Page 1

AIR FEED / CUT-TO-LENGTH

WITH KEYPAD

OPERATING INSTRUCTIONS

RAPID-AIR CORPORATION

4601 KISHWAUKEE ST. • ROCKFORD, IL 61109-2925

Phone: (815) 397-2578 • Fax: (815) 398-3887 • Web Site: www.rapidair.com

Page 2

Air Feed/Cut-to-Length with Keypad

Table of Contents

Charts and Drawings Directory pg. 2

Installation pg. 3

Cutter Data pg. 4

Air Feed Progressions Setup pg. 5

Electrical Setup pg. 8

Pretest Without Material pg. 8

Loading Material pg. 9

Interfacing pg. 10

Programming pg. 11

Troubleshooting Electrics pg. 16

Troubleshooting Air Feed pg. 18

1

Page 3

CHART AND DRAWINGS

Programming Map pg. 20

Manual Sequence pg. 21

Auto Sequence pg. 22

Rapid Master Layout pg. 23

Rapid Master Panel Layout pg. 24

Operator Keypad pg. 25

Electrical Diagram pg. 26

2

Page 4

Operating Instructions

Cut to Length Machine

INSTALLATION:

The Cut to Length (CTL) that you have just received is fully assembled and ready to

be put into production. Due to shipment vibration and handling, the machine should

be checked to ensure all screws and bolts are tight. Remove the cover to the

electrical controls and visually inspect that all parts are in place and secure. If the

machine was damaged in shipment, contact the carrier first to report the damage and

then Rapid-Air.

CAUTION — The CTL machine is top heavy when not sitting on its base legs.

Use extreme caution when moving this machine.

Install machine on a level surface with sufficient clearance for loading and unloading

process material. The machine should be secured to the floor through the 4 holes

provided in the feet of the machine using 7/16 tie-down bolts. Or, can be installed

using 1/2-13 leveling bolts and machine pads. The pads keep the machine from

walking during operation and also act as a noise reduction device.

The machine has two other requirements that need attention before putting the CTL

into production.

1) The customer must provide minimum CFM—RE: chart, at 75 to 120 PSI of dry air to

the machine. Connect a minimum of 5/8” ID hose into the filter regulator provided on

the machine. The inlet to the F-R-L is a NPT female thread.

2) The customer must provide 120 volt, 20 amp, 60 cycle electrical power. If an

extension cord is used between the source and the machine, it should be a minimum

12 gauge wire to keep the voltage loss down and for electrical safety reasons.

3

Page 5

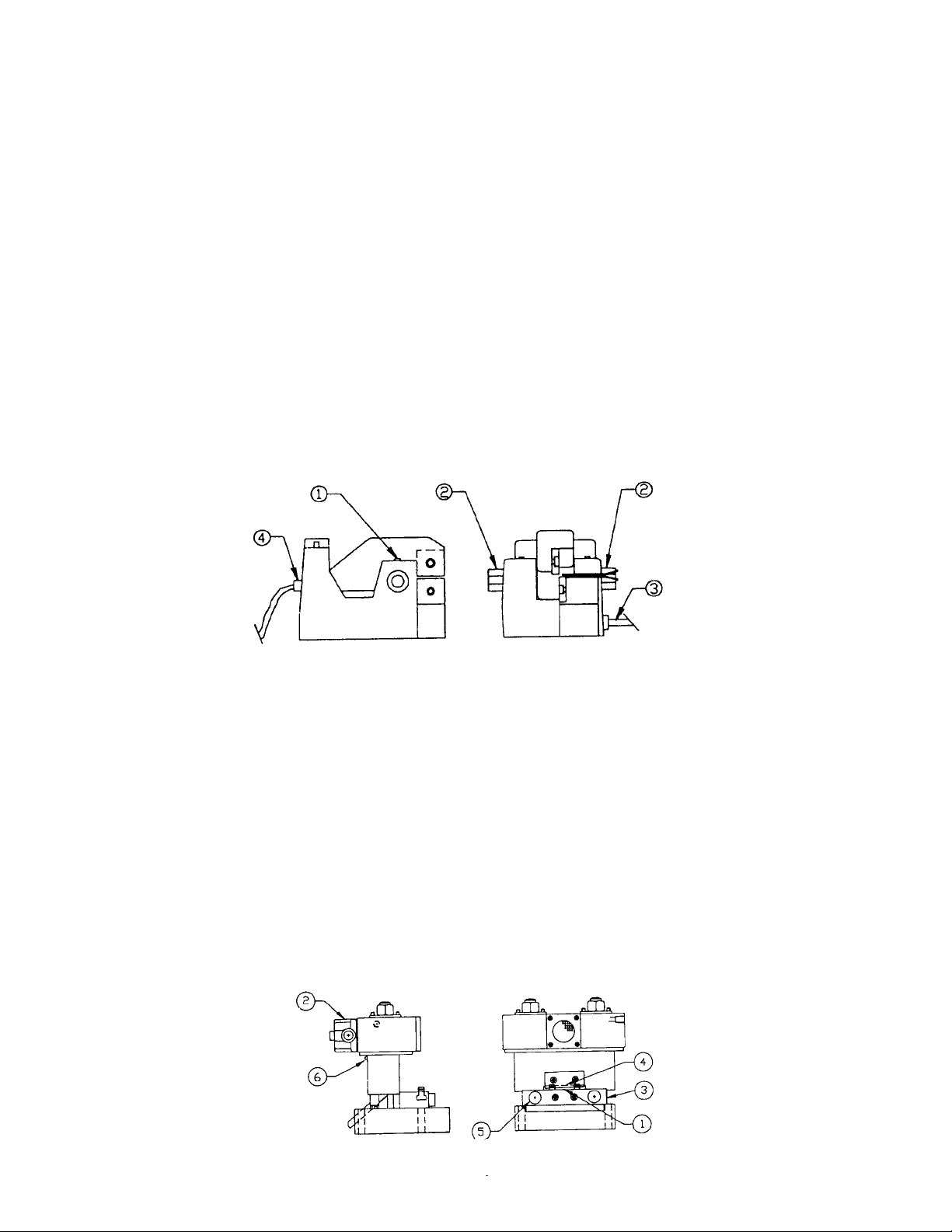

SMALL CUTTER

Cutter Data:

See specific cutter specifications.

Operations:

The solenoid valve, which is remote mounted, is attached to the cutter (item #3) by a

plastic hose and advances the cutter into the material. Compression springs return the

blade to the raised position. The cutter raised position is monitored by a proximity

switch mounted on the rear of the cutter. (item 4)

Adjustments:

The cutter blade may be lowered manually by pushing down on the head of the cutter.

The upper half of the cutter is attached to an adjustable slide. The cutter clearance can

be adjusted by loosening 2 screws (item #1) and rotating the hex nuts (item #2). To

adjust, loosen one side and tighten the opposite side corresponding to the side you

want to adjust in order to line up the blades. Retighten the top screws (item #1). When

greasing, use Mobilux No. 2 or equivalent.

LARGE CUTTER

Cutter Data: Material opening item #1; See specific cutter specifications.

Operations:

The solenoid valve (item #2) advances the cutter into the material and the compression

springs return the blade to the raised position.

Adjustments:

The blade may be lowered manually with an eccentric cam screw (item #6) located on

the upper blade assembly just under the solenoid valve. The lower half of the cutter is

attached to an adjustable slide (item #3). The cutter clearance is adjusted by looseing

(2) hex screws (item #4) on the adjusting slides and turning (2) knurled knobs (item #5)

to move the lower blade horizontally in & out.

4

Page 6

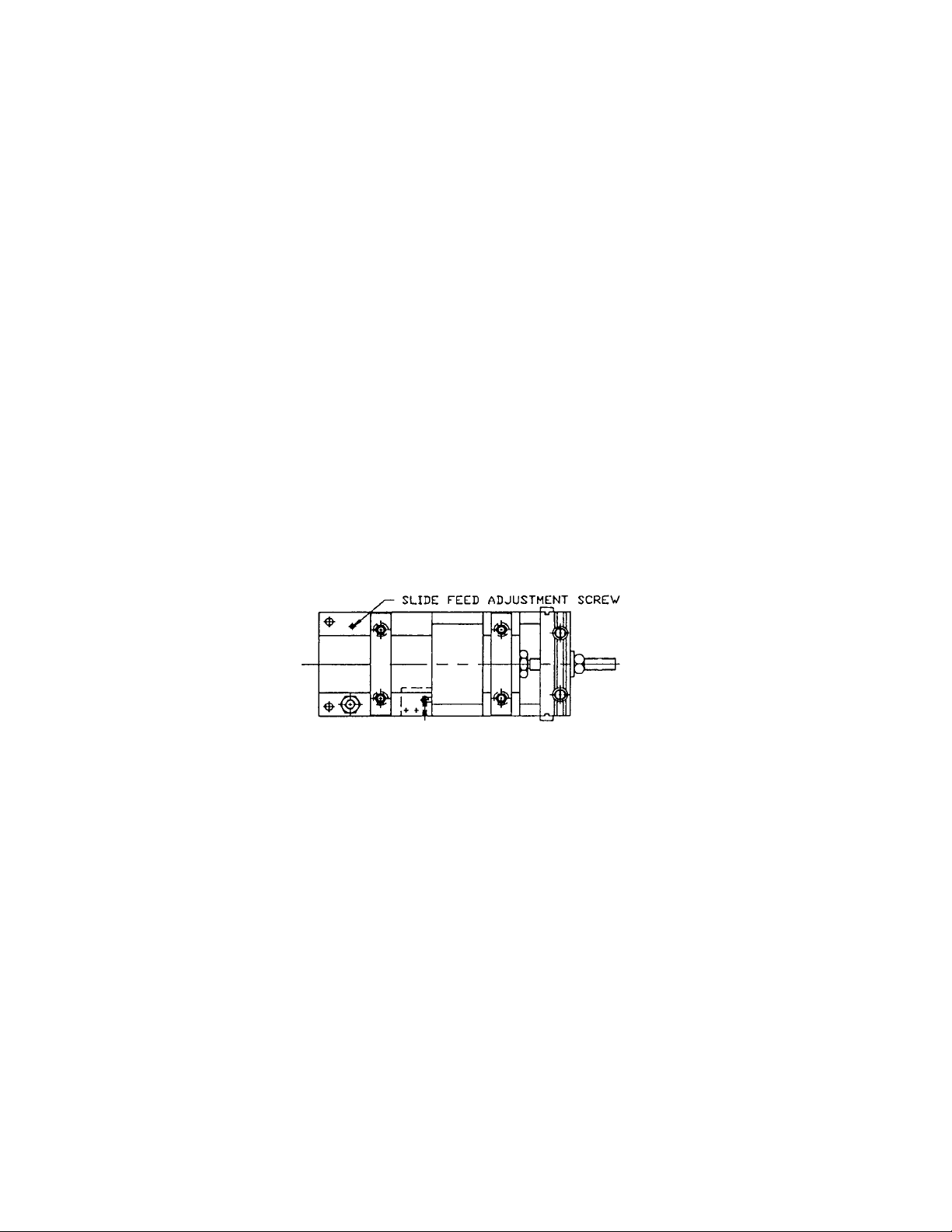

AIR FEED PROGRESSION SET UP

The feed guide rollers are adjustable by loosening the machine screws and moving the

rollers to the desired position. For best results the stock should be centrally located in

the feed.

The notches in the guide rails provide for coarse feed adjustment of the stop block. The

final feed adjustment for stroke length is made by the screw in the center of the stop

block. The final feed adjustment is aided by the use of accurately dimensioned spacers

or gage blocks placed between the adjusting screw and the main cushion bolt, and with

the air pressure turned on to keep the slide block tight against the main body.

With the air pressure off, the material is then inserted between the guide rollers and

passed under the feed clamp. Lift the stock clamp and push the material through to the

starting position. Turn on the air (75-120 PSI) and the feed is ready to operate.

The last adjustment, if necessary, would be the speed adjusting valve. The valve

adjustment is located on top of the main body on the opposite side of the actuating

valve. Adjust the screw for minimum impact by turning clockwise and for faster speed

by turning counterclockwise. When the impact is high, slippage is possible resulting in

poor repeatability and also part fatigue. Refer to the diagram below.

MAINTENANCE

The ram head assembly requires very little maintenance. There are four dynamic “O”

rings that would need to be replaced on the rare occasion of an air leak. These are as

follows per Rapid Master head assembly drawing #24000001 parts list.

item 43, part no. 60108212 1 req.

item 45, part no. 60108234 1 req.

item 90, part no. 60108269 2 req.

To absorb mechanical shock, reduce noise and prolong machine life, a rubber bumper

is incorporated into the assembly. Some stroke accuracy could be affected by rubber

deterioration. Stroke adjustment will compensate for any small overall stroke increase.

The rubber bumper (item 52, part no 35900037), should bbe examined during any “O”

ring maintenance procedure.

5

Page 7

LUBRICATION

For a general guide for the Rapid Master, the lubricator oil release adjustment should

be set to one drop of oil for each 50-80 strokes. (See insert on lubrication of “O” rings.)

LUBRICATION OF “O” RINGS

The “O” Rings furnished with Rapid-Air feeds are made of a Buna N Compound

designed to give long life on service with air, oil and water. This rubber compound

features high abrasiion resistance and good dimensional stability if the

recommendations listed below are followed.

A filter and lubricator should be used; the filter to remove grit that would otherwise act

as an abrasive, and the lubricator to provide an adequate quantity of oil. For best

results, avoid excess of oil.

Parafifin base oils in general will give the best service. The viscosity should be 140170 S.S.U., the API gravity 29.5 minimum and the aniline point between 150 F and

210F. Variation of the aniline point from the limits given is likely to cause either

shrinkage or stretching of the “O” Rings.

Detergent motor oils and all other oils designed for automotive use are generally

unreliable in chemical makeup for use with rubber compounds. Spindle oils are

too low in viscosity.

The group of oils listed below are generally recommended for Buna N compound 366Y

“O” Rings. This grouping is given in good faith but, because of the constant changes

made in oils by the manufacturers, we cannot guarantee any consistency of chemical

makeup. All of these oils have an aniline point of 210, and API gravity of 29.5 minimum

and a viscosity of 140-170 S.S.U. The base stock is paraffin.

Recommended:

Cities Service Oil Co. Pacemaker #1 (Standard hydraulic oil)

Standard Oil of Indiana #5 Hydraulic Oil

Sun Oil Co. Sunvix #916

Texaco Regal A, R & O

Shell Oil Co. Tellus #27

Turbo #27

Sinclair Oil Co Rubilene Extra Light

Atlanta Refining Co. Hytherm Oil #C

New Jersey Lubricant Co A-88/HNR

Standard Oil of Ohio Sohivis #43

Mobil DTE 10W Hydraulic

6

Page 8

RECOMMENDED LUBE FOR ASSEMBLY OF RAPID-AIR FEEDS MIXTURE OF

LUBRIPLATE AND MOLYKOTE

No. 105 Lubriplate

Fiske Bros. Refining Co.

Newark, NJ - Toledo, OH

Molykote

Powder (Molybdenum disulfide)

Dow Corning Corp.

Midland, Michigan

To a 2 lb coffee can filled with lubriplate, add 2 tablespoons of moly kote and thoroughly

mix.

Loctite sealant is used on threaded parts type AV.

7

Page 9

ELECTRICAL SET-UP

1. MASTER POWER ON/OFF BUTTON

Mushroom push/pull lighted pushubtton. Pull to turn on the power and push to

turn off the power.

2. DOOR CLOSED SWITCHES

There is one door closed switch on the slide unit. The slide door has to be

closed in the automatic mode.

3. POSITION SWITCHES

There are two position switches on the air feed, any failure on any of these

switches could stop the running of the complete unit.

4. PRE-OPERATION CHECK

* Check that the air is connected and turned on.

* Pull the “POWER BUTTON” to the “On” position.

* Select “CYCLE PER CUT” - make it 1.

* Select “MANUAL” then press the “FEED AIR” selection button. F1 turns the

air on to hold the material and F2 turns the feed air off to load material. Turn the

feed air on to cycle.

* Press the feed button. The feed should cycle the number of cycles entered in

the cycles per cut.

* Press the cut button. The cutter should cycle one time.

* Press the single cycle button. The feed and cutter should cycle one complete

cycle.

* Increase the feed strokes from 1 to 2. The feed should now feed 2 times to 1

stroke of the cutter.

* Select “AUTO TOTAL”. The machine will start cycling and continue to cycle

until the stop button is pressed.

* Select “AUTO BATCH”. Enter desired batch size and start the cycle. The

machine will cycle until the cycle stop button is pressed or the batch count is complete,

then stop.

PRETEST FOR UNIT WITHOUT MATERIAL

The first step is to turn on the main switch on the electrical enclosure. The button

should illuminate to indicate that there is power to the system.

If you are comfortable with programming a job then continue. If not, please refer to the

“Programming Procedure” located in this manual.

Follow the programming sequence for the operators terminal to input feed parameters.

Your unit has been fully tested before it was shipped to your facility and this procedure

is merely a test to insure that all functions are still functional and the cables are properly

seated.

8

Page 10

Once you have programmed the required parameters. Select the manual mode of

operation.

After you have verified that the feed and cutter are operational, you can experiment

with single cycle moves. The procedure is outlined in the programming section of this

manual.

Now, you can cycle the cutter and watch the feed to verify that the signal from the

cutter switch is functional and actuating at the proper time.

After all the checks have been made and you feel comfortable with the programming of

the unit controller, place the unit in automatic mode. The feed should react upon the

closure of the cut signal and simulate a feed progression of material.

LOADING MATERIAL INTO THE AIR FEED

Upon satisfactory completion of all tests, you should be ready to load a strip of material

into the feed. Step number one is to select the manual mode of operation on the

keypad. You can now open the clamps manually by turning the air-feed air off.

Position the leading edge of the material near the center of the entry guide and adjust

the edge guides on the feed to the proper width setting. Hand feed the material

through the air feed unit until it protrudes out of the feed and starts into the guide on the

ram unit then turn the feed air on to clamp the material.

You are now ready to begin testing the complete system under power. To check the

progression, cycle the unit in the single cycle mode to test for correct progression

length. If the progression is correct, no further adjustments are necessary. If

progression is either short or long, go to the trouble shooting chart and perform the

sequences described there for inaccurate feeding. Once the feed progression has

been accurately set and the repeatability is satisfactory, you are ready for full automatic

mode.

9

Page 11

INTERFACING EXPLANATION

A. TAUT STOCK INPUT

This is a normally open contact from a switch or device that monitors the loop of

material prior to the air feed. When the material reaches a point that it trips the switch,

a taut stock has been reached. This input, when received, immediately drops the

automatic which stops the feed in progress. The material should be repositioned in the

die before restarting the automatic sequence.

This input also could be used as a “No Stock” switch that would monitor whether or not

there is material available to feed.

B. KEYPAD AND DISPLAY INTERFACE (RS 232 PORT)

The keypad/display is the interface between the operator and the resident program.

The cyberpak unit is purchased with a great many capabilities. None of which can be

used unless a program is written to utilize these capabilities. Rapid-Air put a great deal

of time making a program that is user friendly and yet gets the job done efficiently. We

took all the questions and constructive criticism and came up with a program that

would cover all the applications. Yet be easy to interface and program by a customer.

If an operator reads the programming procedure in this manual and then reads the

screen parameters listed as they are displayed and acts on them by inputting data as

needed. The unit can be up and running in a very short time.

1. Select a job number

2. Input or review setup parameters for the unit

3. Thread up material in manual mode

4. If properly interfaced, go into automatic mode

10

Page 12

OPERATOR INPUT TERMINAL-PROGRAMMING PROCEDURE-STANDARD

SOFTWARE

The intent of this section is to familiarize the operator with the program flow and what

to expect with every keypress. Each screen onthe display will be reviewed with special

comments to help clarify what is being asked on the screen. The program flow is

broken down into sections with the main menu being the home position. Reviewing the

flow chart in the back of this manual will help in understanding the sections.

SECTION 1 F1=CYCLES PER CUT ENTRY

SECTION 2 F2=MANUAL MODE

SETUP PARAMETERS

SECTION 3 F3=AUTOMATIC

The first screen to be displayed on the operator terminal will look like this:

RAPID-AIR CORPORATION

ROCKFORD, IL 61109

After a few seconds, the display will clear and the following display will appear:

FEED CYCLES/CUT=XX

F1=SET CYCLE PER CUT

F2=MANUAL MODE

F3=AUTOMATIC MODE

SELECT F1=SET CYCLES PER CUT

The first step in programming the Cut To Length feed is to input the correct cycles to

achieve the desired feed length. When the operator selects F1 on the keypad, the

screen will change to:

SET FEED CYCLES PER CUT

___________ “ENTER”

A NUMBER MUST BE

ENTERED TO CONTINUE

When the enter key is pushed, the screen reverts back to the main menu.

Select F2-Manual. The following screen appears.

MANUAL KEYS ARE

NOW ACTIVE

** USE CAUTION **

F4=EXIT TO MAIN MENU

11

Page 13

1. When pressing the F4 key the display reverts back to the main menu.

2. All manual keys are now active. Pressing any labeled key will activate a movement.

Caution: Make sure there is air to the cutter before cycling or the system will lock

up. To unlock, the main power has to be cycled.

3. Pressing the “Feed Button” will cause the feed to move the number of cycles that

was entered.

4. Pressing the “Cut Button” will cause the cutter to cycle one time.

5. Pressing the “Single Cycle Button” will cause the feed and cutter to perform one

complete cycle.

6. Press the “Total Reset” button and the following display appears.

TOTAL COUNT = XXXXXX

F1=RESET TO ZERO

F4=EXIT DISPLAY

A. Pressing the F1 key will cause the total count to be all zeros.

B. Pressing the F4 key will take you back to the main menu.

7. Press the “Cut Time Button” and the following screen appears.

CUT DWELL TIME=XXX

F1=SET DWELL TIME

F4=EXIT DISPLAY

A. Pressing the F1 key will display a screen which will force you to enter a dwell time

before leaving the screen.

B. Pressing the F4 key will take you back to the main menu.

8. Press the “Clamp Air Button” and the following screen appears.

FEED AIR SELECTION

F1=TURN FEED AIR ON

F2=TURN FEED AIR OFF

F4=EXIT

Use this feature when loading material into the air feed.

9. Press the “Diagnostics Button” and the following display appears.

FEED AT MAIN SW=OFF

FEED AT STOP SW=OFF

CUTTER RET’D SW-ON

DOOR CLOS’D-ON F4=EXIT

12

Page 14

Each time the switch changes state, the screen switches to off or on. If the switch is

energized, the screen displays on. If the switch is de-energized, the screen displays

off.

10. Press the “Count Display Button” and the following screen appears.

PART COUNT DISPLAY

TOTAL COUNT=XXXXXX

BATCH COUNT=XXXXXX

F4=EXIT

Pressing the F4 “Exit” key and the screen reverts back to the previous screen.

Press the F4 exit key until the main menu screen appears.

FEED CYCLES/CUT=XX

F1=SET CYCLE PER CUT

F2=MANUAL MODE

F3=AUTOMATIC MODE

We have covered all the setup operations of the Air Cut To Length. Now we will cover

the automatic portion of the programming.

Press the F3 “Auto” key and the following screen appears.

** AUTOMATIC MODE **

F1=AUTO TOTAL CYCLE

F2-AUTO BATCH CYCLE

F4=EXIT AUTO MODE

Pressing the F1 key will put you in the auto total mode. In this mode the feed, once

started, will feed on command until you stop it by pressing the stop key.

Pressing the F2 key will put you in the auto batch mode. In this mode you put in the

quanity of cycles you want and the feed will stop when this count has been reached.

Press F1 auto total cycle key and the following screen appears.

** AUTO TOTAL MODE **

TOTAL COUNTS = XXXXXX

F1=RUN AUTO TOTAL

F2=EXIT AUTO TOTAL

13

Page 15

At this time the operator can choose to run auto total or exit. If exit is chosen then the

previous screen is displayed. If run is chosen then the following screen is displayed.

** AUTO TOTAL MODE **

FEED PER CYCLE = XX

TOTAL COUNT = XXXXXX

F4=STOP CYCLE

The unit is now in full automatic. Whenever an input for feed is received, the air feed

will feed the cycles programmed and increment the counter by one count.

If you press the F4 “Stop Cycle” key, the automatic cycle will drop out and the next

screen to appear is as follows.

Note: The stop cycle key has to be pressed and held until the sequence that is

currently running is complete.

AUTO CYCLE

WAS STOPPED

F2=CONTINUE CYCLE

F4=STOP AND EXIT

The decision now is whether to continue cycling or stop. If F2 is pressed the feed

would continue where it left off. If F4 is pressed the following screen will appear.

** AUTOMATIC MODE **

F1=AUTO TOTAL CYCLE

F2=AUTO BATCH CYLE

F4=EXIT AUTO MODE

At this time you can choose to go back into auto total. Select auto batch or exit to the

main menu.

Press F2 auto batch cycle and the following screen appears.

BATCH SIZE=XXXXXX

F1=ENTER NEW BATCH

F2=RUN CURRENT BATCH

F4=EXIT AUTO BATCH

If the current batch size is correct then press F2 run current batch. If not then press F1

enter new batch size and the following screen appears.

BATCH SIZE

__________ ENTER

A NUMBER MUST BE

ENTERED TO CONTINUE

14

Page 16

Once the number has been entered, the previous screen appears. Press F2 run

current batch and the following screen appears and cycling begins.

AUTO BATCH F4=STOP

FEED PER CYCLE = XX

BATCH COUNT=XXXXXX

TOTAL COUNT=XXXXXX

The batch count will decreemnt while the total count increments. Once the batch size

gets to zero, the auto cycle stops. Pressing F4 at any time stops the cycle and the

following screen appears.

Note: The stop cycle key has to be pressed and held until the sequence that is

currently running is complete.

AUTO CYCLE

WAS STOPPED

F2=CONTINUE CYCLE

F4=STOP AND EXIT

The decision now is whether to continue cycling or stop. If F2 is pressed then the feed

would continue where it left off. If F4 is pressed the following screen will appear.

** AUTOMATIC MODE **

F1=AUTO TOTAL CYCLE

F2=AUTO BATCH CYCLE

F4=EXIT AUTO MODE

Press F4-Exit and the main menu appears.

This completes the programming procedure section of the Air Cut To Length.

15

Page 17

TROUBLESHOOTING ELECTRICS

PROBLEM

The attempt is made to start

the machine by pulling the

mushroom start button but

no lights illuminate.

The attempt is made to

cycle the feed but the slide

will not move.

When commanded, the

feed moves to the stop

block position, but will not

return to the main body

switch.

POSSIBLE CAUSE

* No power at source

* The machine is not

plugged into the source

power.

*Fuse blown on the control.

*Loose wiring.

*Defective pushbutton.

*Check that there is air

present on the machine.

*Check that the “Feed Air”

switch is in the “ON”

position.

*The Ram returned switch

is not properly adjusted or

is defective.

*The stop block switch is

not properly adjusted or is

defective.

The wiring to or from the

switch is not properly

connected or is incomplete.

REMEDY

*Check building recept. for

voltage.

*Plug cord into 120 volt-1Ph

recept.

*Look for burn spots to see

what caused the blown

fuse - replace fuse.

*Inspect wiring to terminals

for loose wire or loose

screws.

*Disconnect all power,

check out pushbutton.

*Air gauge should read: 75120 PSI.

*The “Feed Air” switch

button is located on the

keypad unit.

Turn valve control on and

off, the main slide valve

should energize and

deenergize.

Readjust or replace the

switch.

*Readjust or replace the

switch.

*Check for loose wiring or

screws.

16

Page 18

PROBLEM PROBABLE CAUSES REMEDY

The attempt is made to

cycle the Cutter, but it won’t

move.

The unit drops out of

automatic at random times.

The total count counter will

not increment.

The total batch counter will

not increment.

*Loose wiring or defective

solenoid valve.

*Door closed switch is

improperly adjusted.

*Loose wiring.

*Check that auto total or

auto batch has been

selected.

*Check that auto total or

auto batch has been

selected.

*Check wiring.

*Readjust swtich.

*Check for loose wires or

screws.

Select auto total or auto

batch.

Select auto total or auto

batch.

17

Page 19

Characteristics and Possible Causes of Troubles with

Rapid-Air Feeds

PROBLEM

Feed and stock clamps work, but

slide block does not move when

actuating valve is depressed.

Excessive leakage of air from

exhuast hole beneath speed

adjusting screw when acutating

valve is in up position.

Excessive leakage of air from

exhuast hole, also sluggish

operation of feed clamp pistons,

acuating valve up.

Excessive leakage of air from

exhaust hole when actuating

valve is in down position. (Note:

that a slight amount of leakage is

normal in this position.)

Stock clamp does not move up

and down when actuating valve is

depressed. Other operations

appear normal.

Excessive leakage of air from

actuating valve vent hole when

actuating valve is in up position.

Gradually reduced speed.

Excessive leakage of air from

pilot operated valve vent hole on

side of feed.

Cushion pistons act too slow and

provide too much cushion

Mist of oil coming from exhaust

hole

POSSIBLE CAUSES

*Pilot operated valve is stuck

* Poppet not seating on bottom of

valve hole.

*Leaking of “O” rings #85, 83, 84,

88, 90 and 100

*Leaking of “O” rings #85 and 90

*Tight “O” rings or grit around

pilot operated valve may prevent

it from moving its full stroke.

*Worn poppet.

*Poppet in backwards

*Worn “O” rings $96 around O.D.

of stock clamp pistons.

“O” Rings #103 beneath actuating

valve retainer #31C is leaking.

*Lack of oil

*Low viscosity oil.

*Speed adjusting screw turned in

too far.

*Oversized poppet.

*Leaking of “O” rings #100, 101 or

102.

*Excessive oil, reduce supply

*Excessive oil, reduce supply

REMEDY

*Check for grit, swollen nylon or

swollen “O” rings

*Check for grit or chips

*Check “O” rings #85, 83, 84, 88,

90 and 100. See assembly

drawing 106 for location

*Check “O” rings #85 and 90.

See assembly drawing #106 for

location.

*Clean grit, cycle feed manually

to break in “O” rigns.

*Insert new poppet

*See feeds parts list #106 for

correction orientation.

*Replace “O” rings. See

assembly drawing #106 for

location.

*Install “O” rings beneath

retainer - not in air groove. See

assembly drawing #106.

*Adjust air/oil mixture.

*Use lighter weight oil

*Readjust screw

*Clean poppet area; check for

free fit

*Check “O” rings #100, 101 and

102. See assembly drawing #106

for location.

*Adjust air/oil mixture

*Adjust air/oil mixture

Con’t next page

18

Page 20

PROBLEM

Feed has difficulty pushing last

part of progression.

Over feeding

Under feeding

Slide block will move out okay,

but will not return without

hesitation

Feed acts sluggish on start up.

Okay after running for a while.

PROBABLE CAUSES

*Feed is not inline with die.

*Stock excessively dirty or oily.

*Feed is operating too fast.

*Stock and feed clamps may be

loose.

*Insufficient air pressure.

*Stock has large slitting burr.

*Stock clamp and feed clamps

are loose.

*Feed is not lubricated.

*Stock excessively dirty.

*Feed may be feeding before

punches are clear from stock or

die.

*Feed may be operating too slow.

*Check speed adjusting screw.

*Check pilot operated valve.

Swollen “O” ring could be binding,

until pressure build up breaks it

free. Check poppet valve.

*Check pilot operated valve for

“O” rings binding. Valve should

move freely in cartridge.

REMEDY

*A slight angular adjustment of

the feed will reduce the binding of

the stock on the die guides.

*Clean unit and stock. Run and

retest.

*Turn speed adjusting screw

clockwise to slow down

*Although nuts are self locking,

they can in time work themselves

loose; retighten the nuts

*Adjust air pressure to between

80 and 100 PSI

*Check clearance between

clamps and stock

*Although nuts are self locking

they can in time work themselves

loose;

Retighten them

*Check lubricator at air inlet, there

should be oil in the bowl.

*Clean away dirt which may be

present between slide block and

main body area.

*Adjust the amount of depression

of the actuating valve.

*Turn speed adjusting screw

counter-clockwise to increase

speed

*Adjust for smooth operation.

*Check moisture content in air

lines. Change “O rings.

*This usually occurs after a period

of non-running. After running unit

for awhile the unit usually frees

up okay.

19

Page 21

Loading...

Loading...