Page 1

SERVO FEED

OPERATING INSTRUCTIONS

MODELS

CJ SERIES

(5-07)

104 & 108 CJ

(not available after 5-07)

106 & 112 CJ

(available after 5-07)

RAPID-AIR CORPORATION

4601 KISHWAUKEE ST. • ROCKFORD, IL 61109-2925

Phone: (815) 397-2578

• Fax: (815) 398-3887 • Web Site: www.rapidair.com

1

Page 2

TAblE OF CONTENTS

INTRODUCTION .......................................................................................................................................... pg. 3

INSTALLATION, MECHANICAL & ELECTRIC PILOT RELEASE

PROGRAMMING PROCEDURE ................................................................................................................. pg. 5-6

FATAL FAULT ERROR CODES ..................................................................................................................... pg. 6

NO MESSAGE FAULTS

SCHEMATICS ............................................................................................................................................... pg. 8-16

............................................................................................................................... pg. 7

............................................................. pg. 4

2

Page 3

INTRODUCTION

The CJ Servo

The CJ servo has many features found

in the more expensive models. Some of

it’s features are:

Input:

120 VAC, 50/60 HZ

Amperage required at input:

10 amps maximum.

Accuracy:

.0025 per feed length at the rolls.

Maximum feed length input:

999.999 inches.

Job storage:

99 jobs

Display:

4 rows by 80 characters, backlit

Fault type:

Displayed on the drive if a fault occurs

otherwise an “8.” is displayed.

Rolls:

Hardened and Ground.

Drive roll parallelism adjustment:

Used to tune the rolls to the material if

needed.

The Rapid-Air CJ feed uses the same

type of programming procedures as it

has in it’s more expensive models. Input

a feed length, strokes per minute, and a

feed arc and the program will adjust the

servo acceleration/deceleration and

maximum servo speed parameters

to the requirement needed to keep up

to the press strokes per minute.

The precision mechanical roll feed has

been designed for compactness, ease

of setup and installation. A 120 VAC

receptacle is all that is required of the

customer. Two cables are supplied with

the control and need to be connected

to the proper locations of the motor.

The electrical controls are housed in a

small box that can be mounted on the

press or if purchased, on a post that

can be positioned close to the press.

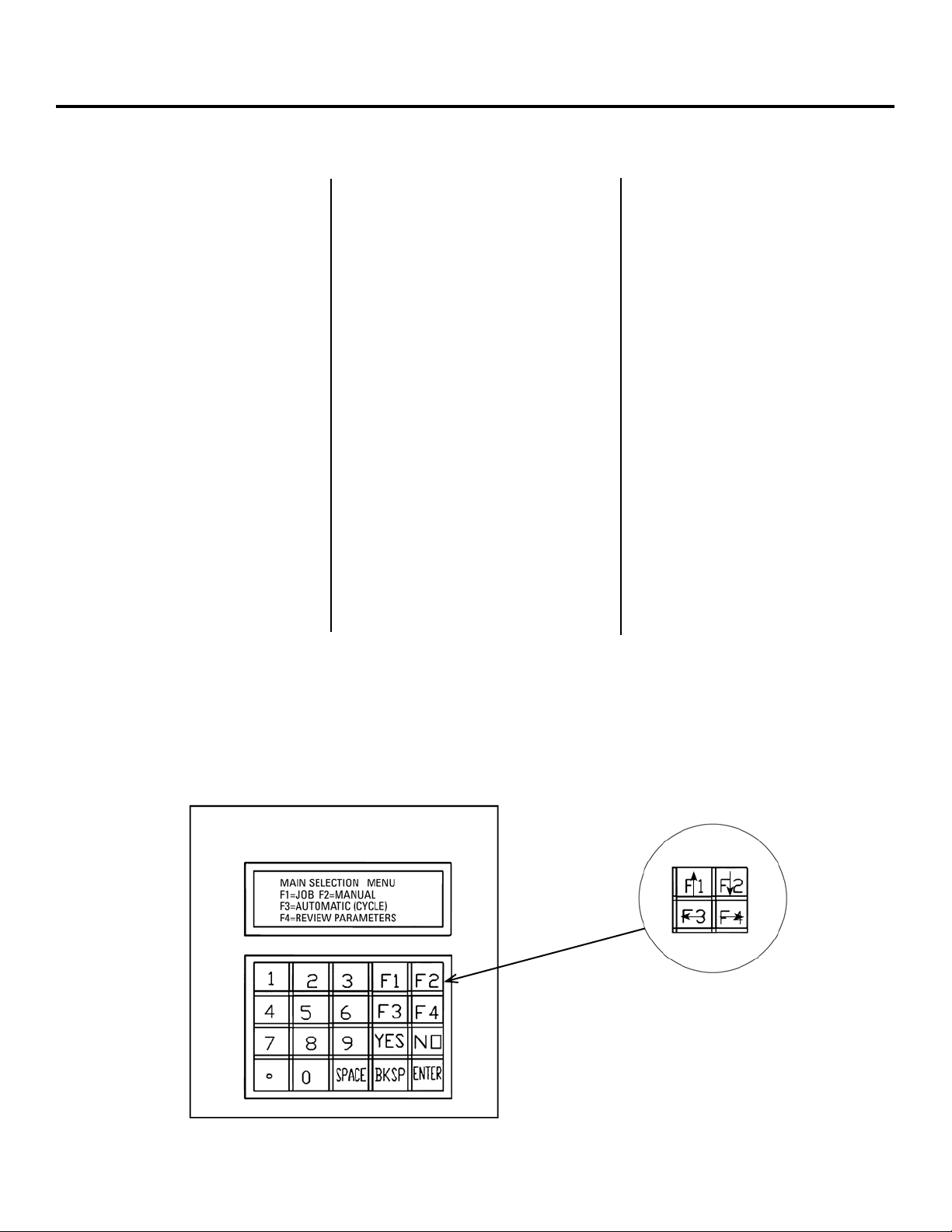

Note:

4 KEYS WERE CHOSEN TO HAVE A

DOUBLE MEANING, ARROWS AND

“F” KEYS. THE ARROWS WERE

BROUGHT OUT AS THE PRIMARY

INSTEAD OF THE “F” KEYS. IF YOU

WOULD BEAR WITH US, WE ARE

LOOKING AT A CORRECTION.

KEYPAD

3

Page 4

INSTAllATION, mEChANICAl & ElECTRIC PIlOT RElEASE

Installation

The Rapid-Air servo was run and fully

tested before being shipped from our

plant. Carefully inspect all parts when

uncrating them. If you find any damaged parts, please report it to the

carrier that delivered the servo drive

and at the same time, report the damage to your distributor.

The servo feed container should

contain:

1 servo feed-- standard

1 console-- standard

Mechanical Pilot Release

All CJ servo feeds are manufactured to

accept an optional mechanical pilot release kit. If the mechanical pilot release

is used, (we recommend it for press

speeds of 250 or greater strokes

per minute.) An adjustable actuator must

be mounted to the press and timed to

1 console stand-- optional

1 servo mounting bracket-- optional

1 cascade roller assembly-- optional

Please contact someone at your

facility to verify what options were

purchased.

If a mounting bracket was purchased

then it should be mounted first being

careful that the center line of the

bracket lines up with the center line

of the die area. The servo can then be

mounted on the bracket. A print of the

open the rolls when needed. Rapid-Air

offers such an actuator but only in one

style and one length. If after inspecting

the print dimensions and it is found that it

would work for you then contact your

distributor to purchase the actuating

arm. If the arm doesn’t seem like it will

bracket can be found in the back of

this manual.

If a bracket was not purchased then

the servo will have to be mounted on

the press bed or customer provided

bracket. Line up the rolls to be centered and perpendicular to the center

line of the die area. Included in the

back of this manual is a hole pattern

layout print for the CJ servo.

work then manufacturing your own arm

is your only recourse. The only

dimension that has to be closely

watched is the travel of the mechanical

actuating arm attached to the feed. The

maximum travel of this arm is .800 before

bottoming out (.250 for 106 & 112 CJ).

Electric Pilot Release

The optional electric pilot release is

mounted on top of the servo with 4

bolts which are included in the kit.

The kit also includes the valve and

the roll release stop for setting the

maximum movement of the roll opening. It is the customers responsibility

to interface the pilot release

valve with the customer supplied,

press mounted, activating switch. The

4

air requirements for the release to

work correctly is 80 to 120 PSI, dry fil

tered and lightly lubricated air. There

should be a minimum of 2 CFM available at all times.

-

Page 5

PROGRAmmING PROCEDURE

Operator Input Section

The intent of this section is to familiarize the operator with the flow of

the program and what to expect with

each key press. Each program screen

of the servo will be displayed

and also comments to clarify possible

questions. There are four sections

that will be explained and they are as

follows

SECTION 1 — JOB NUMBER

SECTION 2 — MANUAL MODE

SECTION 3 — AUTOMATIC MODE

SECTION 4 — REVIEW PARAMETERS

When the servo is first started, and

has performed its startup procedure,

the first screen displayed should look

like this.

MAIN SELECTION MENU:

F1=JOB NUM F2=MANUAL

F3=AUTOMATIC (CYCLE)

F4=REVIEW PARAMETERS

* SELECT F1=JOB NUM

The first step in programming a job is

to select a two digit job number which

will be used to store the parameters

that the operator inputs or to recall

an existing job number that was

previously loaded. When the operator

presses F1 on the keypad, the screen

will change to:

JOB SELECTION MENU

ENTER JOB NUMBER=____

PRESS F4 KEY AFTER

CORRECT # IS ENTERED

JOB NUMBER = ______

F1=PROG. PARAMETERS

F4=DON’T ALTER VALUES

Pressing the “F1 PROG. PARAM

ETERS” key initiates the following

screen. Key in the required parameters.

FEED LENGTH=_________

PRESS SPEED=_________

FEED ANGLE=__________

* ONCE THE PARAMETERS HAVE

BEEN ENTERED, THE PROGRAM WILL

COMPLETE THE MATH ROUTINE

WHICH SELECTS THE PROPER ACCEL/DECELL AND MOTOR SPEED FOR

THE PARAMETERS LISTED AND THEN

THE MAIN MENU IS DISPLAYED

AGAIN.

*SELECT F2 MANUAL

If the operator elects to move the

material from the feed to the die

electrically, the manual mode has to

be selected. Pressing the F2 key will

bring up the manual mode screen.

MANUAL LENGTH=_______

F1=SINGLE_FEED

F2=GO TO INCH MODE

F4=RETURN

Each time the F1 key is pressed, the

servo will move the material the feed

length entered for the job number.

The material will move at the speed

required to keep up with the programmed press strokes per minute.

-

INCH MODE:

F1=JOG FORWARD

F2=JOG REVERSE

F4=RETURN

When the F1 key is pressed, the feed

will advance the material at a slow

rate of speed. When the F2 key is

pressed, the feed will reverse the

material and run at a slow rate of

speed. Press F4 to return to the main

screen.

With the main menu displayed and

Pressing the “F3 AUTOMATIC (CYCLE)”, the following screen appears.

AUTOMATIC JOB=01

FEED LENGTH=______

PRESS SPEED=______

F4=RETURN

In the automatic mode, the feed

length and operator entered press

speed will be displayed. Whenever

the press mounted feed switch is

activated, the servo will feed the

feed length displayed on the screen.

Because there is not an interface in

the control for the pilot release it will

be up to the customer to wire the pilot

release switch to the solenoid that

operates the raising of the rolls.

Press F4 button to return to the main

menu and deactivate the automatic

control.

Press F4 again and the final mode is

review parameters, the parameters

for the job number will then be displayed.

The next screen lets you program

parameters or exit with the existing

parameters.

If the operator would like the material

to move a slower rate then the inch

mode should be selected. Press F2

now to display the inch mode screen.

5

The last function on the keypad is the

“RESET JOB PARAMETERS”. This

function should be used with special

Operator Input Section (cont.)

Page 6

PROGRAmmING PROCEDURE (CONTINUED)

Operator Input Section

caution as all the jobs being used will

reset to the default parameters and

cannot be restored without keying

each job number’s parameters.

The following screen is displayed

when the period is pressed while the

“Main Selection menu” is displayed.

RESET JOB PARAMETERS

TO DEFAULT VALUE

F1=RESET VALUES

F4=RETURN-DON’T RESET

It is very important that the operator make a hard copy of the jobs

on a sheet of paper so there is a

permanent record.

FATAl FAUlT ERROR CODES

7.3.1 Fatal Fault Error Codes

Err# Status Fault Message Possible Cause

Display

1 t Power stage OverTemp Overload, fan malfunction, power stage failure

2 o OverVoltage Excessive decel rate*

3 P OverCurrent Power stage surge current*

4.0 rO External feedback fault Feedback signal through C8 not correctly detected

4.1 r1 Resolver line break Break in resolver feedback detected

4.2 r2 RDC error Fault in resolver-to-digital converted detected

4.3 r3 Sinc Encoder init fail Sinc encoder card has not initialized properly

4.4 r4 A/B line break Break in encoder A/B input lines detected

4.5 r5 Index line break Break in encoder index line

4.6 r6 Illegal halls Illegal hall combination detected

4.7 r7 C/D line break Break in sinc encoder C/D line detected

4.8 r8 A/B out of range Sinc encoder A/B level out of range

4.9 r9 Burst pulse overflow Sinc encoder fault

5 u Under voltage Bus voltage is too low

6 H Motor over temperature Motor overload caused overheating

7.1 A1 Positive analog supply fail Failure in +12V supply

7.2 A2 Negative analog supply fail Failure in -12V supply

8 J OverSpeed Velocity

8.1 J1 OverSpeed Velocity

9 E EEPROM failure Faulty EEPROM

10 e EEPROM checksum fail EEPROM checksum invalid on power up*

12 F Foldback System in FoldBack mode

14.1 d5 Positive over travel fault PFB exceeded PMAX with PLIM=1

14.2 d6 Negative over travel fault PFB exceeded PMIN with PLIM=1

15.1 d1 Numeric position deviation Internal Fault

15.2 d2 Excessive position deviation PE > PEMAX

16 c Communication interface A communication fault has occurred

*These faults can only be cleared by cycling power

6

≥ VOSPD

≥ 1.8 x VLIM

Page 7

NO mESSAGE FAUlTS

7.3.3 No Message Faults

Fault Description Fatal Non-Fatal Flashing Status Steady Status

Display Display

Watchdog (DSP) X

Watchdog (HPC) X

No Compensation X -1

Invalid Velocity Control X -2

Encoder not Initialized on attempt to enable X -3

Encoder Initialization Failure X -4

AutoConfig failure X -5

Hardware CW limit switch open X L1

Hardware CCW limit switch open X L2

Hardware CW and CCW limit switches open X L3

Software CW limit switch is tripped X L4

(PFB>PMAX & PLIM=2)

Software CCW limit switch is tripped X L5

(PFB<PMIN & PLIM=2)

Positive and negative analog supply fail X A3

RAM Failure (during init) X I

EPROM checksum (during init) X c

Altera load failure (during init) E101

Altera DPRAM failure (during init) E102

7

Page 8

104 CJ Servo Feed

8

Page 9

106 & 112 CJ Servo Feeds

9

Page 10

104 & 108 CJ Servo Feeds

10

Page 11

106 & 112 CJ Mechanical Pilot Actuating Arm

11

Page 12

Keypad

12

Page 13

CJ Wiring Schematic

13

Page 14

CJ Series Speed Chart

S.P.M.

104CJ&108CJ&106CJ

112CJ

14

Page 15

ServoStar Drive

15

Page 16

SservoStar Drive (C2)

16

Loading...

Loading...