Rational SelfCookingCenter whitefficiency, SCC_WE Training Manual

Training Manual

SelfCookingCenter® whitefficiency® (SCC_WE)

V02 en, SCC_WE

General hints:

Isolate the appliance from mains supply before opening the appliance

When working with chemicals, i.e. aggressive cleaning materials

always wear protective clothing, goggles and gloves!

After maintenance / repair the appliance must be checked for electrical

safety in accordance with your national, state and local requirements!

Whenever working on any gas component like:

Gas valve, gas blower and / or changing connected type of gas a detailed

ue gas analysis MUST be done using adequate CO and CO2

measuring equipment! This shall ONLY be done by trained technicians!

Always check appliance for possible gas leakages!

© 2011 Rational Technical Services. All rights reserved.

Please note that any technical information concerning Rational products

must NOT be forwarded to any third party.

List of content

Introduction

Basic principle SCC_WE 4

Parts location 5

Changes of the unit 9

Operator panel SCC_WE 10

Operator panel SCC_WE: Manual Modes 11

Survey Pictogram 12

Water level control steam generator SCC_WE 16

SC (Self Clean) Automatic 17

Control panel SCC_WE and display

SCC_WE Electric (Index H): Basic principle 18

Manual modes SCC_WE / Boiling point recognition 19

Control (1)

Selftest 20

Humidity control SCC_WE 22

SCC_WE CPU 24

SCC_WE CPU - Terminal connection - LED Code 25

SD card - Changing PCB, new SD card 26

V02 en, SCC_WE - 2 -

List of content

Control (2)

Fan motor SCC_WE Line 29

Bus connection 30

SolidStateRelay (SSR) internal design / Test 31

SSR 100% - 50% power at 3NAC/400V 32

SSR 100% - 50% power at 3AC 200-240V 33

Control of cooling fan 34

Control of drain valve 35

CDS 36

CareControl 37

Function during CleanJet+Care 38

Service Package

CleanJet: Error messages - Abort program 39

Diagnose - Real Time Data - Start 40

Diagnose - Real Time Data - Content 41

Diagnose - Running times - Start 42

Diagnose - Running times - Content 43

Diagnose - Service error history - Start 44

Diagnose - Service error history - Content 45

Basic settings - Start 46

Basic settings - Content 47

Function test - Start 48

Function test - Content 49

Calibration - Start 50

Calibration - Sequence 51

Setting Show mode - error analysis 53

Error message Service 1 - 25 54

Error message Service 26 - 37 55

Error message Service 40 - 120, blink code motor 56

SCC Software update 57

Download of service data 60

Download of HACCP Data 64

Circuit diagram

Circuit diagram 101 Power 3NAC 400-415V 66

Circuit diagram 101 Heating 3NAC 400-415V 67

Circuit diagram 101 Sensor 68

Circuit diagram Bill of material 69

Circuit diagram 202 Power 3NAC 400-415V 71

Circuit diagram 202 Heating 3NAC 400-415V 72

Circuit diagram 202 Sensor 73

Circuit diagram Bill of material 74

- 3 - V02 en, SCC_WE

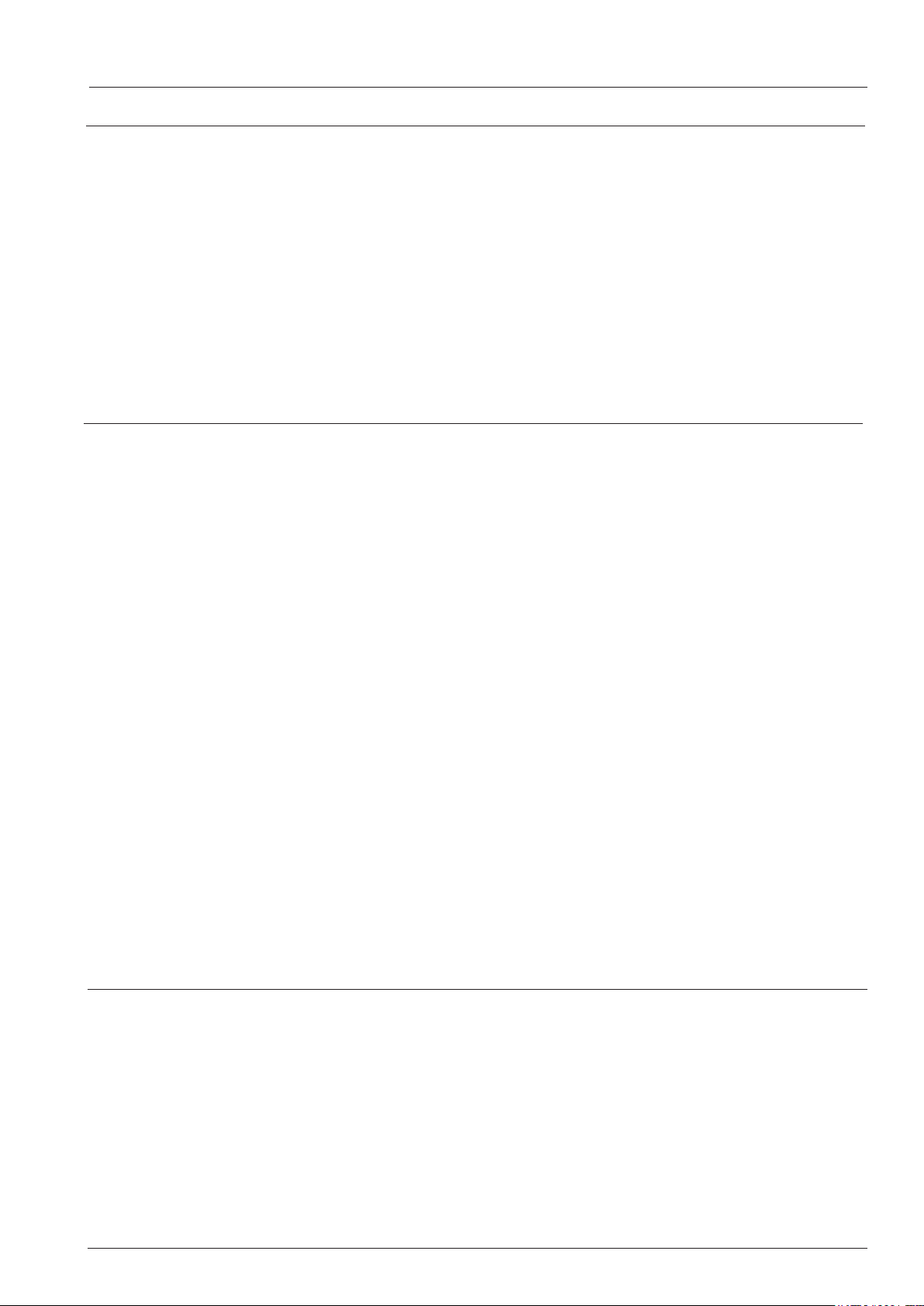

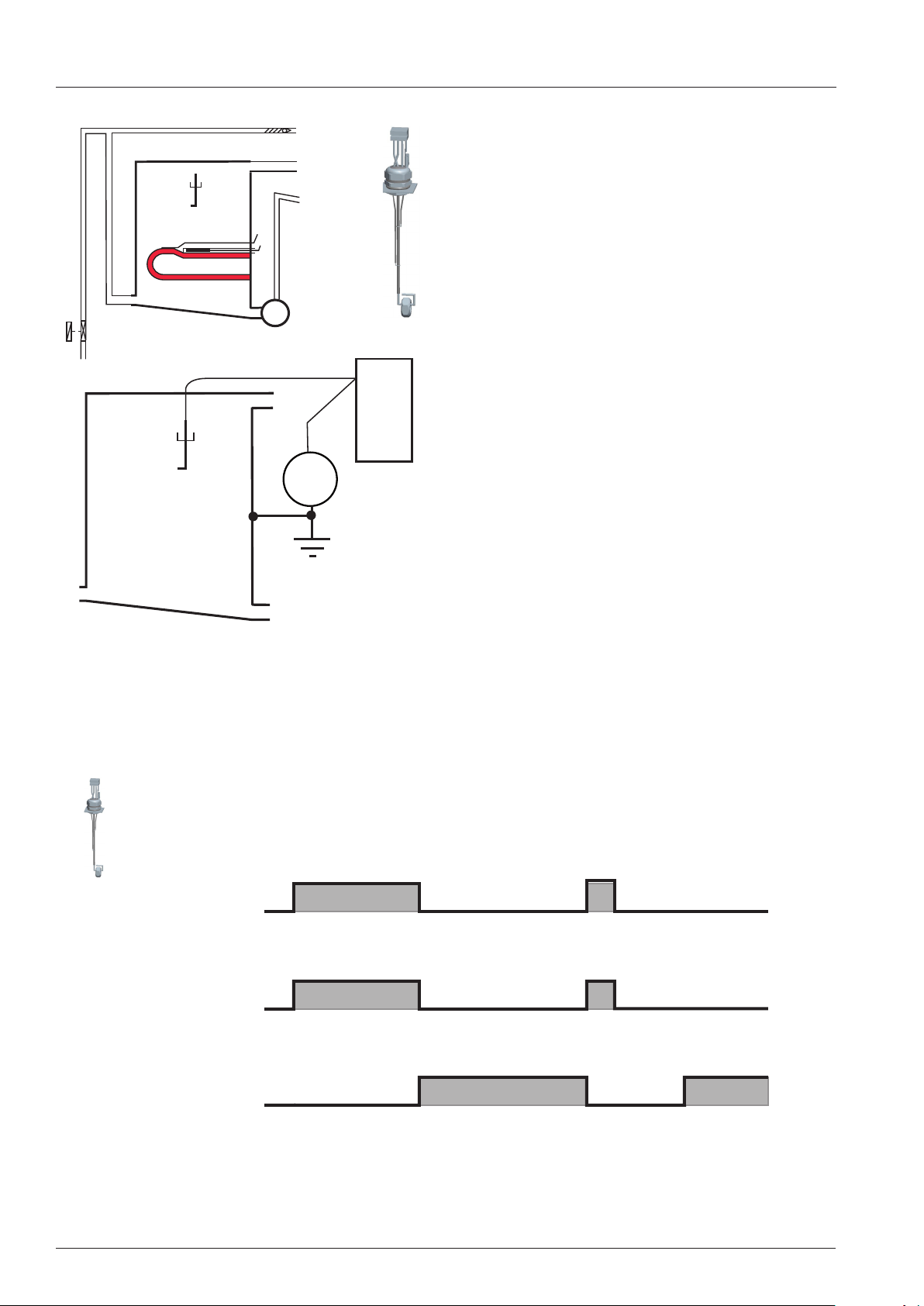

Basic principle SCC_WE

B1

Solenoid filling

Y1

S11

Steam element

Steam generator

Solenoid

moistening

Y3

Solenoid

quenching

Water supply

S2

Level

electrode

Thermocouple

steam generator

Self Clean (SC) pump

Solenoid

Care

Y4

Y2

Check valve

B5

F3

Care

B2

Drain

Safety

thermostat

steam generator

M4

M12

Care pump

Thermocouple

quenching

Venting pipe

S12

M7

Emergency drain

Drain valve

Differential pressure

sensor

P1

Clima valve

Fan motor

Thermocouple humidity

B4

Quenching box

M6

Thermocouple cabinet

Y5

M1

Hot air

element

Door contact switch

Safety thermostat cabinet

F4

Core probe

Air baffle

S3

Hand shower roll guide

B3.1 - 3.6

Cabinet

V02 en, SCC_WE - 4 -

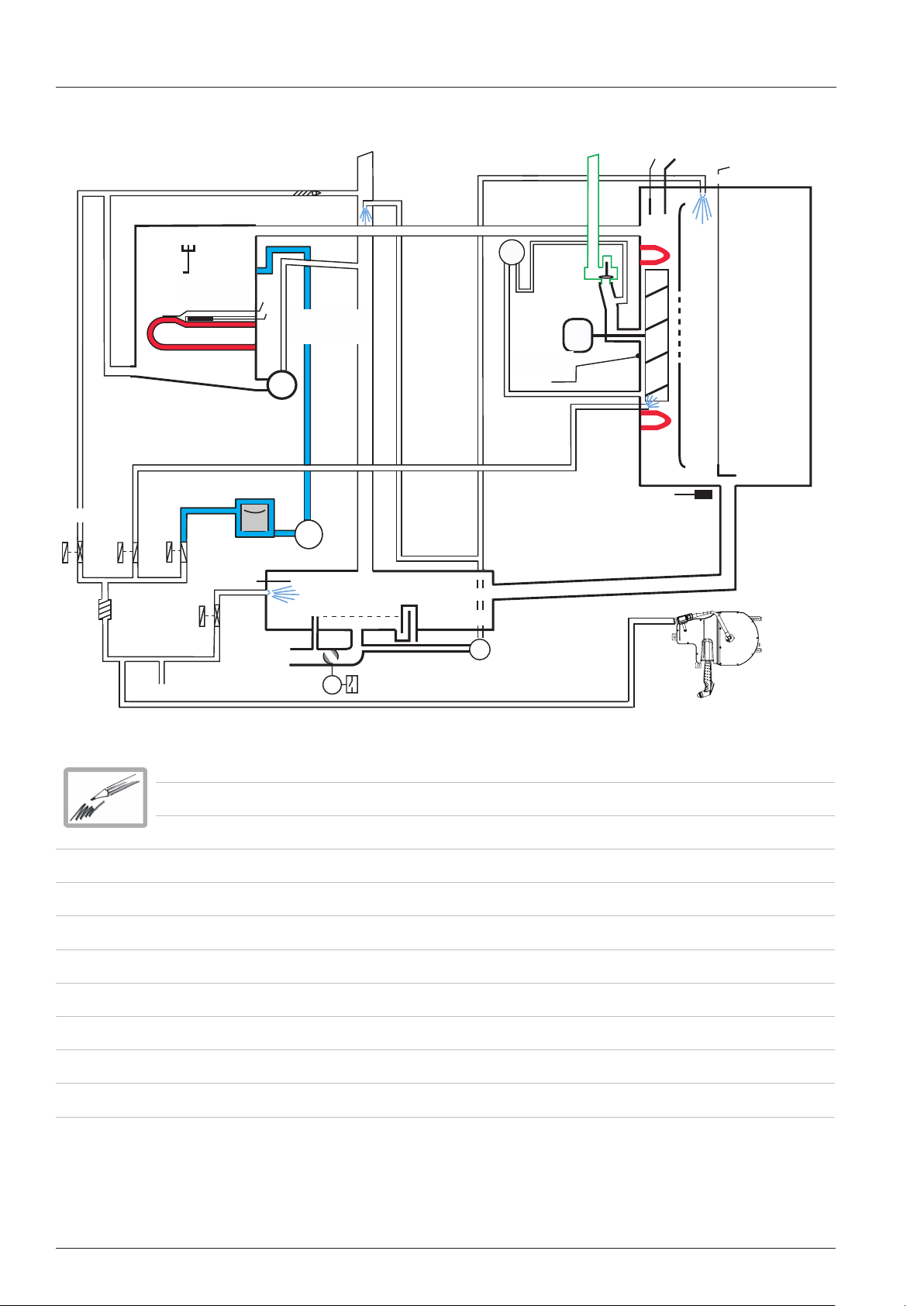

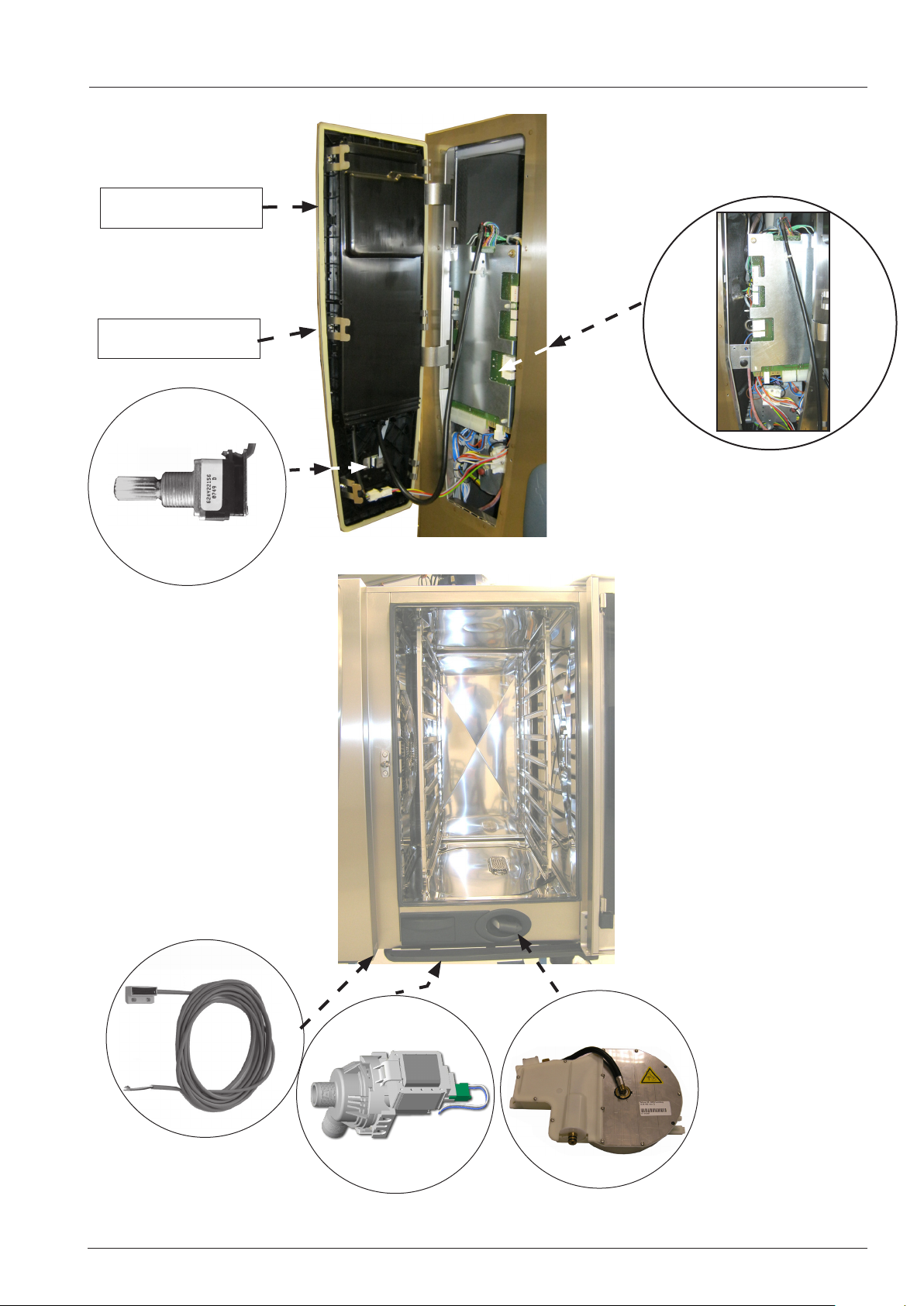

Parts location

Solenoid humidity (Y5)

Differential pressure sensor (P1)

safety thermostat

steam generator

(F3)

level electrode S2

Thermocouple steam

generator (B5)

safety thermostat

cabinet (F4)

CDS (S11)

triple solenoid

Y1 lling - Green

Y3 moistening - Brown

Y4 Care valve - Orange

- 5 - V02 en, SCC_WE

Parts location

Quenching nozzle and

Thermocouple B2

Drain valve

(M7 and S12)

Main contactor (K1)

Noise lter (Z1)

SSR (V1-)

CleanJet Pump

(M6)

SC Pump

(M4)

Solenoid Y2

quenching

Loud speaker T2

V02 en, SCC_WE - 6 -

Parts location

Interface PCB (A1)

TFT Display

Puls generator

(S6)

CPU (A2)

Door contact

switch (S3)

Care Pump

(M12)

- 7 - V02 en, SCC_WE

Hand shower roll

guide

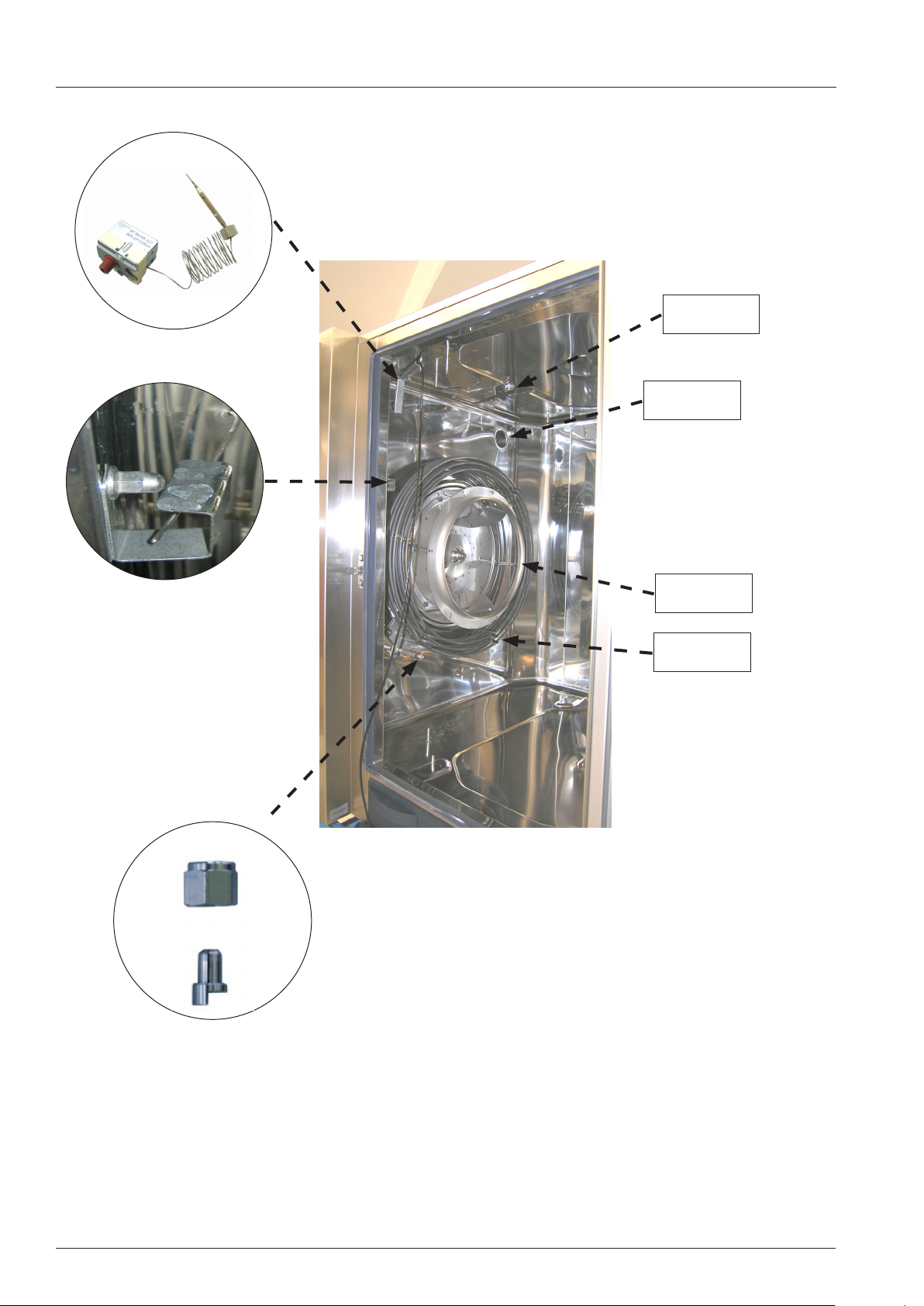

Parts location

Safety thermostat

cabinet (F4)

Cabinet sensor B1

CleanJet

nozzle

Steam inlet

Union nut

Moistening nozzle

Fan wheel

Hot air hea-

ting element

V02 en, SCC_WE - 8 -

Changes of the unit

Differences from SCC_WE (Index H) compared with SCC Index G

1. Unit self test after installation; all components are tested for correct function and determination of

boiling point;

2. Steam mode preset to boiling point (no hot air supply), 30-130°C possible (86 - 266°F)

3. New humidity control (Clima valve) for advanced dehumidification

4. New fan motor rotates left - right

5. New PCB and TFT touch display with Ethernet connection

6. Moistening nozzle integrated into hot air heating element flange of electric units

7. Modified cover for quenching box

8. Cooling fan is temperature controlled

9. Cleaning program „Light“ is split into „Light Quick“ duration approximately 1h 05min and

„Light standard“, duration approximately 1h 46min.

10. Operator and Application manuals are available on display;

- 9 - V02 en, SCC_WE

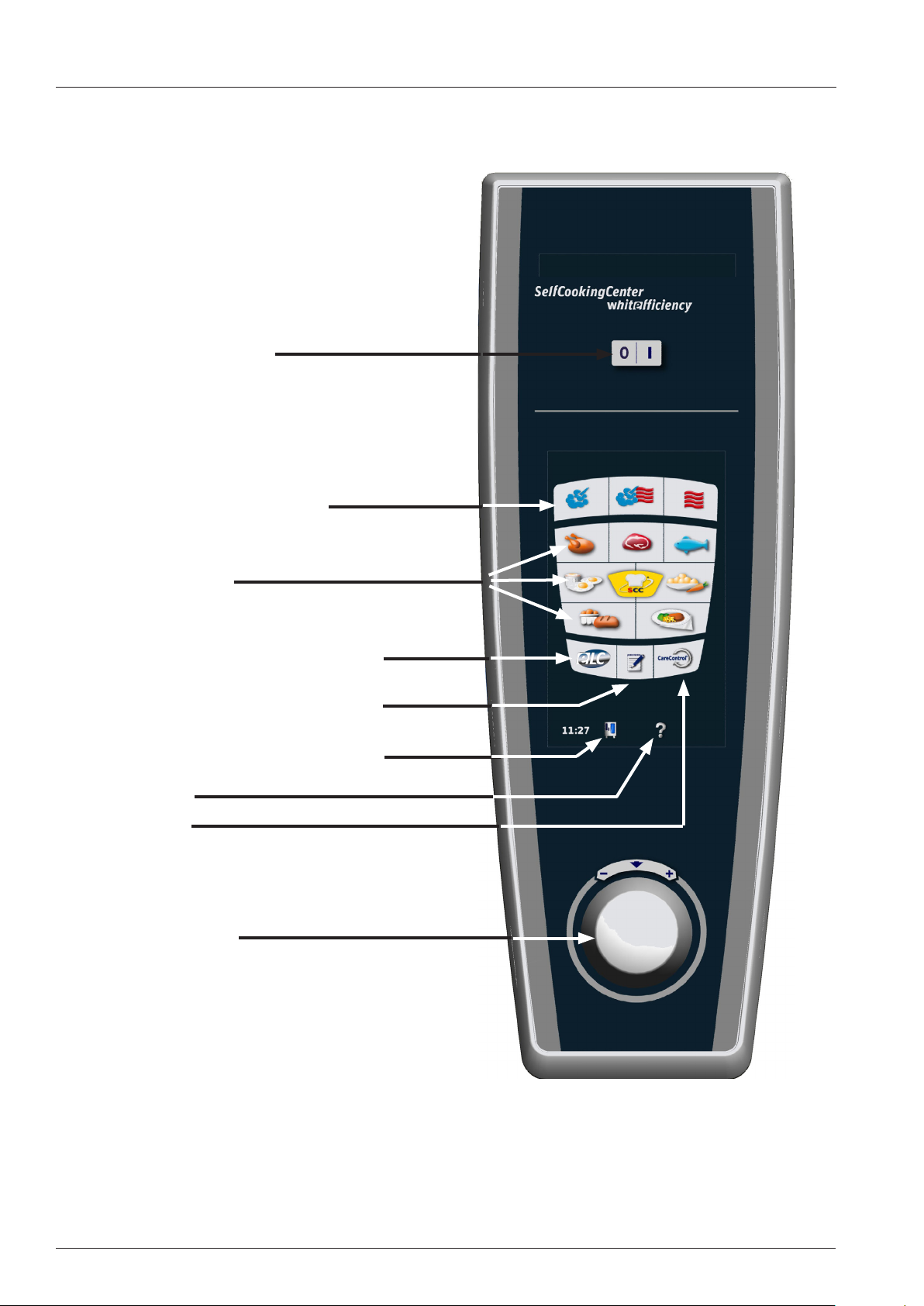

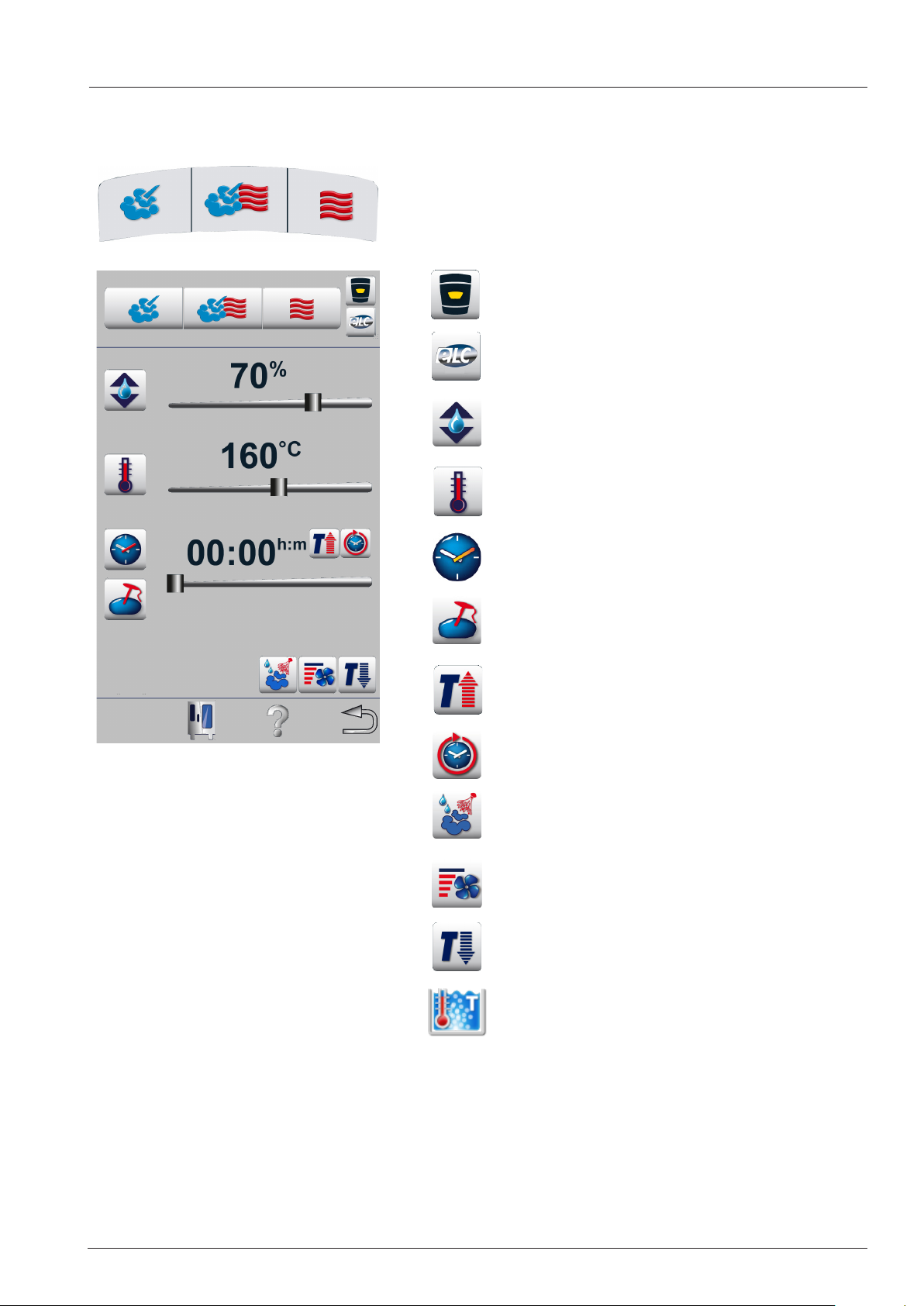

Operator panel SCC_WE

ON/OFF switch

Manual Modes

SCC-Processes

ELC-Key: Activation Efficient Level Control

Program Key: Activation Programming mode

Function Key: Activation personal settings & Service

Help Key

Care Key

Central Dial

V02 en, SCC_WE - 10 -

Operator panel SCC_WE: Manual Modes

Home - back to general display

Efficient Level Control

Humidity setting

Temperature setting

Time setting

Core probe setting

Pre heating

Time: continuous

Moistening

Fan wheel speed setting

Cool Down

Steaming at boiling point (no hot air)

- 11 - V02 en, SCC_WE

Survey Pictogram

Poultry

Large roast

Fish

Egg dishes / Desserts

Side dishes

Bakery products

Finishing

Home - back to general display

Back to previous level

Efficient Level Control

Function key

Settings

HACCP download

Communication (pictures, USB, IP, Sound)

Service

Display configurator

Record Modus (calibrated products)

Store

V02 en, SCC_WE - 12 -

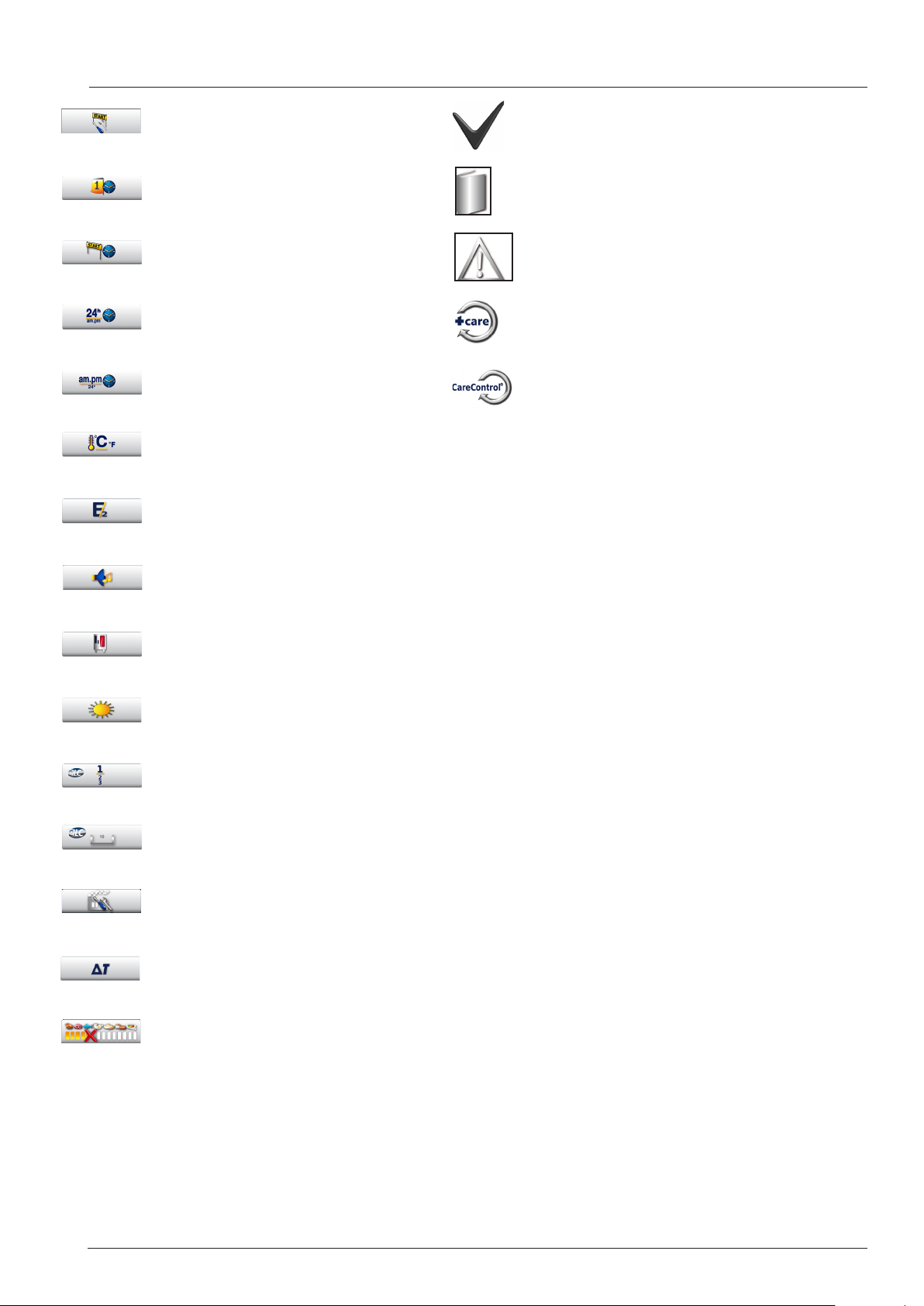

Survey Pictogram

Start Service Level

Date and time

Start time

Time format 24h

Time format am / pm

Temperature setting °C - °F

Half energy

Confirm

Operator and Application Manual

Safety advice

CleanJet +Care

Care Control

Setting ring tones

Show Mode (when in red)

Display brightness

Sequence of levels

Number of levels

Factory settings - english, °C, 24 hours etc

Delta T

Prozess abort key

- 13 - V02 en, SCC_WE

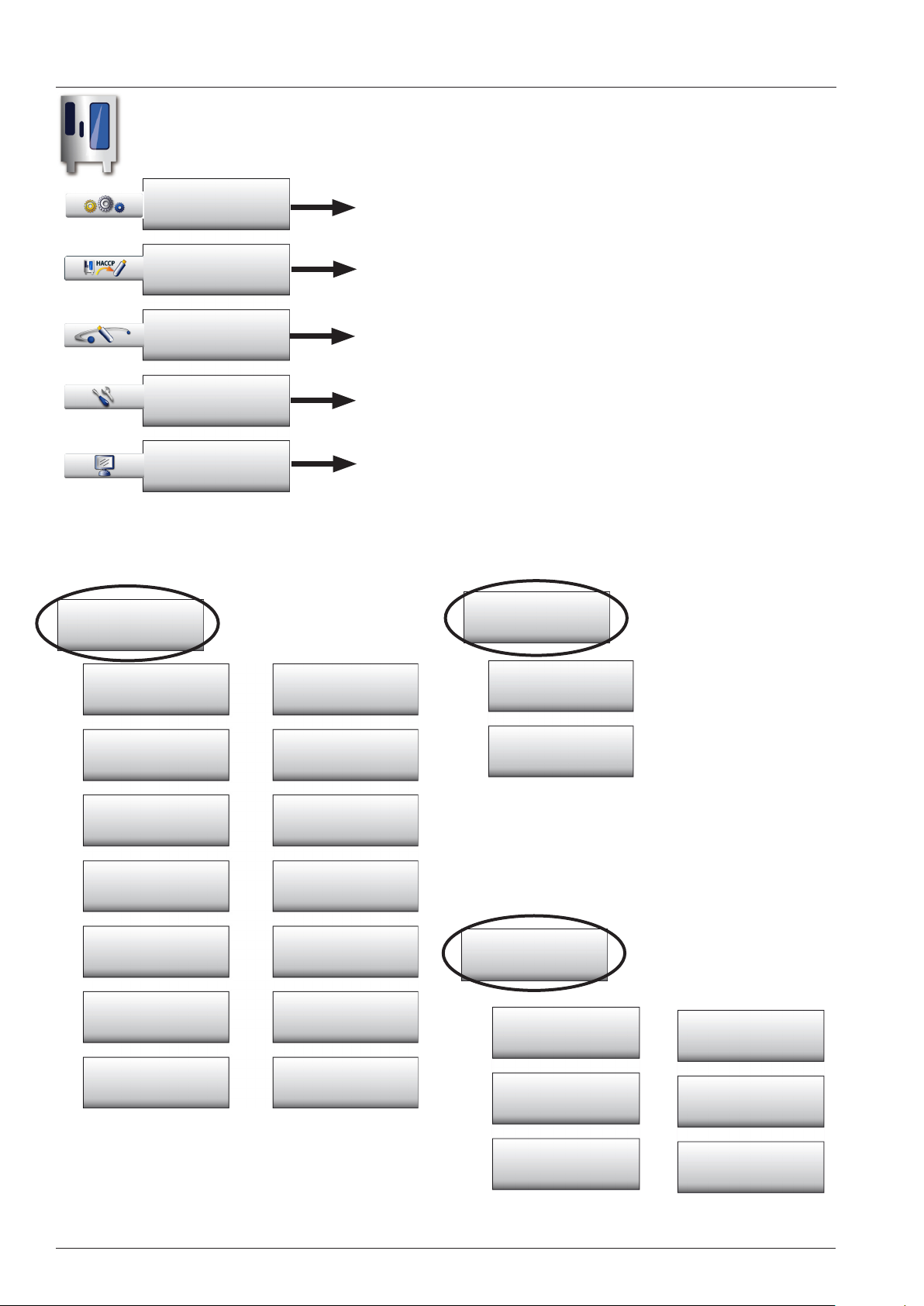

Function Key - Settings - Service - Communication

Function Key

Settings

Settings

HACCP

Communication

Service

Display Configurator

Record modus

Time, Language, °C/°F, Acoustics, Plate weight etc.

Download HACCP Data

Pictures, Ring tones, USB Stick, IP Address

Unit Data, Service package, Hotline numbers, Descaling,

Show Mode

Communication

Date, Time

Start time

Language

°C - °F

Brightness

Number of levels

Plate weight

Bankett

h:m m:s

24h am:pm

Delta T

E/2

Ringing tones

Sequence

of levels

Plate weight

à la carte

USB Stick

Network

Service

Unit Data

Diagnostic

Hotline

Empty Steam

generator

Descaling

(>16%)

Show Mode

V02 en, SCC_WE - 14 -

- 15 - V02 en, SCC_WE

V

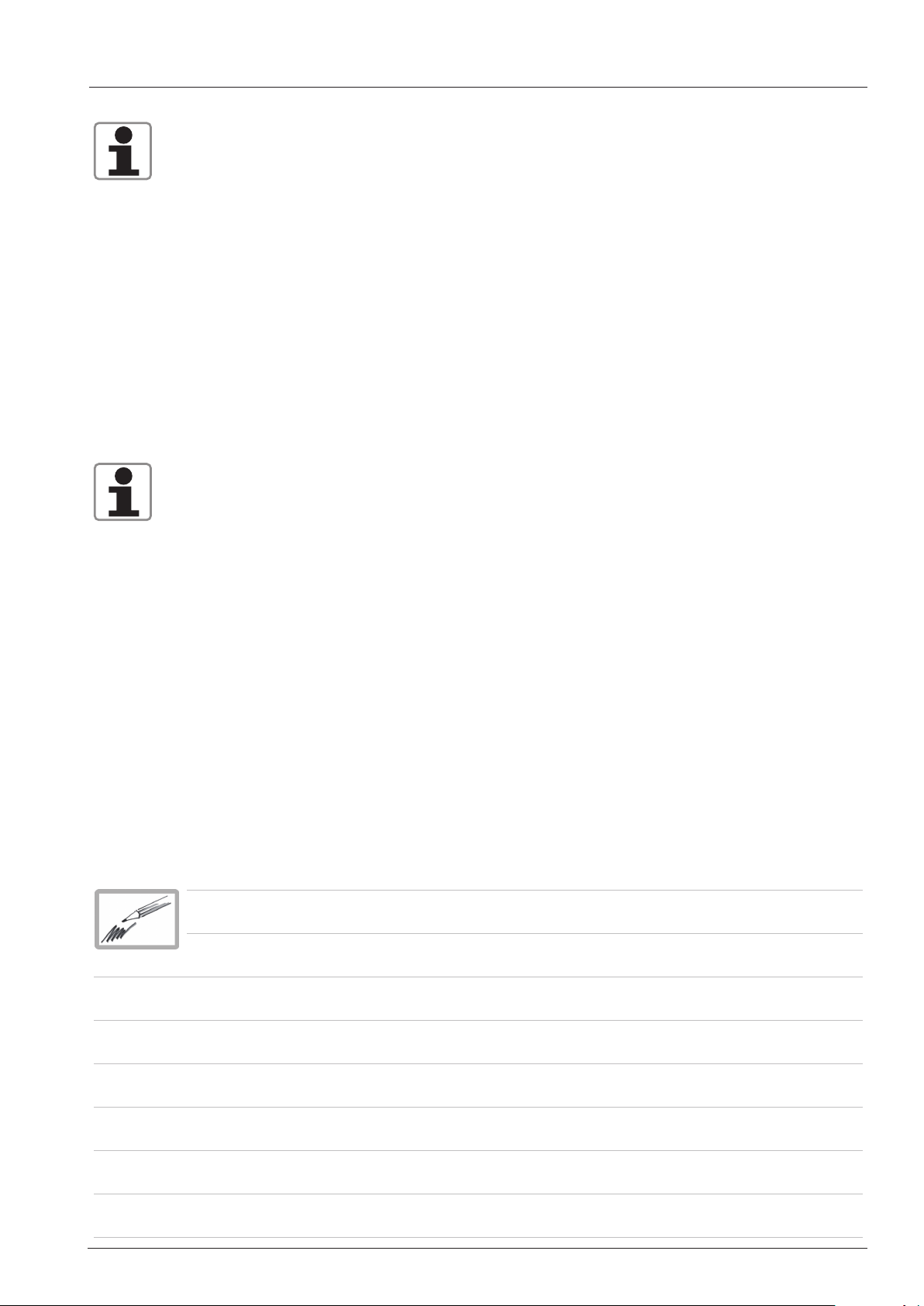

Water level control steam generator SCC_WE

Center level electrode S2 => Ground: 2 - 6V AC:

S2

B5

F3

water level too low

steam heating must switch OFF

solenoid valve filling Y1 ON

M4

Y1

Center level electrode S2 => Ground: 0V AC:

water level reached

steam heating can switch ON

PCB

S2

AC

solenoid valve filling Y1 switched OFF

Level electrode can be measured at X12: 1-4

The level electrode is equipped with two side electrodes to ensure safe water level recognition even

when the center level electrode is scaled. These

side electrodes compensate for the build up of scale.

Permanent water level control;

Maximum continuous steam time: 2 Minutes,

Property of connected water:

Conductivity must be above 50µS/cm;

St.Gen. empty: ca. 2 - 6V AC

St.Gen. full: 0V

SV Filling on 230V

SV Filling off 0V

Heating on 230V

Heating off 0V

Filling SG Max. heating 2 Min. Control Steam heating

V02 en, SCC_WE - 16 -

SC (Self Clean) Automatic

During the production of steam, the concentration of minerals inside the steam generator will

increase over time. These minerals settle on the heating elements and heat exchanger as

well as the interior steam generator walls.

In order to reduce this effect the steam generator will be pumped off and ushed regularly depending

on the duration of steam production. This process needs approximately 45 seconds.

After emptying the steam generator it will be lled automatically with fresh water.

There are 4 conditions to start this SC Automatic:

1. Heating time of the steam generator must exceed 60 min.* and

2. the temperature of the thermocouple steam generator must be below 65°C (149°F) and

3. the temperature of the thermocouple interior cabinet must be below 70°C (158°F) and

4. the unit is switched ON.

In case the unit is used permanently the above mentioned temperature conditions

can not be met.

In this case the „forced SC Automatic“ applies as follows:

1. The heating time of the steam generator reaches twice the set duration*, e.g. 120 min. and

2. the unit door is open for longer than 30 seconds

* The marked values can be changed in unit specific ranges using the diagnostic program.

After completion of the SC-Automatic the accumulated steam heating time is re-set to zero.

SC-Automatic does not replace the need for descaling and/or installing water treatment filter

- 17 - V02 en, SCC_WE

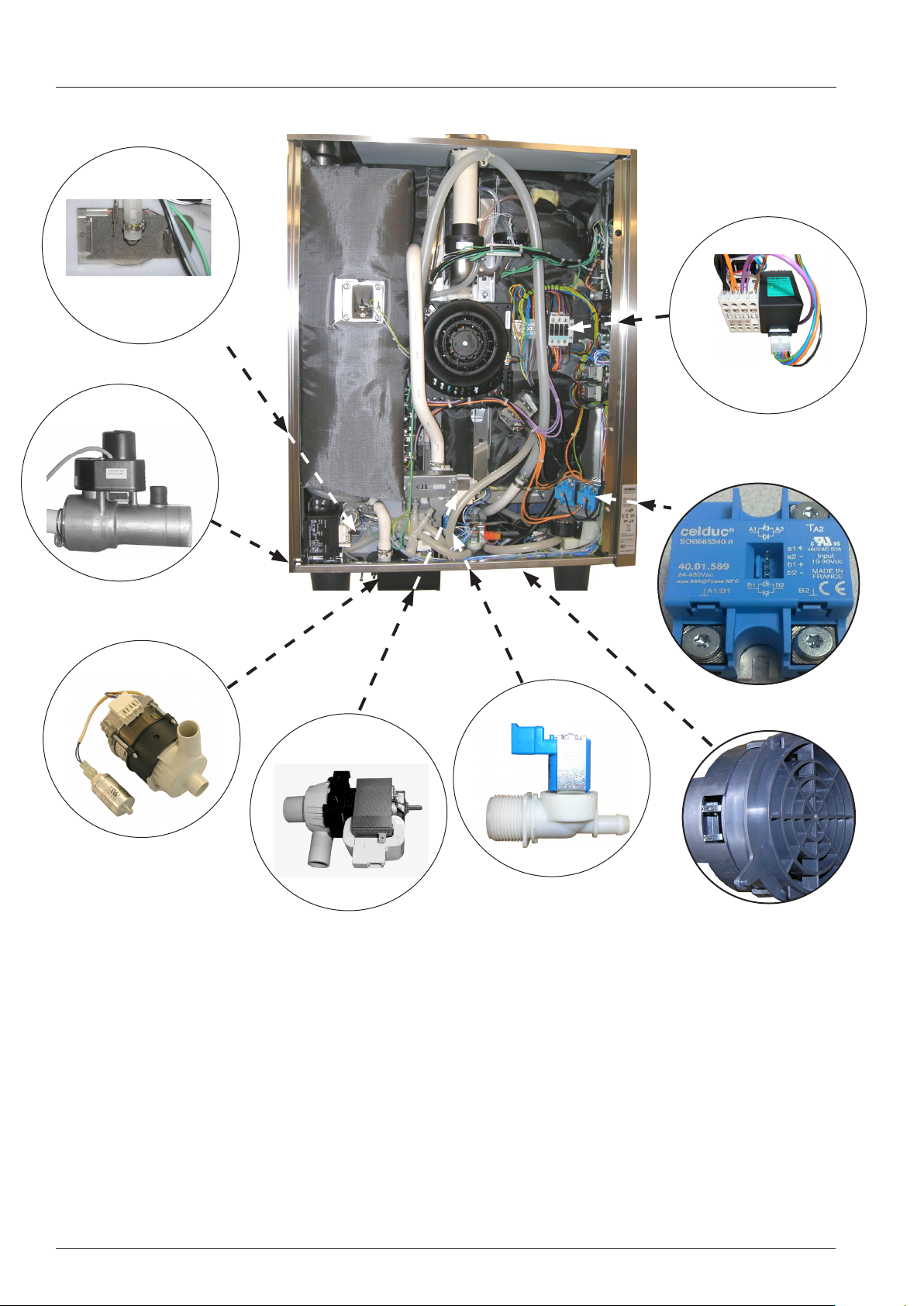

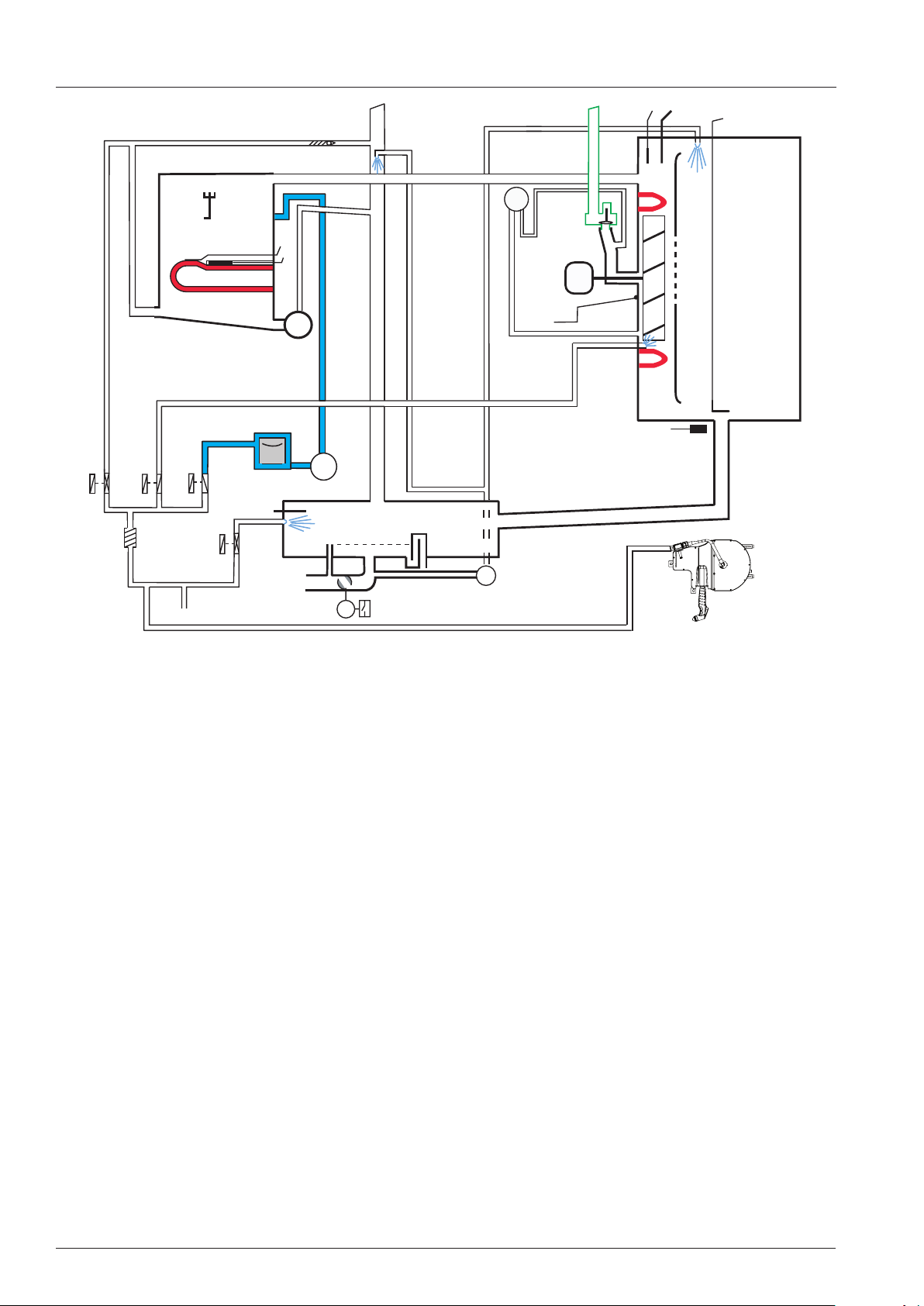

SCC_WE Electric (Index H): Basic principle

B1

B3.1 - 3.6

F4

P1

M4

M6

Y1

Y2

Y3

B2

M1

S2

M7

S12

B4

B5

F3

S3

Y4

S11

M12

Care

Y5

B1 Thermocouple interior cabinet

B2 Thermocouple quenching

B3.1-B3.6 Thermocouples core temperature

B4 Thermocouple humidity

B5 Thermocouple steam generator (preheat, 180°C (356°F) max)

F3 Safety thermostat steam generator 160°C (320°F)

F4 Safety thermostat interior cabinet 360°C (680°F)

M1 Fan motor (Floor unit: top)

M4 SC-pump

M6 CleanJet pump

M7 Motor drain valve / ball valve

M12 Care pump

S2 Level electrode

S3 Door reed switch

S11 CDS sensor

S12 Micro switch drain valve

P1 Differential Pressure sensor humidity

Y1 Solenoid valve filling

Y2 Solenoid valve quenching

Y3 Solenoid valve moistening

Y4 Solenoid valve Care

Y5 Solenoid valve Clima

SCC 201/202 only:

M2 Fan motor bottom with jumper ( Floor units only)

V02 en, SCC_WE - 18 -

Manual modes SCC_WE / Boiling point recognition

Steam mode in relation to boiling point recognition

During self test (after initial installation) the unit will determine the installation altitude by water boiling

point recognition.

As the boiling temperature declines with increasing altitude above sea level, the water boiling point

determines the installation altitude.

During self test the steam production will be active until the quenching sensor B2 reaches 70°C

(158°F). At this time the pcb will memorise the temperature measured by the interior cabinet sensor B1

as the boiling point temperature at the actual point of installation.

To run a manual cooking mode the following steps must be taken:

1. Cooking mode is selected.

2. Time or core temperature is selected.

3. Cabinet door is closed (door contact).

4. Fan motor is running (speed signal via bus).

5. In wet modes (Steam, Combination) the steam generator must be filled with water (level electrode)

6. In wet modes (Steam, Combination) the steam generator will be preheated

(thermocouple steam generator)

Mode

Temperature

range

30° (87°) up to

boiling point

at boiling point

above boiling

point up to

130°(266°)

30° (87°) up to

boiling point

above boiling

point up to

300°(572°)

30 - 300°C

(86 - 572°F)

Responsible sensor

Cabinet sensor B1 controls steam heating

- Humidity setting not possible

Cabinet sensor B1 controls steam heating

- Humidity setting not possible

Humidity control (P1, M1 rpm and B4) controls steam heating,

Cabinet sensor B1 controls Hot air heating at 50%, (only

possible when humidity is above 70%)

- Humidity setting not possible

Cabinet sensor B1 controls Hot air heating up to set temp.;

Cabinet sensor B1 controls steam heating

Cabinet sensor B1 controls Hot air heating up to set temp.;

Humidity control (P1, M1 rpm and B4) controls steam heating,

Alternating supply of steam and hot air depending on the reached

temperature and humidity.

- Humidity setting is possible

30 - 300°C

(86 - 572°F)

Cabinet sensor B1 controls Hot air heating

- Humidity setting is possible (humidity from food only)

Quenching controlled by B2 at 80°C (176°F) Wet, 90°C (194°F) in Hot Air

- 19 - V02 en, SCC_WE

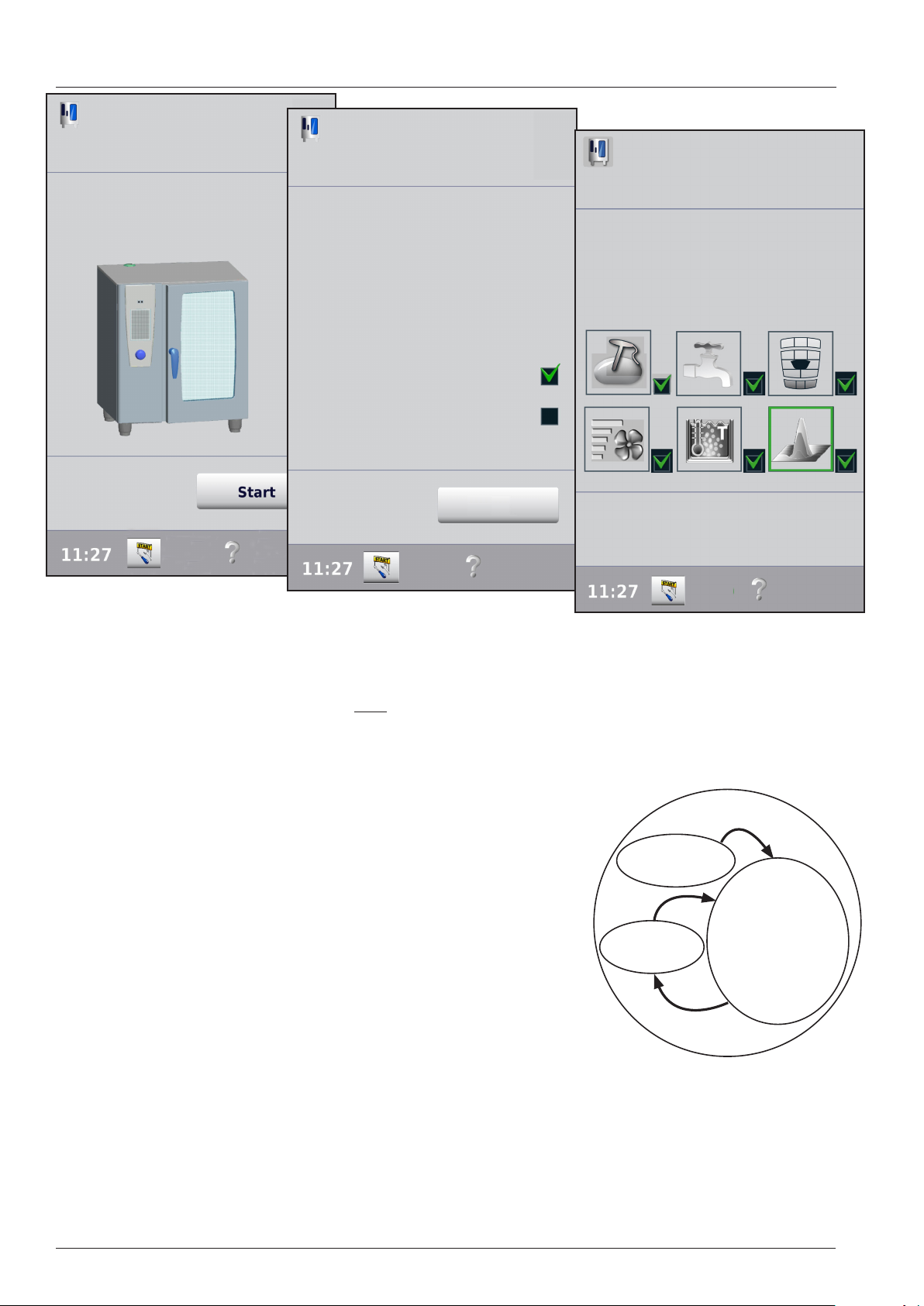

Selftest

Selfttest

Your SCC will carry out an automatic

self test and adjust itself perfectly to

the set-up conditions and the altitude.

Next

Selfttest

Your SCC will carry out an automatic

self test and adjust itself perfectly to

the set-up conditions and the altitude.

To determine the optimum number of

cleaner and rinse aid tablets, please specify

whether the unit is connected to normal

water or soft water. Please press the appropriate button

Unit is connected to soft water

(up to 8,75° e)

Unit is connected to normal water

(over 8,75° e)

Selfttest

Your SCC will carry out an automatic

self test and adjust itself perfectly to

the set-up conditions and the altitude.

Softwater:

7°dH, 12,5°F, 8,7°E, 125ppm, 1,25 mmol/l

Self test

Note: Gas units: In case the unit was NOT delivered with the correct gas type configuration, it must be converted prior of starting the self test. Please refer to gas manual!

SCC_WE and CM_P units will run a automatic Self Test routine after installation.

This Self test will start under the condition, that the tempearture of B1,

B2 and B4 are below 40°C (104°F).

Additionally 1 at and closed GN container (max 20mm) shall be inserted into the cabinet with the opening facing down at a height center to

Component test

the fan wheel. (201 - 202: 2 fan wheels = 2x GN containers)

The self test comprises a component test, calibration and determination of the boiling point

After the component test (S2, M4, Y1-Y4, CDS) the calibration will start

Boiling point

calculation

with the offset setting on P1 before the unit will determine the pressure

values for all fan speeds and directions in cold and dry condiition.

During step 200 the boiling point will be determined and stored.

This is followed by P1 calculating the pressure values for all fan speeds and

directions in steam and later combination mode 170°C (338°F).

Should at a later point in time the unit be reinstalled at a altitude more than 300m different to the original installation height, a new self test should be initialized in order to determine the new boiling point.

Such re-initialization can be be done in Basic settings, self test.

Selftest

Calibration

step 200

Calibration:

During a manual calibration only the P1 pressure values for cold (<40°C), steam (at boiling point) and combination (170°C) are calculated.

There will be NO determination of a new boiling point.

V02 en, SCC_WE - 20 -

Selftest

During the self test the individual component groups are indicated ticked off one by one.

IIn case an error number is displayed switch the unit OFF and ON again to access Service level.

If the door contact, thermocouple interior cabinet, bus cable to motor or ignition box is defective, the selftest will

be interupted

Note: During Self Test it is always possible to access the Service diagnostic mode!

Pre condition before Self test and Calibration

temperature of cooking cabinet sensor B1 is below 40°C (102°F)

temperature of quenching sensor B2 is below 40°C (102°F)

temperature of humidity sensor B4 is below 40°C (102°F)

door contact closed

heating: OFF

fan motor: OFF

left side panel closed, interior cabinet clean, if possible dry;

to achieve best calibration values insert a closed 20mm GN container

with opening facing down onto the rail closest to the center of the fan wheel

(201-202: 2 motors - 2x GN container)

Step Function possible error

message

0 ready fo calibration Any indicated error relates to the corresponding malibration

10 checking calibration

conditions

20 Measuring Offset P1 with

fan motor not turning

100 - 115 pressure measurement cold

table unit 61 - 102

100 - 131 pressure measurement cold

floor unit 201 - 202

200 steam heating up to boiling

point without fan motor

202 steam heating with fan

motor

210 - 225 pressure measurement

steam table unit 61 - 102

210 - 241 pressure measurement

steamfloor unit 201 - 202

300 heating of cabinet to

193°C (380°F)

followed by 60 sec. to 170°C

(338°F) steady condition

301 - 316 pressure measurement

combi table unit 61 - 102

301 - 332 pressure measurement

combi floor unit 201 - 202

999 calibration sucessfull

10

200

e.g. 302

reason for error - remedy

step.

e.g. error 10 will be indicated, when the condition for calibrations is not given.

Reason: B1, B2 or B4 is above 40°C (104°F)

16 steps for each fan motor, (32 steps with floor models), e.g.

100: running fan motor at constant speed „1“

101: store P1 value at this given speed

e.g. error 200 is indicated, when the steam heating will not

reach the necessary 70°C (158°F) to detremine the boiling

point in the allocated time.

Reason: e.g. SSR (energy optimising) or gas burner is not

activated etc.

e.g. error 302 is indicated, if sensor P1 does not give any or

any valid value at this time.

Reason: P1 defective or hoses to P1 blocked by water.

These errors are indicated during the respective calibration

step is running.

After solving the problem the Selftest must be started again.

- 21 - V02 en, SCC_WE

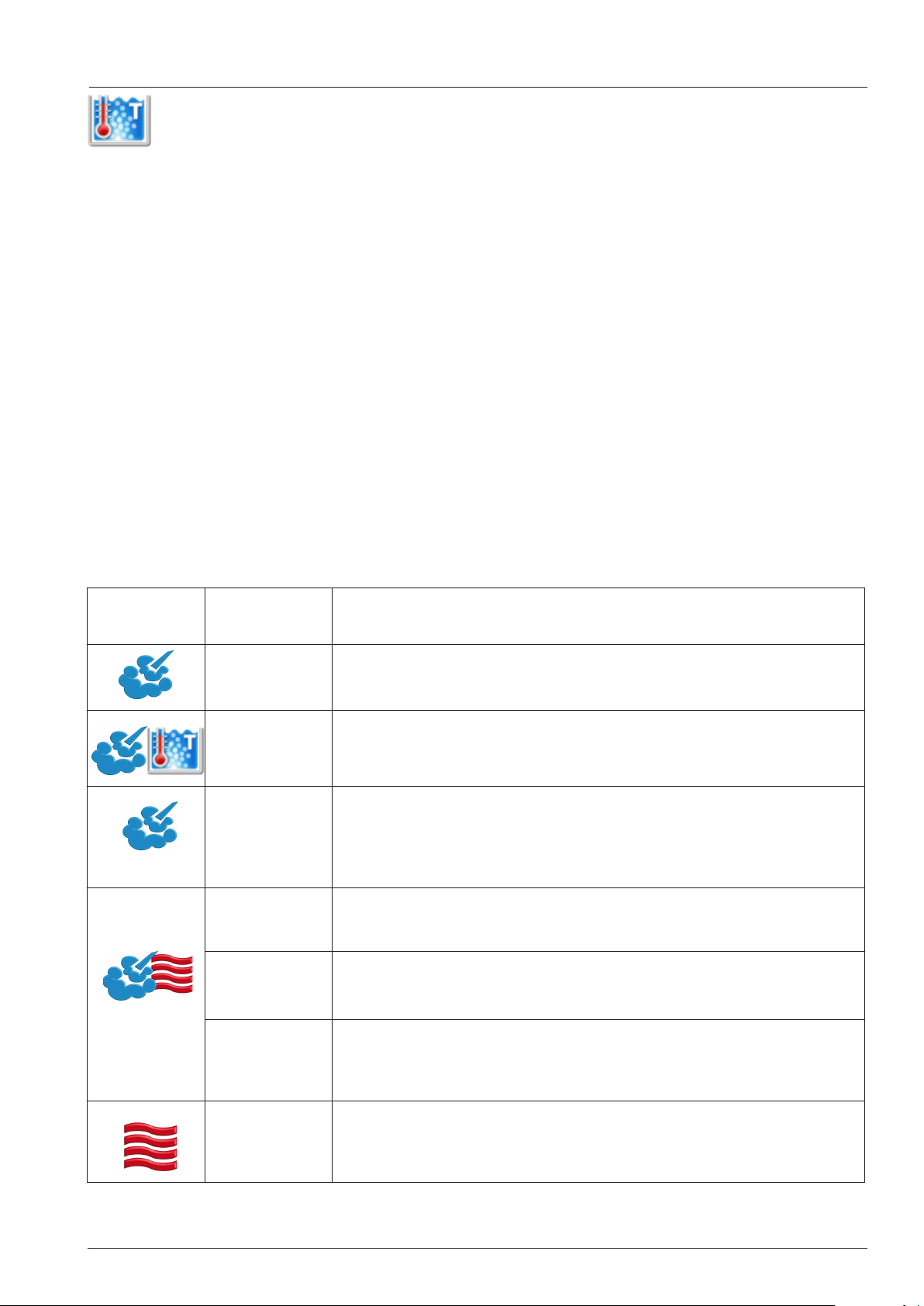

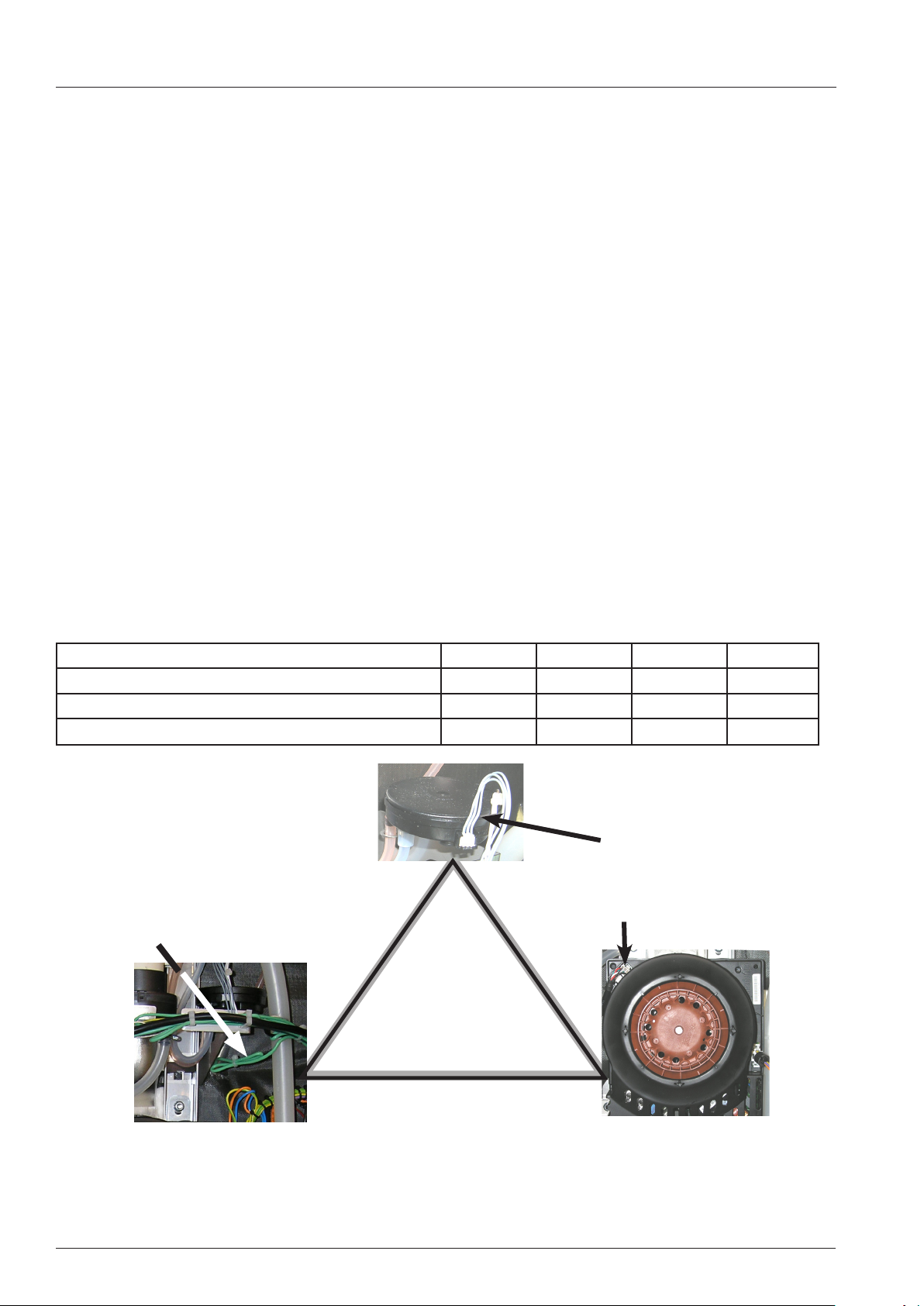

Humidity control SCC_WE

In order to measure the humidity inside the interior cabinet the following pysical principle is used:

When the fan wheel is turning, the rear fins create a differential pressure on pressure sensor p1 via the

connecting hoses (inner and outer connection).

The pressure sensor P1 is supplied with 12V DC. When the fan wheel is at a stand still, the offset voltage is between 0,45 - 0,55V DC.

The differential pressure is dependent on:

1. The speed of the fan wheel

2. The temperature in the cabinet

3. The amount of humidity in the cabinet

The following rules apply:

The output voltage of P1 is higher when the fan wheel turns faster.

The output voltage of P1 is higher when the cabinet temperature is lower.

The output voltage of P1 is higher when the humidity in the cabinet is lower.

This differential pressure is converted into a dc voltage for processing by the pcb.

Sample: SCC_WE 101E

NOTE: The given values are only average values and shall only demonstrate the relationship of pressure values P1 to change in speed, temperature and humidity.

500 rpm 1000 rpm 1450 rpm 1550 rpm

Cold and dry 1,1V 2,2V 2,9V 3,1V

Warm and humid - Steam 100°C (212°F) 0,7V 1,7V 2,0V 2,2V

Hot and humid - Combination 180°C ( 0,6V 1,5V 1,7V 1,9V

Differential pressure sensor P1

Thermocouple B4

Humidity

Humidity control

Bus signal

Motor rpm

V02 en, SCC_WE - 22 -

Humidity control SCC_WE

If the measured humidity value is too high, the clima valve Y5 will be activated and the closing disk will

be lifted. The negative pressure behind the fan wheel will cause dry air from the kitchen be sucked into

the cabinet. The humid air will be displaced and pushed through the cabinet drain into the quenching

chamber.

This Clima valve also functions as the safety relief valve.

Cross section of the clima valve:

Y5

Emergency humidity control:

In case the differential pressure sensor P1 is defective (no signal), the steam generator will be activated by time control automatically to a humidity level of 60%.

At the same time error „Service 36“ will be shown.

Should the signal of P1 be out of the standard range (invalid signal), humidity will be controlled by the

quenching sensor.

At the same time error „Service 37“ will be shown.

- 23 - V02 en, SCC_WE

Loading...

Loading...