Page 1

2-year

RATIONAL

warranty

Secure your 2-year guarantee and your free

membership of ClubRATIONAL

www.rational-online.com/warranty

Operating instructions

CombiMaster

Page 2

Explanation of the pictograms

Danger!

Directly hazardous situation that

could result in very severe injury

or death.

Corrosive substances

Attention: Damage may be caused

if this is ignored.

Warning:

Potentially hazardous situation

that could result in severe injury

or death.

Risk of fire!

Handy tips for everyday use

Caution!

Potentially hazardous situation

that could result in minor injury.

Risk of burns!

- 2 -

Page 3

Dear Customer

Congratulations on the purchase of your new CombiMaster.

Your decision to buy a new CombiMaster means that you now have a top-of-the-range combi-steamer.

Your CombiMaster will give you many years of reliable service in your kitchen thanks to its outstanding

quality of workmanship and almost unlimited cooking potential.

We give a 12 month warranty from the date of initial installation.

The warranty excludes glass damage, light bulbs and seals as well as damage caused by improper

installation, use, maintenance, repair or descaling.

We hope that enjoy using your new CombiMaster.

Your

RATIONAL AG

You can reach our Technical Customer Support Service 7 days a week on: +44 1582 480388

For any queries relating to use please ring the RATIONAL Chef✆Line: +44 7743 389863

Dealer: Installer:

installed on:

Appliance serial number:

We reserve the right to make technical improvements!

- 3 -

Page 4

Contents

Safety Instructions 5

Liability 7

Care, inspection, maintenance and repair 8

Features 9

Notes on using your unit 10

Working with the hand shower 12

General instructions for use 13

Controls 14

Control modes 15

Moist Heat mode 16

Dry Heat mode 18

Combi-Steam mode 21

Vario-Steam mode 23

Finishing

Working with the core temperature probe 27

Cool Down Function 30

®

mode 25

Appliance settings – Celsius / Fahrenheit 30

Cleaning 31

Servicing - Steam generator descaling 33

Aborting the descaling process 36

Draining the steam generator 36

Fault indications 37

Sample applications 38

Before you call customer service 56

Maintenance 58

EU Declaration of Conformity for electrical units 59

EU Declaration of Conformity for gas units 60

ClubRATIONAL 61

- 4 -

Page 5

Safety Instructions

Warning:

Incorrect installation, servicing, maintenance, cleaning or modifications to the unit may result in

damage, injury or death. Read these operating instructions carefully before you start to use the unit.

This unit must only be used to cook food in catering establishments. Any other use is not intended and is

therefore considered dangerous.

It must not be used to cook food containing flammable materials (such as food with alcohol).

Substances with a low flash point can ignite spontaneously - Risk of fire.

Cleaning and descaling products and the associated accessories must only be used for the purposes

described in this manual. Any other use is not intended and is therefore considered dangerous.

In case of damage to the glass plate, please replace the entire plate immediately.

Warning:

Gas units only

- If your unit is installed under an extractor hood, this must be switched on when the unit is in use Combustion gases.

- If your unit is connected to a chimney, the flue duct must be cleaned in compliance with specific

regional regulations - Risk of fire. (Contact your installer.)

- Do not put objects on your unit's exhaust pipes - Risk of fire.

- Do not let objects block or obstruct the area below the unit's base. - Risk of fire!

- The unit must only be used in still conditions. - Risk of fire!

What to do if you smell gas:

- Shut off the gas supply immediately

- Do not touch any electrical controls

- Make sure the area is well ventilated

- Avoid naked flames or sparking

- Use an external telephone to notify the appropriate gas supplier (if the gas supplier is unobtainable

call the nearest fire station).

- 5 -

Page 6

Safety Instructions

Keep this manual handy so that it can always be consulted by anyone using the unit.

This unit must not be used by children or people with limited physical, sensor or mental capacity or those

without the necessary experience and/or knowledge, unless such people are supervised by a person who is

responsible for their safety.

Operate using hands only. Damage caused by the use of pointed, sharp or other objects will invalidate the

warranty.

We recommend regular training of your staff to avoid the risk of accident or damage to the unit. Operators

must also receive regular safety instruction.

Warning:

Daily checks before switching on and use

- Lock the air baffle at the top and bottom as per the instructions - risk of injury from the rotating fan

wheel.

- Make sure that the hanging racks or mobile oven rack are correctly locked in place in the cooking

cabinet - Containers with hot liquids can fall through or slip out of the cooking cabinet - Risk of

combustion.

- Make sure that there are no cleaning fluid residues in the cooking cabinet before you start cooking

with the unit. Thoroughly rinse away any residues with the hand shower - risk of chemical burns.

- 6 -

Page 7

Safety Instructions

Warning:

Safety instructions during use

- If containers are filled with liquid or contents which liquefy during cooking, do not use rack levels

higher than those that allow the user to see into the slide-in containers - Risk of burns!Warning sticker

is enclosed with appliance.

- Always open the cooking cabinet door very slowly (hot vapours) - Risk of burns.

- Always wear thermal protective clothing to hold accessories and other objects in the hot cooking

cabinet - Risk of burns.

- The external temperatures of the unit may exceed 60 °C. Only touch the unit at the controls - Risk of

burns.

- The hand shower and water from the hand shower may be hot – Risk of burns.

- Cool-down mode - Do not use the Cool-down function unless the air baffle has been locked correctly Risk of injury.

- Do not touch the fan wheel - Risk of injury.

- Cleaning - Aggressive chemical fluid - Risk of chemical burns.

Always wear the correct protective clothing, safety goggles, gloves and facemasks during cleaning.

Follow the safety instructions in the “Manual cleaning” section.

- Do not store highly flammable or combustible materials near the unit - Risk of fire

- If mobile units and mobile oven racks are not moved, you must apply the parking brakes to the wheels.

Racks could roll away on uneven floors - Risk of injury.

- If mobile oven racks are used, you must always apply the container lock. Cover any containers with

liquids to prevent the hot liquid spilling out - Risk of burns.

- The transport trolley must be correctly fixed to the unit when you load and remove the mobile plate

rack or mobile oven rack - Risk of injury.

- Mobile oven racks, mobile plate racks, transport trolleys and units on casters can tip over when being

moved over an inclined plane or threshold - Risk of injury.

Liability

Installations and repairs that are not carried out by authorised specialists or using original spare parts,

and any technical change to the machine that is not approved by the manufacturer will invalidate the

manufacturer’s warranty and product liability.

- 7 -

Page 8

Care

Your unit must be cleaned every day to maintain the high quality of the stainless steel, for hygiene reasons

and to avoid operating faults. To do this, follow the instructions in the “Manual cleaning” section..

Warning:

If the unit is not cleaned or is not cleaned well enough, deposits of

grease or food residues in the cooking cabinet may catch fire - Risk of fire.

- To avoid corrosion in the cooking cabinet, your unit must be cleaned every day, even if it is only operated in

“Moist Heat” (steaming) mode.

- Apply vegetable oil or grease to the inside of the cooking cabinet at regular intervals (every 2 weeks or so)

to prevent corrosion.

- Do not use a high pressure cleaner to clean the unit.

- Do not treat the unit with acids or expose to acid fumes – this will damage the passivated coating of the

nickel-chromium steel and the units might discolour.

- Only use cleaning agents made by the unit’s manufacturer. Cleaning agents from other manufacturers may

cause damage and invalidate the warranty.

- Do not use scouring products or scratchy cleaning agents.

- Daily cleaning of the cooking cabinet seal with a non-abrasive cleaning agent will extend the service life.

- Remove and clean the incoming air filter once per month (see Maintenance).

Inspection, maintenance and repair

Danger - High Voltage

- Inspection, maintenance and repair work must only be carried out by trained technicians.

- The unit must be switched off at the mains for cleaning (apart from manual cleaning) and for

inspection, maintenance or repair work.

- If the unit is installed on casters (mobile), freedom of movement must be restricted so that power,

water and drainage pipes cannot be damaged when the unit is moved. If the unit is moved, make sure

that power, water and drainage lines are correctly disconnected. If the unit is returned to its original

position, make sure that the retention device, energy, water and drainage pipes are correctly attached.

- Your unit should be serviced by an authorised service partner at least once a year to ensure that it

remains in perfect working order.

- 8 -

Page 9

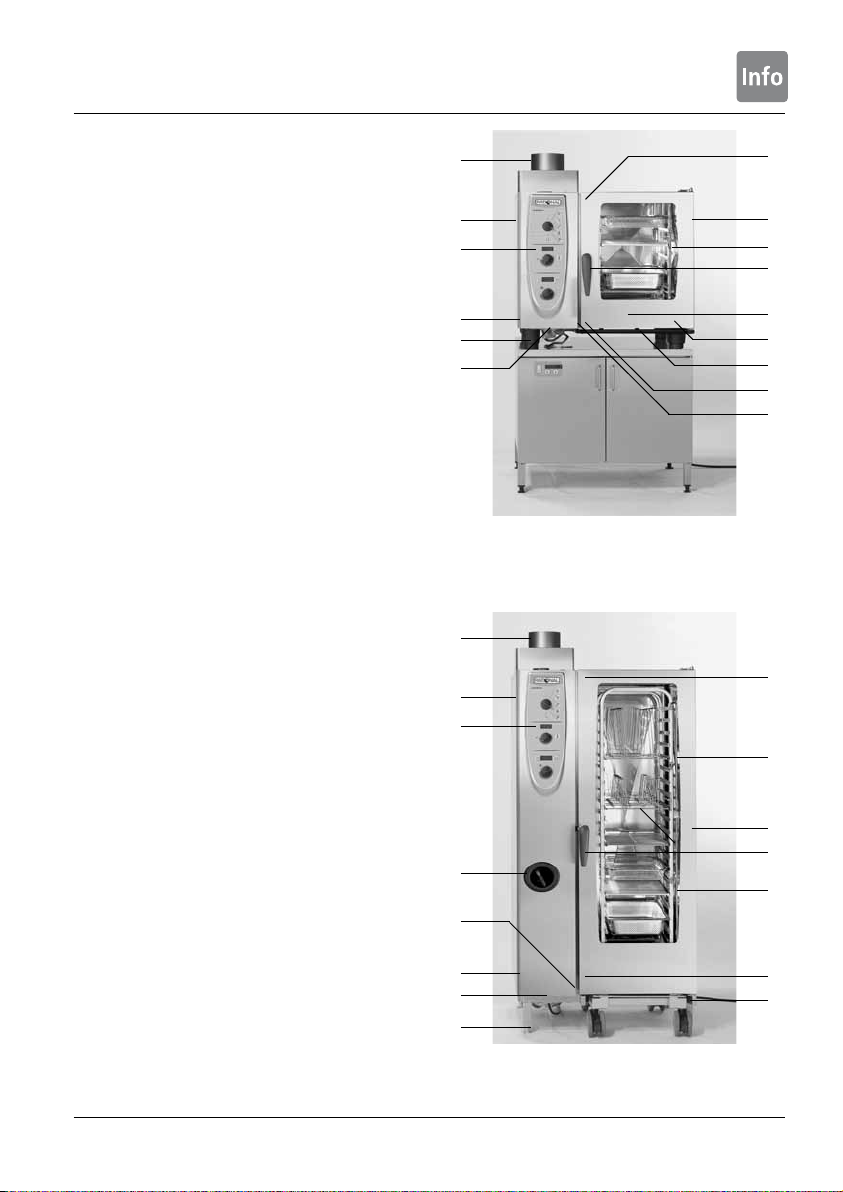

Features

Appliance serial number

(visible only when door is open)

Draft diverter (optional)

(gas appliances only)

Interior lighting

Appliance door with double glass pane

Door handle

Table-top units: one-handed operation with

slam function

Floor models: one-handed operation

Unlocking device to open double glass

door panel (inside)

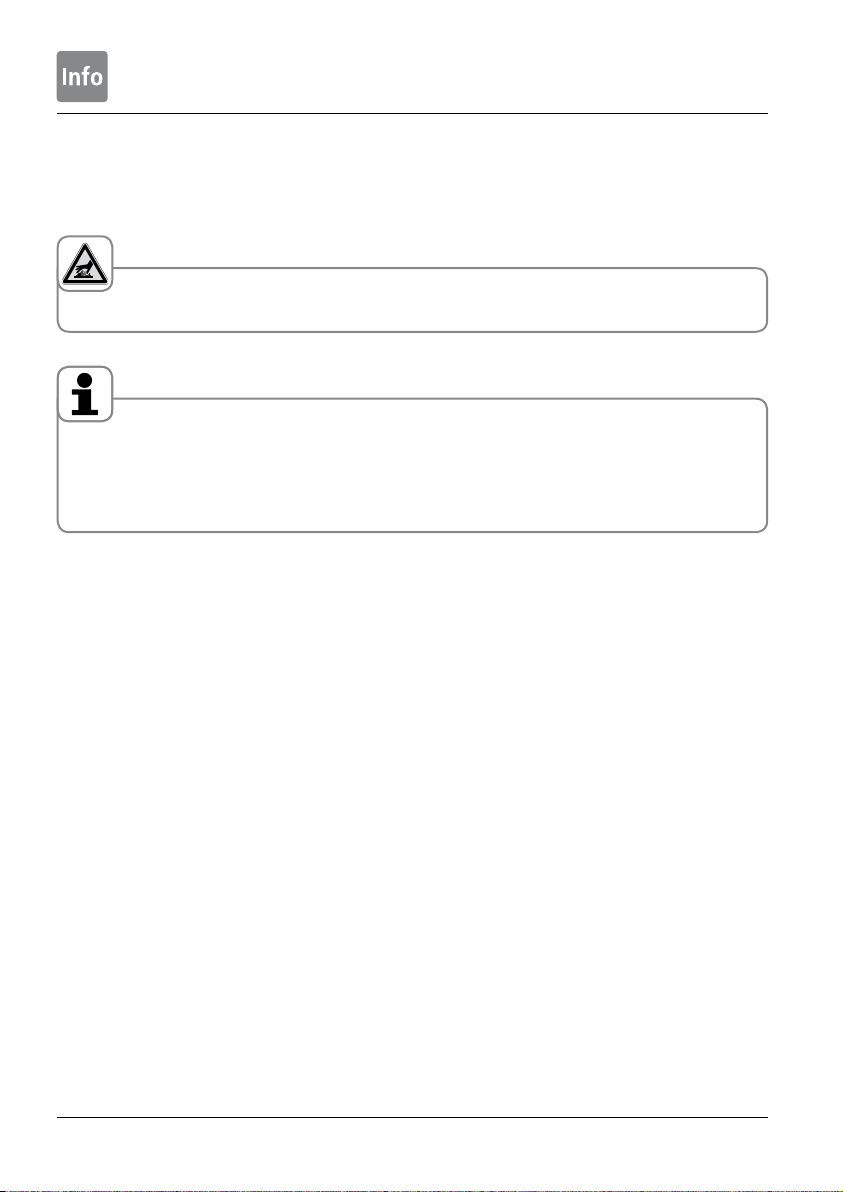

Integral, self-draining door drip pan

(inside)

Drip collector connected directly to

appliance drain

Appliance feet

(height adjustable)

Unit data plate

(with all the important electrical data such as

power input, voltage, number of phases and

frequency, as well as appliance model and

appliance serial number, see also functions/

settings/model, Option number)

Control panel

Protective cover for electrical

installation area

m Hand shower (optional)

(with automatic rewind)

n Run-in guide (Floor models)

o Air filter (Installation area ventilation)

o

Table-top unit 6 x 1/1 GN, identical for 6 x 2/1 GN, 10 x 1/1 GN

and 10 x 2/1 GN.

m

o

Floor unit 20 x 1/1 GN, identical for 20 x 2/1 GN.

m

n

- 9 -

Page 10

Notes on using your unit

- Avoid having heat sources (e.g. grill plates, deep-fat fryers etc.) near the unit.

- You can only use the unit in areas with a room temperature > 5 °C. For ambient temperatures of less than

+ 5 °C, you must heat the cooking cabinet to room temperature (> + 5 °C) before starting.

- As soon as you open the cooking cabinet door, the heating and fan wheel shut down automatically. The

integral fan wheel brake is activated. The fan wheel keeps running for a brief period only.

- A drip tray should always be inserted when grilling and roasting (e.g. chicken) in order to catch the fat.

- Only use genuine heatproof accessories made by the unit manufacturer.

- Always clean accessories before use.

- Leave the unit door slightly open if it is going to be idle for a prolonged period (e.g. overnight).

- The cooking cabinet door has a slam function; the door of the floor unit is not closed tight unless the door

handle is vertical.

- For long stoppages (e.g. non-work day), shut off the water, power and gas supplies to the unit.

- At the end of its service life, the unit must not be disposed of with the general waste and must not be

placed in the recycling containers at local authority collection points. We will be happy to help you with the

disposal of your unit.

Max. load sizes for each unit size

6 x 1/1 GN 30 kg (max. 15 kg per rack)

10 x 1/1 GN 45 kg (max. 15 kg per rack)

20 x 1/1 GN 90 kg (max. 15 kg per rack)

6 x 2/1 GN 60 kg (max. 30 kg per rack)

10 x 2/1 GN 90 kg (max. 30 kg per rack)

20 x 2/1 GN 180 kg (max. 30 kg per rack)

If the maximum load sizes are exceeded, this can damage the unit.

Please note the maximum load sizes for food in the application manual.

- 10 -

Page 11

Notes on using your unit

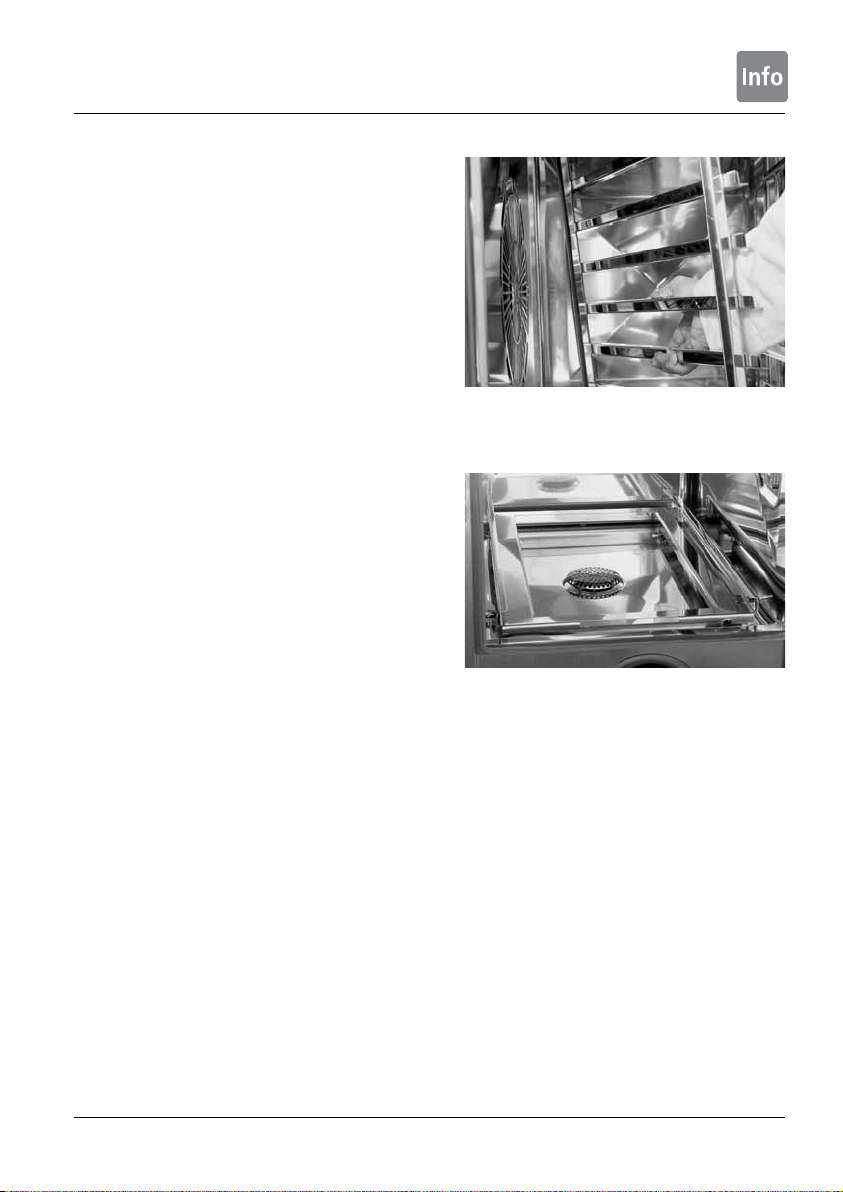

Table-top units with hanging racks

(6 x 1/1 GN, 6 x 2/1 GN, 10 x 1/1 GN, 10 x 2/1 GN)

- To remove, raise the hanging rack slightly in the middle

and pull it out of the front locking mechanism.

- Swivel the hanging rack to the middle of the cooking

cabinet.

- Lift the hanging rack out of its fixing by lifting it up.

Reverse the above sequence to reset.

Working with mobile oven racks, mobile plate racks and transport

trolleys for table-top units (option)

- Remove the hanging rack as described above.

- Place the run-in rail on the fixing provided on the unit's

base. Make sure it is fixed accurately in place (4 pins).

- Remember that the unit must be matched to the exact

height of the transport trolley and must be levelled.

- Move the transport trolley as far as it will go on the

run-in rail and make sure that the transport trolley is

correctly locked on the unit.

- Push the mobile oven rack or mobile plate rack into the

unit as far as it will go, and check that the locking mechanism in the unit is working correctly.

- To remove the mobile oven rack or mobile plate rack, release the locking mechanism and pull the rack out

of the cooking cabinet. First insert the core temperature probe with the run-in rail in the park position.

- Make sure that the mobile oven rack or mobile plate rack is securely locked on the transport trolley during

transportation.

- 11 -

Page 12

Working with the hand shower

- If you use the hand shower, pull the hose at least 20 cm out of the park position.

- You can select 2 jet strengths by pressing the control button.

- Always let the hand shower slide slowly back into the park position.

Caution!

The hand shower and water from the hand shower may be hot – Risk of burns.

The hand shower has no latch position. If you pull hard on the hand shower and it exceeds the

maximum available hose length, it will damage the hose.

Make sure that the hand shower hose is fully rewound after use.

You must not use the hand shower to cool the cooking cabinet.

- 12 -

Page 13

General instructions for use

H2O

The message “H2O” may appear on the display when you switch on. This means that the steam generator is

not yet filled with water. When it is full the display goes out automatically.

If the cooking cabinet is hotter than the set temperature, the button for the selected mode will flash (e.g.

Steam).

(See the „Cool Down“ section for cooling the cooking cabinet).

0:35

Time settings

The cooking time can be set for up to 30 minutes in 1-minute intervals and in 5-minute intervals for more

than 30 minutes .

rES

“RESET” (gas units only)

If the burner malfunctions “rES” will light up on the display. After 15 sec. you will hear an audible signal.

Press the “Clock” button to restart the automatic ignition process. If the “rES” display does not light up

again after approx. 15 seconds, the flame is burning and the unit is operational. Please notify Customer

Support if the display is still lit after pressing the button repeatedly.

- 13 -

Page 14

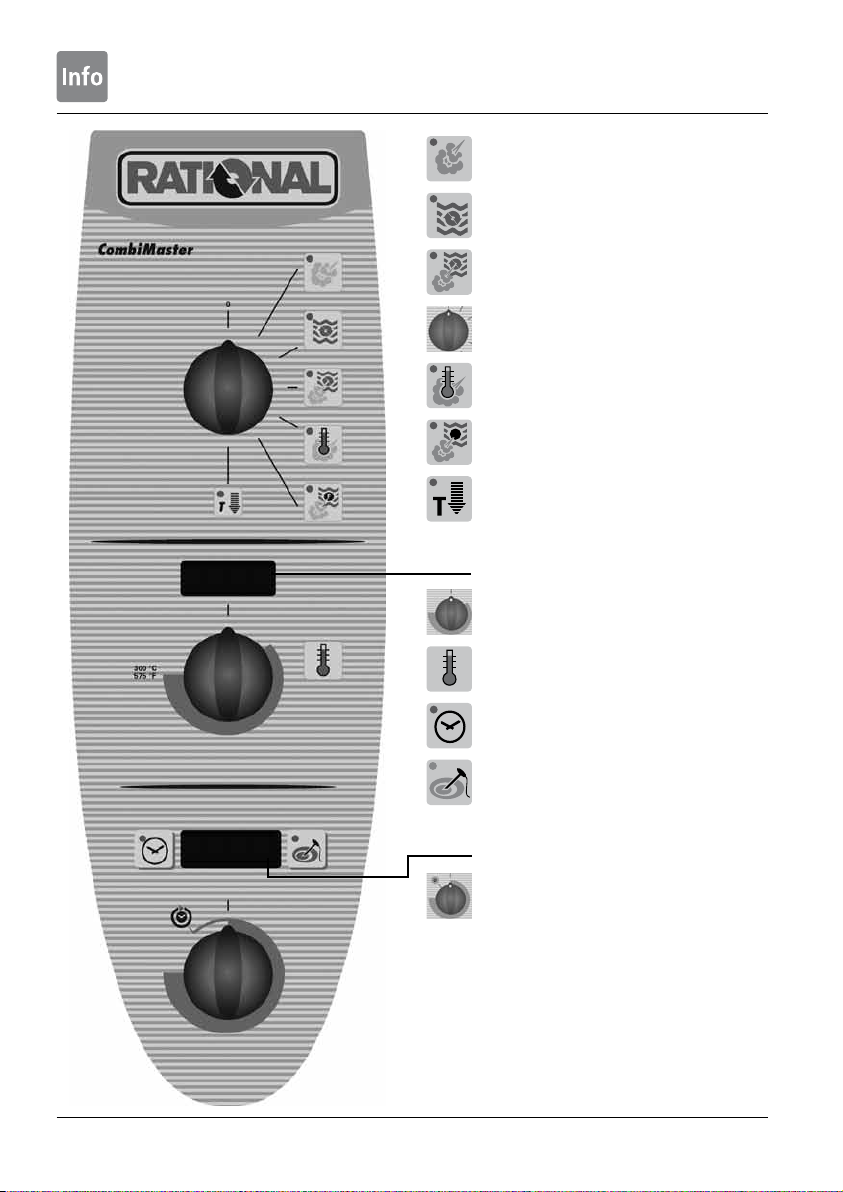

Controls

F

Moist Heat (100 °C)

Dry Heat (30 °C to 300 °C)

Combi-Steam (30 °C to 300 °C)

Control Mode switch

Vario-Steam (30 °C to 99 °C)

®

Finishing

(30 °C to 300 °C)

Additional „Cool Down“ function

Cabinet temperature display

Cabinet temperature dial

Heating mode display

Clock button (0 to 23 hours 59 min.)

Button for core temperature

(0 °C -99°C)

Display for time/core temperature

Dial for time of day/core temperature

- 14 -

Page 15

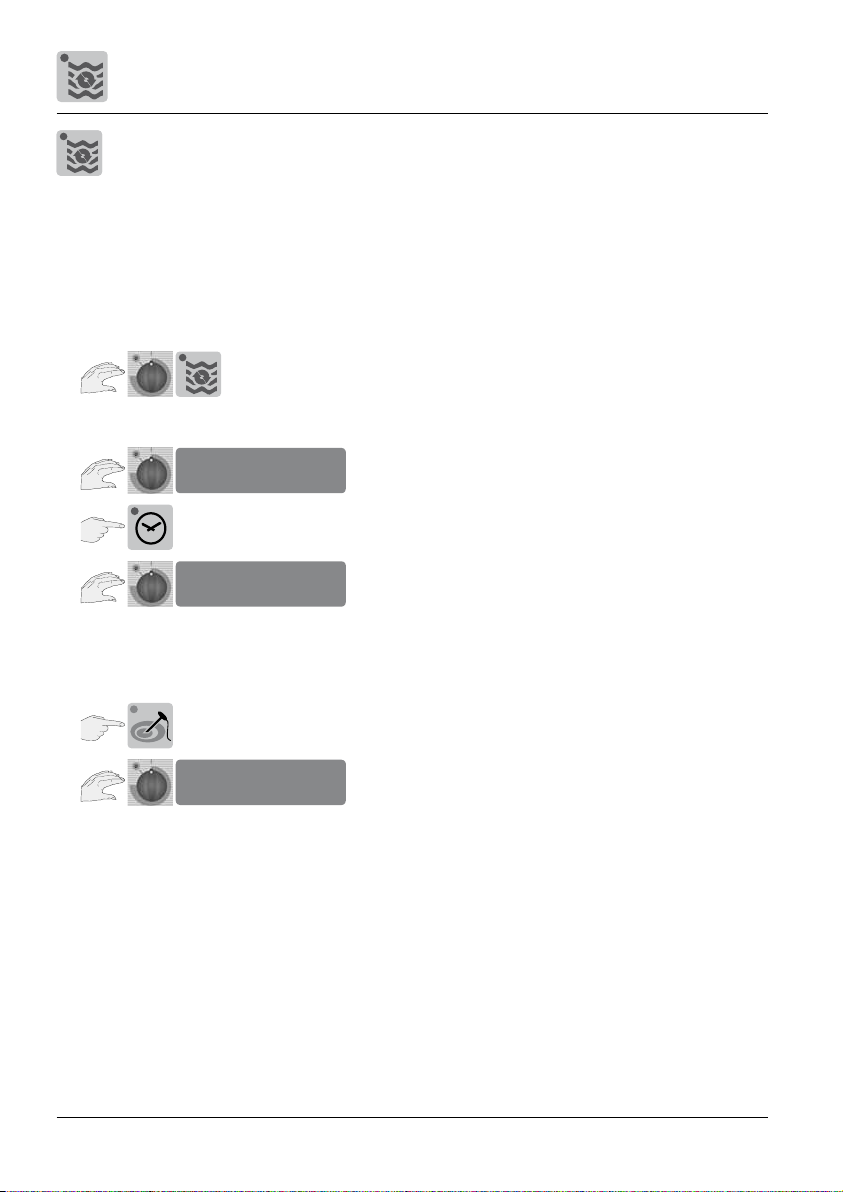

Control modes

F

„Moist Heat“ mode

The high-performance steam generator produces fresh steam. This is fed, unpressurised, into the

cooking cabinet and is circulated at high speed by the fan. The patented control system regulates

the input of steam, supplying only as much as the food is actually able to absorb. In this mode

cabinet temperature is set to a constant 100 °C.

„Dry Heat“ mode

Powerful heating elements heat the dry air. The fan circulates the hot air evenly throughout the

cabinet. Cabinet temperature can be set to between 30 °C and 300 °C.

„Combi-Steam“ mode

Moist Heat and Dry Heat modes are combined by a control system. This creates a hot, humid climate

for especially intensive cooking. The temperature can be set to between 30 °C and 300 °C.

The humidity is controlled continually to prevent the food drying out.

„Vario-Steam“ mode

An electronic control system with temperature sensors accurate to one degree maintains the prese-

lected temperature throughout the cabinet. Sensitive controls and automatic control engineering

ensure that the cooking climate is just right for the product. The cabinet temperature can be variably

set to between 30 °C and 99 °C.

„Finishing®“ mode

The two operating modes moist heat and dry heat are combined. This produces the ideal cook-

ing climate, both preventing the food drying out and the formation of unwanted puddles. Cabinet

temperature can be individually set to between 30° C and 300 °C.

- 15 -

Page 16

Moist Heat mode

„Moist Heat“

The steam generator produces hygienic fresh steam.

In this mode the cabinet temperature is set to a

constant 100 °C.

Cooking modes:

Steaming, stewing, blanching, poaching, simmering,

vacuum cooking, thawing, preserving.

1

Preheat until heating indicator light goes out

Sample dishes

• Mise en place

Tomatoes concassé, garnishes (vegetables, fruit),

mushrooms, blanching juliennes and brunoises,

blanching vegetables for stuffings, roulades etc.,

peeling onions and chestnuts, soaking pulses.

• Starters

Scrambled eggs, poached eggs, hard-boiled eggs,

asparagus, vegetable flans, stuffed vegetables

(onions, kohlrabi, leeks, celery, etc.).

• Soup garnishes

Dumplings, ravioli, vegetable royale.

2

3

Or work with the core

temperature probe

0:25

2

3

Target Actual

76°C 19°C

• Main courses

Boiled beef, cured ham, knuckle of pork, tongue,

boiling fowl, turkey legs, meat in aspic, fish.

• Side dishes

Risotto/rice, dumplings, pasta (noodles), fresh and

frozen vegetables, vegetable casseroles, potato

roulade, boiled/jacket potatoes.

• Desserts

Fresh or frozen fruit (e.g. hot raspberries), stewed

fruit, rice pudding.

- 16 -

Page 17

Moist Heat mode

Hints

• To get the most out of your Combi-Master check

daily the types of food which can be cooked

together using „Moist Heat“. Remember that

fish, meat, vegetables, side dishes and fruit can

be cooked together (as long as they are all being

prepared by the same method).

• Cook potatoes in perforated GN containers,

the perforations let the steam circulate and give

faster, more intensive cooking.

• Vegetable stock can be collected by inserting a

container on the bottom rack.

• It is better to use two shallower GN containers

rather than one high one => this reduces bulk

and avoids heavy layers of food.

• Dumplings should be placed in a shallow solid

GN container.

• Rice and cereals are the only foods to which

you should add water: 1 part grain, 1.5 to 2 parts

water.

• Tomatoes are easy to skin: „Moist Heat“ for

approx. 1 min, then plunge into cold water.

- 17 -

Page 18

Dry Heat mode

„Dry Heat“

Powerful heating elements heat the dry air. Cabinet

temperature can be set to between 30 °C and

300 °C.

Cooking methods:

Baking, roasting, grilling, deep-frying, gratinating,

glazing.

Sample dishes

• Mise en place

Sweating bacon, roasting bones, allowing dough

(yeast) to rise.

• Starters

Meatballs, vegetarian bakes, vegetables au gratin,

vegetable pasties, pies, sirloin, chicken wings,

finger food, duck breasts, quiches, shortcrust

pastry, tartlets.

1

Preheat until heating indicator light goes out.

2

160°C

3

4

Or work with the core

temperature probe

0:25

3

4

Target Actual

76°C 19°C

• Soup garnishes

Savoury straws, cheese croûtons.

• Main courses

Steak, rump steak, T-bone steak, liver, rissoles,

chicken breast, chicken legs, half / whole chickens,

turkey, pheasant, quail, breadcrumbed meat,

breaded convenience food, vegetarian cutlets,

duck breasts, cutlets, pizza.

• Side dishes

Potato pancakes, roast potatoes, potato gratin,

rösti, baked potatoes, Idaho potatoes, potato

soufflés, Macaire potatoes, duchesse potatoes.

• Desserts

Sponges, marble cakes, plain cakes, fancy cakes,

flaky pastry, croissants, bread, rolls, baguettes,

shortcrust pastry, apple strudel, bakery products

(precooked), frozen pastry.

- 18 -

Page 19

Dry Heat mode

Hints

• Cooking times

Cooking times will depend on product

quality, weight and height. Do not

overload grids or containers so that air

can circulate evenly.

• Breaded products

all types of breadcrumb coating can be used.

Browning is improved by brushing with fat or a

blend of paprika and oil. Press the breadcrumbs

in firmly, brush with melted fat and do not

overload the unit. Rule of thumb: allow approx.

8 to 10 minutes per 1cm thickness of meat.

• General notes on pan-frying

- Preheat to as high a temperature as possible

(300 °C) to build up sufficient stored heat.

- Load as quickly as possible in order to

minimise cabinet temperature drop.

- During cooking (with a full load) open the

door briefly to allow excess moisture to escape.

- With flash-fried and fried products which

give off a lot of moisture (e.g. chicken legs),

if possible reduce loads to 75 or up to a

maximum of 50% of the greatest theoretical

load.

Preheat: to 300 °C (at least until heating

indicator light goes out).

Optimum cut thickness: 1,5 to 2 cm.

Optimale Schnittstärken: 1,5 bis 2 cm.

Accessories: Roasting and baking tray or

granite-enamelled container. For even browning

on the top and bottom surfaces, make sure that

the slices are of the same thickness or the same

size.

• Gratinating

light and dark meat dishes, fish, mussels,

asparagus, chicory, broccoli, fennel, tomatoes,

toast.

Preheat: to 300 °C (at least until heating

indicator light goes out). Set to desired

temperature after loading.

E.G.: Grids or containers (20 mm) for

gratinating toast, steaks and soups.

- 19 -

Page 20

Dry Heat mode

• Baking

Preheat to baking temperature. For a full load

you may need to select a higher preheating

temperature.

Baking temperature: approx. 20 to 25 °C

lower than in a conventional oven.

For rolls use only every second shelf.

For frozen convenience products preheat

to 300 °C.

Defrost frozen rolls and leave to rise for a

short time.

Accessories:

Use perforated Teflon-coated baking trays,

Roasting and baking trays or granite enamelled GN

containers.

- 20 -

Page 21

Combi-Steam mode

„Combi-Steaming“

Moist Heat and Dry Heat modes are combined by a

control system. This creates a hot, humid climate for

especially intensive cooking.

The temperature can be set to between 30 °C and

300 °C.

Cooking modes: roasting, baking.

1

Preheat until heating indicator light goes out.

2

160°C

3

Sample dishes

• Mise en place

Roasting bones.

• Vorspeisen

Quiche Lorraine, Gemüseauflauf, Flans, Moussaka,

Lasagne, Canneloni, Paella, Nudelauflauf.

• Starters

Quiche Lorraine, vegetable soufflés, flans,

moussaka, lasagne, canneloni, paella, pasta

bakes.

• Side dishes

Potato gratin, frozen products (potato turnovers),

baked potatoes.

• Desserts

Yeast dough.

4

0:25

Or work with the core

temperature probe

3

4

Target Actual

76°C 19°C

• Miscellaneous

Bread, rolls, pretzels (frozen dough portions).

- 21 -

Page 22

Combi-Steam mode

Hints

• Do not place joints too close together to allow

even cooking.

• Joints with rinds or larger joints should be

steamed for approximately 1/3 of the cooking

time.

• Collect condensate in a container (additional

rail) and make the gravy by adding it to the

lightly roasted bones.

• Preparing sauces

– IPlace a solid container on an additional rail.

– Add bones, mirepoix, seasonings to the

container and roast under the meat.

– Add the collected stock

– Braise for the duration of cooking.

– Very concentrated stock for gravies/sauces.

• Roulades

place in solid GN container, top with hot sauce

and cover with container.

• Baking

Bake yeast dough, flaky pastry, choux pastry on

baking/roasting trays, Teflon trays can also be

used.

- 22 -

Page 23

Vario-Steam mode

„Vario-steaming“

The steam generator produces hygienic fresh steam.

Cabinet temperature can be variably set to between

30 °C and 99 °C.

1

Preheat until heating indicator light goes out.

2

160°C

3

4

Or work with the core

temperature probe

0:25

Sample dishes

• Mise en place

Blanching bacon and ham, poaching fish

garnishes, soups, sauces, stocks, fumets etc.,

pasteurising (semi-preserved foods).

• Starters

Galantines, fish dumplings, terrines, vacuum

dishes.

• Soup garnishes

Stuffing, dumplings, royale.

• Main courses

Fish (salmon, sole etc.), cured ham, poultry,

vacuum dishes (chicken breast, boiled beef, veal

tongue), turkey fillet, chicken breasts, beef fillet,

Vitello sausage.

• Side dishes

Flans, vegetable casseroles, polenta.

3

4

Target Actual

76°C 19°C

• Desserts

Fruit, crème caramel, cabinet pudding.

- 23 -

Page 24

Vario-Steam mode

Hints

• „Vario-Steam“ cooking times

Moist Heat cooking times can be used as

approximate values. As a general rule, the lower

the cooking temperature the longer the cooking

time.

• Approximate cabinet temperatures

„Vario-Steaming“:

Soup garnishes: 75 to 90 °C

Fish, shellfish and 65 to 90 °C

crustaceans: 65 to 90 °C

Meat and sausages 72 to 75 °C

Light meat 75 to 85 °C

Dark meat: 80 to 90 °C

Poultry: 80 °C

Desserts: 65 to 90 °C

• Seasoning

Season with care. Low cooking temperatures

intensify the characteristic taste of seasonings.

When vacuum cooking be sure to add the exact

amount of fumet, essence or reduction!

• Advantages:

– Firm textured fillings.

– Products have intenser taste and aroma.

– Stock loss very low in fatty material.

Approximate temperature: 72 to 80 °C.

• Cook direct in the serving dish,

e.g. fish.

• Preserving fruit/vegetables

Cover the food with hot or cold liquid,

depending on the firmness of the raw product

and the type of preserve you want. The diameter

of the preserving jars used should not exceed

100 mm. The cooking temperature will depend

on the type of product (ripeness, size of pieces).

Approximate temperature: 74 to 99 °C.

Note:

The jars must not be closed

- 24 -

Page 25

Finishing® mode

F

F

F

„Finishing®“

A combination of Moist Heat and Dry Heat

modes. This produces the ideal cooking climate,

by preventing the food drying out and also

the formation of unwanted puddles. Cabinet

temperature can be set to between 30 °C and

300 °C.

1

Preheat to operating temperature.

2

We recommend a cabinet temperature

of between 120 °C and 140 °C, but the

temperature can be varied for different products.

0:25

3

4

As a rule time is between 5 and 8 minutes

for food arranged on plates – but times will

vary depending on the product, product

temperature, number of plates, how full they are

and the desired serving temperature.

0:08

3

4

Target Actual

Sample dishes

• Starters

All types of spaghetti, canneloni, lasagne,

vegetable dishes, cheese and herb noodles,

quiche Lorraine, spring rolls, vegetarian cutlets,

onion flans.

• Main courses

All types of roast, meat loaves, bakes, ready-toserve meals, roulades, stuffed vegetables.

• Side dishes

Rice, potatoes, noodles, pasta, vegetables,

soufflés, gratins.

• Desserts

Strudel, hot fruit.

76°C 19°C

Or work with the core

temperature prober

- 25 -

Page 26

F

Finishing® mode

Hints

• Finishing® utensils

Porcelain plates, earthenware, glass, silverware,

copper pans, stainless steel, aluminium dishes

(brought in).

• Banqueting service/tour groups

Reheat plates in the mobile plate rack.

– Large quantities in next to no time.

– Fast loading and unloading.

– Shorter serving times, so high hourly

throughput, rapid table change, more

turnover.

– For plates up to 31 cm in diameter

• Serving dishes are heated as well, storing heat

until the food reaches the table.

• Thermocover: for bridging short waiting

periods or transporting food

• Arrange food evenly and not too closely on

plates or dishes.

• Before arranging vegetables and side dishes for

mix with a little butter or fat.

• Sauces

Usually added after .

• Bulky items need more time to heat up.

- 26 -

Page 27

Working with the core temperature probe

F

Can be selected for all control modes

Caution!

The core temperature probe can be hot – Risk

of burns.

Wear oven gloves.

1

Insert the needle of the core temperature probe into

the thickest point at an angle of 30-45 degrees.

You must insert the needle through the middle of

the food.

- Always correctly position the core temperature

probe in the park position provided – Risk of

damage.

- Do not let core temperature probe hang out of

cooking cabinet - Risk of damage.

- Remove the core temperature probe from

the food before you take the food from the

cooking cabinet - Risk of damage.

2

160°C

3

4

Target Actual

The timer is not operational.

A buzzer sounds when the preselected temperature

has been reached.

76°C 19°C

- 27 -

Page 28

Working with the core temperature probe

Hints

• When roasting meat for slicing set the core

temperature approx. 5 °C lower, as the joint will

continue to cook during the cool-down phase.

For example: „Roasting“, core temperature

– cooking time ratio.

• To avoid holes (protein coagulation) in the

product, cool the core temperature probe before

use.

• You can change the set temperatures and

cooking modes at any time.

• Core temperature measurement establishes the

optimum serving temperature when

®

.

Approximate core temperature

values

Core

Beef How well done temperature

Fillet of beef medium 55 - 58 °C

Sirloin medium 55 - 60 °C

Beef rose well done 85 - 90 °C

Roast beef well done 80 - 85 °C

Aitchbone well done 90 °C

Pork

Leg well done 75 °C

Leg pale pink 65 - 68 °C

Saddle pale pink 65 - 70 °C

Shoulder well done 75°C

Belly/ well done 75 - 80 °C

stuffed

Belly well done 80 - 85 °C

Knuckle, roasted well done 80 - 85 °C

Knuckle, cured well done 80 - 85 °C

Ham very succulent 64 - 68 °C

Smoked pork chops 65 - 70 °C

(Buffet slices) 55 - 60 °C

knuckle well done 75 - 80 °C

pickled

Cured rib of pork well done 65 °C

Ham in 65 - 68 °C

breadcrumbs

- 28 -

Page 29

Working with the core temperature probe

Approximate core temperature

values

CoreBeef How well done temperature

Veal

Saddle of veal pale pink 58 - 65 °C

Leg of veal, well done 78 °C

and topside

noisettes, fricandeau

Loin with kidneys well done 75 - 80 °C

Roast veal/ well done 75 - 80 °C

shoulder

Breast of veal well done 75 - 78 °C

Saddle of mutton rare 65 - 70 °C

Saddle of mutton well done 80 °C

Leg of mutton rare 70 - 75 °C

Leg of mutton 82 - 85 °C

Lamb

When the meat is well done the core temperature is

between 79 °C and 85 °C. The colour of the meat

core is grey, slightly pale pink. The meat juices are

clear.

Approximate core temperature

values

CoreBeef How well done temperature

Pies and similar

Poultry

Chicken well done 85 °C

Goose/duck well done 90 - 92 °C

Turkey well done 80 - 85 °C

Pies 72 - 74 °C

Meat loaf 72 - 78 °C

Terrines 60 - 70 °C

Galantines 65 °C

Ballotines 65 °C

Foie gras 45 °C

Fish, e.g. salmon medium 60 °C

Leg rare 60 - 62 °C

Leg well done 68 - 75 °C

Saddle rare 54 - 58 °C

Saddle well done 68 - 75 °C

Shoulder well done 78 - 85 °C

- 29 -

Page 30

Cool Down Function

Appliance settings – Celsius / Fahrenheit

You have been running your appliance at high

temperature and you now want to carry on working

at reduced cabinet temperature. Use the „Cool

Down“ function to cool the cabinet quickly and

gently.

Warning:

- Do not use the Cool-down function unless

the air baffle has been locked correctly - Risk

of injury.

- During "Cool Down", the fan wheel does not

switch off when the door is opened.

- Do not touch the fan wheel - Risk of injury.

- During "Cool Down", hot vapours emerge

from the cooking cabinet - Risk of burns.

1

Close door.

2

Open door.

3

Temperatures may be displayed in degrees Celsius

or degrees Fahrenheit.

Changing the Celsius / Fahrenheit display

Simultaneously press „Clock“ button and „Core

temperature“ button and hold down for more than

10 seconds.

100°C

or

212°F

Close cabinet doors before selecting „Cool

Down“.

- 30 -

Page 31

Cleaning

For hygiene reasons and to prevent malfunctions it

is essential to clean your unit every day.

• Follow the safety instructions on the spray

bottle and cleaner canister.

• Use only genuine cleaning agents and

the genuine hand spray gun (article no.:

6004.0100) from the unit manufacturer.

• Never leave hand spray guns under

pressure.

• Never spray other people, animals or

objects.

Here is what to do

1

Cool the cooking cabinet to below 60 °C (see

the “Cool Down” section).

2

Switch unit off.

3

4

Spray the space behind the air baffle, cooking

cabinet, inside of the door and door seal with

cleaner.

5

Reset and lock the air baffle and hanging rack in

place. Close the cooking cabinet door.

Warning:

Do not open the cooking cabinet door while

cleaning is in progress – chemical cleaner and hot

vapour may escape – risk of chemical burns and

scalding.

Swivel hanging rack and air baffle to the middle

Warning:

Aggressive chemical fluid – risk of chemical burns.

It is essential that you use: protective clothing,

safety goggles, gloves, facemask and the unit

manufacturer‘s hand spray gun.

6

7

Hold down the core temperature button for 10

seconds.

CLEn

8

The cleaning program starts.

0:50

- 31 -

Page 32

Cleaning

Warning:

Aggressive chemical fluid – risk of chemical burns.

It is essential that you use: protective clothing,

safety goggles, gloves and facemask.

At the end of the cleaning time, you will be

prompted to open the doors.

12

You exit the cleaning program by selecting a

cooking mode.

You need:

Hand spray gun – article no.: 6004.0100

door

9

When the cleaning program has

finished, rinse the appliance down,

including behind the air baffle.

10

Wipe the cooking cabinet and door seal with

a damp cloth. If necessary, fold back the inner

pane and wipe it down as well.

11

Close the cooking cabinet door.

To dry the cooking cabinet, “Hot air” mode

is automatically switched on for 10 minutes

after the cabinet door is closed.

0:10

Warning:

Aggressive chemical fluid – risk of chemical burns.

It is essential that you use: protective clothing,

safety goggles, gloves and facemask.

Rinse the spray gun nozzle and nozzle extension

with clean water after every use.

Rinse the cleaning bottle with warm water after

use.

Cleaning the cooking cabinet seal every

day will extend its service life. Use a soft cloth and

cleaning agent to clean the cooking cabinet seal.

Do not use scouring products.

Clean the glass windows inside and out and the

outer panels of the unit, ideally using a soft, damp

cloth. Do not use a scouring product.

If there is heavy soiling, allow the residues soften

for 10 minutes in “Moist Heat” mode before

cleaning.

A couple of drops of salad oil will clear any stiffness

in the pump plunger (manual spray gun).

End

- 32 -

Page 33

Servicing - Steam generator descaling

Your appliance is equipped with the patented

automatic Self Clean system. Automatic Self Clean

significantly extends the period between descaling

intervals. The steam generator in your appliance

still needs regular descaling, depending on water

hardness and use.

We recommend the following descaling intervals,

based on 8 hours’ steaming per day:

up to 18 °dH (to 3.2 mmol/litres) at least 1x

annually

up to 24 °dH (to 4.3 mmol/litres) at least 2x

annually

over 24 °dH (to 4.3 mmol/litres) at least 3x

annually

These recommended descaling intervals may

vary from the approximate values given above,

depending on the composition of the water

(e.g. minerals).

4

Rotate cabinet temperature knob to the right

until „CALC“ appears on the display.

CALC

5

The descaling process is started.

If the cabinet temperature is over 40 °C

when descaling commences, „Cool Down“ starts

automatically – see „Cool Down“ display

Steam generator is drained

----

Steam generator descaling

When pumping out has finished the display shows:

CALC

1

Close cabinet doors.

2

You will be asked to top up with descaling fluid.

FILL

3

Press core temperature button down for 10

seconds until the cabinet temperature display

shows „CLEn“.

CLEn

Open cabinet doors.

6

- 33 -

Page 34

Servicing - Steam generator descaling

7

Remove left grid shelf and air baffle.

8

Guide hose into steam inlet opening as far as

the mark

Note

The allocation of marks to unit size is described

in the instructions for the descaler pump.

Warning:

Aggressive chemical fluid – risk of chemical burns.

It is essential that you use: protective clothing,

safety goggles, gloves, facemask and the unit

manufacturer‘s descaler pump.

9

Insert hanging rack and fix hose with wire hooks

10

Place canister of descaling fluid in the cooking

cabinet and run the hose into the canister

Descaling fluid reacts with lime and can

foam over.

Very slowly fill with descaling fluid using the

11

appliance manufacturer’s descaling pump.

Warning:

Aggressive chemical fluid – risk of chemical burns.

There may be residues of the descaling fluid in the

hoses. Rinse the descaling accessories thoroughly

with water.

Wear: protective clothing, safety goggles, gloves

and facemask.

Electric appliances

6 x 1/1 GN 10 x 1/1 GN 6 x 2/1 GN

3,5 litres 6 litres 6 litres

10 x 2/1 GN 20 x 1/1 GN 20 x 2/1 GN

8,5 litres 9 litres 11,5 litres

Gas appliances

6 x 1/1 GN 10 x 1/1 GN 6 x 2/1 GN

4 litres 7 litres 6,5 litres

10 x 2/1 GN 20 x 1/1 GN 20 x 2/1 GN

9 litres 8 litres 11 litres

Remove the descaling accessories (hand

pump and canister) from the cabinet.

- 34 -

Page 35

Servicing - Steam generator descaling

12

Remove descaler accessories from the cooking

cabinet (hand pump and canister).

Thoroughly rinse off any descaling fluid in the

13

cooking cabinet and descaler accessories with

water.

17

You exit the descaling process by selecting a

cooking mode. You can now use your unit for

cooking.

14

Remove descaler accessories, insert air baffle

and left hanging rack, and lock in place

15

After 30 seconds, “door” appears on the

display.

FILL

16

Close the cooking cabinet door.

0:45

The length of the descaling phase is displayed.

0:15

0:30

Note:

You need:

Electric descaler pump – Article no.: 60.70.409

Descaler, 10 litre canister – Article no.: 6006.0110

The steam generator is automatically rinsed several

times. The appliance then automatically switches to

Steam.

End

“End” appears on the display when descaling is

complete.

- 35 -

Page 36

Aborting the descaling process

Draining the steam generator

Aborting the descaling process

If necessary you can discontinue the descaling

process.

Before filling with descaling fluid

1

please hold down the core temperature button

for 10 seconds.

End

Your appliance can now be used for cooking.

After filling with descaling fluid

1

Switch appliance off and wait for 4 seconds

2

Switch appliance on

3

Descaling is discontinued if the

core temperature button is pressed

within 30 seconds.

If the core temperature button is not pressed within

30 seconds descaling will continue.

Draining the steam generator

You can drain the steam generator before moving it

or to stop it freezing.

1

Open cabinet doors.

2

3

Press core temperature button for 10 seconds

until „CLEn“ appears on cabinet temperature

display.

CLEn

4

Rotate cabinet temperature knob to the right

until „SC“ appears on the display.

SC

5

The steam generator is drained.

End

The steam generator is automatically drained

and thoroughly rinsed.

Your appliance can now be used for cooking.

- 36 -

Page 37

Fault indications

Any faults in your appliance

will be indicated on the display.

E 11

Faults in your appliance which allow you to carry

on cooking can be suppressed by pressing the clock

button.

Fault Cause Remedial action

indication

E1 Appliance defective

E2 Heating switched off for more than 2 Check energy optimisation system!

minutes by an external energy

optimising system.

E3 Appliance defective Notify Customer Service!

E4 Appliance defectivet Notify Customer Service!

E5 Core temperature probe defective Appliance can be operated without core

temperature probe.

Notify Customer Service!

E6 Appliance defective Notify Customer Service!

E7 Appliance defective Notify Customer Service!

E8 Appliance defective Notify Customer Service!

E9 Appliance defective Notify Customer Service!

E10 Appliance defective Notify Customer Service!

E11 No control mode displayed after Notify Customer Service!

switching on

E13 Appliance defective Notify Customer Service!

E14 Appliance defective Notify Customer Service!

E15 Appliance defective Notify Customer Service!

E16 Appliance defective Notify Customer Service!

E17 Ambient temperature too low Room temperature must exceed 5 °C!

E18 Appliance defective Notify Customer Service!

E19 Appliance defective Notify Customer Service!

E20 Appliance defective Notify Customer Service!

E21 Appliance defective Notify Customer Service!

E22 Appliance defective Notify Customer Service!

- 37 -

Page 38

load per container Cooking process Maximum load quantity for each type of unit

1⁄1 2⁄1 pre- 10x2/1

st

Step 2nd Step 3rd Step 6x1/1 6x2/1 10x1/1 20x1/1 20x2/1

- 39 -

Sample applications: beef and veal

Product Hints Accessories

haeting 1

Fillet steak season, brush with oil CombiGrill

Rump steak season, brush with oil CombiGrill

do not flatten

Sirloin season, brush with oil Grid

and CNS

Roast beef add mirepoix 100 mm CNS

(Braised beef) Ø 80–100 mm, cover CNS

Beef roulades season, add hot 65 mm CNS

sauce, cover with 20 mm GN

Fillet of beef

Wellington 20 mm granite

Aitchbone Grid

and CNS

Fillet of veal season, brush with oil CombiGrill

Veal cutlets season just before loading CombiGrill

Roast veal Grid and

65 mm CNS

Knuckle of veal Grid and

40 mm CNS

Osso bucco cover CNS 65 mm CNS

Breast of veal Grid and

65 mm CNS

Saddle of veal Grid and

40 mm CNS

Shoulder of veal Grid and

40 mm CNS

9 pcs. 300 ° 230-250 ° 27 pcs. 45 pcs. 45 pcs. 54 pcs. 108 pcs.

7-10 Min.

9 pcs. 300 ° 260 ° 27 pcs. 45 pcs. 45 pcs. 54 pcs. 108 pcs.

8-10 Min.

6 kg 12 kg 200 ° 160-180 ° 120-140 ° 18 kg 36 kg 30 kg 60 kg 100 kg

5-10 Min. CT 56 °

6-8 kg 12-16 kg 200 ° 160-180 ° 120-140 ° 18 kg 36 kg 30 kg 60 kg 100 kg

90-120 Min. CT 80 °

20-25 40-50 200 ° 130-140 ° 75 pcs. 150 pcs. 125 pcs. 250 pcs. 500 pcs.

pcs. pcs. 60-80 Min.

6-8 kg 12-16 kg 200 ° 160-180 ° 120-140 ° 18 kg 36 kg 30 kg 60 kg 100 kg

CT 80-90 ° CT 56 °

6-8 kg 12-16 kg 100 ° 85 ° 18 kg 36 kg 30 kg 60 kg 100 kg

CT 80-90 °

8 pcs. 250 ° 160-180 ° 120-140 ° 24 pcs. 40 pcs. 40 pcs. 48 pcs. 96 pcs.

5-10 Min. CT 68 °

8 pcs. 250 ° 240 ° 24 pcs. 40 pcs. 40 pcs. 48 pcs. 96 pcs.

10-12 Min.

9 kg 16 kg 200 ° 160-180 ° 140 ° 18 kg 36 kg 30 kg 60 kg 100 kg

30 Min. CT 75 °

6 pcs. 12 pcs. 200 ° 140 ° 170 ° 18 pcs. 36 pcs. 30 pcs. 60 pcs. 120 pcs.

CT 85 ° 10 Min.

15 pcs. 30 pcs. 200 ° 130-140 ° 45 pcs. 90 pcs. 75 pcs. 150 pcs. 300 pcs.

ca. 90 Min.

1 pcs. 2 pcs. 100 ° 20 Min. 140 ° 160-200 ° 3 pcs. 6 pcs. 5 pcs. 10 pcs. 20 pcs.

CT 85 ° 10 Min.

1 pcs. 2 pcs. 200 ° 160-180 ° 120-140 ° 2 pcs. 4 pcs. 3 pcs. 6 pcs. 12 pcs.

10 Min. CT 68 °

6-8 kg 12-16 kg 200 ° 160-180 ° 140-160 ° 18 kg 36 kg 30 kg 60 kg 100 kg

10 Min. CT 80-85 °

CT - core temperature.

- 38 -

Page 39

st

Step 2nd Step 3rd Step 6x1/1 6x2/1 10x1/1 20x1/1 20x2/1

Please note that quantities given always refer to a full load. In certain instances reducing the load can improve food

quality. Foods are natural products, cooking times and temperatures are intended as guides and should, if necessary, be

adjusted to suit the individual product.

st

Step 2nd Step 3rd Step 6x1/1 6x2/1 10x1/1 20x1/1 20x2/1

- 39 -

Page 40

load per container Cooking process Maximum load quantity for each type of unit

1⁄1 2⁄1 pre- 10x2/1

st

Step 2nd Step 3rd Step 6x1/1 6x2/1 10x1/1 20x1/1 20x2/1

- 41 -

Sample applications: pork, mutton and lamb

Product Hints Accessories

haeting 1

Pork medallions season, brush with oil CombiGrill

approx. 70 to 80 g

Escalopes au naturel, brush with oil CombiGrill

Pork chops browning fat, Roasting and baking tray

(breaded)

Burgers Roasting and baking tray

Meat balls 20 mm granite

Saddle of pork Grid and

40 mm CNS

Roast pork Grid and

Neck 65 mm CNS

Roast pork with (stuffed pork belly), make portion-sized Grid and

crackling cuts after step 1, then season 40 mm CNS

Smoked neck of pork boned Grid and

65 mm CNS

Knuckle of pork save stock, for use e.g. with sauerkraut Grid and

65 mm CNS

Leg of pork make cuts after step 1, Grid

then season Potato Baker

Ham 3/4 precook ham, Roasting and baking tray

in breadcrumbs then coat

Mincemeat roast use grid if in tins 20 mm granite

Meat loaf pack into aluminium trays Grid

Spare ribs marinate for 12 h after steaming Grid and

20 mm granite

20 pcs. 300 ° 230-250 ° 60 pcs. 100 pcs. 100 pcs. 120 pcs. 240 pcs.

CT 68-72 °

9 pcs. 300 ° 250-270 ° 27 pcs. 45 pcs. 45 pcs. 54 pcs. 108 pcs.

10-12 Min.

8 pcs. 16 pcs. 250 ° 190-220 ° 24 pcs. 40 pcs. 40 pcs. 48 pcs. 96 pcs.

CT 72 °

10 pcs. 30 pcs. 300 ° 200-200 ° 30 pcs. 60 pcs. 50 pcs. 100 pcs. 150 pcs.

CT 76-80 °

45 pcs. 90 pcs. 250 ° 180-200 ° 135 pcs. 270 pcs. 225 pcs. 450 pcs. 900 pcs.

CT 76-80 °

8 kg 16 kg 250 ° 180 ° 130-150 ° 16 kg 32 kg 24 kg 48 kg 96 kg

30 Min. CT 65 °

8 kg 16 kg 250 ° 140-180 ° 16 kg 32 kg 24 kg 48 kg 96 kg

CT 76-80 °

5-7 kg 10-14 kg 100 ° 20 Min. 140-160 ° 200-220 ° 15 kg 30 kg 25 kg 50 kg 75 kg

CT 74-76 ° 15-20 Min.

6-8 kg 12-16 kg 100 ° 80 ° 16 kg 32 kg 24 kg 48 kg 96 kg

CT 65-72 °

7-9 14-18 100 ° 100 ° 18 pcs. 36 pcs. 30 pcs. 60 pcs. 90 pcs.

pcs. pcs. CT 87 °

6-8 100 ° 20 Min. 140-160 ° 220 ° 18 pcs. 36 pcs. 30 pcs. 60 pcs. 90 pcs.

pcs. CT 78-80 ° 15-20 Min.

ca. 6 kg ca. 12 kg 200 ° 160-180 ° 140-160 ° 12 kg 24 kg 18 kg 36 kg 72 kg

20-30 Min. CT 72-78 °

6 kg 12 kg 200 ° 140-160 ° 18 kg 36 kg 30 kg 60 kg 90 kg

CT 80 °

4-6 kg 8-12 kg 200 ° 130 ° 18 kg 36 kg 30 kg 60 kg 90 kg

CT 72-80 °

3 kg 6 kg 100 ° 60 Min. 180-220 ° 9 kg 18 kg 15 kg 30 kg 45 kg

10-15 Min.

CT - core temperature.

- 40 -

Page 41

st

Step 2nd Step 3rd Step 6x1/1 6x2/1 10x1/1 20x1/1 20x2/1

Please note that quantities given always refer to a full load. In certain instances reducing the load can improve food

quality. Foods are natural products, cooking times and temperatures are intended as guides and should, if necessary, be

adjusted to suit the individual product.

st

Step 2nd Step 3rd Step 6x1/1 6x2/1 10x1/1 20x1/1 20x2/1

- 41 -

Page 42

- 43 -

Sample applications: sausages and frozen food

Suitable load per container Cooking process Approx. loading capacity

Food Hints GN container/grid 1⁄1 2⁄1 pre- 10x2/1

haeting 1

Sausages, to reheat 40 mm CNS

Stuffing ffor mise en place cover with foil 20 mm CNS

Live dumplings lightly grease container 20 mm CNS

Semi-preserved filling weight 200 g 20 mm CNS

foods

Sausages in jars Attention: Cook without lid! 20 mm CNS

(250 g)

Test jars to make sure they can withstand heating

30 pcs. 60 pcs. 85 ° 85 ° 180 pcs. 360 pcs. 300 pcs. 600 pcs. 1200 pcs.

CT 72 °

50 pcs. 100 pcs. 85 ° 85 ° 300 pcs. 600 pcs. 500 pcs. 1000 pcs. 2000 pcs.

10-20 Min.

30 pcs. 60 pcs. 100 ° 100 ° 180 pcs. 360 pcs. 300 pcs. 600 pcs. 1200 pcs.

10-15 Min.

40 pcs. 80 pcs. 100 ° 100 ° 120 pcs. 240 pcs. 200 pcs. 400 pcs. 800 pcs.

40-60 Min.

40 pcs. 80 pcs. 100 ° 100 ° 120 pcs. 240 pcs. 200 pcs. 400 pcs. 800 pcs.

50-70 Min.

Frozen convenience

foods:

Chicken drumsticks- prefried 20 mm granite

and thighs

Fish fingers breaded Roasting and

baking tray

Quiche Lorraine Pre-baked in ø 8 cm aluminium tins 20 mm CNS or

2 cm high, preheat 300 °C Perforated aluminium

Lasagne precooked CNS 65 mm

Pizza precooked Perforated aluminium

20 pcs. 40 pcs. 250 ° 160 ° 120 pcs. 240 pcs. 200 pcs. 400 pcs. 800 pcs.

20-25 Min.

50 pcs. 100 pcs. 300 ° 200-220 ° 300 pcs. 600 pcs. 500 pcs. 1000 pcs. 2000 pcs.

20 Min.

24 pcs. 48 pcs. 300 ° 200 ° 144 pcs. 288 pcs. 450 pcs. 900 pcs. 1800 pcs.

20 Min.

10 port. 20 port. 200 ° 140 ° 30 port. 60 port. 50 port. 100 port. 200 port.

30-40 Min.

2 pcs. 4 pcs. 300 ° 200 ° 12 pcs. 24 pcs. 20 pcs. 40 pcs. 80 pcs.

10-12 Min.

CT - core temperature.

- 42 -

Page 43

Please note that quantities given always refer to a full load. In certain instances reducing the load can improve food

quality. Foods are natural products, cooking times and temperatures are intended as guides and should, if necessary, be

adjusted to suit the individual product.

st

Step 2nd Step 3rd Step 6x1/1 6x2/1 10x1/1 20x1/1 20x2/1

- 43 -

Page 44

load per container Cooking process Maximum load quantity for each type of unit

1⁄1 2⁄1 pre- 10x2/1

st

Step 2nd Step 3rd Step 6x1/1 6x2/1 10x1/1 20x1/1 20x2/1

- 45 -

Sample applications: Game, poultry and pies

Product Hints Accessories

haeting 1

Saddle of venison, Grid and

20 mm granit.

Leg of venison debone, season, bard, tie Grid and

CNS 40 mm

Haunch of venison marinate Grid and

CNS 40 mm

Saddle of hare season 20 mm granite

rare

Larded marinate, season, add granite

leg of hare hot sauce, cover with CNS container

Roast venison braised granite

Pheasant bard, season, 20 mm granite

Wild duck season 20 mm granite

Duck-Superspike

Turkey stuff if required CNS 40 mm

Goose stuff if required, season Grid and granite or

Duck-Superspike

Chicken rub seasoning in well Chicken-Superspike

(whole) vertical/horizontal H10

Chicken Grid and

(1/2) 20 mm granite

Chicken legs rub seasoning in well Grid and

20 mm granite

3 pcs. 4 pcs. 250 ° 180-200 ° 140-160 ° 6 pcs. 8 pcs. 10 pcs. 20 pcs. 40 pcs.

5-10 Min. CT 65-70 °

5-6 kg 10-12 kg 250 ° 180-200 ° 140-160 ° 16 kg 32 kg 24 kg 48 kg 96 kg

10 Min. CT 72-80 °

6 kg 12 kg 250 ° 180-200 ° 140-160 ° 16 kg 32 kg 24 kg 48 kg 96 kg

10 Min. CT 68-78 °

6-8 12-16 250 ° 180-200 ° 140-160 ° 24 pcs. 48 pcs. 40 pcs. 80 pcs. 160 pcs.

pcs. pcs. 10 Min. CT 65-70 °

12 pcs. 24 pcs. 250 ° 160-180 ° 140-160 ° 36 pcs. 72 pcs. 60 pcs. 120 pcs. 240 pcs.

5-10 Min. CT 72-80 °

8 kg 16 kg 200 ° 130 ° 24 kg 48 kg 40 kg 80 kg 160 kg

CT 72-80 °

6-8 12-16 200 ° 160-180 ° 18 pcs. 36 pcs. 30 pcs. 60 pcs. 90 pcs.

pcs. pcs. CT 72-80 °

3 pcs. 6 pcs. 200 ° 140-160 ° 18 pcs. 36 pcs. 30 pcs. 60 pcs. 90 pcs.

CT 88 °

1 pcs. 2 pcs. 180 ° 130-150 ° 2 pcs. 4 pcs. 3 pcs. 6 pcs. 12 pcs.

CT 72 °

2 pcs. 4 pcs. 200 ° 140-160 ° 140-160 ° 4 pcs. 8 pcs. 6 pcs. 12 pcs. 24 pcs.

20 Min. CT 88 °

6 pcs. 12 pcs. 200 ° 160-180 ° 20 pcs. 30 pcs. 40 pcs. 60 pcs. 120 pcs.

CT 88 °

8 pcs. 16 pcs. 200 ° 160-180 ° 24 pcs. 48 pcs. 40 pcs. 80 pcs. 120 pcs.

CT 88 °

10-12 20-24 200 ° 160-180 ° 30 pcs. 60 pcs. 50 pcs. 100 pcs. 150 pcs.

pcs. pcs. CT 88 °

CT - core temperature.

- 44 -

Page 45

st

Step 2nd Step 3rd Step 6x1/1 6x2/1 10x1/1 20x1/1 20x2/1

Please note that quantities given always refer to a full load. In certain instances reducing the load can improve food

quality. Foods are natural products, cooking times and temperatures are intended as guides and should, if necessary, be

adjusted to suit the individual product.

st

Step 2nd Step 3rd Step 6x1/1 6x2/1 10x1/1 20x1/1 20x2/1

- 45 -

Page 46

- 47 -

Sample applications: Fish, shellfish and crustaceans

Suitable

Food Hints GN container/grid 1⁄1 2⁄1 pre- 10x2/1

haeting 1

Salmon Salmon, put abdomen CNS 20 mm

(whole) flap outside

Salmon trout fillets, in serving dish, add CNS 20 mm

Salmon steaks fumet or wine

Halibut salt, pepper, chopped herbs CNS 20 mm

(portions)

Sole roulades can also be stuffed CNS 20 mm

Plaice pale side up Roasting and

baking tray

Pan fried trout season, brush with oil Roasting and

baking tray

Blue trout season stock with vinegar, put abdomen CNS 40 mm

flap to the side

Perch first blanch julienne CNS 20 mm

((on vegetable julienne)

Mussels add wine, vegetable julienne, etc. CNS 40 or 65 mm

Fish dumplings CNS 20 mm

Fish terrine Grid

Squid CNS 20 mm

(whole) Grid

load per container Cooking process Approx. loading capacity

1 pcs. 2 pcs. 100 ° 78 ° 2 pcs. 4 pcs. 3 pcs. 6 pcs. 12 pcs.

CT 67 °

20 pcs. 40 pcs. 100 ° 78 ° 120 pcs. 240 pcs. 200 pcs. 400 pcs. 800 pcs.

15 pcs. 30 pcs. CT 68 ° 90 pcs. 180 pcs. 150 pcs. 300 pcs. 600 pcs.

15 port. 30 port. 100 ° 78 ° 90 port. 180 port. 150 port. 300 port. 600 port.

CT 68 °

30 pcs. 60 pcs. 100 ° 78 ° 180 pcs. 360 pcs. 300 pcs. 600 pcs. 1200 pcs.

CT 67 °

4-5 pcs. 8-10 pcs. 250 ° 220-220 ° 30 pcs. 60 pcs. 50 pcs. 100 pcs. 200 pcs.

CT 66 °

3-5 6-10 250 ° 200-220 ° 30 pcs. 60 pcs. 50 pcs. 100 pcs. 200 pcs.

pcs. pcs. CT 66 °

8-10 16-20 100 ° 100 ° 30 pcs. 60 pcs. 50 pcs. 100 pcs. 200 pcs.

pcs. pcs. CT 68 °

10-12 20-24 100 ° 85 ° 36 pcs. 72 pcs. 60 pcs. 120 pcs. 240 pcs.

pcs. pcs. CT 68 °

1-2 kg 2-4 kg 100 ° 95 ° 6 kg 12 kg 10 kg 20 kg 40 kg

10-15 Min.

50 pcs. 100 pcs. 100 ° 75 ° 300 pcs. 600 pcs. 500 pcs. 1000 pcs. 2000 pcs.

8-15 Min.

3 pcs. 6 pcs. 70-75 ° 9 pcs. 18 pcs. 15 pcs. 30 pcs. 60 pcs.

CT 68 °

1 pcs. 2 pcs. 100 ° 100 ° 80 ° 6 pcs. 12 pcs. 10 pcs. 20 pcs. 40 pcs.

CT 90 ° 30 Min.

Frozen convenience

foods:

Fish, gratinated in CNS 20 mm

aluminium foil, multiple portions

Fish fillet CNS 20 mm

(pre-baked)

CT - core temperature.

- 46 -

12 pcs. 24 pcs. 250 ° 200-220 ° 72 pcs. 144 pcs. 120 pcs. 240 pcs. 480 pcs.

10-20 Min.

18 pcs. 36 pcs. 250 ° 180 ° 108 pcs. 216 pcs. 180 pcs. 360 pcs. 720 pcs.

CT 68 °

Page 47

Please note that quantities given always refer to a full load. In certain instances reducing the load can improve food

quality. Foods are natural products, cooking times and temperatures are intended as guides and should, if necessary, be

adjusted to suit the individual product.

st

Step 2nd Step 3rd Step 6x1/1 6x2/1 10x1/1 20x1/1 20x2/1

- 47 -

Page 48

load per container Cooking process Maximum load quantity for each type of unit

1⁄1 2⁄1 pre- 10x2/1

st

Step 2nd Step 3rd Step 6x1/1 6x2/1 10x1/1 20x1/1 20x2/1

- 49 -

Sample applications: vegetables, side dishes

Product Hints Accessories

haeting 1

Broccoli frozen (fresh, perforated container, CNS 65 mm

plunge in iced water) perforated

Cauliflower cut rosettes CNS 65 mm

perforated

Brussels sprouts frozen, season when frozen, butter CNS 65 mm

just before serving perforated

Spinach fresh CNS 65 mm

perforated

Kohlrabi CNS 65 mm

perforated

Carrots parisienne CNS 65 mm

perforated

Petits pois CNS 65 mm

perforated

Asparagus cook in stock/water CNS 65 mm

Tomatoes blanch for e.g. tomatoes concassé, 20 mm

salad perforated

Green beans frozen, whole or cut, fresh CNS 65 mm

blanch, plunge into iced water perforated

Mushrooms sprinkle with lemon, CNS 65 mm

add white wine if desired

Savoy cabbage cut out stalk, CNS 65 mm

(blanch) plunge fresh cabbage into iced water

Peppers use only red and yellow CNS 65 mm

(stuffed)

Cauliflower every 2nd rack Grid

au gratin CNS 20 mm

Vegetable platter pre-prepared, butter /fat Grid or

(Serving dish) just before serving CNS 20 mm

Baked vegetables CNS

65 mm granite

Stuffed cabbage rolls blanch leaves well, 65 mm perforated

(frozen, preheat 300 °C) CNS 65 mm

Peasant-style fill approx. 1- to 2 cm below edge CNS 40 mm

omelette

Soaking cereals preparing cold and leaving to soak CNS

shortens cooking time 65 mm granite

Moussaka fill 2 cm under top edge CNS

65 mm

5 kg 10 kg 100 ° 100 ° 15 kg 30 kg 25 kg 50 kg 75 kg

10-15 Min.

ca. 4 ca. 8 100 ° 100 ° 12 heads 24 heads 20 heads 40 heads 80 heads

heads heads 12-18 Min.

5 kg 10 kg 100 ° 100 ° 15 kg 30 kg 25 kg 50 kg 75 kg

14-18 Min.

2 kg 4 kg 100 ° 100 ° 6 kg 12 kg 10 kg 20 kg 30 kg

2-5 Min.

5 kg 10 kg 100 ° 100 ° 15 kg 30 kg 25 kg 50 kg 75 kg

15-20 Min.

5 kg 10 kg 100 ° 100 ° 15 kg 30 kg 25 kg 50 kg 75 kg

15-18 Min.

5 kg 10 kg 100 ° 100 ° 15 kg 30 kg 25 kg 50 kg 75 kg

15-18 Min.

2-3 kg 4-6 kg 100 ° 100 ° 9 kg 18 kg 15 kg 30 kg 45 kg

12-15 Min.

28 pcs. 56 pcs. 100 ° 100 ° 225 pcs. 336 pcs. 280 pcs. 560 pcs. 1120 pcs.

1-2 Min.

5 kg 10 kg 100 ° 100 ° 15 kg 30 pcs. 25 kg 50 kg 75 kg

15-18 Min.

2 kg 4 kg 100 ° 100 ° 6 kg 12kg 10 kg 20 kg 40 kg

10-12 Min.

2-3 4-6 100 ° 100 ° 9 heads 18 heads 15 heads 30 heads 60 heads

heads heads 6-8 Min.

20-25 40-50 200 ° 160-180 ° 75 pcs. 125 pcs. 125 pcs. 250 pcs. 375 pcs.

pcs. pcs. 45 Min.

30 port. 60 port. 300 ° 250 ° 90 port. 180 port. 150 port. 300 port. 600 port.

8-10 Min.

4 pcs. 8 pcs. 150 ° 110-130 ° 12 pcs. 24 pcs. 20 pcs. 40 pcs. 80 pcs.

8-12 Min.

30 port. 60 port. 180 ° 170 ° 190 ° 60 port. 120 port. 100 port. 200 port. 300 port.

CT 80 ° 10 Min.

25 pcs. 50 pcs. 180 ° 140-160 ° 60 pcs. 120 pcs. 100 pcs. 200 pcs. 300 pcs.

CT 76-80 °

30 port. 60 port. 150 ° 140 ° 160 ° 90 port. 180 port. 150 port. 300 port. 600 port.

35 Min. 10 Min.

2 kg 4 kg 100 ° 100 ° 12 kg 24 kg 20 kg 40 kg 80 kg

30 Min.

30 port. 60 port. 200 ° 140-180 ° 60 port. 120 port. 100 port. 200 port. 300 port.

15 Min. CT 72-78 °

CT - core temperature.

- 48 -

Page 49

st

Step 2nd Step 3rd Step 6x1/1 6x2/1 10x1/1 20x1/1 20x2/1

Please note that quantities given always refer to a full load. In certain instances reducing the load can improve food

quality. Foods are natural products, cooking times and temperatures are intended as guides and should, if necessary, be

adjusted to suit the individual product.

st

Step 2nd Step 3rd Step 6x1/1 6x2/1 10x1/1 20x1/1 20x2/1

- 49 -

Page 50

load per container Cooking process Maximum load quantity for each type of unit

1⁄1 2⁄1 pre- 10x2/1

st

Step 2nd Step 3rd Step 6x1/1 6x2/1 10x1/1 20x1/1 20x2/1

- 51 -

Sample applications: Eggs, side dishes

Product Hints Accessories

haeting 1

Eggs Soft 7 Min. CNS 65 mm perforated

(hard boiled) Hard 15 Min.

Royale in tins or GN containers CNS 65 mm

Egg soufflés bring milk to the boil, then blend in eggs, CNS 65 mm

cover with foil

Scrambled egg beat eggs, whisk in milk or cream, CNS 65 mm

cover

Quiche prebake base 20 mm granite

Boiled potatoes cut into quarters, salt, CNS 100-150

mix well perforated

Jacket potatoes large potatoes can also be cooked on CNS 100-150

the grid as Idaho potatoes perforated

Dumplings lightly oil CNS container CNS 20 mm

Roast potatoes cooked au point, 40 mm granite

watch bulk

Potatoes in foil wrap potatoes in foil, CNS 20 mm

lay on bed of salt

Potato gratin make sure slices are of equal thickness, 40 mm granite

Potatoes Macaire frozen product 20 mm granite

Vacuum cooked quartered, shaped Grid

Potatoes

Rice long grain, stock – water: CNS 65 mm

ratio 2:1, soaking shortens cooking time

Wild rice ratio 3:1, CNS 65 mm

shortened cooking time

Rice pudding 3 parts milk, 1 part round grain rice, CNS 65 mm

cinnamon stick, sugar, vanilla

Pasta spaghetti, noodles, tagliatelle etc. CNS 65 mm

®

(Finishing

)

Canneloni cover evenly with sauce CNS 65 mm

Lasagne CNS 65 mm

60-100 120-200 100 ° 100 ° 300 pcs. 600 pcs. 500 pcs. 1000 pcs. 2000 pcs.

pcs. pcs. 7-15 Min.

4 litre 8 litre 90 ° 77 ° 12 litre 24 litre 20 litre 40 litre 80 litre

50 Min.

4 litre 8 litre 90 ° 85 ° 12 litre 24 litre 20 litre 40 litre 80 litre

15-25 Min.

4 litre 8 litre 100 ° 100 ° 200 ° 12 litre 24 litre 20 litre 40 litre 80 litre

CT 75 ° 5-8 Min.

10 pcs. 20 pcs. 165 ° 150 ° 175 ° 60 pcs. 120 pcs. 100 pcs. 200 pcs. 400 pcs.

10 Min. 10 Min.

8-14 kg 16-28 kg 100 ° 100 ° 24 kg 48 kg 42 kg 80-90 160-180

40-55 Min. kg kg

6-12 kg 14-24 kg 100 ° 100 ° 18 kg 36 kg 36 kg 60-72 120-154

40-55 Min. kg kg

30 pcs. 60 pcs. 100 ° 100 ° 90 pcs. 180 pcs. 150 pcs. 300 pcs. 450 pcs.

30-40 Min.

2 kg 4 kg 300 ° 220 ° 6 kg 12 kg 10 kg 20 kg 30 kg

30-40 Min.

20 pcs. 40 pcs. 200 ° 180 ° 90 pcs. 180 pcs. 150 pcs. 300 pcs. 450 pcs.

45-50 Min.

30 port. 60 port. 140 ° 125 ° 150 ° 60 port. 120 port. 100 port. 200 port. 300 port.

CT 80 ° 10 Min.

40 pcs. 80 pcs. 250 ° 200-220 ° 120 pcs. 240 pcs. 200 pcs. 400 pcs. 800 pcs.

15-18 Min.

4-4,5 kg 8-9 kg 100 ° 20-25 kg 40-50kg 40-50 kg 90 kg 180 kg

30 Min.

2 kg 4 kg 100 ° 100 ° 6 kg 12 kg 10 kg 20 kg 40 kg

35-45 Min.

2 kg 4 kg 100 ° 100 ° 6 kg 12 kg 10 kg 20 kg 40 kg

45-55 Min.

2 kg 4 kg 99 ° 90-99 ° 6 kg 12 kg 10 kg 20 kg 40 kg

50-60 Min.

2 kg 4 kg 100 ° 100 ° 6 kg 12 kg 10 kg 20 kg 40 kg

F

10 Min.

30 port. 60 port. 200 ° 170 ° 90 port. 180 port. 150 port. 300 port. 450 port.

CT 80 °

20 port. 40 port. 160 ° 150 ° 170-190 ° 60 port. 120 port. 100 port. 200 port. 300 port.

CT 80 ° 10 Min.

Pasta soufflé blend egg mixture in well CNS or

granite

20 port. 40 port. 180 ° 150-170 ° 170-190 ° 60 port. 120 port. 100 port. 200 port. 300 port.

CT 80 ° 5 Min.

CT - core temperature.

- 50 -

Page 51

st

Step 2nd Step 3rd Step 6x1/1 6x2/1 10x1/1 20x1/1 20x2/1

Please note that quantities given always refer to a full load. In certain instances reducing the load can improve food

quality. Foods are natural products, cooking times and temperatures are intended as guides and should, if necessary, be

adjusted to suit the individual product.

st

Step 2nd Step 3rd Step 6x1/1 6x2/1 10x1/1 20x1/1 20x2/1

F

- 51 -

Page 52

load per container Cooking process Maximum load quantity for each type of unit

1⁄1 2⁄1 pre- 10x2/1

st

Step 2nd Step 3rd Step 6x1/1 6x2/1 10x1/1 20x1/1 20x2/1

- 53 -

Sample applications: Pasty, bread, rolls, desserts 1

Product Hints Accessories

haeting 1

Apple strudel brush with milk, egg or sugar-water Roasting and baking tray

(Strudel dough

Frozen brush with liaison if desired Roasting and baking tray

apple turnovers preheat

Sponge base 20 mm granite

(Swiss rolls)

Sponge base Ø 26 cm, every 2nd rack Roasting and baking tray

Ring

Flaky pastry, brush carefully with egg, Roasting and baking tray

pies, fleurons

Flaky pastry every 2nd rack Roasting and baking tray

tartlets - fresh

Puff pastries filled evtl. mit Ei bestreichen Roasting and baking tray

(with cheese etc.)

Tray cakes every 2nd rack 20 mm or

40 mm

Christmas stollen line tins well Roasting and baking tray

Croissants – fresh cook "Vario-Steam" 34 °C, Roasting and baking tray

Compote cut fruit up evenly, CNS 65 mm

leave to firm after steaming

Fruit garnishes Cut or shape 20 mm

apples, pears etc.

Hot fruit frozen fruit, raspberries, strawberries, Grid

blackberries, in serving dish

Fruit conserves Ø 10–12 cm, e.g. pears, Grid or

(Jars without lids) filling volume 1 litre 20 mm

Cabinet pudding line tins Grid

(foil or baking paper)

Crème caramel darioles, cocottes, timbales etc. Grid or

(glasses) 20 mm

2 pcs. 4 pcs. 200 ° 140-160 ° 6 pcs. 12 pcs. 10 pcs. 20 pcs. 40 pcs.

40-60 Min.

10 pcs. 20 pcs. 200 ° 150-170 ° 60 pcs. 120 pcs. 100 pcs. 200 pcs. 300 pcs.

15-25 Min.

1 kg 2 kg 200 ° 140-160 ° 6 kg 12 kg 10 kg 20 kg 40 kg

10-20 Min.

2 shapes 4 shapes 200 ° 140-160 ° 6 shapes 12 shapes 10 shapes 20 shapes 40 shapes

15-40 Min.

Dez 15 24-30 180 ° 150-170 ° 160-180 ° 45 pcs. 90 pcs. 75 pcs. 150 pcs. 300 pcs.

pcs. pcs. 8-15 Min. 5-20 Min.

je nach je nach 180 ° 150-170 ° 160-180 °

Größe Größe 5-10 Min. 2-10 Min.

12 pcs. 24 pcs. 180 ° 170 ° 160-180 ° 24 pcs. 48 pcs. 40 pcs. 80 pcs. 160 pcs.

20-25 Min. 5-20 Min.

30 port. 60 port. 180 ° 140-160 ° 90 port. 180 port. 150 port. 300 port. 600 port.

30-50 Min.

2 kg 4 kg 180 ° 140-160 ° 150-170 ° 6 kg 12 kg 10 kg 20 kg 40 kg

10-15 Min. 20-30 Min.

12 pcs. 24 pcs. 180 ° 150-170 ° 160-180 ° 24 pcs. 48 pcs. 40 pcs. 80 pcs. 160 pcs.

CT 85 ° 10 Min.

30 port. 60 port. 120 ° 120 ° 90 port. 180 port. 150 port. 300 port. 600 port.

20-25 Min.

30 pcs. 60 pcs. 100 ° 100 ° 180 pcs. 360 pcs. 300 pcs. 600 pcs. 1200 pcs.

6-8 Min.

15 pcs. 30 pcs. 90 ° 80-90 ° 90 pcs. 180 pcs. 150 pcs. 300 pcs. 600 pcs.

4-6 Min.

10 pcs. 20 pcs. 100 ° 100 ° 30 pcs. 60 pcs. 50 pcs. 100 pcs. 200 pcs.

50-60 Min.

4 pcs. 8 pcs. 90 ° 90 ° 12 pcs. 24 pcs. 20 pcs. 40 pcs. 80 pcs.

45 Min.

40 pcs. 80 pcs. 80 ° 77 ° 120 pcs. 240 pcs. 200 pcs. 400 pcs. 800 pcs.

40-50 Min.

CT - core temperature.

- 52 -

Page 53

st

Step 2nd Step 3rd Step 6x1/1 6x2/1 10x1/1 20x1/1 20x2/1

Please note that quantities given always refer to a full load. In certain instances reducing the load can improve food

quality. Foods are natural products, cooking times and temperatures are intended as guides and should, if necessary, be

adjusted to suit the individual product.

st

Step 2nd Step 3rd Step 6x1/1 6x2/1 10x1/1 20x1/1 20x2/1

- 53 -

Page 54

- 55 -

Sample applications: Pasty, bread, dessert 2

Suitable

Food Hints GN container/grid 1⁄1 2⁄1 pre- 10x2/1

haeting 1

Yeast cakes every 2nd rack 20 mm granite or

Roasting and baking tray

Yeast plaits 20 mm granite

500 g or baking tray perforaded

Cheesecake every 2nd rack 60 mm granite

Marble cake grease tins carefully, Grid or

cut top after baking for 10 minutes Roasting and baking tray

Mixed-grain bread 20 mm granite

or baking tray perforaded

Short pastry and make sure thickness is even 20 mm granite

piped biscuits every 2nd rack Roasting and baking tray

Danish pastries baking temperature depends on filling Roasting and baking tray

or baking tray perforaded

Madeira-type cake tins on grids Grid

Savarin butter and flour tins Grid

Stollen light mix Roasting and baking tray

approx. 200 g

Streusel cake spread crumble evenly 20 mm

granite

Viennese-style spread mix evenly 20 mm granite or

sponge Ø 26 cm flan ring Roasting and baking tray

Rolls frozen Perforated aluminium

Roasting and baking tray

White bread every 2nd rack 20 mm granite

tin (700 g) Roasting and baking tray

Crisp up baguettes, frozen portions, approx. 45-50 g Roasting and baking tray

rolls, day goods or baking tray perforaded

Toast butter lightly if desired Grid or

Roasting and baking tray

Vacuum cooked fruit add wine, liqueur etc. Grid

Cinnamon whirls cook "Variosteam" 30 °C 20 mm granite or.

Roasting and baking tray

Plum cake Yeast dough approx. 5mm thick/prove 20 mm granite or.

Roasting and baking tray

load per container Cooking process Approx. loading capacity

2 kg 4 kg 180 ° 140-160 ° 160-180 ° 6 kg 12 kg 10 kg 20 kg 40 kg

5-10 Min. 15-30 Min.

2 pcs. 4 pcs. 180 ° 140-160 ° 160-180 ° 6 pcs. 12 pcs. 10 pcs. 20 pcs. 40 pcs.

CT 85 ° 10-15 Min.

40 port. 80 port. 180 ° 140-150 ° 140-160 ° 60 port. 120 port. 100 port. 200 port. 300 port.

10-15 Min. 25-45 Min.

4 Kasten- 8 Kasten 180 ° 140-160 ° 12 shapes 24 shapes 20 shapes 40 shapes 80 shapes

shapes shapes 35-55 Min.

3 pcs. 6 pcs. 180 ° 160-180 ° 160-180 ° 9 pcs. 18 pcs. 15 pcs. 30 pcs. 60 pcs.

10 Min. 30-50 Min.

24 pcs. 48 pcs. 160 ° 140-160 ° 72 pcs. 144 pcs. 120 pcs. 240 pcs. 480 pcs.

5-15 Min.

10 pcs. 20 pcs. 200 ° 160-180 ° 160-180 ° 60 pcs. 120 pcs. 100 pcs. 200 pcs. 300 pcs.

CT 85 ° 5-10 Min.

4 pcs. 8 pcs. 200 ° 160-180 ° 12 pcs. 24 pcs. 20 pcs. 40 pcs. 80 pcs.

40-60 Min.

10 pcs. 20 pcs. 180 ° 150-170 ° 30 pcs. 60 pcs. 50 pcs. 100 pcs. 200 pcs.

8-12 Min.

4 shapes 8 shapes 180 ° 140-160 ° 150-170 ° 12 shapes 24 shapes 20 shapes 40 shapes 80 shapes

10-15 Min. 20-30 Min.

40 port. 80 port. 180 ° 140-160 ° 160-180 ° 120 port. 240 port. 200 port. 400 port. 600 port.

5-10 Min. 15-30 Min.

200 ° 140-160 ° 6 pcs. 12 pcs. 10 pcs. 20 pcs. 40 pcs.

10-20 Min.

15 pcs. 30 pcs. 180 ° 140 ° 160-170 ° 45 pcs. 90 pcs. 75 pcs. 150 pcs. 300 pcs.

5 Min. 8-15 Min.

4 pcs. 8 pcs. 180 ° 140 ° 170 ° 12 pcs. 24 pcs. 20 pcs. 40 pcs. 80 pcs.

5 Min. 30-35 Min.

10-12 20-24 180 ° 140-160 ° 140-160 ° 60 pcs. 120 pcs. 100 pcs. 200 pcs. 400 pcs.

pcs. pcs. 5 Min. 5-10 Min.

15-18 30-36 250 ° 250 ° 108 pcs. 216 pcs. 180 pcs. 360 pcs. 720 pcs.

pcs. pcs. 3-5 Min.

4 kg 8 kg 90 ° 80-99 ° 24 kg 48 kg 40 kg 80 kg 160 kg

20-30 Min.

12 pcs. 24 pcs. 180 ° 150-170 ° 150-170 ° 36 pcs. 72 pcs. 60 pcs. 120 pcs. 240 pcs.

5 Min. 5-15 Min.

30 port. 60 port. 180 ° 140-160 ° 90 port. 180 port. 150 port. 300 port. 450 port.

30-40 Min.

CT - core temperature.

- 54 -

Page 55

Please note that quantities given always refer to a full load. In certain instances reducing the load can improve food

quality. Foods are natural products, cooking times and temperatures are intended as guides and should, if necessary, be

adjusted to suit the individual product.

st

Step 2nd Step 3nd Step 6x1/1 6x2/1 10x1/1 20x1/1 20x2/1

- 55 -

Page 56

Before you call customer service

Error Possible cause To eliminate

Water dripping out of the

unit’s door

Noise is heard in the

cooking cabinet while the

unit is in use.

Door is not closed correctly.

Door seal is worn or

damaged.

Air baffles, grid shelves, etc,

are not fixed correctly.

If the door is closed correctly, the door handle

will point down on floor units.