Page 1

Straightener and

puShbutton rapid-roll

operating inStructionS

MODELS

SC SERIES

SA3 THROUGH SDX SERIES

(INCLUDES ADJUSTABLE PLATEN STOCK STRAIGHTENER –

SA3 THROUGH SD. 120VAC, 1PH, 60HZ)

(5-07)

RAPID-AIR CORPORATION

4601 KISHWAUKEE ST. • ROCKFORD, IL 61109-2925

Phone: (815) 397-2578

• Fax: (815) 398-3887 • Web Site: www.rapidair.com

1

Page 2

table of contentS

Platen Adjustment Bulletin ...................................................................................................................... pg. 3

Straightener Specification Sheet ............................................................................................................ pg. 4

Pushbutton Control ..................................................................................................................................... pg. 5

Installation ................................................................................................................................................... pg. 5

Start-Up Procedure .................................................................................................................................... pg. 6

Electrical Controls Layout ........................................................................................................................ pg. 6

Dancer Arm Adjustment Explanation ..................................................................................................... pg. 7

Jog and Dancer Arm Setup & Program Adjustments .......................................................................... pg. 8

Standard Straightener Components ........................................................................................................ pg. 9

Operation...................................................................................................................................................... pg. 10

Maintenance ............................................................................................................................................... pg. 10

Troubleshooting Guide .............................................................................................................................. pg. 11

RAMM Board Explanation ........................................................................................................................ pg. 12

Warranty ....................................................................................................................................................... pg. 13

Electrical Schematics ............................................................................................................................... pg. 14-15

Mechanical Parts List P1V-P4V ........................................................................................................... pg. 16-17

Mechanical Parts List SA ...................................................................................................................... pg. 18-20

Mechanical Parts List SB ...................................................................................................................... pg. 21-25

Mechanical Parts List SBX ................................................................................................................... pg. 26-29

Mechanical Parts List SCX ................................................................................................................... pg. 30-36

Mechanical Parts List SD ...................................................................................................................... pg. 37-43

Typing Stamping Layout ............................................................................................................................ pg. 44

2

Page 3

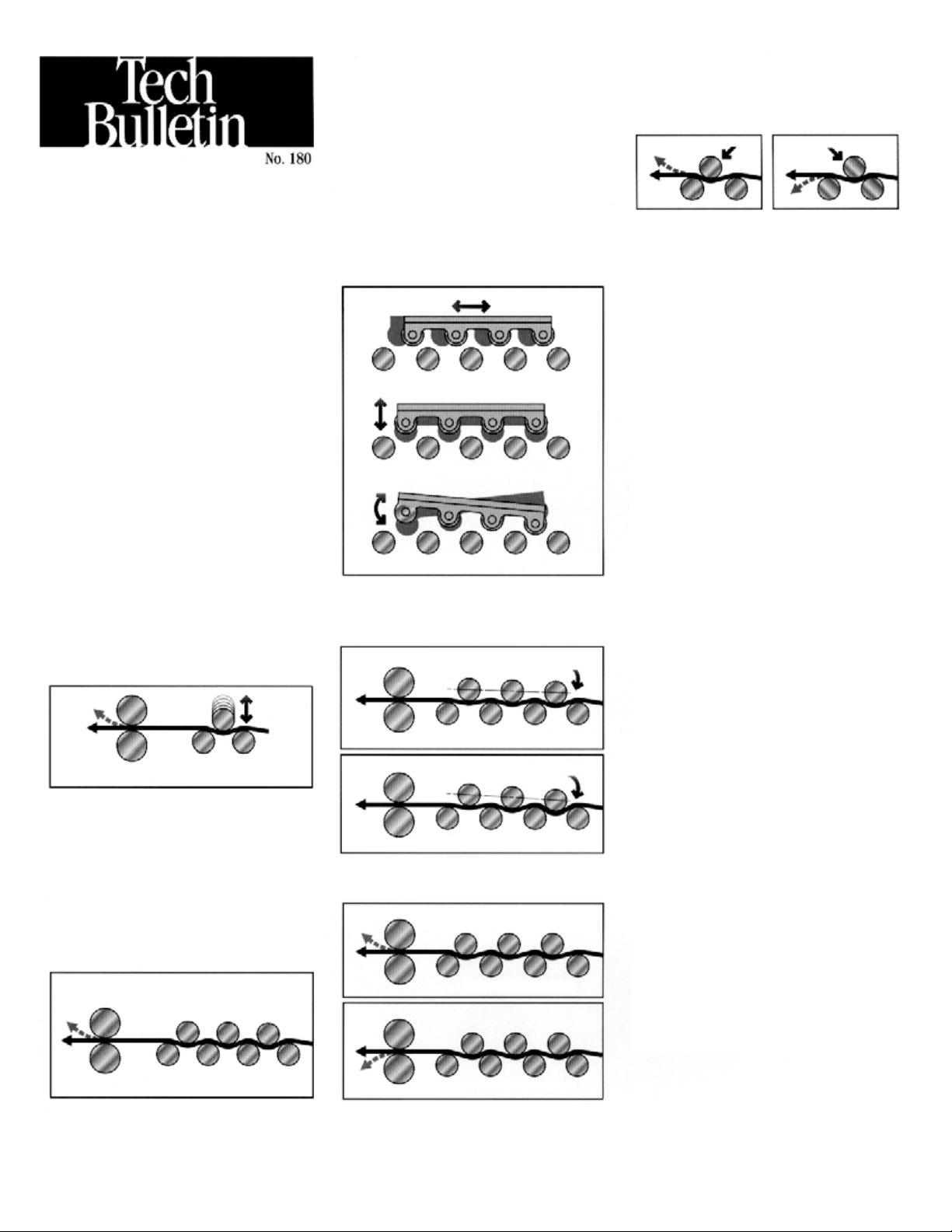

If the straightener is made to correct a clockwise

curvature, it is often impossible to correct a

counterclockwise curvature. The only available

adjustment is the variation of the degree of bend

at each station. This is true even for straighteners

that have banked upper rolls that pivot for

two-point adjustment.

To more easily explain the concept, Figure 8

shows a three-roll combination with the upper

roll forward and Figure 9 shows a three-roll

combination with the upper roll to the rear.

Figure 8 Figure 9

Adjustable Platen

Stock Straighteners

vs.

Straighteners with

Traditional

Vertical Roll

Adjustment

CONCEPT: The concept behind a movable

platen containing the upper bank of rolls for

straighteners can be somewhat difficult to

grasp, but once the principles are understood

the superiority of this system becomes obvious.

To explain the differences between the adjustable platen system and one that uses traditional

single-point vertical roll adjustment, we are

describing both types of systems here.

VERTICALLY ADJUSTABLE UPPER ROLLS:

For centuries the bending of materials has been

done by variations of a three-roll arrangement as

illustrated in Figure 1.

Figure 1

Downward curvature of material

to remove coil set

Bending occurs when one roll is forced into the

space between the other two rolls for downward

curvature of the material to remove coil set.

Pressroom straighteners add multiple three-roll

combinations in order to level the material in

small increments at each stage. This method can

provide acceptable results for some materials,

but is limited because correction of material

curvature is effective in only one direction as

illustrated in Figure 2.

Figure 2

SIX-WAY UPPER ROLL ADJUSTMENT: After

manufacturing straighteners with vertically

adjustable rolls for many years, Rapid-Air

developed and patented the adjustable platen

type straightener as illustrated in Figure 3.

Figure 3

Forward/Back

Up/Down

Up/Down Slant

This design mounts the upper rolls in a platen

which can be adjusted for degree of bend as

illustrated in Figure 4 and Figure 5

Figure 4

Light material distortion

Figure 5

Heavy material distortion

Less deflection

Deeper deflection

and for curvature direction as shown in

Figure 6 and Figure 7.

Figure 6

Rolls forward – curve up

Figure 7

Notice that the sharpest bend occurs where two

rolls are in close proximity. When the upper

roll is forward, the curvature will be up and

when the forward roll is adjusted to the rear,

the bend will be down. The degree of bend can

be adjusted by a combination of vertical and

horizontal adjustments.

ADVANTAGES: The high degree of flexibility

afforded by the adjustable platen design provides

a predictable straightening method for a wide

variety of materials and takes a lot of the “Black

Magic” out of pressroom straightener setup.

The reduction in the flexing and distortion of

the strip of material and the reduction of the

straightening power required allows effectiveness with heavy materials. Additionally, the ability

to place rolls in a proper close proximity allows

effective straightening with very thin materials.

ROLL DIAMETER: The smaller the roll

diameter in a straightener the better it is able to

remove distortions in the strip of material, but

this factor is compromised by the requirement

of larger rolls in wider models of straighteners

in order to prevent deflection of the rolls

themselves. Rapid-Air straighteners are designed

to optimize all factors (including number

of rolls, diameter and position) within the

published material capacities and specifications

for each model.

SWING-OPEN TOP: Rapid-Air developed and

introduced the swing-open top for straighteners

in order to facilitate the cleaning of rolls and the

threading of a new strip of material through the

straightening rolls. For convenience and safety,

each top is counterbalanced and held in the

open position until it is clamped for operation.

Roll adjustment settings are maintained when the

top is closed and locked.

AVAILABILITY: All models of Rapid-Air straighteners are presently available with the adjustable

platen design with an expanded range of models

being introduced in the coming months.

Material curvature is effective

in only one direction

Rolls back – curve down

3

Page 4

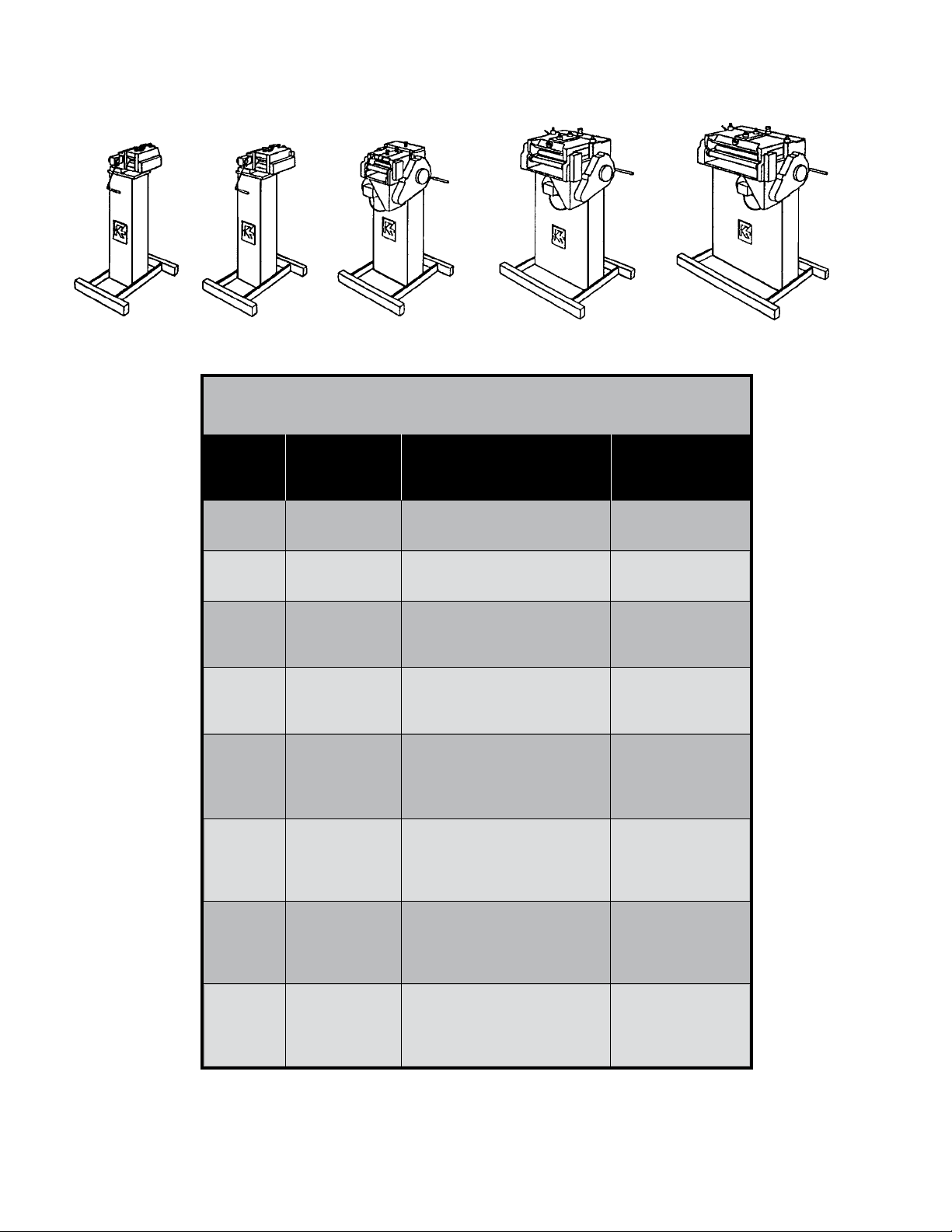

SA

Series

SB

Series

SBX

Series

SCX

Series

rapid-air Straightener Model Selection

SD

Series

Max Effective Max

Material Straightening Speed

Model Width Range per min

SA3 3” (76mm) .002” - .030” (.051-.76mm) 700” (1778cm)

SA3M 3” (76mm) .002” - .030” (.051-.76mm) 1,400” (3556cm)

SB4 4” (102mm) .003” - .050” (.076-1.27mm) 700” (1778cm)

SB4M 4” (102mm) .003” - .050” (.076-1.27mm) 1,400” (3556cm)

SBX4 4” (102mm) .004” - .080” (.10-2.03mm) 825” (2100cm)

SBX8 8” (203mm) .004” - .070” (.10-1.78mm) 825” (2100cm)

SBX12 12” (305mm) .004” - .060” (.10-1.52mm) 825” (2100cm)

SBX4M 4” (102mm) .004” - .080” (.10-2.03mm) 1,650” (4200cm)

SBX8M 8” (203mm) .004” - .070” (.10-1.78mm) 1,650” (4200cm)

SBX12M 12” (305mm) .004” - .060” (.10-1.52mm) 1,650” (4200cm)

SCX6 6” (152mm) .006” - .100” (.15-2.54mm) 825” (2100cm)

SCX12 12” (305mm) .006” - .090” (.15-2.29mm) 825” (2100cm)

SCX18 18” (457mm) .006” - .080” (.15-2.03mm) 825” (2100cm)

SCX24 24” (610mm) .006” - .065” (.15-1.65mm) 825” (2100cm)

SCX6M 6” (152mm) .006” - .100” (.15-2.54mm) 1,650” (4200cm)

SCX12M 12” (305mm) .006” - .090” (.15-2.29mm) 1,650” (4200cm)

SCX18M 18” (457mm) .006” - .080” (.15-2.03mm) 1,650” (4200cm)

SCX24M 24” (610mm) .006” - .065” (.15-1.65mm) 1,650” (4200cm)

SCX6H 6” (152mm) .006” - .080” (.15-2.03mm) 4,100” (10400cm)

SCX12H 12” (305mm) .006” - .070” (.15-1.78mm) 4,100” (10400cm)

SCX18H 18” (457mm) .006” - .060” (.15-1.52mm) 4,100” (10400cm)

SCX24H 24” (610mm) .006” - .055” (.15-1.40mm) 4,100” (10400cm)

SD6 6” (152mm) .006” - .125” (.15-3.18mm) 825” (2100cm)

SD12 12” (305mm) .006” - .125” (.15-3.18mm) 825” (2100cm)

SD18 18” (457mm) .006” - .100” (.15-2.54mm) 825” (2100cm)

SD24 24” (610mm) .006” - .090” (.15-2.29mm) 825” (2100cm)

4

Page 5

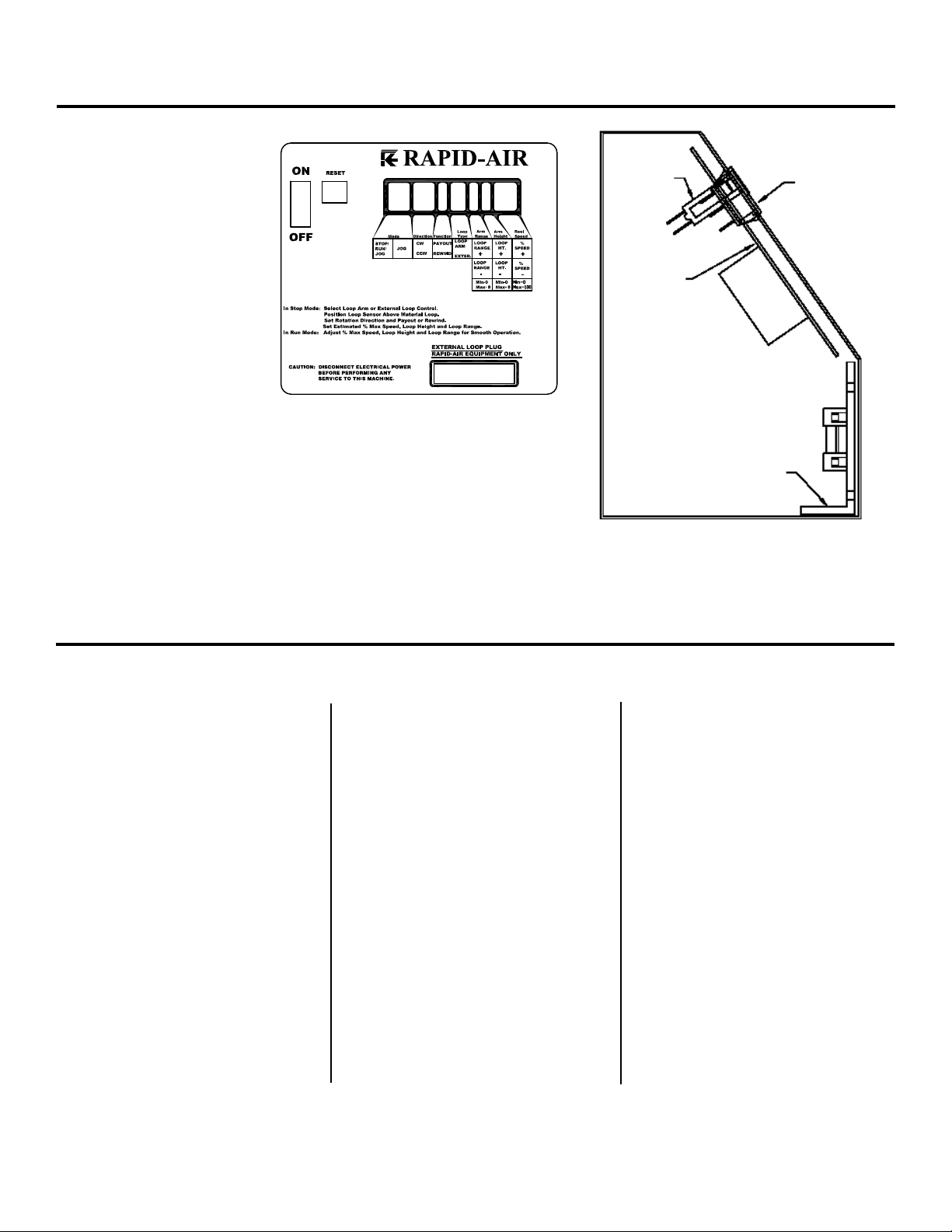

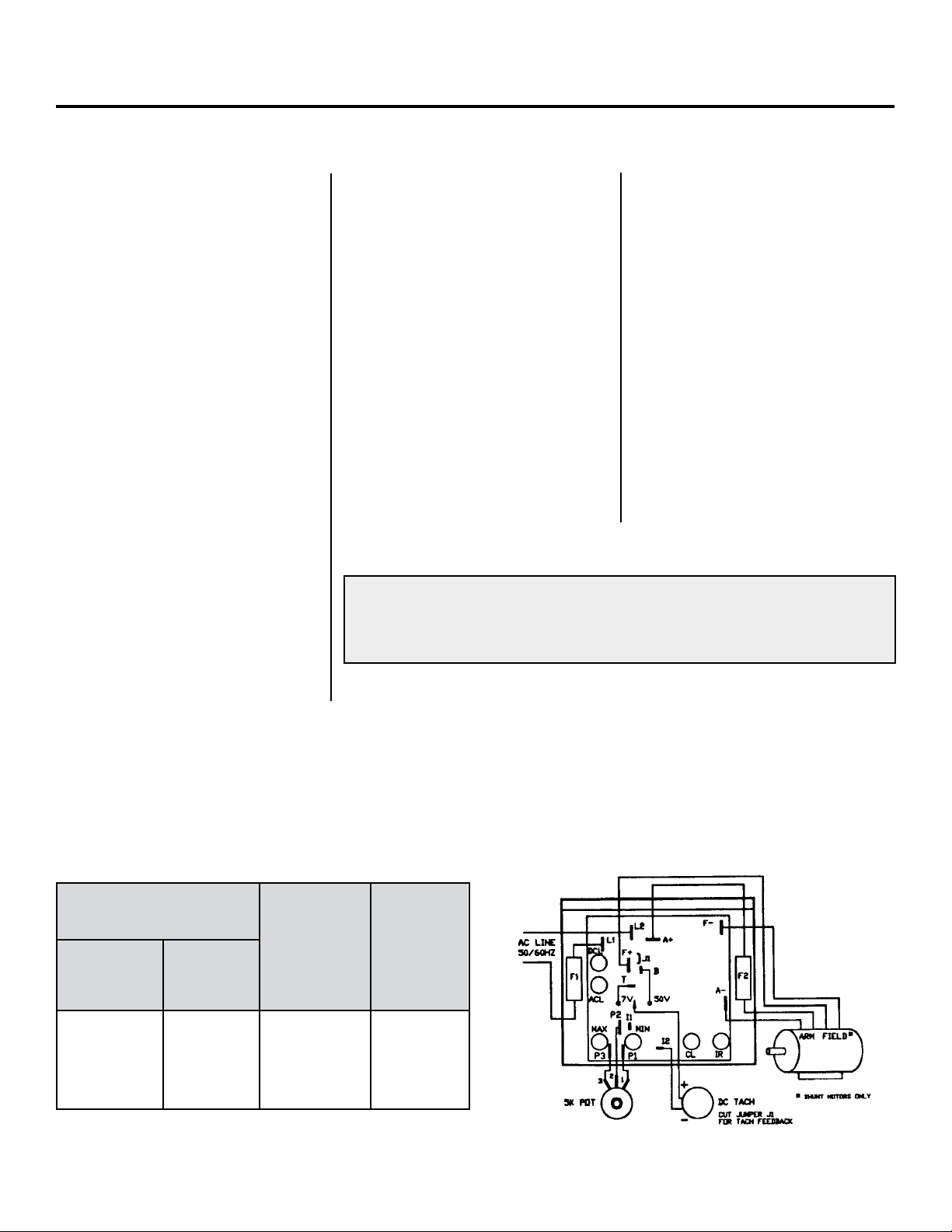

puShbutton control

The main control unit

is located behind the

pushbutton cover.

Here is an illustration of

the layout of the control

panel. This diagram lists

all the components and

the approximate location

of each that could be

used for troubleshooting

the machine if a problem

should occur. The reel

is shipped with—120 VAC

(1 phase) input. Visually

check all electrics before

starting the reel.

MAIN

BREAKER

69100578

CONTROL

BOARD

69100804

ROCKER

SW.

69100315

MOTOR

BOARD

69100014

inStallation

Operating Instructions For SBX Series Powered Straightener

The straightener that you just

received is fully assembled and tested

and ready to be put into position.

CAUTION: Due to shipment vibration,

the straightener should be checked to

be sure that all screws and bolts are

secure and all electrical components

are in place inside the cabinet. Visually inspect the complete machine for

physical damage due to shipment and

handling. If the straightener was damaged in shipment, contact the carrier

first and then Rapid-Air.

Install the straightener on a level

surface with sufficient clearance for

loading the material and adjusting

the roller pressure for straightening.

Align and center the straightener to

the device that it will be supplying the

straightened stock. The straightener

should then be bolted to the floor

especially when used to pull stock

from a non-powered reel.

CAUTION: Before bolting the

straightener down, check for the

longest feed length to be run. The

straightener should be set so that

there will be about two or three feed

lengths in storage in the loop without

re-inducing coil set in the material.

The standard speed straightener

is completely self contained and

only needs to be plugged into a

20 amp, 120 VAC, 60 HZ outlet. If an

extension cord is used as a source

to the straightener power, it should

be a minimum 12 gauge wire to keep

the voltage losses down and also for

electrical safety reasons.

Please check your local safety codes.

The medium and high speed

straighteners require 230 VAC, 60 HZ,

1PH as the supply voltage. Please

refer to the schematics in the manual

for required fuse sizes.

Please check your local safety codes.

Turn on the main power button and

run a test cycle checking the jog

(using the jog button) and run

(using the dancer arm to test that the

speed varies if using the proportional

control). Test all electrical features

before continuing.

5

Page 6

Start up procedure

Prior to applying power to the machine the operator should review all the controls on the machine. A brief summary of the

controls is listed below.

Main Console And Controller

The main pushbutton control box is

mounted on the top of the straightener frame. Located on the face of the

console are eleven pushbuttons, one

display, one on/off switch, one circuit

breaker, one external loop plug and

inside the box is motor board and one

potentiometer when required, all of

which are explained below.

1. % SPEED POT

The % speed function adjusts the

maximum speed that the straightener

will feed and should be set to maintain a constant feed rate. Adjustable

in the run mode.

2. ON/OFF SWITCH

This illuminated switch is the main

power switch for the controller. It must

be “ON” for the machine to function.

3. RUN/STOP/JOG

SELECTOR SWITCH

This function selects between Run,

Stop and Jog. If in Run and the control

arm is moved the rolls will turn. If in

Jog, the Jog button has to be de-

pressed for the rolls to turn. If in Stop,

there should be no movement of the

rolls even if the dancer arm is raised

or lowered or the jog pushbutton is

pressed.

4. JOG BUTTON

Used for intermittent movement of

material on the rolls, mainly used for

set up or getting material thru the

straightener and over to the pulling

device. Active in jog mode only.

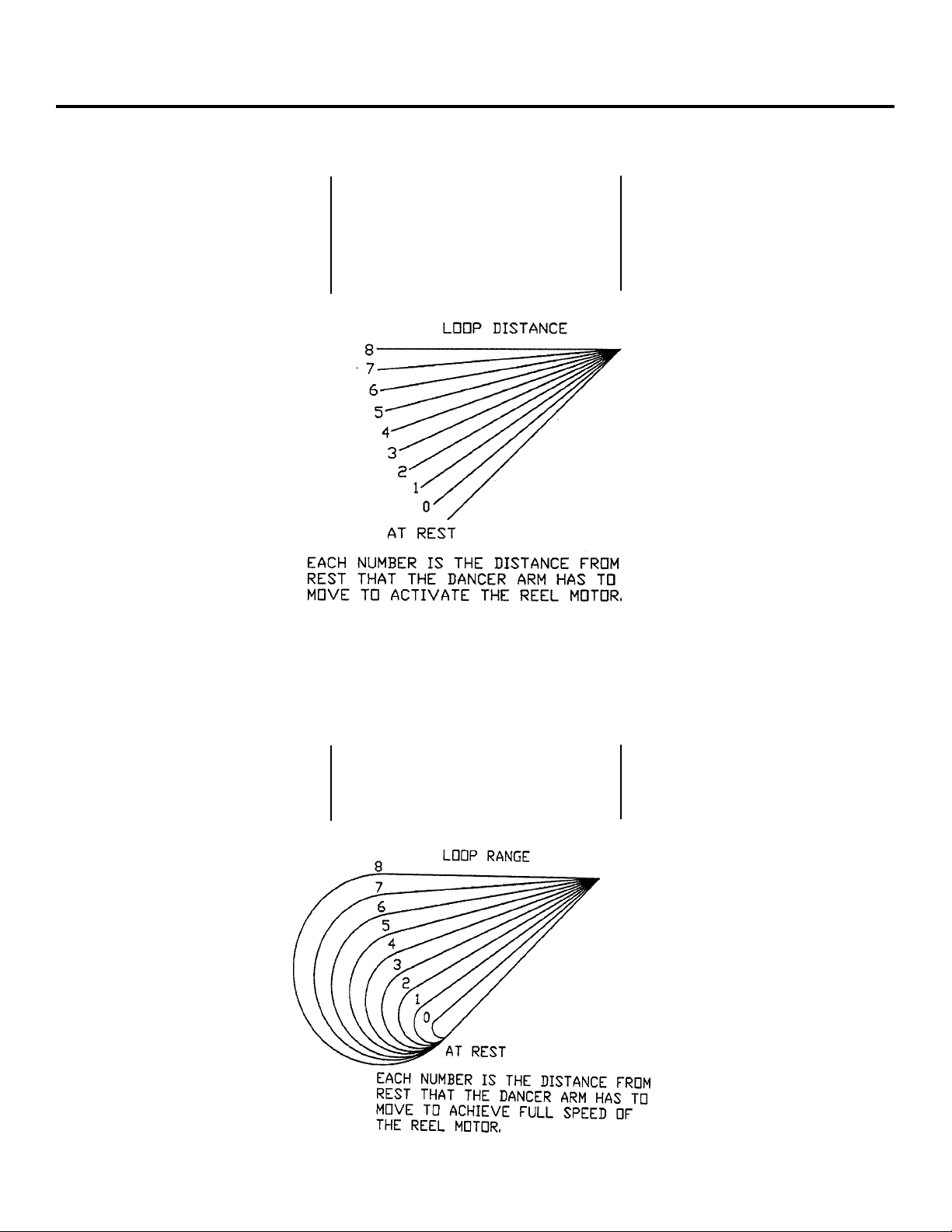

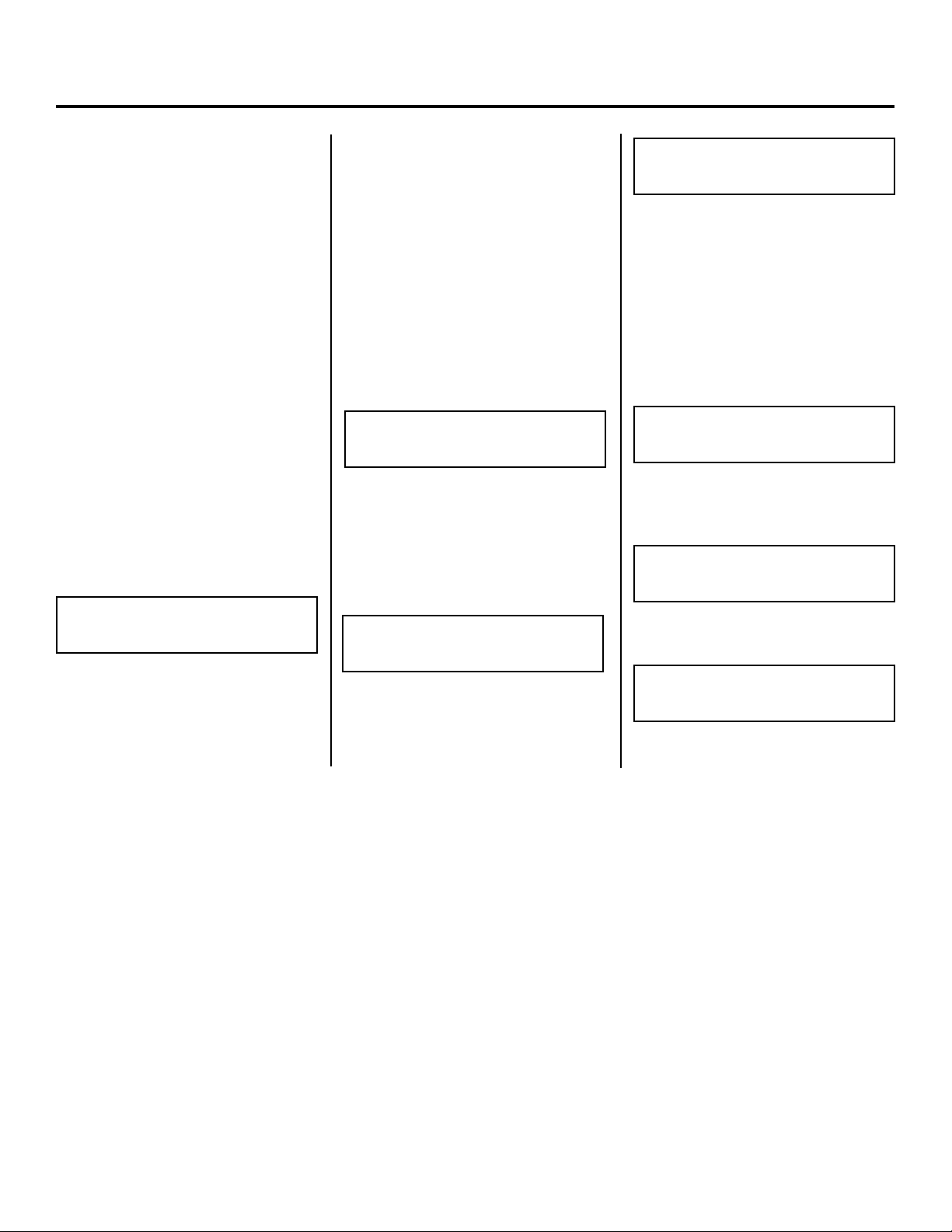

5. DANCER ARM LOOP HEIGHT

AND RANGE ADJUSTMENT

a. Loop Range – The loop range func-

tion adjusts the amount the dancer

arm will travel to provide the full

range of speed of the straightener.

There are eight positions available.

b. Loop Height – The loop height function is used for setting the start position of the control arm. The setting determines when the straightener rolls

will start turning. Each position will

move the operating start position up

from the home position to accom-

modate specific material rest height

requirements.

6. LOOP ARM / EXTERNAL SWITCH

This switch selects either dancer arm

(internal) by displaying “LV” for loop

arm vertical reel or “LH” for loop arm

horizontal reel (PMD) or external loop

control by displaying “RT” for the

RTB and ”RS” for the RS_1. The RLL

will work on the “RT” selection.

7. RESET BUTTONS

a. 15 amp – This is the main circuit

breaker for the 120 VAC input

straightener.

8. REMOTE INTERFACE

PORT “D” CONNECTOR

This connector is used to communicate with external loop control equipment.

CAUTION: Never plug any type of computer or non Rapid-Air equipment into

this plug or severe damage will result.

Always consult with the factory when

installing new external controls for

compatibility and wiring information.

Electrical Component Description

69100804 board - main reel control board

69100014 (RAMM) - D.C. motor board

29100021 dancer arm potentiometer

69100578 circuit breaker

69100315 rocker switch

6

Page 7

dancer arM loop

Dancer Arm Loop Height Adjustment

Eight different loop sensing arm

operating positions can be selected

during set-up. The material thickness

determines the dancer arm rest

position. Once the material is

threaded up and the dancer arm

is resting on the material and the

reel runs in the rest position then

select a higher number on the height

adjustment until the reel stops

rotating. The zero point of the dancer

arm is raised from its no material rest

position to the current rest position

angle shown (as indicated 0-8). The

dancer arm will start the material

dereeling from the new rest position

selected. The function is active and

can be changed in the run mode.

Dancer Arm Loop Range Function

The loop range function selects the

degree of arm movement to achieve

maximum motor speed selected. If a

loop range of “0” was selected then

the arm would only have to move

approximately 10 degrees to have the

reel at full speed whereas if the loop

range “8” was selected then the arm

would have to move almost the full

travel or approximately 90 degrees to

get to full speed. The function is active

and can be changed in the run mode.

7

Page 8

dancer arM adjuStMent explanation

JOG SPEED AND DANCER SET-UP

The straightener was shipped with

the dancer arm set up for its correct

position so the only thing that has to

be reset would be the jog speed if you

need it to jog faster or slower. The

rest of the keypad is pretty much self

explained so become familiar with the

keypad positions for making adjustments on the fly. Turn on the main

power switch and select “LV” for loop

arm vertical at “Loop Type” on the

pushbuttons.

MAKING INTERNAL

PROGRAM ADJUSTMENTS

Turn off the main power switch,

press and hold the “Run/Stop/Jog”

button while turning the main

power switch on. The first screen

you see will display the jog speed

percentage.

JOG SPEED 23% +

NEXT -

If you want the jog speed faster

then press the “Reel Speed “+ ““ %

speed pushbutton. If you want the jog

speed slower then press the “Reel

Speed “-”” % speed pushbutton. The

jog speed is shown in percent of max

jog speed. If the jog speed is “OK “

then push the “Run/Stop/Jog button”

once for next.

The next screen asks if you want to

set up the sensor. As before the percent speed buttons are used for the

yes-no. Select “no” if all you wanted

to do was set the jog speed. Select

“yes” if you want to reset the dancer

arm position setup. And then “next”.

SETUP SENSOR YES

NEXT NO

The next screen asks you to set the

low set point. If the dancer arm is at

“No Material Rest” then just save

the setting by pushing the Stop/Run

Jog pushbutton.

SENSOR LOW SETPOINT

SAVE XXX

The next screen is for setting the high

set point. Raise the dancer arm to

its upper stop position and press the

save or Stop/Run/Jog button once.

SENSOR HIGH SETPOINT

SAVE XXX

The next screen is to set the offset of

the program. Potentiometers are hard

to get set from left to right so we built

in an offset. If you set the low and

high range and go into run and the

reel runs for no reason then an offset

has to put in. Go through the setup

procedure again and put in an offset

of –3 to –5 and now the pot is zero.

LOW OFFSET + 0 +

NEXT -

You have now set the dancer arm

limits. The next screen is to exit the

setup and start working

EXIT SETUP? YES

NO

Choose yes and next and the next

screen appears .

SHUT OFF POWER TO

SAVE AND EXIT

The dancer arm is now ready for

production running.

8

Page 9

Standard Straightener coMponentS

Curve Up/Down Adjustment

Some applications have dies that cannot accept anything but flat stock

and other dies run better with the material curving up or down to miss the

built-in edge required in the die. Before this feature was added, operators

would under straighten or over

straighten the material to suit their

needs but in doing so would severely

change the material entering the die.

This not only caused feeding problems but part quality problems. With

this feature, curve up or down can be

accomplished by changing the position of the rolls without stressing the

material.

optional Straightener coMponentS

Entrance Cascade Roll

The entrance cascade roll assembly

is used to maintain a support arc for

stock entering a feed. The cascade

roll has three extra rollers to help the

material flow better.

Exit Cascade Roll

The straightener is shipped with

the exit side pre-drilled for the

cascade roll or guide roll block.

The entrance and exit use the

same components.

Entrance Guide Roll Block

All straighteners are shipped with

an entrance guide roll block. This

contains a roller and two adjustable

edge guides.

Angle Bracket

Rapid-Air offers this accessory that

mounts between the straightener

head and the base. It angles the

exit side of the straightener twelve

degrees lower than the entrance

side. This feature works very well

when using the straightener to pull

off a non-powered reel.

9

Page 10

operation

Once the straightener has been

tested and all the functions work

then it should be tested for what it

was designed to do and that is to

remove coil set.

Retract all of the idler rolls and the

exit pinch roll to a position so when

the cover is closed the material is

not being deformed. Open the cover

of the straightener and position the

edge guides for maximum width. Cut

and place about a four foot length of

the material onto the straightener

rolls with the exit end of the material extending through the exit pinch

rolls and centered from side to side

in the straightener. Close the cover

and latch it. Adjust the exit pinch roll

enough to grip and hold the material.

Adjust the edge guides so that they

just touch the material.

Adjust the first idler roll knob, this is

the one nearest the entrance of the

straightener, so that it deforms the

material no more than the thickness

of the material. Adjust the second

idler roll knob so it is lightly on the roll.

Run the material to check that the exit

pinch roll is not slipping on the material, readjust if necessary. This piece

will still have coil set in the first two

feet of the material as it was not run

through the complete straightening

cycle. At this time, this piece could be

rerun and checked for straightness or

a new piece could be cut and run and

then be checked.

A good check is to guide the exiting

material, keeping it parallel to the

rolls, until the run is complete and then

hold one end of the material in the air

while peering down the length of the

material. If the material still has “coil

set” then readjust roll pressure on the

last roll, towards the exit end but before

the pinch roll, until the material is

straight. Run one or more short length

setups while making final adjustments.

Once the proper setting has been determined, the quick release top maintains the adjustment during loading.

Thread the material from the reel

through the straightener, under the

dancer arm, and into the pulling

device leaving ample loop between

the straightener and the pulling

device. If the material thickness

is such that when exiting the

straightener, it will not let the

dancer arm down to the rest

position, then either lengthen the

dancer arm or adjust the loop height

until the straightener stops feeding.

Set the % speed potentiometer to

50% for a starting position and

start the pulling device to have

the material feeding. If the straightener gets finished and stops before

material is needed again then the

straightener is set to feed too

fast, slow it down by adjusting the

% speed potentiometer. The ideal

straightening is to have the

straightener slightly exceed the

feed rate required. This minimizes

the starting and stopping and

resultant stock deformation.

Maintenance

Lubrication

Gear transmission:

The reservoir oil capacity is about 3

to 12 oz. depending on the size of the

straightener. The reservoir oil should be

changed every 2000 hours and should

be filled to the oil level site gauge.

Use MOBILE 600W cylinder oil or

equivalent. This is a non synthetic oil.

Rolls:

Although the rolls should be cleaned

periodically they never have to be

10

greased as all the rolls have permanently lubricated bearings.

Drive Belt:

At the oil change interval, check for

belt tension and wear.

Page 11

troubleShooting guide

MAIN SWITCH ON BUT NOT LIT

1. CB tripped.

a. Reset CB

2. Unit not plugged into

main power.

a. Plug into main power source.

3. No power in incoming line.

a. Check outlet.

b. Check power cord.

4. Loose wiring.

a. Check terminals and

connections.

MOTOR CREEPS IN

STOP POSITION

1. “Min” speed pot on RAMM board

out of adjustment.

2. Dancer arm could be bent which

changes the home position of

the arm.

UNIT TURNS BUT WON’T JOG

1. Jog function was not selected.

a. Select jog.

2. Jog speed has not been set up.

a. Call factory.

UNIT ON BUT MOTOR WON’T RUN.

(ARMATURE VOLTAGE PRESENT –

ON RAMM BOARD)

1. Check motor wiring.

a. Replace motor cord or correct

motor wiring. Call factory.

2. Check motor.

a. Worn brushes or motor

defective. Call factory.

b. Check for oil in motor, gear box

seal could have ruptured.

UNIT ON BUT MOTOR WON’T RUN.

(NO ARMATURE VOLTAGE ON

RAMM BOARD)

1. Selector switch not in run

position.

a. Turn selector switch to

run position.

2. If running with a dancer arm

control.

a. Check that the external/loop

arm function is in the loop arm

position.

3. If running with external control.

a. Check that the external/loop

arm function is in the

external position.

4. Loop height switch setting

too high.

a. Set height setting to “0”.

5. Percent speed function set

too low.

a. Adjust percent speed

function to 100%.

6. Fuses blown.

a. Check fuses & circuit breaker.

7. No AC voltage at DC drive board.

a. Check wiring.

8. Check signal voltage between

P2 to P1 on DC drive.

0-6 VDC—RAMM

0-9 VDC—Regen Drive

while moving dancer arm.

a. If there is a signal, check

continuity between I1 & I2.

b. If no continuity, replace D.C.

drive or call factory.

9. Check Pico fuse on 69100804

board (F1).

a. Replace fuse, 1 amp pico

fuse—call factory.

11

Page 12

Safety warning – pleaSe read carefully

RAMM Solid State DC Motor Speed Control

This product should be installed and

serviced by a qualified technician,

electrician or electrical maintenance

personnel familiar with its operations

and the hazards involved. Proper installation (see instruction information

which accompanies product), which

includes wiring, mounting in proper

enclosure, fusing or other over current protection and grounding, can reduce the chance of electrical shocks,

fires or explosion in this product or

products used with this product, such

as electric motors, switches, coils

solenoids and/or relays. Eye protection must be worn when working with

control under power. This product is

constructed of materials (plastics,

metals, carbon, silicon, etc.) which

may be a potential hazard. Individual

material safety data sheets (MSDS)

are available upon request. Proper

shielding, grounding and filtering of

this product can reduce the emission

of radio frequency interference (RFI)

which may adversely affect sensitive

electronic equipment. If information

is required on this product, contact

our factory. It is responsibility of the

ultimate user of this product to read

and comply with this safety warning.

(SW effective 1/89).

***IMPORTANT***

YOU MUST READ THESE

INSTRUCTIONS BEFORE

OPERATING CONTROL

1. Be sure AC line voltage

corresponds to control voltage.

TABLE 1: NOMINAL TRIMPOT SETTINGS

MIN (minimum speed): 15% CL (current limit/torque): 65%

MAX (maximum speed): 65% ACCEL (acceleration start): 20%

IR (IR compensation): 25% DECEL (deceleration stop): 20%

For motor drive board instructions, go to www.info@kbelectrics.com and find

KBMM write up which is closest to the Rapid-Air RAMM board.

2. Install the correct Plug-In

Horsepower Resistor according

to armature voltage and motor

horsepower.

3. Recheck connections: AC line to

L1 and L2; armature to A+ and

A– and field (Shunt motors only

to F+ and F-.) (

in improper direction, interchange

armature leads.)

4. Install proper AC line fuse and

armature fuse as required.

5. Nominal trimpot settings are as

follows (expressed in % of full

CW rotation):

Note: If motor runs

Plug In Horsepower Resistor

A Plug-In Horsepower Resistor must be installed to match the RAMM to the motor

horsepower and voltage. See table 2 for the correct value. Plug-In Horsepower

Resistors are stocked by your distributor.

TABLE 2: PLUG IN HORSEPOWER RESISTOR CHART

MOTOR HORSEPOWER

RANGE **

Armature

Voltage

90-130 VDC

1/4

1/2

3/4

1**

* Motor horsepower and armature voltage must be specified when ordering so that proper

resistor will be supplied.

** For overlapping motor horsepower range use lower value Plug-In Horsepower Resistor.

*** Auxiliary heat sink must be used to achieve HP rating.

Armature

Voltage

180 VDC

1/2

1

1-1/2

2***

Plug-in

Horsepower

Resistor

Resistance

Value (ohms)

.05

.025

.015

.01

Rapid-Air

P/N

69100529

69100530

69100534

69100531

12

Page 13

warranty

Limited Warranty – RAMM 125, 225, 225D

For a period of one (1) year from date of original purchase Rapid-Air Corporation will repair or replace without charge

devices which our examination proves to be defective in material or workmanship. This warranty is valid if the unit has not

been tampered with by unauthorized persons, misused, abused or improperly installed and has been used in accordance

with the instructions and/or ratings supplied. The foregoing is in lieu of any other warranty or guarantee expressed or

implied, and we are not responsible for any expense (including installation and removal), inconvenience, or consequential

damage, including injury to any person, caused by items of our manufacture and/or sale. Some states do not allow certain

exclusions or limitations found in this warranty so that they may not apply to you. In any event, Rapid-Air Corporation’s total

liability, under all circumstances, shall not exceed the full purchase price of this unit.

13

Page 14

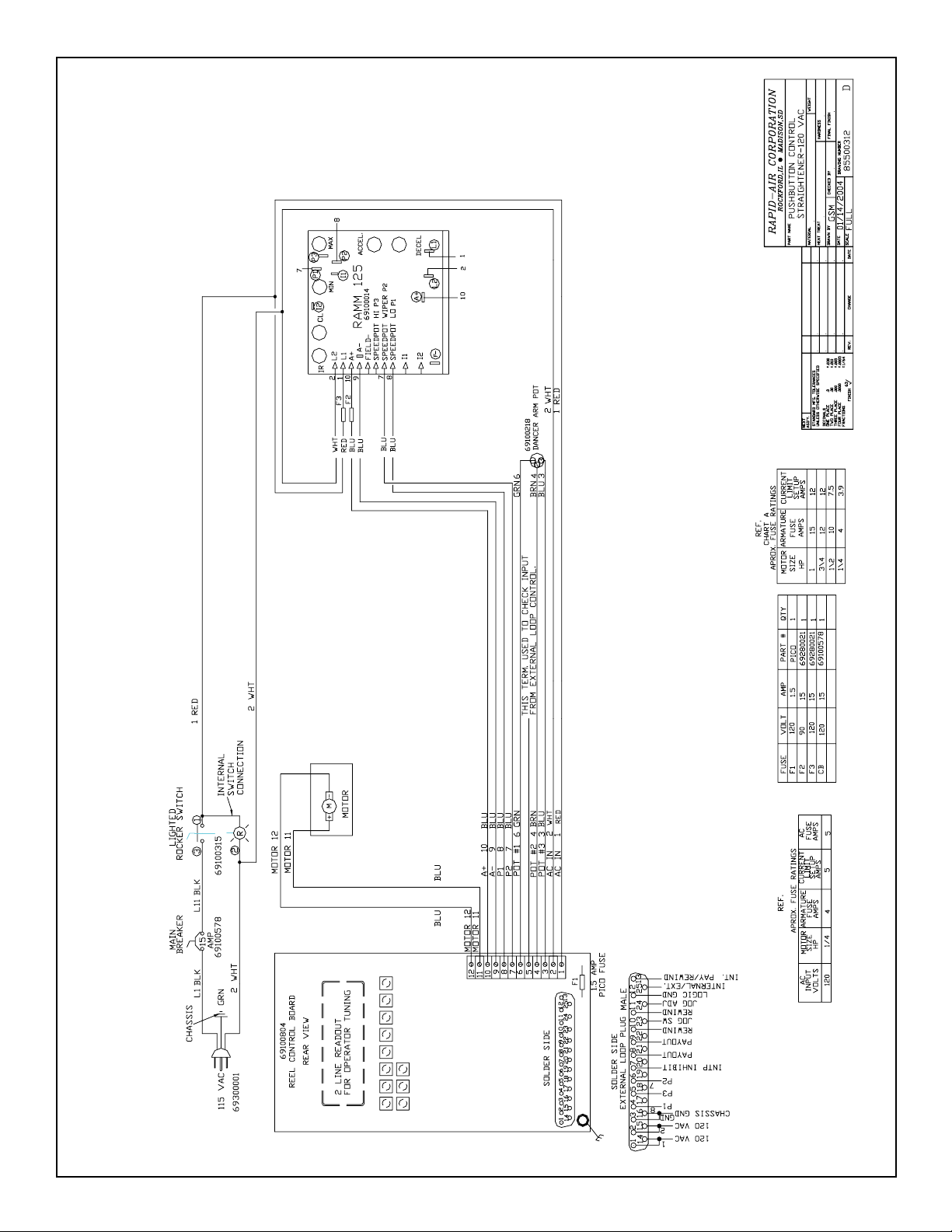

Pushbutton Control Straightener - 120 VAC

14

Page 15

Pushbutton Control Straighteners - 2 and 3HP

15

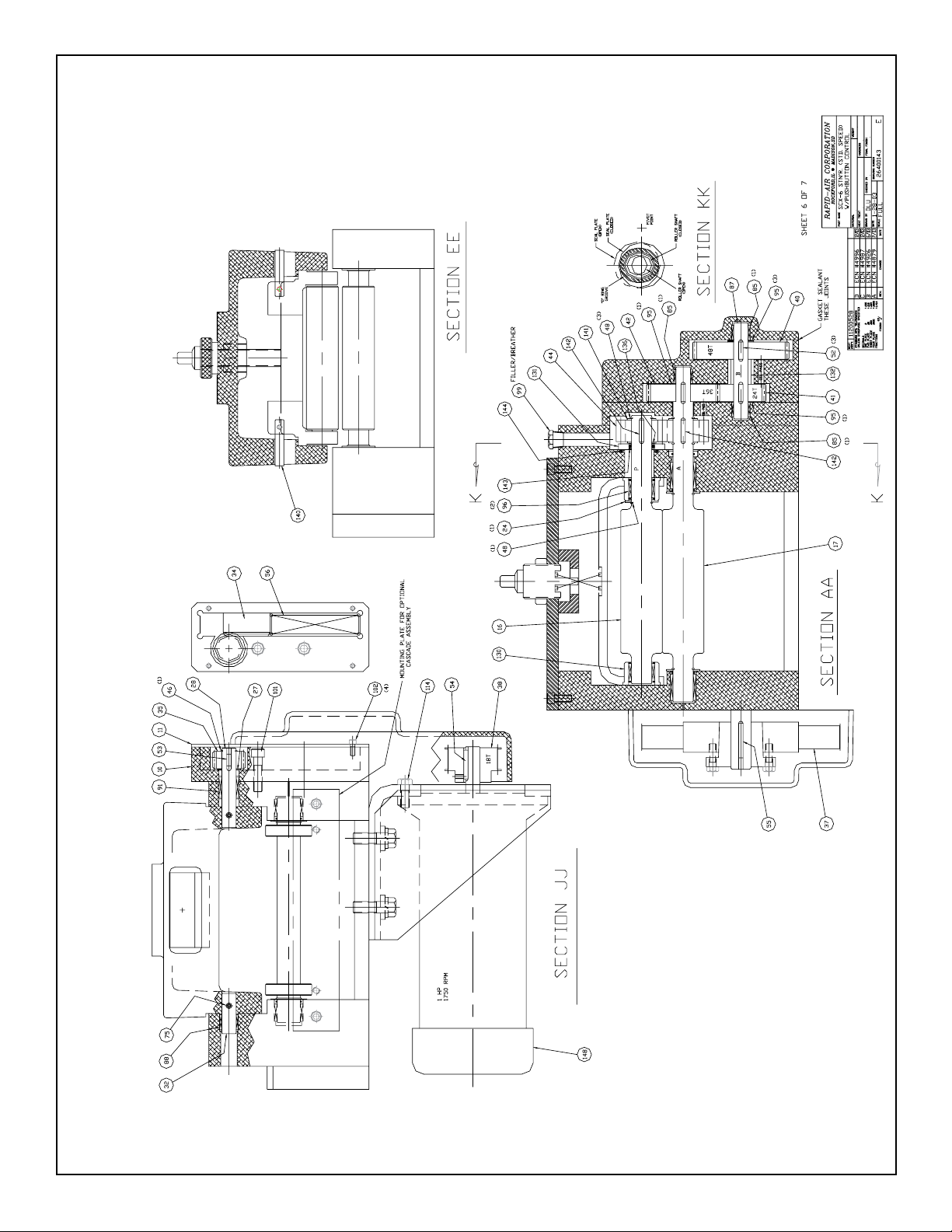

Page 16

Gear Head Assembly - P1V

16

Page 17

Gear Head Assembly - P1V

17

Page 18

SHT.

1/3

26 4 00 0 2 7

ROCKFORD, IL • MADISON, S.D.

RAPID-AIR CORPORATION

PART NAME

PART NO. DESCRIPTION

1 40 32900289 PIN, PIVOT 2

1 39 32900288 PIN, PIVOT 2

1 38 32900287 PIN, PIVOT 2

2 37 32900286 PIN, PIVOT 2

1 36 36100024 FITTING, WORM COVER 3

1 35 32600012 WORM 3

3 34 32600034 GEAR 3

1 33 32600035 GEAR, IDLER 3

1 32 32600071 GEAR, WORM 3

11 31 32600086 GEAR, SPUR 2

1 30 32600087 GEAR, SPUR 3

1 29 32600088 GEAR, SPUR 3

1 28 32600089 GEAR, PINION 2

1 27 32600090 RACK 2

7 26 34200061 ROLLER 2

5 25 34200060 ROLLER, DRIVE LOWER 2

2 24 34200059 ROLLER 3

1 23 32900229 SHAFT, WORM 3

1 22 32900228 SHAFT, WORM GEAR 3

1 21 32900226 SHAFT, IDLER 3

7 20 32900284 SHAFT, ROLLER 2

1 19 32900283 SHAFT, GUIDE 2

1 18 32900280 SHAFT, IDLER 3

6 17 32900279 SHAFT, IDLER 2

1 16 32900282 SHAFT, ROLLER UPPER 3

1 15 32900281 SHAFT, ROLLER LOWER 3

1 14 34100119 SPACER, SQUEEZE 2

1 13 34100121 SPACER, UPPER 3

1 12 34100120 SPACER, LOWER 2

1 11 31900428 GUIDE 2

1 10 31900429 BRACKET, GUIDE SUPPORT 2

1 9 31900408 BRACKET, SQUEEZE 2

1 8 31900407 BRACKET, SQUEEZE 3

1 7 31900406 BRACKET, IDLER 2

1 6 31500124 COVER, GEAR CASE 3

1 5 31500123 COVER, ROLLER SUPPORT 2

1 4 30100054 FRAME, DRIVE SIDE 3

2

ANCHOR, SPRING BOTTOM

2 80 37500044 SPRING, COMP. 2

2 79 37500043 SPRING, TEN. 2

2 78 37500042 SPRING, COMP. 2

2 77 37500041 SPRING, COMP. 2

2 76 37500040 SPRING, COMP. 2

2 75 64510002 BEARING, THRUST 3

2 74 64520008 BEARING, THRUST 3

1 73 64520010 BEARING, THRUST 2

1 72 64500031 BEARING, NEEDLE 3

28 71 64500033 BEARING, NEEDLE 2

5 70 64500036 BEARING, NEEDLE 2

69

6 68 64500034 BEARING, NEEDLE 2

11 67 64500030 BEARING, NEEDLE 2

1 66 64500029 BEARING, NEEDLE 3

5 65 64500028 BEARING, NEEDLE 2

4 64 64500003 BEARING, NEEDLE 3

3 63 64500002 BEARING, NEEDLE 3

2 62 64500032 BEARING, NEEDLE 3

3 61 36700017 KNOB 2

2 60 34200005 ROLLER 2

2 59 36200005 NUT 2

1 58 65230004 NUT, LOCK 2

2 57 36200018 NUT, LOCK 2

1 56 66700041 THUMB, SCREW 2

1 55 36700015 KNOB 2

1 54 31500127 GUARD, LOWER 3

1 53 31500126 GUARD, UPPER 3

52 3

1 51 31500125 COVER 2

1 50 31900415

1 49 31900414 ANCHOR, SPRING TOP 2

1 48 31900413 BAR, CLAMP 2

1 47 31900412 PIVOT, BLOCK 2

1 46 31900411 ADJ. TEE HORIZ. 2

2 45 31900409 LINK 2

F

H

1 44 31900410 LINK, UPPER 2

QTY. ITEM

1 3 30100053 FRAME, CONTROL SIDE 3

1 2 31500111 COVER. WORM 3

1 1 30100057 HOUSING, GEAR 3

SHT.

I ECN 4703 10-01

H ECN 3500 1-94

G ECN 3212 7-92

STANDARD MFG. TOLERANCES

DECIMALS:

ONE PLACE .0 ± .030

PART NO. DESCRIPTION

QTY. ITEM

1 43 22900285 ECCENTRIC TRUNION 3

1 42 32900227 PIN, PIVOT 3

1 41 32900290 PIN, HINGE 2

SHT.

SA3 STRAIGHTENER HEAD ASSY

F ECN 2549 4-90

TWO PLACE .00 ± .010

E ECN 1302 4-87

THIRD PLACE .000 ± .005

C.R.A.

3-27-85

D ECO 1028 7-85

SCALE

HEAT TREAT HARDNESS

DRAWN BY CHECKED BY FINAL FINISH

DATE DRAWING NUMBER SHT

C ECO 0970 5-85

B ECO 0962 5-85

A ECO 0905 4-85

SYMBOL CHANGE DATE

3 ± 1/64

THE ABOVE TOLERANCES APPLY UNLESS

OTHERWISE SPECIFIED

CHAMPERS ± .005

FINISH 63

FRACTIONS

MATERIAL

FOUR PLACE .0000 ± .0005

1 119 63130375 PLUG, PIPE 3

2 118 63130125 PLUG, PIPE 2

1 117 37600058 GASKET 3

1 116 37600059 GASKET 2

1 115 33700016 STUD, ADJ. 2

1 114 33700015 STUD, ADJ 2

1 113 33700014 STUD, ADJ. 2

1 112 65600004 INSERT, THREADED 2

3 111 65600002 INSERT, THREADED 2

5 110 60200049 SEAL, SHAFT 2

1 109 36800010 KEY 3

4 108 36800005 KEY 3

2 107 61810213 KEY, WOODRUFF 3

1 106 62412125 ROLLPIN 2

3 105 62412062 ROLLPIN 2

1 104 62409050 ROLLPIN 3

2 103 62325150 PIN, DOWEL 3

10 102 62305075 PIN, DOWEL 3

2 101 62325100 PIN, DOWEL 2

5 120 65936475 SCREW, SHCS 3/8-16x4-3/4 2

G

SA3 Straightener Head Assembly

1 156 62319025 DOWEL PIN 3

7 155 63800125 BALL 2

1 154 34700034 WASHER 3

1 153 69420011 BREATHER 2

1 152 69420010 BREATHER 3

1 151 39900091 LABEL 3

1 150 39900092 INSTRUCTION PLATE 3

149

1 148 37901000 COUPLING, OLDHAM 3

14 147 35800051 RETAINER, SEAL 2

2 146 34100003 SPACER 3

14 145 34700048 WASHER 3

1 144 64520010 WASHER 2

1 143 34700061 WASHER 2

1 100 62312062 PIN, DOWEL 2

1 142 34700060 WASHER 2

3 141 34700062 WASHER 2

1 140 64520005 WASHER 3

6 99 62312025 PIN, DOWEL 2

11 139 64520002 WASHER 3

H

18

PART NO. DESCRIPTION

2 98 33600168 PIN, INDICATOR 2

3 97 60910037 RING, RETAINING 2

13 96 60910025 RING, RETAINING 2

14 95 60910015 RING, RETAINING 2

1 94 60910031 RING, RETAINING 2

6 93 60910062 RING, RETAINING 3

1 92 60810062 RING, SPIRAL 3

1 91 60108916 “O” RING 3

1 90 60108146 “O” RING 3

1 89 60108024 “O” RING 3

1 88 31800024 PLATE, SEAL 3

14 87 37600062 SEAL, SHAFT 2

1 86 60200005 SEAL, SHAFT 3

3 85 60200043 SEAL, SHAFT 3

1 84 37500046 SPRING, FLAT 2

3

QTY. ITEM

1 83 37500026 SPRING, WAVE 3

1 82 37500012 SPRING, COMP. 2

2 81 37500045 SPRING, COMP. 2

SHT.

SCREW, PHIL. PAN 10-32x3/8

PART NO. DESCRIPTION

2 134 35900007 SCREW, STOCK GUIDE 2

1 133 36100044 SCREW, ADJ. HORIZ. 2

132

21 138 34700057 WASHER 2

6 137 61300037 WASHER 3

2 136 61300010 WASHER 2

2 135 65936175 SCREW, SHCS 3/8-16x1-3/4 3

4 131 65820062 SCREW, HHCS 1/4-20x5/8 3

4 128 65920075 SCREW, SHCS 1/4-20x3/4 3

8 126 65936125 SCREW, SHCS 3/8-16x1-1/4 3

4 130 66612037 SCREW, BHCS 10-32x3/8 3

4 129 66700701

5 125 66212025 SCREW, SHSS 10-32x1/4 2

8 127 65920125 SCREW, SHCS 1/4-20x1-1/4 3

12 124 65912037 SCREW, SHCS 10-32x3/8 2

QTY. ITEM

1 123 65912087 SCREW, SHCS 10-32x7/8 3

1 122 65912200 SCREW, SHCS 10-32x2 3

1 121 66536100 SCREW. FHCS 3/8-16x1 2

Page 19

SA3 Straightener Head Assembly

19

Page 20

SA3 Straightener Head Assembly

20

Page 21

SB4 Straightener Head Assembly

21

Page 22

SB4 Straightener Head Assembly

22

Page 23

BILL OF MATERIAL PAGE 1

SB4 STNR HEAD ASSY 0-700 1PM ASM #26400029

ITM PART # QTY DESCRIPTION

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

33700011 B

36700017 B

37500040 A

31900417 C

31500129 D

32900301 B

60910031 B

37500012

62309025

32900297 B

69420011 N

63800093

32900298 B

62325062

64500040 C

63130250

60500001

34700064 B

64500041 C

34200062 B

62237200 N

31900415 B

31900414 B

31900423 B

32900303 B

31900422 B

31900421 B

60910037 B

64520010 B

31900420 B

67410008

36700018 B

33700017 B

64500018 B

64520006 B

60910062 B

31500130 B

65912050 B

37500051

32600109 B

36800005 N

32600034 B

62319050

34700094 B

34300053 N

32900299 B

65230004 N

36200018 B

62337100

66212025 N

39900092 B

62412125

60108111

39900093 B

1 STUD, ADJ.

3 KNOB

2 SPRING, COMP’N LEE LC-045E-6

1 IDLER ROLL BRKT SB4

1 COVER SB4

5 IDLER SHAFT SB4 STNR

12 RET RING 5100-31

1 SPRING, SPEC STOCK CLAMP F56-A

6 DOWEL PIN Q21-093025

6 LOWER DRIVE ROLLER SB4 STNR

1 BREATHER VENT *FLUID PWR ASP-1-BV

5 BALL Q32-093

5 IDLER SHAFT SB4 STNR

2 DOWEL PIN Q21-250062

11 BEARING NEEDLE TORR M-781 CL END

1 PIPE PLUG Q23-25

2 STAT-O-SEAL WASH, PARKER 600-3/8

10 WASHER, SB4 STNR.

10 BEARING NEEDLE TORR JTT-59 DBL SL

5 IDLER ROLL SB4 STNR

2 PULL DOWEL JERGENS 31707 3/8 X 2

1 ANCHOR, SPRING BOTTOM

1 ANCHOR, SPRING TOP

1 LINK, UPPER SB4 STNR

2 HINGE PIN SB4 STNR

2 LINK, SB4 STNR

1 HORIZ. ADJ. BLOCK, SB4 STNR

1 RET RING 5100-37

3 RACE, THRUST TORR. #TRA-613

1 PIVOT BLOCK, SB4 STNR

1 WAVE WASHER ASC. SPG. W0484-009

1 ADJUSTABLE KNOB, SB4 STNR

1 HORIZ. ADJ. SCREW, SB4 STNR

1 BEARING TORR B1010

2 BEARING TORR TRB-1018

8 RET RING 5100-62

1 COVER, SPRING SB4 STNR

4 SCREW, CAP, SOC. HD. Q8-02050

1 SPRING COMP LEE #LC120L-4

1 RACK SB4 STNR

5 KEY 3/16 x 3/16 x 1/2

4 GEAR-DRIVE

1 DOWEL PIN -- 11 WASHER, THRUST

2 STOCK GUIDE COLLAR STAFFORD 10L

1 GUIDE ROLL SHAFT SB4 STNR

1 NUT, LOCK 3/8-16 JERGENS 28101

2 NUT, LOCK, KNURLED 5/16-24 x 1/4

2 DOWEL PIN Q21-375100

3 SCREW, SOC SET, CUP PT Q10-02025

1 INSTR. PLATE - CURVE ADJ.

1 ROLL PIN Q18-125125

2 O RING Q1-8111

1 LABEL, ROLLER IND SB4 STNR

23

Page 24

BILL OF MATERIAL PAGE 2

SB4 STNR HEAD ASSY 0-700 1PM ASM #26400029

ITM PART # QTY DESCRIPTION

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

81

82

83

84

85

86

87

88

89

90

91

92

93

94

95

96

97

98

99

100

101

102

103

104

105

106

107

108

64500042 C

61200026 B

31500111 B

30100040 R

30100056 D

30100055 D

37500026 N

32900294 B

32900228 B

64500031 C

65912200

64510002 B

64520005 B

36100024

60108916

60810062 B

36800010 A

32600012 B

60200005 B

32900229 B

37901000 B

10000005

65936175

65936100

66220025 N

65920075 B

63130375

63130125

69420010 B

31500120 B

31500119 B

65912075 B

66612037

65936550 N

65936125

34100003

61300037 N

65820062

34100027 B

34100124 B

34100125 C

64500032 C

61810002

60910050 B

31500128 D

32600110 B

65920150 N

32900296 B

60910043 B

34700063 B

60200047

64500001 C

37600060 B

32601200

1 BEARING, NEEDLE TORR. B-76

1 WASHER Q5-26

1 WORM GEAR COVER P1V CSTG#50110009

1 GEAR HOUSING P1V CSTG #50110121

1 CONTROL SIDE FRAME SB4

1 DRIVE SIDE FRAME SB4

1 SPRING-WASHER ASSOC. SPR W1102-01

1 UPPER ROLLER SHAFT SB4 STNR

1 WORM GEAR SHAFT P1V

1 BEARING, NEEDLE TORR B-128

1 SOCKET HD CAPSCREW Q8-02200

2 BEARING, NEEDLE THRUST Q53-2

1 BEARING TORR TRD-1220

1 WORM COVER 113-P1V

1 O RING Q1-8916

1 RET RING SPIROLOX RS 62

1 KEY

1 WORM, P1V STD.

1 OIL SEAL CR 6204

1 SHAFT WORM P1V

1 COUPLING, OLDHAM R3, R4, S4V, S8V

1 FILLER - NO PART REQUIRED

2 SOCKET HD CAPSCREW Q8-066175

2 SOCKET HD CAPSCREW Q8-066100

3 SCREW, SOC HD SET, 1/4-20 X 1/4

4 SCREW, CAP, SOC. HD. Q8-040075

1 PIPE PLUG Q23-37

2 PIPE PLUG Q23-12

1 BREATHER VENT F.P. ENG ASP-3-BV

1 EXIT GUARD LOWER P4V

1 EXIT GUARD UPPER P4V

4 SCREW, CAP, SOC. HD. Q8-02075

8 BHMS 10/32 x 3/8

5 SOC HD CAPSCREW 3/8-16 x 5-1/2

5 SOCKET HD CAPSCREW Q8-066125

2 SPACER 44B-P1V

6 SPLIT LOCK WASHER 3/8 MEDIUM DUTY

4 HEX HD. CAP SCREW Q15-040062

1 SPACER, SQUEEZE ROLL BRACKET P4V

1 UPPER SPACER SB4 STNR

1 LOWER SPACER SB4 STNR

2 BEARING, NEEDLE TORR. JTT-1010

1 #2 WOODRUFF KEY 3/32 X 1/2

1 RET RING 5100-50

1 GEAR COVER SB4

1 SPUR GEAR 38T, 16P, SB4 STNR

5 SOCK HD CAP SCREW 1/4-20 x 1-1/2

1 IDLER SHAFT SB4 STNR

13 RET RING 5100-43

21 WASHER, SB4 STNR.

11 OIL SEAL TROSTEL 01 EB 040 028 02

12 N. BRG. B-78 7/16 x 5/8 x 1/2 LG

1 GASKET, SB4 STNR

12 GEAR –MTE–

24

Page 25

BILL OF MATERIAL PAGE 3

SB4 STNR HEAD ASSY 0-700 1PM ASM #26400029

ITM PART # QTY DESCRIPTION

109

110

111

112

113

114

115

116

117

118

119

120

121

122

123

124

125

126

127

128

129

130

131

132

133

134

135

136

137

138

139

140

141

142

143

144

145

146

147

148

149

150

62309100 B

32900302 B

60200043 B

31800024 B

60108024

66700041 N

61810213

37500023 B

34200040 B

65912100

64520002 B

60108146

32900295 B

66536100 N

64500002 B

64500003 B

62325150

37600058 C

62409050

32600071 B

32900226 A

32600035 B

32900227 A

31900408 B

31900418 B

62325075

32900056 B

37500041 A

37500045 A

37500050 N

62412062

32900300 B

64500025 C

65600007

32600111 B

31900419

61200022

33700015 B

66300250 B

39900051 B

39900261 B

34700034 B

1 PIN, DOWEL 3/32 x 1 INCH LG.

1 IDLER BRKT HINGE PIN SB4 STNR

3 SEAL SHAFT EB-52-40-2 TROSTEL

1 SEAL PLATE P1V

1 O RING Q1-8024

1 SCREW, THUMB 3/8-16 JERGENS 43910

2 KEY Q30-213

1 SPRING, FLAT SQUEEZE 36B-P4V

2 ROLLER, PINCH P4V

1 SOCKET HD CAPSCREW Q8-02100

9 BEARING TORR TRC 1018

1 O RING Q1-8146

1 LOWER ROLLER SHAFT SB4 STNR

1 SCREW, CAP, SOC FLAT HD 3/8-16 x 1

1 BEARING TORR B108

5 BEARING TORR B1012

2 DOWEL PIN Q21-250150

1 GASKET

1 ROLL PIN Q18-093050

1 WORM GEAR P1V

1 IDLER SHAFT P1V

1 GEAR-IDLER

1 PIVOT PIN P1V

1 BRACKET, SQUEEZE ROLLER

1 SQUEEZE ROLL BRACKET SB4 STNR

10 DOWEL PIN Q21-250075

1 TRUNNION, ECCENTRIC S4V

2 SPRING, COMP’N LEE LC-040C-2

2 SPRING, COMP LEE # LC-45E-10

2 SPRING, TENSION LEE #LE-037D-1

3 ROLL PIN Q18-125062

1 HINGE PIN, COVER SB4 STNR

2 BEARING NEEDLE TORR BH-1012

2 INSERT, THD. JERGNES 26123

1 SPUR GEAR 16T, 16P, SB4 STNR

1 CLAMP BAR SB4 STNR

3 WASHER Q5-22

2 STUD, ADJ. 5/16-24 x 1.62

2 SCREW, DRIVE Q17-025

1 NAMEPLATE, .875 x 1.500

1 CAUTION, LABEL

1 THRUST WASHER

* RECORD NUMBER

PSRV

25

Page 26

SBX-4 Straightener (Standard Speed) with Pushbutton Controls

26

Page 27

SBX-4 Straightener (Standard Speed) with Pushbutton Controls

27

Page 28

SBX-4 Straightener (Standard Speed) with Pushbutton Controls

28

Page 29

SBX-4 Straightener (Standard Speed) with Pushbutton Controls

29

Page 30

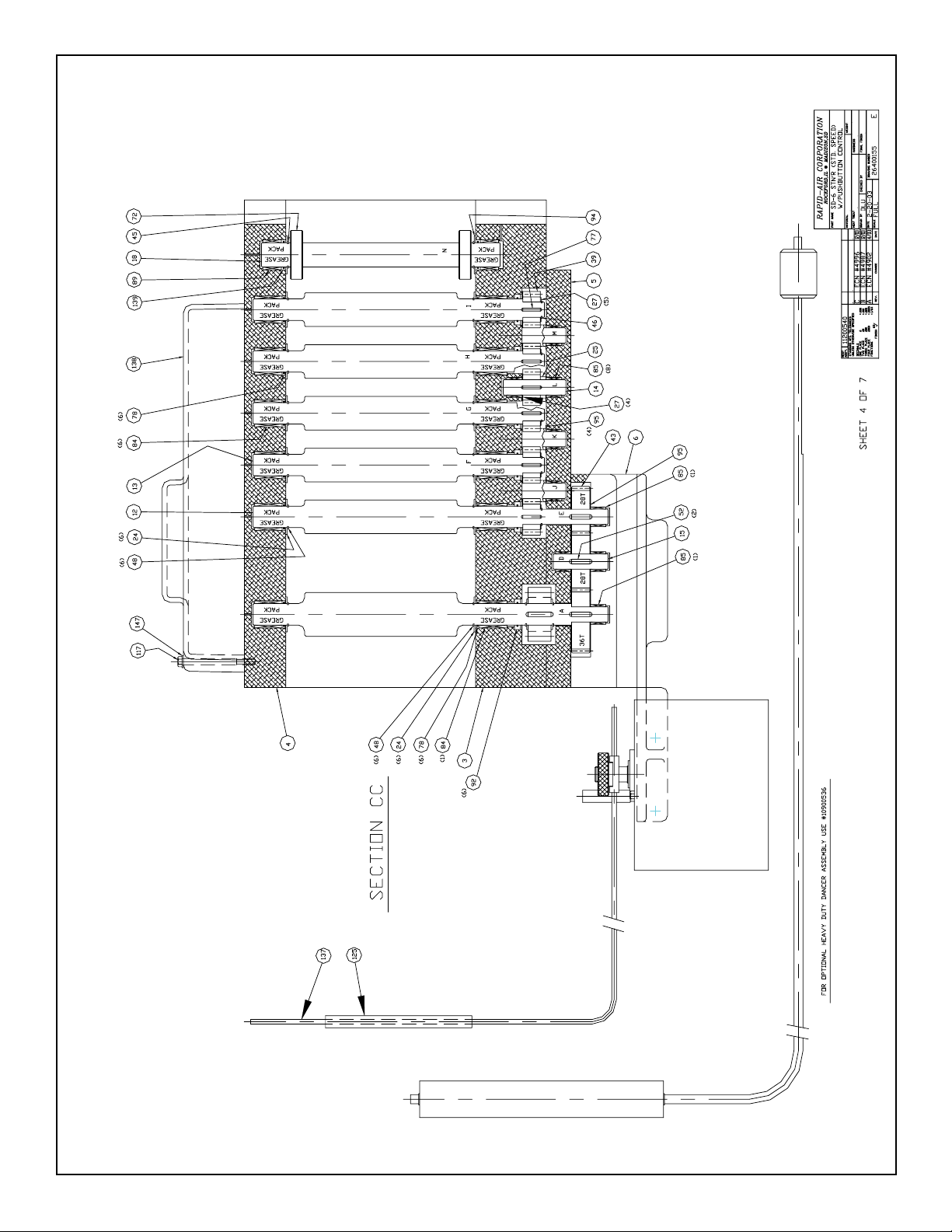

SCX-6 Straightener (Standard Speed) with Pushbutton Controls

30

Page 31

SCX-6 Straightener (Standard Speed) with Pushbutton Controls

31

Page 32

SCX-6 Straightener (Standard Speed) with Pushbutton Controls

32

Page 33

SCX-6 Straightener (Standard Speed) with Pushbutton Controls

33

Page 34

SCX-6 Straightener (Standard Speed) with Pushbutton Controls

34

Page 35

SCX-6 Straightener (Standard Speed) with Pushbutton Controls

35

Page 36

SCX-6 Straightener (Standard Speed) with Pushbutton Controls

36

Page 37

SD-6 Straightener (Standard Speed) with Pushbutton Controls

37

Page 38

SD-6 Straightener (Standard Speed) with Pushbutton Controls

38

Page 39

SD-6 Straightener (Standard Speed) with Pushbutton Controls

39

Page 40

SD-6 Straightener (Standard Speed) with Pushbutton Controls

40

Page 41

SD-6 Straightener (Standard Speed) with Pushbutton Controls

41

Page 42

SD-6 Straightener (Standard Speed) with Pushbutton Controls

42

Page 43

SD-6 Straightener (Standard Speed) with Pushbutton Controls

43

Page 44

Typical Stamping Layout

44

Loading...

Loading...