Rational CombiMaster Plus series, CombiMaster series, SelfCookingCenter WE series, SelfCookingCenter XS series Installation Manual

SelfCookingCenter®

CombiMaster® Plus

CombiMaster®

Original Installation Manual

2

Contents

Contents

Unit type 4

1 Introduction 5

1.1 About this manual 5

1.2 Warnings used 7

1.3 Warranty 8

2 Safety instructions 9

3 Installation instructions 11

4 Unit transportation 13

5 Setting up the unit 16

5.1 Unit dimensions 16

5.2 Minimum distances 18

5.3 Securing the unit 22

5.3.1 Tabletop units 22

5.3.2 Floor units 28

6 Electrical connection 33

6.1 General information 33

6.2 Electrical units 35

6.3 Gas units 35

6.4 Power supply cable 37

6.5 Equipotential bonding (physical earth ground) 38

6.6 Voltage Conversion 39

6.7 Connection values 41

7 Water connection 43

7.1 Prerequisites 43

7.2 Unit water connection 44

7.3 Water treatment 45

7.4 Selecting water filters 46

3

8 Gas connection 48

9 Exhaust gas connection 53

10 Wastewater connection 55

11 Ventilation, technical data, heat dissipation 58

12 Initial start-up 60

13 Options 63

14 Conversion tables 72

Contents

4

Unit type

_____________________________________

______________________________________

______________________________________

_____________________________________

Dealer

Installer

Specify for all queries:

Appliance model

Unit no.:

Set to gas type:

Your unit was checked by:

Unit type

Unit type

5

1 Introduction

1 Introduction

1.1 About this manual

> This installation manual is part of and shipped

with the unit, and contains information on its

safe installation.

> Read this installation manual completely

before installing the unit.

> This installation manual must be kept available

to installers at all times at the installation location.

> Keep this installation manual on hand

throughout the entire life of the unit.

> This installation manual is to be passed on to

any subsequent owners/operators of the unit.

Target group The target group for this installation manual are

knowledgeable technicians who are familiar with

the process of installing and operating the unit.

Illustrations All illustrations in this manual are examples only.

Deviations between these illustrations and the

unit on site are possible.

We reserve the right to make technical changes in the interest of progress!

© 2017 Rational Technical Services. All rights reserved. Forwarding product-specic

information to third parties is prohibited.

6

1 Introduction

This manual applies to the following units:

> all SelfCookingCenter® WE units

> SelfCookingCenter® XS

> all CombiMaster® Plus units

Abbreviations used in this manual:

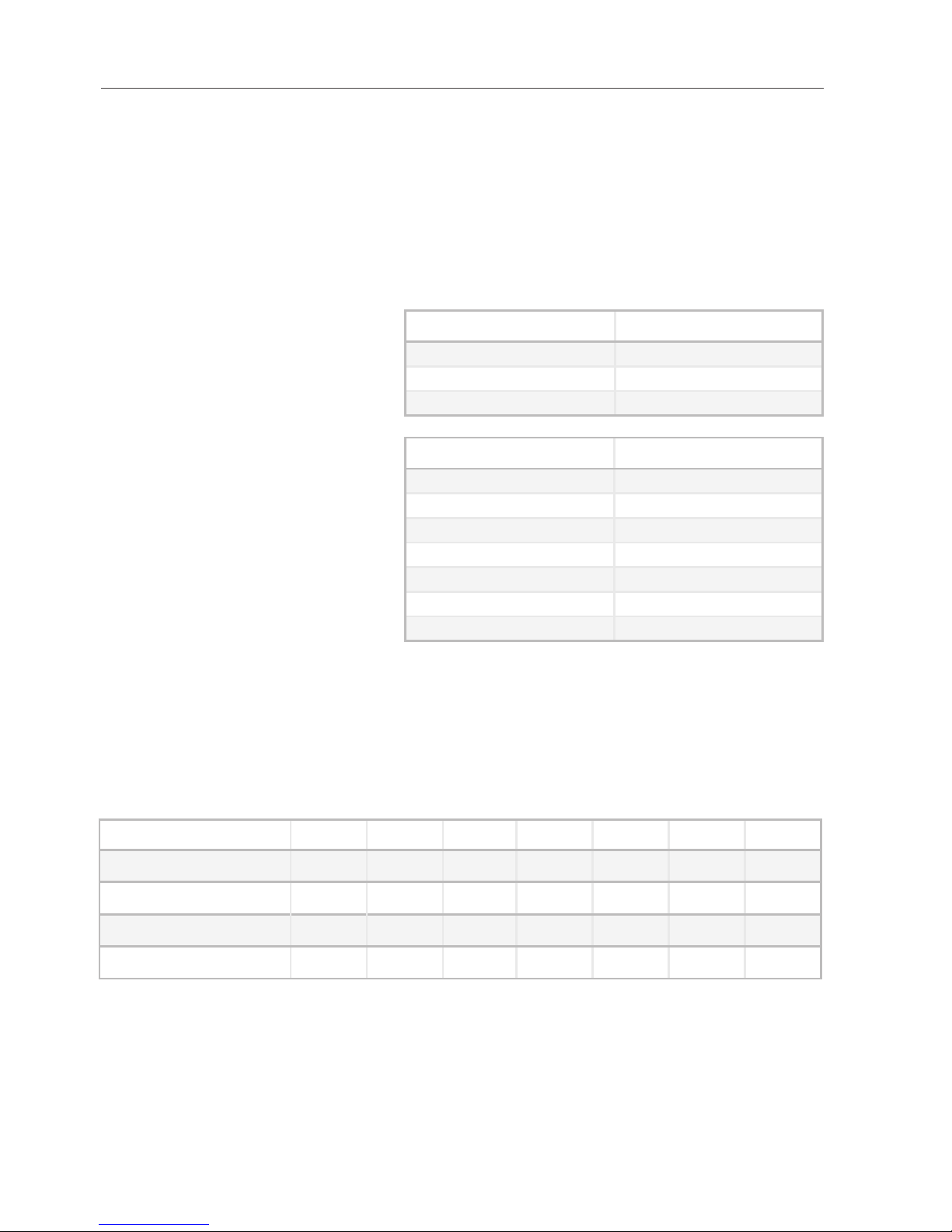

Product name Abbreviation used

SelfCookingCenter® WE SCC

SelfCookingCenter® XS SCC

CombiMaster® Plus CMP

Appliance size Abbreviation used

6 x 2/3 GN 60

6 x 1/1 GN 61

6 x 2/1 GN 62

10 x 1/1 GN 11

10 x 2/1 GN 12

20 x 1/1 GN 21

20 x 2/1 GN 22

Unit sizes 60, 61, 62, 11, and 12 are referred to collectively as tabletop units.

Unit sizes 21 and 22 are referred to collectively as floor units.

Device overview:

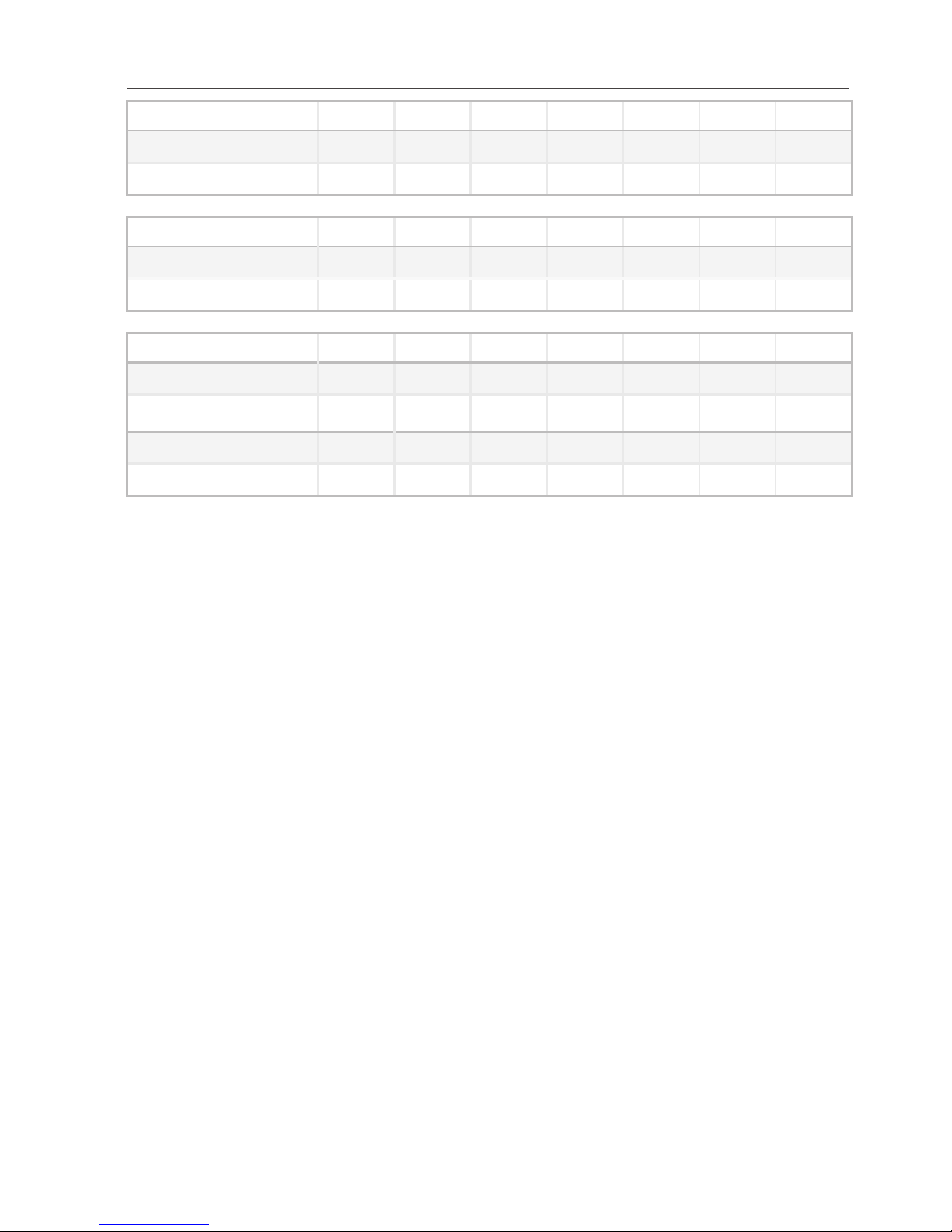

60 61 62 11 12 21 22

SCC Elektro

x x x x x x x

SCC Gas

x x x x x x

CMP Elektro

x x x x x x x

CMP Gas

x x x x x x

7

1 Introduction

1.2 Warnings used

DANGER

Hazardous situation that may result in severe

injury or death.

WARNING

Hazardous situation that could potentially

result in serious injury or death.

CAUTION

Hazardous situation that could result in minor

injury.

CAUTION

Fire hazard!

CAUTION

Danger of burns!

CAUTION

Corrosive chemical substances!

DANGER

High voltage.

Caution, danger to life

Non-compliance can result in severe injury or

death.

NOTICE

Non-compliance may result in material damage.

8

1 Introduction

1.3 Warranty

Exceptions to the warranty include

> Damage to glass, light bulbs and gaskets,

> Damage resulting from improper use, installa-

tion, maintenance, repair or descaling,

> Use of the unit for purposes other than those

for which it is intended,

> Modifications or technical alterations to the

unit not authorized in writing by the manufacturer,

> Usage of non manufacturer-original service

components,

> Damage resulting from failure to observe the

installation instructions in this manual.

9

2 Safety instructions

2 Safety instructions

Incorrect installation > Incorrect installation, service, maintenance

or cleaning of this unit can result in damage,

injury or death, as can modifications to the

unit. Read the installation manual carefully

prior to installation.

Unit usage > The unit may only be used for purposes of

cooking food in commercial kitchens. All other

uses are counter to its intended purpose, and

may be dangerous.

Gas appliances

WARNING

Combustion gases!

When installing under an exhaust hood: Ensure

to switch the exhaust hood on when the unit is

in operation and it is operational.

> Do not place anything near or atop the unit’s

exhaust pipes.

10

2 Safety instructions

Operating personnel > This unit must not be used by children or by

persons with reduced physical, sensory or

mental capabilities, or by persons with insufficient experience and/or knowledge, unless

such persons are under the supervision of

another person who takes responsibility for

their safety.

> To avoid accidents or damage to the unit, it is

imperative that operating personnel receive

regular training and safety instructions.

Explosion hazard

WARNING

Explosion hazard

If you smell gas:

> Shut off gas supply immediately,

> Do not turn on or off any electrical switching

devices,

> Ventilate the room well,

> Avoid any open flames or sparks,

> Use a telephone outside the affected ares to

inform the gas provider immediately. If the

gas provider cannot be reached, call the local

fire department.

11

3 Installation instructions

3 Installation instructions

Standards > Local and country-specic standards and reg-

ulations regarding the installation and operation of commercial cooking appliances must

be observed at all times.

> In all other countries, the corresponding

country-specic standards and regulations

are to be observed.

Liability / Warranty > Damage occurring as a result of non-compli-

ance with installation instructions is excluded

from the warranty.

> Installations and repairs not carried out by

authorized professionals or not using original

spare parts, and technical modications to

the unit which are not approved by the manufacturer in writing, void the manufacturer’s

warranty and product liability.

Conformity > Unit conformity is in reference to the overall

unit at the time of delivery. The operator is

responsible for ensuring extended conformity following any expansions/connection of

additional functions.

Connection work > The necessary connections (water, electricity,

drain and gas) must only be set up by trained

professionals in accordance with local regulations.

Prior to installation > Check the unit for transport damage.

If you suspect the unit has been damaged in

transit, contact your dealer/freight forwarder

immediately! Ensure to note damage at time

of delivery on bill of lading with the driver.

Disposing of old appliances > When the unit reaches the end of its service

life, it must not be taken to a municipal collection point for trash or used electrical appliances. Please conntact your service provider

for disposal.

12

3 Installation instructions

Air lter maintenance: > The unit automatically detects dirty air filters.

It will display a service prompt instructing you

to clean or replace the air filter.

> Never operate the unit without the air filter.

When replacing the air filter, please note:

Tabletop units The user may replace the air filter. To replace the

air filter, carefully latch the new filter into the

correct position. Follow the instructions in the

Building Equipment and Appliances chapter of

the user’s manual.

Unit size 60 Air filter part number: 40.04.771

Unit sizes 61, 62, 11 and 12 Air filter part number: 40.02.684

Floor units Air lters on these units must only be replaced by

authorized service partners.

i

NOTICE

Water protection class and reach-through protection on floor units are only guaranteed if air

filter and cover are correctly installed.

13

4 Unit transportation

4 Unit transportation

CAUTION

Risk of injury!

Unit may tip over.

When transporting: Secure the unit against

tipping.

21, 22: are top heavy.

CAUTION

Risk of injury!

Note unit weights.

Use lifting aids.

Wear safety shoes.

Weight (without packaging)

60 61 62 11 12 21 22

SCC Electro [kg] 72 111 145 136 189 266 343

SCC Electro [lb] 159 245 320 300 417 586 756

SCC Gas [kg] 130 173 159 205 294 381

SCC Gas [lb] 287 381 351 452 648 840

CMP Electro [kg] 62 103 147 132 182 254 334

CMP Electro [lb] 137 227 324 291 401 560 736

CMP Gas [kg] 114 160 143 196 284 354

CMP Gas [lb] 251 353 315 432 626 780

Unit size 60

i

NOTICE

Risk of damage to the unit!

When transporting unit, ensure that air filter

box and USB port remain undamaged.

14

4 Unit transportation

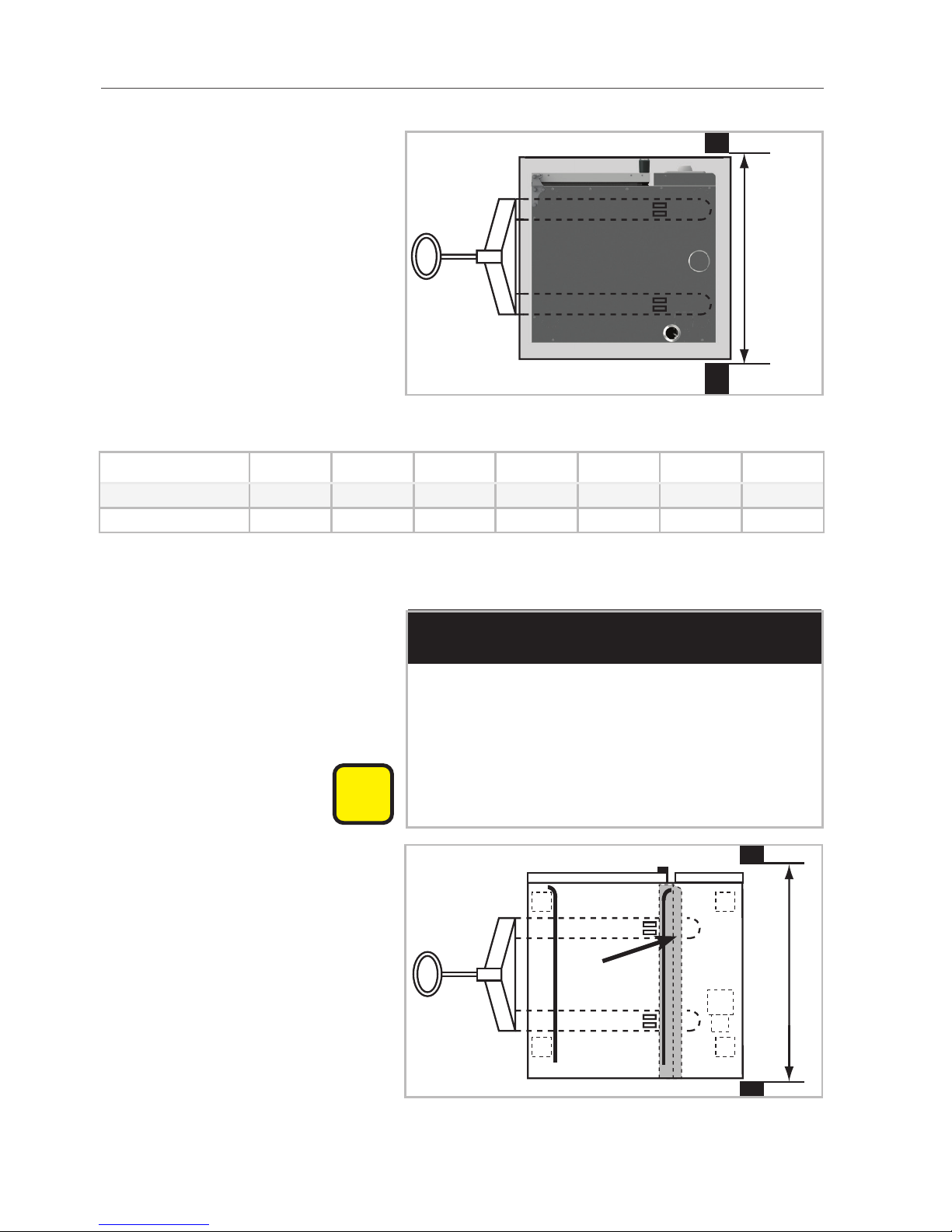

Transporting unit with pallet:

x

Note required door width:

Appliance size 60 61 62 11 12 21 22

x [mm] 880 920 1120 920 1120 950 1150

x [Inch] 34 3/4 36 1/4 44 1/8 36 1/4 44 1/8 37 1/2 45 1/4

Transporting unit without pallet:

i

NOTICE

Risk of damage to the unit!

Only floor units may be transported without a

pallet using pallet truck.

Lay wooden beams underneath in grey area

(see arrow).

x

15

4 Unit transportation

i

NOTICE

Risk of damage to the unit!

Tabletop units not secured with a pallet should

only be transported using carrying straps.

Note required entrance width:

Appliance size 60 61 62 11 12 21 22

x [mm] 630 845 1045 845 1045 925 1145

x [Inch] 24 6/8 33 1/4 41 1/8 33 1/4 41 1/8 36 3/8 45 1/8

Center of gravity Keep the unit’s center of gravity in mind to pre-

vent it from tipping over (especially unit sizes 21,

22).

i

NOTICE

Risk of damage to the unit!

Note height of entrances.

16

5 Setting up the unit

5 Setting up the unit

5.1 Unit dimensions

xy

z

xy

z

xy

z

17

5 Setting up the unit

Width x 60 61 62 11 12 21 22

SCC, CMP [mm] 657 847 1069 847 1069 879 1084

SCC, CMP [Inch] 25 7/8 33 3/8 42 1/8 33 3/8 42 1/8 34 5/8 42 5/8

Depth y 60 61 62 11 12 21 22

SCC, CMP [mm] 623 843 1043 843 1043 909 1114

SCC, CMP [Inch] 24 1/2 33 1/4 41 1/8 33 1/4 41 1/8 35 3/4 43 7/8

Height z 60 61 62 11 12 21 22

SCC, CMP el. [mm] 598 832 832 1092 1092 1842 1842

SCC, CMP el. [Inch] 23 1/2 32 3/4 32 3/4 43 43 72 1/2 72 1/2

SCC, CMP gas [mm] 832 832 1092 1092 1842 1855

SCC, CMP gas [Inch] 32 3/4 32 3/4 43 43 72 1/2 73

18

5 Setting up the unit

5.2 Minimum distances

i

NOTICE

Unit overheating may cause material and unit

damage!

If the ambient temperature to the left of the

unit becomes too high, it may trigger an emergency shutdown of the unit.

i

NOTICE

Unit overheating may cause material and unit

damage!

Do not install fryers to the rear of the unit.

i

NOTICE

Frost may cause unit damage!

Only install units in frost-proof rooms.

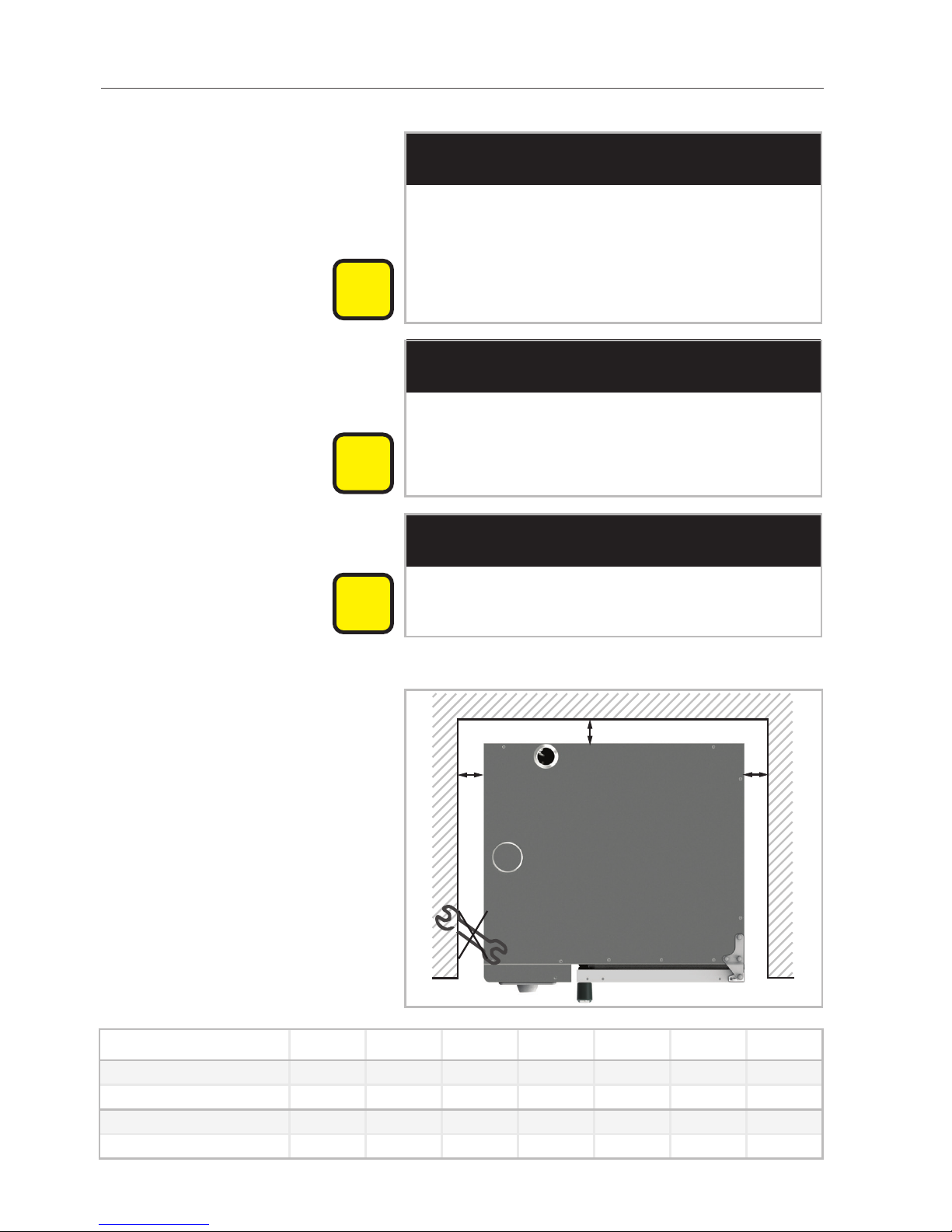

Minimum distance to walls

x

x

y

Appliance size 60 61 62 11 12 21 22

x [mm] 10 50 50 50 50 50 50

x [Inch] 1/2 2 2 2 2 2 2

y [mm] 10 50 50 50 50 500 500

y [Inch] 1/2 2 2 2 2 20 20

19

5 Setting up the unit

Recommendation At least 20” [500 mm] away from left side of the

unit so that service work can be performed.

500 mm

/20"

Minimum distance to other units Minimum 14” [350 mm] distance between left

side of the unit and heat sources.

350 mm/

14”

Heat shield To reduce thermo loads to the unit heat shields

can be used (see options).

20

5 Setting up the unit

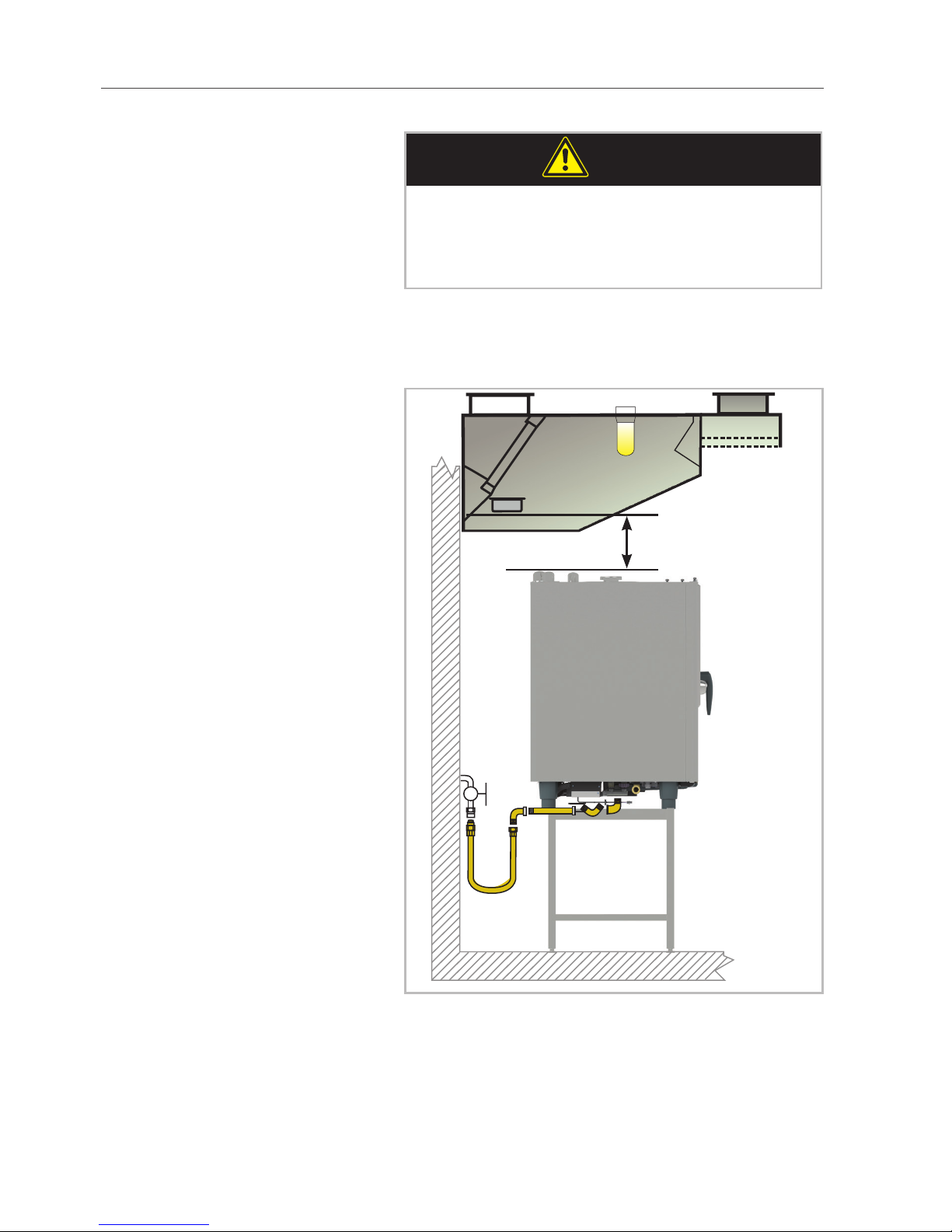

Minimum distance to ceiling

CAUTION

Fire hazard!

Keep minimum clearance between unit and

ceiling.

Gas units: Recommended 16” (400 mm) clearance from

unobstructed rear exhaust pipes and any surface

collecting grease or flammable material.

LEFT SIDE VIEW

minimum

clearance 16“

Gas unit

21

5 Setting up the unit

Electric units: Recommended 10” (254 mm) clearance from

unobstructed rear vent pipes and any surface collecting grease or flammable material.

LEFT SIDE VIEW

Electric unit

minimum

clearance 10“

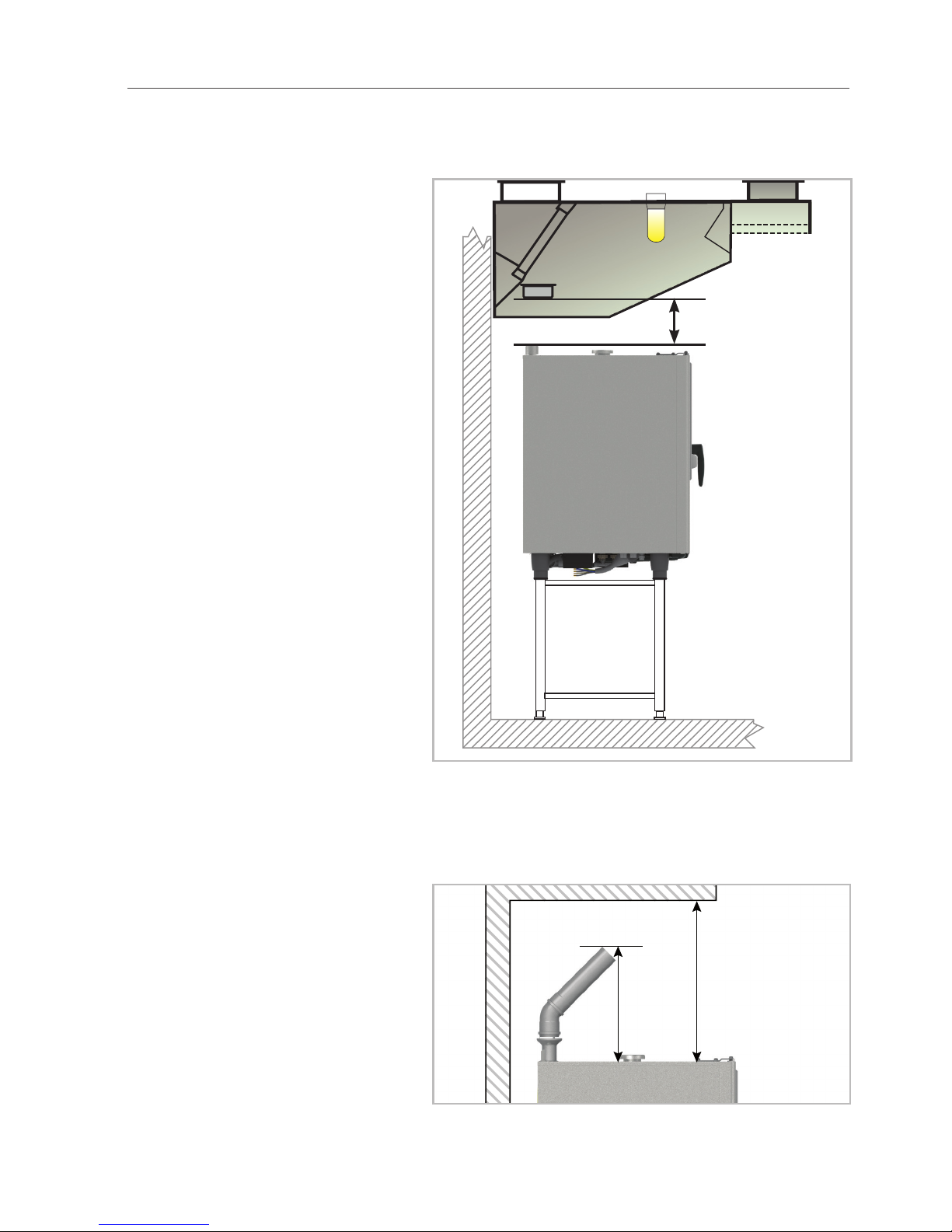

If steam from the venting pipe cannot be direct-

ed into an exhaust hood or a ventilating ceiling,

there must be at least 20” [500 mm] clearance

space above the unit.

min. 20”

[500 mm]

min. 18”

[460mm]

22

5 Setting up the unit

Condensation breaker This clearance space is sufficient to install a

condensation breaker so that exhaust air can be

directed into non-critical areas.

Other

i

NOTICE

Unit malfunction!

Avoid steam or grease sources near the cooling air filter. Moisture intake may result in unit

malfunctions.

5.3 Securing the unit

5.3.1 Tabletop units

For safety reasons, tabletop units should only be

placed atop a manufacturer-original oven stand

or base unit. Maximum working height for the

topmost rack is 63” [1600 mm].

Unit size 60 These units do not have height-adjustable feet;

instead, they are set up directly on the installation surface.

The installation surface must be level, clean and

free of grease. Unevenness across the width of

the unit must be no greater than 0.04” [1 mm].

A sealant band is affixed to the underside of the

unit to seal the installation site. This prevents dirt

from getting underneath the unit. When moving

the unit, take care not to damage this seal.

Mounting onto an oven stand:

Insert the two included neoprene blind rivet nuts

into the holes in the rear part of the underbody.

Place the unit onto the oven stand.

Secure in place using the screws provided.

23

5 Setting up the unit

Unit sizes 61, 62, 11, 12 > Place the unit onto the stand. Catching the

feet of the unit in place using the locating pins

on the stand.

Loading...

Loading...