Page 1

! !

RAPID-AIR

OPERATING INSTRUCTIONS FOR

RAPID-AIR

4601 KISHWAUKEE ST.

ROCKFORD, IL. 61109-2925

PHONE: (815) 397-2578

FAX: (815) 398-3887

WEB SITE: www.rapidair.com

SA3, SA3M, SB4, SB4M

STOCK STRAIGHTENERS

Page 2

! !

TABLE OF CONTENTS

1.

PAGE

STRAIGHTENER "HEAD-ONLY" DRAWING

2.

INSTALLATION

3.

OPERATION

4.

5.

6.

KEYPAD FUNCTIONS

7.

TECH. BULLETIN (straightener roll adjustment)

KEYPAD FUNCTIONS

KEYPAD FUNCTIONS

8.

JOG SPEED ADJUSTMENT AND DANCER ARM CALIBRATION

9.

JOG SPEED ADJUSTMENT AND DANCER ARM CALIBRATION

10.

MAINTENANCE

11.

TROUBLESHOOTING

12.

TROUBLESHOOTING

13.

SA3/SA3M CABINET ASSEMBLY DRAWING

14.

15.

16.

SA3 HEAD ASSEMBLY DRAWING (sheet 2 of 2)

17.

SB4/SB4M CABINET ASSEMBLY DRAWING

SA3 HEAD ASSEMBLY DRAWING (sheet 1 of 2)

SA3M HEAD ASSEMBLY DRAWING (sheet 1 of 2)

18.

SA3M HEAD ASSEMBLY DRAWING (sheet 2 of 2)

19.

SB4 HEAD ASSEMBLY DRAWING (sheet 1 of 2)

20.

SB4 HEAD ASSEMBLY DRAWING (sheet 2 of 2)

21.

SB4M HEAD ASSEMBLY DRAWING (sheet 1 of 2)

22.

SB4M HEAD ASSEMBLY DRAWING (sheet 2 of 2)

23.

WIRING DIAGRAM

Page 3

! !

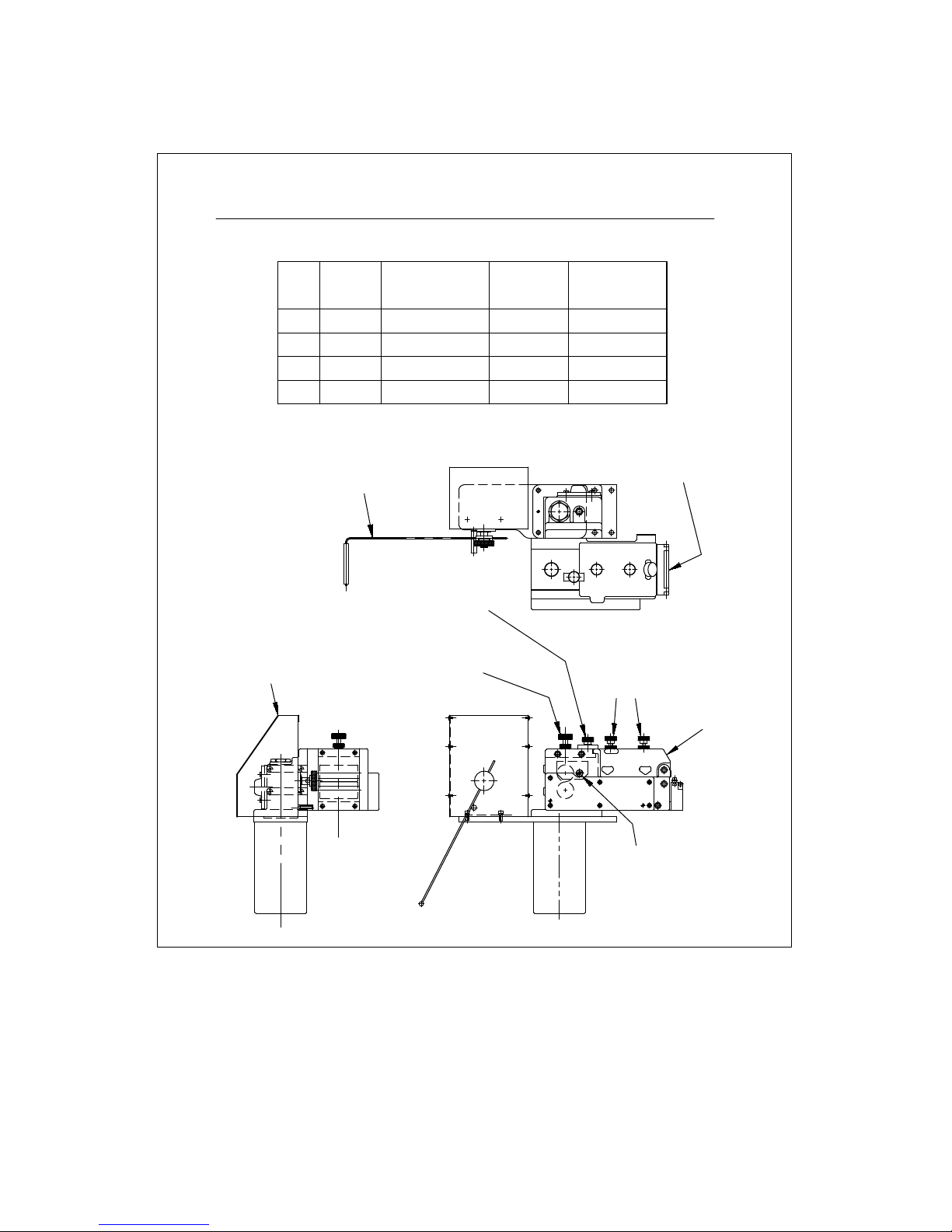

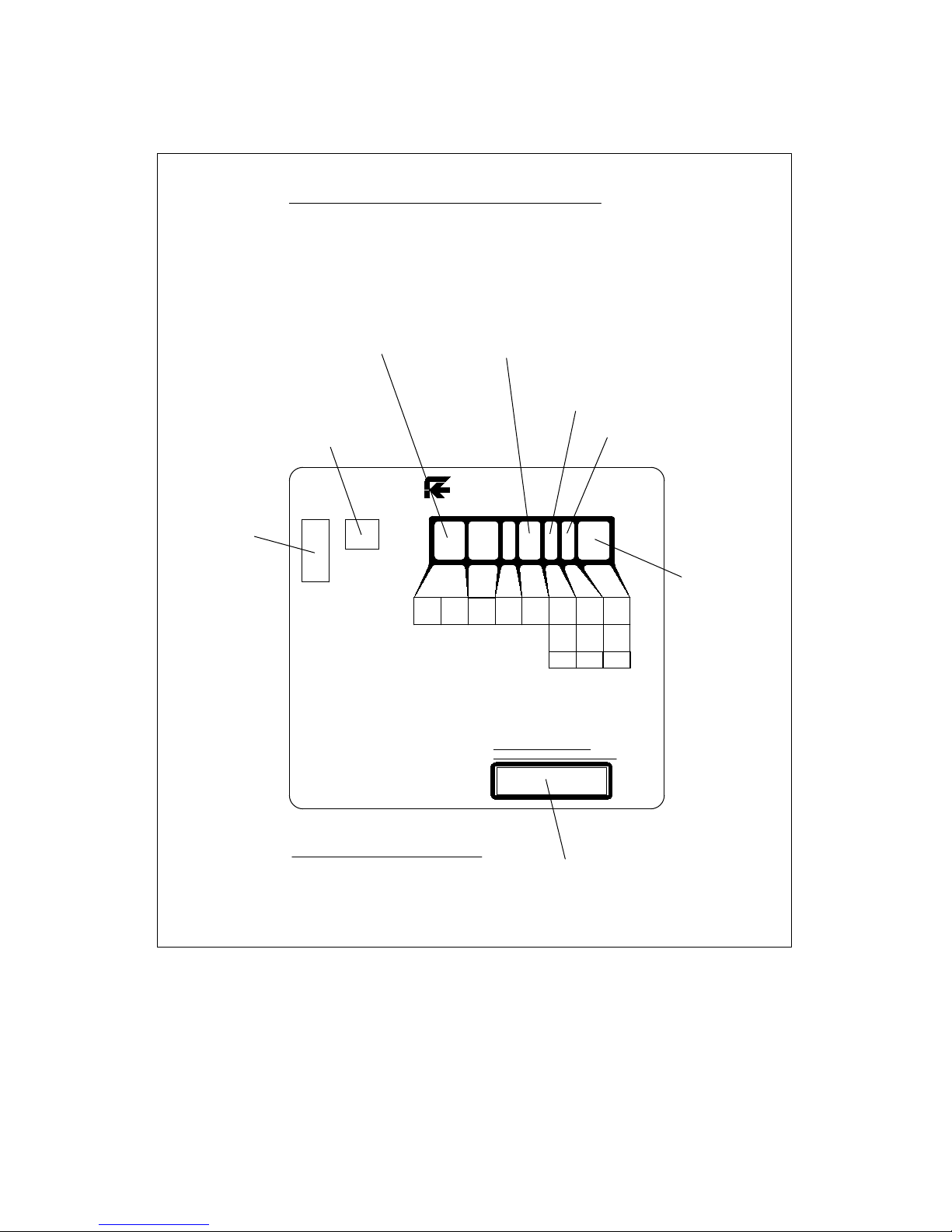

1

(SA3 STRAIGHTENER SHOWN)

PUSHBUTTON

CONTROL

ASSEMBLY

MOTOR

ENTRANCE

GUIDE

ROLLS

DANCER

ARM

ASSEMBLY

PINCH ROLL

ADJUSTING

KNOB

PLATEN

ADJUSTING

KNOBS

C

L

STOCK

ECCENTRIC

ADJUSTMENT

STRAIGHTENER "HEAD-ONLY" DRAWING

SA3

SA3M

SB4

SB4M

MODEL

MAX.

MATERIAL

WIDTH

Effective

Straightening

Range

Max.

Speed

in./min.

AC Input

Power

Required

3"

3"

4"

4"

.002-.030"

(.051-.76mm)

.002-.030"

(.051-.76mm)

.003-.050"

(.076 -1.27mm)

.003-.050"

(.076 -1.27mm)

700"

(1778cm)

1400"

(3556cm)

825"

(2100cm)

1650"

(4200cm)

1/4hp, 115vac, 1ph

1/2hp, 115vac, 1ph

1/2hp, 115vac, 1ph

1/2hp, 115vac, 1ph

TOP

COVER

TOP COVER

LOCKING

KNOB

Page 4

! !

2

1. Your straightener is fully assembled and ready to be put

into position. Visually inspect unit for damaged or loose

parts due to shipment. If there is physical damage contact

carrier.

2. Install your straightener on a level surface with sufficient

clearance for loading material and adjusting the roller

pressure for straightening. Align and center your unit to

the device that will be supplying the stock. For safe operation,

bolt unit to the floor. Before bolting your unit to the floor, check

for the longest feed length and position your straightener so

that there will be about two or three feed lengths in the storage

loop without re-inducing coil set in the material.

CAUTION - Disconnect electrical power before performing

any service to this machine.

INSTALLATION

3.

Before inserting material into your straightener, turn on the main

power button and run a test cycle using the jog button. Also run

a test cycle in the run mode using the dancer arm to test that the

speed varies if using the proportional control. Test all other

electrical features before continuing.

4.

Once these tests have been completed and all the functions are

working properly, your straightener can now be used for what it

was designed to do and that is to remove coil set.

Page 5

! !

3

OPERATION

1.

Retract the upper pinch roll and upper idler roll platen to a

position so that when the cover is closed the material is not

being deformed. Open the cover of the straightener and

position the edge guides for the maximum width. Cut and place

about a four foot length of material onto the straightener rolls

with the exit end of the material extending through the exit

pinch rolls and centered from side to side in the straightener.

Close the cover and latch it. Adjust the exit pinch roll enough

to grip and hold the material. Adjust the edge guides so that

they just touch the material.

2.

Adjust upper idler roll platen (using platen adjusting knobs) to

remove coil set. Most of the coil set should be removed with

the roller closest to the entrance end of the straightener with

declining adjustment as material passes through the rollers

closest to the exit end of the straightener. Never overwork the

material to the point where opposite coil set is established.

3.

Depending on the amount of coil set in your material and the

type of material you are trying to straighten, you may be

required to run the material through the straightener several

times with several adjustments before the required results

are achieved.

4. Refer to the Tech. Bulletin on page 4 in this manual for material

straightening procedures.

Page 6

! !

Page 7

! !

5

OFF

EXTERNAL LOOP PLUG

RAPID-AIR EQUIPMENT ONLY

ON RESET

RAPID-AIR

Mode

STOP/

RUN/

JOG

JOG

Arm

Range

LOOP

RANGE

+

LOOP

RANGE

-

LOOP

ARM

EXTER.

Loop

Type

LOOP

HT.

-

%

SPEED

-

Min-0

Max- 8

Min-0

Max- 8

Arm

Height

LOOP

HT.

+

%

SPEED

+

Start

Speed

CAUTION: DISCONNECT ELECTRICAL POWER

BEFORE PREFORMING ANY

SERVICE TO THIS MACHINE.

Operating Instructions

In Stop Mode: Select Loop Arm or External Loop Control.

Position Loop Sensor Above Material Loop.

Set Estimated % Max Speed, Loop Height and Loop Range.

In Run Mode: Adjust % Max Speed, Loop Height and Loop Range for Smooth Operation.

STRAIGHTENER & POWER ROLL

Min-0

Max-100

POWER ROLL KEYPAD

MAIN

POWER

SWITCH

CIRCUIT

BREAKER

% SPEED

STOP/RUN/JOG

MODE

LOOP TYPE

DANCER OR EXTERNAL

LOOP RANGE

LOOP HEIGHT

Prior to applying power to your straightener the operator should

review all controls on this machine. See pages 5-6 in this manual

for a summary of these controls.

KEYPAD FUNCTIONS

REMOTE INTERFACE

PORT "D"

Page 8

! !

6

Note: Remote interface port "D" connector, if used, communicates

with external loop control.

Warning! - Never plug any type of computer or non Rapid-Air

equipment into this plug or severe damage will result.

Consult factory when installing new external controls.

KEYPAD FUNCTIONS

Run/Stop/Jog

In the Run mode, if the dancer arm is moved the pinch rolls

In the Jog mode, the jog button has to be depressed for the

rolls to turn. Jog function is used mainly for setup.

In the Stop mode there is no movement of the rolls.

On/Off switch

This illuminated switch is the main power switch for the

controller. It must be "ON" for the straightener to function.

Reset switch

This is the main circuit breaker for the straightener.

and lower straightening rolls will turn.

Loop arm/external switch

When using a dancer arm, select loop arm button to display

"LV" for vertical. This button will also allow you to select

"LH" for horizontal. ("LH" is used for Pallet Master decoilers

only)

When using an external loop control, select external loop to

display "RT" for RTB or "RS" for RS2.

Page 9

! !

7

KEYPAD FUNCTIONS

Loop range/height

The loop range function selects the degree of arm movement

to achieve maximum motor speed. If a loop range of "0" was

selected the the arm would only have to travel approximately

6° to have the straightener at full speed. If a loop range of "8"

was selected the arm would travel approximately 60° to have

the straightener at full speed. This function is active in the

8

7

6

5

4

3

2

1

0

AT REST

Loop Range

Each number

is the distance

from rest that

the dancer has

to move to

achieve full speed

of the reel motor

8

7

6

5

4

3

2

1

0

AT REST

Loop Height

Each number

is the distance

from rest that

the dancer has

to move to

start reel rotation

The loop height function selects the degree of arm movement

to start roll rotation. If a loop range of "0" was selected

the the arm would only have to travel approximately 6° to

start roll rotation. If a loop range of "8" was selected the

arm would travel approximately 60° before starting roll

To set the loop height, thread up the material with the dancer arm

resting on the material. If the straightener is running with the

dancer arm in this position adjust the loop height until straightener

stops. This is your new at rest position. This function is active in

% Speed setting

The % speed setting allows you to adjust the maximum speed

the rolls will rotate. This should be set to maintain a constant

feed rate. This function is active in the "RUN" mode.

"RUN" mode.

rotation.

the "RUN" mode.

Page 10

! !

JOG SPEED ADJUSTMENT & DANCER ARM

CALIBRATION

Your straightener was shipped with the dancer arm set up for it's

correct position so the only thing that has to be reset would be

the jog speed if you need your unit to jog faster or slower.

To reset the jog speed, turn off the main power switch. Press and

hold the "Run/Stop/Jog" button while turning the main power switch

on. The first screen you will see will display the jog speed percentage.

SETUP SENSOR

NEXT

To increase the jog speed, press the "Start Speed"

pushbutton. If you want to decrease the jog speed press the

"Start Speed" pushbutton.

%

SPEED

+

%

SPEED

The jog speed is shown in the percent of maximum jog speed.

Once you have set the desired jog speed push the "Run/Stop/Jog"

button once for next. Your jog speed is now set.

The next screen asks if you want to set up the sensor (commonly

referred to as "dancer arm calibration"). Use the percent speed

Select "no" if all you wanted to do was change the jog speed, select

"yes" if you want to calibrate the dancer arm by resetting the sensor.

buttons to select "yes" or "no".

YES

NO

After making your selection, press

"Run/Stop/Jog" for next.

If you selected "yes" the next screen asks you to set the low set point.

If the dancer arm is resting on the positive stop then just save this

setting by pushing the "Run/Stop/Jog" button.

JOG SPEED

NEXT

23%

+

_

_

SENSOR LOW SETPOINT

SAVE

xxx

8

Page 11

! !

JOG SPEED ADJUSTMENT & DANCER ARM

CALIBRATION

The next screen is for setting the high set point. Raise the dancer

arm to it's upper stop position and press the "Run/Stop/Jog" button

once to save this setting.

SENSOR HIGH SETPOINT

SAVE

xxx

The next screen is to set the offset of the program. Potentiometers

are hard to get set perfectly so we've built in an offset. After setting

the high & low points, with the dancer arm resting on the positive

stop, put the unit in the "Run" mode. If the unit starts running with

the dancer arm on the positive stop then an offset needs to be put

in. If an offset needs to be put in go through the setup procedure

LOW OFFSET

NEXT

+0

+

_

You now have set the dancer arm limits. The next screen to appear

allows you to exit the setup. Use the percent speed button to enter

"yes or no".

EXIT SETUP

YES

NO

If "yes" was selected press "Run/Stop/Jog" button and the next screen

SHUT OFF POWER TO

SAVE AND EXIT

again until you get to the low offset screen. Using the percent speed

buttons put in an offset value of -3 to -5. Press the "Run/Stop/Jog"

button to save this setting.

appears.

Power off unit, the dancer arm is now ready for production running.

9

Page 12

! !

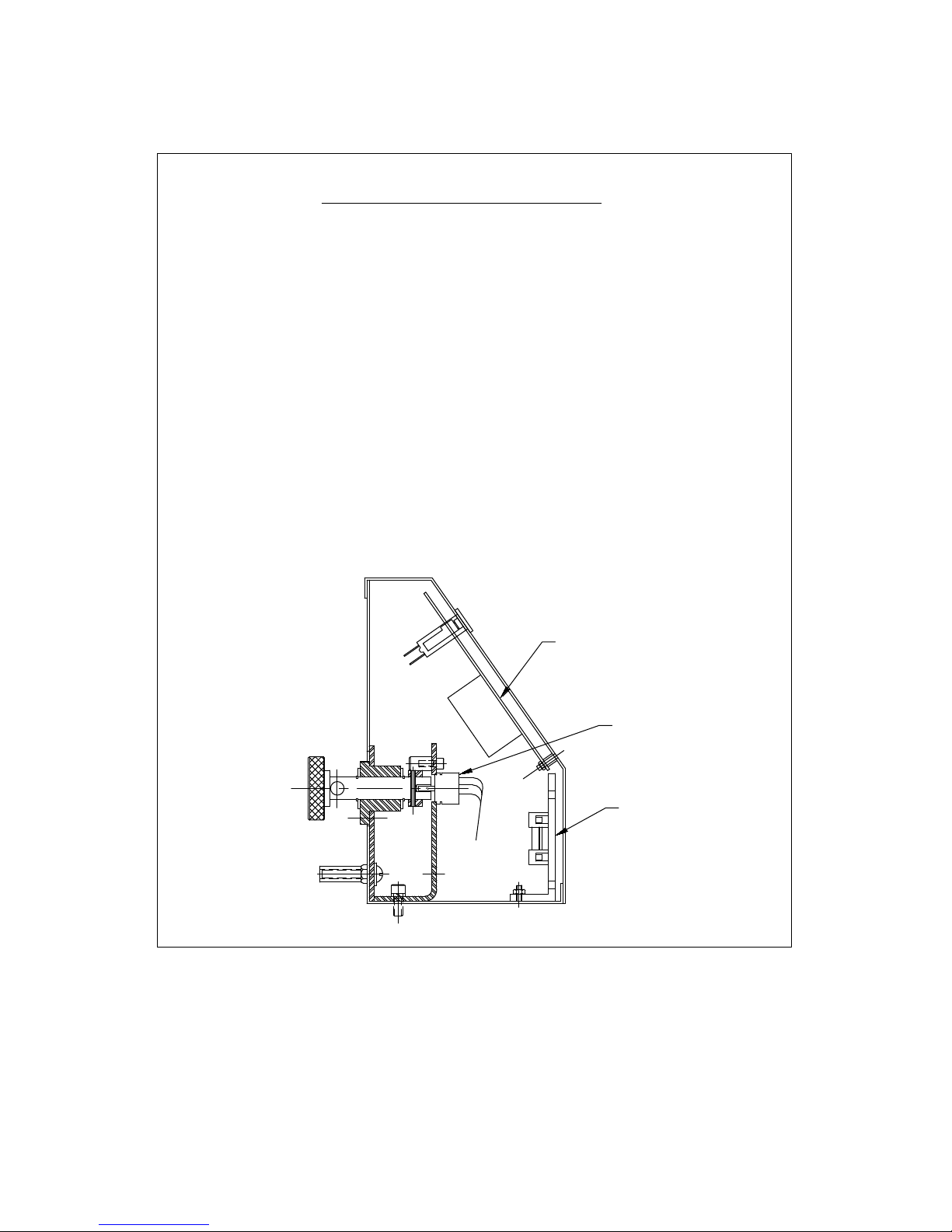

MAINTENANCE

Gearbox lubrication - change oil every 1000 hours as follows:

Electrical - all brushes on motors should be checked every

1500-2000 hours.

10

Your straightener was shipped from the factory with

the upper & lower pinch rolls parallel to each other.

If these pinch rolls should happen to get out of parallel,

use eccentric shaft to adjust rolls. See diagram page 1

for location of eccentric shaft. Loosen socket head cap

screw in center of shaft. Turn shaft until rolls are parallel

with each other. You should be able to grip .001 thick

shim stock along entire width of rollers. After adjustment

is made, re-tighten socket head cap screw.

BREATHER

FILL/

MOTOR

CASE

BREATHER

FILL/

DRAIN

SPUR

GEAR

CASE

OIL

LEVEL

OIL

PLUG

DRAIN

OIL

LEVEL

SA3/SA3M STRAIGHTENER

MOTOR CASE

FILL TO OIL PLUG

APPROX. 4 oz

MOBIL 600 W

SPUR GEAR CASE

NO OIL PLUG OR SIGHT

APPROX. 4 oz.

MOBIL 600W

BREATHER

FILL/

OIL

LEVEL

OIL

PLUG

DRAIN

BREATHER

DRAIN

OIL

LEVEL

FILL/

MOTOR

CASE

SPUR

GEAR

CASE

SB4/SB4M STRAIGHTENER

MOTOR CASE

FILL TO OIL PLUG

APPROX. 4 oz

MOBIL 600 W

SPUR GEAR CASE

NO OIL PLUG OR SIGHT

APPROX. 6 oz.

MOBIL 600W

Page 13

! !

TROUBLESHOOTING

MAIN SWITCH ON BUT NOT LIT

1. Circuit breaker tripped

a. Reset circuit breaker

2. Unit not plugged into main power

a. Plug into main power

3. No power in incoming line

a. Check outlet

b. Check power cord

4. Loose wiring

a. Check terminals and connections

MOTOR CREEPS IN STOP POSITION

1. "Min." speed pot on RAMM board out of adjustment

2. Offset in dancer arm setup out of adjustment (see page 8)

UNIT ON BUT MOTOR WON'T RUN

(armature voltage present on RAMM board)

1. Check motor wiring

a. replace motor cord or correct motor wiring (consult factory)

2. Check motor

a. Worn brushes or defective motor (consult factory)

b. Check for oil in motor, gear box oil seal may have failed

UNIT ON BUT MOTOR WON'T RUN

(no armature voltage present on RAMM board)

1. Selector switch not in "RUN" position

a. Turn selector switch to "RUN" position

2. If running with a dancer arm control

a. Check that the external/loop arm function is in the

loop arm position

3. If running with external control

a. Check that the external/loop arm function is in the

external position

4. Loop height switch setting to high

a. Set height setting to "0"

11

Page 14

! !

TROUBLESHOOTING

5. Percent speed function set too low

a. Adjust percent speed function to 100%

6. Fuses blown

a. Check fuses & circuit breaker

7. No AC voltage at DC drive board

a. Check wiring

8. Check signal voltage between P2 to P1 on DC drive

0-6 VDC - RAMM

0-9 VDC - Regen drive

while moving dancer arm

a. If there is a signal, check continuity between I1 & I2

If no continuity, replace DC drive or consult factory

9. Check pico fuse on 69100804 board (F1)

a. Replace fuse,1 amp pico fuse-consult factory

69100804 Board

69100014

Board

29100021

Potentiometer

12

Page 15

! !

13

RAPIDAIR

40.5"

PASS LINE

20"

28"

SA3/SA3M CABINET ASSEMBLY

Page 16

! !

14

RAPIDAIR

RAPID AIR CORP.

CAUTION

MODEL

SERIAL

UP

CURVE

DN

SB4/SB4M CABINET ASSEMBLY

40.5"

PASS LINE

28"

20"

Page 17

! !

15

FRACTIONS

DECIMALS

DRAWING NUMBER

WEIGHT

HARDNESS

FINAL FINISHCHECKED BY

SCALE

DATE

DRAWN BY

HEAT TREAT

MATERIAL

PART NAME

63

FINISH

1/64

.0005

.005

.010

.030

.0000

.000

.00

.0

FOUR PLACE

THREE PLACE

TWO PLACE

ONE PLACE

UNLESS OTHERWISE SPECIFIED

STANDARD MFG. TOLERANCES

ASS'Y.

NEXT

REV. CHANGE DATE

FULL

E

AA

SECTION

AA

10

20

71

(4)

(2)

26

87 147 95

(2)

145

(2) (2)

B

B

SECTION

BB

C

C

SECTION

CC

74

29 15 52

93

63

102

85

16

62

139

103

62

89

88

85

83

34

108

93

(2)

64

85

34

108

93

(1)

103

77

84

1

2

75

139

140

22

72

90

108

32

63

21

64

33

132

9342123

13

43

34

108

93

3 4

12

11

124

92

146

139

35

64

91

36

109

146

139

75

(1)

(2)

64

86

23

150

129

118

119

151

126 137

128

148

REF. 31700530 NO CONTROL

126

137

135

137

D

D

VIEW

DD

REF. 31701995 WITH CONTROL

MOUNTING PLATE

27 78

80

INNER SPRING

OUTER SPRING

124

51

19

65

73

97

73

65

65

65

100

28

99

97

41

126

121

39

125

SA3 STRAIGHTENER

SHEET 1 OF 2

(1) (1)

102 (1)

102

(1)

NOTE: ITEM #26 ROLLER TO BE PACKED

FULL LENGTH WITH BEARING

LUBRICANT

(1)

(1)

(2)

(1)

(1)

(1)

(4)

(1)

(1)

(1)

(2)

(2)

(2)

(2)

(2)

(1)

(1)

(1)

(1)

(3)

118

(1)

149

127

(6)

102

(2)

131

(4)

(1)

(2)

(1)

(1)

(1)

(1)

(1)

(1)

122

9

14

8

120

102

(4)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(4)

(1)

(1)

(1)

(1)

102

(1)

(1)

104

ROLL

PIN

5

6

USE LOCTITE

518 GASKET

ELIMINATOR

USE LOCTITE

518 GASKET

ELIMINATOR

5-26-2015

W/ONE-PIECE ROLLER)

DLU

26400229

11200573

(1)

A ECN #5562

9/22/16

B

B ECN #5673

11/14/17

SA3 HEAD ASSEMBLY DRAWING

(sheet 1 of 2)

Page 18

! !

16

FRACTIONS

DECIMALS

DRAWING NUMBER

WEIGHT

HARDNESS

FINAL FINISHCHECKED BY

SCALE

DATE

DRAWN BY

HEAT TREAT

MATERIAL

PART NAME

63

FINISH

1/64

.0005

.005

.010

.030

.0000

.000

.00

.0

FOUR PLACE

THREE PLACE

TWO PLACE

ONE PLACE

UNLESS OTHERWISE SPECIFIED

STANDARD MFG. TOLERANCES

ASS'Y.

NEXT

REV. CHANGE DATE

FULL

E

56

58

73

112

114

61

105

141

48

81

115

49

124

50

124

(2)

(2)

79

127

59

60

134

57

141

113

61

105

111

141

76

136

GEAR ROLLOUT

DESCRIPTIONPART NO.QTY.ITEM

123456789101112131415

DESCRIPTIONPART NO.QTY.ITEM

16171819202122

1 30100057 GEAR HOUSING

1 31500111 WORM COVER

1 30100053 CONTROL SIDE FRAME

1 30100054 DRIVE SIDE FRAME

1 31500123 ROLLER SUPPORT COVER

1 31500124 GEAR CASE COVER

1 31900406 IDLER BRACKET

1 31900407 SQUEEZE BRACKET

1 31900408 SQUEEZE BRACKET

1 31900429 GUIDE SUPPORT BRACKET

1 31900428 GUIDE

1 34100120 LOWER SPACER

1 34100121 UPPER SPACER

1 34100119 SQUEEZE SPACER

1 34200447 LOWER PINCH ROLL

1 34200448 UPPER PINCH ROLL

6 32900279 IDLER SHAFT

1 32900280 IDLER SHAFT

1 32900283 GUIDE SHAFT

7 32900284 ROLLER SHAFT

1 32900226 IDLER SHAFT

1 32900228 WORM GEAR SHAFT

23242526272829

30

31

99

(13)

(11)

138

(5)

138

(5)

70

(5)

CLOSED

END

25

110

67

(5)

96 (11)

68

(6)

CLOSED

END

67

(6)

138

(11)

65

(1)

73

97

(1)

18

66

30

SEE

SECTION

CC

45

26

20

(6)

(6)

95

(12)

71

(24)

87

(12)

147

(12)

46

94

143

37

125

(2)

47

142

55

106

329002291 WORM SHAFT

5 34200060 LOWER DRIVE ROLLER

313233343536373839

40

7 34200061 ROLLER

SA3 STRAIGHTENER

DLU

5-26-2015

26400229

SHEET 2 OF 2

414243444546474849

50

1 32600090 RACK

1 32600089 PINNION

1 32600088 SPUR GEAR

11 32600086 SPUR GEAR

1 32600087 SPUR GEAR

1 32600071 WORM GEAR

51525354555657585960616263

1 32600035 IDLER GEAR

3 32600034 GEAR

1 32600012 WORM

1 36100024 WORM COVER

2 32900286 PIVOT PIN

1 32900287 PIVOT PIN

1 32900288 PIVOT PIN

PIVOT PIN1 32900289

1 32900290 HINGE PIN

1 32900227 PIVOT PIN

1 32900285 ECCENTRIC TRUNION

1 31900410 UPPER LINK

2 31900409 LINK

1 31900411 HORIZ. ADJ. TEE

1 31900412 PIVOT BLOCK

1 31900413 CLAMP BAR

1 31900414 TOP SPRING ANCHOR

1 31900415 BOTTOM SPRING ANCHOR

1 31500125 COVER

1 31500126 UPPER GUARD

1 31500127 LOWER GUARD

54

53

130

1 36700015 KNOB

1 66700041 THUMB SCREW

2 36200018 LOCK NUT

1 65230004 LOCK NUT

2 36200005 NUT

2 34200005 ROLLER

3 36700017 KNOB

2 64500032 NEEDLE BEARING

2 64500002 NEEDLE BEARING

646566676869707172737475767778798081828384858687888990919293949596979899100

101

102

103

104

105

106

107

108

109

110

111

112

113

114

115

116

117

118

119

120

121

122

123

124

125

126

4 64500003 NEEDLE BEARING

5 64500028 NEEDLE BEARING

1 64500029 NEEDLE BEARING

11 64500030 NEEDLE BEARING

6 64500034 NEEDLE BEARING

5 64500036 NEEDLE BEARING

28 64500033 NEEDLE BEARING

1 64500031 NEEDLE BEARING

4 64520010 THRUST WASHER

2 64520008 THRUST BEARING

2 64510002 THRUST BEARING

2 37500040 SPRING

2 37500041 SPRING

2 37500042 SPRING

2 37500043

2 37500044

SPRING

SPRING

2 37500045 SPRING

1 37500012 SPRING

1 37500026 WAVE SPRING

1 37500046 FLAT SPRING

3 60200043 SEAL

1 60200072 SEAL

14 37600062 SEAL

1 31800024 SEAL PLATE

1 60108024 "O" RING

1 60108146 "O" RING

1 60108916 "O" RING

1 60810062 SPIRAL RING

98

125(2)

40

96

(2)

44

101

DESCRIPTIONPART NO.QTY.ITEM

127

6 60910062 RETAINING RING

1 60910031

14 60910015

13 60910025

4 60910037

RETAINING RING

RETAINING RING

RETAINING RING

RETAINING RING

2 33600168 INDICATOR PIN

13 62312025 DOWEL PIN

1 62312062 DOWEL PIN

2 62325100 DOWEL PIN

10 62325075 DOWEL PIN

2 62325150 DOWEL PIN

1 62409050 ROLL PIN

3 62412062 ROLL PIN

1 62412125 ROLL PIN

4 36800005 KEY

1 36800010 KEY

5 60200049 SEAL

3 65600002 INSERT

1 65600004 INSERT

1 33700014 ADJ. STUD

1 33700015 ADJ. STUD

1 33700016 ADJ. STUD

2 63130125 PIPE PLUG

1 63130375 PIPE PLUG

5 65936475 SHCS 3/8-16 X 4 3/4

1 66536100 FHSCS 3/8-16 X 1

1 65912200 SHCS #10-32 X 2

1 65912087 SHCS #10-32 X 7/8

12 65912037 SHCS #10-32 X 3/8

5 66212025 SET SCREW

7 65936125 SHCS 3/8-16 X 1 1/4

128

129

130

131

132

133

134

135

136

137

138

8 65920125 SHCS 1/4-20 X 1 1/4

4 65920075 SHCS 1/4-20 X 3/4

4 66612037 BHSCS #10-32 X 3/8

4 65820062 HEX BOLT 1/4-20 X 5/8

1 36100044 HORIZ. ADJ. SCREW

139

140

141

142

143

144

145

146

147

148

2 35900007 STOCK GUIDE SCREW

2 65936175 SHCS 3/8-16 X 1 3/4

2 61300010 WASHER

6 61300037 WASHER

21 34700057 WASHER

9 64520002 WASHER

1 64520005 WASHER

3 34700062 WASHER

149

150

151

152

153

155

156

157

154

1 34700060 WASHER

1 34700061 WASHER

14 34700048 WASHER

2 34100003 SPACER

14 35800051 SEAL RETAINER

1 37901000 OLDHAM COUPLING

1 39900092 INSTRUCTION LABEL

1 39900091 LABEL

1 69420010 BREATHER

1 69420011 BREATHER

1 34700034 WASHER

1 62319025 DOWEL PIN

145

(12)

NOTE: ITEM #26 ROLLER TO BE PACKED

FULL LENGTH WITH BEARING

LUBRICANT

(2)

133

111

(2)

82

7

38

17

(1)

(5)

W/ONE-PIECE ROLLERS

11200573

A

A

A

A ECN #5562

9/22/16

B ECN #5673

11/14/17

B

(sheet 2 of 2)

SA3 HEAD ASSEMBLY DRAWING

Page 19

! !

17

FRACTIONS

DECIMALS

DRAWING NUMBER

WEIGHT

HARDNESS

FINAL FINISHCHECKED BY

SCALE

DATE

DRAWN BY

HEAT TREAT

MATERIAL

PART NAME

63

FINISH

1/64

.0005

.005

.010

.030

.0000

.000

.00

.0

FOUR PLACE

THREE PLACE

TWO PLACE

ONE PLACE

UNLESS OTHERWISE SPECIFIED

STANDARD MFG. TOLERANCES

ASS'Y.

NEXT

REV. CHANGE DATE

FULL

E

AA

SECTION

AA

10

20

71

(4)

(2)

26

87 147 95

(2)

145

(2) (2)

B

B

SECTION

BB

C

C

SECTION

CC

74

29 15 52

93

63

102

85

16

62

139

103

62

89

88

85

83

34

108

93

(2)

64

85

34

108

93

(1)

103

77

84

1

2

75

139

140

22

72

90

108

32

63

21

64

33

132

93

42

123

13

43

34

108

93

3 4

12

11

124

92

146

1393564

91

36

109

146

139

75

(1)

(2)

6486

23

150

129

118

119

151

126 137

128

148

REF. 31700530 NO CONTROL

126

137

135

137

D

D

VIEW

DD

REF. 31701995 WITH CONTROL

MOUNTING PLATE

27 78

80

INNER SPRING

OUTER SPRING

124

51

19

65

73

97

73

65

65

65

100

28

99

97

41

126

121

39

125

SAM3 STRAIGHTENER

SHEET 1 OF 2

(1) (1)

102

(1)

102

(1)

NOTE: ITEM #26 ROLLER TO BE PACKED

FULL LENGTH WITH BEARING

LUBRICANT

(1)

(1)

(2)

(1)

(1)

(1)

(4)

(1)

(1)

(1)

(2)

(2)

(2)

(2)

(2)

(1)

(1)

(1)

(1)

(3)

118

(1)

149

127

(6)

102

(2)

131

(4)

(1)

(2)

(1)

(1)

(1)

(1)

(1)

(1)

122

9

14

8

120

102(4)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(4)

(1)

(1)

(1)

(1)

102

(1)

(1)

104

ROLL

PIN

5

6

USE LOCTITE

518 GASKET

ELIMINATOR

USE LOCTITE

518 GASKET

ELIMINATOR

5-26-2015

W/ONE-PIECE ROLLER)

DLU

26400230

11200574

(1)

A ECN #5562

9/22/16

B

B ECN #5673

11/14/17

SA3M HEAD ASSEMBLY DRAWING

(sheet 1 of 2)

Page 20

! !

18

FRACTIONS

DECIMALS

DRAWING NUMBER

WEIGHT

HARDNESS

FINAL FINISHCHECKED BY

SCALE

DATE

DRAWN BY

HEAT TREAT

MATERIAL

PART NAME

63

FINISH

1/64

.0005

.005

.010

.030

.0000

.000

.00

.0

FOUR PLACE

THREE PLACE

TWO PLACE

ONE PLACE

UNLESS OTHERWISE SPECIFIED

STANDARD MFG. TOLERANCES

ASS'Y.

NEXT

REV. CHANGE DATE

FULL

E

56

58

73

112

114

61

105

141

48

81

115

49

124

50

124

(2)

(2)

79

127

59

60

134

57

141

113

61

105

111

141

76

136

GEAR ROLLOUT

DESCRIPTIONPART NO.QTY.ITEM

123456789101112131415

DESCRIPTIONPART NO.QTY.ITEM

16171819202122

1 30100057 GEAR HOUSING

1 31500111 WORM COVER

1 30100053 CONTROL SIDE FRAME

1 30100054 DRIVE SIDE FRAME

1 31500123 ROLLER SUPPORT COVER

1 31500124 GEAR CASE COVER

1 31900406 IDLER BRACKET

1 31900407 SQUEEZE BRACKET

1 31900408 SQUEEZE BRACKET

1 31900429 GUIDE SUPPORT BRACKET

1 31900428 GUIDE

1 34100120 LOWER SPACER

1 34100121 UPPER SPACER

1 34100119 SQUEEZE SPACER

1 34200447 LOWER PINCH ROLL

1 34200448 UPPER PINCH ROLL

6 32900279 IDLER SHAFT

1 32900280 IDLER SHAFT

1 32900283 GUIDE SHAFT

7 32900284 ROLLER SHAFT

1 32900226 IDLER SHAFT

1 32900228 WORM GEAR SHAFT

23242526272829

30

31

99

(13)

(11)

138

(5)

138

(5)

70

(5)

CLOSED

END

25

110

67

(5)

96 (11)

68

(6)

CLOSED

END

67

(6)

138

(11)

65

(1)

73

(1)

97

(1)

18 66

30

SEE

SECTION

CC

45

26

20

(6)

(6)

95

(12)

71

(24)

87

(12)

147

(12)

46

94

143

37

125

(2)

47

142

55

106

329002291 WORM SHAFT

5 34200060 LOWER DRIVE ROLLER

313233343536373839

40

7 34200061 ROLLER

SAM3 STRAIGHTENER

DLU

5-26-2015

26400230

SHEET 2 OF 2

414243444546474849

50

1 32600090 RACK

1 32600089 PINNION

1 32600088 SPUR GEAR

11 32600086 SPUR GEAR

1 32600087 SPUR GEAR

1 32600085 WORM GEAR

51525354555657585960616263

1 32600035 IDLER GEAR

3 32600034 GEAR

1 32600020 WORM

1 36100024 WORM COVER

2 32900286 PIVOT PIN

1 32900287 PIVOT PIN

1 32900288 PIVOT PIN

PIVOT PIN1 32900289

1 32900290 HINGE PIN

1 32900227 PIVOT PIN

1 32900285 ECCENTRIC TRUNION

1 31900410 UPPER LINK

2 31900409 LINK

1 31900411 HORIZ. ADJ. TEE

1 31900412 PIVOT BLOCK

1 31900413 CLAMP BAR

1 31900414 TOP SPRING ANCHOR

1 31900415 BOTTOM SPRING ANCHOR

1 31500125 COVER

1 31500126 UPPER GUARD

1 31500127 LOWER GUARD

54

53

130

1 36700015 KNOB

1 66700041 THUMB SCREW

2 36200018 LOCK NUT

1 65230004 LOCK NUT

2 36200005 NUT

2 34200005 ROLLER

3 36700017 KNOB

2 64500032 NEEDLE BEARING

2 64500002 NEEDLE BEARING

646566676869707172737475767778798081828384858687888990919293949596979899100

101

102

103

104

105

106

107

108

109

110

111

112

113

114

115

116

117

118

119

120

121

122

123

124

125

126

4 64500003 NEEDLE BEARING

5 64500028 NEEDLE BEARING

1 64500029 NEEDLE BEARING

11 64500030 NEEDLE BEARING

6 64500034 NEEDLE BEARING

5 64500036 NEEDLE BEARING

28 64500033 NEEDLE BEARING

1 64500031 NEEDLE BEARING

4 64520010 THRUST WASHER

2 64520008 THRUST BEARING

2 64510002 THRUST BEARING

2 37500040 SPRING

2 37500041 SPRING

2 37500042 SPRING

2 37500043

2 37500044

SPRING

SPRING

2 37500045 SPRING

1 37500012 SPRING

1 37500026 WAVE SPRING

1 37500046 FLAT SPRING

3 60200043 SEAL

1 60200072 SEAL

14 37600062 SEAL

1 31800024 SEAL PLATE

1 60108024 "O" RING

1 60108146 "O" RING

1 60108916 "O" RING

1 60810062 SPIRAL RING

98

125(2)

40

96

(2)

44

101

DESCRIPTIONPART NO.QTY.ITEM

127

6 60910062 RETAINING RING

1 60910031

14 60910015

13 60910025

4 60910037

RETAINING RING

RETAINING RING

RETAINING RING

RETAINING RING

2 33600168 INDICATOR PIN

13 62312025 DOWEL PIN

1 62312062 DOWEL PIN

2 62325100 DOWEL PIN

10 62325075 DOWEL PIN

2 62325150 DOWEL PIN

1 62409050 ROLL PIN

3 62412062 ROLL PIN

1 62412125 ROLL PIN

4 36800005 KEY

1 36800010 KEY

5 60200049 SEAL

3 65600002 INSERT

1 65600004 INSERT

1 33700014 ADJ. STUD

1 33700015 ADJ. STUD

1 33700016 ADJ. STUD

2 63130125 PIPE PLUG

1 63130375 PIPE PLUG

5 65936475 SHCS 3/8-16 X 4 3/4

1 66536100 FHSCS 3/8-16 X 1

1 65912200 SHCS #10-32 X 2

1 65912087 SHCS #10-32 X 7/8

12 65912037 SHCS #10-32 X 3/8

5 66212025 SET SCREW

7 65936125 SHCS 3/8-16 X 1 1/4

128

129

130

131

132

133

134

135

136

137

138

8 65920125 SHCS 1/4-20 X 1 1/4

4 65920075 SHCS 1/4-20 X 3/4

4 66612037 BHSCS #10-32 X 3/8

4 65820062 HEX BOLT 1/4-20 X 5/8

1 36100044 HORIZ. ADJ. SCREW

139

140

141

142

143

144

145

146

147

148

2 35900007 STOCK GUIDE SCREW

2 65936175 SHCS 3/8-16 X 1 3/4

2 61300010 WASHER

6 61300037 WASHER

21 34700057 WASHER

9 64520002 WASHER

1 64520005 WASHER

3 34700062 WASHER

149

150

151

152

153

155

156

157

154

1 34700060 WASHER

1 34700061 WASHER

14 34700048 WASHER

2 34100003 SPACER

14 35800051 SEAL RETAINER

1 37901000 OLDHAM COUPLING

1 39900092 INSTRUCTION LABEL

1 39900091 LABEL

1 69420010 BREATHER

1 69420011 BREATHER

1 34700034 WASHER

1 62319025 DOWEL PIN

145

(12)

NOTE: ITEM #26 ROLLER TO BE PACKED

FULL LENGTH WITH BEARING

LUBRICANT

(2)

133

111

(2)

82

7

38

17

(1)

(5)

W/ONE-PIECE ROLLERS

11200574

A

A ECN #5562

9/22/16

A

A

B

ECN #5673

11/14/17

B

SA3M HEAD ASSEMBLY DRAWING

(sheet 2 of 2)

Page 21

! !

19

SB4 HEAD ASSEMBLY DRAWING

(sheet 1 of 2)

REV. CHANGE DATE

STANDARD MFG. TOLERANCES

UNLESS OTHERWISE SPECIFIED

NEXT

ASS'Y.

ONE PLACE

TWO PLACE

THREE PLACE

FOUR PLACE

.0

.00

.000

.0000

FINISH

63

DECIMALS

FRACTIONS

.030

.010

.005

.0005

1/64

CHECKED BY

FULL

MATERIAL

HEAT TREAT

DRAWN BY

DATE

SCALE

PART NAME

FINAL FINISH

HARDNESS

DRAWING NUMBER

E

WEIGHT

SHEET 1 OF 2

VIEW C-C

SECTION B-B

UP DN

CURVE

RAPID AIR CORP.

MODEL

SERIAL

CAUTION

107

92

115

(5)

115

(5)

116 117

94

113

63

95

(10)

144

143

25

(2)

133132

21

(1)

137

40

(1)

29

(1)

25

(1)

138

142118

(1)

118

(1)

54

(1)

54

(1)

61

101

102

102

(1)

(1)

112

114

(1)

114

(2)

123

140

146

147

149

REF. PUSHBUTTON CONTROL 28900364

51

REF. USE MOTOR

PLATE 31700530

IF NO PUSHBUTTON

CONTROL IS REQ'D.

**

** ITEM #113 ON USED ON (2)

SCREWS THAT ARE IN OIL

37

(1)

CLOSED END CLOSED END CLOSED END CLOSED END CLOSED END

CLOSED ENDCLOSED ENDCLOSED ENDCLOSED ENDCLOSED ENDCLOSED END

139111

(1) (1)

139111

(1) (1)

80111

(1) (1)

80111

(1) (1)

80111

(1) (1)

80111

(1) (1)

79

(1)

79

(1)

79

(1)

79

(1)

79

(1)

79

(1)

79

(6)

80

81

(6)

(6)

83

(12)

148

(12)

78

(11)

106

(6)

81

(5)

109

(5)

105

(6)

108

(5)

111

(5)

77

79

(2)

78

(1)

80

(1)

141

81

(1)

85

78

(1)

84

6

21

(1)

73

72

75

(1)

GEARTRAIN ROLLOUT

SB4 GEAR HEAD ASS'Y.

w/ONE-PIECE PINCH ROLLS

DLU

5-28-2015

26400231

11200575

A ECN #5673

11/14/17

Page 22

! !

20

SB4 HEAD ASSEMBLY DRAWING

(sheet 2 of 2)

SECTION D-D

SECTION E-E

B

C

B

C

E

E

D

D

CHECKED BY

FRACTIONS

DECIMALS

FOUR PLACE

THREE PLACE

TWO PLACE

ONE PLACE

UNLESS OTHERWISE SPECIFIED

STANDARD MFG. TOLERANCES

ASS'Y.

NEXT

DRAWN BY

.030

REV. CHANGE DATE

63

FINISH

.0000

.000

.00

1/64

.0005

.005

.010

SCALE

DATE

FULL

.0

PART NAME

HEAT TREAT

MATERIAL

FINAL FINISH

DRAWING NUMBER

E

HARDNESS

WEIGHT

DESCRIPTIONPART NO.QTY.ITEM

123456789101112131415

1

1 31500111 WORM GEAR COVER

2

3

4

1 30100040 GEAR HOUSING

1 30100056 CONTROL SIDE FRAME

1 30100055 DRIVE SIDE FRAME

161718192021222324

25

SHEET 2 OF 2

262728293031323334353637383940

5

1 37500026 WAVE SPRING

6

6

3 60200043 TROSTEL SEAL71 31800024 SEAL PLATE81 60108024 "O" RING111 65230004 KNURLED LOCKNUT

2 36200018 KNURLED LOCKNUT

9

1 66700041 ADJUSTING SCREW

41424344454647484950515253545556575859606162636465666768697071727374757677

78

DESCRIPTIONPART NO.QTY.ITEM

13

1 37500023 FLAT SPRING

15

1 65912100 SHCS #10-32 X 1

17

1

1

18

19

1 66536100 FHSCS 3/8-16 X 1

2 62325150 DOWEL PIN

22

67

4 65820062 HEX BOLT 1/4-20 X 5/8

16

(4)

16

(2)

64520002 THRUST WASHER

16

(2)

16

65

2 34100003 SPACER

41

(1)

41

(1)

2 64510002 THRUST BEARING

26

1 32900228 WORM GEAR SHAFT

42

1 64520005 THRUST WASHER

20

64500002 NEEDLE BEARING

40

32600034 GEAR

32

1 32600035 IDLER GEAR

21

(1)

64500003 NEEDLE BEARING

33

1 34700034 SPACER

25

(1)

60910062 RETAINING RING

27

1 64500031 NEEDLE BEARING

28

1 60108146 "O" RING

29

36800005 KEY

(1)

30

1 WORM GEAR311 32900226 IDLER SHAFT

25

(1)

70

1 34100125 LOWER SPACER

37

(4)

62325075 DOWEL PIN

39

1 65912200 SHCS #10-32 X 2381 32900056 ECCENTRIC SHAFT361 31900418 ROLLER BRACKET351 31900408 ROLLER BRACKET

68

1 34100027 ROLLER BRACKET SPACER

69

1 34100124 UPPER SPACER

58

1 69420010 BREATHER

57

63130125 PIPE PLUG

56

1 63130375 PIPE PLUG

53

61300037 LOCKWASHER

66

(2)

2 65936100 SHCS 3/8-16 X 1

52 66

(2)

2 65936175 SHCS 3/8-16 X 1 3/4

6

6466

(2) (2)

65936125 SHCS 3/8-16 X 1 1/4

55

4 65920075 SHCS 1/4-20 X 3/4

43

1 36100024 WORM COVER441 60108916 "O" RING

21

(1)

21

(1)

45

1 60810062 SPIRAL RING

46 47

1 36800010 KEY

1 WORM481 60200072 OIL SEAL491 32900229 WORM SHAFT501 37901000 OLDHAM COUPLING

1

21

(1)

71

(1)

2 64500032 NEEDLE BEARING

71

(1)

798081

82

1 61810002 WOODRUFF KEY

1 60910050 RETAINING RING

74

1 31500128 GEAR COVER

1 32600110 SPUR GEAR

83848586878889

90

145

919293949596979899

100

101

102

103

104

105

106

107

108

109

110

111

112

113

114

115

116

117

118

119

120

121

122

123

124

125

126

127

128

129

130

131

132

133

134

135

136

137

138

139

140

141

142

143

144

145 1 61200026 WASHER

97

2 37500041 SPRING

104

SPRING

86

1 31900419 CLAMP BAR

87

(1)

61200022 WASHER

90

(1)

36700017 KNOB

1 37500012

100

62412062 ROLL PIN

(1)

98

2 37500045 SPRING

120

1 31900415 TOP SPRING ANCHOR

119

1 31900414 BOTTOM SPRING ANCHOR

99

2 37500050 SPRING

62

(2)

62

(2)

66612037 BHSCS #10-32 X 3/8

1089

1 33700011 ADJUSTING STUD

90

(1)

87

(1)

3

3

100

(1)

90

(1)

100(1)

88

(1)

2 33700015 ADJUSTING STUD

88

(1)

103

2 65600007 INSERT

10

(1)

87

(1)

124

2 31900422 LINK

95

(2)

60910031 RETAINING RING

96

1 32900302 HINGE PIN

122

(1)

2 32900303 HINGE PIN

122

(1)

54

(1)

66220025 SET SCREW

130

1 36700018 ADJ. KNOB

128

1 31900420 PIVOT BLOCK

127

(1)

3 64520010 WASHER

127

(2)

129

1 67410008 WAVE WASHER

126

1 60910037 RETAINING RING

131

1 33700017 ADJ. SHAFT

125

1 31900421 HORIZ. ADJ. BLOCK

134

62412125 ROLL PIN1

121

1 31900423 UPPER LINK

G

G

SECTION GG

91

2 37500040 SPRING

60910043 RETAINING RING

6 62309025 DOWEL PIN

6 32900297 LOWER DRIVE ROLL

64500001 NEEDLE BEARING

5 63800093 STEEL BALL

5 32900298 IDLER SHAFT

1 69420011 BREATHER

34700063 THRUST WASHER

32601200 SPECIAL GEAR

60200047 TROSTEL OIL SEAL

1 31900417 IDLER ROLL BRACKET

10 34700064 THRUST WASHER

10 64500041 NEEDLE BEARING

5 34200062 IDLER ROLL

5 32900301 SHAFT

2 60500001 STAT-O-SEAL

65936550 SHCS 3/8-16 X 5 1/25

12

1 32900299 GUIDE ROLL SHAFT

2 34300053 STOCK GUIDE

2 64520006 THRUST WASHER

1 64500018 NEEDLE BEARING

1 37500051 SPRING

1 32600109 RACK

1 62319050 DOWEL PIN

2 62237200 PULL DOWEL

3

1 32600111 GEAR

1 62309100 DOWEL PIN

148 34700094 THRUST WASHER

147

146

1 64500042 NEEDLE BEARING

1 32900296 IDLER SHAFT

24

1 62409050 ROLL PIN

34

1 32900227 PIVOT PIN

59

1 31500120 LOWER EXIT GUARD

1 31500119 UPPER EXIT GUARD

60

2 62337100 DOWEL PIN

76

5 65920150 SHCS 1/4-20 X 1 1/2

1 31500129 COVER

93

62

(4)

1 32900300 HINGE PIN

2 64500025 NEEDLE BEARING

135

136

4 65912050 SHCS #10-32 X 1/2

1 31500130 COVER

110

2 62325062 DOWEL PIN

64500040 NEEDLE BEARING

2 63130250 PIPE PLUG

3 66212025 SET SCREW

1 39900092 INSTRUCTION PLATE

2 60108111 "O" RING

1 39900093 LABEL

1 39900051 NAME PLATE

2 66300250 DRIVE SCREW

149 1 CAUTION LABEL39900261

150

31701995

MOTOR/CONTROL MOUNTING PLATE

(2)

37

25

(2)

29

40

(2)

(2)

25

(1)

(3)

37

29

(1)

(1)

64

(3)

916

5

10

4

1

8

5

13

12

11

closed

end

3

121211

14

8

(1)

USE LOCTITE

#518 GASKET

ELIMINATOR

USE LOCTITE

#518 GASKET

ELIMINATOR

32600071

32600012

34200449 LOWER PINCH ROLL

34200450 UPPER PINCH ROLL

SB4 GEAR HEAD ASS'Y.

w/ONE-PIECE PINCH ROLLS

DLU

5-28-2015

26400231

11200575

A

A

A ECN #5673

11/14/17

Page 23

! !

21

SB4M HEAD ASSEMBLY DRAWING

(sheet 1 of 2)

REV. CHANGE DATE

STANDARD MFG. TOLERANCES

UNLESS OTHERWISE SPECIFIED

NEXT

ASS'Y.

ONE PLACE

TWO PLACE

THREE PLACE

FOUR PLACE

.0

.00

.000

.0000

FINISH

63

DECIMALS

FRACTIONS

.030

.010

.005

.0005

1/64

CHECKED BY

FULL

MATERIAL

HEAT TREAT

DRAWN BY

DATE

SCALE

PART NAME

FINAL FINISH

HARDNESS

DRAWING NUMBER

E

WEIGHT

SHEET 1 OF 2

VIEW C-C

SECTION B-B

UP DN

CURVE

RAPID AIR CORP.

MODEL

SERIAL

CAUTION

107

92

115

(5)

115

(5)

116 117

94

113

63

95

(10)

144

143

25

(2)

133132

21

(1)

137

40

(1)

29

(1)

25

(1)

138

142

118

(1)

118

(1)

54

(1)

54

(1)

61

101

102

102

(1)

(1)

112

114

(1)

114

(2)

123

140

146

147

149

REF. PUSHBUTTON CONTROL 28900364

51

REF. USE MOTOR

PLATE 31700530

IF NO PUSHBUTTON

CONTROL IS REQ'D.

**

** ITEM #113 ON USED ON (2)

SCREWS THAT ARE IN OIL

37

(1)

CLOSED END CLOSED END CLOSED END CLOSED END CLOSED END

CLOSED ENDCLOSED ENDCLOSED ENDCLOSED ENDCLOSED ENDCLOSED END

139111

(1) (1)

139111

(1) (1)

80111

(1) (1)

80111

(1) (1)

80111

(1) (1)

80111

(1) (1)

79

(1)

79

(1)

79

(1)

79

(1)

79

(1)

79

(1)

79

(6)

80

81

(6)

(6)

83

(12)

148

(12)

78

(11)

106

(6)

81

(5)

109

(5)

105

(6)

108

(5)

111

(5)

77

79

(2)

78

(1)

80

(1)

141

81

(1)

85

78

(1)

84

6

21

(1)

73

72

75

(1)

GEARTRAIN ROLLOUT

SB4M GEAR HEAD ASS'Y.

w/ONE-PIECE PINCH ROLLS

DLU

6-11-2015

26400232

11200576

A ECN #5673

11/14/17

Page 24

! !

22

SB4M HEAD ASSEMBLY DRAWING

(sheet 2 of 2)

SECTION D-D

SECTION E-E

B

C

B

C

E

E

D

D

CHECKED BY

FRACTIONS

DECIMALS

FOUR PLACE

THREE PLACE

TWO PLACE

ONE PLACE

UNLESS OTHERWISE SPECIFIED

STANDARD MFG. TOLERANCES

ASS'Y.

NEXT

DRAWN BY

.030

REV. CHANGE DATE

63

FINISH

.0000

.000

.00

1/64

.0005

.005

.010

SCALE

DATE

FULL

.0

PART NAME

HEAT TREAT

MATERIAL

FINAL FINISH

DRAWING NUMBER

E

HARDNESS

WEIGHT

DESCRIPTIONPART NO.QTY.ITEM

123456789101112131415

1

1 31500111 WORM GEAR COVER

2

3

4

1 30100040 GEAR HOUSING

1 30100056 CONTROL SIDE FRAME

1 30100055 DRIVE SIDE FRAME

161718192021222324

25

SHEET 2 OF 2

262728293031323334353637383940

5

1 37500026 WAVE SPRING

6

6

3 60200043 TROSTEL SEAL71 31800024 SEAL PLATE81 60108024 "O" RING111 65230004 KNURLED LOCKNUT

2 36200018 KNURLED LOCKNUT

9

1 66700041 ADJUSTING SCREW

41424344454647484950515253545556575859606162636465666768697071727374757677

78

DESCRIPTIONPART NO.QTY.ITEM

13

1 37500023 FLAT SPRING

15

1 65912100 SHCS #10-32 X 1

17

1

1

18

19

1 66536100 FHSCS 3/8-16 X 1

2 62325150 DOWEL PIN

22

67

4 65820062 HEX BOLT 1/4-20 X 5/8

16

(4)

16

(2)

64520002 THRUST WASHER

16

(2)

16

65

2 34100003 SPACER

41

(1)

41

(1)

2 64510002 THRUST BEARING

26

1 32900228 WORM GEAR SHAFT

42

1 64520005 THRUST WASHER

20

64500002 NEEDLE BEARING

40

32600034 GEAR

32

1 32600035 IDLER GEAR

21

(1)

64500003 NEEDLE BEARING

33

1 34700034 SPACER

25

(1)

60910062 RETAINING RING

27

1 64500031 NEEDLE BEARING

28

1 60108146 "O" RING

29

36800005 KEY

(1)

30

1 WORM GEAR311 32900226 IDLER SHAFT

25

(1)

70

1 34100125 LOWER SPACER

37

(4)

62325075 DOWEL PIN

39

1 65912200 SHCS #10-32 X 2381 32900056 ECCENTRIC SHAFT361 31900418 ROLLER BRACKET351 31900408 ROLLER BRACKET

68

1 34100027 ROLLER BRACKET SPACER

69

1 34100124 UPPER SPACER

58

1 69420010 BREATHER

57

63130125 PIPE PLUG

56

1 63130375 PIPE PLUG

53

61300037 LOCKWASHER

66

(2)

2 65936100 SHCS 3/8-16 X 1

52 66

(2)

2 65936175 SHCS 3/8-16 X 1 3/4

6

6466

(2) (2)

65936125 SHCS 3/8-16 X 1 1/4

55

4 65920075 SHCS 1/4-20 X 3/4

43

1 36100024 WORM COVER441 60108916 "O" RING

21

(1)

21

(1)

45

1 60810062 SPIRAL RING

46

47

1 36800010 KEY

1 WORM481 60200072 OIL SEAL491 32900229 WORM SHAFT501 37901000 OLDHAM COUPLING

1

21

(1)

71

(1)

2 64500032 NEEDLE BEARING

71

(1)

798081

82

1 61810002 WOODRUFF KEY

1 60910050 RETAINING RING

74

1 31500128 GEAR COVER

1 32600110 SPUR GEAR

83848586878889

90

145

919293949596979899

100

101

102

103

104

105

106

107

108

109

110

111

112

113

114

115

116

117

118

119

120

121

122

123

124

125

126

127

128

129

130

131

132

133

134

135

136

137

138

139

140

141

142

143

144

145 1 61200026 WASHER

97

2 37500041 SPRING

104

SPRING

86

1 31900419 CLAMP BAR

87

(1)

61200022 WASHER

90

(1)

36700017 KNOB

1 37500012

100

62412062 ROLL PIN

(1)

98

2 37500045 SPRING

120

1 31900415 TOP SPRING ANCHOR

119

1 31900414 BOTTOM SPRING ANCHOR

99

2 37500050 SPRING

62

(2)

62

(2)

66612037 BHSCS #10-32 X 3/8

10

89

1 33700011 ADJUSTING STUD

90

(1)

87

(1)

3

3

100

(1)

90

(1)

100

(1)

88

(1)

2 33700015 ADJUSTING STUD

88

(1)

103

2 65600007 INSERT

10

(1)

87

(1)

124

2 31900422 LINK

95

(2)

60910031 RETAINING RING

96

1 32900302 HINGE PIN

122

(1)

2 32900303 HINGE PIN

122

(1)

54

(1)

66220025 SET SCREW

130

1 36700018 ADJ. KNOB

128

1 31900420 PIVOT BLOCK

127

(1)

3 64520010 WASHER

127

(2)

129

1 67410008 WAVE WASHER

126

1 60910037 RETAINING RING

131

1 33700017 ADJ. SHAFT

125

1 31900421 HORIZ. ADJ. BLOCK

134

62412125 ROLL PIN1

121

1 31900423 UPPER LINK

G

G

SECTION GG

91

2 37500040 SPRING

60910043 RETAINING RING

6 62309025 DOWEL PIN

6 32900297 LOWER DRIVE ROLL

64500001 NEEDLE BEARING

5 63800093 STEEL BALL

5 32900298 IDLER SHAFT

1 69420011 BREATHER

34700063 THRUST WASHER

32601200 SPECIAL GEAR

60200047 TROSTEL OIL SEAL

1 31900417 IDLER ROLL BRACKET

10 34700064 THRUST WASHER

10 64500041 NEEDLE BEARING

5 34200062 IDLER ROLL

5 32900301 SHAFT

2 60500001 STAT-O-SEAL

65936550 SHCS 3/8-16 X 5 1/25

12

1 32900299 GUIDE ROLL SHAFT

2 34300053 STOCK GUIDE

2 64520006 THRUST WASHER

1 64500018 NEEDLE BEARING

1 37500051 SPRING

1 32600109 RACK

1 62319050 DOWEL PIN

2 62237200 PULL DOWEL

3

1 32600111 GEAR

1 62309100 DOWEL PIN

148 34700094 THRUST WASHER

147

146

1 64500042 NEEDLE BEARING

1 32900296 IDLER SHAFT

24

1 62409050 ROLL PIN

34

1 32900227 PIVOT PIN

59

1 31500120 LOWER EXIT GUARD

1 31500119 UPPER EXIT GUARD

60

2 62337100 DOWEL PIN

76

5 65920150 SHCS 1/4-20 X 1 1/2

1 31500129 COVER

93

62

(4)

1 32900300 HINGE PIN

2 64500025 NEEDLE BEARING

135

136

4 65912050 SHCS #10-32 X 1/2

1 31500130 COVER

110

2 62325062 DOWEL PIN

64500040 NEEDLE BEARING

2 63130250 PIPE PLUG

3 66212025 SET SCREW

1 39900092 INSTRUCTION PLATE

2 60108111 "O" RING

1 39900093 LABEL

1 39900051 NAME PLATE

2 66300250 DRIVE SCREW

149 1 CAUTION LABEL39900261

150

31701995

MOTOR/CONTROL MOUNTING PLATE

(2)

37

25

(2)

29

40

(2)

(2)

25

(1)

(3)

37

29

(1)

(1)

64

(3)

916

5

10

4

1

8

5

13

12

11

closed

end

3

121211

14

8

(1)

USE LOCTITE

#518 GASKET

ELIMINATOR

USE LOCTITE

#518 GASKET

ELIMINATOR

32600085

32600020

34200449 LOWER PINCH ROLL

34200450 UPPER PINCH ROLL

SB4M GEAR HEAD ASS'Y.

w/ONE-PIECE PINCH ROLLS

DLU

6-11-2015

26400232

11200576

A

A

A ECN #5673

11/14/17

Page 25

!

REV. CHANGE DATE

NEXT

ASS'Y.

STANDARD MFG. TOLERANCES

UNLESS OTHERWISE SPECIFIED

ONE PLACE

TWO PLACE

THREE PLACE

FOUR PLACE

.0

.00

.000

.0000

.030

.010

.005

.0005

1/64

FINISH

63

PART NAME

MATERIAL

HEAT TREAT

DRAWN BY

DATE

SCALE

CHECKED BY FINAL FINISH

HARDNESS

WEIGHT

DRAWING NUMBER

DECIMALS

FRACTIONS

FULL

D

APROX. FUSE RATINGS

MOTOR

ARMATURE

3\4

1\4

1\2

1

SIZE

HP

12

10

4

15

FUSE

AMPS

REF.

CHART A

CURRENT

12

3.9

7.5

12

SETUP

AMPS

LIMIT

REF.

LOBLU

I2

F

-

SPEEDPOT

I1

L2

A+

P1

L1

DECEL

SPEEDPOT HI

RAMM 125

SPEEDPOT WIPER

BLU

BLU

WHT

BLU

RED

A-

FIELD

-

L2A+L1

IR

CL

P2

P3

MIN

I1

ACCEL.

MAX

P2

I2

P1

P3

PART #

69280021

F1

FUSE

90

VOLT

15

AMP QTY

MOTOR

SIZE

120

VOLTS

INPUT

AC

1/4

4

5

APROX. FUSE RATINGS

ARMATURE

HP

FUSE

AMPS

LIMIT

AMPS

SETUP

CURRENT

CB

5

AMPS

FUSE

AC

F3

F2

69280021

120

15

1

1

MOTOR

-

+ M

BLU

GRN

BRN

6

4

3

DANCER ARM POT

69100218

1

3

2

GRN

CHASSIS

115 VAC

RED

BLK

2 WHT

L1

15

AMP

L11

BLK

2

R

3 1

BREAKER

MAIN

RED

1

LIGHTED

ROCKER SWITCH

CONNECTION

SWITCH

INTERNAL

1

1

2

3

4

5

678

9

101112

69100804

THIS TERM. USED TO CHECK INPUT

FROM EXTERNAL LOOP CONTROL.

MOTOR 11

MOTOR 12

POT #3

POT #2

POT #1

REEL CONTROL BOARD

REAR VIEW

2

WHT

1.5 AMP

PICO FUSE

F2

F3

F1

69100014

85500312

PUSHBUTTON CONTROL

STRAIGHTENER-120 VAC

GSM

01/14/2004

69300001

69100578

69100315

MALE

120 15

69100578

1

2 LINE READOUT

FOR OPERATOR TUNING

A- 9

P1

8

P2

7

643

2

1

A+

10

120

1.5 1

PICO

BLU

BLU

BLU

BLU

GRN

BRN

BLU

WHT

RED

AC IN

AC IN

BLU BLU

MOTOR 12

MOTOR 11

2 WHT

2

1

10

9

8

7

23

WIRING DIAGRAM

Loading...

Loading...