Page 1

Distributed by

Any reference to Raytheon or

RTN in this manual should be

interpreted as Raymarine.

The names Raytheon and RTN

are owned by the

Raytheon Company.

Page 2

Installation and Operating Handbook

Autohelm”

ANNOGUE

Page 3

.;-:

AUTOHELM

5000

The Autohelm 5000 is a modern high

performance autopilot specifically developed

for sailing and motor vessels of up to 40’(13m)

LOA.

It is exceptionally easy to operate and its

advanced micro-electronic control circuit gives

outstanding steering performance.

The Autohelm 5000 is distinguished by its

automatic course locking capability which

permits change-over from manual to automatic

steering by a single push-button control. From

then on the original heading is rigidly

maintained by the automatic trim system which

continuously monitors trim changes and offsets

the mean wheel position to compensate. In

addition, the rate of

in proportion to the rate at which the vessel

moves off course, giving the

smooth steering capability of an experienced

helmsman.

wheel

rotation is regulated

Autohelm

5000 the

The basic system comprises a Drive Unit

and Control Unit inter-connected by a

pluggable multi-core cable. A complete range

of optional remote control accessories are

available which are also pluggable to the

Control Unit. After fitting the system it is only

necessary to make a single adjustment to the

Control Unit

response range to the character of a particular

vessel.

The Autohelm 5000 is exceptionally easy to

install and prepare for sea trials. Sound

installation however is vital if the system’s high

standard of performance and reliability is to be

achieved. The installation notes should be

followed carefully and in cases where special

advice may be needed you are encouraged to

contact our Technical Sales Department where

expert assistance is always available.

in‘,order

to match the system’s

Page 4

I .O

SYSTEM DESCRIPTION

The Autohelm 5000 is a modular system

that can be built up from a minimum number of

standardised units to match the individual

requirements of a wide range of sailing and

power vessels. The rudder drive system may be

chosen from a range of rotary, linear and

hydraulic drive units to best suit the vessel’s

particular steering system.

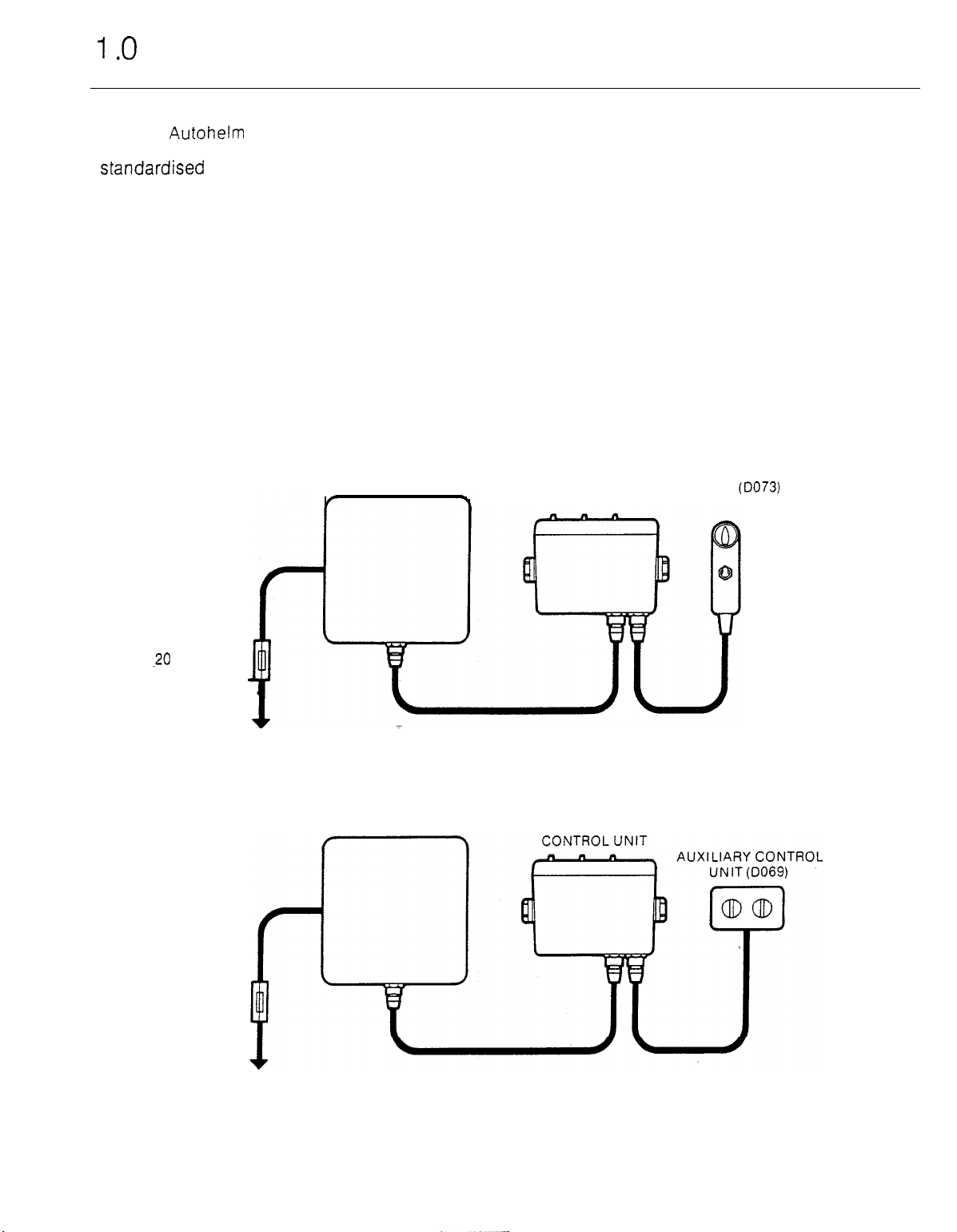

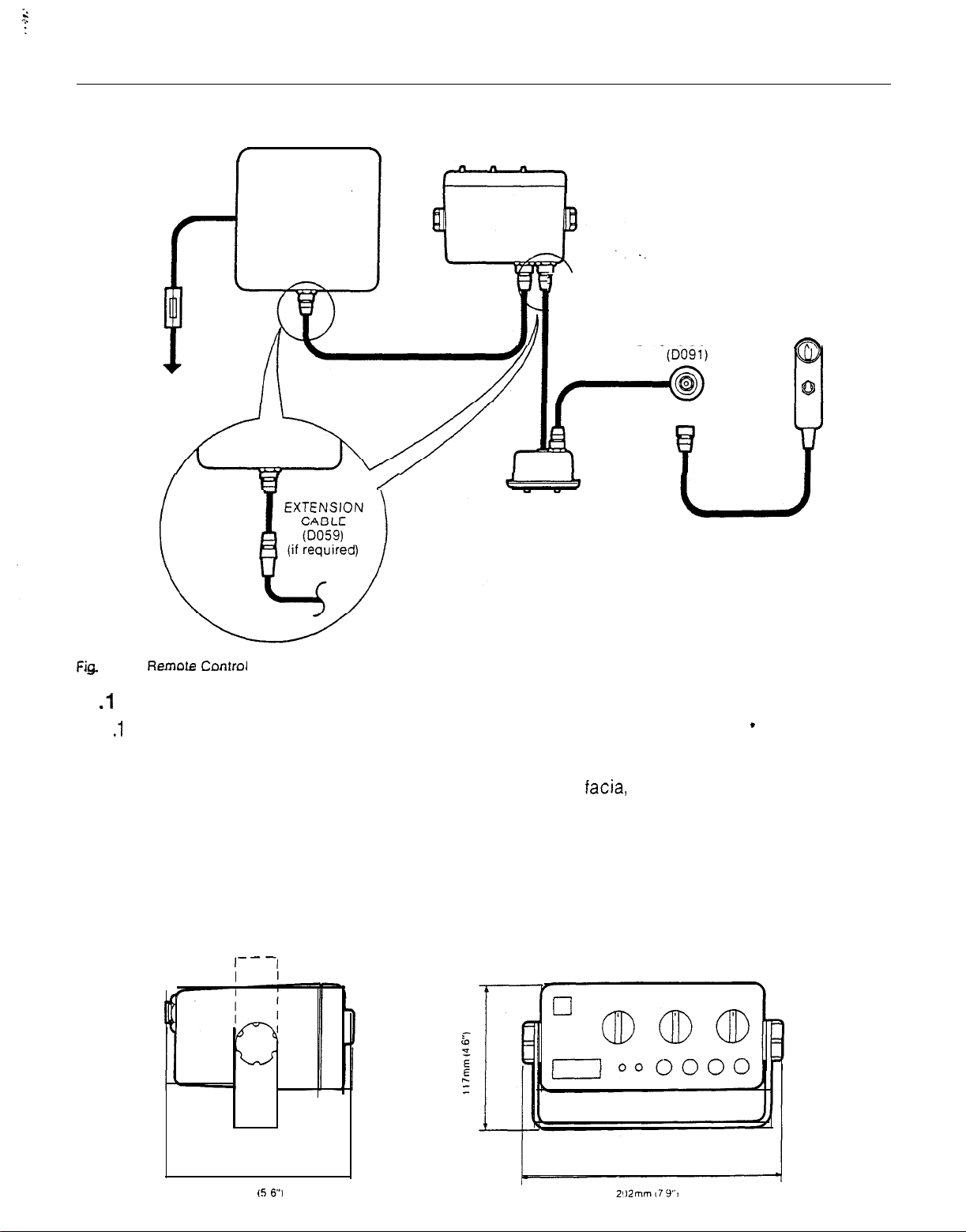

The most basic installation (Fig. 1) consists

of a control unit inter-connected by a pluggable

cable system to a drive unit. This installation

would be suitable for a motor vessel with a

single enclosed steering position, and where no

requirement exists for remote control facilities.

Hand-held remote control unit type DO73 may

be plugged directly into the Control Unit

auxiliary socket.

DRIVE UNIT

A simple remote control installation is

illustrated in Fig. 2. The auxiliary control unit

repeats the basic working controls of the main

control unit and is suitable for extending

autopilot control to a secondary steering

position. Alternatively, in the case of a sailing

yacht for example, the auxiliary control unit

provides a watertight cockpit control enabling

the control unit to be mounted in a protected

position below deck.

The full remote control system (Fig. 3)

provides the addition of a hand-held remote

control unit.

DIRECT REMOTE

CONTROL (D073)

CONTROL UNIT

(OPTION)

.20

AMP FUSE

DC SUPPLY

Fig. 1 Basic System

20 AMP FUSE

DC SUPPLY

DRIVE UNIT

Fig. 2 Basic Remote Control System

Page 5

f

DRIVE UNIT

\

CONTROL UNIT

20 AMP

FUSE

DC

SUPPLY

Fig

3 Full Remote

/

Contrd

Ef

System

/

1 .l CONTROL SYSTEM

1.1 .l CONTROL UNIT

The control unit is common to all installations

and is provided with six metres of multi-core

cable with pre-connected plugs and sockets to

connect to the drive unit. It houses the main

control circuit PCB together with the automatic

course following compass system. The control

unit case is splash proof, but not watertight, and

is, therefore, intended for mounting in a dry and

protected position. Two sockets are provided

on the rear case for connecting the drive unit

and remote control system.

1

J

REMOTE SOCKET

AUXILIARY

CONTROL UNIT

HAND HELD

REMOTE CONTROL

(0093)

m

.

Rotary controls for course alteration, rudder

response and sea state are grouped on the

control unit

facia,

together with the push-button

primary working controls. A secondary gain

control is inset into the rear case to allow

adjustment of the system’s rudder response

range to match the widely differing steering

characteristics of both planing and

displacement vessels. The control unit is

suitable for use on 12 volt systems.

r-

I-- -1

142mm (5

VI

-i

Page 6

1

.1.2

REMOTE CONTROL

ACCESSORIES

1 .I .3

AUXILIARY CONTROL UN IT

Autopilot control may be transferred to the

auxiliary control unit by depressing the Remote

push-button on the main control unit

auxiliary control unit is watertight and designed

for flush mounting in severely exposed

positions.

It is provided with six metres of cable

terminated in a waterproof plug for direct

connection to the control unit. A connector is

situated on the rear case for connecting handheld remote control deck socket.

1

.1.4

REMOTE CONTROL UNITS

The remote control is a hand-held unit that

enables the autopilot to be overriden and the

vessel to be power steered from anywhere on

board. The unit is fitted with a six-metre flying

lead, Type DO73 is suitable for direct

connection to the Control Unit auxiliary socket.

Type DO93 is fitted with a waterproof plug for

connection to a waterproof deck socket.

facia.

The

Auxiliary control Unit DO69

35mm

I1

38”)

56mm (2.2”)

(3.2”) 81 mm

1 OOmm

r

86mm (3 38”)

(3

9U

i

1.15

REMOTE SOCKET

The remote socket provides a watertight

socket for the hand-held remote control. The

socket is supplied with 6 metres of 3 core cable

terminating in a

the Auxiliary Control Unit.

1

.1.6

CABLE EXTENSION

The cable extension facilitates the lengthening

of all multi-core cables in six-metre increments.

The extension cable is terminated with

compatible waterproof connectors for insertion

into the cable harness in the positions shown in

Fig. 3.

plugfor

direct connection to

1 .I .7 CATALOGUE NUMBERS

CONTROL SYSTEMS

Control Unit

Auxiliary Control Unit

Remote Control

Direct Remote Control

Remote Socket

Cable Extension

DRIVE SYSTEMS

Rotary

Linear

Hydraulic

2068

DO69

DO93

DO73

DO91

DO59

12v

only

Z069

2070

2071

Hand Held Remote Control Unit

Direct Remote Control

Remote Socket DO91

I

(D093t

(0073)

0

Page 7

1.2 DRIVE SYSTEMS

Mechanical steering systems may be driven by

either a rotary or linear drive unit. Some steering

systems are fitted with an autopilot drive shaft,

and in such cases the choice of a rotary drive

system is straightforward. In general, if a drive

shaft exists and lost motion does not exceed

2% of total rudder movement, the rotary drive

unit becomes the most economic choice. In all

other cases the linear drive unit will provide the

simplest installation since it may be connected

directly to a tiller link on the rudder stock. Total

independence of the mechanical steering

linkage also allows the linear drive unit to be

used to power steer the vessel in the event of

steering linkage failure, and this is an important

safety feature. In addition, minimisation of

working parts improves the overall efficiency of

the rudder drive system and reduces lost

motion to an absolute minimum.

All vessels with hydraulic steering systems

will require a hydraulic drive unit.

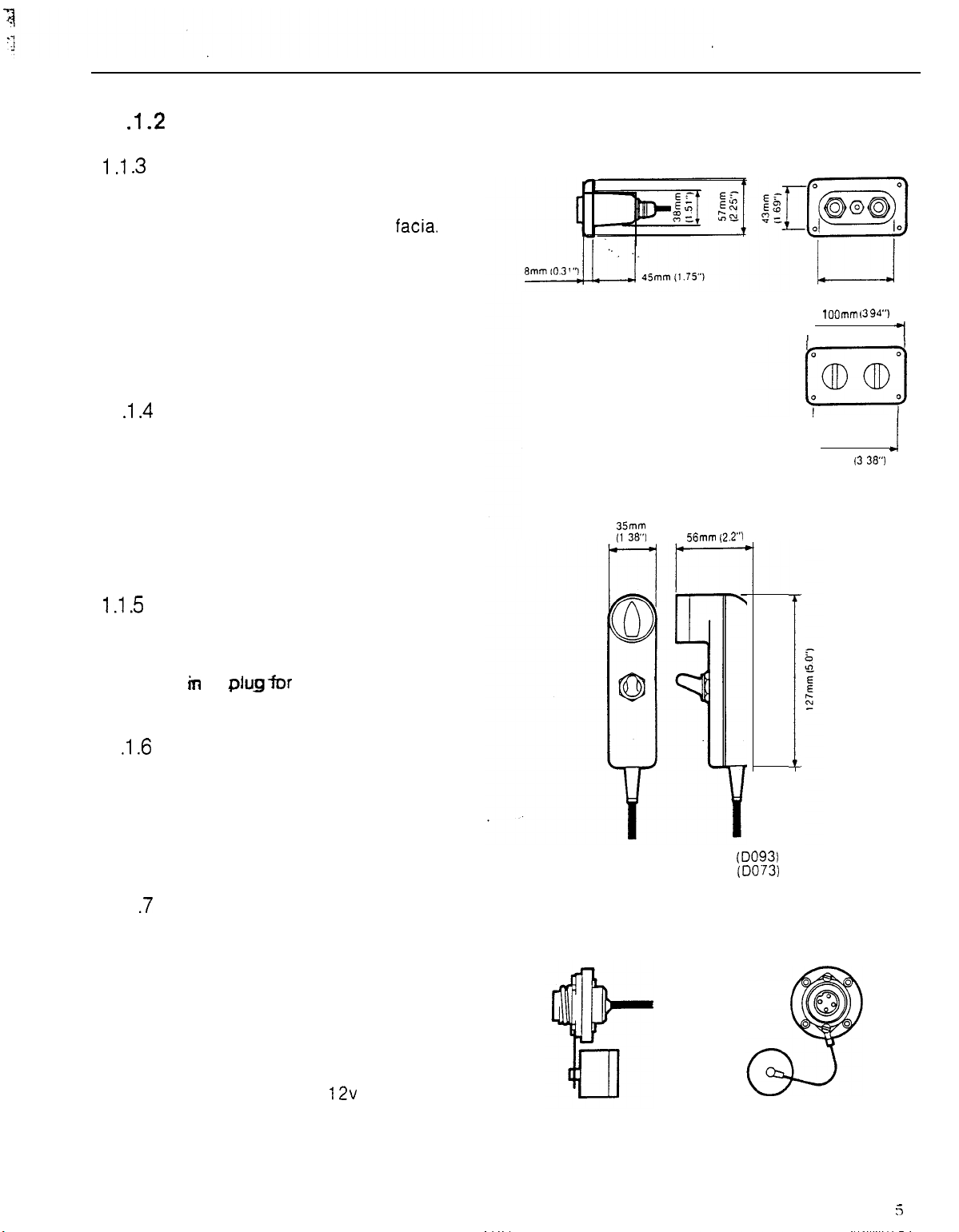

1.2.1 ROTARY DRIVE UNIT

The output shaft is driven by a continuously

rated servo motor via an efficient reduction

gearbox. The gearbox is dry lubricated to permit

operation in any attitude. A fail safe friction

clutch within the gear train engages

automatically when the autopilot is switched to

Duty and will disengage instantly even under

extreme load when the autopilot is switched

to Set.

Supply voltage

Peak output torque

Maximum shaft speed

Power consumption (typical

average)

Suitable for vessels up to

175mm

(6.88”)

12 volts

240lb.in. (27Nm)

18

rpm

1 S-3 amps

40ft.

LOA (12m)

2 Holes: 12Smm (0.5”) diameter

r----i

Page 8

1.2.2 LINEAR DRIVE UNIT

The output ram of the linear drive unit is driven

by a declutchable re-circulating ball leadscrew

which enables the drive unit to .be permanently

coupled to the rudder stock via a simple crank

or tiller arm. The drive is automatically engaged

by means of an internal friction clutch when the

autopilot is switched to Duty and will

disengage instaltly even under heavy load

when the autopilot is switched to Set or Off.

25mm

(1

.o”) 207mm (6.15”)

Supply voltage

Peak thrust

Maximum stroke speed

Maximum stroke

Overall length at mid stroke

Tiller arm length

(+35” rudder)

Maximum rudder torque

Power consumption (typical

average)

Suitable for vessels up to

51 mm (2.0”)

12 volts

550lbs (225Kg)

1.2in./sec.

(30mm/sec.)

12in.

(300mm)

27.5in.

(700mm)

1

Oin. (260mm)

500lb.in.

(570Nm)

1

Z-3

amps

40ft.

LOA (12m)

JJ

! 1

I

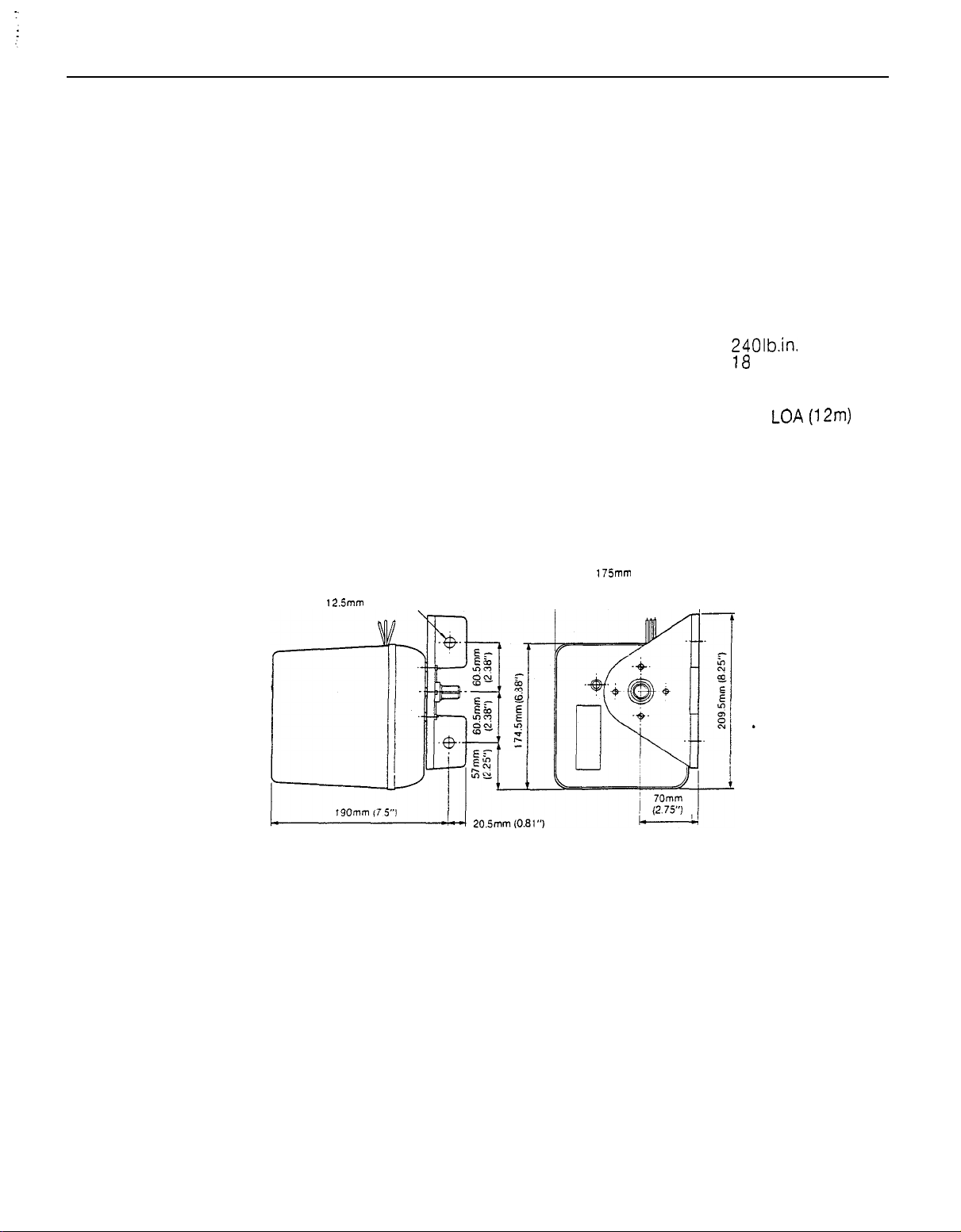

1.2.3 HYDRAULIC DRIVE UNIT

The hydraulic drive unit consists of a precision

gear pump with integral valve block driven by a

continuously rated servo motor. A special

pressure balance valve corrects the effects of

hydraulic slip and isolates the pump from the

steering circuit when the autopilot is not

energised.

,

700mm lZ7.5”)

Supply voltage

Regulated peak pressure

Flow control

Peak flow rate (unloaded)

Maximum ram capacity

Power consumption (typical

average)

Overall length

1

_ ,- _

,

--+j$--

/

I

mm (0.7”) RADIUS

r

260mm

(10.0”)

12 volts

4501b.in2

(30 bar)

integral pilot

check and

pressure

balance valve

sys tern

40in3/mm

(650cc/min)

1 5in3 (25Occ)

2-3.5 amps

9.5in.

(240mm)

/L/

240mm (9.5”) 117mm (4.6”)

Page 9

2.0 INSTALLATION

The Atitohalm 5CCC is

install and prepare for sea trials. Sound

installation however is vital if the system’s high

standard of performance and reliability is to be

achieved. The installation notes should be

followed carefully and in cases where special

advice may be needed you are encouraged to

contact our Technical Sales Department where

expert assistance is always available.

excepticnally

easy

tc

2.1 CONTROL SYSTEM

2.1.1

CONTROL UNIT

The control unit is the most sensitive part of the

system and care should be taken to select a

mounting position that is reasonably free from

vibration and protected from external weather

conditions. The control unit is mounted in an

aluminium frame which can be pivoted to

permit fixing to either horizontal or vertical

surfaces. The frame is finally fixed into position

by two No. 8 (4mm) diameter countersunk head

stainless steel or brass screws.

In the case of a vessel with an enclosed

wheelhouse, it would normally be desirable to

mount the control unit sufficiently near to the

wheel so that the controls are easily accessible

to the helmsman. However, since the control

unit incorporates a magnetic compass it is

necessary to position it at least 2ft 6in (80cm)

away from the nearest steering compass in

.order to avoid

Deviation of the control unit compass is much

less critical because of its auto-following

capability. Nevertheless excessive deviation

should be avoided as far as possible in order to

maintain uniform sensitivity on all headings. The

control unit should thus be mounted as far

away as possible from iron or other magnetic

devices. If any doubt exists, the chosen site

should be checked by means of a handbearing

compass. The handbearing compass should be

fixed into the chosen position and the vessel

swung through 360 degrees. Relative

differences in reading between the

handbearing compass and the main steering

compass should not vary by more than 20

degrees.

In rare cases even the above extreme

deviation tolerance may not be achievable, in

which case an alternative site remote from the

steering position must be selected. In such a

case it will be necessary to operate the

autopilot through an auxiliary control unit

situated near the steering position. Installation

in steel hulled vessels invariably presents

difficulties and the advice of a compass

adjuster should always be sought.

Sarling

steering position are a special case where it is

devi&on

yachts with a single external

Df both compasses.

essential to operate the autopilot via a

proof auxiliary control unit. The auxiliary control

unit would normally be mounted in the cockpit

adjacent to the steering position and the

control unit situated below in a suitably

protected position.

The compass within the control unit is

capable of satisfactory operation at roll and

pitch angles of up to

unit should, therefore, be positioned as near to

horizontal as possible to maximise gimbal

action in all directions. In the case of a sailing

yacht where sustained heel angles may on

occasions exceed the above limit, it will be

necessary to readjust the control unit to a near

horizontal position on each tack. To faciliate

this, the control unit’s suspension frame should

be mounted parallel to the direction of the heel

axis.

-r-30

degrees. The control

weathsr-

2.1.2 AUXILIARY CONTROL UNIT

The Auxiliary Control Unit is connected directly

to the auxiliary connector on the Control Unit.

The unit is waterproof and should be positioned

close to the steering wheel. It is designed for

discreet flush mounting and a pattern is

provided to assist panel cutting before fitting.

Matching black self-tapping screws are

provided to secure the auxiliary control unit

facia in position. A good quality silicone sealant

should be used to seal between the facia and

the mounting panel.

2.1.3

HAND-HELD REMOTE’CONTROL

SYSTEM

It is usually desirable to arrange for operation

of the hand-held control unit from anywhere on

deck. For this purpose up to two remote

sockets may be strategically positioned to

make this practical without the need for long

and potentially hazardous flying leads on the

hand-held unit. In the case of a sailing yacht for

example, one socket position in the foredeck

area and another in the cockpit usually makes

a perfect arrangement. The sockets are flush

mounted and a pattern is provided to simplify

panel cutting. Matching black self-tapping

screws are also supplied. A good quality

silicone sealant should be used to seal the joint

between the socket facia and the mounting

face. When more than one remote control

socket is required, the three core interconnecting cables may be paralled together

using a standard cable junction box before

connection to the Auxiliary Control Unit.

8

Page 10

2.2 DRIVE SYSTEM

The following notes describe the installation of

both the rotary and linear drive units.

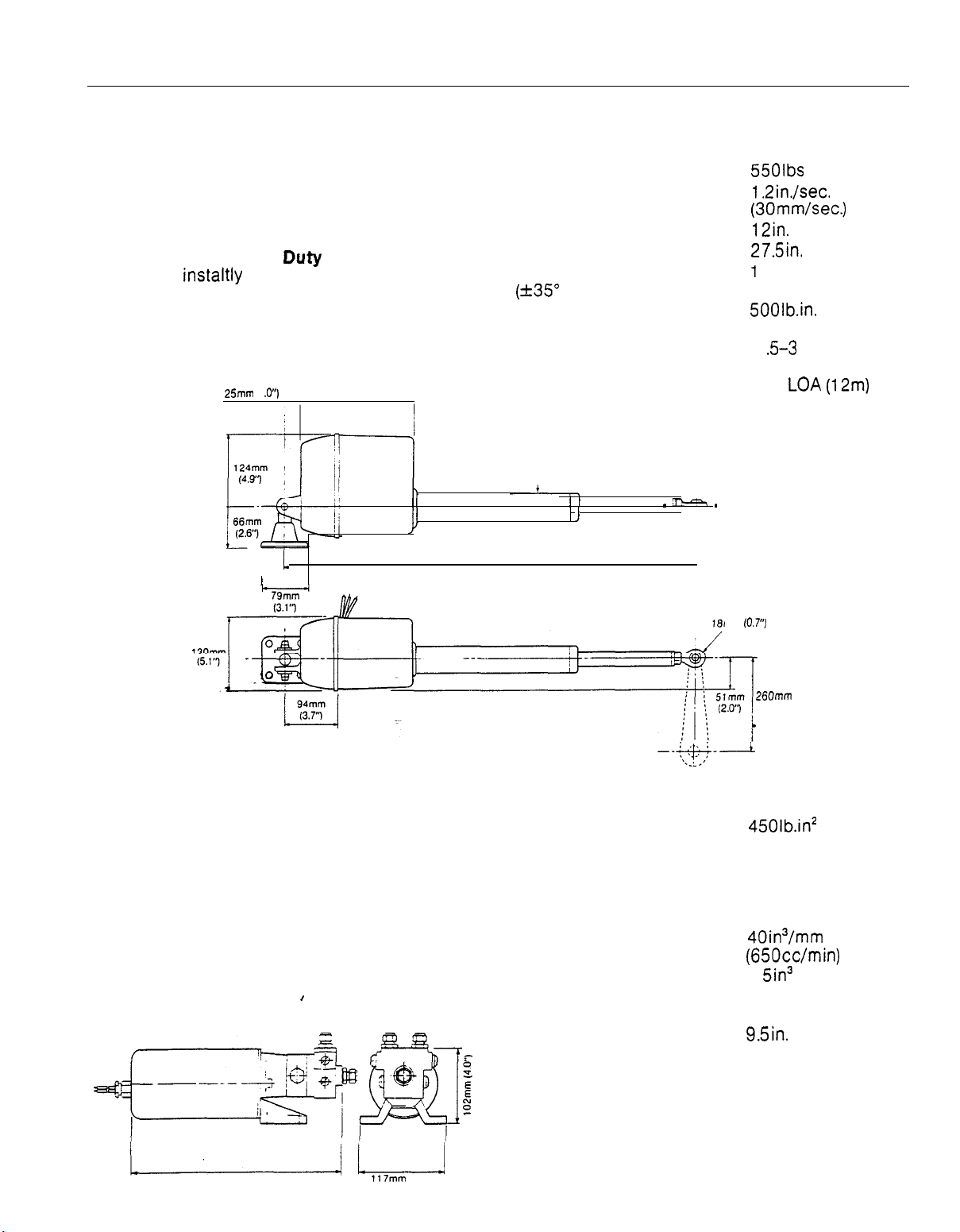

2.2.1 ROTARY DRIVE UNIT

The rotary drive unit is coupled to the vessel’s

steering mechanism by a simple chain drive.

Most steering gear manufacturers supply

special autopilot drive attachments and many

include this facility as standard.

Fig. 7 shows recommended rudder hardover

to hardover times for both planing and

displacement vessels up to 42 feet (13m)

The charts shown in Fig. 8 enables the chain

reduction ratio for optimum rate of rudder

application to be selected for both planing and

displacement vessels. To use the charts, it is

first necessary to determine the number of turns

of the driven sprocket when the rudder is driven

from hardover to hardover.

LOA.

equally spaced caphead screws, and may be

rotated through 90 degrees to provide a more

convenient mounting position if required (Fig. 6)

tn

some cases, it may be necessary to

fabricate a special frame to mount the drive

unit. It should be noted that chain tension can

exceed

3OOlb (.l.50kg),

and thus an extremely

rigid mounting structure is vital to maintain

good chain alignment. Installation failures

frequently occur in this area, and as a general

rule it is desirable to ‘over engineer’ the drive

unit mounting.

3.22-3.24mm

(0.127”-0

1275”)

1

Example:

A 40 foot

(12m) LOA

displacement vessel

requiring two turns of the driven sprocket to

drive the rudder from hardover to

hardover

will

require a chain reduction ratio of approximately

3:l (as indicated by the dotted line on the

chart). The table on the left hand side of the

chart gives suitable sprocket combinations. In

this example, the required reduction ratio of 3:l

would be best achieved by a 38 tooth sprocket

driven by a 13

Mti.mcket

on the drive unit.

It should be borne in mind that the

reduction ratios recommended are for the

‘average case’ and that vessels broadly

classified by length and hull type can vary

significantly in steering characteristics.

Selection of the correct chain reduction ratio is

not over critical however, and any slight

mismatch can usually be corrected later during

sea trials by an adjustment to the gain control

on the control unit.

Standard

for the chain drive. Sprockets of 13, 15, 17,

3W’

pitch chain is recommended

19

and 25 teeth are available as standard

accessories. Bore and

keyway

dimensions for

the drive unit sprocket are detailed in Fig. 4. If

sprockets other than those supplied by

Nautech are fitted, it is essential that bore and

keyway

dimensions specified in Fig. 4 are

strictly adhered to. The recommended driven

sprockets tabulated In Fig. 8 are common

standard sizes and should be obtainable from

local suppliers of chain drive equipment. All

sprockets must be “keyed” and grub screwed

to their shafts, and finally secured with ‘Loctite’.

The drive unit is mounted by bolting to a

substantial frame member (Fig. 5). The

‘1

shaped mounting foot is secured by four

19mm

(0.75”)

9 46-9 61 mm

(0.3725”-0.3765”l

Fig. 4

LJ

/

GRUB SCREW

/

127mm

(0.5”)

Page 11

Rrovision

must also be

r;;ade

for chain

adjustment, which is most easily achieved by

removable shims placed under the mounting

foot, or by elongated clearance holes in the

mounting frame as illustrated in Fig. 6. Both

sprockets must be accurately aligned to run in

the same plane, and this must be carefully

checked by means of a straight-edge.

The grease lubricated gearbox permits

mounting of the drive unit in any convenient

attitude without risk of oil leakage. The drive

unit’s sprocket may also face any direction,

since steering sense can be corrected by

means of a phase switch located in the control

unit.

Finally, the chain should be tensioned until

it is ‘just’ tight and contributes negligible lost

motion to the drive system. Total lost motion

between the driven sprocket attached to the

steering system and the rudder stock should

not exceed 2% of total movement. If lost motion

exceeds this level, it should be corrected,

otherwise steering performance will be

impaired.

HARDOVER-HARDOVER

TIME RECOMMENDATIONS

40

1

.-

.,

FFFT

Fig. 8

Fig. 7

Page 12

-.

2.2.2 LINEAR DRIVE UNIT

The linear drive unit couples directly to the

rudder stock at the tiller arm length

recommended in Fig. 9. It is usually

preferable to couple the linear drive unit to the

rudder stock via an independent tiller arm

(Edson

offer a standard fitting). In certain cases,

however, it may be possible to couple the

pushrod to the same tiller arm or rudder

quadrant employed by the main steering

linkage. It is important to note that the linear

drive system can exert a thrust of 550lbs. If any

doubt exists about the strength of the existing

tiller arm or rudder quadrant the steering gear

manufacturer must be consulted.

The method of bolting the pushrod ball end

to the tiller arm or rudder quadrant is illustrated

in Fig. 11. It is vitally important that the

coupling bolt is fully tightened and the nut

locked by means of the locking tab provided.

The standard ball end fitting will allow for a

maximum angular misalignment between the

pushrod and the tiller crank plane of rotation of

up to 5”. Accurate angular alignment is

extremely important and under no

circumstances should the above extreme limits

be exceeded. The body of the drive unit is

mounted by bolting to a substantial frame

member (Fig. 10). As a general rule it is

desirable to ‘over engineer’ the linear drive

unit’s mounting structure to ensure reliability

and maintenance of correct alignment. An

excessively

fletibk

mount can also severely

impair the steering performance of the

autopilot.

It is important to ensure that the total rudder

movement is limited by the rudder stops built

into the vessel rather than the end stops of the

linear drive output.

INS CM

‘*1’- ‘._ .,

lI: *;L.-.yy

5-

Fig. 9

LINEAR DRIVE

TILLER ARM LENGTHS

30

I

I 1

8

9

10

25

I

30

I

35

LOA

1

11

I

METRES

I

12 13

I

40

I

FEET

1 1

Page 13

2.2.3 HYDRAULIC DRIVE UNIT

The hydraulic drive unitshould be mounted

clear of spraj/ and the possibility of immersion

in water. It should be located as near as

possible to the hydraulic steering cylinder. It is

important to bolt the hydraulic drive unit

securely to a substantial member to avoid any

possibility of vibration that could damage the

inter-connecting pipework.

The drive amplifier (Fig. 13) should be

mounted between the drive unit and the power

supply (batteries) in order to minimise the total

length of power cable. It should also be

mounted in a position clear of bilge water and

spray. The drive amplifier is mounted by first

removing the cover marked ‘Autohelm’ and

bolting or screwing to a suitable vertical

bulkhead through the four holes in the

(Fig. 14).

There are three basic types of hydraulic

steering system (Fig. 12). Typical connection

points for the drive unit are shown in each case.

In all cases it is strongly recommended that

the steering gear manufacturer be

consulted. The drive unit valve block is tapped

l/4” BSP

to accept suitable pipe fittings and

Dowty sealing washers are supplied (Fig. 15).

.base

222mm (8

Fig. 13 Drive Amplifier

CONTROL UNIT

COiVfylECTlON SOCKET

8

7”)

POWER SUPPLY CABLE

*

fve

I

-ve

Two Line System

Two Line

Pressurised System

-RESERVOIR LINE

PRESSURISED

I

EARTHING TERMINAL CONNECTION

Fig. 14 Drive Amplifier Wiring Diagram

DRIVE UNIT

.

Three Line System

RESERVOIR LINE

Fig.

12

w

Page 14

Minimisation of hydraulic fluid loss during

connection of the drive unit will help to reduce.

the time and effort required later to bleed the

system of trapped air. Absolute cleanliness is

essential since even the smallest particle of

foreign matter could interfere with the correct

function of precision check valves in the

steering system.

When the installation has been completed

the hydraulic pump may be operated by

switching the control unit to Duty and operating

the Steer control. Greater motor movements will

be obtained if the gain control on the course

computer is set to No. 10 and the rudder

control set to maximum.

The hydraulic steering system should be

bled according to the manufacturer’s

instructions. From time to time during the

bleeding process the drive unit should be run

in both directions to clear trapped air from the

pump and inter-connecting pipe work.

If air is left in the system the steering will

feel spongy particularly when the wheel is

rotated to the hardover position. Trapped air will

severely impair correct operation of the

autopilot and the steering system and must be

removed.

During the installation of the system it has

not been necessary to keep track of the

connection sense to the hydraulic steering

circuit since operating sense of the autopilot

can be corrected if necessary by reversing the

polarity of*

pump

drive motor connections

(see section 3.3.1).

To check correct phasing of

the_autopilot,

switch to Duty and rotate the Steer control

clockwise. If phasing is correct starboard

rudder movement will result. If opposite rudder

movement occurs, reverse the phase switch

direction to correct as described in Section 3.2.

The gain control located on the back of the

Control, Unit sets the rudder response of the

autopilot to match the particular installation.

The recommended gain control setting is given

in Fig. 16.

CONNECTION OF

HYDRAULIC LINES TO PUMP

DOWTY SEAL

’

BSP FITTING

Assembly for W’ BSP Line Fitting

Fig. 15

ii3

50b

#=%I

Assembly for

IN3

30-

DOWTY SEAL

-

I

‘h” NPT FllTlNG

l/d’

NPT Line Fitting

RECOMMENDED GAI

CONTROL SETTINGS

1

5-

O-

1

_#”

__.ii.

N

Fig. 16

15

/

I

I

I

1

2 3

GAIN CONTROL AVERAGE SE-tllNG

II

4 5

”

6 7

11

8 910

1

13

Page 15

2.3 CABLING AND POWER SUPPLIES

2.3.1 SIGNAL CABLING

Cable inter-connections between system subunits are shown schematically in Figs. 1, 2, and

3. The interconnecting multi-core cable

between the control unit and drive unit is 20

feet (6m) long, and is supplied with the control

unit. All other interconnecting cables are

supplied with their related sub-unit and are also

20feet (6m) in length. All 7 core cables are

supplied with pre-wired waterproof connectors

and are extendable in 20 feet (6m) increments

by the addition of standard cable extensions

(Cat. No. 059) as shown in Fig. 3.

Cable connector clamp nuts should be

securely tightened to ensure watertight joints.

All cables should be run at least 3ft (1 m) from

existing cables carrying radio frequency or

pulsed signals, and should be clamped at 1.5

foot (05m) intervals.

2.3.2 DC SUPPLY CABLE

As a general rule the DC supply cable to the

drive unit should be kept as short as possible,

and have a conductor area of 1 .O sq.mm per

metre run to minimise voltage drop.

Example:

Length of cable Conductor area Cable size

Up to

2.5m

Upti4m

The two supply cables must run directly from

the vessel’s battery or alternatively from the

main distribution panel, and a 20 amp fuse or

overload trip should be included in the circuit.

It is important not to tap into supplies to other

into supplies to other equipment to avoid the

possibility of mutual interference.

The drive unit is supplied with

power supply cable tails. These should be

connected to the main power supply cable via

a heavy-duty terminal block. The red cable tail

should be connected to the positive supply and

the black cable to the negative supply. If

polarity is accidentally reversed the equipment

will not operate, but no damage will result.

The drive unit case must be bonded to the

metal hull or engine frame and a heavy duty

conductor (2.5mm2) should be used for this

purpose.

2.5 sq.mm 50/0.25mm

4

scpnm

56/0.3mm

1.5ft (0.5m)

14

Page 16

3.0 OPERATION

3.1 BASIC PRINCIPLES

The following description of the Autohelm 5000

principle of operation will help in providing a

complete understanding of its controls. The

control unit houses an extremely sensitive

setting electronic compass. When the autopilot

is in operation, deviation from course is

continuously monitored by the compass and

corrective rudder is applied by the drive unit to

return the vessel to course. The amount of

applied rudder is proportional to the course

error at any time, and thus when the original

course is restored the rudder will be

neutralised. The amount of the rudder applied

for a given off-course error is adjustable to

match both the steering characteristics of the

vessel and speed through the water. A vessel

with a small rudder for example, will require

more corrective helm than a similar sized vessel

with a larger rudder. Similarly, a high speed

power boat will require considerably less

corrective helm at planing speeds than it will at

lower displacement speeds (Fig.1 8.)

The characteristic which distinguishes the

Autohelm 5000 is its ability to make automatic

correction for changes in trim or weather helm.

When changes in trim occur the set course can

only be maintained by the application of

permanent rudder offset to restore balance.

Many automatic pilots are incapable of this and

will allow the vessel to bear on to a new

heading to achieve a new state of balance.

Under these circumstances the Autoheim 5000

detects that the original course has not been

restored and will continue to apply additional

helm in the appropriate direction until the

vessel returns to the original heading. This

facility ensures that the originally set course is

held irrespective of changes in balance that

may occur during the course of a passage.

3.2 CONTROLS

3.2.1 CONTROL UNIT

Fig.1 .I shows the position of all controls. Each

control has the following functions:

OFF

Push to de-energise the autopilot. The electro-

magnetic clutch in the drive unit is disengaged

for manual steering.

auto-

DUTY

Push to fully energise the autopilot for

automatic steering duty.

REMOTE

Push to transfer basic automatic pilot control to

the auxiliary control unit.

SEA

Rotate to adjust compass sensitivity to suit sea

conditions. In position ‘0’ the compass is fully

sensitised for operation in calm sea conditions.

Clockwise rotation to position ‘7’ progressively

densensitises the compass for operation in

rough sea conditions. Adjustment of this

important control is fully discussed later.

RUDDER

Rotate to adjust rudder response. In position ‘0’

rudder movement is minimised. Clockwise

rotation to position ‘7’ progressively increases

the amount of applied rudder. Adjustment

technique is fully discussed later.

STEER

Rotate counter-clockwise or clockwise to alter

course to port or starboard respectively. Each

scale division represents 5 degrees of course

alteration. The steer control will rotate

automatically when the control unit is switched

to

Set.

The controls on the rear case are used to

adjust the auto-pilot’s response to suit the

particular installation and the vessel’s steering

characteristics.

Each control has the following functions:

GAIN

Presets the overall system gain to compensate

for variations in the mechanical reduction

between the drive unit and the rudder and the

vessel’s steering characteristics. For initial sea

trial purposes this control is set according to

the recommendations given in Fig.1 8.

PHASE SWITCH

The phase switch is located on the internal

PCB and is accessible by removal of a blank

rubber grommet from the rear case. The phase

switch reverses the direction of corrective

rudder action and its setting procedure is

described later.

SET

Push to energise the compass circuit and

initiate the automatic compass setting

sequence. The compass is finally set to the

manually steered heading when both the red

and green pilot lights are extinguished.

NB Recommended gain control settings for

hydraulic drive installations are given in

the hydraulic drive unit instructions.

Page 17

RECOMMENDED GAIN

CONTROL SETTINGS

GAIN

CONTROL

Fig. 17

DRIVE UNIT AUXILIARY

SOCKET

PHASE SWITCH

CONTROL SOCKET

3.2.2 AUXILIARY CONTROL UNIT

Autopilot control may be transferred to the

auxiliary control unit (Fig.1 9) by depressing the

Remote push-button on the main control unit

facia.

Two independent rotary switches are

provided on the auxiliary control unit. The first

permits Mange-over betweenSet and Duty

modes. The second control permits remote

alteration of heading. Switch movement to the

left or right initiates course alteration to port or

starboard respectively at approximately one

degree per second.

Fig. 18

l-l

7 8

”

/ I

I

25

I

‘,_

,,. _s.,

I

9 10

I

30

.

I I

11

I

35 40

LOA

I

12

I

METRES

1

13

I

FEET

3.2.3 REMOTE CONTROL UNIT

The hand-held remote control unit

enables the autopilot to be switched out and

the vessel to be power steered from anywhere

on board. Its flying lead may be plugged into

any one of the remotely positioned waterproof

sockets and should be switched to Auto for

normal automatic steering operation. The

autopilot may be overriden by switching to

Manual and the vessel then power steered by

means of the control wheel. The automatic trim

system continues to operate in the manual

steering mode and a straight course will be

steered when the ‘boat’ on the control wheel is

aligned with the remote control centre line. The

original course is remembered and will be

resumed immediately the change-over switch is

returned to Auto. If the vessel has been power

steered by the remote control for a long period

it is important to check that there is no chance

of collision when the original automatic

heading is acquired by switching back to Auto.

16

(Fig.20)

Fig.

Fig.

26

19

.CONTROL

WHEEL

Page 18

4.0 FUNCTIONAL TEST PROCEDURES

The following functional test procedure is

recommended before attempting sea trials.

4.1 MAIN CONTROL UNIT

0

Switch to Set and observe that the compass

automatically sets to the present heading.

The Steer control will rotate while the

compass is setting and slow down as the

null position is approached. When the

compass is finally set both pilot lights will be

extinguished.

0

Switch to Duty and check that the drive unit

clutch is engaged by attempting to rotate

the steering wheel.

0

Adjust the Sea and Rudder controls to ‘0’.

Then adjust the Steer control one or two

divisions clockwise and then counterclockwise. The steering wheel should rotate

in the same direction as the Steer control. If

opposite wheel rotation occurs, reverse the

phase switch. (A small screwdriver will be

required to operate the phase switch after

removal of the blank rubber grommet from

the rear case).

0

Increase Rudder control setting and note

that larger wheel movements result when the

Steer control is adjusted.

.*

Increase theSea control setting and note

that larger movements of the Steer control

are necessary in either direction

steering wheei movement commences.

b.efore

4.2 AUXILIARY CONTROL UNIT

0 Switch the auxiliary control unit to Set and

then depress Remote on the main control

unit. In this position the compass

automatically sets to the present heading.

0 Switch the auxiliary control unit to Duty and

check that.the drive unit clutch is engaged

by attempting to rotate the steering wheel.

4.3 MECHANICAL TEST

PROCEDURES

Before attempting sea trials it is important to

verify that the vital link between the Autohelm

5000 drive actuator and the vessel’s steering

system is free of obstruction and operating

correctly.

It is strongly advised that the following

simple checks are carried out.

Warning

When the steering system is being moved

manually or under drive from the actuator do

not touch any part of the system, sprockets,

chains or limit stops. The forces exerted are

considerable and could cause injury.

Rotary Drive Unit

Locate the actuator and with an assistant to

turn the main steering wheel switch on the pilot.

0 Press Set - turn the steering wheel from

hardover to hardover.

’

The automatic trimming capability of the 0 Ensure that the chain and sprockets driving

autopilot can be observed by the following test:

Switch to Set to realign the compass. Then

switch to Duty and offset the Steer control by

approximately two divisions i.e. approximately

10 degrees of heading change. This effectively

simulates a condition where the need for

standing helm has developed and the vessel is

not returning to course. You will notice that after

an initial fixed helm has been applied the drive

unit continues to apply further helm movements,

but at a much slower rate. If left in this condition

the wheel will eventually rotate hardover. If,

however, the vessel is moving through the water

the progressive application of additional helm

will eventually return the vessel to its original

course with the necessary standing helm

applied. This can be simulated by rotating the

steer control back to the original course

position. The progressive application of

standing helm will cease when the compass

senses that the original course has been

restored.

the actuator move freely and in alignment.

0 Ensure that chain tension is adjusted

correctly (see 2.2.1)

0 Select Duty and rotate the Rudder control

several turns to the right to drive the rudder

hardover.

0 When the actuator drives the rudder onto the

mechanical limit stops ensure that the

mounting of the drive actuator shows no

sign of movement.

0 Rotate the Rudder control in the opposite

direction to reverse the rudder drive to the

opposite end stop. Check for any movement.

Page 19

Linear Drive Unit

0 Proceed as for rotary drive unit.

Hydraulic System

0 Proceed as for the rotary drive unit.

0 Check that at no point during movement of

the steering quadrant and linear drive

actuator from hardover to hardover does the

actuator foul any part of the quadrant,

steering mechanism or yachts structure. Any

fouling under load could damage the drive

actuator.

0 Check that the Drive actuator operates

horizontally and that angular movement of

the ball end fitting is minimal

(So

maximum).

0 Select Duty and rotate the Rudder control

several times to drive the rudder hardover.

0

When the rudder is driven hardover check

that the mechanical limit stop on the

vessel’s steering system is reached before

the actuator reaches its mechanical limit.

0

When the rudder drives hard against the end

stop check there is no visible movement of

the actuator mounting pedestal or the

structure supporting it.

0 Rotate the Rudder control in the opposite

direction and repeat the checks with the

rudder driven hardover

inthe

opposite

direction.

l Check that all unions are tight and there is

no seepage of hydraulic fluid.

l Select Duty and rotate the Rudder control

several times to drive the rudder hardover.

l Rotate the Rudder control in the opposite

direction and drive the rudder hardover in

the opposite direction.

0 Check that the steering ram moves smoothly

and that there is no excessive play or

jerkiness in the movement.

The performance of the Autohelm 5000 will

only reach the designed levels if the installation

of the actuator and steering system is correctly

engineered and adjusted. It is strongly advised

that these be checked before sea trials.

Page 20

5.0 SEA TRIALS

Initial sea trials should be carried out in calm

conditions and with plenty of sea room. The

previously conducted functional test will have

verified that the autopilot is operating correctly

and that you are familiar with all of its controls.

Check that the gain control on the rear of

the control unit is adjusted to the setting

recommended for the particular vessel category

given in Fig. 3.1, Then set the Sea control to ‘0’

and the Rudder control to ‘4’.

Initial sea trials on fast planing vessels

should be conducted at no more than half

engine throttle under which conditions the

recommended mid-way setting of the rudder

control should give acceptable steering

performance. A mid-way setting of the rudder

control will also give acceptable steering

performance in sailing and displacement power

vessels under all conditions for initial trial

purposes. Fine setting of the Rudder control is

discussed later.

5.1 FIRST TRIALS

.The following initial trial procedure is

recommended:

0 Steer manually on to a fixed heading and

hold the course steady.

0

Switch the autopilot to Set and allow up to

1.5 seconds for the compass to adjust

automatically to the manually steered

:

heading.

0 Switch to Duty and the autopilot will

automatically take control. In calm

conditions an extremely constant heading

will be maintained.

0 Increase the setting of the Sea control until

a good heading is achieved with a minimum

number of wheel movements. Correct setting

of this control for varying sea conditions is

essential to avoid unnecessary wear and

tear on the autopilot and to minimise

electrical power consumption.

0 Alter course to port or starboard using the

Steer control on the main control unit, (or

the Left/Right control on the auxiliary

control unit with the main control unit

switched to Remote). Major course

alterations are best applied by switching to

Set and then manually steering the vessel

on to the new heading. When the new

course is acquired, hold for a few seconds

and then switch the autopilot back to Duty

to maintain the new heading.

0 If a hand-held remote control is fitted, switch

from Auto to Manual and then power steer

the vessel by the control wheel. Switch back

to Auto and the vessel will return promptly

to the original heading.

0 When the autopilot is set to Duty return to

manual steering may be instantly achieved

by switching to Set or Off on the main

control unit. It is very important to remember

that manual control can only be obtained on

the auxiliary control unit if the main control

unit is switched to Remote. The importance

of being able to regain manual control of

steering must-be stressed. The Off button is

coloured red for easy identification and

manual take-over procedures should be

practised at an early stage.

5.2 RUDDER CONTROL ADJUSTMENT

The gain control on the rear of the control unit

has been previously set according to the

recommendation given in Fig. 3.1. This control

sets the range of adjustment available on the

main panel Rudder control and in all but

extreme cases should not need further

adjustment.

In all cases, excessive rudder application

results in ‘oversteer’ which can be recognised

by the vessel swinging slowly from side to side

of the controlled heading. In addition, distinct

overshoot will be observed when the course is

changed. This extreme condition may be

corrected by reducing the Rudder control

setting.

Similarly, insufficient rudder application will

result in sluggish steering response which is

particularly apparent when changing course

using the Steer control. This condition is

corrected by increasing the Rudder control

setting.

Oversteering and understeering tendencies

are most easily recognised in calm sea

conditions where wave action does not mask

basic steering performance.

The operational adjustment technique for the

Rudder control varies significantly between

planing and displacement craft and is

described separately below.

5.2.1 PLANING

Planing craft operate over a very large speed

range. Rudder effectiveness increases very

significantly at higher hull speeds and it is thus

necessary to reduce the Rudder control setting

as speed increases to avoid oversteer. In

normal cases the rudder control setting would

be reduced almost to ‘0’ at maximum planing

speed and increased towards ‘7’ at minimum

displacement speeds. Oversteer can be

extremely violent at planing speeds and it is

thus essential to reduce the rudder setting

before opening the throttle.

CRAFT

,,

19

Page 21

5.2.2 DISPLACEMENT POWER

VESSELS

The Rudder control setting is much less critical

on this type of vessel and it is not normally

necessary to change the setting for different

engine speeds. As a general guide initial

testing should be carried out at setting ‘4’ and

reduced as much as possible ‘consistent with

good heading control to minimise wear and

tear on the steering ‘system.

5.2.3 SAILING CRAFT

Sailing craft average hull speeds do not vary

greatly and thus the Rudder control setting can

remain fixed most of the time. Initial testing

should be carried out at setting ‘4’. Sailing craft,

however, are particularly stable when sailing

close hauled and under these conditions it is

usually possible to reduce the Rudder control

setting to minimise rudder movement and

hence power consumption. Conversely, when

sailing down wind, directional stability is least,

and improved course holding will result from

increasing the rudder setting. The optimum

range of adjustment is easily found by

experiment.

._

. .

.

Page 22

6.0 OPERATING HINTS

Unlike sailing yachts, power vessels do not

generally suffer with violent changes in trim,

and thus, provided the operating instructions

are carefully followed, extremely good course

holding performance will result in all weather

conditions.

Sailing yachts are very different since in

gusting wind conditions violent changes in trim

often occur. When a yacht is sailing badly out

of balance, sudden gusts will generally cause it

to luff violently to windward. When hand

steering, the tendency is overcome by applying

sufficient weather helm to maintain the original

heading. The Autohelm 5000’s automatic

weather helm compensation circuit however, is

intended only to take account of the gradual

changes in standing helm that typically occur

when passage making due to changing wind

conditions.

When a sudden change in helm balance

occurs the automatic compensation circuit will

take approximately one minute to restore the

original heading. In gusty conditions the course

will tend to meander particularly if the sails are

badly balanced. Significant improvement to

course keeping can be obtained by ensuring

that sail balance is maintained.

Bear in mind the following important points.

It is also worth mentionina the more obvious

and that is that an autopilot cannot anticipate.

Sailing downwind in breaking seas needs

particular care.

One should avoid sailing under autopilot

when the

should be brought at least 30 degrees towards

the beam, and in breaking seas it is often better

to remove the mainsail altogether and to sail

under boomed out headsail alone.

Providing you ensure that your vessel is

properly canvassed for the prevailing

conditions, your Autohelm 5000 will be capable

to sailing you through gale force winds.

Moreover, it is at times like this that it will

endear itself most of all by leaving you fresh

and alert to sail in safety.

Passage making under automatic pilot is a

wonderful experience that can easily lead you

into the temptation of relaxing permanent

watch-keeping. This must be avoided however

clear the sea ahead may appear to be.

Remember, a large ship can cover two miles in

five minutes - just the time it takes to brew a

cup of coffee!

wi‘nd.is

dead astern. Ideally, the wind

: 0

00 notallow the yacht to heel

0 Ease the mainsheet traveller to leeward to

reduce heeling and weather helm.

0

If necessary reef the mainsail a little early.

excessive!y.

Page 23

7.0 ROUTINE MAINTENANCE

The autooilot is one of the most used and

hardest working items of equipment on board

and, therefore, must receive its fair share of

attention and routine maintenance. The working

parts of the drive unit and the control unit are

sealed and lubricated for life during manufacture

and do not need servicing

Regular inspection and routine maintenance

of the installation is recommended in the

following areas:

1 Check tension and alignment of the drive

chain and lubricate with a good quality

waterproof light grease.

2 Check for the development of excessive lost

motion (backlash) in the steering gear and

correct if necessary. Lost motion at the wheel

should not exceed 5% of the total wheel

movement from lock to lock.

3 Check that all inter-connecting cable sockets

are fully tightened and free from corrosion.

4 Check that external waterproof sockets are

capped when not in use and periodically

spray with

corrosion.

5 Check that the power supply cable

connections are tight and free from

corrosion.

The Autohelm 5000 has an advanced microelectronic circuit requiring special equipment

and knowledge to service. In the unlikely event

of failure occuring in any part of the system you

are advised to contact your nearest appointed

Service Agent who will provide you with

competent and efficient service.

WD40

(or similar) to protect from

..

Page 24

Nautech Limited, Anchorage Park, Portsmouth

Hampshire PO3

5TD,

England. Telephone

Fax (0705) 694642, Telex 86384 NAUTEC G

(0705)

693611

Loading...

Loading...