Page 1

smart mini servo feed

cut-to-length

oPerating instructions

MODELS

SMS2, SMS4, SMS8

RAPID-AIR CORPORATION

4601 KISHWAUKEE ST. • ROCKFORD, IL 61109-2925

Phone: (815) 397-2578 • Fax: (815) 398-3887 • Web Site: www.rapidair.com

1

Page 2

table of contents

INTRODUCTION, INSTALLATION AND SET-UP ..................................................................................... pg. 3

ADJUSTMENT, CABLING AND INTERFACING ...................................................................................... pg. 4

PRETEST WITHOUT MATERIAL AND LOADING MATERIAL ................................................................ pg. 5

TROUBLESHOOTING .................................................................................................................................. pg. 6-7

MAINTENANCE PROCEDURES, PRECAUTIONS AND SAFETY ........................................................... pg. 7

CUTTER MAINTENANCE ........................................................................................................................... pg. 8

FSC8/SMS8 CONTROL ASSEMBLY .......................................................................................................... pg. 9

RSC14/SMS2 SERVO CONTROL ASSEMBLY .......................................................................................... pg. 10

PROGRAMMING PROCEDURE ................................................................................................................. pg. 11-13

TROUBLESHOOTING .................................................................................................................................. pg. 14-15

LED STATUS SYMBOLS ............................................................................................................................. pg. 16-18

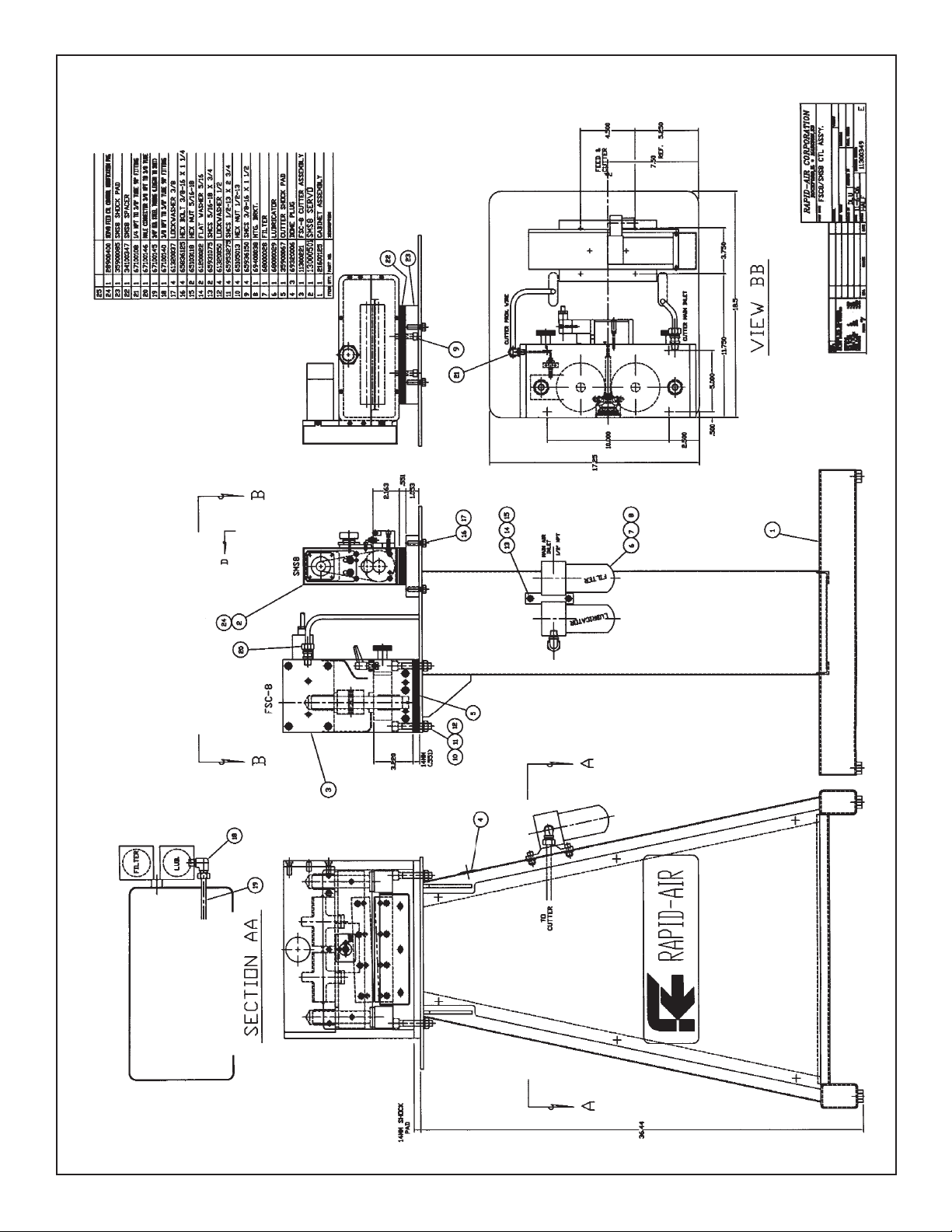

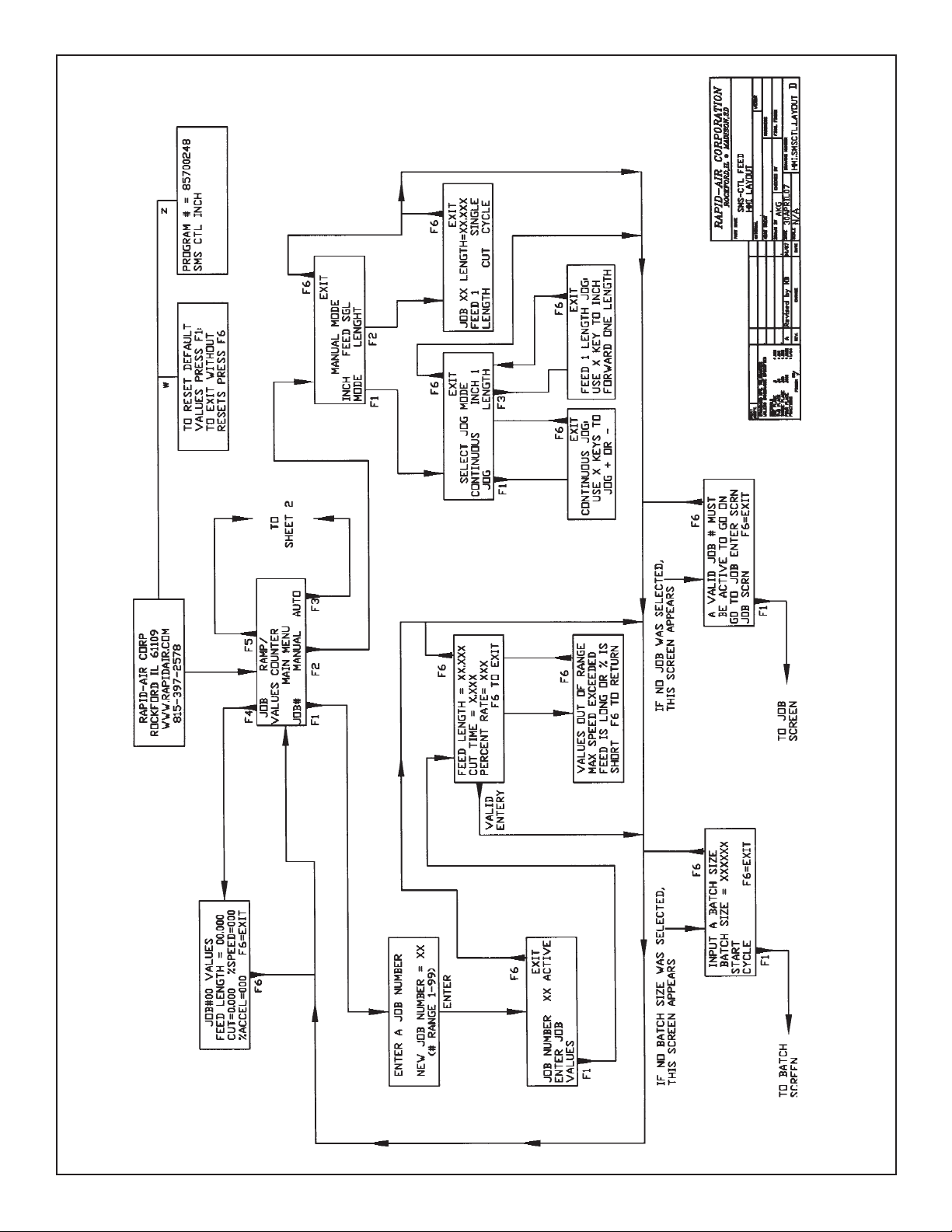

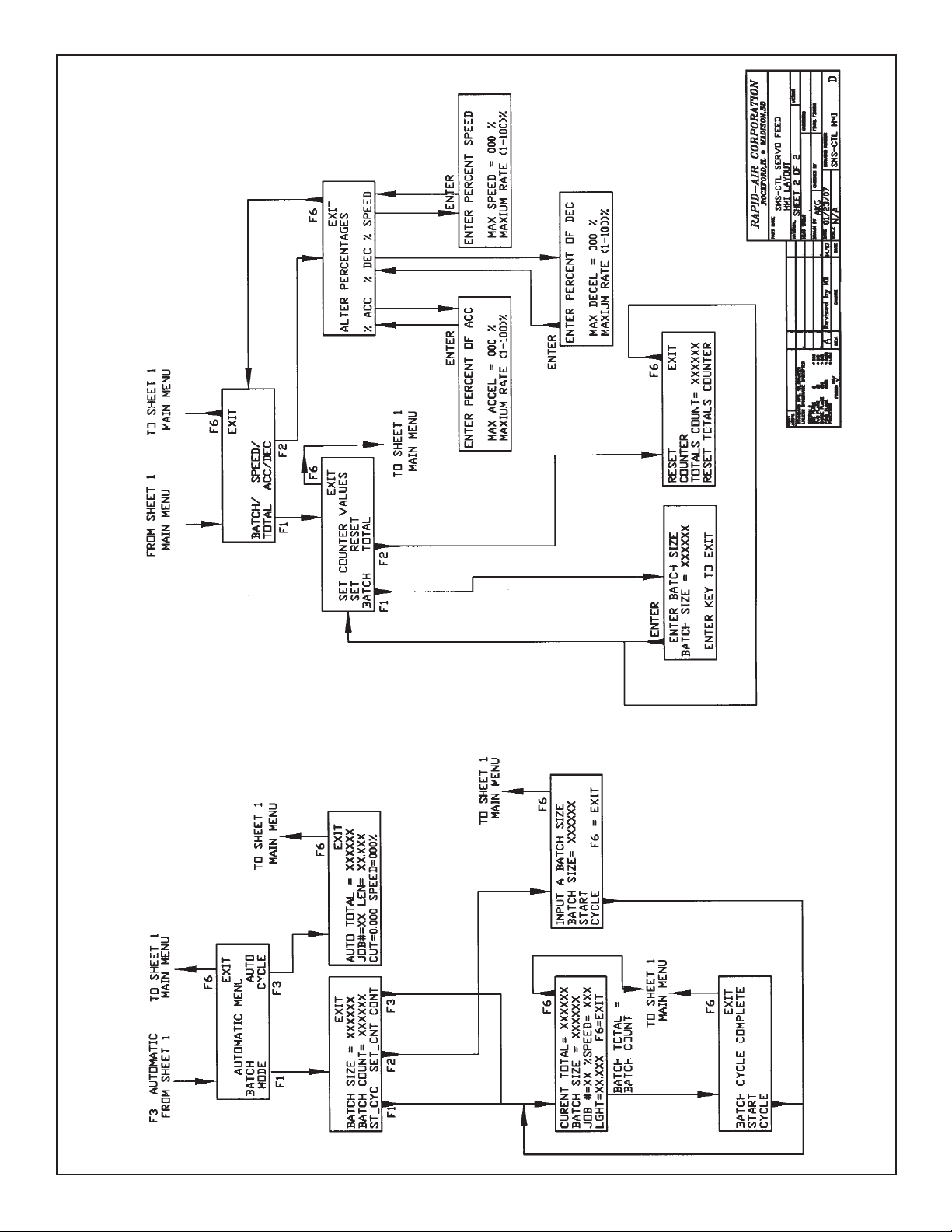

SMS - CTL FEED DIAGRAM ....................................................................................................................... pg. 19

SMS - CTL SERVO FEED DIAGRAM ......................................................................................................... pg. 20

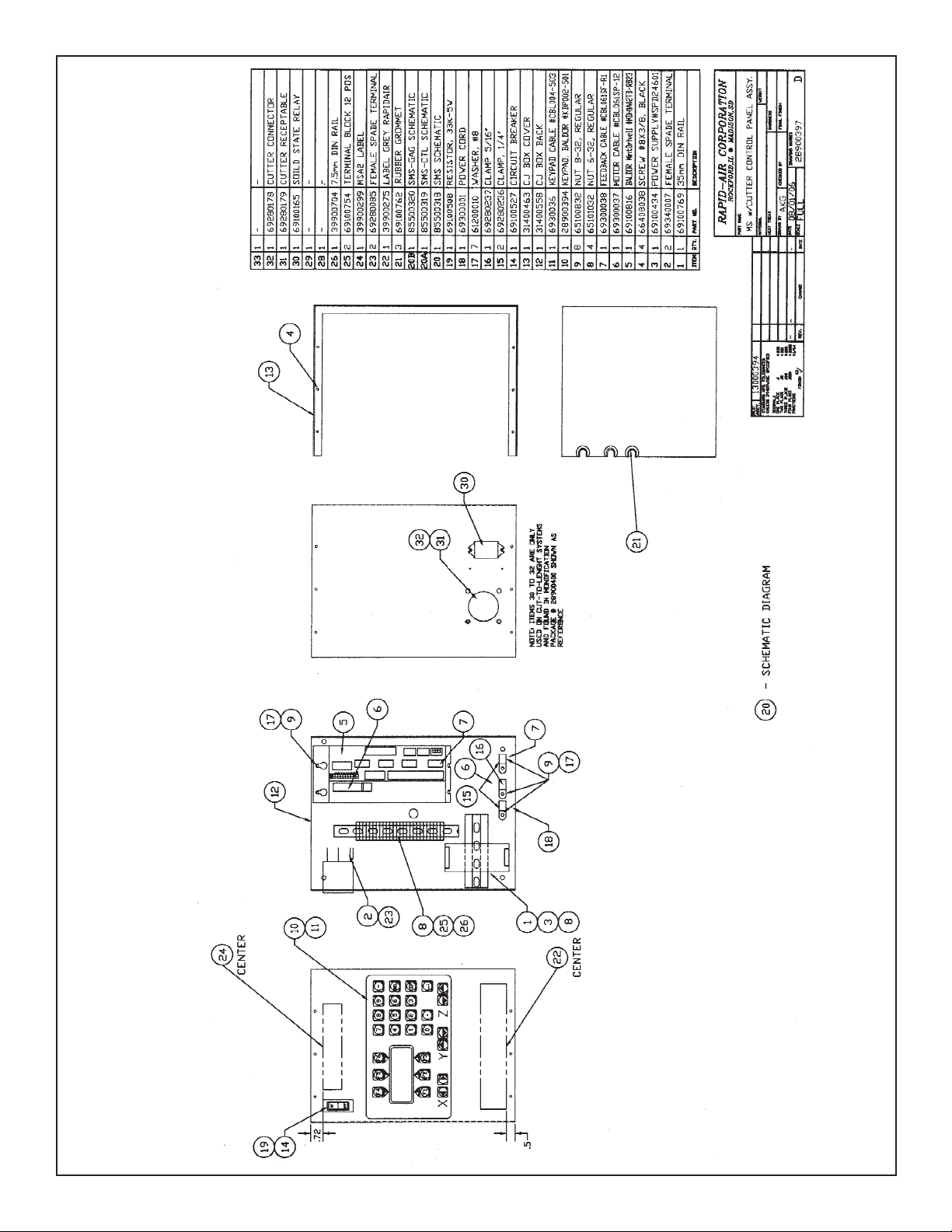

SMS WITH CUTTER CONTROL PANEL ASSEMBLY .............................................................................. pg. 21

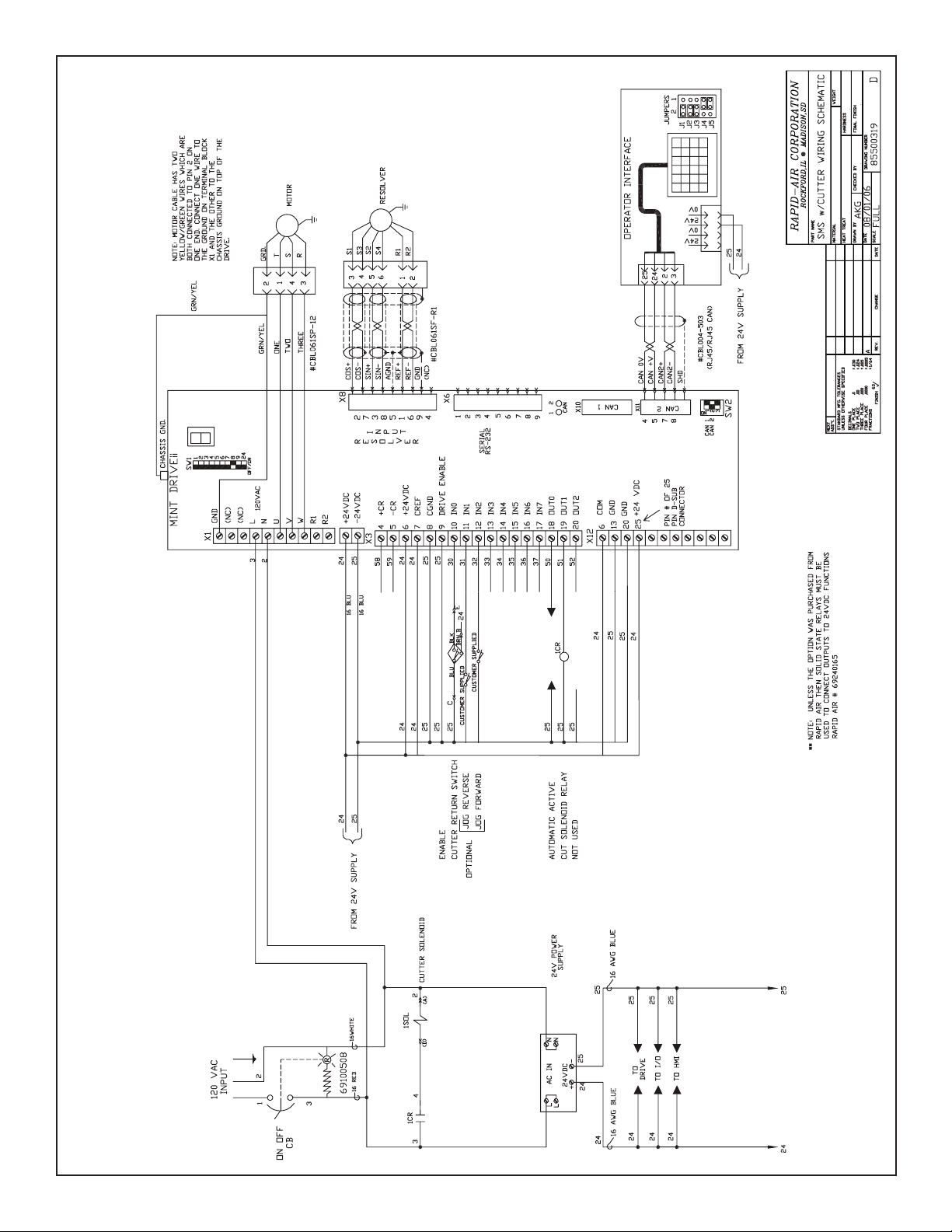

SMS WITH CUTTER WIRING SCHEMATIC ............................................................................................. pg. 22

WARRANTY ................................................................................................................................................. pg. 23

2

Page 3

introduction, installation and set-uP

Smart Mini Servo Feed With Cut-To-Length Introduction

The Rapid-Air Servo Cut-To-Length

Feed system carries with it the

quality and reliability you have grown

to expect from a Rapid-Air product.

The motion control system is a

programmable industrial computer

and this advanced technology,

combined with a highly engineered

precision roll feed, is an unchallenged

combination in the press industry.

The compact mechanical package,

direct coupled with a brushless servo

drive motor, offers response and feed

speed accuracy unparalleled in any

other powered roll feed. Operator

interface is so simplified, a typical

setup person can have the servo

feed programmed and running in a

matter of minutes. A step by step

prompt appears on a four line

80-character display, which asks

simple questions of the operator.

Entry of feed length, cutter dwell time,

and % maximum speed are all that is

required for a new setup. Routine jobs

can be stored, recalled, changed and

saved or run with a simple 2 digit job

number entry. Up to 99 jobs may be

stored and recalled at will.

A resolver, direct coupled to the

servo drive motor for precise digital

position feedback, enable roll

positioning accuracy to +/- .0025 for

any programmed feed length or speed.

Operator programmed feed length,

up to 99.999 inches and % max speed

selection along with full jog features

on a pendant unit, allow the operator

to thread the material and inch it into

position. The inch feature enables the

operator to jog the servo feed forward

or reverse at a slow rate. The operator

can select jog to length or jog continuous to aid in threading up material.

The Rapid-Air Servo Roll Feed has

been designed to mount on a

free-standing table as close as

possible to the cutter.

The precision mechanical roll

feed unit has been designed for

compactness, ease of setup and

installation. Three cables with twist

lock connectors, two cables for the

servo, one connected to the cutter,

and one air line are the only external

connections required. The electrical

controls are housed in a small cabinet

which should be mounted close to

the press working area. The operator

keypad and display are mounted on

top of the control cabinet.

Installation And Mechanical Setup Of Servo And Cutter

If you purchased the servo/cutter

combination already mounted on a

base then the servo and cutter were

aligned at the factory. A good

practice is to check all hold down

bolts to be sure that they did not

come loose during shipment.

If you purchased the servo and cutter

and are going to mount it on a base

at your facility, then a base should

be selected that will hold the weight

of the servo and the cutter and also

the cycling shocks incurred during

production.

When mounting the two devices,

the pass line height of the cutter

and the servo roller center line should

be equal. Even more critical is the

parallelism between the two devices.

The cutter should be mounted first

then the servo center line should

be aligned to the cutter center line

with the servo rollers parallel to the

cutter blade.

The servo should be mounted as

close to the cutter as possible and depending on thickness of the material

a bridge should be installed between

the servo and cutter to minimize

material droop or buckling during feed.

3

Page 4

adjustment, cabling and interfacing

Drive Roll Parallelism Adjustment

Every servo feed has an eccentric

adjustment screw to adjust the upper

roller to be in parallel to the lower

roller. The maximum adjustment is

.008” on the eccentric.

The adjustment screw is located

opposite the belt cover and is held

fast by a socket head cap screw.

The actual adjustment screw is an

eccentric sleeve which is turned

clockwise or counter-clockwise to

raise or lower one end of the upper roll.

The parallel adjustment is factory

set when the unit is manufactured

but if material tracking seems to be a

problem then this could be a way of

solving the problem. To test if the rolls

need adjustment, do the following.

1. Remove the front and rear roll

covers.

2. Shine a light from the rear

of the feed toward the

main rollers.

3. Inspect from the main rolls

side to see if the rollers are

parallel. If they are, then the

material could be the cause

of the material walking. If

they are not parallel then an

adjustment has to be made.

4. To make the adjustment:

a. Locate eccentric screw

and loosen socket head

lock screw.

b. Turn slotted eccentric

sleeve while viewing rolls

until the rolls are parallel.

c. Tighten 10-32 screw and

reassemble parts, then retry

running material.

For a more accurate adjustment use a

feeler gauge to check the parallelism.

This completes the eccentric adjustment write-up, if there are further

questions, please call the factory.

* Before attempting to solve a

possible roll parallelism problem by

readjusting the rolls or calling the

factory, perform the following test.

Step 1) A 3 to 5 foot length of material

should be cut from the storage loop

preceding the servo feed.

Step 2) Lay the material next to a

straight line to see if the material

is cambered. If it is, then this could

be the reason that the material

is walking. If not, then turn the

material upside down from the way

it was being fed and insert into the

feed. If the material walks in the

opposite direction then the material

could be to blame.

Electrical Cables And Air Line

120 VAC INPUT

The input voltage to the control is

120 Vac, 1 Ph, 60 Hz. The max

amperage needed is 7.5 amps and

the control has a circuit breaker

with a trip amperage of 10 amps.

The electrical control enclosure is

shipped completely ready to be

connected to the mechanical feed.

Connected to the enclosure are (2)

cables with keyed screw type

connectors for connection to the

motor. The third connector is used to

interface the cutter to the controls.

Position the electrical enclosure

at a convenient location near the

mechanical feed and attach the

cables. The motor cables are easily

identifiable by the amount of pins in

the plugs. The solenoid cables, if

any, can now be attached and

checked for proper location when

Interfacing Servo Feed With A Cutter

The Servo Drive unit is programmed

to feed each time a signal is received

from the cutter switch. The servo will

feed one progression and wait for the

next signal before it will feed again in

automatic mode.

The command is in the form of a

normally open contact from a proximity switch, located on the cutter and is

activated when the cutter is returned.

If the feed/cutter was purchased

the feed is up and running.

An air line must be connected

from the shop air to the air inlet

of the servo feed. The air should

be at least 80 PSI continuous and

should be dry filtered and lightly

lubricated for the best operation

of the servo feed. The air inlet

is NPT pipe tap. The minimum

air line size requirement is 1/2” ID

hose. - (2 CFM)

complete, then the interfacing was

done for you.

This completes the initial setup of the

servo feed to the cutter or other device.

The servo is now ready to run as intended.

4

Page 5

Pretest and loading material

Pretest For Servo Feed And Cutter Without Material

Now that your servo/cutter combination is in place, and the cables have

been attached, you can proceed

with testing the unit. The first step

is to turn on the main switch on the

electrical enclosure.

At this time the display should show

the Rapid-Air screen for 5 seconds

before starting the main setup program. If you are comfortable with

programming a job then continue, if

not, please refer to the Operator Interface Terminal located in this manual.

Follow the programming sequence

for the operators terminal to input

parameters into job storage. Your servo feed has been fully tested before it

was shipped to your facility and this

procedure is merely a test to insure

that all functions are still functional

and the cables are properly seated.

Once you have programmed the

required parameters, select the

manual mode of operation. If the

option of air regulated upper feed roll

was purchased, check that the main

air is at least 80 psi and check that the

roll pressure gauge is functional by

adjusting the pressure up and down,

this is accomplished by turning the

pressure adjusting knob. Check that

you have enough tension on the

material to avoid slipping during

feeding. Open and close the feed rolls

manually. Visually inspect that the

rolls open and close when using the

manual levers.

Select the “inch” function (F1 on

keypad) on the manual mode screen.

Visually check that the rolls rotate

both forward and reverse with the

corresponding key. The speed is preset to creep the rolls at a slow speed

for manual positioning of the material.

CAUTION: Do not attempt to place

your fingers or any foreign material

into the rolls. Injury to the operator or

damage to the servo rolls could result.

After you have verified that the

rolls are operational, you can experiment with the single cycle moves.

The procedure is outlined in the

programming section of this manual.

After all the checks have been made

and you feel comfortable with the

programming of the servo controller,

place the servo in automatic mode.

Now cycle the press in either the

inch, single stroke or continuous run,

the servo feed should react upon

the closure of the press window

and signal and simulate a feed

progression of material.

Loading Material Into The Servo Feed

Upon the satisfactory completion of all

the tests, you should be ready to load

a strip of material into the servo feed.

Step number one is to select the

manual mode of operation on the

operators console. You open the

rolls manually by lifting the lever

mounted on the side of the servo

feed. Position the leading edge of

the material with the center of the

material near the center of the entry

rolls. Adjust the edge guides on the

cascade rolls to the proper width

setting. Open the feed rolls. Hand

feed the material into the servo unit

until it protrudes out of the feed rolls

and starts into the guide on the cutter.

Close the feed rolls.

Check the roller force pressure to be

sure that there is enough pressure

to prevent slippage but not too much

to induce camber into the material.

The pressure setting is the amount of

force necessary to move the material

into the press at the speed and

feed programmed. You may find it

necessary to readjust the force as

you finalize the setup procedure. The

amount of force needed will vary

depending on the width and type of

material being fed. Make a note of the

final setting to aid in the setup of the

servo feed the next time the same

material is run.

You are now ready to begin testing

the complete system under power.

To check the progression, cycle the

servo and cutter first in the manual

mode then in the single cycle mode.

If the progression is correct, no further adjustments are necessary. If the

progression is either short or long, go

to the troubleshooting chart and perform the sequences described there

for inaccurate feeding, once the feed

progression has been accurately set

and the repeatability is satisfactory,

you are ready for full automatic mode.

5

Page 6

troubleshooting

Problem Cause Remedy

No power indication

No display on operators console

Power on – no motion

Material will not enter rolls

Material will not feed

– Disconnect off.

– Blown fuse.

– Master button in.

– Program fault.

– Faulty wiring.

– Program fault

– Drive fault

– Program error.

– Feed roll adjusting mechanism

too close.

– Material too thick.

– Low roller force.

– Oily material.

– Program fault.

– Obstruction.

– Turn disconnect on.

– Check / replace fuse.

– Pull button out.

– Check lights on P.C.

– Check plug on console.

– Check lights on drive.

– Check lights on servo drive readout.

– Check parameters.

– Open adjustment mechanism.

– Check servo parameters.

– Raise roller pressure.

– Clean material.

– Check parameters.

– Check path.

Material feeds short

Material feeds long

Material camber

– Accel to fast.

– Low roller force.

– Oily material.

– Obstruction in path.

– High % max speed.

– Material slippery.

– Decell set too high.

– High roller force.

– Bad stock.

– Lower accel speed.

– Raise roller pressure.

– Clean material.

– Check path.

– Lower % max feed speed.

– Lower % decell.

– Lower % decell.

– Lower roller pressure.

– Check stock at input for camber.

6

Page 7

troubleshooting (continued)

Problem Cause Remedy

Material feeds off center

No automatic cycle

Servo squeals

Fault signal on drive is displayed

Cannot program unit from display

– Edge guides not set properly.

– Material not centered to feed.

– Bad material.

– No cutter signal.

– Controller fault.

– Servo fault.

– Program error.

– Servo velocity gain too high.

– Belt too loose or tight.

– Servo fault.

– Material jam.

– Power surge / failure.

– Program fault.

– Set edge guides.

– Center material.

– Try new roll of material.

– Check cutter prox. SW. input to

servo control.

– Check lights on drive.

– Check parameters on display.

– Consult factory.

– Readjust belt tension.

– Recycle power.

– Check cutter.

– Check / recycle power.

– Check drive and call factory.

maintenance Procedures, Precautions and safety

Maintenance Procedures Precautions And Safety

DAILY

Wipe off feed rolls.

Clean any dirt from servo unit.

Clean any dirt from operators pendant.

WEEKLY

Check wear pattern of rolls.

MONTHLY

Check cables for cuts or wear.

NEVER – Put screwdrivers or foreign materials in feed rolls.

NEVER – Hold onto material as it is being fed through the servo.

NEVER – Wear neckties around the servo feed rolls.

NEVER – Force the rolls open by prying on them.

NEVER – Modify the mechanical aspects of the servo feed.

CAUTION – Contact the factory before drilling any holes in the unit.

CAUTION – Wear proper eye protection when working around the servo.

CAUTION – Do not wear loose clothing around the servo feed rolls.

7

Page 8

cutter maintenance

Small Cutter

CUTTER DATA: See specific cutter specifications.

OPERATIONS: The solenoid valve, which is remote

mounted, is attached to the cutter (item #3) by a

plastic hose and advances the cutter into the material. Compression springs return the blade to the

raised position. The cutter raised position is monitored by a proximity switch mounted on the rear of

the cutter (item #4).

ADJUSTMENTS: The cutter blade may be lowered

manually by pushing down on the head of the cutter. The upper half of the cutter is attached to an adjustable slide. The

cutter clearance can be adjusted by loosening 2 screws (item #1) and rotating the hex nuts (item #2). To adjust, loosen one

side and tighten the opposite side corresponding to the side you want to adjust in order to line up the blades. Retighten the

top screws (item #1). When greasing, use Mobilux No. 2 or equivalent.

Large Cutter

CUTTER DATA: Material opening (item #1); see

specific cutter specifications.

OPERATIONS: The solenoid valve (item #2)

advances the cutter into the material and the

compression springs return the blade to the

raised position.

ADJUSTMENTS: The blade may be lowered

manually with an eccentric cam screw (item #6)

located on the upper blade assembly just under

the solenoid valve.

The lower half of the cutter is attached to an adjustable slide (item #3). The cutter clearance is adjusted by loosening (2)

hex screws (item #4) on the adjusting slides and turning (2) knurled knobs (item #5) to move the lower blade horizontally in

and out.

8

Page 9

FSC8/SMS8 Control Assembly

9

Page 10

RSC14/SMS2 Servo Control Assembly

10

Page 11

Programming Procedure

Operator Interface Terminal

This section is to familiarize an operator with the terminal screen (program)

flow. Also, the section will explain

how to move from screen to screen.

The screen flow is divided into five

parts as set up in the home screen

– “MAIN MENU”. These divisions are:

1. F1 - JOB ENTRY

2. F2 - MANUAL MODE

3. F3 - AUTOMATIC MODE

4. F4 - REVIEW JOB VALUES

5. F5 - RAMP/COUNTER

The final section is the TROUBLESHOOTING and ERROR CODES.

OVERVIEW

The first screen displayed will look like:

RAPID-AIR CORPORATION

ROCKFORD, IL 61109

WWW.RAPIDAIR.COM

815-397-2578

While the above screen is displayed,

the system is starting up and doing

a self-diagnostic test. If the selfdiagnostic test passes, the program

will start automatically. After a short

delay the main screen will appear.

The “MAIN SCREEN” will look like:

JOB RAMP/

VALUES COUNTER

MAIN MENU

JOB # MANUAL AUTO

SCREEN HINTS

Movement from screen to screen uses

the “F” keys. The “F” key functional

descriptions usually appear above

(F1 to F3) or below (F4 to F6) the keys.

Occasionally, the text will describe the

action caused by an “F” key.

To enter a value, locate the curser (an

underscore line) that will be found below the first character of the number

the program is requesting. As each

character is typed, the cursor will

move to the next digit. The Enter key

may be depressed at any time to enter

current value into memory. When a

value is entered, the program will

check value to ensure that it is a valid

value. A valid entry is a value, which

is in the correct range. A value’s

range is shown by parentheses. If an

invalid number is entered, the cursor

will return to the first character of

the invalid value entered. The cursor will move to the beginning of the

next value needed after a valid entry.

Entering the last value on a screen

will cause the display to move to the

next screen.

SECTION 1 F1 - JOB NUMBER Entry

A job number must be active to do

a manual single feed; an automatic

move, review job values, or edit ramps

or counters. The values entered for

each job will be stored in memory and

available each time that job is selected.

To select an existing job or create a

new job, press F1 while on the “MAIN

SCREEN”. Pressing F1 will display the

“ENTER A JOB SCREEN”. It is:

ENTER A JOB NUMBER

NEW JOB NUMBER = 00

(JOB # RANGE 1-99)

A two-digit number must be entered. An

invalid number will cause the curser to

return to the first digit. After entering a

valid job number, depressing the enter

key will display the following screen:

EXIT

JOB NUMBER 00 ACTIVE

ENTER JOB

VALUES

Selecting F1 will allow values for all

the necessary data for a job to be

entered. The feed advisor will make

the calculations for the job. F6 will

exit to the “MAIN MENU” without

entering or changing any values for

that job. When the F1 is pressed

after selecting enter job values,

the following screen will appear:

FEED LENGTH = 00.000

CUT TIME = 0.000

PERCENT RATE = 000

The feed length is first value required.

A valid feed length distance is 0.001

inches to 99.999 inches. The cut time

is the time the knife blade solenoid is

energized. A valid cut time is between

0.001 and 2.000 seconds. The final

item on this screen is the percent

rate. A valid percent rate is between

1 and 100. After entering valid

values for all three items, the

Feed Advisor will calculate the

motor speed, acceleration and

deceleration. If the speed, accel and

decel are within acceptable limits,

the main screen will reappear. If the

values are outside acceptable limits,

the following screen will appear.

VALUES OUT OF RANGE

MAX SPEED EXCEEDED

FEED IS LONG OR % IS

SHORT F6 TO RETURN

Pushing F4 will take an operator back

to the feed advisor screen. After entering valid data, the “MAIN MENU”

will be displayed.

NOTE: If a job number is not selected

and the selected task requires a job

with a feed length and speed to be

active, the following screen will appear. After a valid job is entered the

program will return to the original task.

11

Page 12

Programming Procedure (continued)

A VALID JOB # MUST

BE ACTIVE TO GO ON

GO TO JOB ENTER SCRN

JOB SCRN F6=EXIT

SECTION 2 F2 - MANUAL MODE

Pressing F2, manual mode while on

the “MAIN MENU”, will cause the

following the screen.

EXIT

MANUAL MODE

INCH FEED SGL

MODE LENGTH

F1, inch mode, produces the following:

EXIT

SELECT JOG MODE

CONTINUOUS INCH 1

JOG LENGTH

F3, feed sgl length, produces the fol-

lowing:

EXIT

JOB 00 LENGTH = 00.000

FEED 1 SINGLE

LENGTH CUT CYCLE

F6, exit, in both screens moves the

display up one level to “MANUAL

MODE”. F1, Continuous jog, allows

an operator to jog each axis in either

direction. The X-axis keys move the

feed axis.

F3, inch 1 length, allows an operator

to inch the material forward one feed

length. The “X” axis keys will move

the axis while a key is pressed until

one feed length is reached. If the key

is released before one feed length is

reached, the axis will stop and wait

until the jog key is pressed again or

one feed length is reached.

SECTION 3 F3 - AUTOMATIC MODE

Pressing F3, automatic mode while

on the “MAIN MENU”, will cause the

following the screen.

EXIT

AUTOMATIC MENU:

BATCH AUTO

MODE MODE

F1, batch mode, controls batches from

the “BATCH START” screen.

INPUT A BATCH SIZE

BATCH SIZE = 000000

START

CYCLE F6 = EXIT

The F3 key, CONT (continue), will restart a batch stopped before reaching

the full batch size by exiting with the

F6 key. The “BATCH MENU” screen is:

BATCH TOTAL = 000000

BATCH SIZE = 000000

JOB#=00 SPM = 000

BLANK = 00.000 F6 = EXIT

NOTE: If the batch size is set to

000000, the “BATCH SET” screen will

appear. The “BATCH SET” screen will

allow an operator to set the batch

count. The “BATCH SET” screen can

also be found under ramp/count selection on the “MAIN MENU” screen.

The “BATCH SET” screen is shown

above under F2. After the batch size

is entered and F1 (start cycle) is

pressed, the program will return to

“BATCH SET” screen.

When the batch total equals the

batch size, the feed will stop and will

display this screen.

F6, exit, in both screens moves the

display back to “MANUAL MODE”.

F1, inch mode, give the operator two

additional choices. These are:

F1, Continuous jog

EXIT

CONTINUOUS JOG:

USE X KEYS TO

JOG + OR -

F3, inch 1 length

EXIT

FEED 1 LENGTH JOG:

USE X KEY TO INCH

FORWARD ONE LENGTH

EXIT

BATCH SIZE = 000000

BATCH COUNT = 000000

ST_CYC SET_CNT CONT

The F1 key, ST_CYC (start cycle), will

begin the feed/cut cycle. The “BATCH

MENU” screen appears as follows.

CURRENT TOTAL = 000000

BATCH SIZE = 000000

JOB # =00 % SPEED = 000

LGHT = 00.000 F6 = EXIT

The F2 key, SET_CNT (set count), will

allow the operator to set the batch

size or change the batch size. The

“BATCH SET” screen is:

12

EXIT

BATCH CYCLE COMPLETE

BATCH COUNT = 000000

NEW CYCLE

F6, exit, will return to the “MAIN

MENU” screen. F1, start new cycle,

will reset the batch count total to 000000

and will start feeding another batch.

Depressing F3, auto mode, while on the

“AUTOMATIC MODE” screen will display:

EXIT

AUTO TOTAL = 000000

JOB # =00 LENGT = 00.000

CUT = 000 SPEED = 000 %

The automatic cycle will continue

until the F6 key, exit, is pressed.

Page 13

Programming Procedure (continued)

SECTION 4 F4

F4, job values, on the “MAIN MENU”

screen displays the following screen

until F6, exit, is pushed. This screen

lists the current active job number,

the feed length, the SPM, the percentage of speed, the percentage of

acceleration, and if a pilot is used.

JOB # 00 VALUES =

FEED LENGTH = 00.000

CUT = 000 % SPEED = 000

ACCEL = 000 F6 = EXIT

SECTION 5 F5 - RAMP/COUNTER

F5, ramp/counter, on the “MAIN

MENU” screen displays the following

screen:

EXIT

BATCH/ SPEED/

TOTAL ACC/DEC

- JOB VALUES REVIEW

EXIT

SET COUNTER VALUES

SET RESET

BATCH/ TOTAL

F1, set batch, on the “SET COUNTER

VALUES” screen leads to “BATCH

SET” screen discussed above in

SECTION 3.

F2, reset totals, on the “SET COUNTER VALUES” screen resets the total

counter to 000000.

F6, exit, will return to the “RAMP/

COUNTER” screen.

F2, speed/acc/dec, on the “RAMP/

COUNTER” screen leads to:

EXIT

ALTER PERCENTAGES

%ACC %DEC %SPEED

F6, exit, will return to the “RAMP/

COUNTER” screen.

ENTER PERCENT OF ACC

MAX ACCEL = 000 %

MAXIMUM RATE (1 - 100) %

ENTER KEY TO EXIT

The enter key returns the display to

the “ALTER PERCENTAGES” screen.

F2, % dec, allows the deceleration

percentage to be altered with:

ENTER PERCENT OF DEC

MAX DECEL = 000 %

MAXIMUM RATE (1 - 100) %

ENTER KEY TO EXIT

The enter key returns the display to

the “ALTER PERCENTAGES” screen.

F3, % speed, allows the speed

percentage to be altered with:

ENTER PERCENT OF SPEED

MAX SPEED = 000 %

MAXIMUM RATE (1-100) %

ENTER KEY TO EXIT

F1, batch/total, on the

“RAMP/COUNTER” screen leads to:

F1, % acc, allows the acceleration

percentage to be altered with:

The enter key returns the display to

the “ALTER PERCENTAGES” screen.

13

Page 14

troubleshooting

A normally running drive will display an 8 in the LED box, top center. The LED box will display error and fault codes. The keypad

can display additional error codes and information about system operational problems.

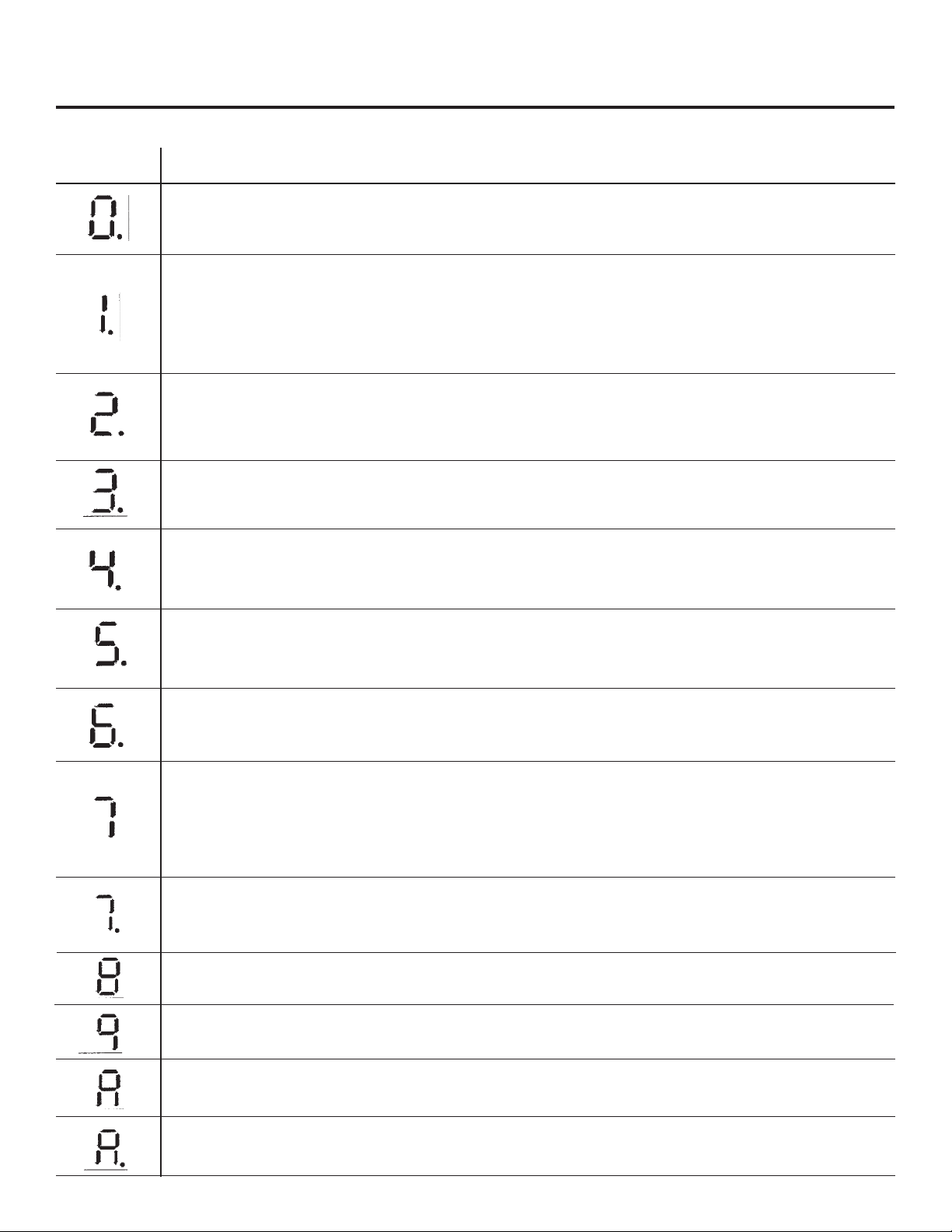

LED Box Error Codes

Display Description

0.

1.

2.

3.

4.

5.

6.

7 (not flashing)

7.

8

9

A

b.

c

E.

F.

I

Internal communications error

DC Bus overvoltage level – possibly too high of deceleration

Internal overcurrent, short circuit, over temperature or under voltage fault

Drive overcurrent – check motor cable

DC Bus voltage is below the minimum value – too high an acceleration rate

Feedback trip – check feedback cable

2

Motor or drive I

2

Motor I

Drive over temperature – check internal drive fan

Drive enabled (normal operating mode)

Drive is in torque mode – Not used in Rapid-Air Smart Mini

Drive in Analog Mode – Not used in Rapid-Air Smart Mini

Power base not ready (only on 3 phase drives) – loss of a phase

Cam profile active – Not used in Rapid-Air Smart Mini

General error – error number is on keypad display (see run-time errors below)

Position or velocity following error – possible motor or resolver failure

Drive in electronic gearing mode.

T foldback – motor overloaded or stalled for too long a time

T overload – motor overloaded or stalled

H

h or h.

I

J

J.

o

º.

P. (.flashing)

P. (.steady)

•

r

S

-

-.

=

S

•

1

Drive in a hold state – DIP switch change or PLC request

Homing – Not used in Rapid-Air Smart Mini

Incremental move

Jog move

Preset jog active

Offset move

Overspeed

Positional move

Preset trapezoidal move active – Not used in Rapid-Air Smart Mini

DB (regen resistor) overload

Stop command active

Drive disabled

Crash

Suspend command active

Drive under speed control

Initialization error at power up

14

Page 15

troubleshooting (continued)

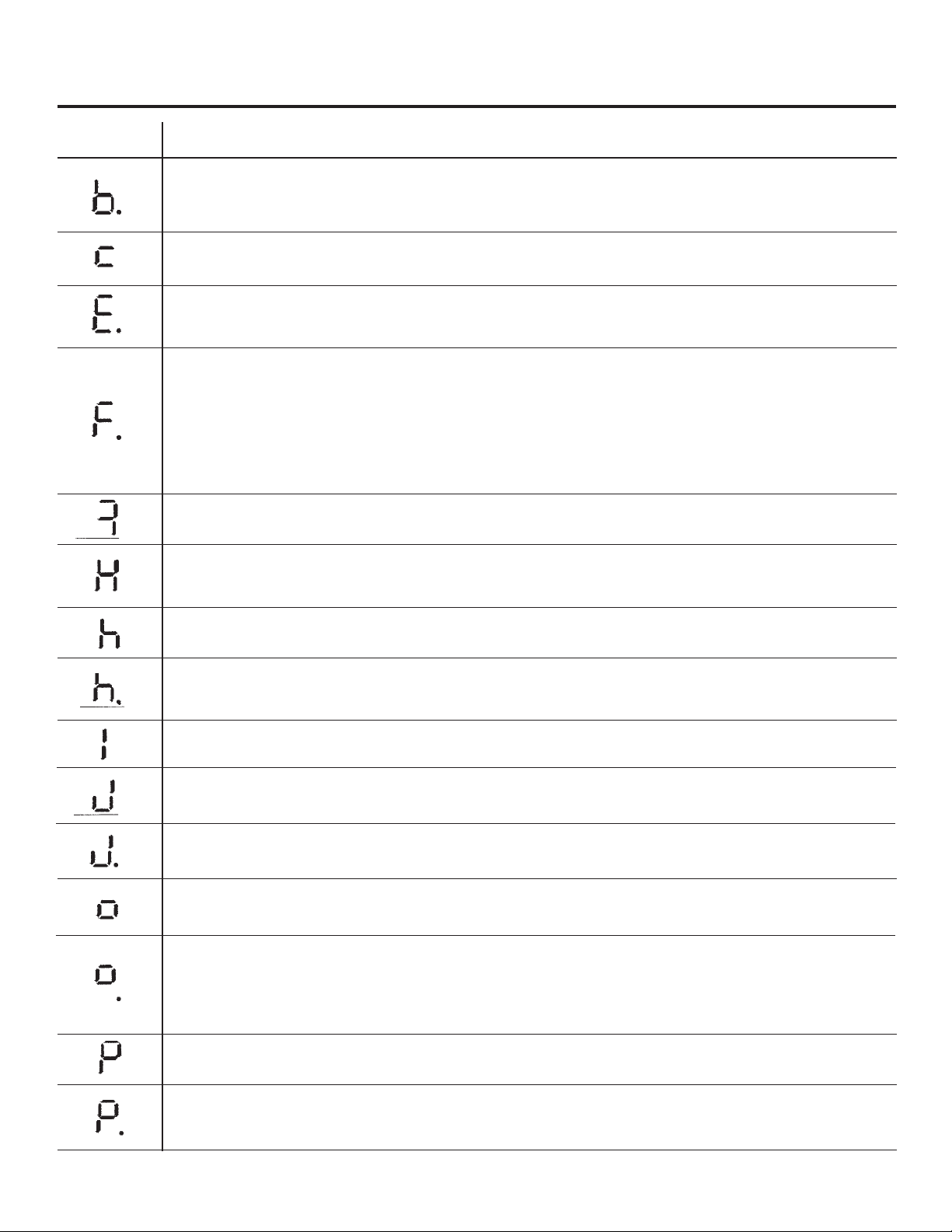

Can Status LEDs

There are two CAN LEDs , the left

LED shows activity on the CAN1

(CANopen) bus. The right LED shows

activity on the CAN2 (Baldor CAN)

bus. Each LED can appear green

or red. The states have the following

meanings:

=

NOT LIT: No power to the card.

= GREEN: The bus is operational;

it is experiencing little or no errors.

RUN TIME MML ERROR CODES

Errors 0 to 500 are caused by specialized keywords, and are known as Mint Motion Library (MML) errors.

Errors 3100 and up are general keywords. The most common are also below.

Number Name Description

1 Synchronous MML error Generic error generated when no more specific info is available.

3 Data out of range Data values out of acceptable range for a variable.

9 Out of heap memory Controller is out of memory space.

10 Action not possible Tried to write to a motion keyword while the axis is in motion.

14 Unable to initialize CAN A node returned an error message, other than synchronous or remote.

21 CAN node failed to reply Communication over the CAN bus has timed-out.

22 CAN node not live This error will be generated if you try accessing a node that has died.

27 Problem writing to EEPROM Communication with a remote node timed-out.

28 CAN node - Baud rate The CAN node does not support the requested baud rate.

29 CAN node reported error An error has occurred and cannot be determined further.

34 CAN transmit buffer full This error number should not be reported.

37 Non-volatile data corrupted An error accessing EEPROM or NVRAM data has occurred.

40 Drive is not enabled You have tried starting a move while the drive is disabled.

41 No connection exists There is no connection between the CAN open nodes.

50 Error programming flash The controller has failed to write data to the flash memory.

90 Action not possible The command is not possible whilst the drive is enabled.

121 Error accessing EEPROM EEPROM access has failed.

135 Axis/drive not commissioned The axis/drive is not commissioned.

137 Feedback device comms message is corrupt.

138 Feedback device comms are busy.

139 Feedback device has an error.

147 Static data overrun Static variable is filled, but data remains.

= RED, FLASHING: The bus is passive;

it is experiencing some errors.

= RED: The bus is off; it has experi enced a fatal number of errors.

ERROR CODES IN GENERAL

Various error codes can be displayed

on the operator keypad display. Errors

are divided into two categories –

Run-time Errors and Compilation Errors.

Compilation errors have numbers 2100

to 2400. Compilation errors are based

on programming rules are probably

not arise in normal use, therefore,

are not listed below. If an error with

a number between 2100 and 2400

appears, please consult the Rapid-Air

representative. The most common

Run-time errors and possible causes

are listed below.

RUN TIME GENERAL ERROR CODES

Number Name Description

3100 Division by zero This occurs when the denominator of a division is zero.

3102 Out of memory Array too large to fit in the remaining memory, or function does

not terminate before the internal stacks run out of free storage.

15

Page 16

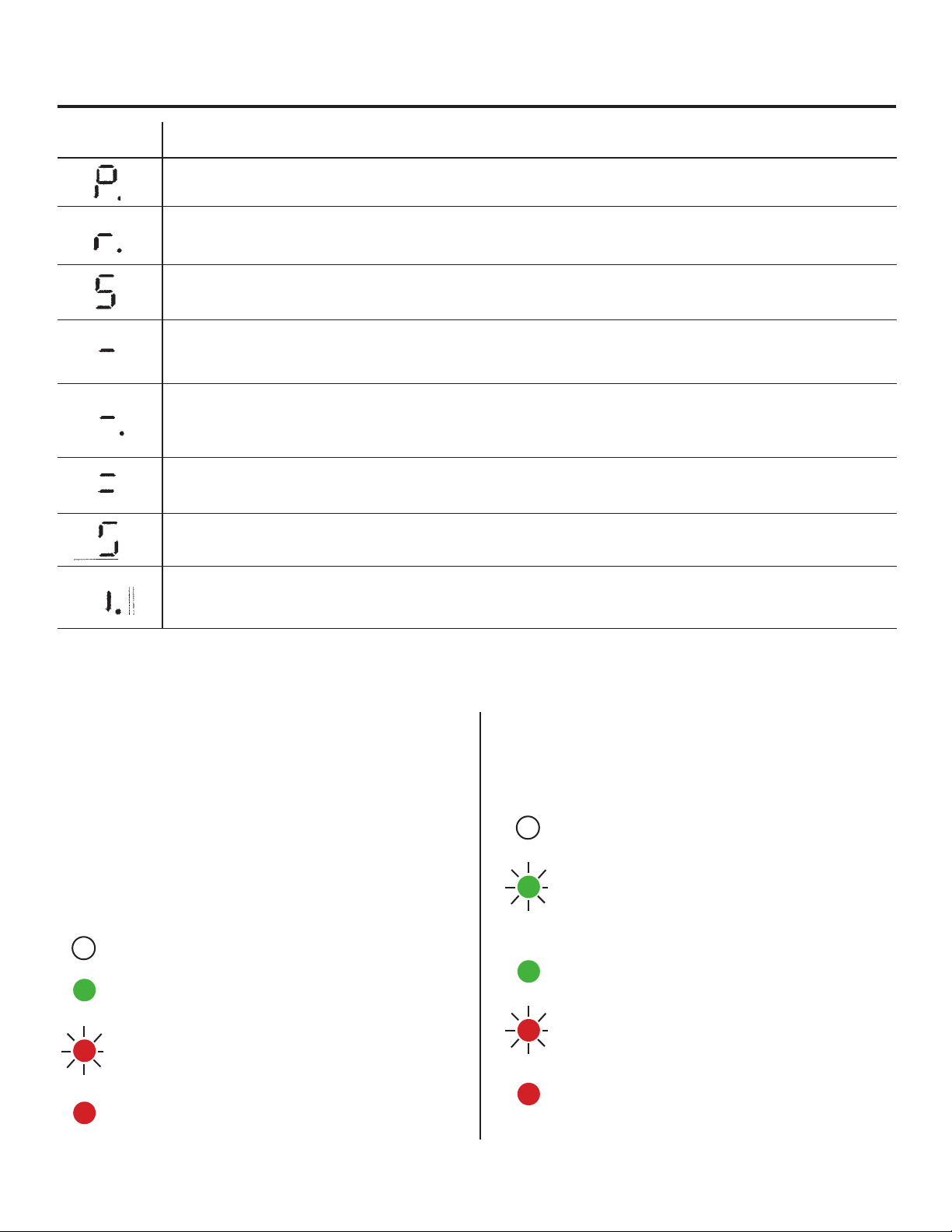

led status symbols

Symbol Description

Drive / comms watchdog. Internal communications failure. Clear the error; if the problem persists then

contact Baldor technical support.

Over volts. The DC Bus voltage has exceeded the overvoltage level. Check the AC supply voltage is correct

for the unit. Check the DC Bus level. This should be close to the nominal voltage. If the input voltage is correct, then this error may be the result of high deceleration rates. If it is not possible to reduce the deceleration rate, then an external regen resistor should be used. To help you determine the cause of this fault, use

the WorkBench v5 Scope tool to monitor the DC Bus level during moves.

Intelligent Power Module (IPM) trip. The IPM has detected an internal overcurrent, short circuit, over temperature or under voltage fault. Clear the error. If the problem persists, contact Baldor Technical Support or

Rapid-Air.

Overcurrent trip. Current has exceeded 300% of Drive Rated Current. Check the motor cable and

connections for short circuits.

Under volts. The DC Bus voltage has fallen below the minimum undervolts level. This error will only be generated if the drive is in the enabled state. Check the AC supply voltage is correct for the unit. The error could

also occur during high acceleration profiles; to prevent this, reduce the acceleration rate.

Feedback trip. This error indicates loss of encoder/resolver feedback and may indicate that the feedback

cable has become detached, one of the signals has broken, or noise is present. Check the wiring in the

Feedback cable; check the cable screens; check the feedback device fitted to the motor (if possible).

Motor or Drive I

their limit and disabled the drive.

2

T overload. The motor I2T or the drive l.T current protection algorithms have exceeded

(Symbol not flashing)

Motor I

to a level where the drive/motor can recover. The motor / drive can run with demand currents greater than

their rated value for a period of time; after that time the drive will either trip or automatically foldback the

demand current.

Overtemperature. The temperature of the drive has exceeded the trip level or the Motor overtemperature

trip input has been activated. Check that the drives internal fans are functioning. Increase ventilation to the

drive or reduce the ambient temperature.

Drive enabled. The drive is enabled.

Torque mode. The drive is in Torque mode.

Hold to Analog. The axis is in Hold To Analog mode.

Auto tune test driving motor. Autotune is active and driving the motor.

2

T / It foldback. Motor I2T or Drive I.T algorithm has resulted in the demand current being folded back

Warning! The motor shaft may move.

16

Page 17

led status symbols (continued)

Symbol Description

Power base not ready. This error condition applies only to 3-phase models. These drives have a pre-charge

circuit which must activate after power-up before the drive can be enabled. If the drive is enabled before

this then the error occurs. The error could also indicate the loss of one or more of the input phases.

Cam. A cam profile is in progress.

General error. The motion toolbar displays the status of AXISERROR, which is a bit pattern of all latched errors.

Position or velocity following error. A following error has occurred. Following errors could be caused by a

badly tuned drive/motor, especially at high acceleration and deceleration rates where the following error

will typically be greater. The following error limit can be adjusted to suit your application. Following error

could also be the caused by encoder/resolver loss. Confirm that the motor is not overloaded

or stalling. Check the tuning of the drive using the WorkBench v5 Fine-tuning tool. The KVELFF parameter

can be used to reduce following errors during moves.

Follow mode. The drive is in pulse follower or electronic gearing modes.

Hold. The Hold DIP switch is active or the PLC Task has requested a Hold state. Motion will be ramped to

zero demand and will then hold on position while the switch is active.

Homing. The drive is currently homing.

Preset homing active. The drive is currently homing. This motion has been triggered from a Preset move

table.

Incremental move. An incremental move is in progress.

Jog. The drive is Jogging.

Preset jog move active. The drive is Jogging. The Jog was triggered from a Preset jog table.

Offset move. The drive is performing an offset move.

Overspeed. The measured speed of the motor has exceeded the trip level defined by DRIVESPEEDFATAL.

When accelerating to a demand speed close to the trip level, there will typically be a certain amount of

overshoot. Using the Fine-tuning tool, check the amount of overshoot you get with the acceleration and

demand speeds being used in your application.

Positional Move. A point-to-point move is in progress.

(Decimal point flashing)

Preset moves are active, but currently idle (no motion)

17

Page 18

led status symbols (continued)

Symbol Description

Preset trapezoidal move active (in motion).

DB Overload. The regeneration resistor (Dynamic Brake) has been overloaded.

Stop. A STOP command has been issued or the stop input is active.

Drive disabled. The drive must be enabled before operation can continue. A number of actions are required

to enable the drive. See the installation manual supplied with your product.

Crash (various). The drive enable input or the Enable DIP switch have become inactive whilst the drive was

in the enable state (or the drive was enabled whilst they were inactive) - bit 13 in AXISERROR will be set. The

drive can be programmed to ignore this state using DRIVEENABLEINPUTMODE.

Suspend. The SUSPEND command has been issued and is active. Motion will be ramped to zero demand

whilst active.

Speed demand. The drive is under speed control.

Initialization error. An initialization error has occurred at power on.

FlexDrive”, Flex+Drive” And

MintDrive” Options

CAN OPTION / CAN & AUXILIARY I/O OPTION

There are two CAN LEDs on these option cards. On

both options, the left LED shows activity on the CAN1

(CANopen) bus. When the CAN & Auxiliary I/O option is

fitted in a MintDrive”, the right LED shows activity on the

CAN2 (Baldor CAN) bus. Each LED can appear green

or red. The states have the following meanings:

= Not lit: No power to the option card.

= Green: The bus is operational; it is experiencing

little or no errors.

= Red, flashing: The bus is passive;

it is experiencing some errors.

= Red: The bus is off; it has experienced a fatal

number of errors.

DeviceNet Option

There is one Bus Activity LED on this option, which

can appear green or red. The states have the following

meanings:

= Not lit: No power to the option card or there is

no DeviceNet master on the bus.

= Green, flashing: There are one or more devices

on the bus, but there is no communication with

this unit.

= Green: The option is being polled by the

master and is operating correctly.

= Red, flashing: Minor fault, for example an

I/O connection may have timed out.

= Red: Major communications fault, for example,

an incorrect baud rate, a duplicated node ID

(MAC ID), or a bus-off fault.

18

Page 19

SMS - CTL Feed

19

Page 20

SMS - CTL Servo Feed

20

Page 21

SMS with Cutter Control Panel Assembly

21

Page 22

SMS with Cutter Wiring Schematic

22

Page 23

warranty

Warranty Terms & Conditions

ALL SALES BY THE COMPANY ARE MADE SUBJECT TO THE FOLLOWING TERMS AND CONDITIONS. PLEASE READ.

WARRANTY – The Company warrants, for a period of one year from date of shipment by the Company, that the product

shipped is free from defects in material and workmanship. THIS WARRANTY IS EXCLUSIVE AND IN LIEU OF ALL IMPLIED

WARRANTIES IN LAW, INCLUDING MERCHANT - ABILITY. The Company obligation under this warranty is limited to

repairing or replacing, F.O.B. Madison, SD, any part or parts proved to have been defective when shipped. In no event

shall the Company be liable for special or consequential damages. Provisions set forth in specifications are descriptive

and subject to change and are not intended as warranties.

CUSTOMER LICENSE AGREEMENT – The RAPID-AIR CORPORATION reserves the rights in it’s software. The software

program is licensed by RAPID-AIR to the original purchaser of the equipment which contains the software for use only on

the terms set forth in this license.

You may use the program only on the programmable servo computer furnished with the system and only in conjunction

with the servo feed supplied with the system.

You may not without expressed permission from Rapid-Air:

A. Copy, distribute, or document the program for others.

B. Modify or merge any portion of the program for use on non compatible hardware.

C. Make alterations to the program.

23

Loading...

Loading...