Page 1

CABINET REEL

OPERATING INSTRUCTIONS

MODELS

R50, R60 & R70 SERIES

RAPID-AIR CORPORATION

4601 KISHWAUKEE ST. • ROCKFORD, IL 61109-2925

Phone: (815) 397-2578 • Fax: (815) 398-3887 • Web Site: www.rapidair.com

Page 2

OPERATING INSTRUCTIONS CABINET REEL

INSTALLATION

1. The machine that you have just received is fully assembled and ready to be put into position. Due to shipment vibration the machine should be checked to be sure all screws and

bolts are tight; visually inspect the machine for damage parts due to shipment. If the machine was damaged in shipment, contact the carrier first to report the damage, and then

Rapid-Air.

2. Install the machine on a level surface with sufficient clearance for loading and unloading

coils.

3. The machine is completely self-contained and need only be plugged into a 20 amp, 120 volt,

60 HZ outlet. If an extension cord is used as the source to the machine, it should be a minimum #12 gauge wire to keep the voltage loss down and for electrical safety reasons.

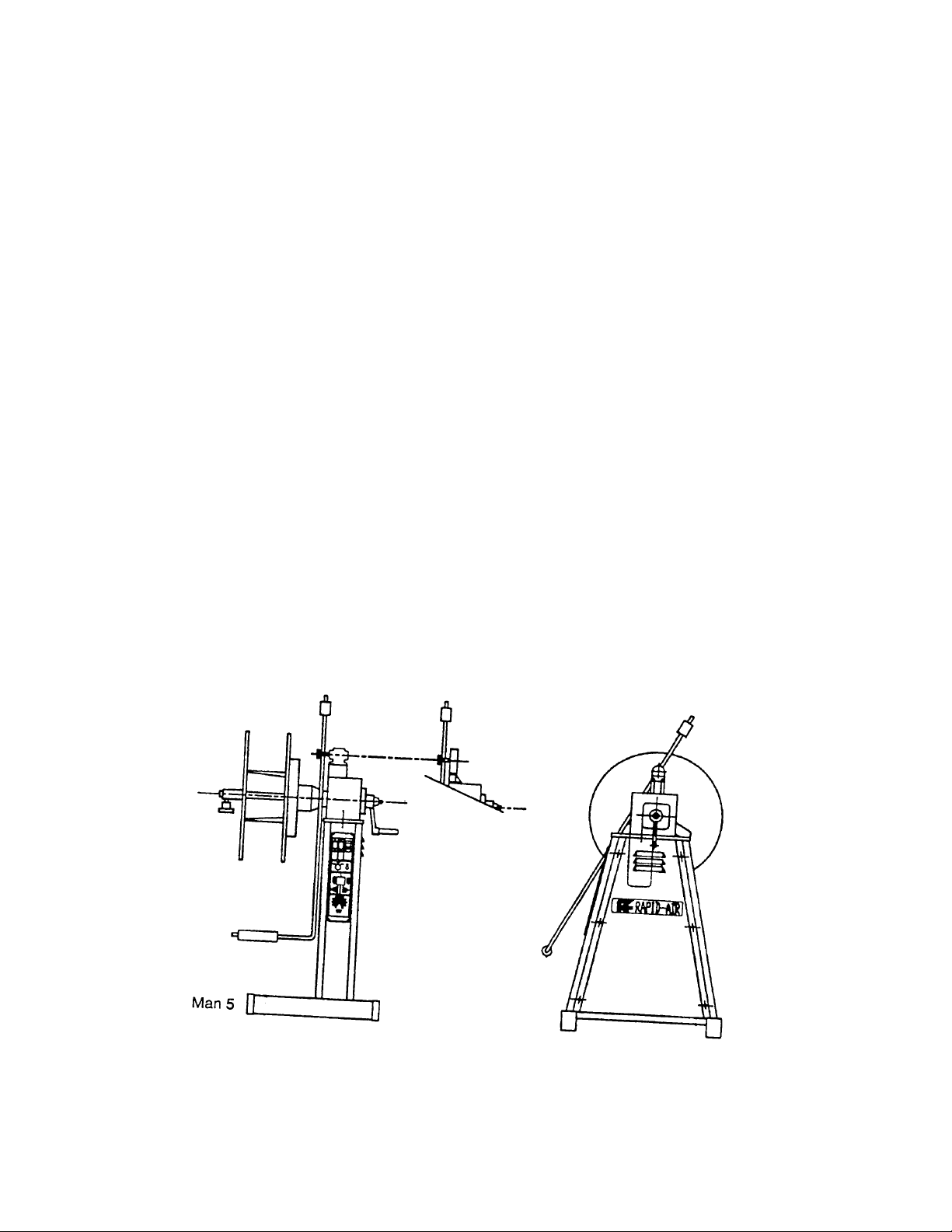

See Drawing (fig. Man5)

1

Page 3

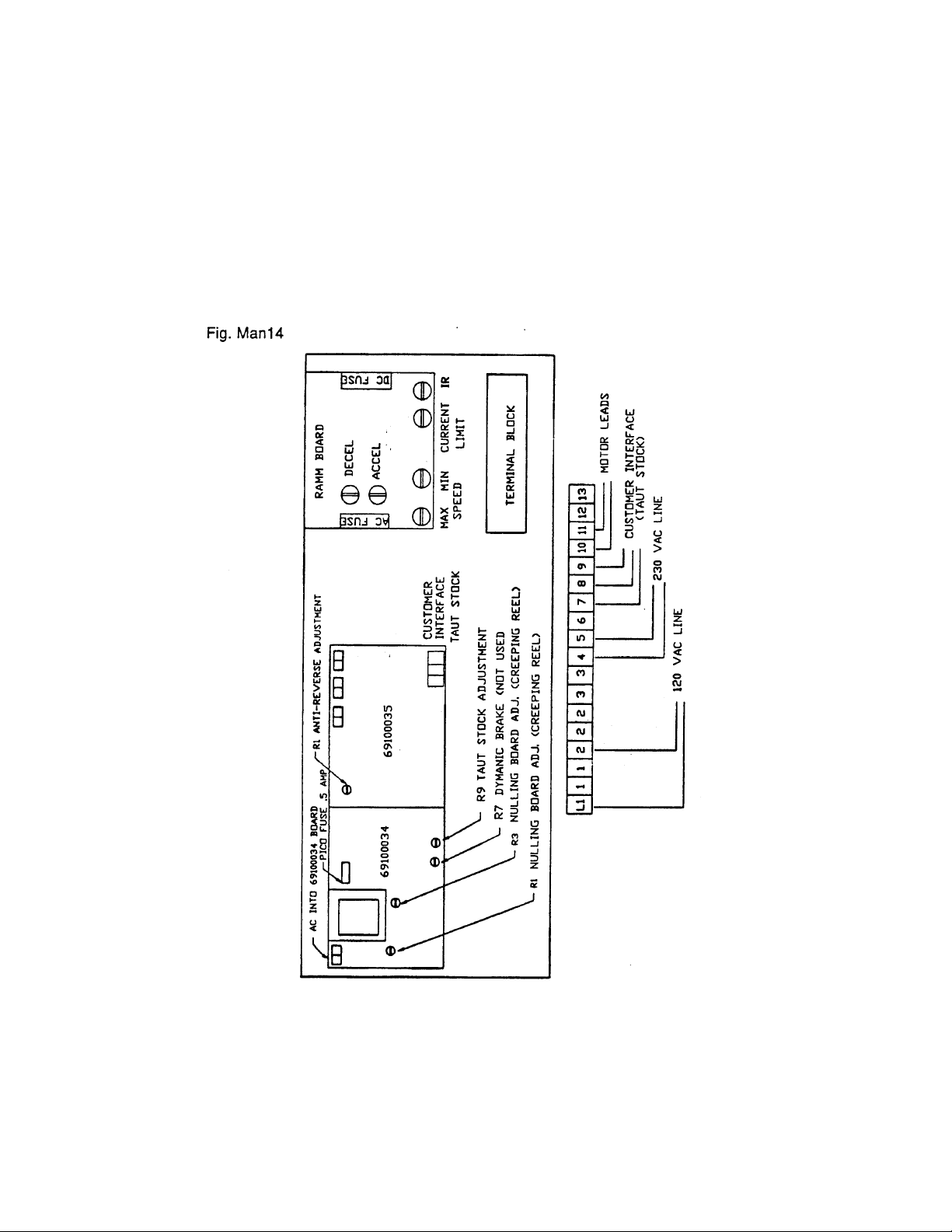

The main control is located behind the side access cover. Fig. Man14 is an illustration of the

layout of the control panel. This diagram lists all the components and the approximate location

of each that could be used for troubleshooting the machine if a problem should occur. The reel

can be ordered with—120 vac (1 phase) input. Terminal 4 & 5 will not be used and cannot be

used unless the Ramm is changed to a 220 volt controller. If using 220 vac 1 phase wire as indicated by drawing fig. Man14. This unit cannot be used with 120 vac 1 phase input unless the

Ramm board is changed to a 120 volt controller.

2

Page 4

Mechanical Operating Procedure

To Load or Unload a Coil Ring

a) If your reel has a fixed center shaft go to Step—1

b) If your reel has an adjustable center shaft go to Step—2

Step 1:

Release and remove the outer coil retainer from the shaft. Load or unload the coil ring. Replace and secure the outer coil retainer. The reel is now ready for production.

Step 2:

Release and remove the outer coil retainer from the shaft. If unloading, adjust the centering

arms to a position that they have released the coil. Remove the coil ring. If loading, place the

coil ring on the adjustable centering arms, adjust the centering arms until they are tight on the

coil. Replace and secure the outer coil retainer. The reel is now ready for production.

The dancer arm was designed to operate from either side of the reel. The main reason for this

was so the reel controls could be lined up on the same side as the punch controls.

To switch the dancer arm to operate on the opposite side that it is currently located on, first remove the counter weight it equipped with one, then turn the locking knob to disengage the lock

on the dancer arm hub. Remove the dancer arm and relocate it to the other side. Turn the hub

60 degrees and insert the dancer arm into the slot. Set to desired position. Turn the locking

knob until tight on the dancer arm. Then replace counter weight, if so equipped. The dancer

arm is now ready for production running.

3

Page 5

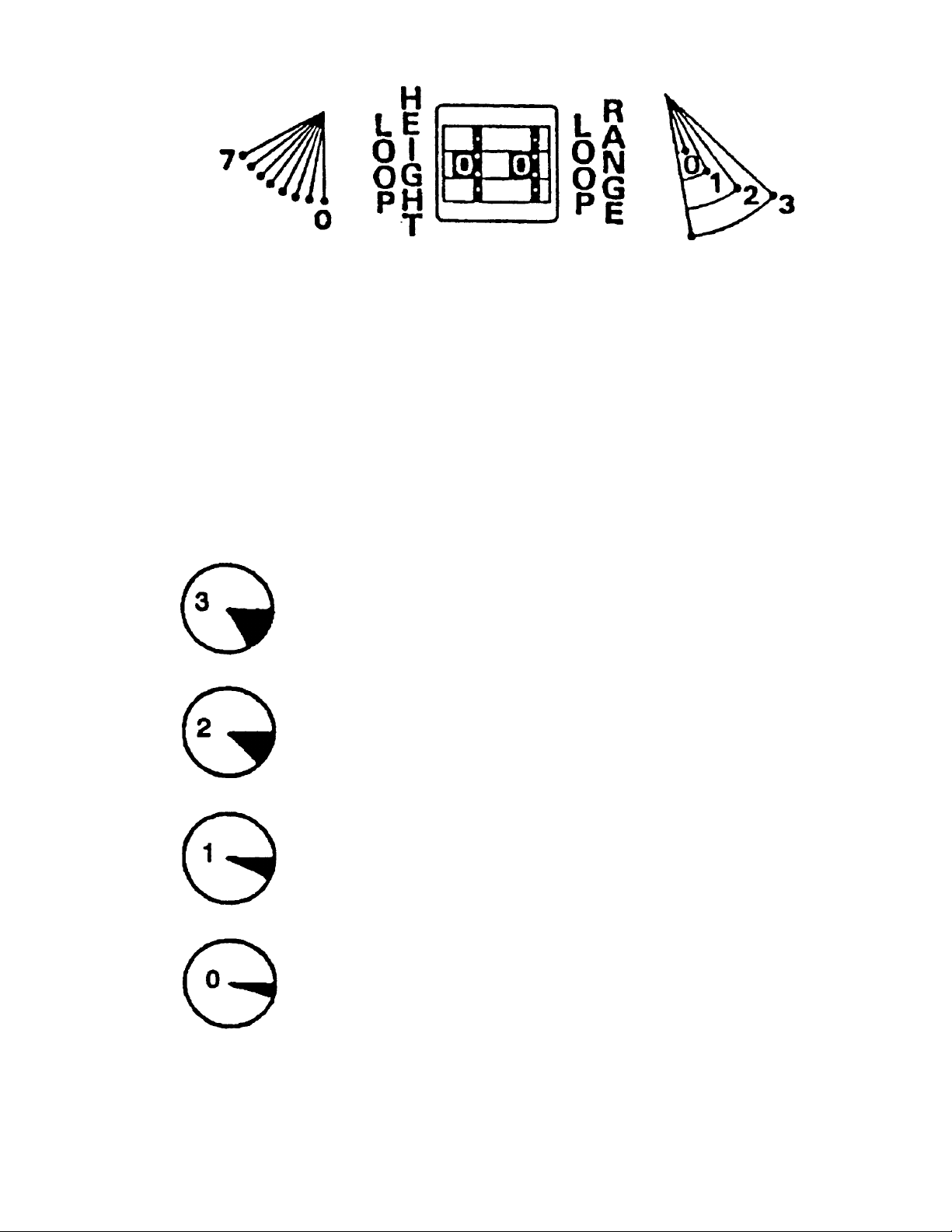

DANCER ARM LOOP HEIGHT ADJUSTMENT

Eight different loot sensing arm operating positions are selected

manually during set-up. By incrementing the thumbwheel height

switch, the zero point of the dancer arm is raised from it’s rest position to the angle shown (as indicated 0-7). The dancer arm will move

from rest position to the angle selected before the pallet reel begins to

rotate.

DANCER ARM LOOP RANGE FUNCTION

30 degree—Loop sensing arm travels through a full 30 degree arc to

vary turntable rotation speed from slow to full speed as controlled by

% speed pot.

20 degree—Loop sensing arm travels through a 20 degree arc to vary

turntable speed from slow to full speed as controlled by % speed pot.

10 degree—Loop sensing arm travels through a 10 degree arc to vary

turntable rotation speed from slow to full speed as controlled by %

speed pot.

5 degree—Only the first 5 degrees of loop sensing arm travel is required to control turntable rotation from slow through full speed as

controlled by % speed pot.

4

Page 6

START UP PROCEDURE

Prior to applying power to the machine the operator should review all the controls on the machine. A brief summary of the controls is listed below.

MAIN CONSOLE & CONTROLER

The main control console & controls are mounted on the end of the cabinet. Located on the

face of the console are four switches and one potentiometer which are explained below.

1. DIRECTION CONTROL— The direction control switch selects the direction the reel will

turn, clockwise or counterclockwise.

2. % SPEED POT— The % speed pot adjusts the maximum speed that the reel will rotate and

should be set to maintain a constant feed rate.

3. ON/OFF SWITCH— The illuminated switch is the main power switch for the controller. It

must be “ON” for the machine to function.

4. PAYOUT/REWIND SWITCH— The payout/rewind switch selects whether the dancer

arm will cause the reel to function at a low speed at the bottom of the arc and increase the reel

speed as the arm raises. (Payout); or cause the reel to function at a low speed at the top of the

arc and increase the reel speed as the arm lowers. (Rewinds)

5. RUN/STOP/JOG SELECTOR SWITCH— The switch selects between Run & Jog. If in

Run and the control arm is moved the coil plate will turn. If in Jog, the Jog button has to be depressed for the coil plate to turn.

6. JOG BUTTON— Used for intermittent movement of the coil plate, mainly for set up, speed

is adjusted on the 69100053 terminal board on the electrical control sub panel.

7. DANCER ARM LOOP HEIGHT & RANGE ADJUSTMENT—

a. Loop Range— The loop range thumbwheel adjusts the amount of travel the dancer arm will

move to provide the full range of speed of the pallet reel.

b. Loop Height— This thumbwheel is used for setting the start position of the control arm.

The setting determines when the pallet reel will start turning. Each position will move the operating angle of the arm so that top-to-bottom travel is located to accommodate specific material

and loop height requirements.

ELECTRICAL COMPONENT DESCRIPTION

69100034 board—proportional control board

69100035 board—rotational isolation board

69100053 board—terminal board

PC control board (RAMM) - D.C. motor board

5

Page 7

TAUT STOCK

The Taut Stock feature monitors the loop between the reel and the external equipment. If the

loop gets small enough to possibly cause damage to the reel, the interface contacts change state

and stops the external equipment.

If it is desired to monitor the reel then the following write-up will explain how to connect and

adjust this feature.

The “TAUT STOCK” feature is built into the Rapid-Air board #69100035 and wires to external terminals 7-8-9. The terminal #9 is common and from terminal 8 to 9 is a normally closed

contact with power on the unit. Terminal 7 to 9 is a normally open contact with power on the

unit. These contacts are from “Relay 2” chip. See diagram. This relay has to be in place for

taut stock to work. There is also a 4 prong post labeled “JUMP” that has to be connected so

that relay 2 can be activated. To correctly apply the jumper, locate the post and then locate the

plastic 2 prong jumper, insert the jumper so that he left 2 vertical posts are covered. Once this

is in place the taut stock feature can be tuned.

To tune the taut stock, check that there are no connections on the terminals 7-8 & 9, except

those that were factory connected. Attach an OHM meter to terminal 9 & 8 with the meter set

to OHMS.

Start the reel and raise the dancer arm so that the reel is running at maximum speed. Raise the

dancer arm up to a point that the stock would be taut. Hold the dancer arm at this position and

adjust the pot “R9” of board 69100034 until the contact changes state. Release the dancer arm.

The contact should return to normal state. Raise and lower the dancer arm 2 to 3 times to insure

that the contact functions properly. Disconnect the OHM meter and connect the customer interface. CAUTION!

6

Page 8

TROUBLE SHOOTING GUIDE

MAIN SWITCH ON BUT NOT LIT

1. CB tripped

a. Reset CB

2. Unit not plugged into main power.

a. Plug into main power source.

3. No power in incoming line.

a. Check outlet.

b. Check power cord.

4. Loose wiring

a. Check terminals and connections.

MOTOR CREEPS IN STOP POSITION

1. R1 & R3 pot on 69100034 board not correctly adjusted.

a. Readjust pots so table stops. Call factory.

UNIT TURNS BUT WON’T JOG

1. Selector switch not in jog position.

a. Select jog.

2. Jog pot on 69100053 board not adjusted correctly.

a. Adjust pot. Call factory.

3. Maximum speed pot on Ramm board set too low.

a. Adjust pot.

UNIT ON BUT MOTOR WON’T RUN. (ARMATURE VOLTAGE PRESENT—ON

RAMM BOARD)

1. Check TB-4 of 69100035 board. Terminal 1 & 2

a. If voltage not present replace 69100035 board. Call factory.

2. Check motor wiring

a. Replace motor cord or correct motor wiring. Call factory.

3. Check motor

a. Worn brushes or motor defective. Call factory.

NOTE: Refer to drawing RA-2 for location of components, sequence check form Ramm board

to motor.

UNIT ON BUT MOTOR WON’T RUN. (NO ARMATURE VOLTAGE ON RAMM

BOARD)

1. Selector switch not in run position.

a. Turn selector switch to run position.

2. Transition plug not installed.

a. If not using E control, install transition plug supplied with unit.

3. Thumbwheel height setting too high.

a. Set height setting to “0”.

7

Page 9

4. Percent speed pot set too low.

a. Adjust percent speed pot to 100%.

5. Fuses blown.

a. Check fuses on DC drive board.

6. No AC voltage at DC drive board.

a. Check wiring.

7. Check Signal voltage between P2 to I2 on DC drive.

0-6 VDC—Ramm

0-9 VDC—Regen Drive

while moving dancer arm.

a. If there is a signal, check continuity between I1 & I2.

If continuity, replace 69100035 board or call factory.

If no continuity, replace D.C. drive or call factory.

8. Check line voltage input of 69100034 board, 120 VAC, TB-1

a. Check wiring. Call factory.

9. Check pico fuse 69100034 board (f1).

a. Replace fuse—call factory.

10. Check for 0—12 VDC between pin #1 (+V) and pin #2 (GND) of panduit connector TC3 on

board #69100034.

a. If no voltage present call factory.

11. Check for DC voltage between pin #6 (V0) and pin #2 GND of panduit connector TC#, on

board #69100034, while moving the dancer arm from minimum to maximum position.

a. If voltage is present, turn power off and check the ribbon cable connections between

panduit connector #TC3 of 69100034 board and panduit connector #TC3 of 69100035

board and panduit connector #PT3 of 69100053 board. This should be a continuity

check for tight connections. Call factory for assistance.

b. If voltage is not present move on to step 12.

12. Check voltage between pin #2 of TB-2 & pin #5 of TB-7 on 69100053 board while moving

the dancer arm from minimum to maximum position.

a. If voltage varies 2.5-4 volt from minimum to maximum position, the dancer arm pot

is OK, but the 69100034 board could be defective. Call factory.

b. If voltage does not vary when moving the dancer arm from minimum to maximum

position—call the factory for assistance.

8

Page 10

RAPID-AIR CORPORATION

RAMM

SOLID STATE

DC MOTOR

SPEED CONTROL

SAFETY WARNING—PLEASE READ CAREFULLY

This product should be installed and serviced by a qualified technician, electrician or electrical

maintenance personnel familiar with its operation and the hazards involved. Proper installation

(see instruction information which accompanies product), which includes wiring, mounting in

proper enclosure, fusing or other overcurrent protection and grounding, can reduce the chance

of electrical shocks, fires or explosion in this product or products used with this product, such

as electric motors, switches, coils solenoids and/or relays. Eye protection must be worn whe

working with control under power. This product is constructed of materials (plastics, metals,

carbon, silicon, etc.) which may be a potential hazard. Individual material safety data sheets

(MSDS) are available upon request. Proper shielding, grounding and filtering of this product

can reduce the emission of radio frequency interference (RFI) which may adversely affect sensitive electronic equipment. If information is required on this product, contact our factory. It is

the responsibility of the ultimate user of this product to read and comply with this safety warning. (SW effective 1/89)

***IMPORTANT***

YOU MUST READ THESE INSTRUCTIONS BEFORE OPERATING CONTROL

1. Be sure AC line voltage corresponds to control voltage.

2. Install the correct Plug-In Horsepower Resistor according to armature voltage and motor

horsepower.

3. Recheck connections: AC line to L1 and L2; armature to A+ and A– and field (Shunt motors only to F+ and F-.) (Note: If motor runs in improper direction, interchange armature

leads.)

4. Install proper AC line fuse and armature fuse as required.

5. Nominal trimpot settings are as follows (expressed in % of full CW rotation):

TABLE 1: NOMINAL TRIMPOT SETTINGS

MIN (minimum speed): 15% CL (current limit/torque): 65%

MAX (maximum speed): 65% ACCEL (acceleration start): 20%

IR (IR compensation): 25% DECEL (deceleration stop): 20%

9

Page 11

PLUG IN HORSEPOWER RESISTOR

A Plug-In Horsepower Resistor must be installed to match the RAMM to the motor horsepower

and voltage. See table 2 for the correct value. Plug-In Horsepower Resistors are stocked by

your distributor.

TABLE 2. PLUG IN HORSEPOWER RESISTOR CHART*

* Motor horsepower and armature voltage must be specified when ordering so that proper resistor will be supplied.

** For overlapping motor horsepower range use lower value Plug-In Horsepower Resistor.

*** Auxiliary heatsink must be used to achieve HP rating.

MOTOR

HORSEPOWER RANGE **

Armature

Voltage

90-130 VDC

1/4

1/2

3/4

1***

Armature

Voltage

180 VDC

1/2

1

1-1/2

2***

Plug-in

Horsepower

Resistor

Resistance

Value (ohms)

.05

.025

.015

.01

Rapid-Air

P/N

69100529

69100530

69100534

69100531

10

Page 12

INTRODUCTION

The RAMM Full Wave Solid State DC Motor Speed Control represents the latest state of the

art design achievable through modern technology.

Features Include:

Integrated Circuitry

Used to control and amplify command and reference levels with both closed and open loop

feedback to provide superior motor regulation. (Speed changes due to load, line voltage, or

temperature variations are held to minimum levels).

High Quality Components

Selected and tested for proven dependability.

Transient Protection

Used to prevent failure of the power bridge circuit caused by voltage spikes on the AC line.

High Reliability

When used in accordance with instructions in this manual, the RAMM will provide years of

trouble free operation.

A. Initial Setup and Wiring

i. General Instructions

1. Install proper size Plug-In Horsepower Resistor.

(see table 2)

2. The RAMM can be connected to a standard 120V or 240V 50/60 Hz AC line (be

sure the AC input voltage corresponds to the control voltage rating and the motor rating). (e.g.

90-130 VDC motor on 120VAC and 180 VDC motor on 240 VAC)

3. Follow the recommended supply wire sizes as per table 3.

4. Follow the NEC and other electrical codes that apply.

CAUTION: SEPARATE BRANCH PROTECTION MUST BE PROVIDED ON 240V

CIRCUITS.

5. Connect control in accordance to connection diagram.

TABLE 3. MINIMUM SUPPLY WIRE SIZE REQUIREMENTS

*Maximum recommended wire size

MAX.

MOTOR

AMPS

(DC AMPS)

6.0

12.0

16.0

MAX.

MOTOR

HP

90V

1/2

1

1 1/2

MAX.

MOTOR

HP

180V

1

2

3

MINIMUM WIRE SIZE

(AWG) Cu only

MAX. MAX.

MOTOR MOTOR

RUN RUN

16 14

14 12*

12 12

11

Page 13

Fig. 1. Basic RAMM Connection Diagram

CAUTION: Do not bundle potentiometer connections (P1, P2, P3) and inhibit

connections (I1, I2) with AC line or motor wires.

B. VOLTAGE FOLLOWING. All models can be controlled with an isolated analog reference voltage (0-6VDC) in lieu of the main speed potentiometer. The voltage is connected to P2

(+) and F-. The control output voltage will linearly follow the input voltage. The source impedance of the input should be 10K ohms or less. The Min trimpot can be used to provide an

offset speed. If an offset is not required adjust the Min to 0+ or 0– speed as desired. The Max

trimpot is rendered inoperative in the voltage following mode. Use auxiliary trimpot to limit

the control range. If the input signal is not isolated, or is a current signal (4-20ma), the RASI240D) Signal Isolator must be used. It will allow direct connection to process controllers and

microprocessors.

CATUION: 1. The voltage feeding P2 and F– must be isolated form the AC line.

Do not ground P2 or F– to set up a zero ground reference.

2. Do not bundle signal wires to P

connections. If signal wires are over 18”, use shielded cables.

2 and F– with AC line motor

C. FUSING. The RAMM has provision for a built in AC line fuse and armature fuse. The AC

line fuse protects the control against catastrophic failure. If the fuse blows, the control is miswired, the motor is shorted or grounded, or the RAMM control is defective. The armature fuse

provides overload protection for the motor and control. Choose the proper size armature fuse

by multiplying the maximum DC motor amps by 1.7. On domestic 240 Volt AC lines, separate

branch circuit protection for each line must be used. All fuses should be normal blow ceramic

3AG or ABC or equivalent.

1. AC Line Fuse is chosen according to the maximum rating of the control:

12 AMP fuse for all motors up to 3/4 HP-90V and 1 1/2 HP-180VDC.

25 AMP fuse for all motors 1 and 1 1/2 HP-90v and 2 and 3 HP-180VDC.

12

Page 14

(Use Buss ABC, Littlefuse 326 ceramic fuse or equivalent.)

2. Armature Fuse can be chosen in accordance with the fuse chart. Note: The armature fuse is

calculated based on the approximate full load DC current rating of the motor times a from

factor of 1.5. If motor has characteristics not consistent with these approximations, a different fuse value may have to be used. Fuses are available from your distributor.

TABLE 4. ARMATURE FUSE CHART

90VDC 180VDC

MOTOR MOTOR

HORSEPOWER

1/4 1/2

1/2 1

3/4 1 1/2

1 2

1 1/2 3

APPROX.

DC MOTOR

CURRENT

(AMPS)

2.5

5.0

7.5

10.0

15.0

FUSE

RATING

(AC

4

8

12*

15

25*

*Also used as AC line Fuse.

ADJUSTMENTS AND CONTROL FUNCTIONS

WARNING: If adjustments are made under power, insulated adjustment

tools must be used and eye protection must be worn.

The RAMM has been factory adjusted to provide 0-full speed using the speed control knob.

Minimum and Maximum speed trimpots are provided to change the speed from other than 0full speed. The Acceleration (ACCEL) trimpot is provided to allow for a smooth start over an

adjustable time period each time the AC power is applied or the speed pot is rotated. The DECEL trimpot controls the amount of ramp-down when the speed pot is adjusted to a lower

speed. The Current Limit (CL, or torque output) adjustment is factory set to approximately 1

1/2 times the motor rating. The IR Compensation (IR) is factory adjusted to provide excellent

motor regulation under normal operation.

13

Page 15

NOTE: In order for the IR comp and CL trimpot settings to be correct, the proper Plug-in

Horsepower Resistor must be installed for the particular motor and input volt age

being used. Do not attempt to change the settings of the trimpots unless absolutely

necessary since they are factory adjusted to near optimum settings.

The following procedure, presented in order of adjustment sequence, should be used when readjusting all trimpot functions.

Fig 2. ACCEL/DECEL

TRIMPOT ADJUSTMENT

A. Acceleration Start. The ACCEL is factory set at approximately .2 seconds. To readjust to

different times, set the knob to the desired position as indicated in Fig 2.

B. Deceleration. The DECEL is factory set to provide a ramp-down time of .2 seconds. To

change the ramp-down time, adjust the DECEL trimpot as indicated in Fig 2.

C. Minimum Speed Adjustment. If a higher than zero minimum speed is desired, readjust

the minimum speed by turning the speed control knob to zero setting (full CCW position).

Then adjust the Min. Speed Trimpot to the desired setting.

NOTE: The min. speed adjustment will affect the max. speed setting. Therefore, it is

necessary to readjust the max. speed after the min. speed is adjusted.

D. Maximum Speed Adjustment. Turn Speed Control Knob to full speed (maximum CW position). Adjust max. speed trimpot to new desired setting.

NOTE: Do not attempt to adjust the max. speed above the rated motor RPM since unstable motor operation may occur. For moderate changes in the max. speed, there will be a

slight effect on the min. speed setting.

E. Current Limit (CL/Torque Adjustment). CL circuitry is provided to protect the motor

and control against overloads. The CL also limits the inrush current to safe level during startup.

The CL is factory set to approximately 1.5 times the full load rating of the motor. (CL trimpot

is nominally set to approximately 65% of full CW rotation).

14

Page 16

To set the CL to factory specifications adjust as follows:

1. Set speed control knob at approximately 30-50% CW rotation.

Set CL trimpot to full CCW position.

2. Connect a DC ammeter is series with the armature lead.

3. Lock shaft of motor (be sure CL pot is in full CCW position).

Apply power and rotate CL pot CW slowly until DC ammeter reads 1.5 times motor

rating (do not exceed 2 times motor rating, Max. CW position.)

NOTE: If only an AC ammeter is available, it can be installed in series with the AC line.

Follow above instructions; however, set AC amperage at .75 times motor rating.

F. IR Compensation Adjustment. IR compensation is provided to substantially improve load

regulation. If the load presented to the motor does not vary substantially, the IR adjustment

may be set at a minimum level (approximately 1/4 of full setting). The control is factory adjusted to approximately 3% regulation. If superior performance is desired (less than 1% speed

change of base speed from 0 to full load), then the IR comp. Should be adjusted as follows:

NOTES: 1. Excessive IR comp. will cause control to become unstable, which causes

motor cogging.

2. For tach feedback applications the IR comp can be set to minimum rotation

(full CCW).

1. Set IR comp. trimpot at approximately 25% of CW rotation. Run motor unloaded at approximately 1/3 speed and record RPM.

2. Run motor with maximum load and adjust IR comp. trimpot so that the motor speed under

load equals the unloaded speed per step 1.

3. Remove load and recheck unloaded RPM. If unloaded RPM has shifted, repeat procedure

for more exact regulation.

The RAMM is now compensated to provide minimal speed change under large variations of

applied load

15

Page 17

LIMITED WARRANTY—RAMM 125, 225, 225D

For a period of one (1) year from date of original purchase Rapid-Air Corporation will repair or replace

without charge devices which our examination proves

to be defective in material or workmanship. This warranty is valid if the unit has not been tampered with by

unauthorized persons, misused, abused or improperly

installed and has been used in accordance with the instructions and/or ratings supplied. The foregoing is in

lieu of any other warranty or guarantee expressed or

implied, and we are not responsible for any expense

(including installation and removal), inconvenience, or

consequential damage, including injury to any person,

caused by items of our manufacture and/or sale. Some

states do not allow certain exclusions or limitations

found in this warranty so that they may not apply to

you. In any event, Rapid-Air Corporation’s total liability, under all circumstances, shall not exceed the

full purchase price of this unit.

16

Page 18

Page 19

Loading...

Loading...