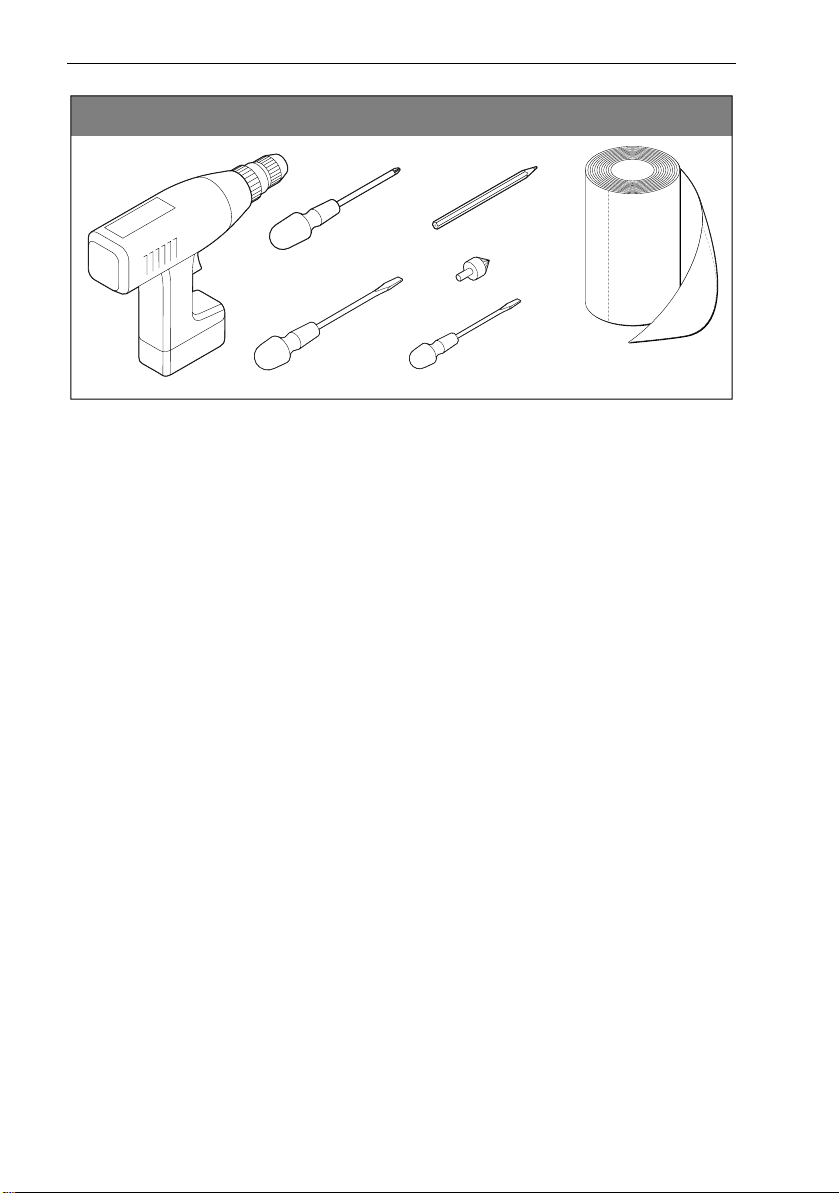

Tools & materials required

Pencil

Screwdriver,

No. 2 Pozidriv

Drill

Screwdriver,

medium,

flat blade

Countersink

bit

Screwdriver,

small,

flat blade

Absorbent,

disposable wipes

D7331-1

Page 7

S1000 Autopilot Installation Guide 5

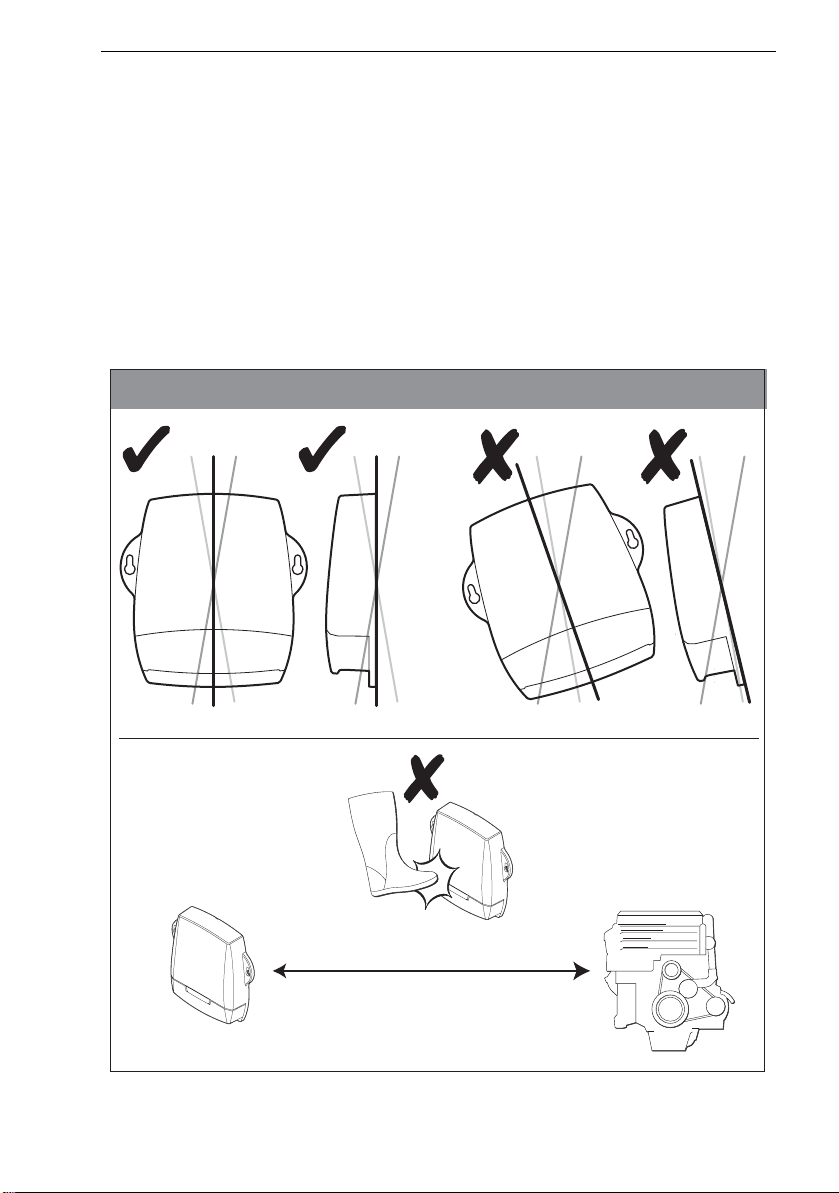

Planning

In order to make the installation as trouble free as possible, we strongly recommend you

spend adequate time planning the best locations for your autopilot components. This is

particularly important when considering the position of the autopilot pump, as hydraulic

hoses are supplied in fixed lengths, so there are some limitations on the positioning of the

autopilot pump with respect to the boat’s helm pump.

If you have internet access, please view the installation video on line at www.raymarine.com.

Before you disturb your hydraulic steering system, we strongly recommend that you consult

the manufacturer and read the steering system manuals.

Locating the course computer

5˚ 5˚

5˚ 5˚ 5˚ 5˚ 5˚ 5˚

At least 3 ft (1 meter)

D7552-1

Page 8

6 S1000 Autopilot Installation Guide

R

e

s

e

v

i

r

r

o

B

l

e

e

w

S

c

r

e

d

Po

r

t

R

e

s

e

v

i

r

r

o

B

l

e

e

w

S

c

r

e

d

Po

r

t

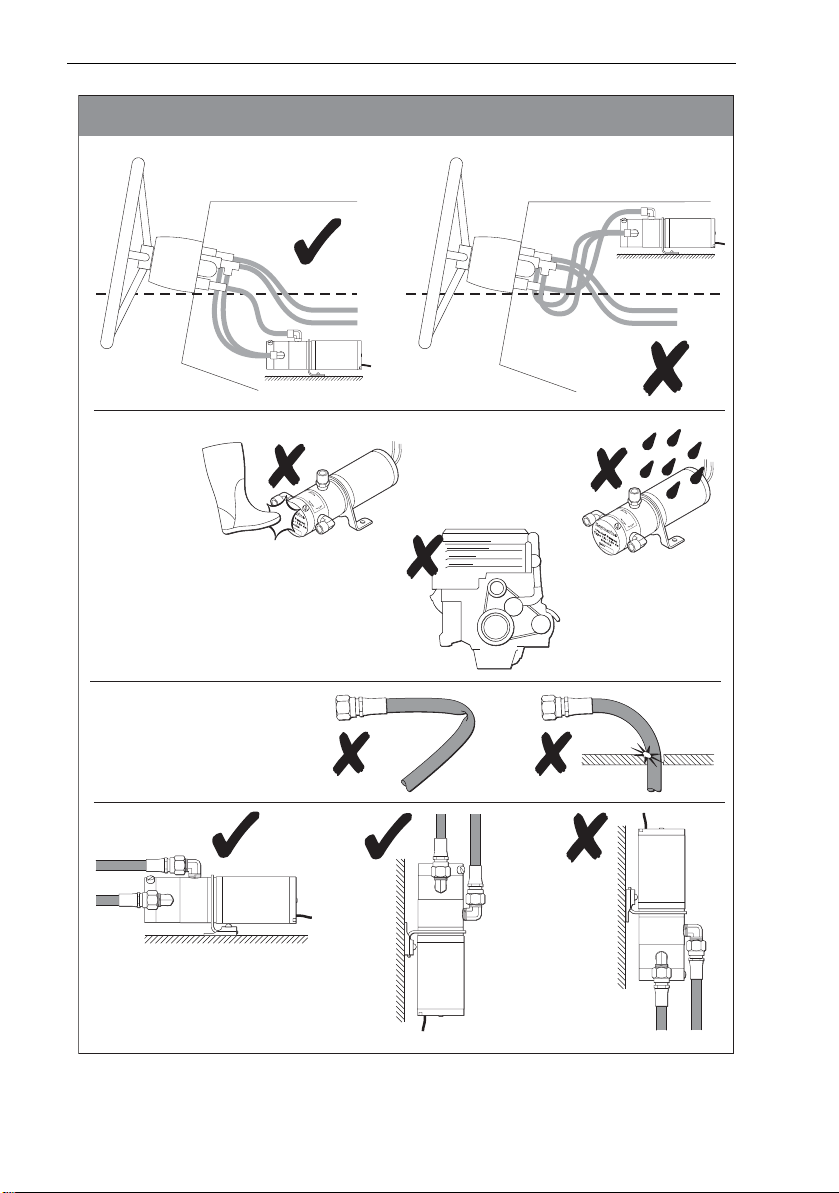

Locating autopilot pump

Autopilot pump to be lower

than helm pump.

Provide protection

from physical

damage.

P

o

r

t

Do not fit in engine compartments, near

fuel tanks or in any other area where fuel

vapor is likely.

No sharp bends, kinks or

chafing of tube.

Mount pump location either

horizontally or with connector end up.

Do not mount pump with connector

end down.

Install in a dry location.

P

o

r

t

D7350-1

Page 9

S1000 Autopilot Installation Guide 7

P

o

rt

B

r

e

c

S

d

e

e

l

r

i

o

v

r

e

e

s

R

w

Po

rt

B

r

e

c

S

d

e

e

l

r

i

o

v

r

e

e

s

R

w

P

ort

B

r

e

c

S

d

e

e

l

r

i

o

v

r

e

e

s

R

w

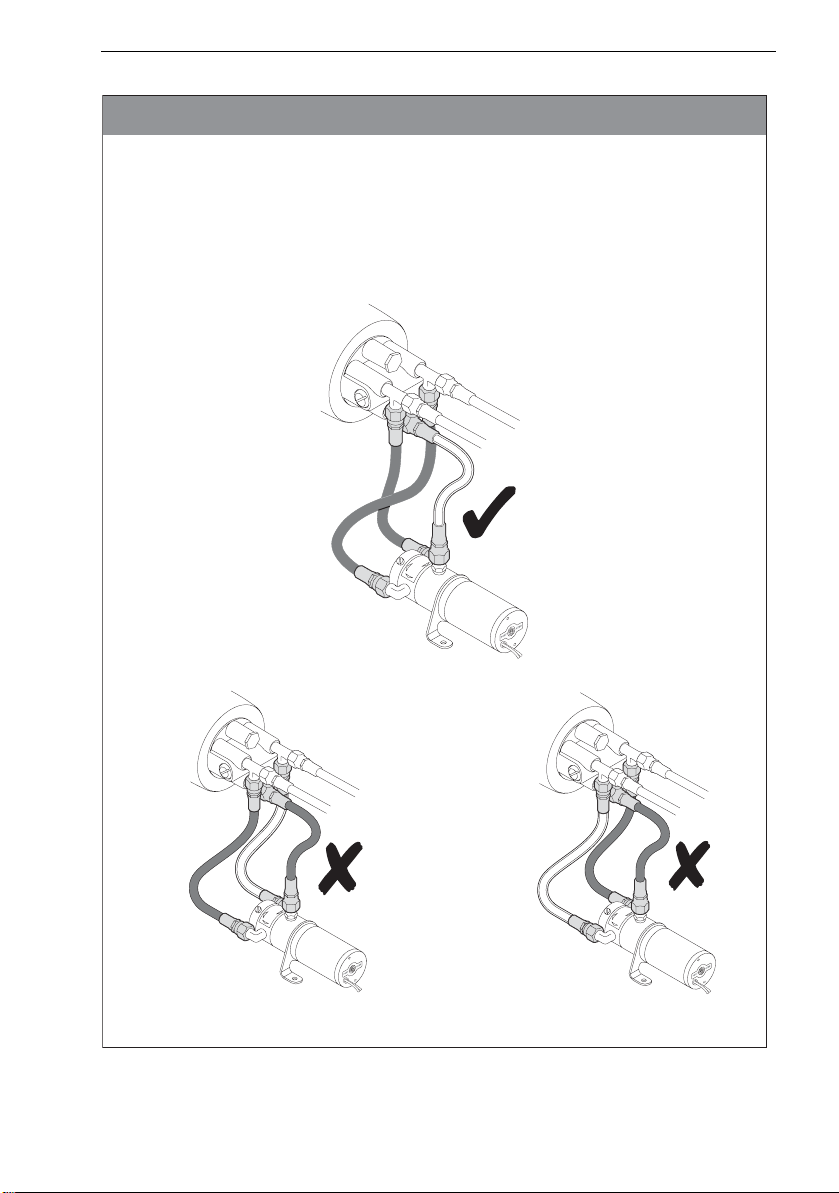

Using the hydraulic hoses

Three, pre-assembled hydraulic hoses are supplied. Two of these are dark-colored, high

pressure steering hoses and the third is a transparent low-pressure hose.

The transparent hose is intended to help you check for air bubbles when bleeding the

system and must be used only to connect the autopilot pump reservoir to the lower

connector on the helm pump. It must NOT be used anywhere else in the system.

rt

o

P

t

r

o

P

t

r

o

P

D7553-2

Page 10

8 S1000 Autopilot Installation Guide

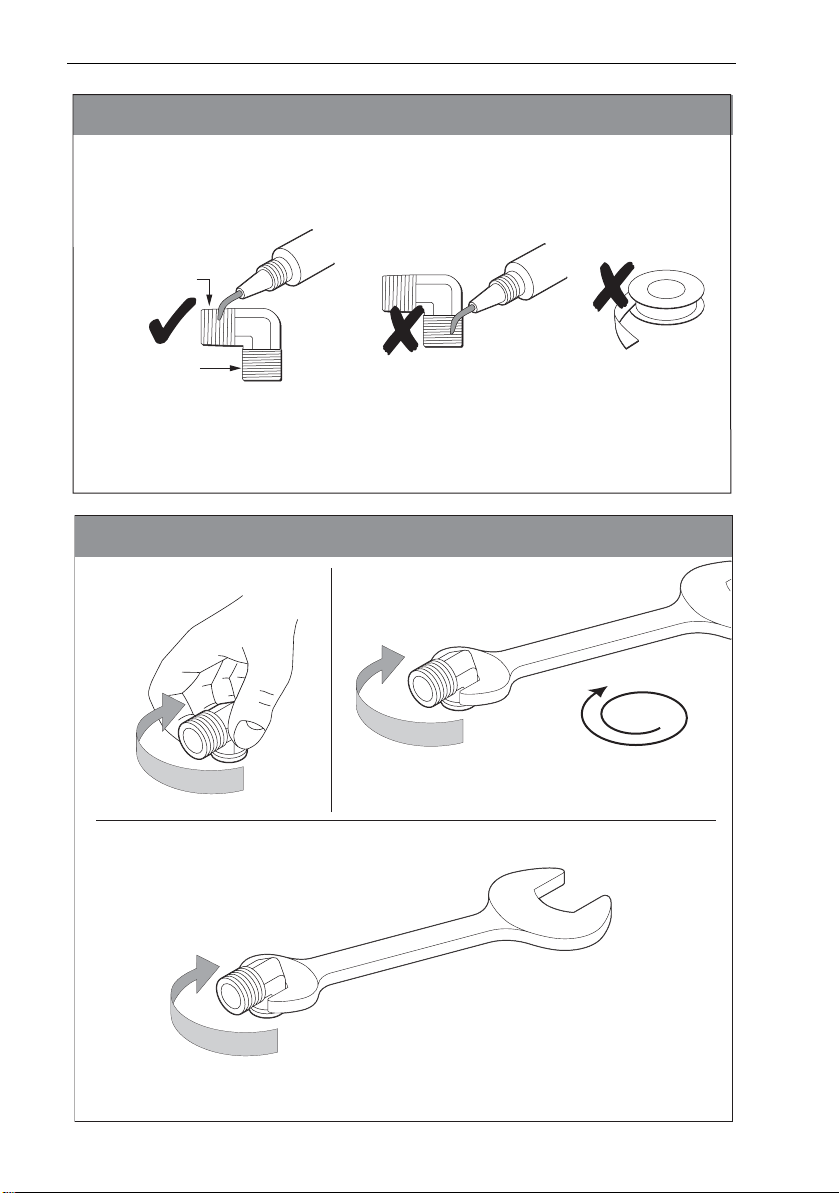

Sealing hydraulic joints

CAUTION:

Do not use sealing tape on any part of a hydraulic system, as this can

disintegrate and the resulting particles can cause blockages in the

hydraulic system.

Tapered thread

Thread for hose

connection

Note: The hydraulic fittings supplied with the autopilot pump have sealant preapplied to the tapered threads. You only need to apply sealant to any extra joints

you may obtain. The recommended sealant for doing this, is Loctite 542.

Do not apply sealant to

hose connection thread.

Installing tapered thread fittings

Hand tighten

1.

3.

CAUTION:

Do not exceed 13 ft/lbs (17.6 Nm) torque.

DO NOT EXCEED 2.5 TURNS in total, from

hand tight.

2.

CAUTION:

Do not exceed 13 ft/lbs

(17.6 Nm) torque.

1.5 turns

From hand tight, use a wrench to tighten the joint a

further 1.5 turns. This should make it leakproof.

D7545-1

To change the orientation of the joint to align it with the

hose, further tighten the joint, to a maximum of one

further turn, until the joint is facing the required

direction.

D7546-1

Page 11

S1000 Autopilot Installation Guide 9

P

o

r

t

B

r

e

c

S

d

e

e

l

r

i

o

v

r

e

e

s

R

w

R

e

s

e

v

i

r

r

o

B

l

e

e

w

S

c

r

e

d

P

ort

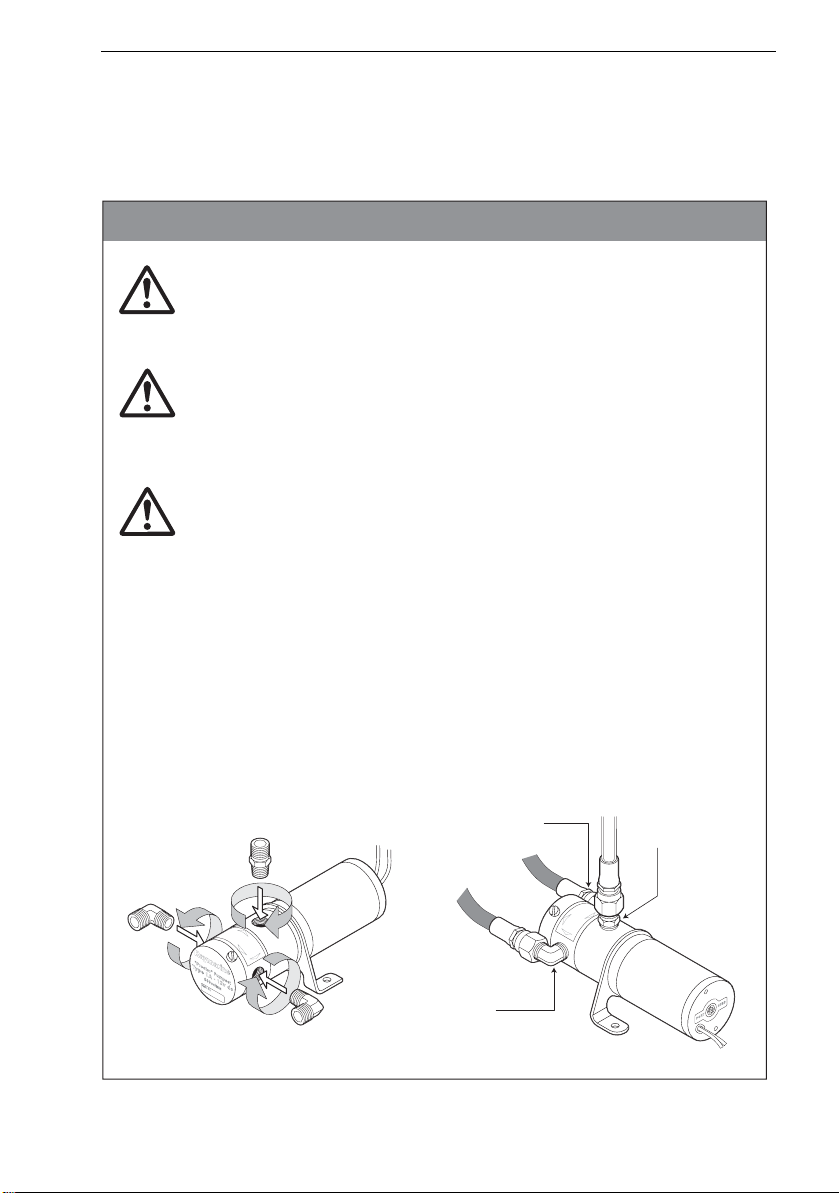

Installation procedures

1. Connecting the autopilot pump

O

Connecting the autopilot pump, sheet 1

WARNING:

Do not allow hydraulic fluid to come into contact with your skin.

Wear the protective nitrile gloves provided when working with

hydraulic fluid.

WARNING:

A sudden release of pressure from a hydraulic system could result in

personal injury. Before disconnecting any part of a hydraulic

steering system, safely release any pressure in accordance with the

manufacturer’s instructions.

WARNING:

The autopilot pump is not suitable for use in the vicinity of

engines, fuel tanks or in any other area where fuel vapor is likely

to be present.

CAUTION:

Do not use the transparent hose for connecting any part of the

steering system other than between the autopilot pump reservoir

and the lower connector on the helm pump.

1. 2.

Secure the required hydraulic joints

(elbow or straight) into the autopilot

pump, as described under

tapered thread fittings.

Installing

Connect the hydraulic hoses to the

autopilot pump. Ensure the transparent

hose is connected to the reservoir

connector.

Starboard

connector

t

r

o

P

o

r

t

Port

connector

Reservoir

connector

P

D7345-1

Page 12

10 S1000 Autopilot Installation Guide

0

Connecting the autopilot pump, sheet 2

Connecting the autopilot pump, sheet 2

4.

Set steering to dead ahead

Set steering to dead ahead

3.

3.

and do not move it until

and do not move it until

instructed.

instructed.

Remove & retain the plug from the

Remove & retain the plug from the

5.

5.

helm pump lower connector, and

helm pump lower connector, and

drain the fluid into one of the cups

drain the fluid into one of the cups

provided. Discard the drained fluid in

provided. Discard the drained fluid in

accordance with local regulations.

accordance with local regulations.

4.

Remove & retain the helm pump

Remove & retain the helm pump

breather cap.

breather cap.

Label the port ram hose to aid future

Label the port ram hose to aid future

6.

6.

reassembly, then disconnect both ram

reassembly, then disconnect both ram

hoses & straight connectors from the

hoses & straight connectors from the

helm pump.

helm pump.

Using the Installing tapered thread fittings

Using the Installing tapered thread fittings

7.

7.

procedure, fit 'T' connectors to the helm pump

procedure, fit 'T' connectors to the helm pump

port and starboard connectors, and a straight

port and starboard connectors, and a straight

connector to the helm pump lower connector.

connector to the helm pump lower connector.

D7483-1

D7483-2

Page 13

S1000 Autopilot Installation Guide 11

P

ort

B

r

e

c

S

d

e

e

l

r

i

o

v

r

e

e

s

R

w

P

or

t

B

r

e

c

S

d

e

e

l

r

i

o

v

r

e

e

s

R

w

P

ort

B

r

e

c

S

d

e

e

l

r

i

o

v

r

e

e

s

R

w

Connecting the autopilot pump, sheet 3

Connect hydraulic steering hoses from

8.

autopilot pump Port and Starboard

Re-connect the ram hoses to the

9.

appropriate helm pump 'T' connectors.

connectors to the Port and Starboard

connectors on the helm pump, so that

Port connects to Port, and Starboard

connects to Starboard .

t

r

o

P

10.

Connect the transparent hose from autopilot pump reservoir hose to the

straight connector at the helm pump lower connector.

to steering

ram

t

r

o

P

This completes the connection of

the autopilot pump.

Now bleed the steering system.

t

r

o

P

D7484-2

Page 14

12 S1000 Autopilot Installation Guide

P

ort

B

r

e

c

S

d

e

e

l

r

i

o

v

r

e

e

s

R

w

2. Bleeding the steering system

WARNING:

Do not allow hydraulic fluid to come into contact with your

skin. Wear the protective nitrile gloves provided when

working with hydraulic fluid.

Connecting the autopilot pump will introduce air into the steering system, making it feel

‘spongy’ and ‘lumpy’ to operate. To return the steering system to smooth operation, use the

procedure given here to bleed the air from the system.

Bleed procedure, sheet 1

Top up the helm pump with hydraulic fluid.

1.

Loosen the autopilot

2.

pump bleed screw 2 full

turns.

t

Por

D7336-1

Page 15

S1000 Autopilot Installation Guide 13

P

ort

B

r

e

c

S

d

e

e

l

r

i

o

v

r

e

e

s

R

w

P

ort

B

r

e

c

S

d

e

e

l

r

i

o

v

r

e

e

s

R

w

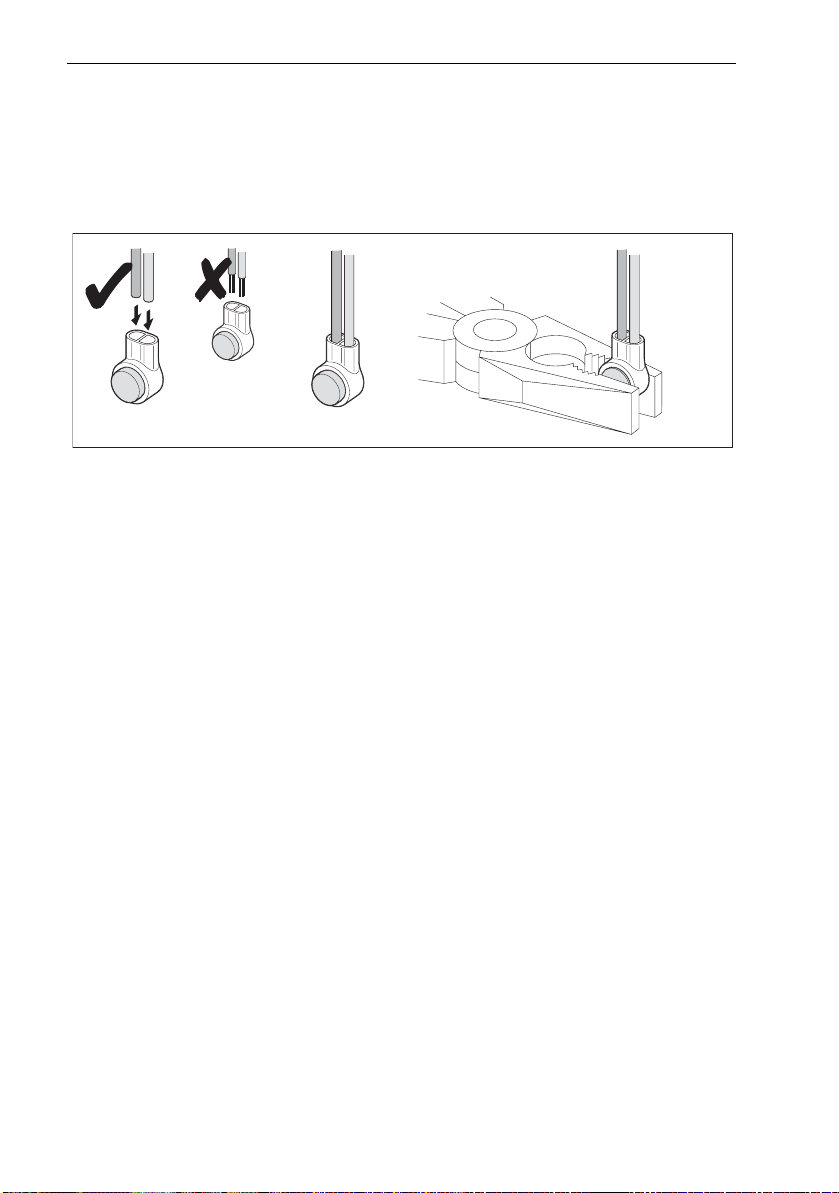

Bleed procedure, sheet 2

3.

Using a suitable screwdriver, turn the

autopilot pump shaft so that the flat on the

shaft is toward the PORT side of the pump.

SLOWLY turn the wheel counter-clockwise and observe

4.

the bubbles in the transparent tube. Keep the helm

pump reservoir topped up while doing this. Keep

turning the wheel counter-clockwise until there are no

more bubbles i.e. so the hydraulic fluid in the

transparent tube is clear.

t

r

o

P

t

r

o

P

D7339-2

Page 16

14 S1000 Autopilot Installation Guide

P

ort

B

r

e

c

S

d

e

e

l

r

i

o

v

r

e

e

s

R

w

P

or

t

B

r

e

c

S

d

e

e

l

r

i

o

v

r

e

e

s

R

w

Bleed procedure, sheet 3

Using a suitable screwdriver, turn the autopilot

5.

pump shaft so that the flat on the shaft is toward

the starboard (STBD) side of the pump.

SLOWLY turn the wheel clockwise and observe the bubbles

6.

in the transparent tube. Keep the helm pump reservoir

topped up while doing this. Keep turning the wheel

counter-clockwise until there are no more bubbles i.e. so

the hydraulic fluid in the transparent tube is clear.

t

r

o

P

t

r

o

P

D7337-2

Page 17

S1000 Autopilot Installation Guide 15

P

ort

B

r

e

c

S

d

e

e

l

r

i

o

v

r

e

e

s

R

w

Bleed procedure, sheet 4

Top up the hydraulic fluid.

7.

Correct fluid level

Helm pump

8.

Turn the autopilot pump bleed screw, fully clockwise, and hand-tighten it.

Replace the helm pump breather cap.

9.

t

Por

This completes the

bleed procedure.

Now secure the pump.

D7486-1

Page 18

16 S1000 Autopilot Installation Guide

P

ort

B

r

e

c

S

d

e

e

l

r

i

o

v

r

e

e

s

R

w

P

ort

B

r

e

c

S

d

e

e

l

r

i

o

v

r

e

e

s

R

w

3. Securing the pump

Securing the pump

2.

Place the pump at the intended

1.

location and mark holes for the

fixing screws.

t

r

o

P

Drill two 1/8" (3.4 mm) pilot holes

for the fixing screws.

Countersink the pilot holes to prevent

3.

damage to the mounting surface.

Slide the anti-vibration mounts onto

4.

the pump bracket feet, then secure

the pump with the screws provided.

When the autopilot pump is

secure, fit the course computer.

t

r

o

P

D7488-2

Page 19

S1000 Autopilot Installation Guide 17

4. Fitting the course computer

Securing course computer

Mark holes for fixing screws.

1.

3.

Countersink the pilot holes to prevent

damage to the mounting surface.

2.

Drill two 1/8" (3.4 mm) pilot holes

for fixing screws.

Partially screw in the screws provided,

4.

then slot the course computer onto the

screws, and tighten screws.

The course computer is now secure.

D7338-1

Page 20

18 S1000 Autopilot Installation Guide

5. Fitting miscellaneous items

Safety alarm

Locating

Securing

Mark holes for fixing screws.

1. 2.

Countersink the pilot holes to prevent

3.

damage to the mounting surface.

4.

Drill two 1/8" (3.4 mm) pilot holes.

Secure the safety alarm with the

screws provided.

Fitting batteries in S100 Remote

2 x AAA batteries (supplied).

When replacing, use only high-quality

alkaline, AAA size batteries.

D7607-1

D7504-2

Page 21

S1000 Autopilot Installation Guide 19

Fitting S100 Remote cradle

At fixed position

Mark holes for the fixing screws.

1.

Drill three 1/8" (3.4 mm) pilot

2.

holes for the fixing screws.

Countersink the pilot holes to

3.

prevent damage to the mounting

surface.

On belt clip

1.

2.

3.

k

c

i

l

C

4.

Secure the cradle.

To separate cradle from clip

D7683-1

Page 22

20 S1000 Autopilot Installation Guide

In-line power switch

Locating

Fit the in-line power switch in a

readily-accessible location.

Securing

1.

3.

4.

5.

2.

Cut 11/16" (18 mm)

1

inch (5 mm)

/

5

maximum

Ensure the protrusion on the

switch barrel goes fully into

the mounting hole.

D7591-1

[

When all items have been fitted,

connect up the system electrics.

Page 23

S1000 Autopilot Installation Guide 21

P

o

r

t

B

r

e

c

S

d

e

e

l

r

i

o

v

r

e

e

s

R

w

6. Electrical connections

Overview

Summary

WARNING:

Before making electrical connections to any part of the S1000

system, ensure the power source for the system is switched off.

Course Computer

RF ground

In-line power switch

Port

See Diagram A

See Diagram B

Autopilot

Pump

Data

cable

NMEA Spur

Alarm

SeaTalk

See Diagram B

See Diagram C

& Diagram D

See Diagram C

See Diagram C

D7522-1

Page 24

22 S1000 Autopilot Installation Guide

Connecting wires

When you need to join wires, use the either the supplied Scotchlock connectors or terminal

block, as appropriate.

Note:

Scotchlock connectors are suitable for joining thin, data wires. They are NOT suitable for

connecting the safety alarm.

S1000 Autopilot Grounding

The S1000 Autopilot system requires an RF ground connection to be made, to ensure

complete conformance with the EU regulations requirements AFTER installation. The RF

ground connection is also essential to maintain the electromagnetic performance of the

system in all installations, regardless of local regulations requirements (world wide).

Failure to provide an RF ground when the S1000 Autopilot is installed could result in a

degraded electromagnetic performance and may affect the operation of the system.

D7547-1

The recommended MINIMUM requirement for an RF ground lead is:

• F lat, tinned copp er b rai d, 0.25 in ch ( 6.5 mm ) width minimu m. Equiv alent stranded wire

diameter 0.16 inch (4 mm)

Page 25

S1000 Autopilot Installation Guide 23

O

O

Diagram A: Connecting RF ground - preferred method

Course computer

S1000 Autopilot

Product Code: A18107

0191

FCC ID PJ5S1000

IC: 4069B-S1000

Raymarine Ltd

Portsmouth PO3 5TD England

POWER PUMP

If the boat does not have a ground plate, use the alternative method

shown in the following diagram, to connect the RF ground.

Boat hull

RF Ground Plate

Alternative method

Note: Use this method of connecting the terminal, ONLY if the boat does

not have an RF grounding plate.

When using this method, do NOT connect the terminal to any other point.

Course computer

S1000 Autopilot

Product Code: A18107

Product Code: A18107

0191

FCC ID PJ5S1000

IC: 4069B-S1000

Raymarine Ltd

Portsmouth PO3 5TD England

POWER PUMP

Now connect the power &

the autopilot pump.

D7539-2

Page 26

24 S1000 Autopilot Installation Guide

O

Diagram B: Connecting power & autopilot pump

Course computer

S1000 Autopilot

Product Code: A18107

0191

FCC ID PJ5S1000

IC: 4069B-S1000

Raymarine Ltd

Portsmouth PO3 5TD England

POWER PUMP

12 V

Power supply

10 A fuse

Black

In-line

power switch

Integral

Red

Brown

Blue

Integral

ferrite

Autopilot pump

Now make the necessary

Data Cable connections.

D7541-1

Page 27

S1000 Autopilot Installation Guide 25

Diagram C: Connecting the Data Cable

Course Computer

GPS requirement

The S1000 must receive GPS information to

function correctly. Use the Data Cable supplied,

to connect the Course Computer to a GPS, using

either of the following methods:

1. To a Raymarine GPS via SeaTalk connections.

2. To a Raymarine GPS via NMEA spur.

3. To a non-Raymarine GPS via NMEA spur.

NMEA connector (not

Clip ferrite to

Data Cable,

as close to

the connector

as possible

Data

cable

NMEA Spur

When connecting NMEA data from an external source, always

connect via the NMEA spur on the Data Cable. Do NOT connect

NMEA data from an external source directly to the connector on

the Course Computer.

For details of the NMEA Spur

connections, refer to Diagram D

supplied), from GPS

Each time power is applied to an S1000 Autopilot connected to a

Raymarine GPS (via NMEA or SeaTalk), the S1000 will set the GPS

filtering to WEAK.

Connector

Purple

White

block

Red

Black

Yellow: SeaTalk Data

Red: SeaTalk +12 V

Black: SeaTalk 0 V

If you want to connect to an external SeaTalk system, ensure each of these

SeaTalk wires connects to the wire of the same color in the external system.

When you have completed the electrical connections,

secure the wires at the Course Computer.

Safety

alarm

SeaTalk

D7549-1

Page 28

26 S1000 Autopilot Installation Guide

Diagram D: NMEA connections

Course Computer

Using with Raymarine GPS

If a Raymarine GPS (such as the Raystar 120 or 125)

is to be connected to the S1000 Autopilot via NMEA,

NMEA in and out, +ve and -ve lines must all be

the

correctly connected.

Each time power is applied to an S1000 Autopilot

connected to a Raymarine GPS (via NMEA or SeaTalk),

the S1000 will set the GPS filtering to WEAK.

Data

cable

NMEA Spur

SeaTalk & safety

alarm

connections

(see Diagram C)

NMEA

Connector

Pin 1

Pin 2

Pin 3

Pin 5

CAUTION:

Before making any changes to the Data Cable,

disconnect it from the Course Computer.

If it is more convenient to connect the NMEA spur to the GPS

without using the NMEA connector, you can remove the

connector and prepare the cable end as appropriate for your

preferred method of connection. Refer to the wire identification

table below, as necessary

Wire

color

Brown

Green

Orange

Blue

Pin

number

1

2

3

5

NMEA signal

at S1000

-- ve out

+ve out

+ve in

-- ve in

Connection at

3rd party GPS

NMEA --ve receive

NMEA +ve receive

NMEA +ve transmit

NMEA --ve transmit

When you have completed the electrical

connections, secure the wires at the

Course Computer.

D7596-1

Page 29

S1000 Autopilot Installation Guide 27

Secure wires

Course Computer

POWER PUMP

D7551-1

This completes the installation procedure. Now carry out the

(below).

Post installation

procedures

Page 30

28 S1000 Autopilot Installation Guide

7. Post installation

When you have completed the installation of your S1000 Autopilot, use the following

procedures to:

• First carry out the

the system for leaks, then

• Carry out the

the steering in the correct direction, and to set up the autopilot correctly.

Manual checks

With autopilot power off, turn the wheel from hard over port, to hard over starboard. If the

steering operates satisfactorily and turns in the correct direction, proceed with the other post

installation checks.

If the steering feels uneven and/or less responsive than it was before you installed your S1000

Autopilot, you may need to bleed the entire steering system. To do this, use the purge

procedure at the following web address:

http://www.seastarsteering.com/OUTBOARD/oboard.htm?../FILL_PURGE/FillPurge.htm&1

Check for leaks (sheet 1)

Manual checks

below, to check the the steering operation and check

Autopilot checks & setup

procedures below, to check the autopilot operates

Ensure all hydraulic joints are secure, then turn

1.

the wheel to port. When the hard over point is

reached, continue turning to port to pressurize the

port lines, until the safety valve releases. At this

point, the fluid in the port lines will be at

maximum pressure and the wheel has a 'lumpy'

feel when turned further to port.

With the port lines at maximum pressure, check

2.

the port lines for leaks, paying particular

attention to the joints.

If a leak occurs, turn the wheel to starboard to

release the pressure, then repair the leak and

repeat steps 1 & 2.

Continue on sheet 2

D7502-1

Page 31

S1000 Autopilot Installation Guide 29

Check for leaks (sheet 2)

3.

Turn the wheel to starboard, and when the hard

over point is reached, continue turning to

starboard to pressurize the starboard lines, until

the safety valve releases. At this point, the fluid in

the starboard line will be at maximum pressure

and the wheel has a 'lumpy' feel when turned

further to starboard.

4.

With the starboard lines at maximum pressure,

check the starboard lines for leaks, paying

particular attention to the joints.

If a leak occurs, turn the wheel to port to release

the pressure, then repair the leak and repeat

steps 3 & 4.

5.

After 24 hours, re-check the steering system to

ensure there are still no hydraulic fluid leaks.

D7550-1

Autopilot checks & setup

WARNING:

Before switching on power to the course computer, make

sure that personnel are clear of the steering gear and

outboard motor(s), and that the boat is securely moored.

1. Switch on power to the S1000 system.

2. Carry out the

Checking direction of turn - sheet 1

Before casting off, check that the S1000 operates the boat's steering system in the correct

direction:

At the S100 Remote, hold down STANDBY for 2

1.

seconds, to enter Setup mode.

Checking direction of turn

procedure (below).

SETUP

Continue on sheet 2

D7704-1

Page 32

30 S1000 Autopilot Installation Guide

Checking direction of turn - sheet 2

2.

Hold down < and > in turn, and as each of these is pressed, ensure that the outboard

motor(s) turn(s) to give the correct direction of steer.

If the outboard motor(s) does/do not move correctly, DO NOT USE THE BOAT. At the

3.

S100 Remote, hold down STANDBY for 2 seconds to leave Setup mode and return to

Standby mode, then check that the S1000 components have been installed correctly. In

particular, check that the autopilot pump wiring and hydraulics are connected

correctly.

D7705-2

Page 33

S1000 Autopilot Installation Guide 31

Specifications

System

Approved by: FCC (USA), CE (Europe), IC (Canada)

Autopilot pump

Current consumption: 4 A at 100 psi (69 kP), 7 A at 500 psi (3449 kP)

Dimensions: 6.5 in (165 mm) x 2.5 in (65 mm) x 3.2 in (82 mm)

Weight: 3 lbs (1.4 kg)

Course computer

Voltage: 10 V dc to 16 V dc

Current consumption: 4 A nominal, with autopilot pump running

Dimensions: 6.5 in (165 mm) x 6.7 in (170 mm) x 1.73 in (44 mm)

Data In/Out: SeaTalk, NMEA 0183

S100 Remote

Voltage: 3 V, supplied by two internal, ‘AAA’ batteries.

Dimensions: S100 Remote only: 101 mm x 60.5 mm x 35 mm

Remote in cradle:103 mm x 66 mm x 44 mm

Waterproofing: IPX 6 and IPX 7

Hydraulic fittings

Tapered thread: ¼ NPT (National Pipe Thread)

Hose connection thread:

Hydraulic fluid

Recommended Type: SeaStar/BayStar Marine Steering Fluid

Other suitable Types: Texaco HO15

9

/

UNEF (Unified Extra Fine)

16

Shell Aero 4

Esso Univis N15

Chevron Aviation Fluid A

Mobil Aero HFA

Fluids meeting MIL H5606 specifications

Page 34

32 S1000 Autopilot Installation Guide

General Information

Safety notices

WARNING: Product ins tallation & operation

This equipment must be installed and operated in accordance with the Raymarine

instructions provided. Failure to do so could result in personal injury, damage to

your boat and/or poor product performance.

WARNING: Electrical safety

Make sure you have switched off the power supply before you start installing this

product.

Information

To the best of our knowledge, the information in this guide was correct when it went to press. However, Raymarine

cannot accept liability for any inaccuracies or omissions it may contain.

In addition, our policy of continuous product improvement may change specifications without notice. Therefore,

Raymarine cannot accept liability for any differences between the product and this guide.

EMC Installation Guidelines

All Raymarine equipment and accessories are designed to the best industry standards for use in the recreational

marine environment.

Their design and manufacture conforms to the appropriate Electromagnetic Compatibility (EMC) standards, but

correct installation is required to ensure that performance is not compromised. Although every effort has been taken

to ensure that they will perform under all conditions, it is important to understand what factors could affect the

operation of the product.

The guidelines given here d escribe the conditions for optimum EMC performance, but it is recognized that it may not

be possible to meet all of these conditions in all situations. To ensure the best possible conditions for EMC

performance within the constraints imposed by any location, always ensure the maximum separation possible

between different it ems of electrical equipment.

For optimum EMC performance, it is recommended that wherever p ossible:

• Raymarine equipment and cables connected to it are:

• At least 3 ft (1 m) from any equipment transmitting or cables carrying radio signals e.g. VHF radios, cables

and antennas. In the case of SSB radios, the distance should be increased to 7 ft (2 m).

• More than 7 ft (2 m) from the path of a radar beam. A radar beam can normally be assumed to spread 20

degrees above and below th e radiating elem ent.

• The equipment is supplied from a separate battery from that used for engine start. Voltage drops below 10 V in

the power supp ly to our produ cts, and starte r motor transients, can cause the equ ipment to reset. This wil l not

damage the equipment, but may cause the loss of some information and may change the operating mode.

• Raymarine specified cables are used. Cutting and rejo ining these cables can compromise EMC performance and

must be avoided unless doing so is detailed in the installation manual.

• If a suppression ferrite is attached to a cable, this ferrite should not be removed. If the ferrite needs to be

removed during installation it must be reassembled in the same position.

Page 35

S1000 Autopilot Installation Guide 33

Suppression Ferrites

The following illustration shows typical cable suppression ferrites used with Raymarine equipment. Always use the

ferrites supplied by Raymarine.

D3548-6

Connections to Other Equipment

If your Raymarine equipment is to be connected to other equipment using a cable not supplied by Raymarine, a

suppression ferrite MUST always be attached to the cable near the Raymarine unit.

Page 36

34 S1000 Autopilot Installation Guide

Raymarine UK Ltd,

Quay Point ,

Northarb our Road

Portsmouth,

Hampshir e PO6 3TD,

United Kingdom.

Tel: +44 (0) 23 9269 3611

Fax: +44 (0) 23 9269 4642

www.raymarine.com

Raymarine Inc,

21, Manchester Street,

Merrimack,

New Hampshire 03054-4801

USA.

Tel: +1 603.881.5200

Fax: +1 603.864.4756

www.raymarine.com

,

Loading...

Loading...