Page 1

Operating Instructions

SelfCookingCenter

®

whitefficiency

®

Page 2

Dear Customer,

Congratulations on your new SelfCookingCenter

®

whitefficiency

®

. Thanks to an easily

understandable visual control concept, you and your SelfCookingCenter

®

whitefficiency

®

will achieve excellent results in no time at all – with hardly any time or expense spent on

training.

In SelfCooking Control

®

mode you simply select the relevant food and the desired cooking

result at the push of a button – that’s it! There is no longer any need for conventional

inputs such as temperature, time and humidity or complicated programming and constant

monitoring.

Of course the SelfCookingCenter

®

whitefficiency

®

also provides the versatile facilities of

a perfect Combi-steamer. It takes no time at all to create your own cooking programs in

Programming Mode.

We give a 24 month warranty from the date of initial installation, providing the warranty

registration has been filled in and completed. The warranty excludes glass damage, light

bulbs and seals as well as damage caused by improper installation, use, maintenance,

repair or descaling. We hope that enjoy using your new SelfCookingCenter

®

whitefficiency

®

.

Your

RATIONAL AG

You can reach our technical Customer Support Service 7 days a week on +44 (0) 1582

480388

For any queries relating to us please ring the RATIONAL Chef✆Line: +44 (0) 7743 389863

We reserve the right to make technical changes in the interest of progress!

Dealer: Installer:

installed on:

Unit number:

Page 3

Contents

Explanation of the pictograms 5

Initial start-up 6

Safety Instructions 8

Liability 12

Care, inspection, maintenance and repair 13

Features 16

Notes on using your unit 17

Working with the core temperature probe 20

Working with the hand shower 22

General instructions for use 23

General notes 24

Help function 25

Explanation of pictograms 25

Overview of the cooking modes 26

Display after switch-on 26

3 different operating modes 27

SelfCookingControl ® mode 28

Explanation of pictograms 28

Information and requests during the cooking process 29

Options following the end of cooking 29

Information button 30

Combi-steamer mode 31

Explanation of pictograms 31

Programming mode 33

Explanation of pictograms 33

Image view 35

Cleaning request 36

Page 4

Contents

Starting cleaning 38

Cleaning stages 42

CleanJet ® +care failure 43

Maintenance 44

Air filter service 44

Replacing the door seal 45

Replacing the halogen lamp 45

Descaling the moisturing nozzle 46

Fault messages 48

Before you call Service: 53

Club RATIONAL 56

EU Declaration of Conformity for electrical appliances 57

EU Declaration of Conformity for gas appliances 58

Page 5

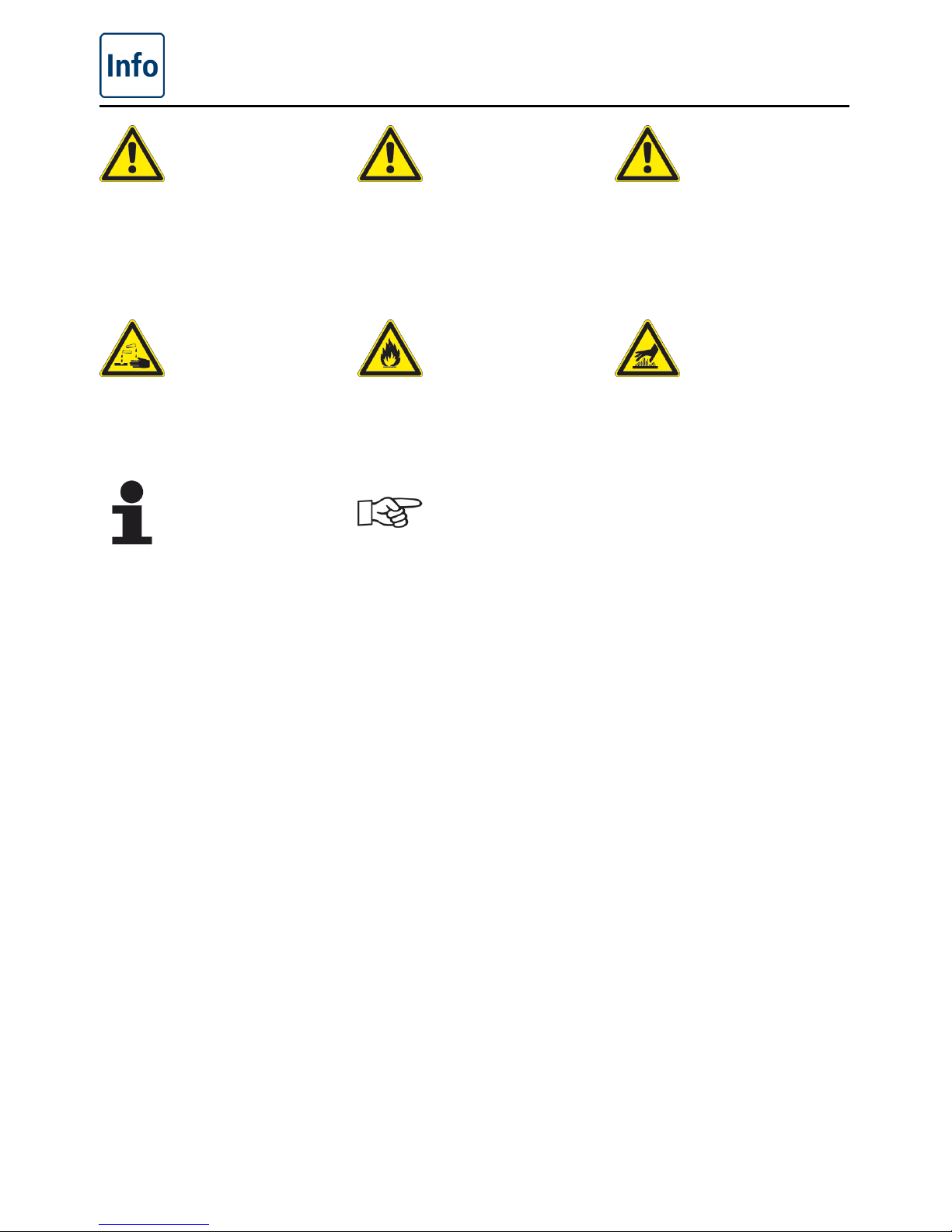

Explanation of the pictograms

5 / 61

Danger!

Imminently hazardous

situation, which, if not

avoided, will result in severe

injuries or death.

Warning!

Potentially hazardous

situation that may result in

severe injury or death.

Caution!

Potentially hazardous

situation that may result in

severe injury or death.

Corrosive

substances

Risk of fire! Risk of burns!

Attention:

Damage may be caused if

this is ignored.

Handy tips for everyday use

Page 6

Initial start-up

6 / 61

During initial start-up of your new device, you will be requested to start an automatic one-off

self-test. This self-test takes about 45 minutes and is used to adapt the device to the specific

environmental conditions. Please note the following:

- For the self-test to be carried out, all the packaging materials must be have been removed

from the device; check the grid shelves and the air baffle for a correct fit.

- The device must be connected in accordance with the installation instructions.

- For device size 6 x 1/1, 10 x 1/1, 6 x 2/1 and 10 x 2/1 GN place a flat GN container with

the opening facing downwards into the centre of the grid shelves.

- For the device size 20 x 1/1 and 20 x 2/1 GN place two GN containers in the mobile oven

rack. Place one flat container with the opening facing downwards in the centre in front of

both the upper and lower fan wheel.

- For further details please follow the instructions shown on the display and the installation

manual.

Risk of fire!

Remove the packaging material, starter kit as well as grids and containers.

The cooking cabinet door must not be opened during the self-test. Opening the cooking cabinet

door will lead to failure of the self-test. Restart the self-test by switching the device off. Always

allow a hot device to cool down first. If the test is interrupted you will be requested next day by

the device to start the self-test again.

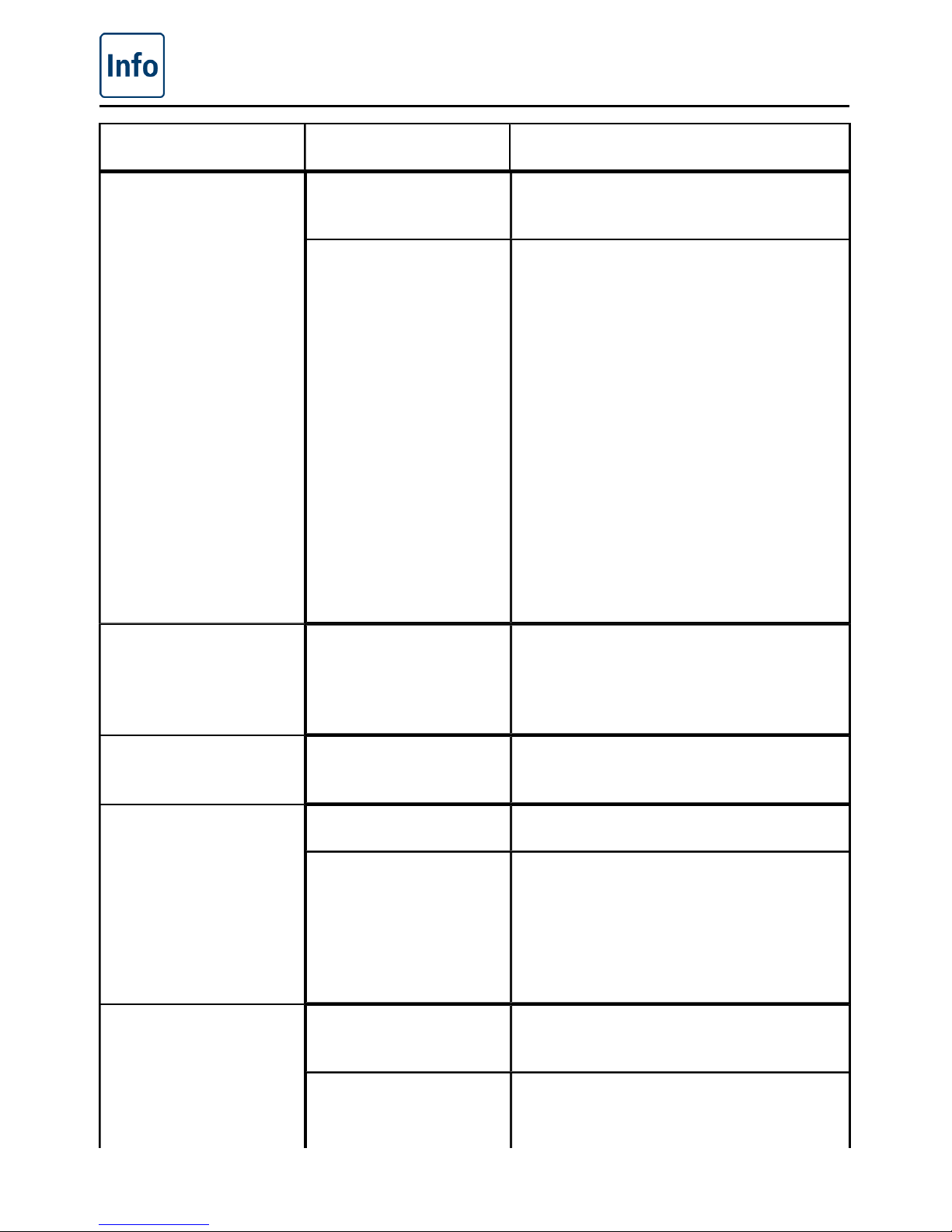

step info/button instructions

1

START

Follow the instructions on the display. Press

the button to start the self-test.

2

Select type of connection to normal or soft

water.

3

Next

Click “next” to confirm.

Page 7

Initial start-up

7 / 61

step info/button instructions

4

The following test will take place automatically.

The status is displayed in the upper field, the

time remaining until the self-test has been

completed is shown in the lower time field.

Where gas appliances are used, exhaust gas measurement must always be carried out when

the self-test has been completed.

Page 8

Safety Instructions

8 / 61

Keep this manual handy so that it can always be consulted by anyone using the unit.

This unit may not be used by children or anyone with limited physical, sensory or mental

abilities or a lack of experience and/or knowledge, unless these people are supervised by

someone responsible for safety.

Only use your hands to operate the controls. Damage caused by the use of pointed, sharp

or other objects will invalidate the warranty.

We recommend regular training of your staff to avoid the risk of accident or damage to the

unit. Operators must also receive regular safety instruction.

Warning!

Daily checks before switching on and use

- Lock the air baffle at the top and bottom as per the instructions - risk of injury from the

rotating fan wheel.

- Make sure that the hanging racks or mobile oven rack are correctly locked in place in the

cooking cabinet – Containers with hot liquids can fall through or slip out of the cooking

cabinet – risk of burns.

- Make sure that there are no residues of cleaning agents in the cooking cabinet before you

start cooking with the unit. Remove any cleaning agent residue and rinse thoroughly with

a hand shower – risk of chemical burns.

Page 9

Safety Instructions

9 / 61

Warning!

Country-specific and local standards and regulations relating to the installation and

operation of industrial cooking devices must be complied with.

Incorrect installation, servicing, maintenance, cleaning or modifications to the unit may

result in damage, injury or death. Read these operating instructions carefully before you

start to use the unit.

This unit must only be used to cook food in catering establishments. Any other use is not

intended and is therefore considered dangerous.

It must not be used to cook food containing flammable materials (such as food with

alcohol). Substances with a low flash point can ignite spontaneously - Risk of fire

Cleaning and descaling products and the associated accessories must only be used for

the purposes described in this manual. Any other use is not intended and is therefore

considered dangerous.

In case of damage to the glass plate, please replace the entire plate immediately.

Page 10

Safety Instructions

10 / 61

Warning!

Gas units only

- If your appliance is installed under an extractor hood, this must be switched on when the

appliance is in use – Combustion gases!

- If your appliance is connected to a chimney, the flue duct must be cleaned in compliance

with specific regional regulations – risk of fire. (Contact your installer.)

- Do not put objects on your unit's exhaust pipes – risk of fire.

- Do not let objects block or obstruct the area below the unit's base – risk of fire.

- The unit must only be used in still conditions – risk of fire.

What to do if you smell gas:

- Shut off the gas supply immediately

- Do not touch any electrical controls

- Make sure the area is well ventilated

- Avoid naked flames or sparking

- Use an external telephone to notify the appropriate gas supplier (if the gas supplier is

unobtainable call the emergency services on 999).

Page 11

Safety instructions and liability

11 / 61

Warning!

Safety instructions during use

- If containers are filled with liquid or contents which liquefy during cooking, only use rack

levels at a height at which the user can see into the slide-in containers – risk of burns.

There is a warning sticker enclosed with the unit.

- Always open the cooking cabinet door very slowly (hot vapors) – risk of burns.

- Always wear thermal protective clothing to hold accessories and other objects in the hot

cooking cabinet – risk of burns.

- The external temperatures of the unit may exceed 60 °C. Only touch the unit at the controls

– risk of burns.

- Hand shower and hand shower water may be hot – risk of burns.

- Cool-down mode – Do not use the cool down function unless the air baffle has been locked

correctly – risk of injury.

- Do not touch the fan wheel – risk of injury.

- Cleaning – aggressive chemical fluid – risk of chemical burns. Always wear the correct

protective clothing, safety goggles, gloves and facemask during cleaning. Follow the safety

instructions in the “CareControl” section.

- Do not store highly flammable or combustible materials near the unit – risk of fire.

- Apply the parking brakes on mobile units and mobile oven racks when these are not being

moved. Racks could roll away on uneven floors – risk of injury.

- If mobile oven racks are used, you must always apply the container lock. Cover any

containers with liquids to prevent the hot liquid spilling out - Risk of burns.

- The transport trolley must be correctly fixed to the unit when you load and remove the

mobile plate rack or mobile oven rack – risk of injury.

- Mobile oven racks, mobile plate racks, transport trolleys and units on casters can tip over

when being moved over an inclined plane or threshold – risk of injury.

Page 12

Safety instructions and liability

12 / 61

Liability

Installations and repairs that are not carried out by authorised specialists or using genuine

spare parts, and any technical change that is not approved by the manufacturer will invalidate

the manufacturer’s warranty and product liability.

Page 13

Care, inspection, maintenance and repair

13 / 61

Your unit must be cleaned every day or when a request for cleaning appears to maintain the

high quality of the stainless steel, for hygiene reasons and to avoid operating faults. To do

this, follow the instructions in the “CareControl” section.

Continuous operation at high cooking cabinet temperatures (≥260°C) or the use of high

browning levels (brown 4/5) and a production with predominantly high-fat and gelatincontaining foods may lead to more rapid wear of the door seal.

Daily cleaning of the cooking cabinet seal with a non-abrasive cleaning agent will extend the

service life.

Warning!

If the unit is not cleaned or is not cleaned well enough, deposits of grease and/or food

residues in the cooking cabinet may catch fire – risk of fire.

- To avoid corrosion in the cooking cabinet, your unit must be cleaned every day, even if it

is only operated in “moist heat” (steaming) mode.

- Apply vegetable oil or grease to the inside of the cooking cabinet at regular intervals (every

2 weeks or so) to prevent corrosion.

- The unit must not be cleaned with high pressure cleaner, steam cleaner or a direct water

jet.

- Do not treat the unit with acids or expose to acid fumes since this will damage the

passivated coating of the nickel-chromium steel and the unit might discolour.

- Only use cleaning agents made by the unit manufacturer. Cleaning agents from other

manufacturers may cause damage and invalidate the warranty.

- Do not use scouring products or scratchy cleaning agents.

Page 14

Care, inspection, maintenance and repair

14 / 61

Warning!

Servicing the incoming air filter. The device automatically recognises when the air filter is

soiled. You receive a service message and a request to clean or replace the air filter when the

air filter is soiled. The unit must not be operated without air filter. Please heed the following

when replacing the air filter:

Unit size 6 x 1/1 GN, 6 x 2/1 GN, 10 x 1/1 GN and 10 x 2/1 GN

Air filter part number: 40.03.461

This air filter can be removed and cleaned by the user. During replacement the air filter must

be locked carefully into the right position. Please follow the instructions in the “Maintenance”

section on how to replace the air filter.

Unit size 20 x 1/1 GN and 20 x 2/1 GN

This air filter can only be replaced by an authorised service partner.

Warning! The device’s water jet protection is only guaranteed with the filter and cover

completely mounted.

Page 15

Care, inspection, maintenance and repair

15 / 61

Inspection, maintenance and repair

Danger – high voltage

- Inspection, maintenance and repair work may only be carried out by trained technicians.

-

The unit must be switched off at the mains on-site when cleaning (except CleanJet

®

+care

cleaning), carrying out inspection, maintenance or repair work.

- If the appliance is installed on casters (mobile versions) freedom of movement of the

appliance must be restricted so that energy, water and drainage pipes cannot be damaged

when the unit is moved. If the unit is removed, make sure that power, water and drainage

lines are correctly disconnected. If the unit is returned to its original position, make sure

that the retention device, energy, water and drainage pipes are correctly connected.

- Your unit should be serviced at least once a year by an authorised service partner to

guarantee its perfect technical condition.

Page 16

Features

16 / 61

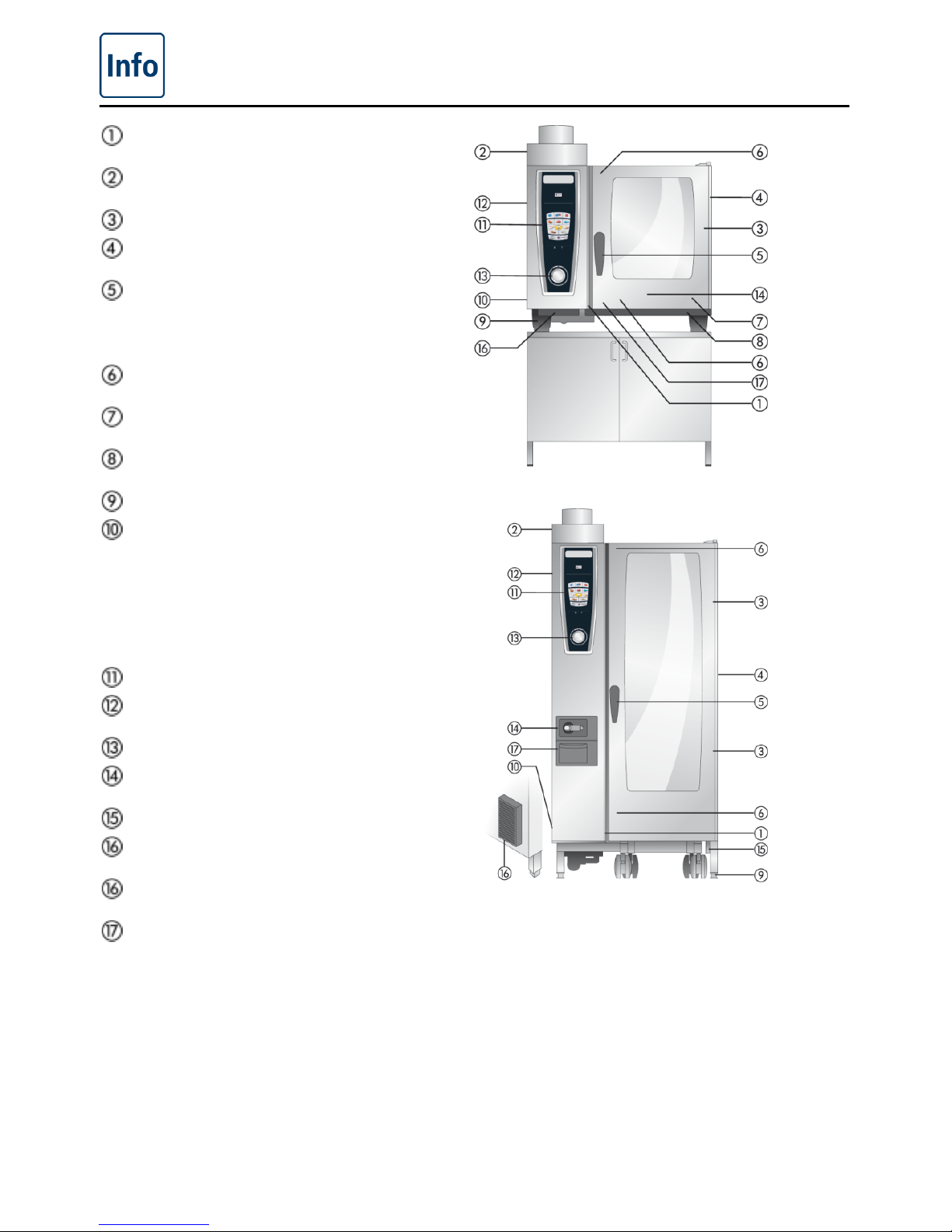

Appliance number

(visible only when door is open)

Draft diverter (optional)

(gas appliances only)

Interior lighting

Appliance door with double glass

panel

Door handle

Table-top units: One-handed operation

with slam function

Floor units: One-handed operation

Unlocking device to open double

glass door panel (inside)

Integrated and self-emptying door drip

pan (inside)

Drip collector connected directly to

appliance drain

Unit feet (height-adjustable)

Rating plate

(contains important data such as power

consumption, type of gas, voltage,

number of phases and frequency, as

well as device type, device number (see

the section on device type and software

identification) and option number)

Control panel

Protective cover for electrical

installation area

Central dial

Hand shower (with automatic retraction

system)

Run-in guide (floor units)

Air filter table-top unit (installation area

ventilation)

Air filter floor unit (installation area

ventilation, back of the unit)

Drawer/flap for care tabs

Table-top unit on base cabinet US IV

Floor unit

Page 17

Notes on using your unit

17 / 61

- Avoid having heat sources (e.g. grill plates, deep-fat fryers etc.) near the unit.

- Only use the unit in areas with a room temperature > 5 °C. For ambient temperatures of

less than + 5 °C, you must heat the unit to a temperature > + 5 °C before starting.

- As soon as you open the cooking cabinet door, the heating and fan wheel shut down

automatically. The integrated fan wheel brake becomes active and the fan wheel runs on

briefly.

- A drip tray should always be inserted under the food when grilling and roasting (e.g.

chicken) in order to catch the fat.

- Only use genuine heatproof accessories made by the unit manufacturer.

- Always clean accessories before use.

- Leave the unit door slightly open if it is going to be idle for a prolonged period (e.g.

overnight).

- The cooking cabinet door has a slam function; the door of the floor unit is not closed tight

unless the door handle is vertical.

- For long stoppages (e.g. non-work day), shut off the water, power and gas supplies to

the unit.

- This unit must not be disposed of with general waste nor can it be delivered to a local

authority collecting point. We will be happy to help you with the disposal of your unit.

Please contact our technical customer services by calling 0044 (0) 1582 480388

If the unit is without voltage or switched off for less than 15 minutes, the

process being executed will continue from where it was interrupted.

Page 18

Notes on using your unit

18 / 61

Max. load sizes for each unit size

6 x 1/1 GN 30 kg (max. 15 kg per rack)

6 x 2/1 GN 60 kg (max. 30 kg per rack)

10 x 1/1 GN 45 kg (max. 15 kg per rack)

10 x 2/1 GN 90 kg (max. 30 kg per rack)

20 x 1/1 GN 90 kg (max. 15 kg per rack)

20 x 2/1 GN 180 kg (max. 30 kg per rack)

Exceeding the maximum load size can lead to damage on the device.

Please note the specifications for maximum load sizes for food in the application manual.

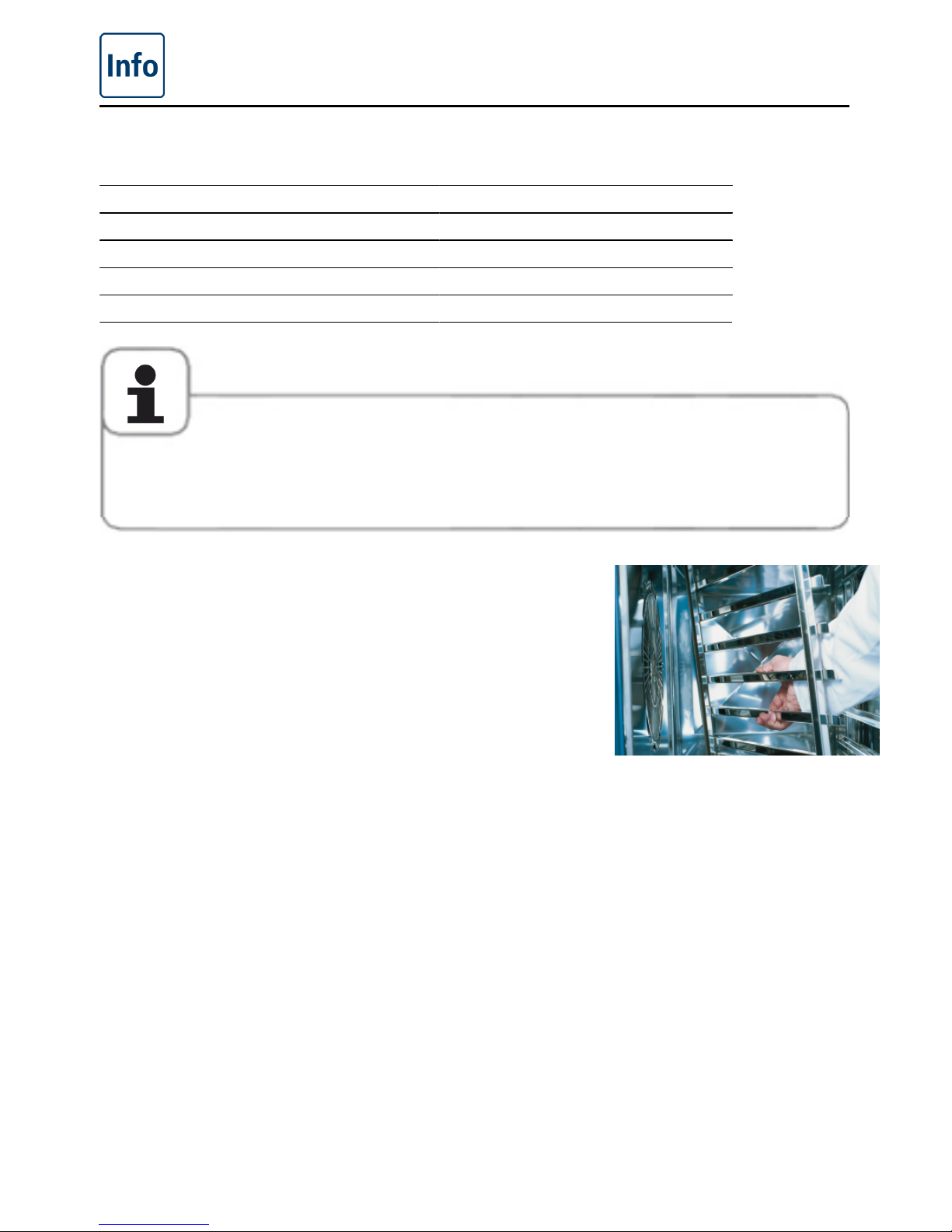

Table-top units with hanging racks

(6 x 1/1 GN, 6 x 2/1 GN, 10 x 1/1 GN, 10 x 2/1 GN)

- To remove, raise the hanging rack slightly in the middle.

Pull it out of the front locking mechanism first, then

the lower mechanism and finally the upper locking

mechanism.

- Swivel the hanging rack to the middle of the cooking

cabinet.

- Release the hanging rack from its fixing by lifting it up.

Reverse the above sequence to reset.

Page 19

Notes on using your unit

19 / 61

Working with mobile oven racks, mobile plate racks

and transport trolleys for table-top units (option)

- Remove the hanging rack as described above.

- Place the run-in rail on the fixing provided on the unit's

base. Make sure it is fixed accurately in place (4 pins).

- Remember that the unit must be matched to the exact

height of the transport trolley and must be levelled.

- Move the transport trolley as far as it will go on the

run-in rail and make sure that the transport trolley is

correctly locked on the unit.

- Push the mobile oven rack or mobile plate rack into

the unit as far as it will go, and check that the locking

mechanism in the unit is working correctly.

- To remove the mobile oven rack or mobile plate rack,

release the locking mechanism and pull the rack out of

the cooking cabinet. First insert the core temperature

probe with the run-in rail in the park position.

- Make sure that the mobile oven rack or mobile plate

rack is securely locked on the transport trolley during

transportation.

Page 20

Notes on using your unit

20 / 61

Working with the core temperature probe

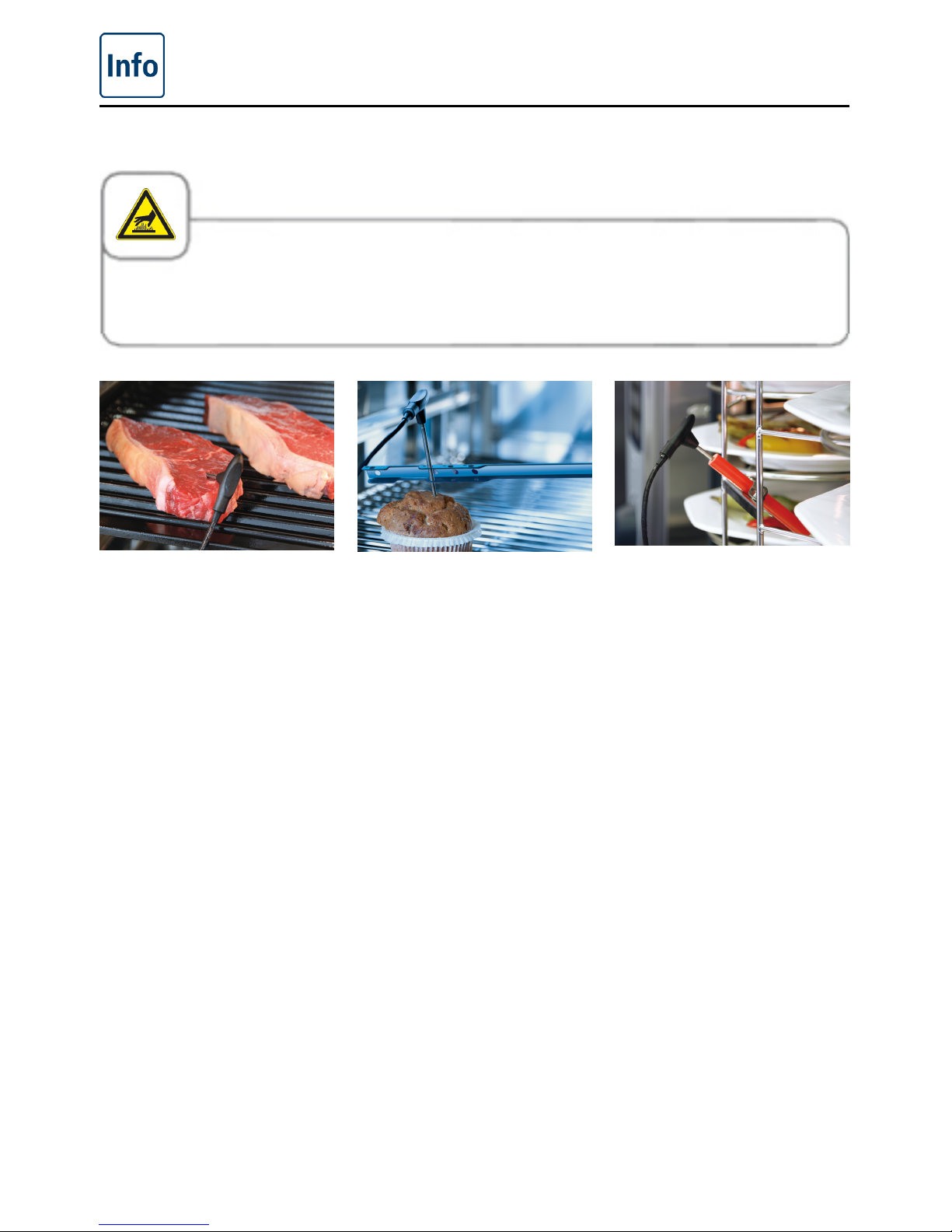

Caution!

The core temperature probe and its positioning aid may both be hot – risk of burns.

Insert the core temperature

probe into the thickest point

of your cooking product.

You must insert the needle

through the middle of

the food (see application

manual).

Use the positioning aid if

the core temperature probe

could fall out of the food

(for instance if the food

to be cooked is of a soft

consistency or not very

thick).

For Finishing

®

with the

plate rack, insert the core

temperature probe into the

ceramic tube on the mobile

plate rack.

Page 21

Notes on using your unit

21 / 61

Use a starting bit to make a hole in frozen foods. Drill a hole in the

thickest part of the food to be cooked. To do this, place the food on a

firm base and protect your hands.

- Always correctly position the core temperature probe and the positioning aid in the park position

provided – risk of damage.

- Do not let the core temperature probe hang out of cooking cabinet – risk of damage.

- Remove the core temperature probe from the food before you take the food from the cooking

cabinet – risk of damage.

If necessary, cool down the core temperature probe using the hand shower before use.

Caution!

Protect your arms and hands from burns and from the probe tip – risk of injury.

Page 22

Notes on using your unit

22 / 61

Working with the hand shower

- If you use the hand shower, please pull the hose at least 20 cm out of the park position.

- You can select 2 jet strengths by pressing the control button.

- Always let the hand shower slide slowly back into the park position.

Caution!

The hand shower and water from the hand shower may be hot – risk of burns.

- If you pull hard on the hand shower and it exceeds the maximum available hose length, it will

damage the hose.

- Make sure that the hand shower hose is fully rewound after use.

- You must not use the hand shower to cool the cooking cabinet. – Risk of damage to the cooking

cabinet and air baffle, or of the cooking cabinet glass cracking.

- According to WRAS-standard the handshower should be used only for rinsing the internal

cabinet.

Page 23

General instructions for use

23 / 61

Your unit has a touch screen. You can make settings on your unit by just touching it lightly

with your finger.

You can change the

settings using the central

dial.

Alternatively, rough settings

can be made by adjusting/

pulling the slide.

Your settings are accepted

within 4 seconds. Otherwise

you can press the central

dial.

Page 24

General instructions for use

24 / 61

General notes

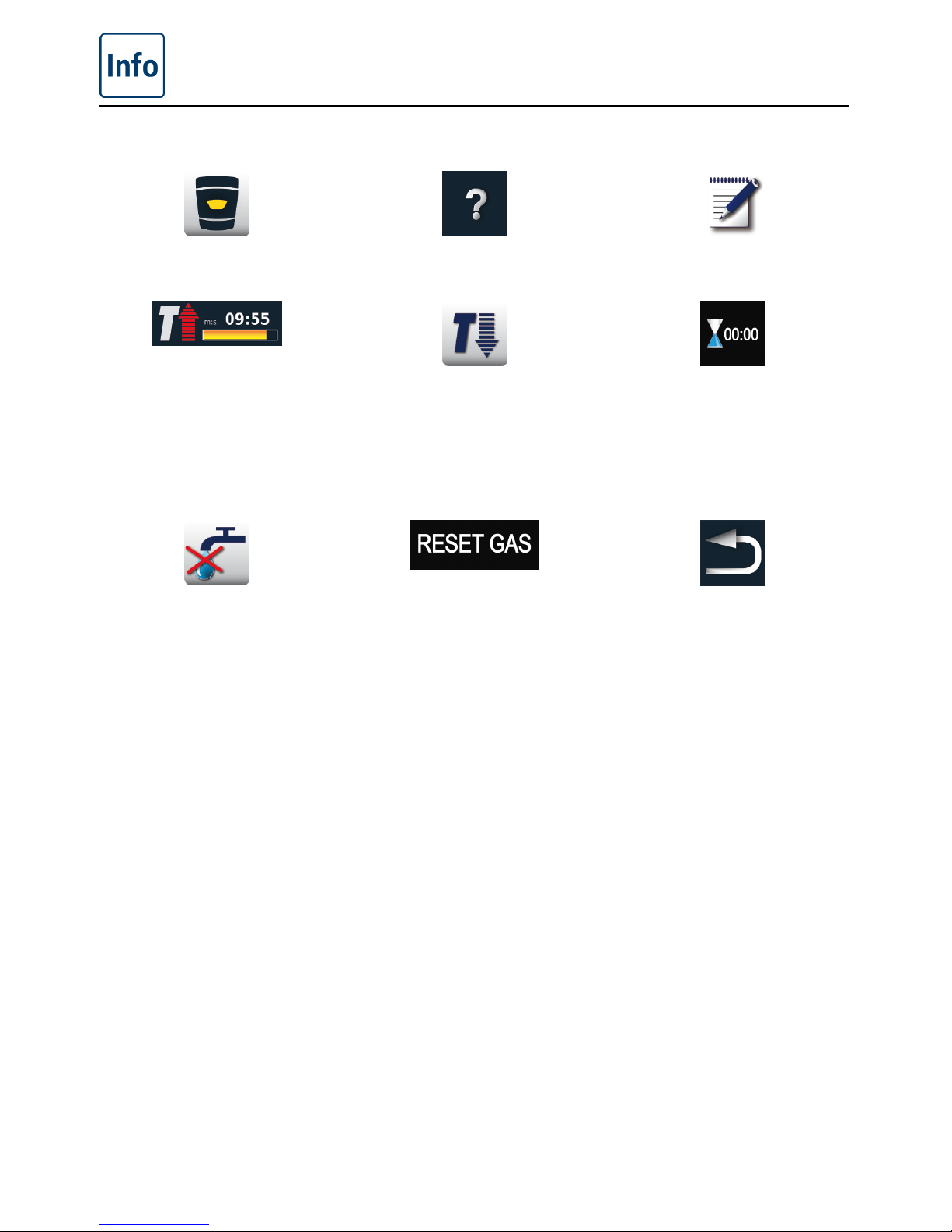

Back to start level Help function Programming mode

Status display preheat,

red arrow for preheat, blue

arrow for cool down.

Cooking cabinet too hot

– button flashing (see

the “Cool Down” section

on cooling the cooking

cabinet).

The end of cooking is

indicated by an acoustic

signal and animated

graphics.

Low water level – Open the

water tap. Display goes out

after filling.

“Gas burner fault” Press

“RESET GAS” – New

ignition process. If the

display lights up repeatedly,

inform Service!

back/cancel

Page 25

General instructions for use

25 / 61

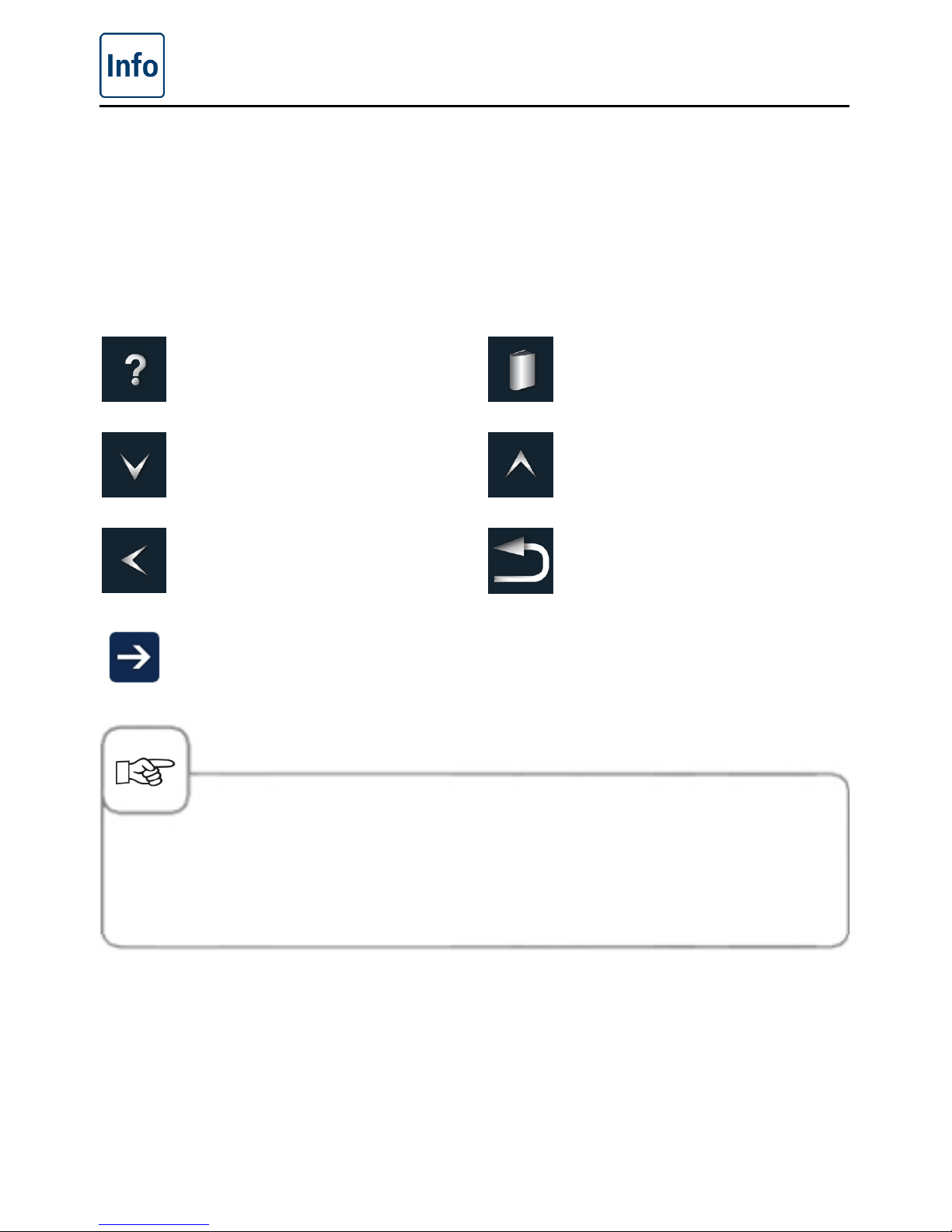

Help function

So that you can use your device’s many possibilities as easily and efficiently as possible,

detailed operating instructions and user help texts with practical examples and useful tips are

stored on the device. The help function can be selected using the “?” button. The following

functions are available in the help function.

Explanation of pictograms

Start help function

Scroll forward one page

Open the previous chapter

Next chapter/more information

Open the selection menu and

select manual

Scroll back one page

Leave the help function

- The respective table of contents will open when you select a manual. Choose the chapter you

are interested in.

- If the help function is opened during cooking operation, the help function is closed automatically

as soon as an action becomes necessary.

Page 26

Overview of the cooking modes

26 / 61

Display after switch-on

On/Off switch

MySCC

Help function

CareControl

Combi-steamer mode

Steam

Dry heat

Combination of steam and dry

heat

SelfCooking Control mode

Meat

Poultry

Fish

Side dishes

Egg dishes/dessert

Baking

Finishing

®

Further functions

Efficient LevelControl

®

system

mode

Programming mode

Page 27

Overview of the cooking modes

27 / 61

3 different operating modes

SelfCooking Control

mode

Combi-steamer mode Programming mode

After switching on or

operating the home button

you enter SelfCooking

Control

®

mode.

See the SelfCooking

Control

®

mode section for a

description.

You enter combi-steamer

mode by pressing

the button “steam”,

“combination” or “dry heat”.

See the Combi-steamer

mode section for a

description.

Pressing the “program”

button switches to

programming mode.

See Programming mode

chapter for description.

Page 28

SelfCookingControl

®

mode

28 / 61

SelfCookingControl

®

detects the size of the food and the load size. Cooking time,

temperature and cooking cabinet humidity are adapted continually. The remaining time is

displayed. See the application manual for examples and useful tips.

Explanation of pictograms

Cooking speed

Delta-T

Cooking time

Browning

Food thickness

Proving volume

Cooking cabinet humidity

Moisturing

Air speed

Core temperature/cooking level

Core temperature/cooking level

Core temperature/cooking level

Core temperature/cooking level

How well done

Size of food

Searing temperature

Crisp

Gratinate

Page 29

SelfCookingControl

®

mode

29 / 61

Convenience level Steam baking

Information and requests during the cooking process

Preheat display

Cool down display

Request to cancel

Score

Add liquid

Options following the end of cooking

Keep at temperature

Heat to serving temperature

Crisp

Reposition core temperature

probe

Continue with time

Load new batch

Page 30

SelfCookingControl

®

mode

30 / 61

Information button

The information button always shows you how many process steps the current cooking

process is made up of and which subsequent options can be selected in addition.

Indication of cooking sequence

As an example, here is the cooking sequence for “roasting”:

Preheat Load Set CT Sear Cool

Cook

Options

Continue

with transfer

Hold New load

Page 31

Combi-steamer mode

31 / 61

All combi-steamer functions are available in combi-steamer mode. You enter combisteamer mode by pressing the button “steam”, “dry heat” or “combination of steam and dry

heat”.

3 manual operating modes

Steam

Dry heat

Combination of steam and dry

heat

Explanation of pictograms

MySCC

CareControl

Exact percentage setting for

humidity in the cooking cabinet

Cooking cabinet temperature

setting

Cooking time setting

Core temperature setting

Preheat

Continuous operation

Moisturing

Page 32

Combi-steamer mode

32 / 61

Help function

Request the programming

function

back/cancel

Air speed

Cool down

The current cooking data such as actual cooking cabinet humidity and temperature can be

requested by pressing the cooking cabinet temperature button.

Hold the button down for 10 seconds to display the actual values continuously until the next

setting is made.

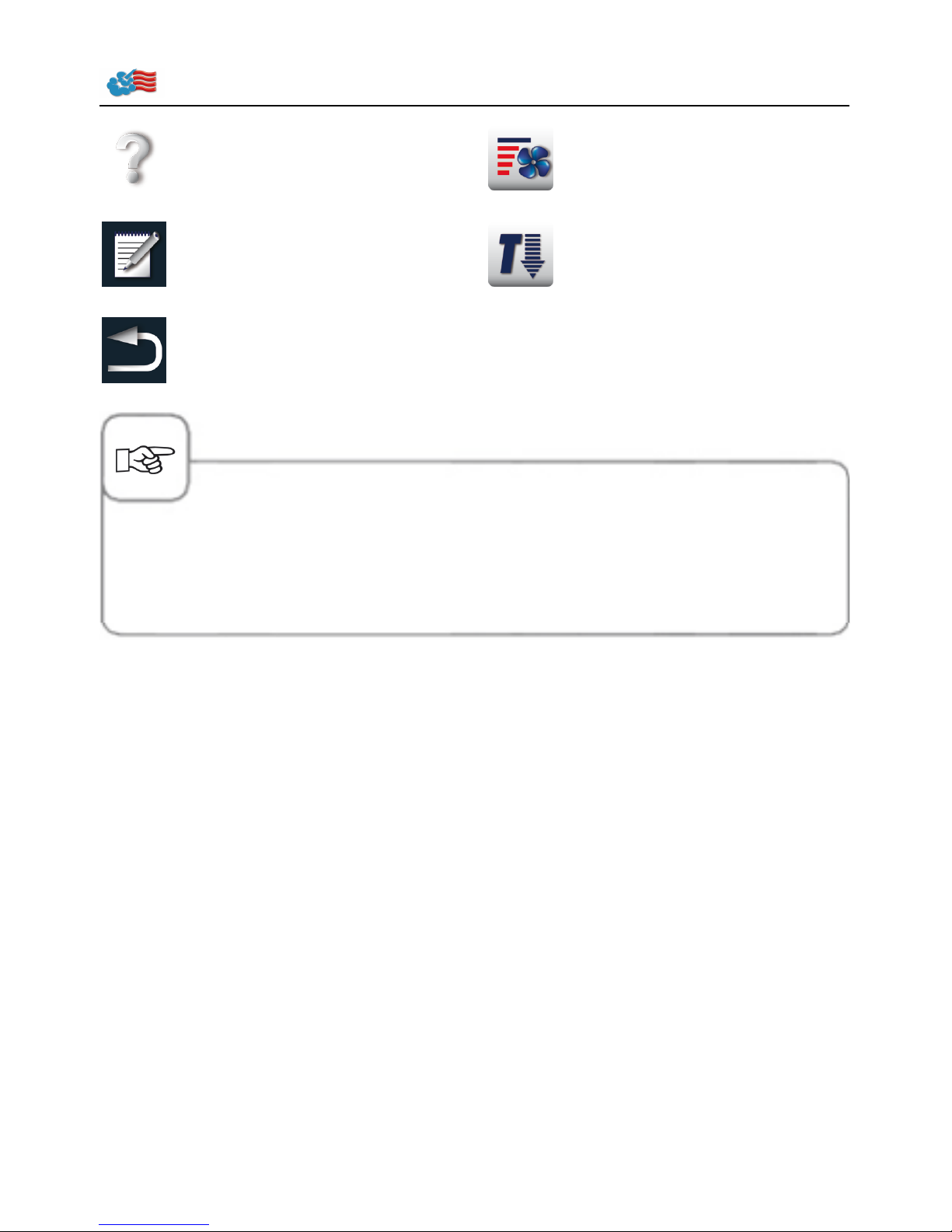

Page 33

Programming mode

33 / 61

It takes no time at all to create your own cooking programs in programming mode. The

7 operating modes (meat, poultry, fish, bakery products, side dishes, egg dishes/dessert,

finishing) can be copied, adapted and saved under a new name according to your individual

requirements, or you can create your own manual programs with up to 12 steps.

Press the button to enter

programming mode.

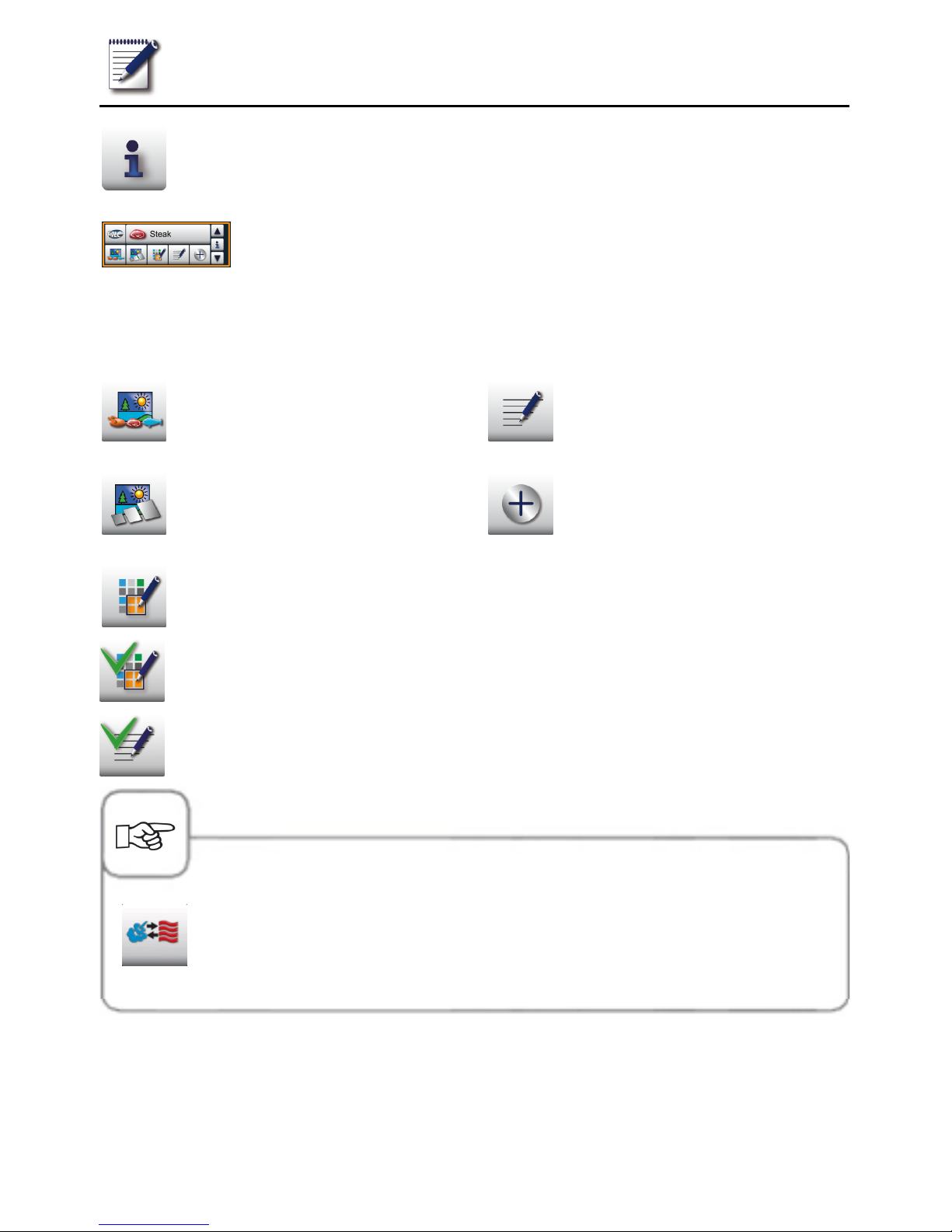

Explanation of pictograms

Select program

Selection window – start program

New program

New ELC program

Copy program

Delete program

Change program

Image view

List view

Open MyDisplay

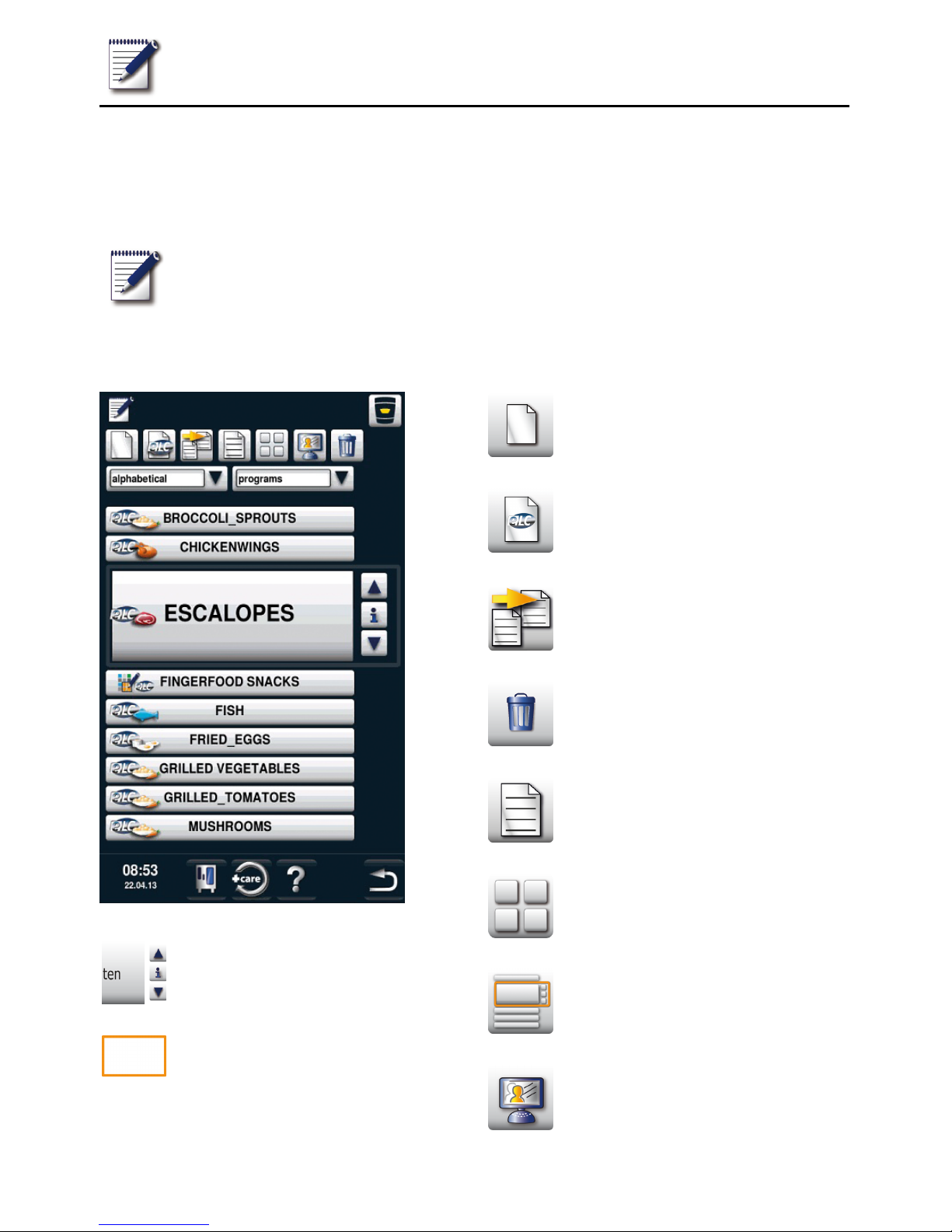

Page 34

Programming mode

34 / 61

Selection window – indicate

program details

Selection window with

the information button

pressed

In addition to the program names, further information can be requested or stored using the

following buttons.

Image of the food for the program

Image of the accessories for the

program

Group allocation (e.g. breakfast)

Notes on the program

Additional attributes can be

selected

The assignment to a group is indicated by pressing the "Group assignment"

button.

An existing assignment is signalled by a green check mark.

Programme notes saved are displayed directly by pressing the "Notes"

button. Available notes are signalled by a green check mark.

The pictogram shows the operating mode of the stored program such as

combination of steam and dry heat, for example. Other pictograms are

shown correspondingly for SelfCooking Control® cooking processes and

EPS.

Page 35

Programming mode

35 / 61

Image view

In the image view, the representation of all programs is reduced to a title image. If there is

no image available, the title of the program is shown as a text in the image view.

Change to the image view.

Change the view from 20 images

to 16 images per side, for

example.

You can scroll in your view by

pressing the arrow or using the

setting wheel.

The last image chosen is always shown when the view is requested again.

Page 36

CareControl

36 / 61

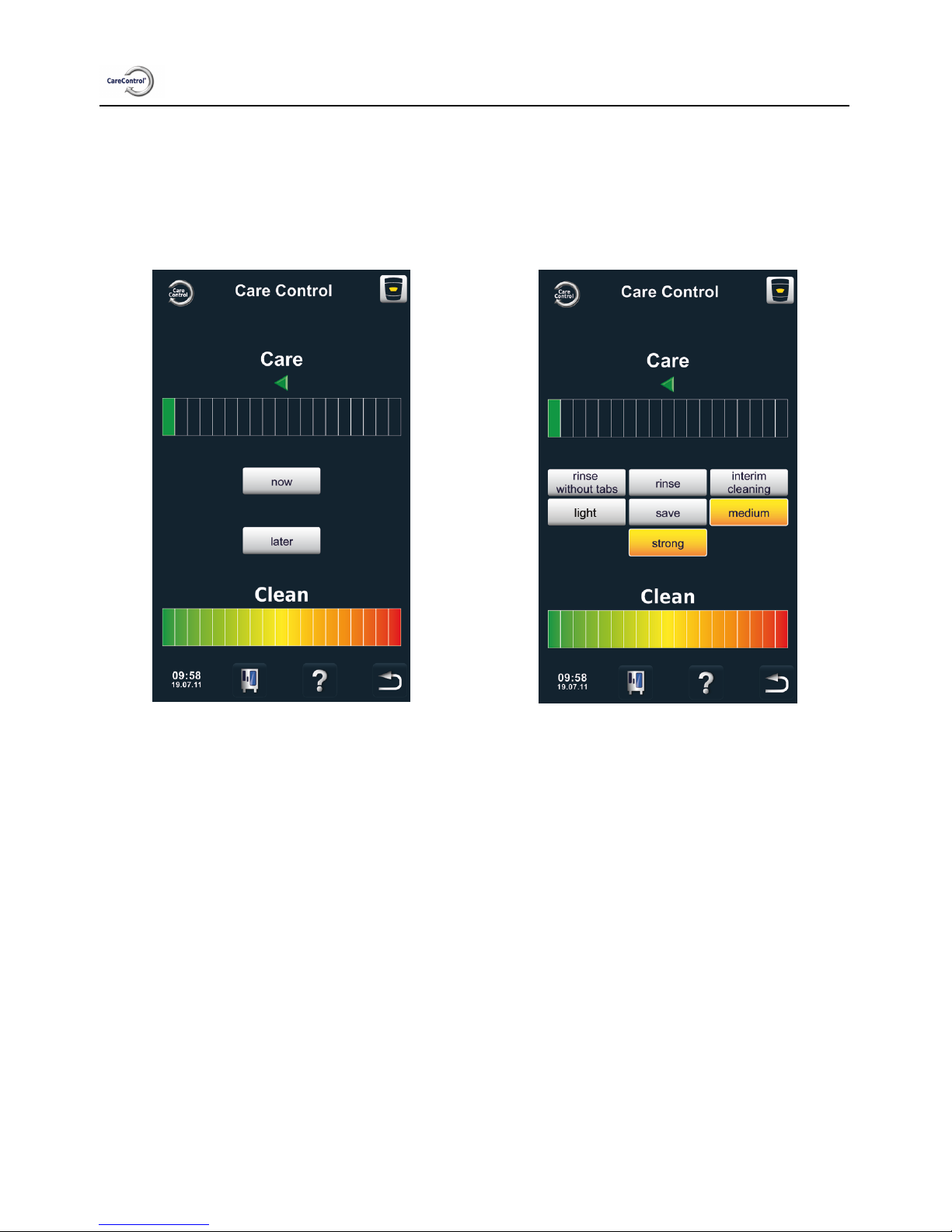

Cleaning request

CareControl recognises when CleanJet

®

+care cleaning has to be carried out. CareControl

takes individual cleaning and working habits into account, such as longer breaks or the end

of work. The recommended cleaning stages are marked in different colours.

Automatic display of cleaning request

as soon as CleanJet

®

+care cleaning is

necessary.

The recommended cleaning stage is

highlighted in colour.

Page 37

CareControl

37 / 61

step info/button instructions

1

Please clean + care

You are requested to clean the unit.

2

CleanJet+care

Start CleanJet

®

+care by pressing the button

or select “later”.

3

medium

Select the recommended cleaning stage

highlighted in colour e.g. “medium” and follow

the instructions shown in the menu.

The CleanJet

®

+cleaning request is repeated at regular intervals until a CleanJet

®

+care

cleaning process is carried out.

Page 38

CareControl

38 / 61

Starting cleaning

CleanJet

®

+care is the automatic cleaning system for cleaning the cooking cabinet.

With 7 cleaning steps, it allows you to adjust the cleaning process to match the individual

degree of soiling.

Warning!

- For hygiene reasons and to prevent malfunctions it is essential to clean the unit every day - risk

of fire.

- Please note that your unit must be cleaned every day, even if only “steaming” operation is used.

- Use only the appliance manufacturer’s cleaning agent and care tabs. The use of other chemical

cleaners may damage the appliance. We will not be liable for the consequences!

- You may experience foaming if too much chemical cleaner is used.

- Never put tabs in the hot cooking cabinet (>60 °C).

- Leave the unit door slightly open if it is going to be idle for a prolonged period (e.g. overnight).

- Cleaning the cooking cabinet seal every day will extend the service life. Use a soft cloth and

cleaning agent to clean the cooking cabinet seal. Do not use scouring products.

- Clean the glass windows on the inside and out and the outer panels of the unit, ideally using a

soft, damp cloth. Do not use a scouring product.

Page 39

CareControl

39 / 61

step info/button instructions

1 Press the button

2

The cooking

cabinet is too hot

“Cooking cabinet too hot” appears when the

cooking cabinet temperature exceeds 75 °C.

Select “cool down” (see the “Cool Down”

section).

4

light

Select cleaning stage e.g. “light”.

5

Open door

Open the cooking cabinet door, remove

containers and trays (stainless steel grids,

CombiFry

®

and superspike poultry grids can

remain in the cooking cabinet).

6

Warning!

Always wear gloves when handling cleaner and

care tabs – risk of chemical burns.

7

Unpack the number of cleaner tabs indicated

and place them in the recess in the air baffle

(tab basket) in the cooking cabinet. See photo

below.

8

Unpack the number of care tab packages

indicated and fill these into the care container.

See photo below.

8

close door

Cleaning starts automatically when oven door

was closed!

Page 40

CareControl

40 / 61

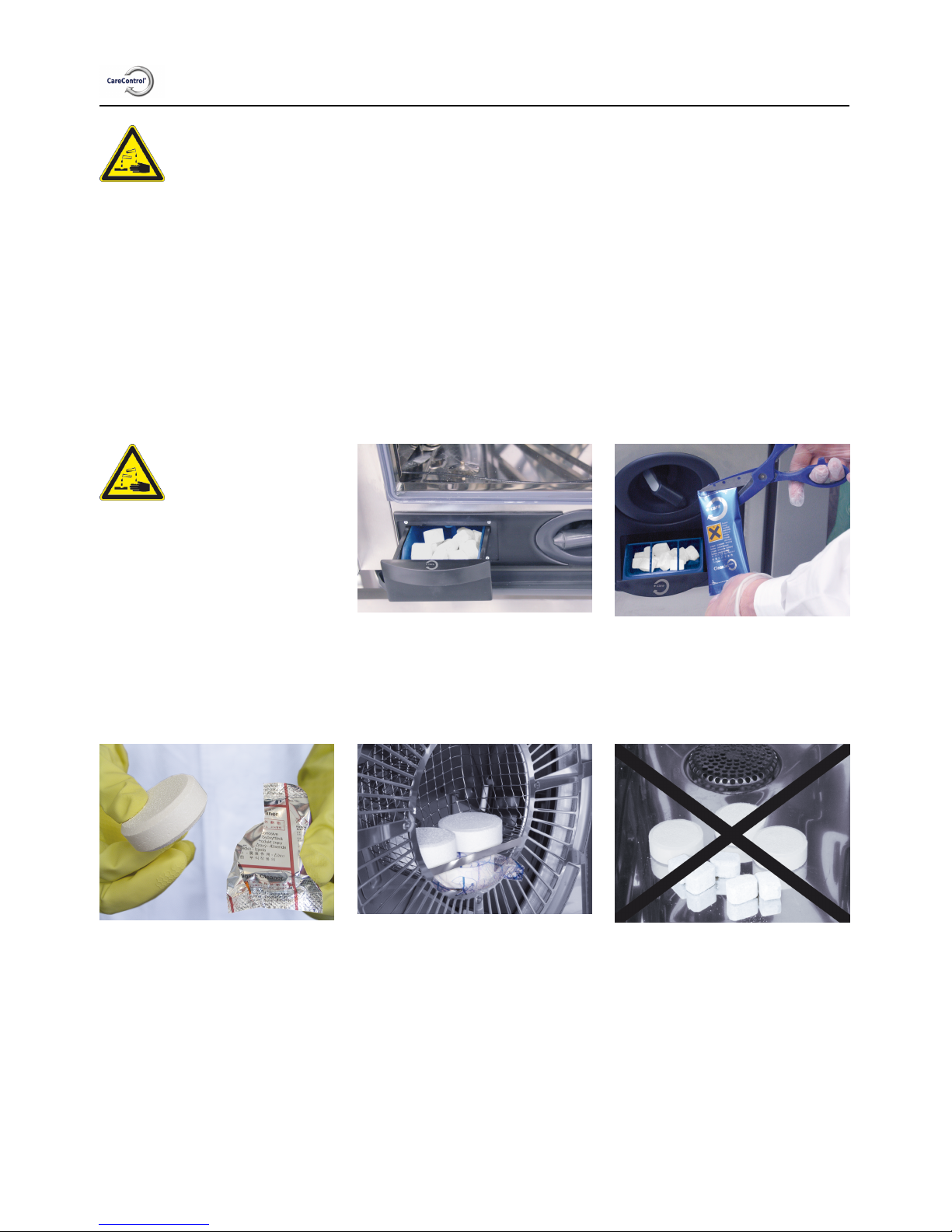

Warning!

- Do not open the cooking cabinet door while cleaning is in progress – chemical cleaner

and hot vapour may escape – risk of chemical burns and scalding.

-

After terminating or after CleanJet

®

+care cleaning has been completed, check the

complete cooking cabinet for cleaner residue (including behind the air baffle). Remove

residue and use the hand shower to rinse the complete cooking cabinet thoroughly

(including behind the air baffle) – risk of chemical burns.

Instructions on handling chemicals:

Warning!

Always take suitable safety

precautions when using

cleaner and care tabs, e.g.

only touch the tabs when

wearing gloves – risk of

chemical burns.

Table-top units: Fill

the number of care tabs

packages indicated into the

drawer.

Floor units: Fill the number

of care tabs packages

indicated into the flap.

Cleaner tab: remove

protective foil.

Place cleaner tabs into the

recess in the air baffle.

Do not place tabs in the

cooking cabinet - risk of

damage.

Page 41

CareControl

41 / 61

Before you start the CleanJet

®

+care cleaning, make sure that the hanging racks or mobile

oven rack are inserted correctly in the cooking cabinet.

If you are using softened water, you can reduce the recommended number of cleaner tabs by

up to 50 %. If foaming occurs even though the amount is correct, then the number of detergent

tablets should be reduced. If heavy foaming still occurs despite low dosage, please contact

your Service Partner/Customer Service for the use of further measures such as the defoamer

tab.

Page 42

CareControl

42 / 61

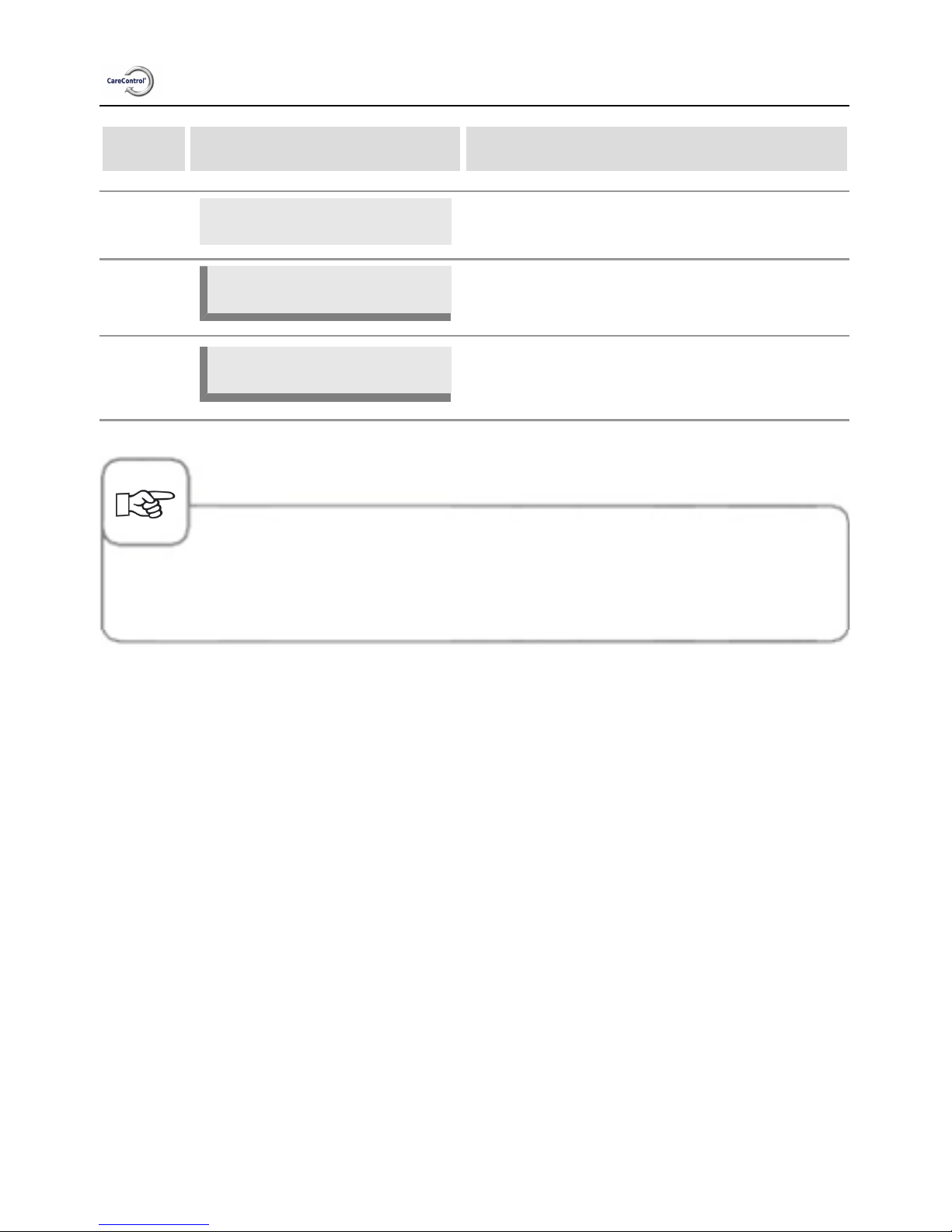

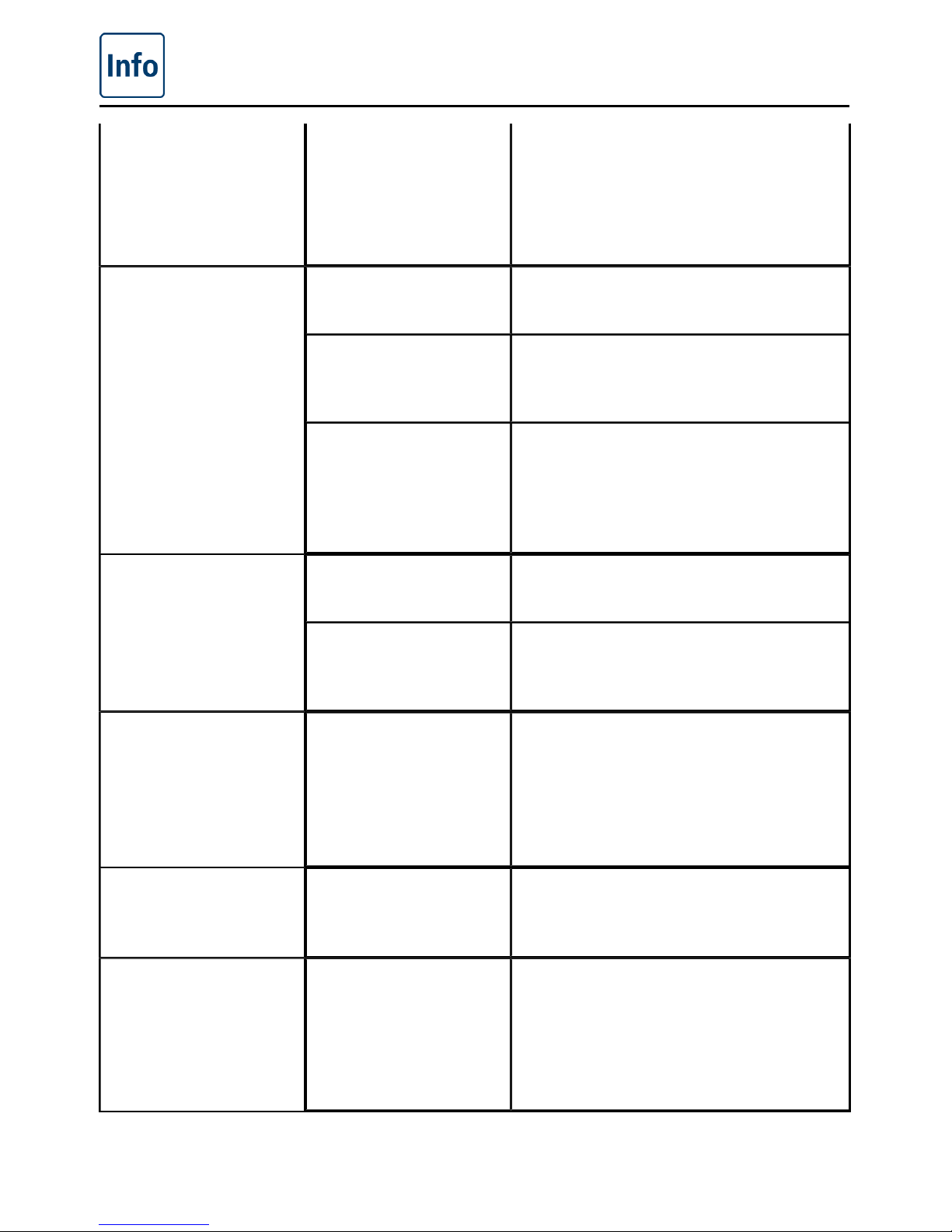

Cleaning stages

cleaning stage description/application tabs

rinse without tabs Rinse cooking cabinet with warm water. No

rinse

For non-greasy limescale deposits, e.g. after

baking or steaming.

Care

interim cleaning

“Short cleaning time” - for all soiling, but

without drying and rinsing.

Cleaning agent

light

For lighter soiling, e.g. after mixed loads,

applications up to 200 °C.

Cleaning agent &

Care

save

For light soiling (up to 200°C) with as

economical a use of chemicals and water as

possible.

Cleaning agent &

Care

medium

For roasting and grilling deposits, e.g. after

cooking chicken, steaks or grilled fish.

Cleaning agent &

Care

strong

For heavy roasting and grilling deposits, e.g.

multiple loads of chicken, steaks, etc.

Cleaning agent &

Care

Page 43

CareControl

43 / 61

CleanJet

®

+care failure

After a power failure lasting longer than 10 minutes or after the unit is switched off the display

reads "Interrupt CleanJet". If Interrupt CleanJet

®

is not confirmed within 20 seconds by

pressing the display, the activated CleanJet

®

+care program runs through to the end without

interruption.

step info/button instructions

1 Switch the unit off and then on again.

2

cancel CleanJet?

Press the button and confirm cancellation.

3

Open door

Follow the instructions on the display and

open the door carefully – hot vapours!

4

Warning!

Always wear gloves when handling cleaner tabs

– risk of chemical burns.

5

Remove tabs

Remove cleaner tabs (if still present) and

close the cooking cabinet door.

6

00:09

The cooking cabinet is rinsed automatically,

the remaining time till the end is indicated.

7

Cleaning incomplete

You can now use your unit for cooking again.

Page 44

Maintenance

44 / 61

Air filter service

Table-top units type 6 x 1/1 GN, 6 x 2/1 GN, 10 x 1/1

GN and 10 x 2/1 GN:

Loosen the air filter by pressing the frame in the two

roughened spots. Tilt the filter down and remove it

completely from the unit.

Clean the air filter in the dishwasher (not with CleanJet

®

!) and then allow it to dry. If the air filter is still very

sticky and soiled after cleaning it will have to be

replaced.

Then insert the air filter with the rear hooks in the holes

on the underside of the unit first, and then lock in place

by pushing from bottom to top (opposite procedure to

removing the filter).

Air filter no.: 40.03.461

Floor units type 20 x 1/1 GN and 20 x 2/1 GN:

Please contact your Service partner for replacement of

the air filters on the floor units 20 x 1/1 GN and 20 x 2/1

GN.

Page 45

Maintenance

45 / 61

Replacing the door seal

The door seal is fitted in a groove on the cooking

cabinet.

- Pull the old seal out of the groove.

- Clean the guide rail.

- Insert new seal into the groove (moisten the

retaining lips with soapy water).

- The rectangular part of the seal must be seated fully

in the holding frame.

Cooking cabinet seal:

6 x 1/1 GN No: 20.00.394

6 x 2/1 GN No: 20.00.395

10 x 1/1 GN No: 20.00.396

10 x 2/1 GN No: 20.00.397

20 x 1/1 GN No: 20.00.398

20 x 2/1 GN

No: 20.00.399

Replacing the halogen lamp

First switch off the unit at the mains!

- Cover the unit drain in the cooking cabinet.

- Remove the frame with glass and seal.

- Replace halogen bulb (article no.: 3024.0201), do

not touch the bulb with your hands).

- Replace sealing frame as well (article no.:

40.00.094).

- Screw the frame in place with glass and seals.

Page 46

Descaling the moisturing nozzle

46 / 61

Please check the moisturing nozzle for scale residue once a month.

step info/button instructions

1 Switch the unit off

2

Swing the hanging rack and the air baffle into

the centre.

3

Loosen the union nut on the moisturing nozzle

(turn anti-clockwise – spanner size 15).

Warning!

Aggressive chemical liquid – risk of chemical

burns!

Wear: protective clothing, safety goggles,

protective gloves, face mask.

Following descaling, rinse the moisturing nozzle

thoroughly with water.

4

Place the moisturing nozzle in the descaling

liquid and allow it to react (moisturing nozzle

must be free of scale)

Page 47

Descaling the moisturing nozzle

47 / 61

step info/button instructions

5

Assemble in reverse order – note the

installation position

Page 48

Fault messages

48 / 61

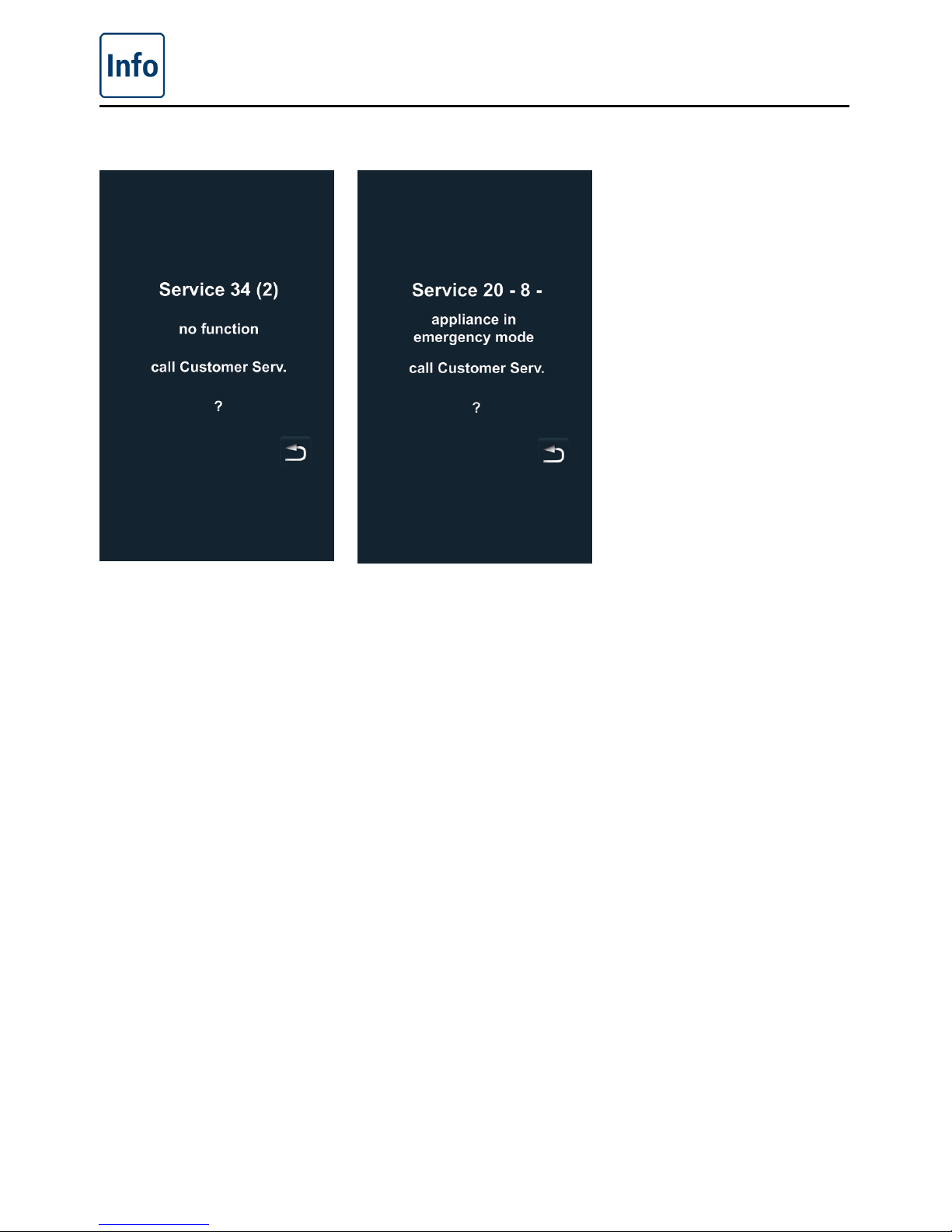

Displays for general faults

If faults occur on your unit,

they are indicated on the

display: Please note the

phone number for fast

contact with your customer

service department.

Faults on your unit which

allow you to carry on

cooking can be suppressed

by pressing the “back”

button.

Page 49

Fault messages

49 / 61

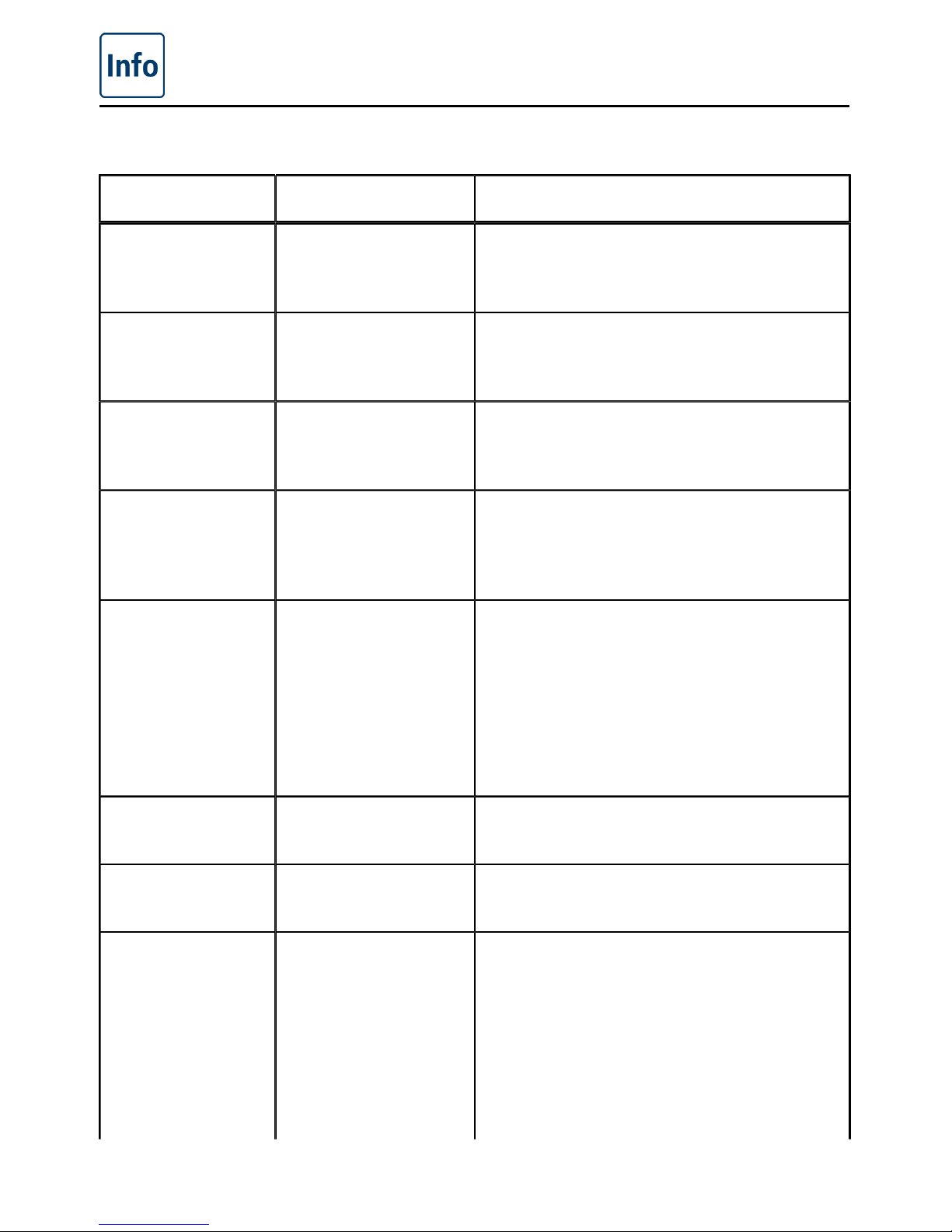

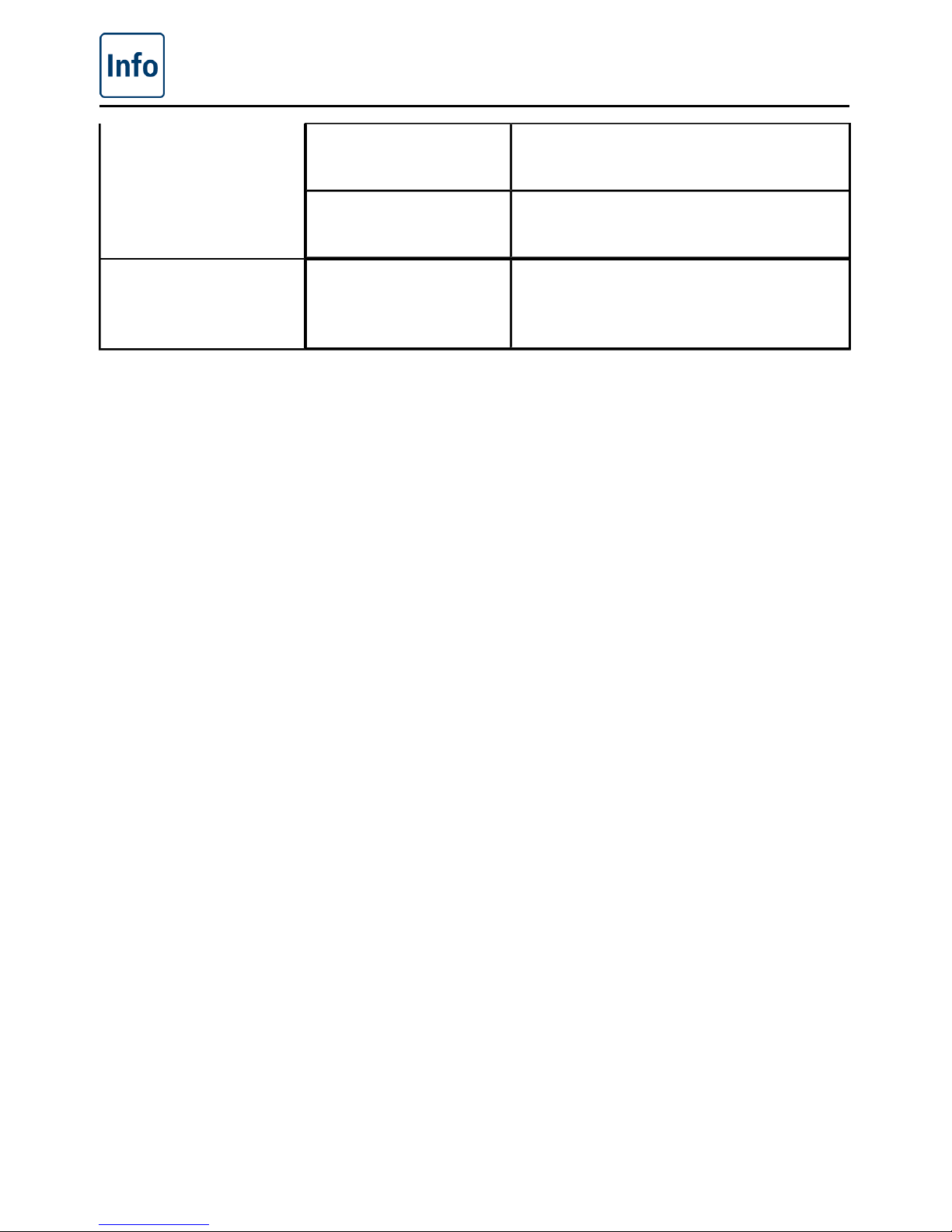

Please follow the remedial measure suggested in the table below.

fault indication when and how remedial action

Service 10 When it has been

switched on for 30

seconds,

Can be rejected by pressing the “back”

button. The unit can be used for cooking.

Please notify Customer Service.

Service 11 When it has been

switched on for 30

seconds,

Can be rejected by pressing the “back”

button. The unit can be used for cooking.

Please notify Customer Service.

Service 12 When it has been

switched on for 30

seconds,

Can be rejected by pressing the “back”

button. The unit can be used for cooking.

Please notify Customer Service.

Service 14 When it has been

switched on for 30

seconds,

Can be rejected by pressing the “back”

button. The unit can only be used in “dry

heat” cooking mode. Please notify Customer

Service.

Service 20 Displayed for 30

seconds when

the cooking mode

is changed, on

switching on and

when the SelfCooking

Control

®

modes are

selected.

Working with SelfCooking Control

®

- cooking

modes and programs is not possible.

It is possible to work in combi-steamer

mode with some restrictions. Please notify

Customer Service.

Service 23 Displayed

continuously.

Switch the unit off and notify Customer

Service.

Service 24 Displayed

continuously.

Switch the unit off and notify Customer

Service.

Service 25 Displayed for 30

seconds during

CleanJet

®

+care

cleaning.

CleanJet

®

+care is not working.

- Open the water tap fully.

- Check the incoming screen - Remove the

container from the cooking cabinet.

- If no faults are found, please notify

Customer Service.

-

If Service 25 occurs during CleanJet

®

+care cleaning, please remove the tabs

from the cooking cabinet and rinse the

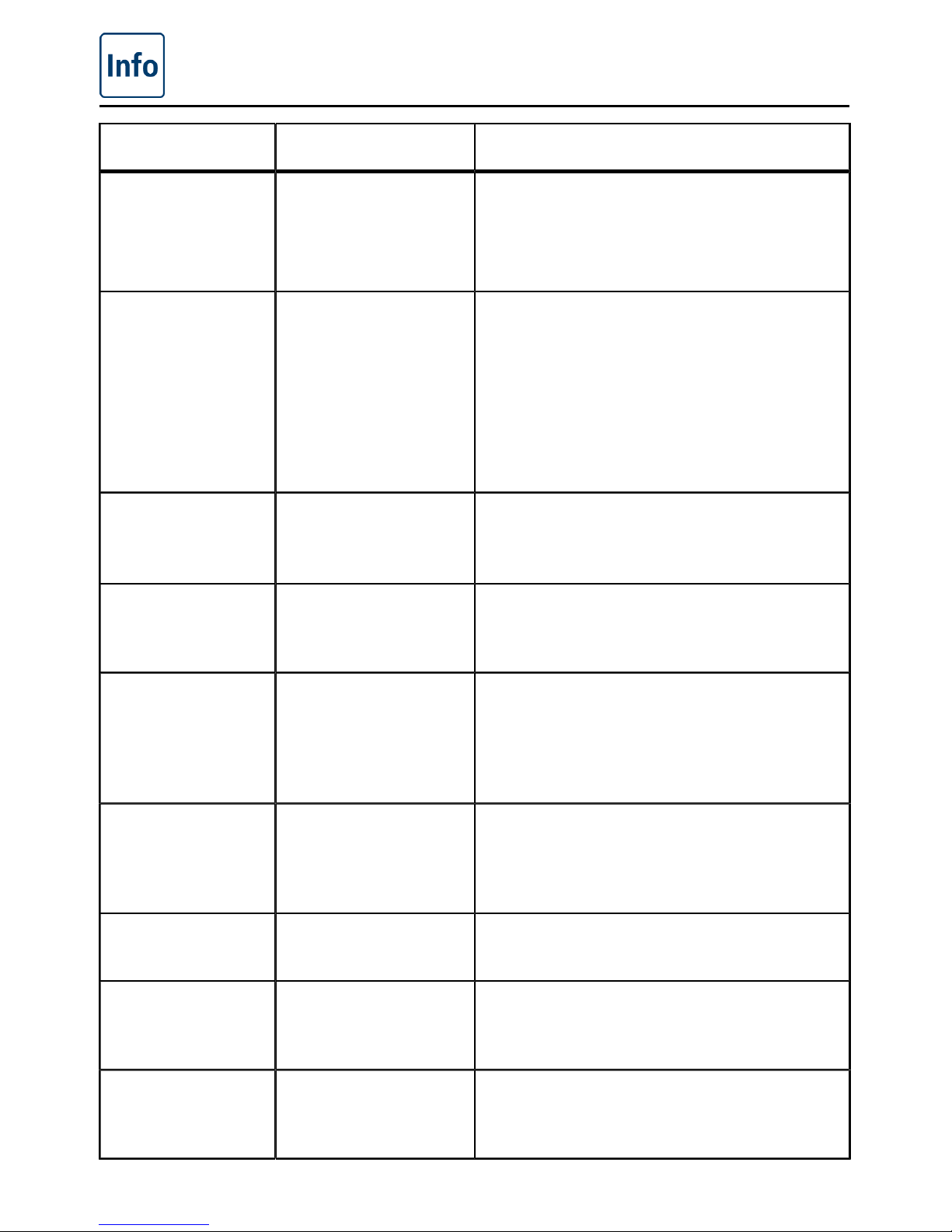

Page 50

Fault messages

50 / 61

fault indication when and how remedial action

cooking cabinet thoroughly with the hand

shower (also behind the air baffle).

- The unit can be used for cooking

temporarily.

Please notify Customer Service.

Service 26 Displayed

continuously.

If the fault message occurs during CleanJet

®

cleaning, please run "Interrupt CleanJet

®

. If

the fault message continues to be displayed

after running "Interrupt CleanJet

®

", remove

the tabs from the cooking cabinet and rinse

the cooking cabinet thoroughly with the hand

shower (also behind the air baffle). Please

notify Customer Service.

Service 27 When it has been

switched on for 30

seconds,

CleanJet

®

+care is not possible. Switch off

the power at the mains for 5 seconds, then

switch on again.

Service 28 When it has been

switched on for 30

seconds,

Please notify Customer Service.

Service 29 Displayed

continuously.

Check the air filter under the control panel,

and replace if necessary. Check whether

the unit is being affected by an external heat

source. If the service message persists,

notify Customer Service.

Service 31 When it has been

switched on for 30

seconds,

Core temperature probe is defective. The

unit can be used for cooking without the core

temperature probe. Please notify Customer

Service.

Service 32 Gas

units

Displayed

continuously.

Close the gas valve. Please notify Customer

Service.

Service 33 Gas

units

This is displayed

continuously after

being reset 4 times.

Close the gas valve. Please notify Customer

Service.

Service 34 Displayed

continuously.

Follow any requests shown on the display,

if the fault is not eliminated, please notify

Customer Service.

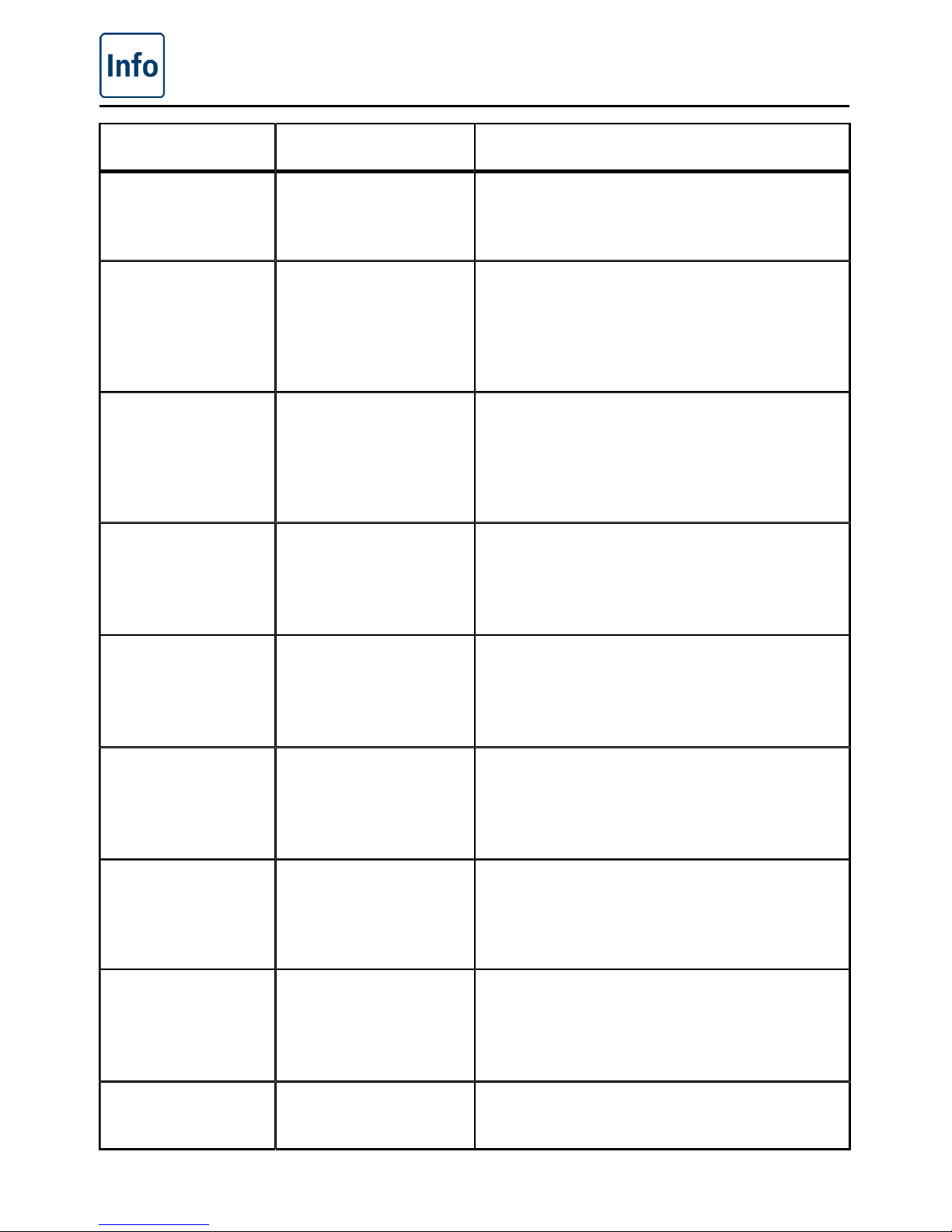

Page 51

Fault messages

51 / 61

fault indication when and how remedial action

Service 35 When it has been

switched on for 30

seconds,

Please connect UltraVent

®

to the power

supply.

Service 36 Displayed for 30

seconds after

switch-on and when

operating mode is

changed.

Cooking only possible with some restrictions

– Notify Customer Service.

Service 37 Displayed for 30

seconds after

switch-on and when

operating mode is

changed.

Cooking only possible with some restrictions

– Notify Customer Service.

Service 40 Displayed for 30

seconds during

CleanJet

®

+care

cleaning.

Restart CleanJet

®

+care cleaning. If the

error occurs again, please contact Customer

Service.

Service 41 Displayed for 30

seconds during

CleanJet

®

+care

cleaning.

Restart CleanJet

®

+care cleaning. If the

error occurs again, please contact Customer

Service.

Service 42 Displayed for 30

seconds during

CleanJet

®

+care

cleaning.

Restart CleanJet

®

+care cleaning. If the

error occurs again, please contact Customer

Service.

Service 43 Displayed for 30

seconds during

CleanJet ®+care

cleaning.

Restart CleanJet

®

+care cleaning. If the

error occurs again, please contact Customer

Service.

Service 44 Displayed for 30

seconds during

CleanJet

®

+care

cleaning.

Restart CleanJet

®

+care cleaning. If the

error occurs again, please contact Customer

Service.

Service 110 Displayed

continuously.

Please notify Customer Service.

Page 52

Fault messages

52 / 61

fault indication when and how remedial action

Service 120 Displayed

continuously.

Please notify Customer Service.

Page 53

Before you call Service:

53 / 61

error possible cause Rectification

Water dripping out of

the unit’s door.

Door is not closed

correctly.

If the door is closed correctly, the door

handle will point down on floor units.

Door seal is worn or

damaged.

Replace the door seal (see the

"Maintenance” section of the manual).

Care instructions for a maximum service

life:

- At the end of production, always

clean the door seal thoroughly with a

damp cloth.

- If lots of grilled products are cooked

(considerable build-up of grease),

then the door seal must also be

cleaned with a damp cloth between

cycles.

- If the unit is to be operated for a

long time without products, we

recommend that the cooking cabinet

temperature should not exceed 180

°C.

Noise is heard in the

cooking cabinet while

the unit is in use.

Air baffles, hanging

racks, etc., are not

fixed correctly.

Fix the air baffles and hanging racks

correctly in the cooking cabinet.

Cooking cabinet light

not working.

Halogen lamp is

defective.

Replace the lamp (see the

“Maintenance” section of the manual).

Low water level, water

tap symbol is flashing.

Water tap closed. Open the water tap.

Water intake filter on

the unit is clogged.

Check and clean the filter. To do this:

Close the water tap, unscrew the water

intake on the unit, then remove and

clean the filter in the water intake. Insert

the filter, connect the water intake and

check for leaks.

Water running out of

the bottom of the unit.

The unit is not level. Level the unit using a spirit level (see

Installation Manual).

Drain is blocked. Remove and clean the outlet (HT pipe)

on the back of the unit. Blockages can

occur if products with a high proportion

Page 54

Before you call Service:

54 / 61

of fat are cooked frequently or if the

drop on the outlet pipe is too shallow.

To remedy: Run the outlet pipe as

described in the installation instructions.

Clean the unit regularly with CleanJet

®

+care.

The unit does not

indicate a function

after it is switched on.

External main switch is

switched off.

Switch on at the main switch.

Fuse on the premises’

distribution board has

tripped.

Check the fuses on the premises’

distribution board.

The ambient

temperature after

switching the unit off

remained below 5 °C

(41 °F) for a long time.

Heat the cooking cabinet to above 20

°C (68 °F). The appliance must only

be used in frost-free conditions (see

installation instructions).

Foam forms on the

unit at the top of the

outlet pipe during

CleanJet

®

+care

cleaning.

Water is too soft.

Please notify Customer Service.

The outlet is not

installed correctly.

Install the outlet as described in the

installation manual.

The run time is

suddenly incremented

once more during

a CleanJet

®

+care

process.

The CleanJet

®

+care

process is interrupted.

Make sure that the air baffle and the

grid shelves are fixed correctly in the

cooking cabinet. There must be no

containers or sheets in the cooking

cabinet during the CleanJet

®

+care

process.

Device indicates

“Please replace filter”.

The air filter is soiled. Please replace the air filter. See also

the “Maintenance” section. Press the

“back” arrow to confirm the message.

The gas unit indicates

“change polarity”.

The power supply is

not connected with the

correct polarity.

If the gas unit is connected to a socket,

remove the connector and turn through

180°.

Have an electrician permanently

connect the unit with the correct polarity

(without a connector).

Page 55

Before you call Service:

55 / 61

Gas unit constantly

displays Reset.

The gas supply to the

unit is interrupted.

Open the gas tap, switch on the

ventilation cover.

The gas pressure is

too low.

Have the gas supply to the unit

checked.

Cooking mode button

flashing.

The cooking cabinet is

too hot.

Use Cool Down to cool the cooking

cabinet (see the “Cool Down” section of

the “General User Instructions” manual).

Page 56

Club RATIONAL

56 / 61

As an active SelfCookingCenter

®

whitefficiency

®

user we would like to warmly invite you

to attend the Academy RATIONAL day seminar. Here you can experience in a relaxed

atmosphere how you can use the SelfCookingCenter

®

whitefficiency

®

optimally and

efficiently in your kitchen. Dates and locations as well as your personal invitation can be

obtained through your specialist retailer or directly from: www.club-rational.com. Participation

in the seminar is free of charge.

Register now and become a member.

Members of the Club RATIONAL also have access to a wide range of information and free

downloads, and can also communicate with RATIONAL chefs or colleagues. Register for the

club now under www.club-rational.com. Membership of Club RATIONAL is also free.

Your club benefits at a glance:

Free upgrades

So you always have the latest SelfCookingCenter

®

software

Recipes – simply at the push of a button

The best recipes for your SelfCookingCenter

®

whitefficiency

®

!

Download area

Documentation for all unit series

Chef Line also by e-mail

Expert help from one chef to another

Service Info also by e-mail

RATIONAL Service – always there for you

Quarterly newsletter

So you are always well-informed

Frequently-Asked Questions

What you've always wanted to know

Register right away!

www.club-rational.com

Page 57

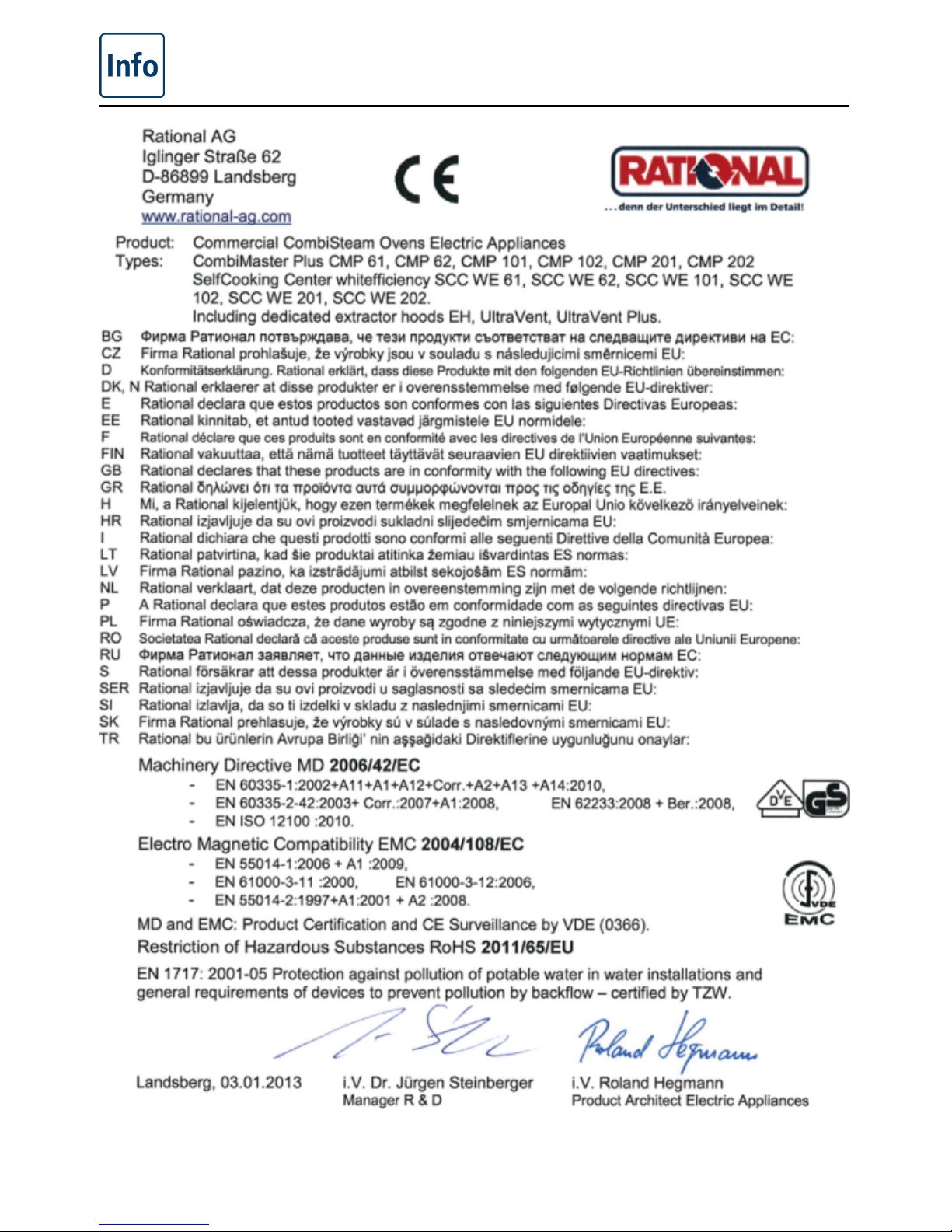

EU Declaration of Conformity for electrical

appliances

57 / 61

Page 58

EU Declaration of Conformity for gas appliances

58 / 61

Page 59

...

59 / 61

SelfCooking Center

®

whitefficiency

®

, CombiMaster

®

Plus are trademarks of RATIONAL AG.

This product incorporates the following software:

1. the software developed independently by RATIONAL AG

2. the software licensed under the GNU Gerneral Public License, Version 2 (GPL v2)

3. the software licensed under the GNU LESSER General Public License, Version 2.1 (LGPL

v2.1) and/or,

4. open sourced software other than the software licensed under the GPL v2 and/or LGPL

v2.1

For the software categorized as (3), (4) and (5), please refer to the terms and conditions of

GPL v2 and LGPL v2.1, as the case may be at

http://www.gnu.org/licenses/old-licenses/gpl.-2.0.html and

http://www.gnu.org/licenses/old-licenses/lgpl-2.1.html

At least three (3) years from delivery of products, RATIONAL AG will give to any third party

who contact us at the contact information provided below, for a charge no more than our cost

of physically performing source code distribution, a complete machinereadable copy of the

corresponding source code covered under GPL v2/LGPL v2.1.

Contact Information:

sourcecode@rational-online.com

Page 60

80.05.002 · V-04 · MDS/Ad · 08/13 · englisch

Loading...

Loading...