MK II Wheel

Drive

Installation Guide

Document number: 87063-1

Date: December 2005

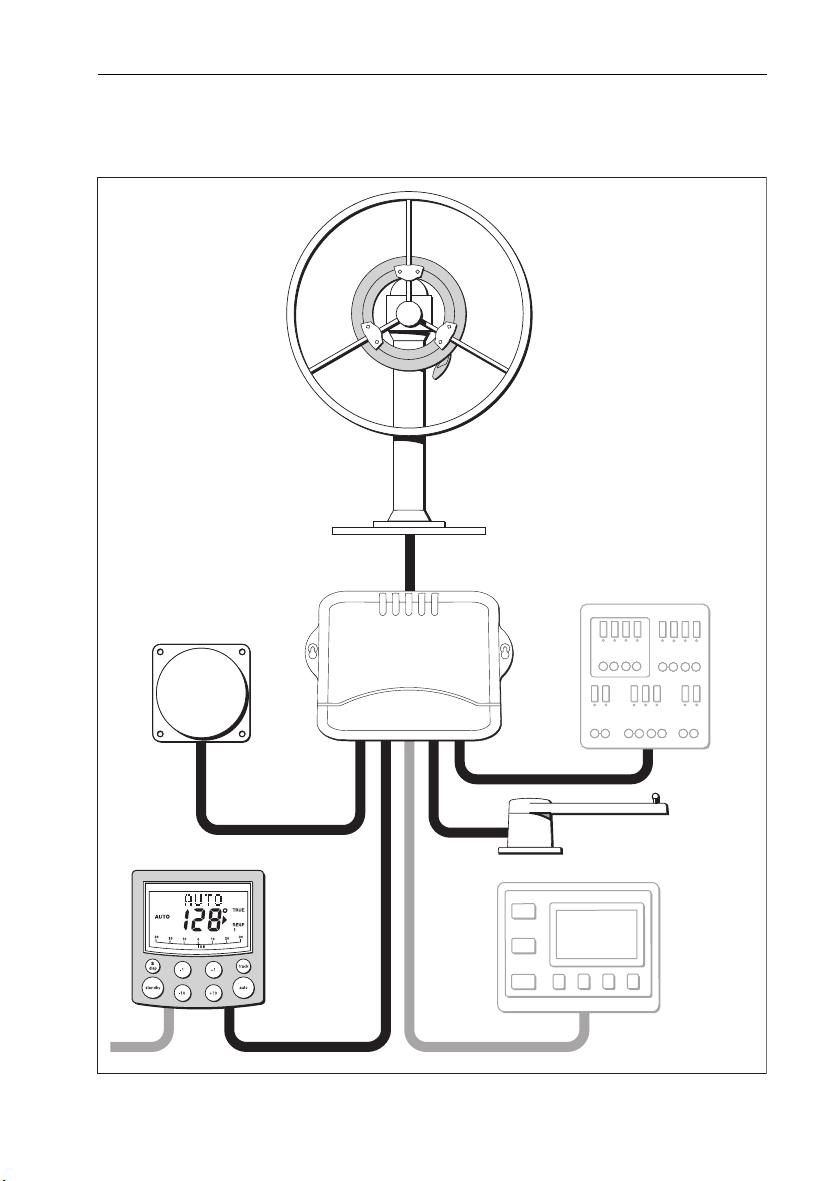

MK II Wheel Drive 3

System layout

Wheel drive

Fluxgate compass

Control unit

Course computer

Boat's electrical

distribution panel

Rudder position sensor

NMEA

instrument

or navigator

D8908-1

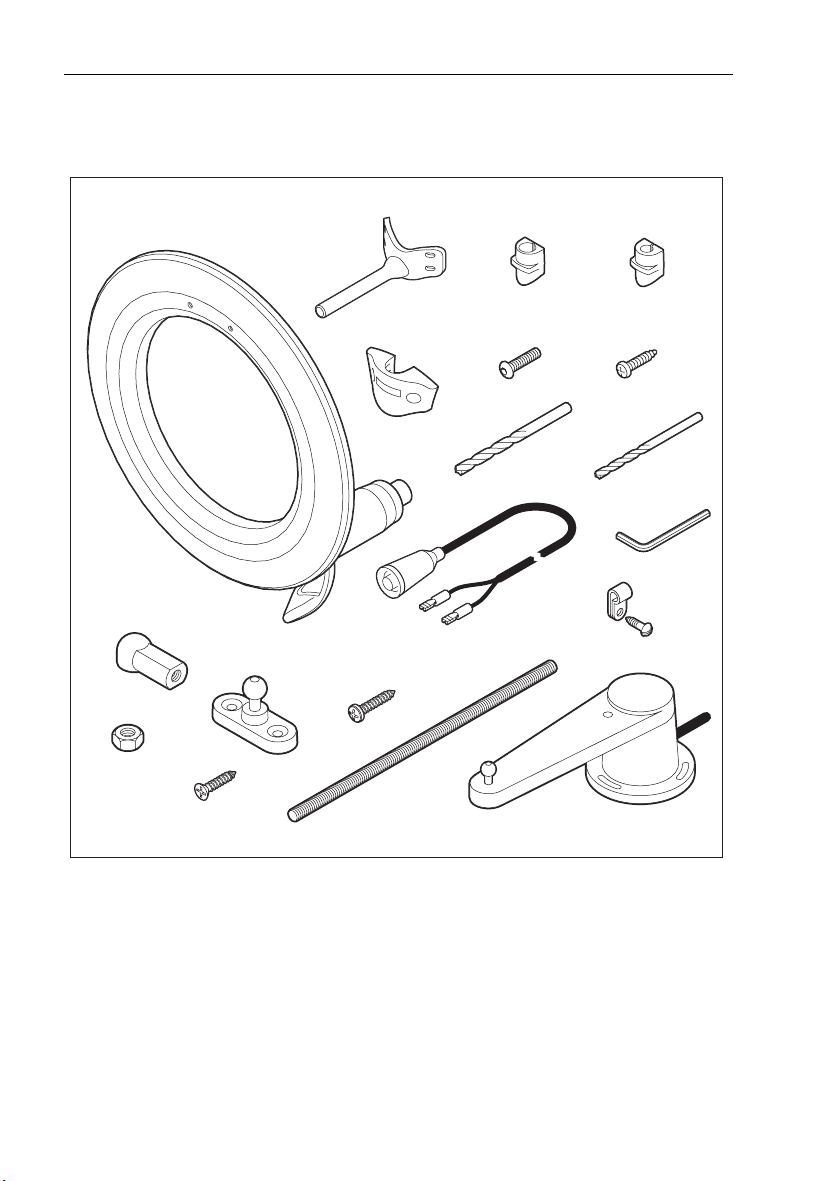

4 MK II Wheel Drive

Parts supplied

Wheel drive parts

Wheel drive

Ball joint (x2)

Nut (x2)

Tiller pin

Pedestal bracket

Spoke clamp (x3)

No 8 x ¾ inch

Pan head screw (x3)

16 mm spoke

clamp insert (x3)

Clamp screw,

M5 x 16 mm (x6)

6 mm

drill bit

Stud

Power cable

4.5 m (15 ft)

12 mm spoke

clamp insert (x3)

Bracket screw,

No 10 x 3/4 in (x4)

4 mm

drill bit

3 mm

allen key

Cable clip

and screw,

No 6 x 1/2 in

Rudder position sensor

No 8 x ¾ inch

Countersunk head screw (x2)

Optional: Bulkhead/box pedestal fitting kit E15017 (if required)

D8885-1

MK II Wheel Drive 5

Tools required

1. Tape measure (metric/imperial)

2. Pliers and cross-head/pozi-drive screwdriver

3. Hammer and center punch

4. Pencil, masking tape

5. Spanner (Wrench) for the wheel nut

6. Washing-up liquid (to lubricate the spokes)

7. Hacksaw to cut the pedestal bracket

8. Power/battery Drill

9. 4 mm + 6 mm drill bits (supplied)

10. 3 mm allen key (Hex key, supplied)

6 MK II Wheel Drive

Wheel drive

The Raymarine wheel drive will fit 3, 4, 5, 6, 7 or 8 spoke wheels. It is designed to operate with

steering systems with between 1 to 3.5 turns lock to lock.

Clamp screw,

M5 x 16 mm (x6)

Wheel drive

front cover

Pre-drilled spoke

clamp holes (x2)

Bracket screw,

No 10 x 3/4 inch (x4)

Pedestal

bracket

Bracket pin

Cable plug

Cable socket

Motor tube

Spoke clamp (x3) Clamp insert (x3)

Wheel drive – main parts

Installation stages

Installing the wheel drive involves four steps:

1. Drilling the spoke clamp holes in the front cover.

2. Securing the wheel drive to the wheel.

3. Attaching the pedestal bracket.

4. Connecting the drive to the course computer.

Clutch lever

D8886-1

MK II Wheel Drive 7

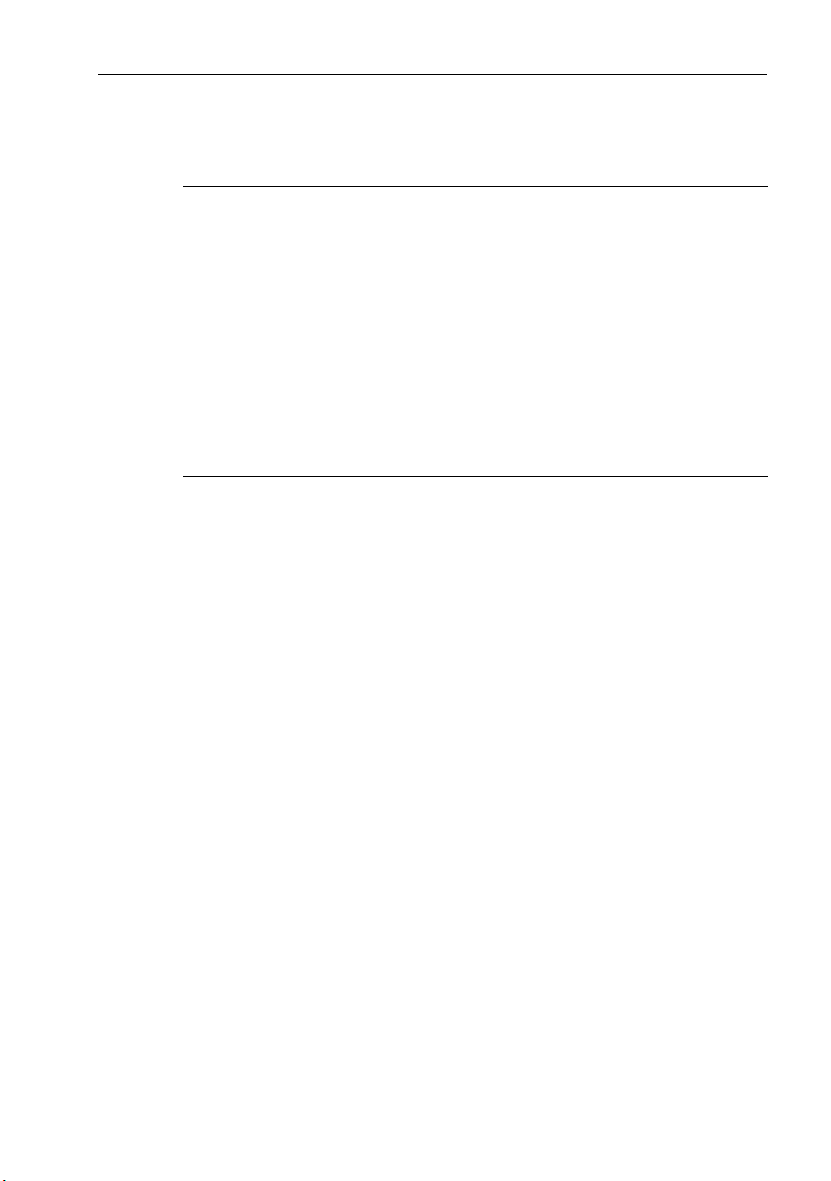

Drilling the spoke clamp holes

1. Remove the wheel drive front cover:

• the front cover is held onto the wheel drive by three ‘push-fit’ posts which sit in three

sockets on the drive ring

• to remove the cover, hold the motor in one hand and use your other hand to pull the

cover up and away from the drive unit (as shown below)

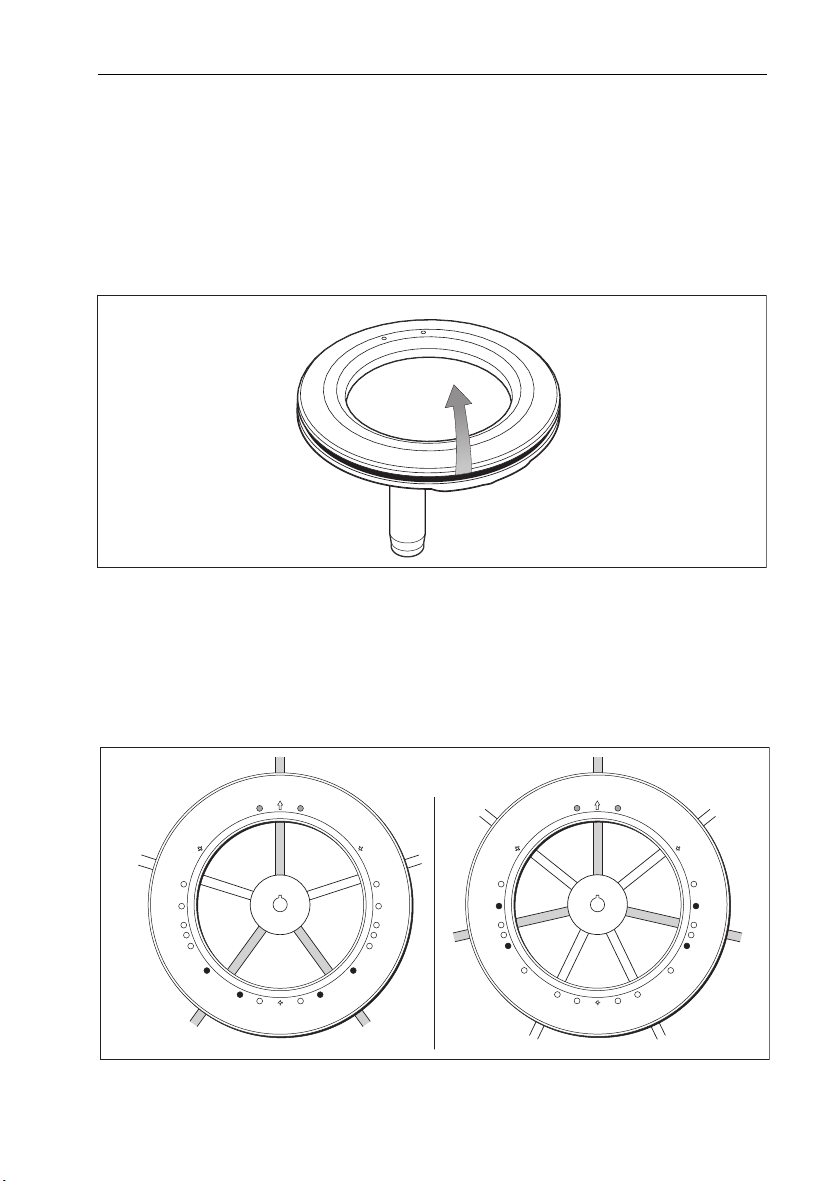

2. Identify the appropriate spoke clamp holes for your wheel. With the arrow at the top, refer

to the following diagrams:

• the holes are numbered inside the cover (e.g. if you have a 5 spoke wheel, you need to

drill the 4 locations marked with ‘5’)

• mark the appropriate spoke clamp holes and check them by holding the cover against

your wheel

5 spokes 7 spokes

Top 2 spoke clamp holes

are pre-drilled

D8888-1

D8889-1

8 MK II Wheel Drive

3 or 6 spokes 4 or 8 spokes

Note:

The wheel drive is designed to work with 3 spoke clamps on 4 or 8 spoke wheels. For cosmetic

Top 2 spoke clamp holes

are pre-drilled

reasons, however, you may want to fit an extra spoke clamp to the fourth spoke. Raymarine dealers can

supply an extra spoke clamp (part number A18089).

3. Drill the appropriate spoke clamp holes using the larger of the supplied drill bits (6.0 mm

1

or

/4in):

• drill from the inside, placing a piece of scrap wood under the cover to produce a clean

exit hole

• you will need to drill 4 new holes so the cover has 6 holes in total (2 for each spoke

clamp)

Note:

The spoke clamps will cover these exit holes, so they will not be visible when the wheel drive is

installed.

D8892-1

Piece of scrap wood

D8894-1

MK II Wheel Drive 9

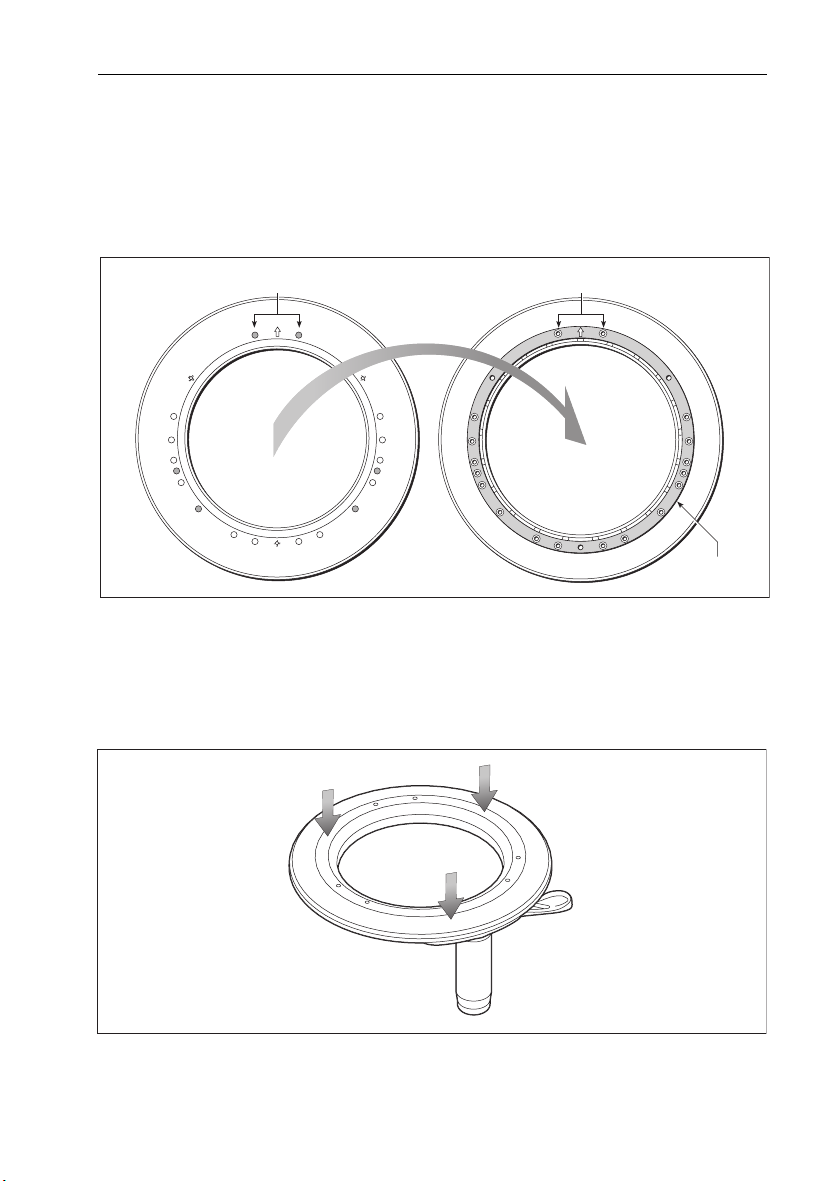

4. Align the cover with the wheel drive:

• the two pre-drilled holes (marked with an arrow) must line up with their matching pair

of threaded inserts on the drive ring (also marked with an arrow)

• make sure that the other spoke clamp holes align with their threaded inserts

Note:

The cover will only fit back onto the wheel drive when you have aligned the two parts correctly.

Pre-drilled holes

(marked with arrow)

Pair of threaded inserts

(marked with arrow)

Front cover Drive unit

5. Fit the cover back onto the wheel drive:

• press the cover in the three places shown on the diagram below to push each of the

posts back into its locating socket

Note:

This step is easier with the clutch engaged.

TOP

Drive ring

D8896-1

D8897-1

Loading...

Loading...