Page 1

SmartPilot

Series

S1WheelPilot

S1 TillerPilot

Operating Guide

Document r efer ence: 8128 31

Date: Octo ber 20 06

Page 2

Autohelm, HSB (High Speed Bus), SailPilot, SeaTalk and SportPilot are registered trademarks of Raymarine Ltd.

Raymarine, AST (Advanced Steering Technology), AutoAdapt, AutoLearn, AutoRelease, AutoSeastate, AutoTack, AutoTrim,

FastTrim, GyroPlus, RayGyro, RayPilot and WindTrim are trademarks of Raymarine Ltd.

Raymarine and SeaTalk are trademarks of Raymarine Ltd

Handbook contents © Raymarine Ltd. 2005.

Page 3

Important Information

About th e documentation pr ovided

Welcome to Raymarine SmartP ilot. T he autopilot s ystem that will steer y our boat

to a heading au tomatically , ac curately , reliably and comfortably.

SmartPilot do cumentation is arran ged so that you can install, commissio n and

quickly use y our SmartPilot, k eeping to han d only the informati on necessary .

•

•

•

•

Warranty

T o register your n ew Raymarine product, please take a few minutes to fill o ut the

warranty ca rd. It is important that you complete the o wner information and

return the car d to us to receive full warranty ben efits. Y ou can also register o nline

at

Installation Sheets

stand sheets guid e you through the in stallation process . Th ese can be dis

carded once the in stallation is compl ete.

SmartPilot Co mmissioning Guide

sion and con figure the system. Supp lied with systems only .

Quick Start Guide

with this handy guide to the main op erations.

Operating Guide

SmartPilot’ s features and func tions.

www.raymarine.com

One per element of the system, these easy to u nder

Describes how to conn ect, commis

Once commissioned, use your Smart Pilot rig ht away

This ha ndbook. Conta ins a detailed descriptio n of the

i

Safety not ices

WARNING: Cal ibration

We supply t his product c alibrated to def ault settin gs that shou ld

provide ini tial stable perfor mance for most boats. T o ensure

optimum perf ormance on your boat, you mu st complete th e

procedur es in

WARNING: Na vigation aid

Although we have designed th is product to be a ccurate and

reliable , many factors can af fect its perfor mance. As a result, it

should only be u sed as an aid to n avigation and sh ould never

replace common sense and nav igational judgement. Always

maintain a permanen t watch so you can respond t o situations as

they deve lop.

SmartP ilot Commissioning Guide

before use .

Page 4

ii S1 Wheel and Tiller Pilots Operating Guide

Y our Raymarine SmartPilot will add a new dimensio n to your boating enjoyment.

However , it is the skipp er’s respon sibility to ensure the safety of the boat at all

times by followin g these basic rules:

• Ensure that someon e is present at the helm A T ALL TIMES , to tak e manual

control in an emergency .

• Make sure that al l members of crew know how to diseng age the autopilot.

• Regularly check for ot her boats and any ob stacles to navigation – n o matter

how clear the sea appears , a dangerou s situation can develop ra pidly .

• Maintain an accu rate record of the boat’ s position b y using either a naviga

tion aid or visual bearings.

• Maintain a conti nuous plot of you r boat’ s position on a curren t chart. Ensure

that the lock ed autopilot hea ding will steer the boat clear of all o bstacles.

Make prop er allowance for tidal set – the autopilot cann ot.

• Even when your autop ilot is lock ed onto the desired track usin g a navigation

aid, alway s maintain a log and make regular p ositional plots . Navigation sig

nals can produce sig nificant errors u nder some ci rcumstances and the autopi

lot will not be able to detect these errors.

Product disposal

Waste Elect rical and Elect ronic (W EEE) Direct ive

The WEEE Direct ive requires the recycling of wa ste electrical and

electronic equipmen t.

Whilst the WEEE Di rective does not apply to som e of Raymarine's produ cts, we

support its po licy and ask you to b e aware of how to dispose of this p roduct.

The crossed out wheelie bin symbol, illustrated above, and found on ou r products

signifies that this pr oduct should no t be disposed of in general waste or landfill.

Please contact yo ur local dealer , national distribu tor or Raymarine T echni cal

Services for information o n product dispo sal.

EMC Conformanc e

All Raymarin e equipment and accesso ries are designed to the best indu stry

standards for use in th e recreational marine environ ment. Their design and

manufacture co nforms to the appropr iate Electromagnetic Com patibility (EMC)

standards , but correct in stallation is required to ensure that performance is no t

compromised.

Page 5

Important Information iii

Handbook inf ormation

T o the best of our knowledge , the information in this hand book was correct when

it went to press . However , Raymari ne cannot accept liab ility for any inaccu racies

or omissions it may contain. In addition, our policy of continu ous product

improvement may change specificatio ns without notice . As a result, Raym arine

cannot accep t liability for any d ifferences between the product and the

handbook.

Page 6

iv S1 Wheel and Tiller Pilots Operating Guide

Page 7

v

Contents

Important Information

About th e doc umentation provid ed ......... ..... ..... .... ..... ..... ..... .... ..... ..... ..... .... ..... ..... .i

Warranty .................................................................................................................i

Safety notices .......... ....... ....... ....... ....... ....... ........ ....... ....... ....... ....... ....... ....... ....... ....i

WARNING: Calibration

WARNING: Navigation aid

Product disp osal ...... ....... ....... ....... ....... ....... ........ ....... ....... ....... ....... ....... ....... ....... ... ii

EMC Conformance ........... ....... ........ ....... ....... ....... ....... ....... ....... ....... ........ ....... .......ii

Handbook in formation ..... ....... ........ ....... ....... ....... ....... ....... ....... ....... ........ ....... ......iii

Contents ................................................................................................................ v

Chapter 1: Basic operation

1.1 Introduction .....................................................................................................1

SmartPilot Fun ctions ....... ..... ..... .... ..... ..... ..... .... ..... ..... ..... .... ..... ..... ..... .... ..... .....1

Extended systems....... ....... ........ ....... ....... ....... ....... ....... ....... ....... ........ ....... .......2

1.2 Using the control unit .... ....... ....... ....... ....... ....... ....... ........ ....... ....... ....... ....... .....3

Switching on and off...... ....... ....... ....... ....... ....... ....... ........ ....... ....... ....... ....... .....3

Startup mode .......................................................................................... 3

Keypad fun ctions........... ....... ....... ....... ....... ....... ....... ........ ....... ....... ....... ....... .....3

What does the display tell me?.. ....... ....... ....... ....... ....... ....... ....... ........ ....... .......5

1.3 Using the SmartPilot to steer your boat ..... ....... ..... ....... ....... ....... ........ ....... .......6

CAUTION: Maintain a permanent watch

CAUTION: Risk of gybe

How do I automa tically steer to a heading?......... ....... ....... ....... ....... ....... ....... ...6

WARNING: Wheel drive clutch

How do I return to ha nd steering? ...... ....... ....... ....... ........ ....... ....... ....... ....... .....7

CAUTION: ...........................................................Wheel drive systems

How do I chang e course in Auto mode?........ ....... ....... ....... ..... ....... ....... ....... .....7

Can I dodge an ob stacle and then resume cou rse? ..... ....... ....... ....... ....... ....... ...8

Off Course alarm....... ....... ....... ....... ....... ........ ....... ....... ....... ....... ....... ....... ....... ...9

1.4 How do I adjust the performance of my SmartPilot? .............. .... ........ ....... .......9

1.5 Sailing functions .... ....... ....... ....... ....... ....... ....... ....... ........ ....... ....... ....... ....... ...11

T acking (AutoT ack).......... ....... ....... ....... ........ ....... ....... ....... ....... ....... ....... ....... .11

CAUTION: Allow time for course changes

AutoTack angle ...................................................................................... 12

Preventing gybes with AutoTack............................................................ 12

Gusty conditio ns....... ....... ....... ....... ....... ........ ....... ....... ....... ....... ....... ....... ....... .13

CAUTION: Risk of gybe

1.6 Display lighting & contrast? ........ ....... ....... ....... ....... ........ ....... ....... ....... ....... ...14

Adjusting th e display lighting........ ....... ........ ....... ....... ....... ....... ....... ....... ....... .14

.................................................................................................i

.................................................................................i

..........................................................................i

..........................................................................................1

.................................................6

...................................................................................6

..................................................................6

7

............................................11

.................................................................................13

Page 8

vi S1 Wheel and Tiller Pilots Operating Guide

Adjusting the co ntrast........... ....... ....... ....... ....... ....... ....... ........ ....... ....... ....... ...14

Chapter 2: Advanced operation

2.1 How do I follow a route set on a Chartplotter? ........... ....... ....... ....... ....... ....... .17

How do I activate T rack m ode?....... ....... ....... ........ ....... ....... ....... ....... ....... ....... .17

CAUTION: Make suitable preparations for entering track mode

How do I leave T rack mode?...... ........ ....... ....... ....... ....... ....... ....... ....... ........ .....18

Cross track error?...... ....... ....... ....... ....... ....... ........ ....... ....... ....... ....... ....... ....... .18

CAUTION: The direction of turn and the displayed bearing to way

point may be different from that expected.

Tidal stream co mpensation....... ........ ....... ....... ....... ....... ....... ....... ....... ........ .....20

How do I dodge an obstacle in T rack mode?. ........ ....... ....... ....... ....... ....... ....... .21

What happens when I arri ve at a waypoint?............ ....... ........ ....... ....... ....... ...21

How do I skip a waypoint? (SeaTalk chartplotters) ................................ 22

WARNING: Ensure navigation safety

What is the Waypoint Advance alarm? .................................................22

What happens when I g et to the end of the route?... ....... ........ ....... ....... ....... ...22

2.2 Using Wind Vane mo de .......... ....... ....... ....... ........ ....... ....... ....... ....... ....... ....... .23

What is W ind V ane mode?........ ..... ..... ..... .... ..... ..... ..... .... ..... ..... ..... .... ..... ..... ...23

Wind informatio n........... ....... ....... ....... ....... ....... ....... ....... ........ ....... ....... ....... ...23

True and apparent wind......................................................................... 23

WindTrim ...............................................................................................23

How do I select Wind V ane mode?........ ....... ........ ....... ....... ....... ....... ....... ....... .24

How do I leave Wind V ane mode?............ .... ........ ....... ....... ....... ....... ....... ....... .24

How do I dodge an obstacle in Wind V ane mode?.... ....... ........ ....... ....... ....... ...25

What is a Wind Shift w arning ?............ ..... .... ..... ..... ..... .... ..... ..... ..... .... ..... ..... ...25

How do I use AutoT a ck in Wind Va ne mode? ......... ..... ....... ....... ....... ....... ....... .25

AutoTack angle ...................................................................................... 26

Operating hints for Win d Vane mod e.. ....... ....... ....... ....... ........ ....... ....... ....... ...26

2.3 How do I display boat data? ............. .... ....... ........ ....... ....... ....... ....... ....... ....... .27

Can I display W aypoint n ames?...... ....... ....... ........ ....... ....... ....... ....... ....... ....... .27

2.5 User Calibration Op tions ...... .... ..... ..... ..... .... ..... ..... ..... .... ..... ..... ..... .... ..... ..... ...30

How do I access User Calibratio n settings?............ ....... ....... ....... ....... ........ .....30

User Calibration pages.......... .... ..... ..... ..... .... ..... ..... ..... .... ..... ..... ..... .... ..... ..... ...30

AutoTack angle ...................................................................................... 30

Gybe inhibit............................................................................................30

Wind selection... ....... ....... ....... ....... ....... ....... ........ ....... ....... ....... ....... ....... ....... .31

WindTrim ...............................................................................................31

Response level .......................................................................................31

Chapter 3: Fault Fin ding & Mainte nance

3.1 Fault finding ........ ....... ....... ....... ........ ....... ....... ....... ....... ....... ....... ....... ........ .....33

SmartPilot alarm messag es....... ........ ....... ....... ....... ....... ....... ....... ....... ........ .....34

3.2 General maintenance ...... ....... ....... ....... ....... ........ ....... ....... ....... ....... ....... ....... .36

...............................................................................17

.17

.......................................19

22

...............................................................33

Page 9

vii

Routine checks. ....... ....... ....... ....... ....... ....... ....... ....... ........ ....... ....... ....... ....... ...36

CAUTION: Do not dismantle SmartPilot products

Cleaning the displa y ... ....... ........ ....... ....... ....... ....... ....... ....... ....... ........ ....... .....36

CAUTION: Avoid damage when cleaning

Wheel drive... ....... ....... ....... ........ ....... ....... ....... ....... ....... ....... ....... ........ ....... .....37

Routine maintenance .............................................................................37

Cleaning the wheel drive ....................................................................... 37

CAUTION:

EMC advice........ ....... ....... ....... ....... ....... ........ ....... ....... ....... ....... ....... ....... ....... .39

Product supp ort........ ....... ....... ....... ....... ........ ....... ....... ....... ....... ....... ....... ....... .39

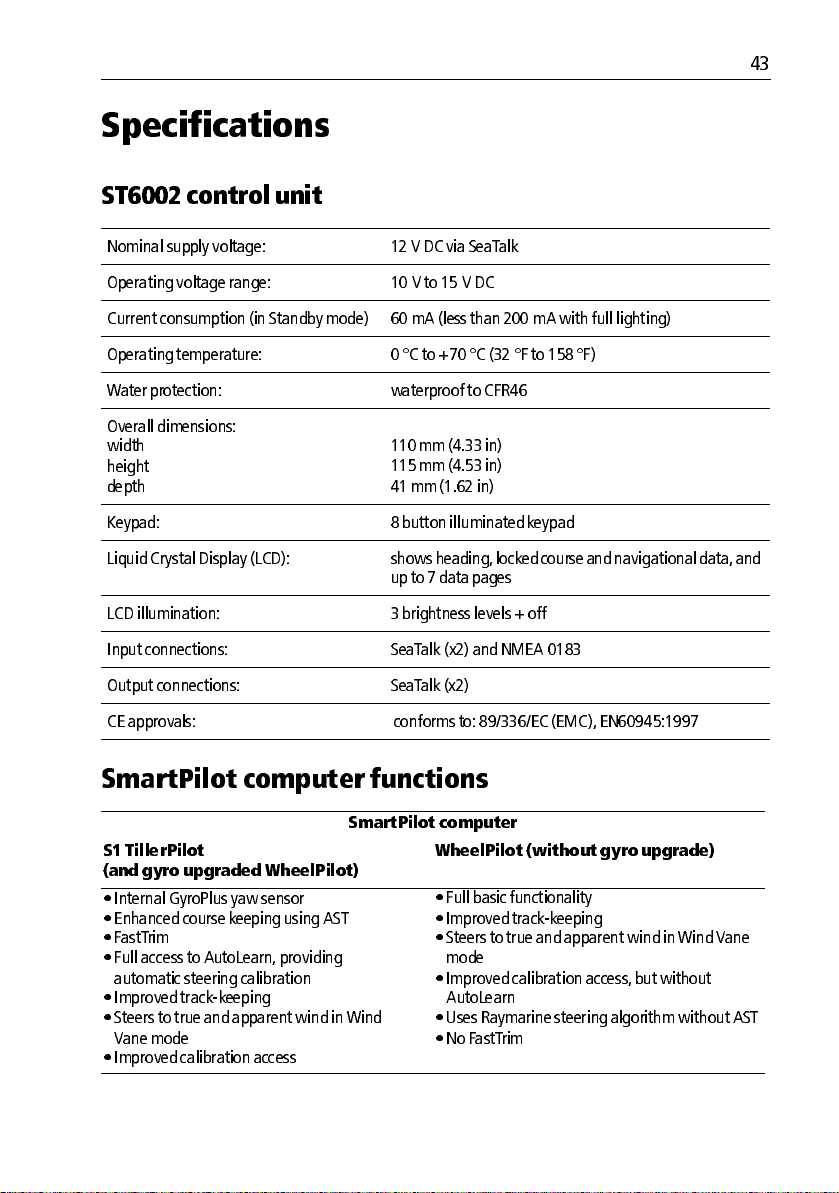

Specifications

ST6002 contro l unit .......... ....... ........ ....... ....... ....... ....... ....... ....... ....... ........ ....... .....43

SmartPilot c omputer function s ..... ..... ..... .... ..... ..... ..... .... ..... ..... ..... .... ..... ..... ..... .... .43

Glossary

Index

...........................................................................................................................44

.................................................................................................................................47

.........................................................................................................37

Adjusting the clutch...............................................................................37

Replacing the belt ..................................................................................38

User serviceable parts ............................................................................38

World wide web..................................................................................... 39

Telephone help line................................................................................ 40

Help us to help you ................................................................................ 40

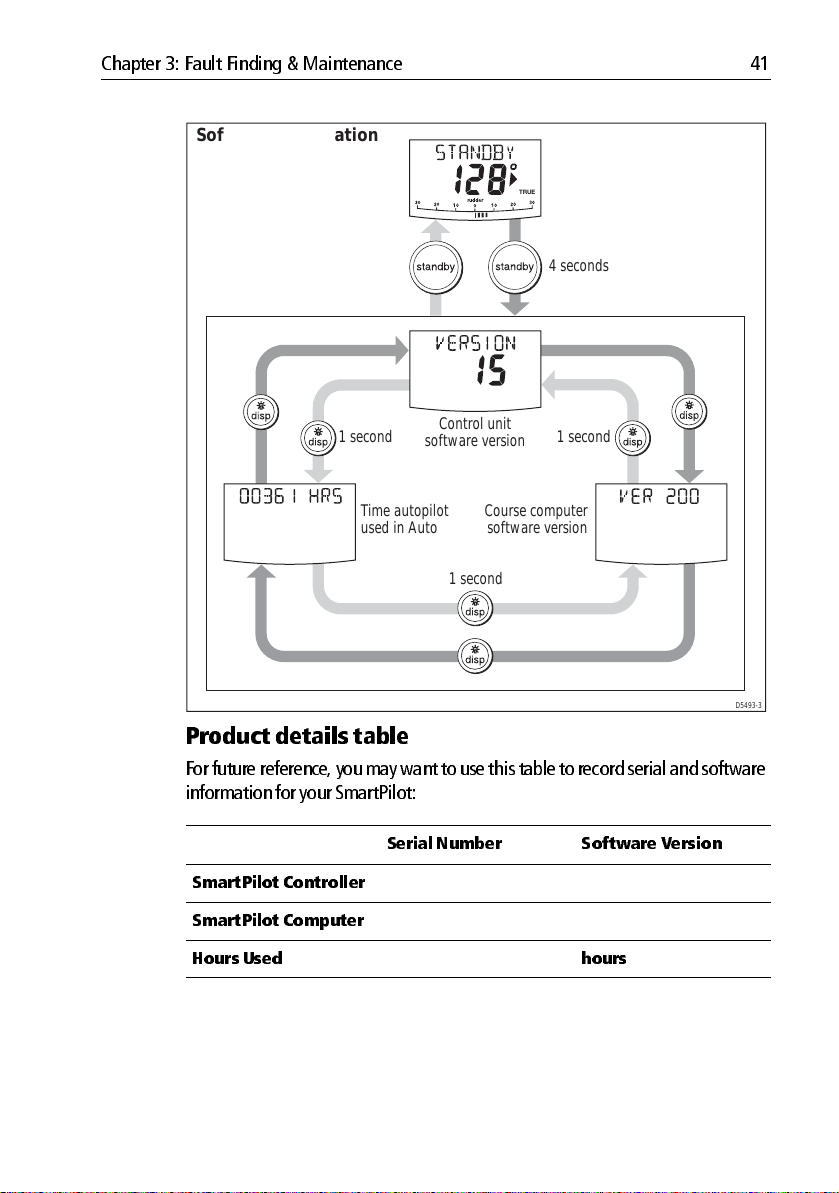

Product details table .............................................................................. 41

................................................................................................................43

..............................................36

.............................36

Page 10

viii S1 Wheel and Tiller Pilots Operating Guide

Page 11

Chapter 1: Basic operation

1.1 Introduction

D

IS

P

STA

-

1

N

D

B

Y

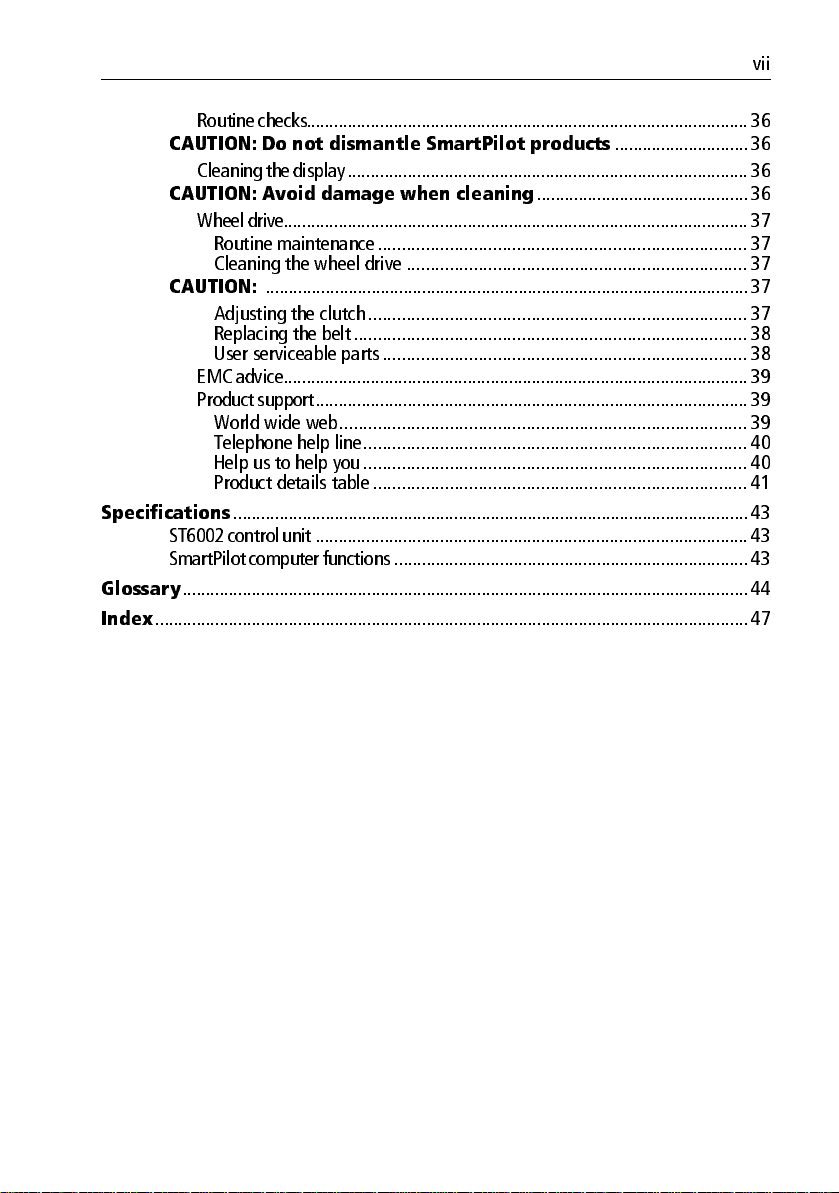

The Smar tPilot controller is a SeaT alk® c ompatible autop ilot control unit . It is

designed as the mai n controller for the SmartP ilot system.

+

1

-

10

TR

A

C

K

10

A

U

T

O

D8727-1

1

The Smar tPilot controller o perates in the following mo des:

•

Standby:

•

Auto:

•

Track:

SmartPilot off . Y ou have manua l control of the boat.

The SmartP ilot steers the boat to mainta in a locked h eading.

The SmartPi lot steers the boat to maintain a track between two way

points created on a navigation aid.

•

Wind V ane:

The SmartPil ot steers the boat to maintain a c ourse relative to a

true or apparent win d angle.

The Smar tPilot controller also provides:

• automatic tac k (AutoT ack) in Auto and Wind Van e modes.

• waypoi nt advance feature in T rack mo de.

SmartP ilot Funct ions

The fun ctions provided with yo ur SmartPilot system d epend on whether the

SmartPilot co mputer contains a Gyro Plus yaw sensor to measure th e boat’s rate

of turn.

Page 12

2 S1 Wheel and Tiller Pilots Operating Guide

•

S1 TillerPilot

•

S1 WheelPilot

has a built in Gyro .

does not contain a builtin Gyro.

This c an be upgraded with a dealerfitted Gyro plus unit to give the same func

tionality as the S1 TillerPilot .

:

T able 11:

S1 TillerPilot

(with GyroPlus)

Internal GyroPlu s yaw sensor provides

enhanced course keeping us ing AST

(Advanced Steering T echnology)

Steering to true and apparent wind in

Wind Vane mode

Equipped with AutoLearn, Rayma

rine’s selflearnin g calibratio n sys tem

S1 WheelPilot

(without GyroPlus)

Full basic functionality : uses Rayma

rine steering algorithm without AST

Steering to tr ue and apparent win d in

Wind Vane mode

Extended systems

Y ou can connect the SmartPilot con troller to other Raymarine SeaT alk equipment

so it can send and recei ve SeaTalk da ta:

• it can use way point informa tion from a SeaT alk naviga tion instrument to pro

vide track control.

• it can use b oat speed from a SeaT alk speed instr ument to optimize t rackkeep

ing performanc e.

• it can use wind inform ation from a SeaT alk wind instru ment for Wind V ane

steering.

Y ou can also use th e SmartPilot with any navig ator or wind instrumen t that

transmits Nationa l Marine Electronics Assoc iation (NMEA) 0183 data.

The SmartP ilot control un it can display SeaT alk and NMEA instrument data in a

userdefined selection of data pages .

For furth er information on oth er connections to yo ur system see

Commissioni ng Guide.

SmartPilot

Page 13

Chapter 1: Basic operation 3

1.2 Using t he control unit

Switchi ng on and o ff

All the time that p ower is applied to the SmartPi lot controller, you can use the

disp

button to switch the instru ment off and on as follows:

• T o switch the SmartPil ot controller off , ensure it is in the Stan dby mode , then

disp

hold down the

switch off count down of 4 seconds occurs . Keep the

during thi s period, to switch off the instru ment.

• To switch the instrument back on, hold down the

imately 1 second.

When the power supply is switched off, the SmartPilot con troller buttons have no

effect.

Notes: (1)

Each time power to the SmartPilot con troller is switched on, the contro ller

is initially in the on con dition. You do no t need to use the

to switch t he contro ller on.

(2)

When the SmartPilo t controller is on, t he operation of the

will perform ot her operat ing fun ctions , as describ ed below .

Startup mode

The Smar tPilot always po wers up in Standby mo de with the display showin g the

boat’ s current compa ss heading.

button for a pproximately 5 seconds. After this time, a

disp

button pressed

disp

button for approx

disp

button

disp

button

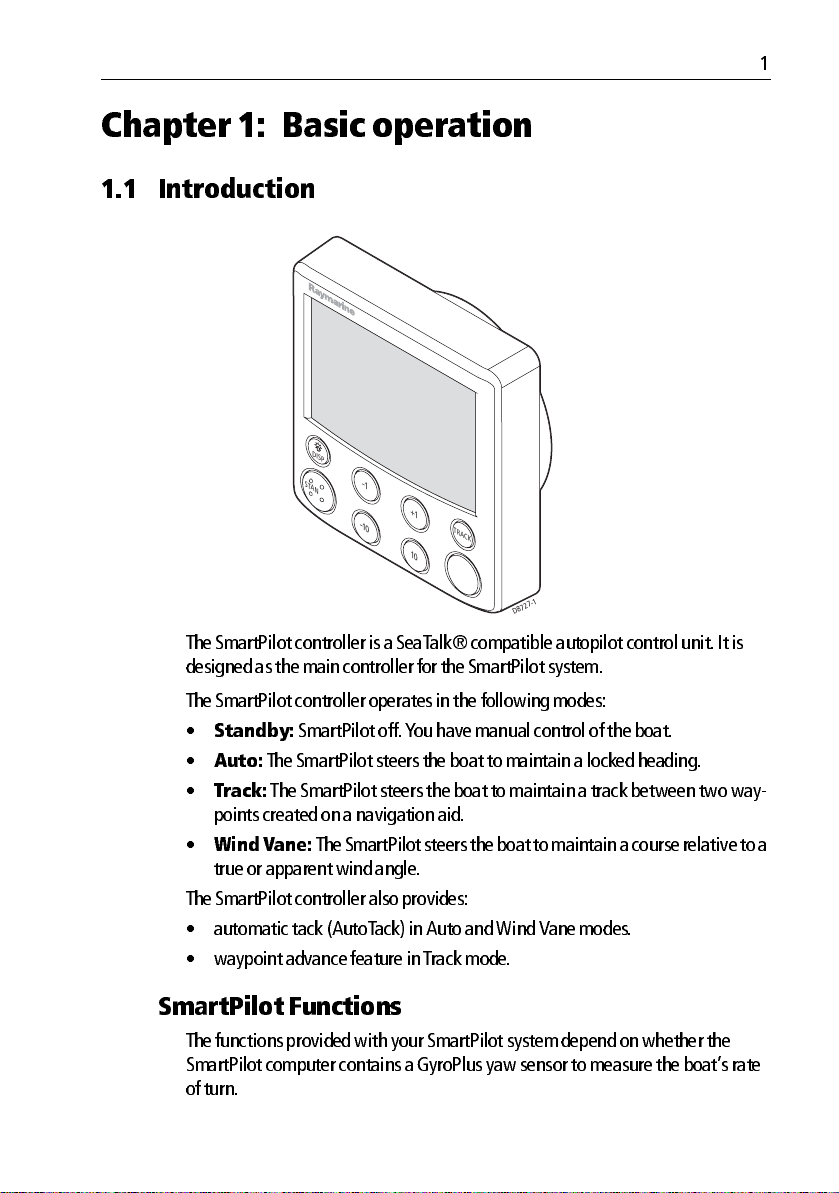

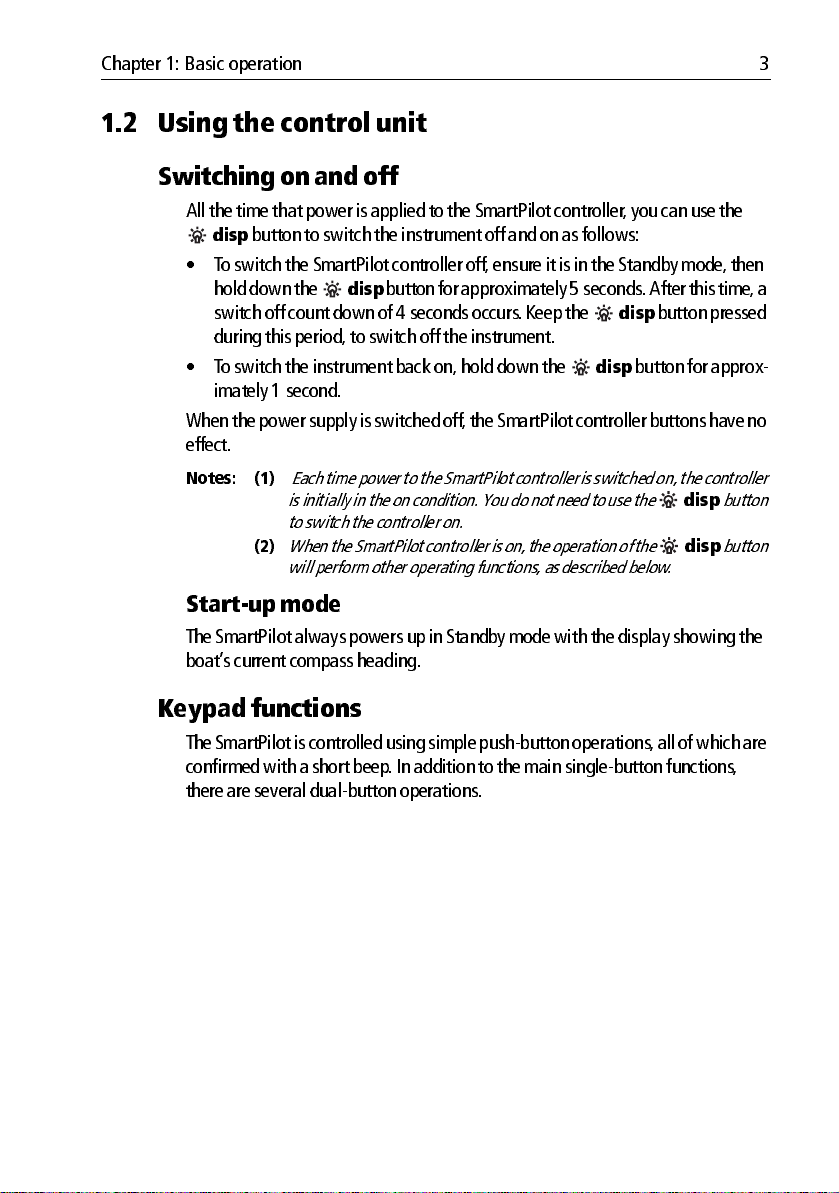

Keypad functions

The Smart Pilot is controlled using sim ple pushbutton operat ions, all of which are

confirmed with a sh ort beep. I n addition to the ma in singlebutton functions ,

there are several dualbutto n operations .

Page 14

4 S1 Wheel and Tiller Pilots Operating Guide

-1 plus +1

-1 plus -10

Press together for

AutoTack to port

Press for Response level

Press for 1 second

for Rudder Gain

+1 plus +10

Press together for

AutoTack to starboard

DISP

Press to display data pages

Press for 1 second for lamp

adjust

Press for 3 seconds for

contrast adjust

Press for 9 seconds

(in Standby mode) for

power down

When powered down, press

for 1 second to power up

STANDBY

Press for Standby mode

Press for 2 seconds to enter

Calibration mode

Course change keys

Port 1˚ Starboard 1˚

Port 10˚ Starboard 10˚

STANDBY plus AUTO

Press for Wind Vane mode

(if a wind vane is connected)

TRACK

Press for Track

mode from Auto

(if a navigator is

connected)

Press to accept

waypoint advance

Press for 1 second

to skip waypoint

AUTO

Press for Auto mode

D5449-3

Page 15

Chapter 1: Basic operation 5

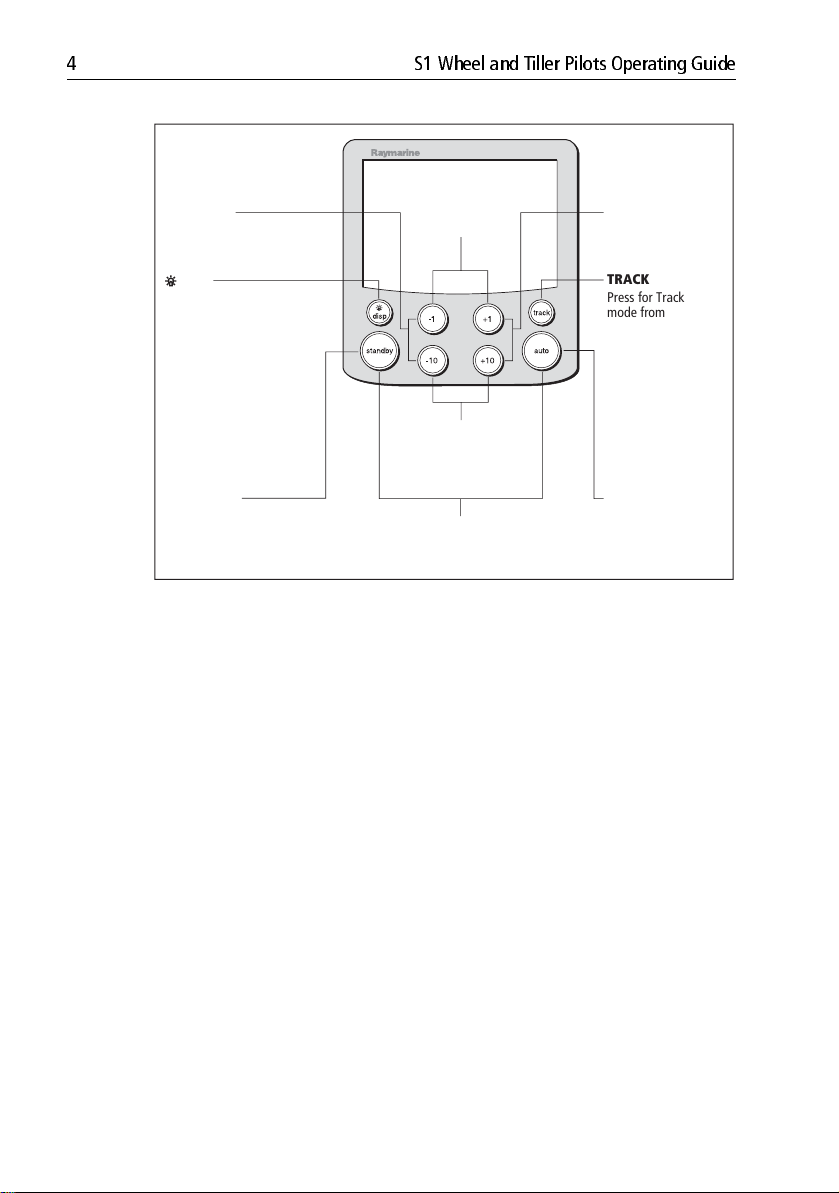

What does the display tell me?

The Smar tPilot display screen provides the following info rmation:

Variable text region (up to 9 characters/digits)

Distance units:

• no units = kilometres

n

S

MAG

TRUE

m

M

• nm = nautical miles

• SM = statute miles

Heading indicators

Port and Starboard

direction-to-steer

indicators

Rudder position indicator

D5457-3

The bar gra ph is used on S1 WheelPilot systems to indicat e the current position of

the rudder, as measured by the rudder posi tion sensor. This may be turn ed on/off

using the disp lay calibration setti ngs (See your commissio ning guide for mor e

details).

Page 16

6 S1 Wheel and Tiller Pilots Operating Guide

1.3 Using the SmartPil ot to steer your boat

CAUTION: Maintain a permanent watch

Automatic course contr ol makes it easier to sail a boat, but it is

NOT a substit ute for good seaman ship. AL WA YS ma intain a

permanen t watch by th e helm.

CAUTION: Risk of gybe

Always be aware of the relative wind angle, especially wh en using

the au topilot to sail down wind.

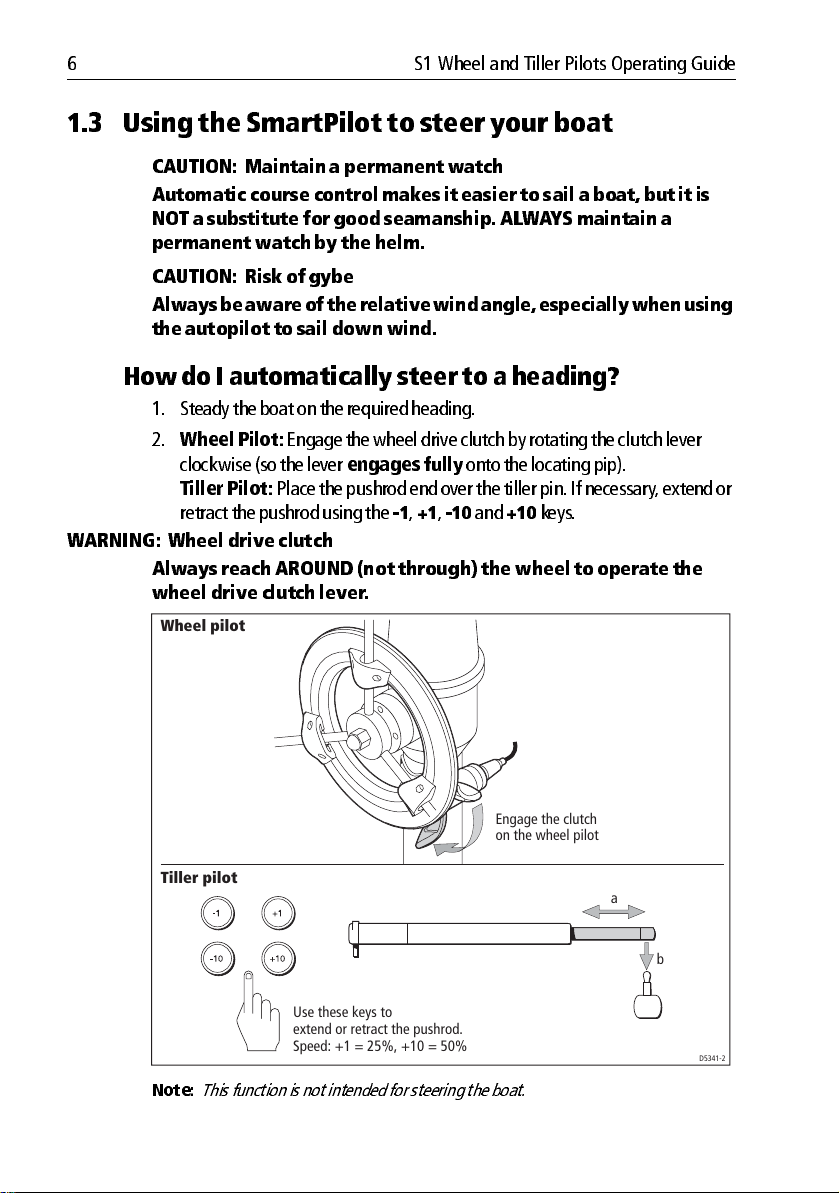

How do I automat ically st eer to a hea ding?

1. Steady the boat on the required heading.

2.

Wheel Pilot:

clockwise (so the lever

Tiller Pilot:

retract the pushrod using the

WARNING: Whee l drive clutch

Always reach AROUND (not th rough) t he wheel to oper ate the

wheel drive c lutch lever.

Wheel pilot

Engage the wheel drive clutch by rotating the clutc h lever

engages fully

onto the locating pip).

Place the pushrod end over the tiller pin. If necessary , extend or

1, +1, 10

and

+10

keys.

Tiller pilot

Use these keys to

extend or retract the pushrod.

Speed: +1 = 25%, +10 = 50%

Note:

This function is not int ended for steering the boat.

Engage the clutch

on the wheel pilot

a

b

D5341-2

Page 17

Chapter 1: Basic operation 7

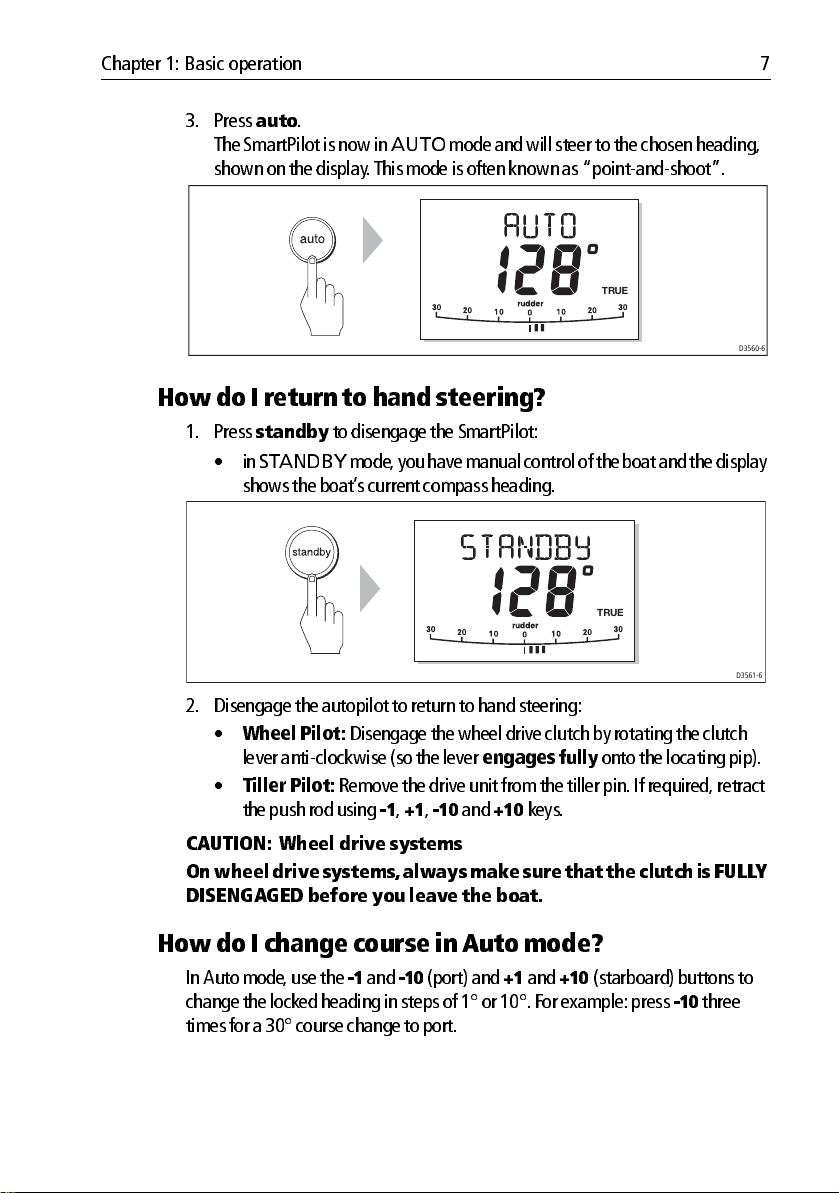

3. Press

auto

.

The Smart Pilot is now in

AUTO

mode and will steer to the ch osen heading,

shown on the disp lay . Th is mode is often known as “po intandshoot ”.

How do I r eturn t o hand stee ring?

1. Press

2. Disengage the au topilot to return to h and steering:

standby

•in

STANDBY

to disengage the SmartPil ot:

mode , you have manua l control of the bo at and the display

shows the boat’ s current comp ass heading.

•

Wheel Pilot:

lever anticlo ckwise (so t he lever

•

Tiller Pilot:

the push rod usi ng

Disengage the wheel drive clutc h by rotating the cl utch

engages fully

Remove the drive unit from the tiller pin . If required, retract

1, +1, 10

and

+10

TRUE

keys.

TRUE

D3560-6

D3561-6

onto the locatin g pip).

CAUTION: Whe el drive systems

On wheel drive systems, always make sur e that th e clutch is FU LL Y

DISENGAGED before you leave t he boat.

How do I change course in Auto mode?

In Auto mo de, use the 1 and

change the locked heading in steps of 1° or 10°. For example: press

times for a 30° course ch ange to port.

10

(port) and +1 and

+10

(starboard) buttons to

10

three

Page 18

8 S1 Wheel and Tiller Pilots Operating Guide

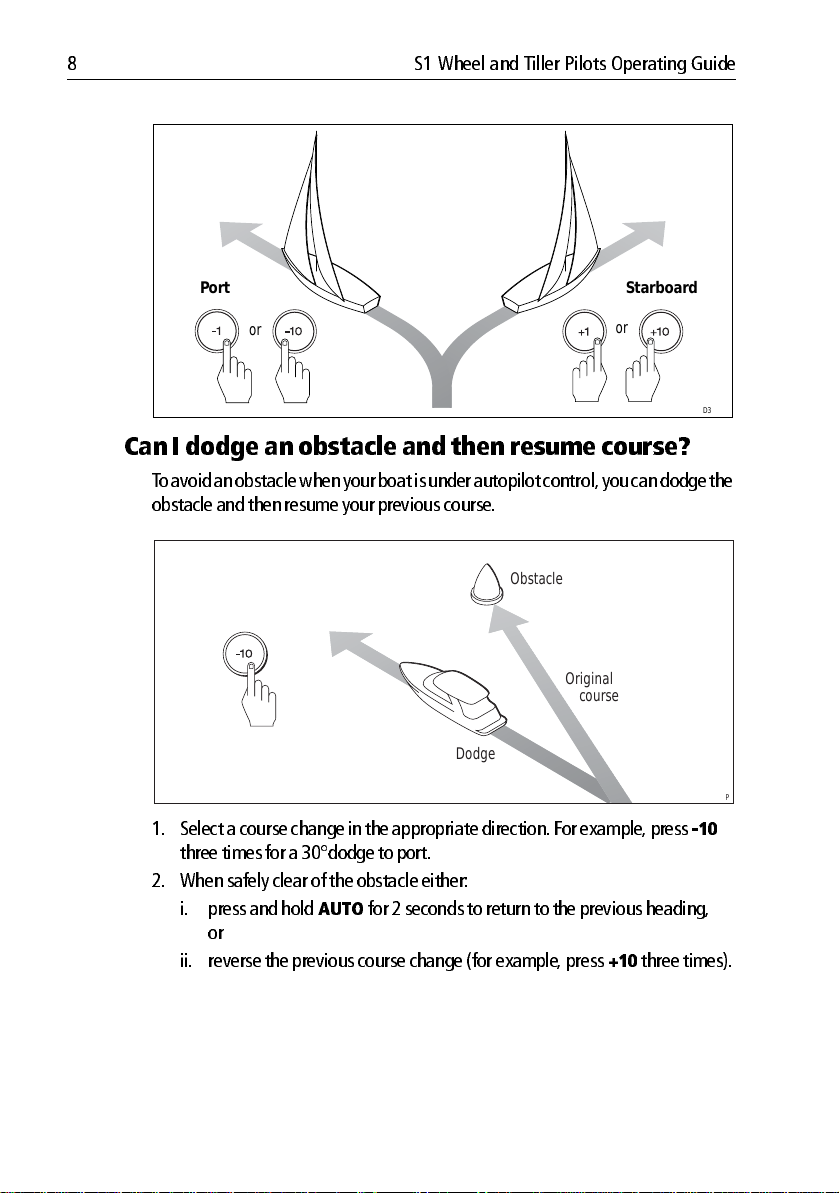

Port Starboard

or

or

Can I dodge an obstacle and then resume course?

T o avoid an o bstacle when your boat is under au topilot control, you can do dge the

obstacle and th en resume your previous cou rse.

Obstacle

Original

course

Dodge

1. Select a course change in the appropriate direct ion. For examp le, press

three times for a 30°dod ge to port.

2. When safely clear of the ob stacle either:

i. press and hold

or

ii. reverse the previous course change (for example , press

AUTO

for 2 seconds to return to th e previous heading,

+10

three times).

D3303-3P

10

D3320-3

Page 19

Chapter 1: Basic operation 9

Off Cour se alarm

= deviation to port

= deviation to starboard

D3315-5

The SmartP ilot warns you when you have been off course from the locked headi ng

for long er than 20 seconds . It shows whether the deviatio n is to po rt or starboa rd.

The w arning automati cally clears if the heading recovers or if you change cou rse.

1. T o cancel the off course w arning, press

standby

to return to manual steer

ing.

2. Check whether your b oat is carrying too m uch sail, or whether the sails are

badly bala nced. Y ou can usu ally significantly improve course k eeping by

improving th e sail balance.

Note:

The default off course angle is set at 20º. You can adjust this angle in Dealer Cali

bration (see SmartPilo t Commission ing Guide).

1.4 How do I adjus t the perf ormance of my SmartPilot?

The pri ncipal method o f adjusting the performan ce of SmartPilot systems is by

changing the response level. Th is is the only user adjustm ent you should need to

make to y our Sm artPilot on a regula r basis .

The respo nse level controls the relationsh ip between the SmartPilot’ s course

keepin g accuracy and th e amount of helm/d rive activity . When you tu rn on your

SmartPilot it will alway s be at the defau lt level. (Thi s level can be ad justed in User

Calibration

When you req uire extra tight course k eeping (e.g . for pilotage in con fined and

sheltered waters), in crease the setting. If yo u want to minim ize drive activity and

conserve battery po wer , decrease the setting.

Y ou can mak e temporary ad justments to the response level when usi ng your

SmartPilot on a daytoday basi s. By doin g this you can matc h performance to

conditio ns as they occur .

see page 31 )

Page 20

10 S1 Wheel and Tiller Pilots Operating Guide

Note:

You will los e these t emporary changes t o respo nse level whenev er the s ystem is

powered off. You can make permanent ad justments in User Calibrat ion (See page 31). This

determines t he default powerup r espons e level.

Adjusting perform ance

TillerPilot ( and gyro upgr aded WheelPilot )

S1 Tiller Pilot (and gyro up graded WheelPilo t) systems have 9 levels of response:

•

level 9 to 7

give the tightest course k eeping and greatest ru dder activity

(and power con sumption). T his can lead to a rough passage in open waters as

the SmartPilot ma y ‘fight’ the sea.

•

levels 6 to 4

should give good co urse keeping with crisp, well co ntrolled

turns under no rmal operating con ditions .

•

level 3 to 1

minimizes the amou nt of pilot activity. This con serves power , but

may compro mise shortterm coursek eeping accu racy .

With these points in mind, you sho uld use the following p rocedure to mak e

temporary ad justments to the response level when requ ired:

1. Display the

RESPONSE

screen by pressing the

1

and +1 buttons together

momentarily.

Note:

The

RESPONSE

sioning Guide) s o you can also access it by pr essing

data pages.

2. Press 1 or

+1

screen is set as a default data p age (see Smart Pilot Co mmis

disp

and then s crolling throug h the

buttons to change the respon se level.

3. Press

Decrease

response

disp

or wait for 5 seconds to return to the previous displ ay .

Increase

response

D5452-3

Page 21

Chapter 1: Basic operation 11

Adjusting perform ance

S1 WheelP ilot (without gyr o)

S1 WheelPilot sy stems (without a gyro up grade) have three different response

levels:

• Response Level 1: Aut oSeastate on (Automatic deadband)

The SmartPilot will gradually ignore repetitive boat movements and

only react to true variations in course. This provides the best compromise between power consumption and course keeping accuracy.

• Response Level 2: Aut oSeastate off (Minimum deadba nd)

This setting provides tighter course keeping but will lead to increased

power consumption and drive unit activity.

• Response Level 3: Aut oSeastate off + yaw damping

This setting provides the tightest possible course keeping by introducing

counter rudder yaw damping You can adjust the counter rudder setting in

Dealer Calibration (see SmartPilot Commissioning Guide).

To make a

1. Display the

2. Press

3. Press

Note:

powered off. You can make permanent adjust ments in User Calibration (see page 31).

temporary

1

or +1 buttons to chan ge the response between levels 1 to 3.

disp

or wait for 5 second s to return to the previous disp lay .

You will los e these t emporary changes t o respo nse level wh enever the s ystem is

change to the respon se setting:

RESPONSE

screen by pressing the

1

and +1 buttons together.

1.5 Sailing func tions

Ta cking (Aut oTac k)

CAUTION: Allow tim e for course ch anges

When ma king major course changes, the trim on the boat m ay

change su bstantially . Due to this , the Sm artPilot may take some

time to settle accurately onto the new course.

The Smart Pilot has a built in automatic tac k facility (AutoT ack) that turns the boat

in the required di rection for a tacking man euver .

When you A utoT ack the boat turns th rough the AutoT a ck angle (100° default).

Y ou should then trim the helm to mirro r the wind angle from the previou s tack.

• To AutoTack to port

i. Press the 1 and

ii. Use the

angle.

+1

and

10

buttons together. The boat will then AutoT ack.

+10

buttons to trim the helm back to the required win d

Page 22

12 S1 Wheel and Tiller Pilots Operating Guide

• To AutoTack to starboard:

i. Press the +1 and

ii. Use the

1

and

+10

buttons together. The boat will then A utoT ack.

10

buttons to trim th e helm back to the required wind

angle.

AutoTack - Port

Helm

trim

AutoTack

Helm trim

+

Wind Wind

AutoTack

angle

AutoTack - Starboard

Helm trim

AutoTack

angle

+

AutoTack

+

AutoTack angle

Y ou should set the A utoTac k angle to 20° greater than the ac tual required change

of heading.

Example

If you wish to tack through 8 0° (i.e when sailing at 4 0° to the wind) you should set

the AutoT ack ang le to 100°. T he SmartPilot will Aut oT ack through the larg er

angle , you should then use the SmartPilot con trols to trim the helm bac k to the

required 40° relative to th e wind.

Helm

trim

+

D9318-1

Y ou can adju st the default AutoT ack ang le in User Calibration (see

page 30

).

Preventing gybes with AutoTack

The gy be inhibit feature prevents an A utoT ack away from th e wind – this will

prevent the AutoT ack featu re from gybing.

Note:

For the gybe inhibit featur e to work, the SmartPilot needs suitable wind inform a

tion.

Gybe inhibit is switched on as a default but can be disabled in User Calibration if

required

(see page 30)

.

Page 23

Chapter 1: Basic operation 13

With gybe in hibit on:

• you will be able to perform an AutoT ack int o the wind.

• the autopilo t will prevent the boat from performi ng an AutoT ack aw ay from

the wind, to prevent acc idental gybes .

With gybe in hibit off:

• you can perfor m an AutoT ack into o r away from the wind.

Note:

Gybe inhibit is switched on as a default but can be disabled in User Calibration (see

page 30).

Gusty co nditions

CAUTION: Risk of gybe

Always be aware of the relativ e wind angle, especially wh en using

the Aut opilot to sail down wind.

In gusty conditions, the course may tend to wander slightly , partic ularly if the sails

are badly bala nced. If you tak e the following preca utions, the SmartPilot will be

able to maintai n competent contro l even in gale force condition s:

• Y ou can imp rove course keeping by improving the sail balance:

• do not allow the b oat to heel over excessively .

• ease the mainsheet traveller to leewa rd to reduce heeling and weather

helm.

• if necessary , reef the mainsa il a little early .

• In very strong wind s and large seas, you should avoid sailing with the wind

dead astern:

• ideally , br ing the wind at least 30° awa y from a dead run.

• in severe conditions , you m ay also need to remove the mainsa il and sail

under headsail only.

Page 24

14 S1 Wheel and Tiller Pilots Operating Guide

1.6 Displa y lighting & con trast ?

Adjusting the display lighting

Y ou can adju st the display and k eypad ligh ting by:

1. Pressing

turn on the ligh ts.

.

1 second

disp

for 1 second from any mode to access the

LAMP

screen and

D3313-5

2. Press the

LAMP 3

LAMP 2, LAMP 3

disp

button to cy cle through the po ssible illumination settings:

(the brightest setting)

, LAMP 2, LAMP 1, OFF, LAMP 1,

and so on:

• as you chang e the setting, the illumin ation on any oth er SeaTa lk instru

ments or control units will also change.

3. The disp lay automatical ly returns to the previous mo de if you do not press a

button for 10 seconds:

• if you press anoth er mode button within 10 seconds you will selec t the

mode assigned to that button (for example:

standby

Notes: (1)

Notes: (1)

selects Standby mod e).

You can also adjust the lighting level from any other SeaTalk instrum ent

or contro l unit.

When you s witch off th e unit you los e any chan ges you have m ade to

the lightin g level.

auto

selects Auto mode ,

Adjusting the contrast

T o set the display co ntrast level:

disp

1. With the autopi lot in Standby mo de, press the

access the

2. Press the

LAMP

screen.

disp

button for one secon d again, to disp lay the

screen.

3. Use the

+1

and

1

buttons to set the required contrast level (from 1 to 15).

button for on e second to

CONTRAST

Page 25

Chapter 1: Basic operation 15

4. The di splay automatica lly returns to the previous mo de if you do not press a

button for 10 seconds:

Note:

if you p ress an other mo de butt on within 10 seconds you will s elect the mo de as

signed to that bu tton (for example:

mode).

auto

selects Auto mode,

standby

selects Standby

Page 26

16 S1 Wheel and Tiller Pilots Operating Guide

Page 27

Chapter 2: Advanced operation

2.1 How do I foll ow a route s et on a Chart plotter?

CAUTION: Sa fety in T ra ck mode

T rack mode pr ovides accur ate tra ck keeping even in complex

navigationa l situations . However, it is still th e skipper’ s

responsibility to ensur e the safet y of their boat at all time s

thr ough caref ul navigation and freque nt position check s. T rack

mode assists pre cise navigation and removes the tasks of

compensating f or wind and tidal drif t. However, you MUS T still

maintain an accur ate log with r egular plots .

In T rack mo de, the Sm artPilot mainta ins a route between w aypoints created on a

navigation sy stem. It makes an y course changes necessary to keep you r boat on

course , automaticall y compensating for tidal streams and leeway.

T rack mode is avail able only if you have con nected the SmartPilot to a suitable

navigation sy stem providing SeaT alk or NMEA in formation.

Commission ing Guide for connecti on details)

Y our SmartPil ot system can receive route inform ation from:

• a SeaT alk navigation in strument or chartplo tter .

• a navigation syst em transmitting data in NMEA 0183 format.

(See SmartPilot

17

How do I a ctivate T r ack mode?

CAUTION: Ma ke suitable pr eparation s for enterin g track mode

When you enter T ra ck mode, th e SmartP ilot will bring the boat

onto the track in a controlled way . The closer the boat is to the cor

rect heading and t rack, t he quicker it will settle the boat onto t he

new course . To av oid an unexpect ed turn, align the boat a pproxi

mately with the required track before entering Track mode.

Starting with the Smart Pilot in A UTO mode an d your chartplo tter following a

route.

1. Press

2. Wai t for the warning to sou nd.

track

to enter T rack mode .

The disp lay will show the bearing to the next planned waypo int and the direc

tion in which th e boat will turn to reach thi s waypoint.

Page 28

18 S1 Wheel and Tiller Pilots Operating Guide

3. If it is safe for the boat to turn on to the new course , press the

• the SmartPilot will tu rn the boat onto the new cou rse.

• the display will sh ow the heading required to achieve the required track.

Note:

If the boat is more than 0.3 nm from the track, th e Large Cross Track Error warnin g

will sound (see page 18 ).

Waypoint arrival Waypoint advance

Next target

Waypoint at 270˚

Target

Waypoint

TRUE

Old target

Waypoint

How do I leave T ra ck mode?

Y ou can leave T rack mode at an y time by:

• pressing

• pressing

auto

to return to Auto mode.

standby

to steer manually in Standby mode .

track

button:

New target

waypoint at 270˚

TRUE

D5416-4

Cross track error?

Cross track error (XTE) is the di stance between the current positio n and a planned

route . The SmartPi lot receives the cross track error informati on from the

navigation equi pment, and displays the XTE in nautical miles (nm), statute miles

(SM) or kilometres (km).

Cross tr ack err or course corr ection

The auto pilot will automati cally steer to correct the cou rse whenever it detects a

cross track error .

Page 29

Chapter 2: Advanced operation 19

CAUTION: Th e direction of turn an d the displayed bearin g to

waypoint may be different from that expected.

Example:

Course correction

Example1:

Initial turn toward waypoint

Target

Waypoint

Example2:

Initial turn away from actual

waypoint position.

Target

Waypoint

Cross

track error

Cross

track error

TRUE TRUE

D9416-1

Page 30

20 S1 Wheel and Tiller Pilots Operating Guide

Large cr oss trac k error

If the cross track error is greater tha n 0.3 nm, the Smart Pilot will sound the L arge

Cross T rack Er ror warning and show whether you are to the p ort (Pt) or starboard

(

Stb

) of the planned track.

Cross track error (XTE)

more than 0.3 nm

Actual route

Planned route

Waypoint 1

Waypoint 2

Tidal stream compensa tion

Under most con ditions, t he SmartPilot will hold the selected track to within ± 0.05

nm (300 ft) or better . It takes acco unt of the boat’s speed when compu ting course

changes to ensure o ptimum performan ce.

Waypoint 2

Boat's speed over ground

Tidal component

D5415-4

Waypoint 1

Boat's speed through water

D3261-4

Page 31

Chapter 2: Advanced operation 21

How do I d odge an obs tacle in T r ack mode ?

In T rack mode yo u still have full control from the keypad. Y ou can mak e a dodge

maneuver by usin g the course change bu ttons (

1,+1

,

10

or

+10

) to select the

desired course cha nge.

On making a dod ge maneuver , the auto pilot will revert to A UTO mode . Once you

are safely past the obstac le, re initiate T rac k mode to continue on your planned

route.

What hap pens when I arrive at a waypoint ?

As the boat arrives at the targ et waypoint the ch artplotter will select the next

target wayp oint and transmit th is to the SmartPilot. It will then detect the new

target wayp oint name , sound a W aypoint Ad vance warning and display the

Way point Advan ce (NEXT WPT) screen. This sh ows the new bearing to the next

waypoi nt and the direction th e boat will turn to acqui re the new track.

Waypoint arrival and advance

Next target

Waypoint at 270˚

New target

waypoint at 270˚

Target

Waypoint

TRUE

Waypoint arrival Waypoint advance

Old target

Waypoint

How do I get to the next waypoint in a route?

When the W aypoint Ad vance warning sounds , the SmartPilot suspen ds T rack

mode and mai ntains the current boat heading.T o adv ance to the next waypoin t:

1. Check that it is safe to turn on to the new track.

2. Press the

turn the boat tow ards the next waypo int.

Note:

maintain the current headi ng and continue sound ing the warning.

track

button. T his will cancel the W aypoint Advance warni ng and

If you do not press

track

to accept the Waypoint Advance, the SmartPilot will

TRUE

D5416-4

Page 32

22 S1 Wheel and Tiller Pilots Operating Guide

How do I skip a waypoint? (SeaTalk chartplotters)

If you want to advance to the next wayp oint

target waypo int, you can skip a waypoint by pressing

display will then show the W aypoint Advance screen for the next waypoin t. Check

it is sa fe to tu rn, t hen press

WARNING: Ensure nav igation safety

Skipping a waypoint will take you str aight to t he next way point.

Check your navigation befor e making th e turn.

Always be aware of the r elative wind an gle, especially when

turnin g away from t he wind.

track

to turn the boat towar ds the next waypoint.

before

you have arrived at the

track

for 1 se con d. T he

What is the Waypoint Advance alarm?

The SmartP ilot activates the W aypoint A dvance alarm (NEXT WPT?) in T rack

mode whenever the target wa ypoint name chan ges. T his occurs when:

• you select autom atic acquisition b y pressing

• you request w aypoint adv ance by pressing

(with SeaT alk navigators onl y)

• the boat arrives at the target and the navigator accepts the next wa ypoint

• you activat e the Man Overboard (MOB) function (see

When the alarm sou nds, th e SmartPilot continu es on its current heading but

displays:

• the bearing to the next w aypoint

• the direction the b oat will turn to tak e up that bearing

track

from Auto

track

for 1 second in T rack mode

page 28

)

How do I respond t o a Waypoint Advance alarm?

T o respond to a W aypoin t Advance alarm:

• check that it is safe to turn onto the new

waypoin t advance

• alternatively , yo u can cancel the alarm with out accepting the w aypoint

advance by pressing:

•

auto

to continue on the same heading, or

•

standby

to return to manual control

track

, then press track to accept the

What happens when I get to the end of the route?

The SmartP ilot displays the

reached the last way point on a route in Tra ck mode.

• press

auto

to continue on the same head ing.

ROUTE COMPLETED

warning when yo u have

Page 33

Chapter 2: Advanced operation 23

• or press

Note:

DATA when you reach the final waypoint.

standby

If waypoints are provid ed using an NMEA connection the controller will display NO

to return to manual co ntrol.

2.2 Using Wind V ane mode

Note:

You can only select Wind Vane mo de if the SmartPilot is receiving suitable SeaTalk

or NMEA wind direction infor mation.

What is Wind V ane mode?

When the SmartPil ot is in Wind V ane mode it uses the fluxgate comp ass as the

primary heading reference. As changes in the true or apparent wind angle occur,

it adjusts the lock ed heading to maintain the origi nal wind angle .

Wind i nform ation

T o use Wind V ane mode , the SmartPilot mu st receive wind information from one

of the following sources:

• SeaT alk wind instrumen t connected to the auto pilot via SeaT alk

• NMEA wind instrum ent

• Raymarine push pit wind vane conn ected via a SeaT alk interface

T rue and apparent wind

SmartPilots can maintain a course relative to eith er an apparent or true wind

angle in Wind Vane mode

The default setting is apparent wind. If req uired, you can chang e this to true wind

in User Calibration (see

page 31

).

WindTrim

In Wind V ane mode the SmartP ilot uses WindT rim to eli minate the effects of

turbulence an d short term wind variati ons. T his provides smoo th and precise

performance with m inimal power consum ption. Y ou can adjust the wind

response (WindT rim) level in User Calibration (see

the SmartPilot resp onds to changes in th e wind direction. H igher wind trim

settings will result in a p ilot that is more responsive to win d changes .

page 31

) to contro l how quickly

Page 34

24 S1 Wheel and Tiller Pilots Operating Guide

How do I select Wi nd V ane mode ?

Y ou can select Win d Vane mod e from either Standby or Au to mode:

1. Steady the boat on to the required wind ang le.

2. Press

3. In Wind V ane mode , the SmartPilot will th en adjust the boat’ s heading to

standby

and

auto

together to select Wind V ane mode and lock the

current wind angle:

• the display shows the locked heading (e.g. 128°) and the wind angle

(e.g.

WIND 145P

indicates an wind an gle of 145° to port)

• if the SmartPilot do es not enter Wind V ane mode, it is not receiving wind

data check the instrum ent and connectio ns

+

MAG

D3565-6

maintain the lo cked wind ang le.

How do I leave Wind Vane mode?

Y ou can leave Wind V ane mode by :

• pressing

• pressing

auto

to return to Auto mode.

standby

to return to manu al control.

How do I adjust the locked wind angle

Y ou can adjust the locked wind angl e by using the 1, +1,

change course . For example , to bear away by 10° when the boat is on a starboard

tack:

10

• press

to turn the boat 10 ° to port – the lock ed wind angle and locked

heading will bo th change by 10 °.

• the autopilot will then adjust the lock ed heading as requ ired to maintain the

new wind angle.

Note:

Because turning the boat affects the relation ship between the true and apparent

wind angles, you should only u se this method to m ake minor adjustm ents to the wind an

gle. For major changes, return to Stan dby mode, s teer onto the n ew heading, then r eselect

Wind Vane mo de.

10

and

+10

buttons to

Page 35

Chapter 2: Advanced operation 25

How do I dodge an obstacle in Wind V ane mode?

In Wind V ane mode you still have full control from the k eypad. Y o u can make a

dodge maneuver by using the course change buttons (

select the desired cours e change.

After you have avoided the hazard, you can cancel the dodge cou rse change by

making an equ al course change in the op posite direction.

1,+1

,

10

or

+10

) to

What is a Wind Shift warning?

If the autopilo t detects a wind shift of more than 15 ° it will sound the wind shift

warning and display the

• T o cancel the warn ing, and retain th e existing wind angle and new head ing,

standby

press

• Alternatively , to cancel the warning and return to the previous h eading:

• adjust the lock ed wind angle u sing the

• press

standby

ing, an d press

with the new wind angle .

WIND SHIF T

and

auto

together.

to return to hand steering, steer onto the requ ired head

standby

and

message:

1, +1, 10

auto

together to retu rn to Wind Vane m ode

and

+10

buttons.

How do I use AutoTack in Wind Vane mode?

Note:

If you use t he AutoTack function in Wind Vane mode, m ake sure the wind van e has

been centered accurat ely.

The Smart Pilot has a built in automatic tac k facility (AutoT ack) that turns the boat

in the required di rection for a tacking man euver .

When you A utoT ack in Wind V ane mode , the boat turns th rough the AutoT a ck

angle (100° defau lt). The SmartPi lot will then trim the helm to m irror the lock ed

wind angle from th e previous tack.

• T o AutoT ack to p ort: press the 1 and

• T o AutoT ack to star board: press the +1 and

10

buttons together.

+10

buttons tog ether .

Page 36

26 S1 Wheel and Tiller Pilots Operating Guide

AutoTack - Port

Automatic

Helm

trim

Wind Wind

AutoTack - Starboard

Automatic

Helm

trim

AutoTack

+

AutoTack

angle

AutoTack

angle

AutoTack

+

AutoTack angle

When sailing in Wind Van e mode you should set the AutoT ack angle to 20 °

greater than the actua l required change of head ing.

Example

If you wish to tack through 8 0° (i.e when sailing at 4 0° to the wind) you should set

the AutoT ack ang le to 100°. T he SmartPilot will Aut oT ack through the larg er

angle and then tri m the helm back to the wind v ane locked head ing.

Y ou can adju st the default AutoT ack ang le in User Calibration (see

page 30

Oper ating hi nts for Wi nd V ane mode

• Always trim your sails carefully to minimize the amoun t of standing helm.

• Reef the headsail and main sail a little early rather than too late.

• In Wind V ane mode the SmartPilot will react to long term wind shifts, but will

not correct for shor tterm changes such as gu sts.

• In gusty and unsteady inshore co nditions , it is best to sail a few degrees fur

ther off the wind so that chan ges in wind direction can be tolerated.

D9320-1

).

Page 37

Chapter 2: Advanced operation 27

2.3 How do I displ ay boat data?

Use the

disp

button to show ‘da ta pages’ of SeaT alk or NMEA data:

1. Press

Notes: (1)

Default data pages

disp

to access the first data page , and press it aga in to cycle throug h

each data page in turn:

• when you cyc le past the last data page , the display retu rns to the current

SmartPilot mo de screen (for example, AUT O).

• 4 data pag es are set in the factory as a default (see diagram): within User

setup you can select up to 15 pages and control the informatio n they dis

play (see

SmartPilot Co mmission ing Gu ide

If the SmartPilot system canno t obtain the required informa tion, the data

page will show dashes instead of a value.

(2)

The directionto steer arrows relate to the data page informat ion.

(3)

Most data pages sho w repeated data so you cannot adjust th em: the

exceptions are the

which you can adjust using th e

RESPONSE

).

and

RUDDER GAIN

1

and

+1

data pages ,

buttons

Data page 4

Data page 3

Autopilot mode

Press for 1 sec to

return to previous

data page

Data page 1

Data page 2

Can I dis play Wa ypoint na mes?

If waypoi nts have been given names , the SmartPilot con troller will display th em

on the Cross T rack Error (

Waypoint (

DTW

• waypoi nt names of five characters or less are display ed together with the

page name (as shown b y screen A below).

• waypoi nt names of more than five characters alt ernate with the page name

(as shown by screenB below).

XTE

) data pages:

), Bearing T o W aypoint (

BTW

) and Distance T o

D5455-3

Page 38

28 S1 Wheel and Tiller Pilots Operating Guide

• if the waypoin t name has more than nin e characters, the display only sh ows

the first n ine ch aracters .

TRUE TRUE

A

TRUE

2.4 Alarms

The SmartP ilot may activate th e alarms listed on the followin g pages. When

displayin g an alarm the sounder will beeping and the disp lay will show the

appropriat e alarm message.

Responding to alarm s

• Unless otherwise st ated, you shou ld deal with al arms by pressing

clear the alarm and retu rn to hand steering.

• In some situatio ns, the auto pilot will raise more than one alarm. When you

have dealt with the first alarm, th e autopilot will disp lay the next alarm.

Message Description and possible actions

LARGE XTE

MOB

B

D8561-1

standby

Large cr oss track err or

Activated when t he cross track erro r exceeds 0 .3 nm . T he alarm

clears if the heading recovers.

Man OverBoard alarm

The SmartPilot activ ates the Man Overboard alarm if it receives a

man overboard (MOB) mess age from another instru ment on the

SeaTalk s ystem. I t dis plays t he text M OB inst ead of t he waypoi nt

number for the XTE, DTW an d BTW data pages .

If the autopilot is in T rack mode, it will soun d the Waypoint

Advance alarm to notify you of the change in waypo int.

to

Page 39

Chapter 2: Advanced operation 29

Message Description and possible actions

NEXT WPT?

OFFCOURSE

(PT or Stb)

Waypoint a dvance ala rm

The SmartPi lot activ ates th e Wayp oint Adv ance alarm whenever

the target waypoint num ber changes. T his occurs when:

• you select automatic acquisition by pressing

• you request waypoint adv ance by pressing

in Track mod e (with SeaTalk navigators only)

• the boat arrives at the target waypoint and the navigato r

accepts the next waypoint

• you activate the Man Overboard (MOB) function in T rack

mode

When the alarm sounds , the pilot contin ues on its current heading

but disp lays:

• the bearing to the n ext wayp oint

• the direction the boat will turn to tak e up that bearing

Responding to a W aypoint Adv ance alar m

To respon d to a Wayp oint Ad vance alar m:

• check that it is safe to turn onto the new track, then press

track

to accept the w aypoint advan ce

• alternatively, you can cancel the alar m without accepting the

waypoint adv ance by press ing:

steering, or

Note: Way point ad vance o nly oper ates if th e Smartpilo t is receiv

ing valid bearing to way point and waypoint number information.

Off course alarm

When the vessel has been off cours e from the lock ed heading for

longer than 20 s econds .

• PT = Deviation to port

• Stb = Deviation to starboard

You can adjust this s pecified alarm angle in Dealer setup, see your

Commission ing gu ide for details.

If this h appens fr equently yo u sho uld check s ail balance and also

review autopilot performance . See

auto

to return to Auto mode .

standby

page 9

track

track

to return to hand

.

from Auto

for 1 second

SHALLOW

WINDSHIFT

Shallow ala rm

The SmartPilot activ ates the Shallow alarm if it receives a shallow

depth alarm via SeaT alk:

•press

Large wi nd shift warning

Indicates a chan ge in t he apparent wind an gle of mo re than 15º.

See

page 25

standby

.

or

disp

to cancel the alarm

Page 40

30 S1 Wheel and Tiller Pilots Operating Guide

2.5 User Calibrat ion Options

The cali bration informatio n in this handbo ok relates to only those setting s that

can be adjusted d uring normal op eration (

available cali bration settings , see

Note:

Many of the settings are sailb oat specific and will only be displayed if your vessel

type is set to

SAILBOAT

.

SmartPilot Com missioning Guid e.

How do I access Us er Calibr ation s ettings?

Y ou can only access the calibration m ode from Standby mo de:

1. With the SmartP ilot in Standby m ode, press an d hold the

2 seconds . The di splay will change to sh ow

2. Press the

3. Press

The first pag e of User Calibration will now be disp layed.

4. T o access other User Calibratio n pages, press

items within that gro uping:

5. When you reach an item y ou wish to ad just, use the

tons to change the val ue.

6. When you have mad e all the changes you w ant to make , press and ho ld

standby

disp

button once , the display will now show

auto

to enter User Calibration.

for two seconds to exit calibra tion mode and save chang es.

USER CAL

DISPLAY CAL

disp

). For infor mation on all

standby

USER CAL

to scroll down th rough the

1, +1, 10

.

button for

.

and

+10

but

User Calibration pages

AutoTack angle

The Au toTack ang le is the angle through which the boat will turn when y ou select

an automatic tack.

Screen T ext Options

AUT O TACK 40° to 125° in 1° steps

Gybe inhibit

With gybe in hibit on:

• you will be able to p erform an AutoT ack into the wind

• to prevent accidental gybes, the SmartPilot will prevent the boa t from per

forming an Au toT ack away from the win d

Page 41

Chapter 2: Advanced operation 31

With gybe in hibit off , you can perform an AutoT ack into or aw ay from the wind.

Screen T ext Options

GYBE STO P ON (Default) = Gybe in hibit o n (gybes prevented)

OFF = Gybe inhibit off (gybes permitted)

Wind selection

This sc reen determines whether the boat steers to ap parent or true wind in Win d

Van e mode.

Options

WIND APP (Default) SmartPilot steers t o apparen t wind an gle

WIND TRUE Smar tPilot steers to true wind angle

WindTrim

WindT rim co ntrols how quickly the SmartPilot respond s to changes in the wind

direction. Higher win d trim setting s will result in a system th at is more r esponsive

to wind changes.

Screen T ext Options

WIND TRIM Range = 1 to 9

1 to 3

Least responsiv e to wind changes (less system

activity)

4 to 6

Moderate response to wind chang es

7 to 9

Most respons ive to wind changes (more system

activity)

Response level

This sets t he default SmartPilot respon se level setting. The respon se level controls

the relationship between course keep ing accuracy and the amount of helm/ drive

activity . You can make temporary changes to response during normal operation,

as described in

Chapter 1, SmartPilot Operatio n

.

Page 42

32 S1 Wheel and Tiller Pilots Operating Guide

S1 TillerPilot (and gyro upgraded WheelPilot) systems

Screen T ext Options

RESPONSE

Range = 1 t o 9

levels 9 to 7

est rudder activit y (and power consumption). T his can lead

to a rou gh pas sage in open w aters as the Smar tPilot may

‘fight’ t he sea.

levels 6 to 4

well controlled t urns under n ormal o perating conditions .

levels 3 to 1

conserves p ower , but may comp romise s hortt erm cours e

keeping accur acy .

Variation

Screen T ext Options

VARIA TION

Apply heading co rrection to allow for v ariance of magnetic

north.

Degrees North, South , East & West.

(Not normally us ed)

gives the tig htest course keeping and great

should give good course keepin g with crisp ,

minimizes the amount of pilot activity . This

Page 43

Chapter 3: Fault Finding & Maintenance

All Raymarin e products are designed to provide many years of trou blefree

operation. We also put them thro ugh comprehen sive testing and quality

assurance p rocedures before sh ipping .

This chapter provides information ab out identifyin g problems , interpreti ng alarm

messages , maintaining your SmartPilot an d obtaining pro duct support.

If a fault o ccurs with yo ur SmartPilot, use the fault find ing tables in this section to

help id entify th e prob lem and provid e a so lution. If y ou c annot resolve the

problem yo urself, refer to the product supp ort information.

3.1 Fault fi nding

SYMPTOM POSSIBLE CA USE and S OLUTION

33

Display is blank

Data page display shows

stationary da shes

Display shows rotati ng dashes

Displayed compa ss heading

does not agr ee with the b oat’s

compass

No display ba r on the display

Rudder bar d isplay moves in

opposite dir ection to rudder

Boat turns slowly a nd takes a

long time to come onto course

Boat ove rshoots when turning

onto a new course

The SmartPilot ‘ hunts’ when

trying to positio n the rudder

No power – check the power and SeaTalk fuses on

course comput er , then check mai n fuse/ circuit

breaker.

The contro l unit is no t receiving necessary d ata from

other instrument s – check cabling.

Compass calibratio n in progress (see SmartPilo t

Commission ing Guide).

Y ou have not calibrated the compass . Carry out th e

deviation and alignment pr ocedures (see SmartPilot

Commission ing Guide).

Rudder bar s witched off i n Display Calibratio n –

select

RUDD BAR

Reverse the red an d green rudder p osition senso r

connections at the course comput er .

Rudder gain too low. Co mplete AutoLearn or increase

gain setting.

Rudder gain too high. Com plete AutoLearn or

decrease gain setti ng.

Adjust the

Commission ing Guide). Increase the damping one

level at a time until the autopilot stops hunting, and

always use t he lowest a cceptable valu e.

RUDD DAMP

or

STEER BAR

setting (see SmartPilot

.

Page 44

34 S1 Wheel and Tiller Pilots Operating Guide

SYMPTOM POSSIBL E CAUSE a nd SOLUTION

The SmartPilot a ppears to be

unstable on Northerly

headings in the Northe rn

hemisphere (or S outherly

headings in the S outhern

hemisphere)

You cannot enter Seatrial

Calibration

The SmartPilot w ill not ‘talk ’

to other SeaTalk instruments

Position informatio n not

received

The SmartPilot w ill not auto

advance to the next waypo int

NonRaymarine 24 V

autopilots clutch slipp ing

When holding a constant

course in ST ANDBY mode, the

heading continuously changes

Jog (+ and keys used to

extend / r etract til ler drive)

doesn’t work i n standby

mode.

Northerly/ Southerly heading correction (AutoAdapt)

is not set up (see SmartPilot Commissionin g Guide).

[Does not apply t o S1G , S2 G and S3G sy stems .]

Seatrial calibration lock is on – turn off the calibration

protection feature in Dealer Calibratio n (see

lot Commiss ioning Guide

Cabling problem – make sure all the cables are con

nected properly.

Navigator not transmi tting t he correct p osition data.

No bearing to wayp oint information received from

the naviga tor.

Check that t he clutch fu se is in the co rrect pos ition.

E.g. 24 V p osition for 2 4 V clut ches .

The Autopilo t is connected to a Raymarine Pathfind er

unit with the “Bridge NMEA Heading ” option

switched on. Disable this featu re on t he P athfin der

unit.

Vess el type is set i ncorrectly . Check vess el type is set

to SAILBOAT .

Refer to the separate commissio ning guide for

details.

).

SmartPi

SmartPilot alarm messages

When the SmartPilo t detects a fault or failure on the system, it will activ ate one of

the alarm messages listed in the following table .

• Unless otherwise stated, yo u should respond to the alarm by pressing

standby

to resolve the problem.

• In some situatio ns, the SmartP ilot will raise more than on e alarm. When you

have dealt with the first alarm, it will display the next alarm.

to clear the alarm and return to manual con trol, before you attempt

Page 45

Chapter 3: Fault Finding & Maintenance 35

ALARM MESS AGE POSSIBLE C AUSE and S OLUTION

CURRENT LIMIT

DRIVE STOPPED

LOW BA TTERY

LRN FAIL 1, 2

or

MOT POW

SWAPPED

NO DA T A

Serious drive failure – the driv e is t aking too much cu rrent du e to

shortcircuit or jamming. Check the drive unit.

The autopil ot is unable to tu rn the rudder (this occurs if the weather

load on helm is to o high, or if the rud der position senso r has passed

beyond the preset rudder limit s or rudder endsto ps).

Check drive and rudder positio n sensor .

Supply voltage has dropp ed below acceptable limits.

To respond to a Low Battery alarm:

• press standb y to clear the alarm and return t o hand steering

• start the engine to recharge the battery

AutoLearn not completed success fully .

4

Failur e codes:

1

= AutoLearn has n ot been car ried out (default s etting)

2

= AutoLearn failed, usually due to manual interr uption

4

= AutoLearn failed, probably due to driv e or compass failure

Repeat the AutoLearn procedur e.

Motor cables ar e connected to power term inals (and po wer cables

are connected to motor terminals) at cour se computer . T urn off

power and swap over connections .

Caused by any of t he following situat ions:

• the compass is not conn ected

• the autopilot is in Wind V ane mode and it has not received wind

angle data fo r 30 seconds

• the autopilot is in T rack mode and:

• the autopilot is no t receiving SeaTalk navigat ion data, or

• the position sen sor (GPS , Loran, Decca) is receiving a low

strength signal – t his will clear when the s ignal im proves

Check connections to the compass , wind instru ment and naviga

tor.

Note:

The auto pilot stop s adjusting the heading as soon as it loses

data.

NO PILOT

NO RUDREF

The contro ller is not receivin g data from th e SmartPilo t compu ter .

Check connections and check cours e comput er is s witched on.

Poss ible fault with rudder positio n sensor – check connections .

Page 46

36 S1 Wheel and Tiller Pilots Operating Guide

ALARM MESS AGE POSSIBLE CA USE and S OLUTION

RG FAIL

SEATALK

FAIL 1

or

SEATALK

and

2

and

GyroPlus yaw sensor has failed:

• If you have a S1G, S2G or S3G cour se computer with internal

GyroPlus sensor – call a Raymarin e service agen t.

• If you have a NonG

yaw sensor – check the sensor and connection s, then call a Ray

marine service ag ent.

SeaTalk dat a prob lem on o ne of t he SeaT alk lines – check con nec

tions.

The control un it cannot transm it data to the SeaT alk system. Mak e

FAIL

sure all SeaTalk cables are connected properl y.

3.2 Gener al maintenanc e

Routine checks

CAUTION: Do not dismantle Sma rtPilot pr oducts

The Smart Pilot computer and contr oller should be serv iced only

by author ized Raymarine se rvice techn icians. Th ese products do

not contai n any user serviceable part s.

The SmartP ilot computer do es NOT contain userserviceable parts . If you remove

the main cover y ou wil l inv alidate th e warra nty. The c ontroller is also a seal ed

unit, so user mai ntenance is limited to the fol lowing checks

• make sure all cable connectors are firmly attached

• examine for signs of wear or dama ge – replace any dama ged cables

Note:

Do not use chemical or abrasive materials to clean the SmartPilot computer. If the

case is dirty, wipe it with a clean, damp cloth.

s

course computer with extern al GyroPlus

Cleaning the display

CAU TI ON: Av oi d da mag e wh en cl ean in g

Take care when cleaning th e display . Avoid wiping t he display

screen with a dry clot h as this could scr atch t he scree n coating. If

necessary , use only a m ild detergent .

• Never use chemical or abrasive materia ls to clean the controller. If it is dirty ,

wipe it with a clean, dam p cloth.

• In certain c onditions, condensation may appear inside the d isplay screen. T his

will not ha rm the unit, and you can clear it b y switching on t he illumination for

a short time .

Page 47

Chapter 3: Fault Finding & Maintenance 37

Wheel dr ive

Routine maintenance

After each trip , flush inside the d rive unit by inserting a ho se pipe in the free slot

on the back cover.

Cleaning the wheel drive

CAUTION:

Do not use mi neralbase d solvents (such as WD40) to lubricat e or

clean th e wheel drive as they will damage the mater ial.

We recom mend that you co mplete the following step s each season to prevent th e

buildup of salt on the wheel drive bearings and drive belt:

1. Remove the wheel drive from the wheel:

• remove the wheel from the pedestal

• remove the spok e clamp screws

• remove the wheel drive front cover

2. Check inside the drive uni t for any signs of damage .

3. Tho roughly flush the wheel d rive interior with fresh water to remove any salt

buildup on the bearings and drive belt.

Do not lubricate any part of the wh eel drive. It is designed t o run

without lub rication.

4. Replace the front cover then fit wheel dr ive back onto the wheel.

5. Fit the wheel and wheel drive back onto the pedestal.

6. Clean the wheel drive case (using m ild detergent if necessary), then flush

thorough ly with fresh w ater.

Adjusting the clutch

Y ou need to adjust the clutch if the drive belt slips in Auto mode or drags in

Standby mo de. In n ormal use, you can tell if the clutch is slipping if the motor

operates but the dri ve does not turn the wheel.

T o adjust th e clutch, first m ake sure th at the autopilo t is in Standby mode and th e

clutch is diseng aged. Th en:

1. Use a 3 mm allen k ey (supplied) to l oosen the clutch knob screw about 2 turns

anticlockwise.

2. T urn the clut ch knob either 4 clicks clockwise t o tighten the clu tch, or 4 clicks

anticlockwise to lo osen the clutch.

3. Use the allen key to retighten the clutch kno b screw .

Page 48

38 S1 Wheel and Tiller Pilots Operating Guide

4. Check that the wheel still moves freely with the clutch off .

Note:

If the wheel d oes not move fr eely, reduce th e clutch t ension b y turn ing th e clutch

knob 2 clicks anticlockwise and check again

5. Check the drive’ s operation with the clu tch engaged.

This p rocedure is usually suffic ient to correct a slipping or dragging dr ive belt. In

some cases , however , you ma y need to repeat the steps to adju st the clutch

further.

Adjusting the clutch

Clutch knob

screw

Clutch knob

Loosen the screw

(2 turns)

1

To loosen

the clutch

(4 clicks)

To tighten

the clutch

(4 clicks)

2

Tighten the screw

(2 turns)

3

D5349-2

Replacing the belt

The drive belt is desi gned to be user serviceable. If there is insu fficient adjustment

to cure a slippin g clutch, or if the drive belt is da maged in any way (if it is broken,

frayed or stretched), you should replac e the drive belt. Y ou can obt ain a

replacement belt from any Raymarine dealer (part number A1808 3). Fitting

instruction s are su pplied with th e belt.

User serviceable parts

Y ou can obta in the following 400 0 mk2 wheel drive spare parts from yo ur

Raymarine dealer:

Page 49

Chapter 3: Fault Finding & Maintenance 39

Part de scription Part number

Fr ont cov er A18074

Clutch lever A18077

Clutch knob A18078

Pedest al brack et (torq ue restr aint) A18080

Drive belt A18083

Clutch kit (clutch eccentric and clutch roller) A18084

Single spok e clamp, screws and inserts A18089

EMC advi ce

• When powered up , all electrica l equipment prod uces electromagnetic field s.

These can cause adjacent pieces of electrical equipment to interact with one

another , with a consequent adverse effect on op eration.

• T o minimize th ese effects and enable you to get the best po ssible perfor

mance from you r Raymarine equipmen t, guidelines are given in the installa

tion instruct ions, to enable you to ensure min imum interaction between

different items of equipm ent, i.e. ensure optimum Electr omagnetic Compa ti

bility (EMC).

• Always rep ort any EMCrelated prob lems to your nearest Raymar ine dealer .