SERVICE MANUAL

AA-99-01.1AA-99-01.1

AA-99-01.1

AA-99-01.1AA-99-01.1

(Replaces AA-99-01)

June - 2007

SOLSOL

SOL

SOLSOL

TMTM

TM

EFMEFM

EFM

EFMEFM

VENTBORNE ROBOTIC AVENTBORNE ROBOTIC A

VENTBORNE ROBOTIC A

VENTBORNE ROBOTIC AVENTBORNE ROBOTIC A

TMTM

AND EFMD AND EFMD

AND EFMD

AND EFMD AND EFMD

TMTM

TM

TMTM

TT

OMIZERSOMIZERS

T

OMIZERS

TT

OMIZERSOMIZERS

MODEL: 76480, 76482, 76485, 76488MODEL: 76480, 76482, 76485, 76488

MODEL: 76480, 76482, 76485, 76488

MODEL: 76480, 76482, 76485, 76488MODEL: 76480, 76482, 76485, 76488

IMPORIMPOR

IMPOR

IMPORIMPOR

carefully read SAFETY PRECAUTIONS,carefully read SAFETY PRECAUTIONS,

carefully read SAFETY PRECAUTIONS,

carefully read SAFETY PRECAUTIONS,carefully read SAFETY PRECAUTIONS,

starting on page 1, and all instructions instarting on page 1, and all instructions in

starting on page 1, and all instructions in

starting on page 1, and all instructions instarting on page 1, and all instructions in

this manual. Keep this Service Manual forthis manual. Keep this Service Manual for

this manual. Keep this Service Manual for

this manual. Keep this Service Manual forthis manual. Keep this Service Manual for

future reference.future reference.

future reference.

future reference.future reference.

TT

ANTANT

T

ANT

TT

ANTANT

: Before using this equipment,: Before using this equipment,

: Before using this equipment,

: Before using this equipment,: Before using this equipment,

Service Manual Price: Service Manual Price:

Service Manual Price: €

Service Manual Price: Service Manual Price:

40.00 (Euro)40.00 (Euro)

40.00 (Euro)

40.00 (Euro)40.00 (Euro)

$50.00 (U.S.)$50.00 (U.S.)

$50.00 (U.S.)

$50.00 (U.S.)$50.00 (U.S.)

NOTE:NOTE:

NOTE: This manual has been changed from revision

NOTE:NOTE:

AA-99-01AA-99-01

AA-99-01 to revision

AA-99-01AA-99-01

AA-99-01.1AA-99-01.1

AA-99-01.1.

AA-99-01.1AA-99-01.1

Reasons for this change are noted under “Manual Change Summary” inside the back cover of this

manual.

AA-99-01.1

CONTENTSCONTENTS

CONTENTS

CONTENTSCONTENTS

SAFETY:SAFETY:

SAFETY:

SAFETY:SAFETY:

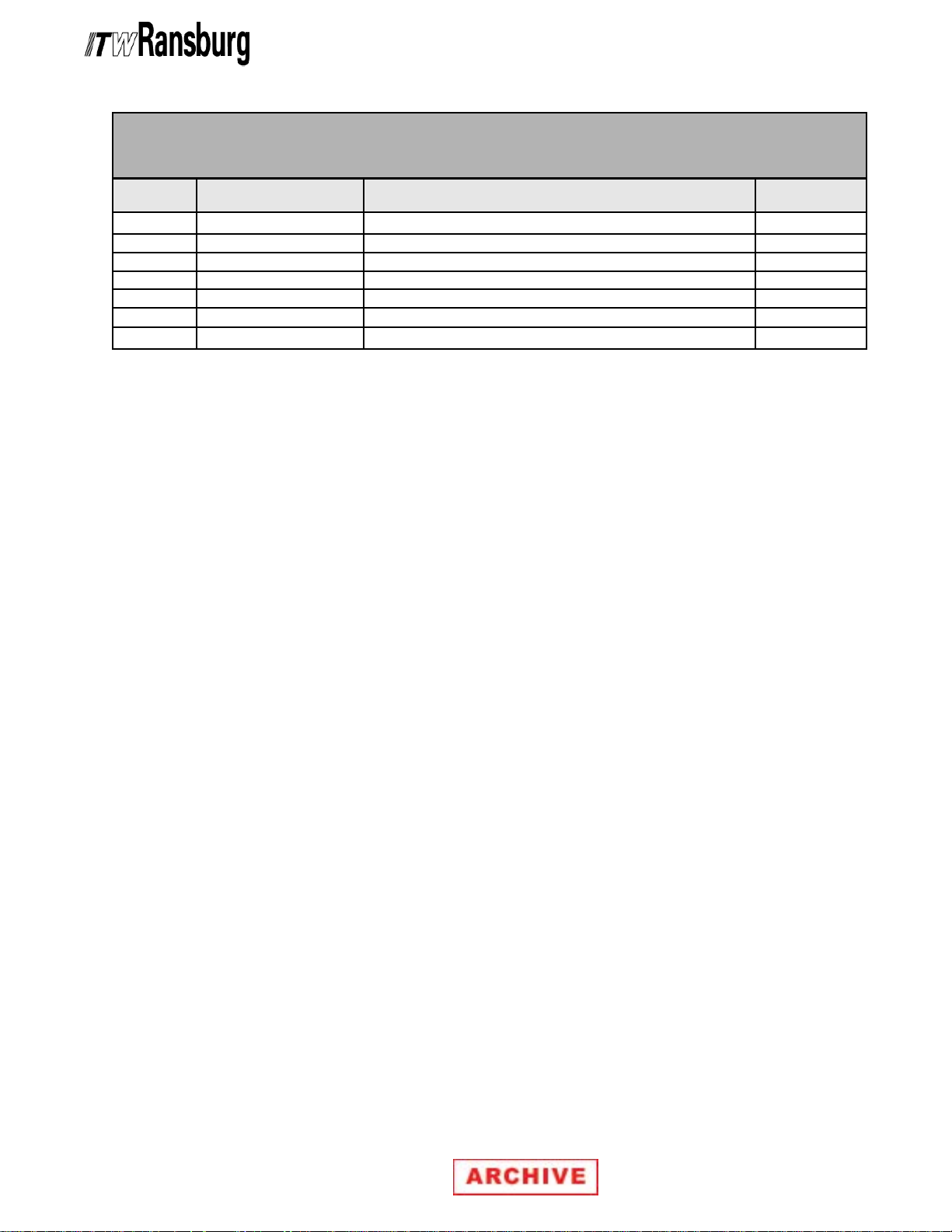

EFM(D) Solventborne Robotic Atomizers - Contents

PAGEPAGE

PAGE

PAGEPAGE

1-41-4

1-4

1-41-4

SAFETY PRECAUTIONS............................................................................................................

HAZARDS / SAFEGUARDS.......................................................................................................

INTRODUCTION:INTRODUCTION:

INTRODUCTION:

INTRODUCTION:INTRODUCTION:

THE ITW RANSBURG ELECTROSTATIC PROCESS.............................................................

EFM AND EFMD SOLVENTBORNE GUNS..............................................................................

SPECIFICATIONS.......................................................................................................................

MANIFOLD SELECTION GUIDE................................................................................................

APPLICATOR TOOL-POINT REPRESENTATION...................................................................

INSTALLATION:INSTALLATION:

INSTALLATION:

INSTALLATION:INSTALLATION:

EFM AND EFMD ROBOTIC ATOMIZER INSTALLATION........................................................

POWER SUPPLY ASSEMBLY...................................................................................................

LOW VOLTAGE CABLE CONNECTIONS.................................................................................

ROBOT MANIFOLD ASSEMBLY................................................................................................

EFM SPRAY GUN.......................................................................................................................

ROBOT MANIFOLD AND SPRAY GUN INSTALLATION /

PARTS LIST.................................................................................................................................

OPERATION:OPERATION:

OPERATION:

OPERATION:OPERATION:

1

2-4

5-85-8

5-8

5-85-8

5

5-6

6

7

8

9-149-14

9-14

9-149-14

9

9

10

11

11

13-14

15-1815-18

15-18

15-1815-18

SPRAY APPLICATOR CONTROLS...........................................................................................

POWER SUPPLY CONTROLS..................................................................................................

GENERAL INFORMATION AND ADJUSTMENTS...................................................................

SIMPLIFIED AIR AND FLUID FLOW PASSAGE LAYOUT.......................................................

INTRINSIC SAFE WIRING..........................................................................................................

MAINTENANCE:MAINTENANCE:

MAINTENANCE:

MAINTENANCE:MAINTENANCE:

ROUTINE MAINTENANCE SCHEDULE....................................................................................

PROCEDURES............................................................................................................................

SERVICE......................................................................................................................................

SPRAY HEAD ASSEMBLY / PARTS LIST.................................................................................

FLUID REGULATOR OR DUMP VALVE / PARTS LIST...........................................................

REMOVING GUN FROM THE ROBOT MANIFOLD

ASSEMBLY / PARTS LIST..........................................................................................................

AIR CARTRIDGE VALVES.........................................................................................................

SOLENOID TRIGGER VALVES / PARTS LIST.........................................................................

LECU5004 MICROPAK CONTROL UNIT..................................................................................

76494-XXX ROBOT MANIFOLD ASSEMBLY............................................................................

ACCESSORIES...........................................................................................................................

(Continued On Next Page)(Continued On Next Page)

(Continued On Next Page)

(Continued On Next Page)(Continued On Next Page)

15

15

15-17

17

18

19-3419-34

19-34

19-3419-34

19-20

20-21

21

22-24

25-26

27

28-29

29-30

31

31

31-34

AA-99-01.1

EFM(D) Solventborne Robotic Atomizers - Contents

PARTS IDENTIFICATION:PARTS IDENTIFICATION:

PARTS IDENTIFICATION:

PARTS IDENTIFICATION:PARTS IDENTIFICATION:

PAGEPAGE

PAGE

PAGEPAGE

35-7035-70

35-70

35-7035-70

76479 SPRAY HEAD ASSEMBLY / PARTS LIST.......................................................................

76490 APPLICATOR MANIFOLD PLATE ASSEMBLY / PARTS LIST......................................

76494 MANIFOLD ASSEMBLY / PARTS LIST............................................................................

76480 EFM APPLICATOR ASSEMBLY / PARTS LIST..............................................................

76366 VALVE MANIFOLD ASSEMBLY / PARTS LIST...............................................................

76481 APPLICATOR HOUSING ASSEMBLY / PARTS LIST....................................................

76482 EFM APPLICATOR ASSEMBLY / PARTS LIST..............................................................

76484 VALVE MANIFOLD ASSEMBLY / PARTS LIST...............................................................

76483 APPLICATOR HOUSING ASSEMBLY / PARTS LIST....................................................

76485 EFMD APPLICATOR ASSEMBLY / PARTS LIST............................................................

76487 VALVE MANIFOLD ASSEMBLY / PARTS LIST...............................................................

76486 APPLICATOR HOUSING ASSEMBLY / PARTS LIST....................................................

76488 EFMD APPLICATOR ASSEMBLY / PARTS LIST............................................................

76368 VALVE MANIFOLD ASSEMBLY / PARTS LIST...............................................................

76489 APPLICATOR HOUSING ASSEMBLY / PARTS LIST....................................................

WARRANTY POLICIES:WARRANTY POLICIES:

WARRANTY POLICIES:

WARRANTY POLICIES:WARRANTY POLICIES:

LIMITED WARRANTY..................................................................................................................

35-36

37-38

39-42

43-44

45-46

47-48

49-50

51-52

53-54

55-56

57-59

61-62

63-64

65-67

69-70

7171

71

7171

71

AA-99-01.1

AA-99-01.1

EFM(D) Solventborne Robotic Atomizers - Safety

SAFETYSAFETY

SAFETY

SAFETYSAFETY

SAFETY PRECAUTIONSSAFETY PRECAUTIONS

SAFETY PRECAUTIONS

SAFETY PRECAUTIONSSAFETY PRECAUTIONS

Before operating, maintaining or servicing any

ITW Ransburg electrostatic coating system, read

and understand all of the technical and safety

literature for your ITW Ransburg products. This

manual contains information that is important for

you to know and understand. This information

relates to USER SAFETY and PREVENTING

EQUIPMENT PROBLEMS. To help you recognize this information, we use the following symbols. Please pay particular attention to these

sections.

A WARNING!A WARNING!

A WARNING!

A WARNING!A WARNING!

to a situation that might cause serious injuryto a situation that might cause serious injury

to a situation that might cause serious injury

to a situation that might cause serious injuryto a situation that might cause serious injury

if instructions are not followed.if instructions are not followed.

if instructions are not followed.

if instructions are not followed.if instructions are not followed.

A CAUTION! states information that tellsA CAUTION! states information that tells

A CAUTION! states information that tells

A CAUTION! states information that tellsA CAUTION! states information that tells

how to prevent damage to equipment or howhow to prevent damage to equipment or how

how to prevent damage to equipment or how

how to prevent damage to equipment or howhow to prevent damage to equipment or how

to avoid a situation that might cause minorto avoid a situation that might cause minor

to avoid a situation that might cause minor

to avoid a situation that might cause minorto avoid a situation that might cause minor

injury.injury.

injury.

injury.injury.

states information to alert youstates information to alert you

states information to alert you

states information to alert youstates information to alert you

> The user

the Safety Section in this manual and the

ITW Ransburg safety literature therein identified.

> This manual

oughly understood by

operate, clean or maintain this equipment!

Special care should be taken to ensure that

WARNINGSWARNINGS

the

WARNINGS and safety requirements

WARNINGSWARNINGS

for operating and servicing the equipment

are followed. The user should be aware of

and adhere to

codes and ordinances as well as

33 SAFETY STANDARD, 33 SAFETY STANDARD,

33 SAFETY STANDARD, prior to install-

33 SAFETY STANDARD, 33 SAFETY STANDARD,

ing, operating, and/or servicing this equipment.

W A R N I N GW A R N I N G

W A R N I N G

W A R N I N GW A R N I N G

!!

!

!!

MUSTMUST

MUST read and be familiar with

MUSTMUST

MUSTMUST

MUST be read and thor-

MUSTMUST

ALLALL

ALL personnel who

ALLALL

ALLALL

ALL local building and fire

ALLALL

NFPA-NFPA-

NFPA-

NFPA-NFPA-

A NOTE is information relevant to the pro-A NOTE is information relevant to the pro-

A NOTE is information relevant to the pro-

A NOTE is information relevant to the pro-A NOTE is information relevant to the procedure in progress.cedure in progress.

cedure in progress.

cedure in progress.cedure in progress.

While this manual lists standard specifications

and service procedures, some minor deviations

may be found between this literature and your

equipment. Differences in local codes and plant

requirements, material delivery requirements, etc.,

make such variations inevitable. Compare this

manual with your system installation drawings

and appropriate ITW Ransburg equipment

manuals to reconcile such differences.

Careful study and continued use of this manual will

provide a better understanding of the equipment

and process, resulting in more efficient operation,

longer trouble-free service and faster, easier

troubleshooting. If you do not have the manuals

and safety literature for your Ransburg system,

contact your local ITW Ransburg representative

or ITW Ransburg.

W A R N I N GW A R N I N G

W A R N I N G

W A R N I N GW A R N I N G

!!

!

!!

> The hazards shown on the following page

may occur during the normal use of this

equipment. Please read the hazard chart

beginning on page 2.

11

1

11

AA-99-01.1

EFM(D) Solventborne Robotic Atomizers - Safety

AREAAREA

AREA

AREAAREA

Tells where hazards

may occur.

Spray AreaSpray Area

Spray Area

Spray AreaSpray Area

HAZARDHAZARD

HAZARD

HAZARDHAZARD

Tells what the hazard is.

Fire Hazard

Improper or inadequate operation

and maintenance procedures will

cause a fire hazard.

Protection against inadvertent

arcing that is capable of causing

fire or explosion is lost if any safety

interlocks are disabled during

operation. Frequent power supply

shutdown indicates a problem in

the system requiring correction.

SAFEGUARDSSAFEGUARDS

SAFEGUARDS

SAFEGUARDSSAFEGUARDS

Tells how to avoid the hazard.

Fire extinguishing equipment must be present in the

spray area and tested periodically.

Spray areas must be kept clean to prevent the

accumulation of combustible residues.

Smoking must never be allowed in the spray area.

The high voltage supplied to the atomizer must be

turned off prior to cleaning, flushing or maintenance.

When using solvents for cleaning:

Those used for equipment flushing should have flash

points equal to or higher than those of the coating

material.

Those used for general cleaning must have flash

points above 100°F (37.8°C).

Spray booth ventilation must be kept at the rates

required by NFPA-33, OSHA, and local codes. In

addition, ventilation must be maintained during

cleaning operations using flammable or combustible

solvents.

Electrostatic arcing must be prevented.

Test only in areas free of combustible material.

Testing may require high voltage to be on, but only as

instructed.

Non-factory replacement parts or unauthorized

equipment modifications may cause fire or injury.

If used, the key switch bypass is intended for use only

during setup operations. Production should never be

done with safety interlocks disabled.

Never use equipment intended for use in waterborne

installations to spray solvent based materials.

The paint process and equipment should be set up

and operated in accordance with NFPA-33, NEC, and

OSHA requirements.

AA-99-01.1

22

2

22

EFM(D) Solventborne Robotic Atomizers - Safety

AREAAREA

AREA

AREAAREA

Tells where hazards

may occur.

General UseGeneral Use

General Use

General UseGeneral Use

andand

and

andand

MaintenanceMaintenance

Maintenance

MaintenanceMaintenance

ElectricalElectrical

Electrical

ElectricalElectrical

EquipmentEquipment

Equipment

EquipmentEquipment

HAZARDHAZARD

HAZARD

HAZARDHAZARD

Tells what the hazard is.

Improper operation or maintenance

may create a hazard.

Personnel must be properly trained

in the use of this equipment.

High voltage equipment is utilized.

Arcing in areas of flammable or

combustible materials may occur.

Personnel are exposed to high

voltage during operation and

maintenance.

Protection against inadvertent

arcing that may cause a fire or

explosion is lost if safety circuits

are disabled during operation.

Frequent power supply shut-down

indicates a problem in the system

which requires correction.

An electrical arc can ignite coating

materials and cause a fire or

explosion.

SAFEGUARDSSAFEGUARDS

SAFEGUARDS

SAFEGUARDSSAFEGUARDS

Tells how to avoid the hazard.

Personnel must be given training in accordance with

the requirements of NFPA-33.

Instructions and safety precautions must be read and

understood prior to using this equipment.

Comply with appropriate local, state, and national

codes governing ventilation, fire protection, operation

maintenance, and housekeeping. Reference OSHA,

NFPA-33, and your insurance company requirements.

The power supply, optional remote control cabinet,

and all other electrical equipment must be located

outside Class I or II, Division 1 and 2 hazardous

areas. Refer to NFPA-33.

Turn the power supply OFF before working on the

equipment.

Test only in areas free of flammable or combustible

material.

Testing may require high voltage to be on, but only as

instructed.

Production should never be done with the safety

circuits disabled.

Before turning the high voltage on, make sure no

objects are within the sparking distance.

Explosion Hazard /Explosion Hazard /

Explosion Hazard /

Explosion Hazard /Explosion Hazard /

IncompatibleIncompatible

Incompatible

IncompatibleIncompatible

MaterialsMaterials

Materials

MaterialsMaterials

33

3

33

Halogenated hydrocarbon solvents

for example: methylene chloride

and 1,1,1,-Trichloroethane are not

chemically compatible with the

aluminum that might be used in

many system components. The

chemical reaction caused by these

solvents reacting with aluminum

can become violent and lead to an

equipment explosion.

Aluminum is widely used in other spray application

equipment - such as material pumps, regulators,

triggering valves, etc. Halogenated hydrocarbon

solvents must never be used with aluminum equipment during spraying, flushing, or cleaning. Read the

label or data sheet for the material you intend to spray.

If in doubt as to whether or not a coating or cleaning

material is compatible, contact your material supplier. Any other type of solvent may be used with

aluminum equipment.

AA-99-01.1

EFM(D) Solventborne Robotic Atomizers - Safety

AREAAREA

AREA

AREAAREA

Tells where hazards

may occur.

Toxic SubstancesToxic Substances

Toxic Substances

Toxic SubstancesToxic Substances

Spray Area /Spray Area /

Spray Area /

Spray Area /Spray Area /

High VoltageHigh Voltage

High Voltage

High VoltageHigh Voltage

EquipmentEquipment

Equipment

EquipmentEquipment

HAZARDHAZARD

HAZARD

HAZARDHAZARD

Tells what the hazard is.

Certain material may be harmful if

inhaled, or if there is contact with

the skin.

There is a high voltage device that

can induce an electrical charge on

objects which is capable of igniting

coating materials.

Inadequate grounding will cause a

spark hazard. A spark can ignite

many coating materials and cause

a fire or explosion.

SAFEGUARDSSAFEGUARDS

SAFEGUARDS

SAFEGUARDSSAFEGUARDS

Tells how to avoid the hazard.

Follow the requirements of the Material Safety Data

Sheet supplied by coating material manufacturer.

Adequate exhaust must be provided to keep the air

free of accumulations of toxic materials.

Use a mask or respirator whenever there is a chance

of inhaling sprayed materials. The mask must be

compatible with the material being sprayed and its

concentration. Equipment must be as prescribed by

an industrial hygienist or safety expert, and be

NIOSH approved.

Parts being sprayed must be supported on conveyors

or hangers and be grounded. The resistance between

the part and ground must not exceed 1 megohm.

All electrically conductive objects in the spray area,

with the exception of those objects required by the

process to be at high voltage, must be grounded.

Any person working in the spray area must be

grounded.

Robot Work Area -Robot Work Area -

Robot Work Area -

Robot Work Area -Robot Work Area General Use andGeneral Use and

General Use and

General Use andGeneral Use and

MaintenanceMaintenance

Maintenance

MaintenanceMaintenance

Personnel SafetyPersonnel Safety

Personnel Safety

Personnel SafetyPersonnel Safety

Unless specifically approved for use in hazardous

locations, the power supply and other electrical

control equipment must not be used in Class 1,

Division 1 or 2 locations.

Improper use or maintenance can

lead to hazardous conditions,

particularly from unexpected robot

manipulator movement.

Skin puncturing by sharp electrode. Take precautions to see that flesh is not punctured

Applicator adjustments or maintenance should be

done after the robot is taken out of service. Do not

adjust or repair the applicator if the robot is operating

or standing ready to start.

Refer to robot operating instructions for the procedures

to take the robot out of service.

by sharp electrode.

AA-99-01.1

44

4

44

EFM(D) Solventborne Robotic Atomizers - Introduction

INTRODUCTIONINTRODUCTION

INTRODUCTION

INTRODUCTIONINTRODUCTION

THE ITW RANSBURGTHE ITW RANSBURG

THE ITW RANSBURG

THE ITW RANSBURGTHE ITW RANSBURG

ELECTROSTELECTROST

ELECTROST

ELECTROSTELECTROST

PROCESSPROCESS

PROCESS

PROCESSPROCESS

This process is a method for electrostatically

applying coatings to objects. A power supply

produces a high voltage charge which is supplied

to the applicator, creating an electrostatic field

between the applicator and the target object. The

target is electrostatically grounded through its

support which may be either stationary or moving.

A regulated fluid system delivers coating material

to the applicator, where it is atomized forming a

spray mist. There, under the influence of the

electrostatic field, the atomized coating becomes

electrostatically charged. The charged particles

are attracted to and deposited on the grounded

target object. The forces between the charged

particles and the target are sufficient to turn

overspray around and deposit it on the back

surface of the target. Therefore, a higher

percentage of the spray is deposited.

AA

TICTIC

A

TIC

AA

TICTIC

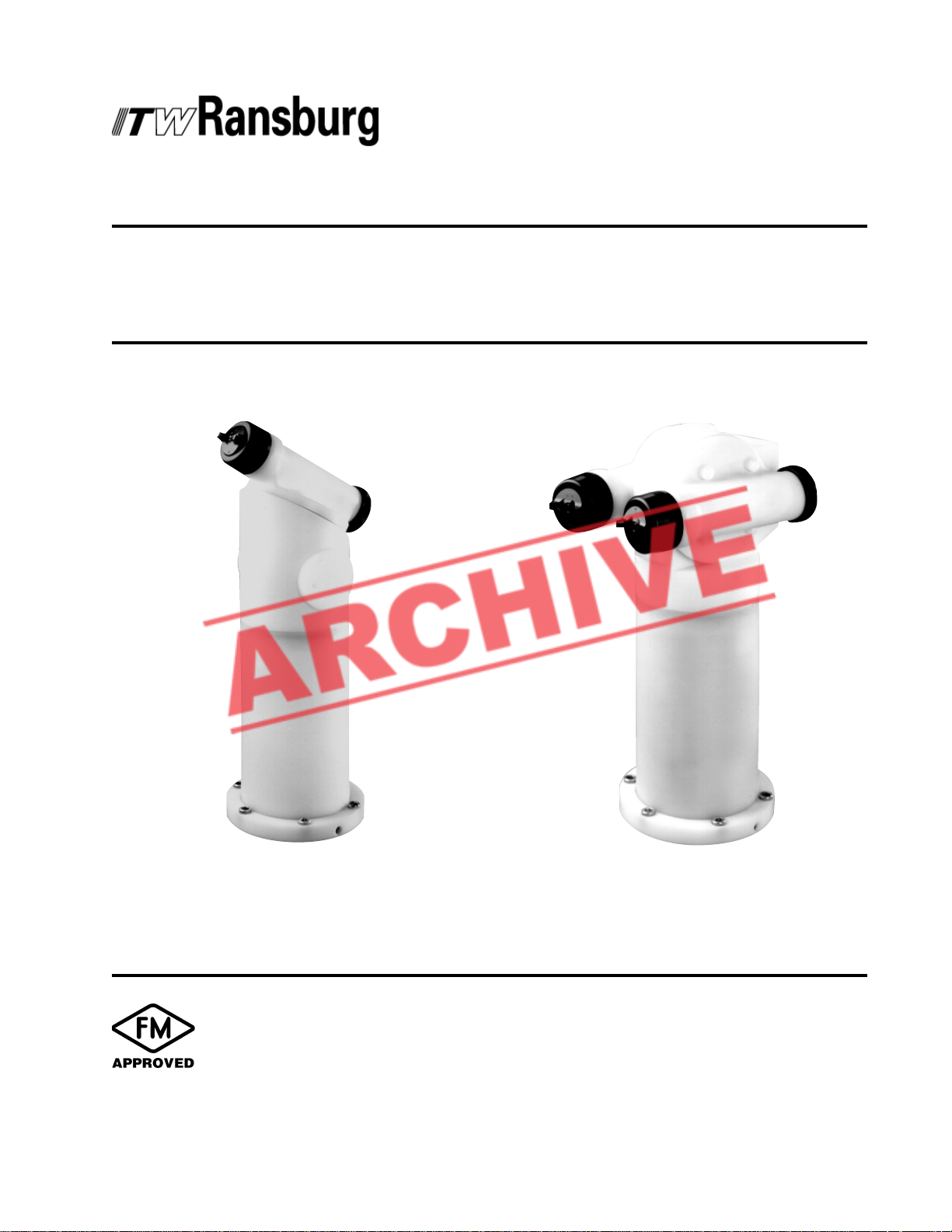

There are two single-head models of the EFM

Applicator. Each model differs in the applicator to

axis orientation of the spray head, these models

are:

76480-02 EFM 60° Applicator

76482-02 EFM 90° Applicator

Two dual-head versions of the EFM Solventborne

Applicator are also available, designated EFMDTM.

The dual-head version is identical to the EFM

applicator with the exception of an additional spray

head mounted to the applicator body. EFMD

Solventborne Applicators are primarily used where

high volume fluid delivery is required. These

applicators supply twice the fluid delivery over

Single-Head EFM Solventborne Applicators. The

EFMD Solventborne Applicator is available in two

different configurations as follows:

76485-02 EFMD 60° Applicator

76488-02 EFMD 90° Applicator

Both EFM and EFMD Solventborne Applicators

are comprised of five major sections:

EFM AND EFMDEFM AND EFMD

EFM AND EFMD

EFM AND EFMDEFM AND EFMD

SOLSOL

SOL

SOLSOL

APPLICAAPPLICA

APPLICA

APPLICAAPPLICA

The EFMTM Solventborne Applicator line consists

of single and dual-headed 100 kV automatic

electrostatic spray applicators. Developed for

use on robots or reciprocators, the EFM

solventborne applicator incorporates a quickdisconnect manifold and swivel tubing connections

to minimize downtime. Internal fluid and air

solenoids and an internal high voltage power supply

provide the user a compact, efficient tool for the

application of electrostatic coatings. Because this

is a grounded fluid system, the EFM solventborne

applicator is highly suitable for applying a wide

range of solvent reduced coatings such as enamels,

lacquers, two-component and other such coatings.

55

5

55

VENTBORNEVENTBORNE

VENTBORNE

VENTBORNEVENTBORNE

TT

ORSORS

T

ORS

TT

ORSORS

1. Spray head(s)

2. Valve manifold assembly

3. Quick-disconnect base manifold

assembly

4. Robot-mounted manifold assembly

5. High voltage cascade.

The spray head(s) and valve manifold contain the

fluid, air, and high voltage passages. Although the

quick-disconnect base manifold and robotmounted manifold are fabricated from aluminum,

all fluid passages are contained within stainless

steel and nylon fittings and are compatible with

halogenated hydrocarbon solvents. The robot

manifold incorporates stainless steel swivel fluid

connections. The swivel connections reduce

stress on the fluid lines minimizing breakage. No

aluminum parts are exposed to the fluid path on

either manifold. The high voltage cascade is

entirely encapsulated with a solvent resistant

epoxy.

AA-99-01.1

EFM(D) Solventborne Robotic Atomizers - Introduction

The high voltage supply for the EFM and EFMD

applicators consists of two major components:

The MicroPakTM Power Supply Control Unit

(LECU5004), and the HP404 Cascade (75933-

00).

The MicroPak power supply control unit provides

a low voltage signal through the robot manifold to

the EFM or EFMD spray applicator. The high

voltage cascade located within the applicator

converts the low voltage DC signal to a high

voltage electrostatic output. See

Control Unit Service ManualControl Unit Service Manual

Control Unit Service Manual

Control Unit Service ManualControl Unit Service Manual

LECU5004, MicroPak control unit.

SPECIFICASPECIFICA

SPECIFICA

SPECIFICASPECIFICA

Robot/Mounting Compatibility:Robot/Mounting Compatibility:

Robot/Mounting Compatibility:

Robot/Mounting Compatibility:Robot/Mounting Compatibility:

Applicator ControlApplicator Control

Applicator Control

Applicator ControlApplicator Control

Unit:Unit:

Unit:

Unit:Unit:

TIONSTIONS

TIONS

TIONSTIONS

ABB Robotics

Fanuc P150/155/200

Motion Machine Gun Bar

LECU5004 MicroPak

control unit

for details of the

MicroPakMicroPak

MicroPak

MicroPakMicroPak

Output Voltage:Output Voltage:

Output Voltage: 30-100 kV

Output Voltage:Output Voltage:

Output Range:Output Range:

Output Range: 0-125 μA

Output Range:Output Range:

SolenoidSolenoid

Solenoid

SolenoidSolenoid

Parameters:Parameters:

Parameters:

Parameters:Parameters:

Paint Flow Rate:Paint Flow Rate:

Paint Flow Rate:

Paint Flow Rate:Paint Flow Rate:

Operating Air PressuresOperating Air Pressures

Operating Air Pressures

Operating Air PressuresOperating Air Pressures

Atomizing Air:Atomizing Air:

Atomizing Air: 100 psig max.

Atomizing Air:Atomizing Air:

Fan Air:Fan Air:

Fan Air:

Fan Air:Fan Air:

Trigger Air:Trigger Air:

Trigger Air: 70 psig min./100 psig max.

Trigger Air:Trigger Air:

Regulator Pilot:Regulator Pilot:

Regulator Pilot: 60 psig max.

Regulator Pilot:Regulator Pilot:

Dump Pilot:Dump Pilot:

Dump Pilot:

Dump Pilot:Dump Pilot:

Operating FluidOperating Fluid

Operating Fluid

Operating FluidOperating Fluid

Pressure: Pressure:

Pressure:

Pressure: Pressure:

Robot Manifold Tubing RequirementsRobot Manifold Tubing Requirements

Robot Manifold Tubing Requirements

Robot Manifold Tubing RequirementsRobot Manifold Tubing Requirements

Atomizing Air:Atomizing Air:

Atomizing Air:

Atomizing Air:Atomizing Air:

Fan Air:Fan Air:

Fan Air: 1/2" OD Nylon

Fan Air:Fan Air:

15.5 VDC@0.035A, 1/2W

Variable to 1500 cc/min.

100 psig max.

60 psig max.

300 psig max.

1/2" OD Nylon

WeightWeight

Weight

WeightWeight

Single-Headed:Single-Headed:

Single-Headed:

Single-Headed:Single-Headed:

Dual-Headed:Dual-Headed:

Dual-Headed: 76485-02 (60°) 9.50 lbs.

Dual-Headed:Dual-Headed:

Manifold:Manifold:

Manifold: 76494-XX 2.00lbs.

Manifold:Manifold:

LengthLength

Length

LengthLength

Single-Headed:Single-Headed:

Single-Headed: 76480-02 (60°) 15-5/8"

Single-Headed:Single-Headed:

Dual-Headed:Dual-Headed:

Dual-Headed:

Dual-Headed:Dual-Headed:

Manifold:Manifold:

Manifold:

Manifold:Manifold:

76480-02 (60°) 8.25 lbs.

76482-02 (90°) 8.25 lbs.

76488-02 (90°) 9.50 lbs.

(No tubing or Cable)

76482-02 (90°) 14-1/2"

76485-02 (60°) 13-7/8"

76488-02 (90°) 13-3/8"

76494-16X 16'

76494-25X 25'

76494-50X 50'

Trigger Air:Trigger Air:

Trigger Air: 3/16" OD Nylon

Trigger Air:Trigger Air:

Regulator Pilot:Regulator Pilot:

Regulator Pilot: 3/16" OD Nylon

Regulator Pilot:Regulator Pilot:

Dump Pilot:Dump Pilot:

Dump Pilot: 3/16" OD Nylon

Dump Pilot:Dump Pilot:

Fluid:Fluid:

Fluid:

Fluid:Fluid:

Polyethylene: 1/4" or 3/16" ID

Teflon: 1/4" or 3/16" ID

Dump:Dump:

Dump:

Dump:Dump:

Polyethylene: 1/4" or 3/16" ID

Teflon: 1/4" or 3/16" ID

* See "Manifold Selection Guide" in the "Introductin"

section for proper manifold tubing size, material length

order number.

AA-99-01.1

66

6

66

EFM(D) Solventborne Robotic Atomizers - Introduction

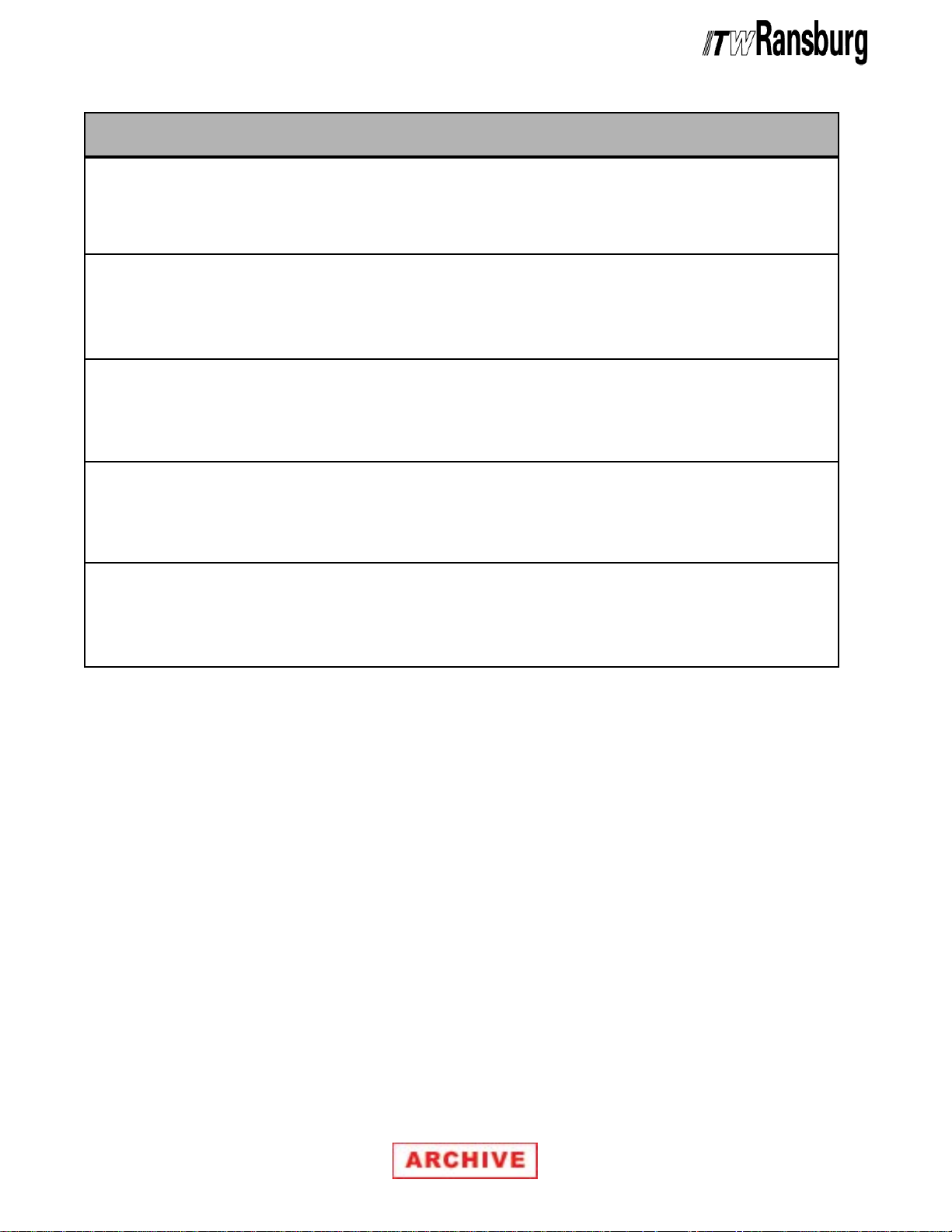

MANIFOLD SELECTION GUIDEMANIFOLD SELECTION GUIDE

MANIFOLD SELECTION GUIDE

MANIFOLD SELECTION GUIDEMANIFOLD SELECTION GUIDE

WITH 3/16" ID POLYETHYLENE PAINT AND DUMP TUBING, ORDER:WITH 3/16" ID POLYETHYLENE PAINT AND DUMP TUBING, ORDER:

WITH 3/16" ID POLYETHYLENE PAINT AND DUMP TUBING, ORDER:

WITH 3/16" ID POLYETHYLENE PAINT AND DUMP TUBING, ORDER:WITH 3/16" ID POLYETHYLENE PAINT AND DUMP TUBING, ORDER:

76494-16A for 16' length tubing

76494-25A for 25' length tubing

76494-50A for 50' length tubing

WITH 1/4" ID TEFLON PAINT AND DUMP TUBING, ORDER:WITH 1/4" ID TEFLON PAINT AND DUMP TUBING, ORDER:

WITH 1/4" ID TEFLON PAINT AND DUMP TUBING, ORDER:

WITH 1/4" ID TEFLON PAINT AND DUMP TUBING, ORDER:WITH 1/4" ID TEFLON PAINT AND DUMP TUBING, ORDER:

76494-16B for 16' length tubing

76494-25B for 25' length tubing

76494-50B for 50' length tubing

WITH 3/16" ID TEFLON PAINT AND DUMP TUBING, ORDER:WITH 3/16" ID TEFLON PAINT AND DUMP TUBING, ORDER:

WITH 3/16" ID TEFLON PAINT AND DUMP TUBING, ORDER:

WITH 3/16" ID TEFLON PAINT AND DUMP TUBING, ORDER:WITH 3/16" ID TEFLON PAINT AND DUMP TUBING, ORDER:

76494-16C for 16' length tubing

76494-25C for 25' length tubing

76494-50C for 50' length tubing

WITH 1/4" ID POLYETHYLENE PAINT AND DUMP TUBING, ORDER:WITH 1/4" ID POLYETHYLENE PAINT AND DUMP TUBING, ORDER:

WITH 1/4" ID POLYETHYLENE PAINT AND DUMP TUBING, ORDER:

WITH 1/4" ID POLYETHYLENE PAINT AND DUMP TUBING, ORDER:WITH 1/4" ID POLYETHYLENE PAINT AND DUMP TUBING, ORDER:

76494-16D for 16' length tubing

76494-25D for 25' length tubing

76494-50D for 50' length tubing

WITH 3/16" ID TEFLON PAINT AND 1/4" ID TEFLON DUMP TUBING, ORDER:WITH 3/16" ID TEFLON PAINT AND 1/4" ID TEFLON DUMP TUBING, ORDER:

WITH 3/16" ID TEFLON PAINT AND 1/4" ID TEFLON DUMP TUBING, ORDER:

WITH 3/16" ID TEFLON PAINT AND 1/4" ID TEFLON DUMP TUBING, ORDER:WITH 3/16" ID TEFLON PAINT AND 1/4" ID TEFLON DUMP TUBING, ORDER:

76494-16E for 16' length tubing

76494-25E for 25' length tubing

76494-50E for 50' length tubing

77

7

77

AA-99-01.1

EFM(D) Solventborne Robotic Atomizers - Introduction

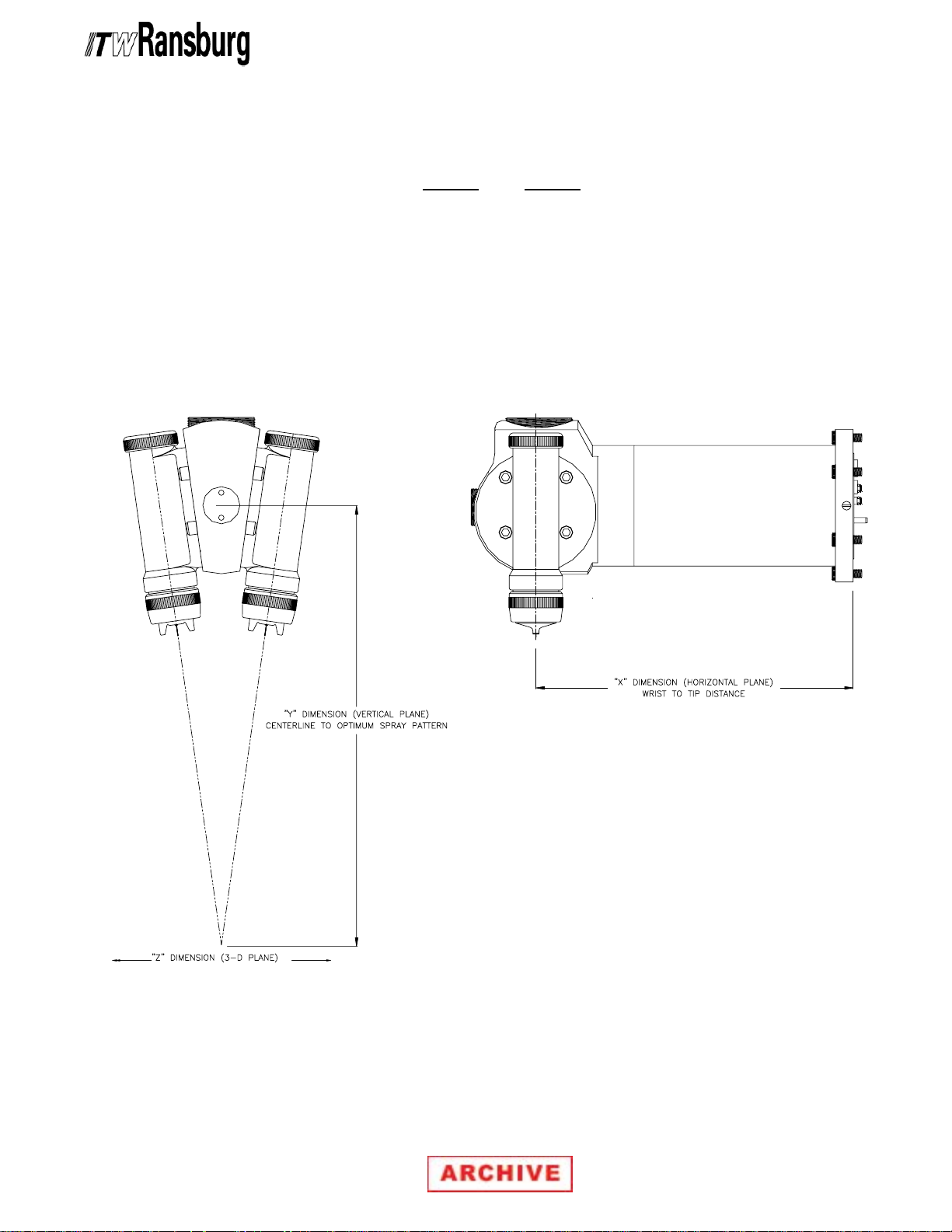

To allow for ease of configuration, operation, and modification of robot teach patterns, the following

spray point verticies are provided. Refer to Figure 1 for explanation of coordinates.

XX

X

XX

76480-02 EFM-6076480-02 EFM-60

76480-02 EFM-60° 14.812 13.397

76480-02 EFM-6076480-02 EFM-60

76482-02 EFM-9076482-02 EFM-90

76482-02 EFM-90° 12.894 14.313

76482-02 EFM-9076482-02 EFM-90

76485-02 EFMD-6076485-02 EFMD-60

76485-02 EFMD-60° 13.252 14.738

76485-02 EFMD-6076485-02 EFMD-60

76488-02 EFMD-9076488-02 EFMD-90

76488-02 EFMD-90° 11.240 15.078

76488-02 EFMD-9076488-02 EFMD-90

Y Y

Y

Y Y

AA-99-01.1

Figure 1: Applicator Tool-Point RepresentationFigure 1: Applicator Tool-Point Representation

Figure 1: Applicator Tool-Point Representation

Figure 1: Applicator Tool-Point RepresentationFigure 1: Applicator Tool-Point Representation

88

8

88

EFM(D) Solventborne Robotic Atomizers - Installation

INSTINST

INST

INSTINST

EFM AND EFMDEFM AND EFMD

EFM AND EFMD

EFM AND EFMDEFM AND EFMD

ROBOTIC AROBOTIC A

ROBOTIC A

ROBOTIC AROBOTIC A

INSTINST

INST

INSTINST

This information is intended

general installation parameters of this product

and, where applicable, its working relationship to

other ITW Ransburg system components in typical

use. Each installation is unique and should be

directed by an authorized ITW Ransburg

representative or conducted from the ITW

Ransburg installation drawings provided for your

particular installation.

POWER SUPPLPOWER SUPPL

POWER SUPPL

POWER SUPPLPOWER SUPPL

ASSEMBLASSEMBL

ASSEMBL

ASSEMBLASSEMBL

ALLAALLA

ALLA

ALLAALLA

ALLAALLA

ALLA

ALLAALLA

TIONTION

TION

TIONTION

TT

OMIZEROMIZER

T

OMIZER

TT

OMIZEROMIZER

TIONTION

TION

TIONTION

YY

Y

YY

ONLYONLY

ONLY to indicate the

ONLYONLY

YY

Y

YY

NOTESNOTES

NOTES

NOTESNOTES

Refer to the ITW Ransburg Service Manual

MicroPak Control UnitMicroPak Control Unit

MicroPak Control Unit

MicroPak Control UnitMicroPak Control Unit

regarding power supply installation.

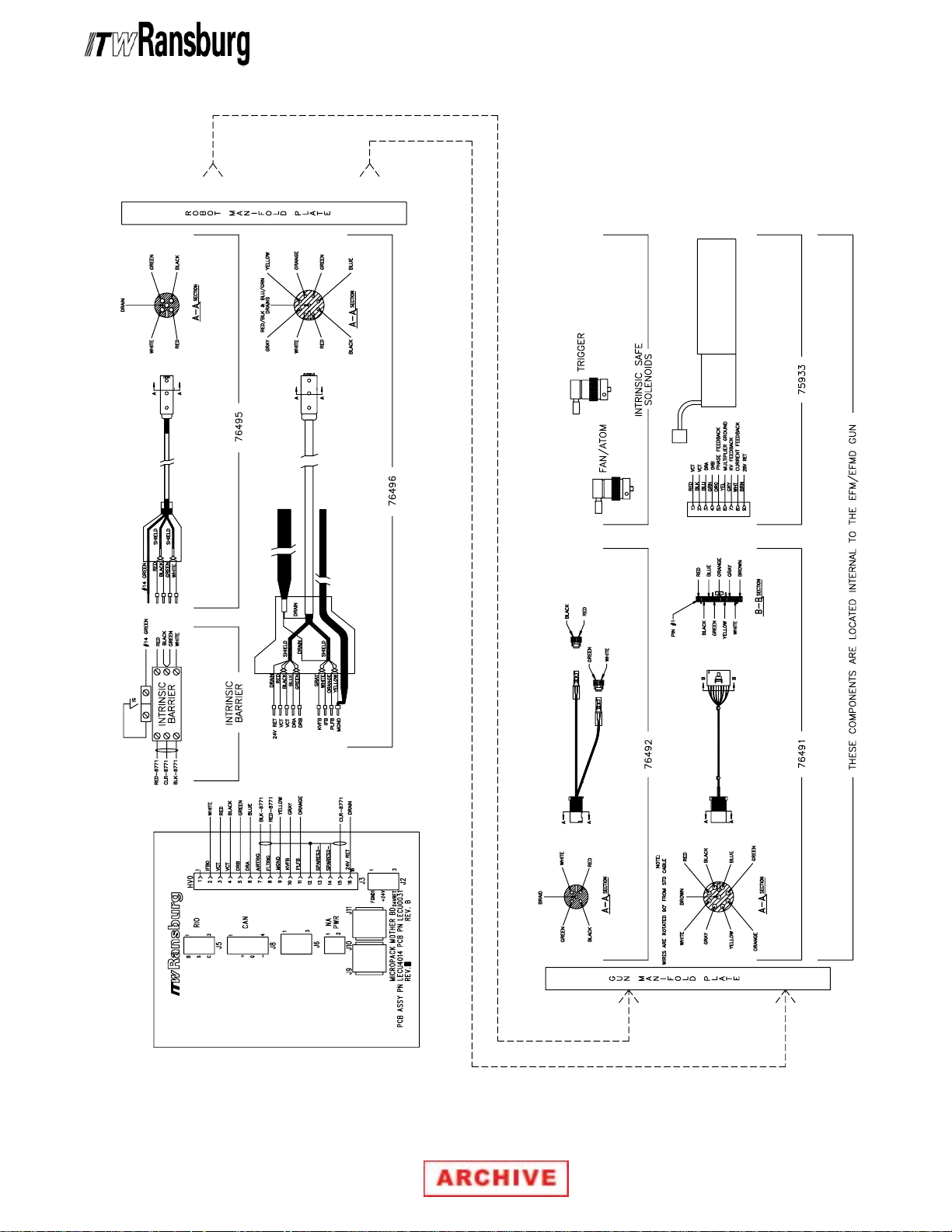

Two low voltage control cables, 76495 and 76496,

connect from the Output terminal connection

(J3), located on the back of the power supply

assembly. These cables connect from the terminal

block (J3) to the robot manifold plate.

W A R N I N GW A R N I N G

W A R N I N G

W A R N I N GW A R N I N G

!!

!

!!

> The power supply

outside the

OSHA and NFPA-33).

> User should be aware of, and adhere to,

all local fire codes and ordinances.

> The user

disconnect between the power source and the

power supply which complies with appropriate codes.

HAZARDOUSHAZARDOUS

HAZARDOUS area (Reference

HAZARDOUSHAZARDOUS

MUSTMUST

MUST provide a properly fused

MUSTMUST

, for complete information

MUSTMUST

MUST be located

MUSTMUST

99

9

99

AA-99-01.1

EFM(D) Solventborne Robotic Atomizers - Installation

AA-99-01.1

Figure 2: Low Voltage Cable ConnectionsFigure 2: Low Voltage Cable Connections

Figure 2: Low Voltage Cable Connections

Figure 2: Low Voltage Cable ConnectionsFigure 2: Low Voltage Cable Connections

1010

10

1010

EFM(D) Solventborne Robotic Atomizers - Installation

ROBOT MANIFOLDROBOT MANIFOLD

ROBOT MANIFOLD

ROBOT MANIFOLDROBOT MANIFOLD

ASSEMBLASSEMBL

ASSEMBL

ASSEMBLASSEMBL

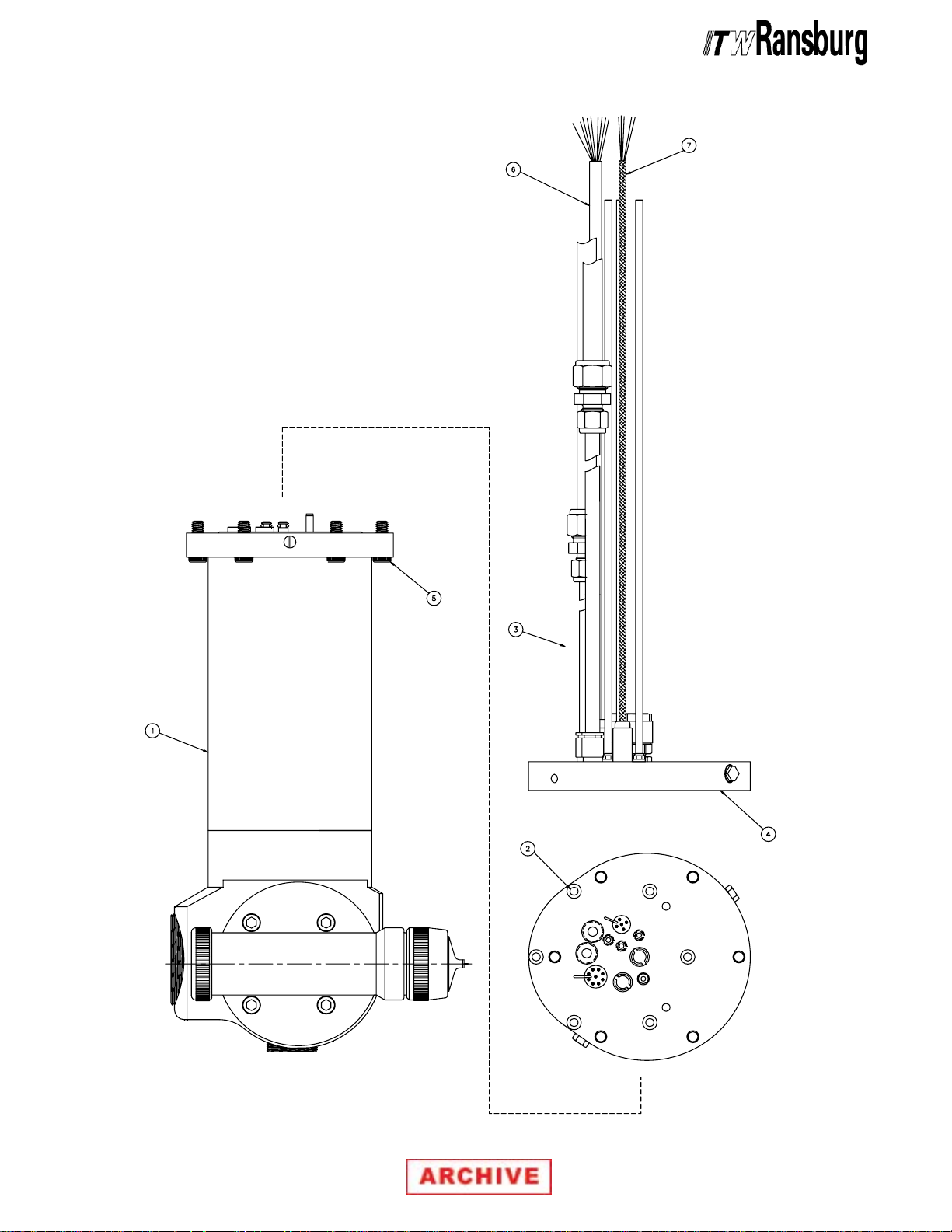

(See Figure 3)(See Figure 3)

(See Figure 3)

(See Figure 3)(See Figure 3)

Bundle the seven lengths of tubing along with the

two low voltage power cables [6 & 7] and route

them through the center of the robot face plate past

the horizontal arm to the bulkhead bracket. Use

the six 5mm x 20mm socket head cap screws [2]

included with the robot manifold assembly to attach

the manifold assembly to the face plate of the

robot.

Connect the tubes to the appropriate fittings on the

bulkhead bracket. Connect low voltage power

cables [6 & 7] of the robot manifold assembly to the

MicroPak Controller. Shown is the version used

with the P-150 series robots which connects to a

terminal strip.

If a terminal strip or connectors are used at the

bulkhead plates, you must run the exact same

cable from the terminal strip back to the MicroPak

controller. Intrinsic safety rules must be followed

when running these cables. See "Intrinisic Safe

Wiring" in the "Operation" section of this manual.

!!

!

!!

YY

Y

YY

C A U T I O NC A U T I O N

C A U T I O N

C A U T I O NC A U T I O N

EFM SPRAEFM SPRA

EFM SPRA

EFM SPRAEFM SPRA

APPLICAAPPLICA

APPLICA

APPLICAAPPLICA

(See Figure 3)(See Figure 3)

(See Figure 3)

(See Figure 3)(See Figure 3)

Attach EFM spray applicator [1])to robot manifold

plate [4] with six (6) 5/16-18 x 1 inch hex socket

screws [5] included with each applicator.

Nylon guide pins (A10004-00) and nylon hex

socket screws (EMF-204-1) are offered as an

option. These nylon parts may be used in place of

the metal hex socket screws and metal guide pins.

The plastic parts are designed to break quickly if

aa applicator crash occurs. Possible applicator

or robot damage may be avoided if the spray

applicator breaks away from the robot wrist during

contact with the workpiece.

W A R N I N GW A R N I N G

W A R N I N G

W A R N I N GW A R N I N G

!!

!

!!

> Install and route the hoses and cable so

that they are

excess of 120

cable bends are

(15cm) radius and are not subjected to more

than 360° of torsional twist. Failure to comply

with these parameters could cause equipment

malfunctions that might create

CONDITIONS!CONDITIONS!

CONDITIONS!

CONDITIONS!CONDITIONS!

YY

Y

YY

TT

OROR

T

OR

TT

OROR

NOTNOT

NOT exposed to temperatures in

NOTNOT

° F. Ensure that all hose and

NOT LESS THANNOT LESS THAN

NOT LESS THAN a 6 inch

NOT LESS THANNOT LESS THAN

HAZARDOUSHAZARDOUS

HAZARDOUS

HAZARDOUSHAZARDOUS

> Leave 12-24 inches of extra length on all

lines to prevent extreme tension being applied

to these lines during robot movement.

1111

11

1111

AA-99-01.1

EFM(D) Solventborne Robotic Atomizers - Installation

NOTES

AA-99-01.1

1212

12

1212

EFM(D) Solventborne Robotic Atomizers - Installation

1313

13

1313

Figure 3: Robot Manifold and Spray Applicator InstallationFigure 3: Robot Manifold and Spray Applicator Installation

Figure 3: Robot Manifold and Spray Applicator Installation

Figure 3: Robot Manifold and Spray Applicator InstallationFigure 3: Robot Manifold and Spray Applicator Installation

AA-99-01.1

EFM(D) Solventborne Robotic Atomizers - Installation

ROBOTROBOT

ROBOT

ROBOTROBOT

(Figure 3)(Figure 3)

(Figure 3)

(Figure 3)(Figure 3)

Item #Item #

Item #

Item #Item #

1 76488-02 EFM Spray Applicator 1

2 TR-SSF-024 5mm x 20mm Socket Head Cap Screws 6

3 76494-xx Robot Manifold Assembly 1

4 76560-01 Manifold Plate 1

5 SSF-3125 5/16-18 x 1" Hex Socket Screws 6

6 76496-xx Low Voltage Power Cable 1

7 76495-xx Intrinsic Safe Solenoid Cable 1

MANIFOLD MANIFOLD

MANIFOLD

MANIFOLD MANIFOLD

Part #Part #

Part #

Part #Part #

AND SPRA AND SPRA

AND SPRA

AND SPRA AND SPRA

DescriptionDescription

Description

DescriptionDescription

YY

APPLICA APPLICA

Y

APPLICA

YY

APPLICA APPLICA

TT

OR OR

T

OR

TT

OR OR

- P- P

- P

- P- P

ARAR

TS LISTTS LIST

AR

TS LIST

ARAR

TS LISTTS LIST

QtyQty

Qty

QtyQty

AA-99-01.1

1414

14

1414

EFM(D) Solventborne Robotic Atomizers - Operation

OPERAOPERA

OPERA

OPERAOPERA

These instructions indicate the general operating

parameters for this product in a normal working

relationship with other ITW Ransburg system

components in typical use. Each user application

is unique and operation should be initiated under

the guidance of an authorized ITW Ransburg

representative and/or be based on carefully

conducted tests and on careful observation of the

initial production characteristics.

SPRASPRA

SPRA

SPRASPRA

CONTROLSCONTROLS

CONTROLS

CONTROLSCONTROLS

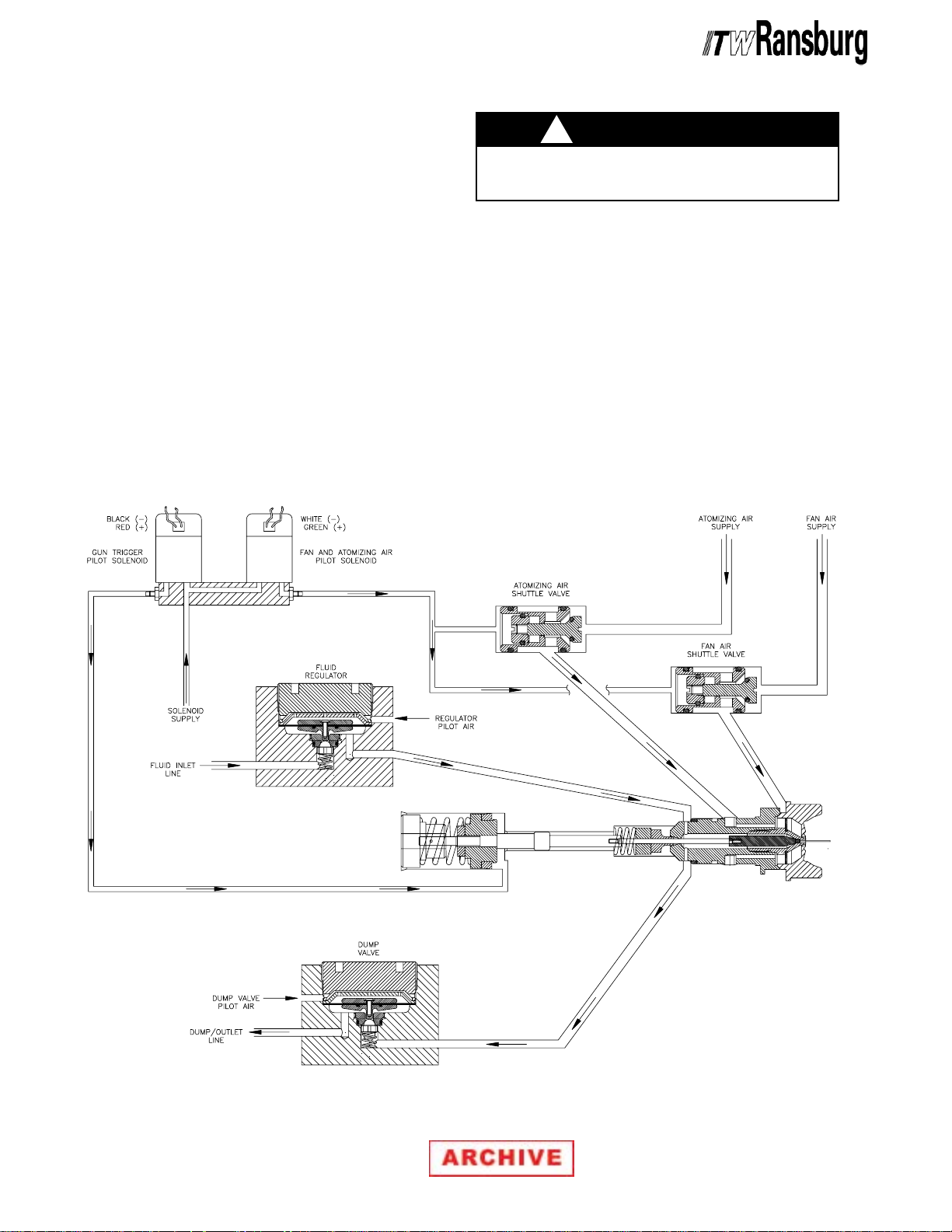

Fluid flow, trigger, dump, atomization air pressure,

and fan air pressure are all remotely controlled

from the robot PLC. Atomization air, fan air, and

fluid trigger timing are adjusted electronically from

the LECU5004 MicroPak Control Unit. Figure 4 in

the "Operation" section generalizes the function of

the air and fluid passages internal to the applicator.

POWER SUPPLPOWER SUPPL

POWER SUPPL

POWER SUPPLPOWER SUPPL

CONTROLSCONTROLS

CONTROLS

CONTROLSCONTROLS

Refer to ITW Ransburg Service Manual

Control UnitControl Unit

Control Unit

Control UnitControl Unit

power supply operation.

YY

Y

YY

TIONTION

TION

TIONTION

APPLCIA APPLCIA

APPLCIA

APPLCIA APPLCIA

, for complete information regarding

YY

Y

YY

TT

T

TT

OROR

OR

OROR

MicroPakMicroPak

MicroPak

MicroPakMicroPak

All of the display signals are buffered and

continuously available for remote panels or PLC

monitoring. There is also an array of LEDs, which

display the status of the controller for operator

convenience.

GENERALGENERAL

GENERAL

GENERALGENERAL

AND ADJUSTMENTSAND ADJUSTMENTS

AND ADJUSTMENTS

AND ADJUSTMENTSAND ADJUSTMENTS

Paint ConductivityPaint Conductivity

Paint Conductivity

Paint ConductivityPaint Conductivity

The EFM/EFMD spray applicators are capable of

spraying typical automotive and industrial solvent

base paints including metallic and mica paints.

Spray tests, however, should always be conducted

before selecting an atomizer for use with highly

conductive paints.

TT

arget Distancearget Distance

T

arget Distance

TT

arget Distancearget Distance

The distance between the applicator tip and the

article being painted should be between 10 and 14

inches. Excessive distance causes a waste of

coating material and wrap back (paint particles

being deposited on the applicator body or the robot

arm). At close distances the voltage at the tip of

the applicator will be reduced, which decreases

the charging effect of the applicator.

INFORMA INFORMA

INFORMA

INFORMA INFORMA

NOTENOTE

NOTE

NOTENOTE

TIONTION

TION

TIONTION

VV

oltageoltage

V

oltage

VV

oltageoltage

The LECU5004 MicroPak Control Unit provides a

low voltage signal to the high voltage cascade

within the spray applicator. The unit may be

configured for local mode operation. The output

voltage/current levels are set by potentiometers

on the front panel in this mode. The unit may also

be configured for remote analog control (0-10

VDC) from a PLC controller.

Display FunctionDisplay Function

Display Function

Display FunctionDisplay Function

The display board continually displays the kV and

current output information.

1515

15

1515

> When using paints with metal par-

ticles, a problem of alignment may occur. When alignment is achieved, applicator current increases to maximum and

applicator tip voltage decreases to near

zero kV. Alignment can normally be

controlled by making sure that the power

supply is turned on slightly after paint

begins to flow and by turning the power

supply off shortly before the paint stops

flowing. This timing function is controlled

by the LECU5004 MicroPak Control Unit

and is adjustable by the user. Refer to

ITW Ransburg Service Manual

MicroPak Control UnitMicroPak Control Unit

MicroPak Control Unit

MicroPak Control UnitMicroPak Control Unit

tails.

, for more de-

AA-99-01.1

EFM(D) Solventborne Robotic Atomizers - Operation

NOTENOTE

NOTE

NOTENOTE

> If alignment occurs, turning off the

power supply will not usually break the

aligned metal particles. The paint located

between the applicator and the point of

first ground must be purged from the fluid

passages before normal spray can resume.

W A R N I N GW A R N I N G

W A R N I N G

W A R N I N GW A R N I N G

!!

!

!!

> Most paints and solvents, including those

listed in "Polar and Non-Polar Solvents Chart"

in the "Maintenance" section, are toxic to a

certain degree and flammable or combustible.

Use them only in a well ventilated atmosphere.

Use protective equipment as required in the

Material Safety Data Sheet supplied with the

substance.

Fluid Flow RateFluid Flow Rate

Fluid Flow Rate

Fluid Flow RateFluid Flow Rate

Fluid flow is adjusted through the robot PLC by

varying the pilot pressure to the fluid regulator

within the EFM or EFMD spray applicator. Fluid

pressures from the circulating system may be as

high as 300 psig.

Atomizing AirAtomizing Air

Atomizing Air

Atomizing AirAtomizing Air

Adjustments are made through the robot PLC or a

manually adjustable air regulator. The lowest air

pressure required to break up the paint should be

used. Lower atomizing air pressures result in less

overspray and increased transfer efficiency.

Fan AirFan Air

Fan Air

Fan AirFan Air

Adjusting the fan air increases or decreases the

size of the spray pattern. Increasing pressure

decreases pattern size. Pattern adjustment should

be made to suit the size and shape of the object

being painted. This adjustment is made through

the robot PLC or a manually adjustable air regulator.

TT

rigger Control Airrigger Control Air

T

rigger Control Air

TT

rigger Control Airrigger Control Air

The EFM and EFMD applicators require a minimum

of 70 psig trigger control air pressure to ensure

proper operation of the applicator piston and air

shuttle valves.

TT

rigger Trigger T

T

rigger T

TT

rigger Trigger T

The LECU5004 MicroPak Control Unit provides a

means for the adjustment of the timing interval

between air, fluid, and high voltage. When the

applicator receives a trigger on signal from the

robot PLC, the air solenoid valve actuates. At the

same time the fluid solenoid valve timer is activated.

After the timer times out, the fluid solenoid and the

high voltage timer are activated. This timer delays

the start of the high voltage until after both the air

and fluid are activated.

Timing can be set in nine different timing

sequences, from a minimum of zero to a maximum

of 450 milliseconds. When the electrical signal

from the robot PLC is removed, the timing operates

in reverse. High voltage is shut off, fluid shuts off,

and, finally, the air solenoid valve shuts off. See

ITW Ransburg Service Manual

Control UnitControl Unit

Control Unit

Control UnitControl Unit

supply operation and control features.

imingiming

iming

imingiming

, MicroPak, MicroPak

, MicroPak

, MicroPak, MicroPak

, for additional information on power

> It has been observed when spraying

metallic paints that mottling (marble effect) can be reduced by increasing the

fan air pressure slightly higher than the

atomizing air.

AA-99-01.1

NOTENOTE

NOTE

NOTENOTE

1616

16

1616

EFM(D) Solventborne Robotic Atomizers - Operation

Electrostatic VElectrostatic V

Electrostatic V

Electrostatic VElectrostatic V

Normally the voltage should be set to 90 kV at the

power supply. Some conditions may dictate lower

voltage settings. If Faraday cage areas are

predominant on the item being painted, a lower

voltage setting will aid in coating these areas.

Paints having high metallic flake content will

sometimes align at high voltages. Metallic flakes,

when aligned, become a direct electrical path to

ground and will reduce tip voltage. This problem

can be minimized by making sure that the paint is

being sprayed from the applicator prior to turning

the voltage on. In some cases, a reduction in

applied voltage may be the only way to reduce

alignment.

oltageoltage

oltage

oltageoltage

W A R N I N GW A R N I N G

W A R N I N G

W A R N I N GW A R N I N G

!!

!

!!

> If target distance is less than 4 inches, an

arc could occur.

1717

17

1717

Figure 4: Simplified Air and Fluid Flow Passage LayoutFigure 4: Simplified Air and Fluid Flow Passage Layout

Figure 4: Simplified Air and Fluid Flow Passage Layout

Figure 4: Simplified Air and Fluid Flow Passage LayoutFigure 4: Simplified Air and Fluid Flow Passage Layout

AA-99-01.1

EFM(D) Solventborne Robotic Atomizers - Operation

INTRINSIC SAFE WIRINGINTRINSIC SAFE WIRING

INTRINSIC SAFE WIRING

INTRINSIC SAFE WIRINGINTRINSIC SAFE WIRING

Wiring PracticesWiring Practices

Wiring Practices

Wiring PracticesWiring Practices

Instrinsically safe wiring must be separated from

non-intrinsically safe wiring in order to prevent the

transfer of unsafe levels of energy to the hazardous

area. The following are a few recommended

practices:

Safe AreaSafe Area

Safe Area

Safe AreaSafe Area

In the non-hazardous area, intrinsically safe and

non-intrinsically safe wiring must be separated by

one of the following methods:

1. Raceway or conduit

2. Grounded metal or insulated partition between

the intrinsically safe and non-intrinsically safe

wiring

NOTENOTE

NOTE

NOTENOTE

> These sections are to be used as

guidelines or recommendations only. For

rules and more detailed practices, refer

to National Electrical Code.

Hazardous AreaHazardous Area

Hazardous Area

Hazardous AreaHazardous Area

In the hazardous area, all intrinsically safe and

non-intrinsically safe wiring must be separated by

the same methods suggested for the safe area.

However, the following requirements must also be

followed:

1. In enclosures containing multiple intrinsically

safe circuits, the terminals for connection must

have a spacing of at least 6mm or a grounded or

insulated partition between the circuits.

2. Devices like limit switches or pressure switches

must not contain a non-intrinsically safe circuit in

addition to an intrinsically safe circuit unless:

3. Airspace of at least 50mm (2 inches) between

intrinsically safe and non-intrinsically safe wiring

and the wires must be tied down to prevent

loosening and shorting together.

The same methods are used for intrinsically safe

and non-intrinsically safe terminals.

RequirementsRequirements

Requirements

RequirementsRequirements

Intrinsically safe wiring must be identified, preferably by color coding of light blue. If light blue is

used on non-intrinsically safe wiring, the intrinsically safe wiring may be marked by other means

such as tagging. This alternate means, however,

must be visible after installation.

a. It is enclosed in a separate compartment, or

b. It is separated by 50mm spacing or contains

a grounded metal or insulated partition.

3. When conduit or raceway is utilized to enclose

intrinsically safe wiring, it must be sealed or vented

so not to transfer the hazardous atmosphere to a

safe area.

AA-99-01.1

1818

18

1818

EFM(D) Solventborne Robotic Atomizers - Maintenance

MAINTENANCEMAINTENANCE

MAINTENANCE

MAINTENANCEMAINTENANCE

Good maintenance is essential to safe and

productive operation. Schedules should be

established by the user, based on the following

general information and observations of the initial

production requirements. The ITW Ransburg

maintenance and safety information should be

made available to each operator.

Normal fire protection measures are necessary,

including proper storage of paints and solvents

and the proper disposal of waste. Ready access

to appropriate fire extinguishing equipment is

required. For details, consult the appropriate

NFPA safety information, your local fire codes,

local painting equipment standards. Reference

OSHA, NFPA-33, and your insurance carrier's

information for additional information.

W A R N I N GW A R N I N G

W A R N I N G

W A R N I N GW A R N I N G

!!

!

!!

> An electrical discharge or spark may

create an electrical and/or fire hazard during

maintenance. Do not clean or service the

spray applicator with the power supply on.

Verify that the power supply has been locked

out and tagged out per OSHA.

ROUTINE MAINTENANCEROUTINE MAINTENANCE

ROUTINE MAINTENANCE

ROUTINE MAINTENANCEROUTINE MAINTENANCE

SCHEDULESCHEDULE

SCHEDULE

SCHEDULESCHEDULE

Follow these maintenance steps to extend the life

of the applicator and ensure efficient operation:

Several Times DailySeveral Times Daily

Several Times Daily

Several Times DailySeveral Times Daily

1. Turn the LECU5004 MicroPak Control Unit

OFFOFF

OFF!

OFFOFF

2. Inspect the fluid nozzle and electrode wire for

paint accumulation. Clean as frequently as

necessary. (See "Procedures"

nance" section.)

W A R N I N GW A R N I N G

W A R N I N G

W A R N I N GW A R N I N G

!!

!

!!

> Take precautions to see that skin is not

punctured by sharp electrode.

Daily (Or at Shift Start)Daily (Or at Shift Start)

Daily (Or at Shift Start)

Daily (Or at Shift Start)Daily (Or at Shift Start)

1. Turn the LECU5004 MicroPak Control Unit

OFFOFF

OFF and:

OFFOFF

in the "Mainte-

> Unexpected robot movement can be

hazardous. Do not adjust or repair the spray

applicator when the robot is operating or waiting to start. The robot must be locked out and

tagged out per OSHA.

> Solvents used for equipment flushing must

have flash point ratings equal to or greater than

the flash point rating of the coating material.

Solvents used for general cleaning must have

flash point ratings higher than 100

1919

19

1919

°F (37.8°C).

• Check within 20 feet of the point of operation

(of the applicator) and remove or ground

ALLALL

ALL loose or ungrounded containers.

ALLALL

• Inspect workholders for accumulated coating

materials (remove such accumulations if

present)

• Check that the nozzle assembly is clean

and undamaged.

• Straighten the applicator electrode if

necessary.

C A U T I O NC A U T I O N

C A U T I O N

C A U T I O NC A U T I O N

!!

!

!!

> Do not bend the applicator electrode while

wiping. Never immerse the applicator in solvents. This will cause damage to the electrical

components.

AA-99-01.1

EFM(D) Solventborne Robotic Atomizers - Maintenance

2. Turn the LECU5004 MicroPak Control Unit

ONON

ON! Energize high voltage.

ONON

Shut-Down (Or at Shift End)Shut-Down (Or at Shift End)

Shut-Down (Or at Shift End)

Shut-Down (Or at Shift End)Shut-Down (Or at Shift End)

1. Turn the LECU5004 MicroPak Control Unit

OFF.

2. Flush the lines and allow the solvent to remain

in the lines. See "Procedures" in the "Maintenance"

section.

1. Turn the LECU5004 MicroPak Control Unit

OFF.

2. Flush the lines and allow the solvent to remain

in the lines. See "Procedures"

section.

3. Wipe the applicator and robot wrist with a cloth

and a suitable, clean non-polar solvent.

WeeklyWeekly

Weekly

WeeklyWeekly

1. Check the entire system for damage, leaks and

paint accumulation.

2. Clean the atomizer assembly.

in the "Maintenance"

2. Turn off the solvent supply, actuate paint

pushout air at color changer and trigger the applicator. Allow all of the fluid to drain from the spray

applicator fluid passages.

3. Clean the exterior surfaces of the spray gun

with a solvent soaked rag. As long as the gun is

intact, a

ing, however, after cleaning, wipe off all surfaces

with a

residue on the applicator's surface. See "Polar

and Non-Polar Solvents" below regarding proper

solvent selection.

4. Remove piston cap [1]. Removing the piston

cap releases tension on all internal spray head

components. Remove spring retainer [2] and

piston spring [3], which are loose after removing

the piston cap.

5. Remove the air cap retainer [21] and air cap

[20]. Soak in a non-polar solvent if necessary. If

paint remains in the air cap holes, clean with a

toothpick or similar soft wood object. Air caps are

best cleaned in an ultrasonic cleaner.

polarpolar

polar solvent may be used for all clean-

polarpolar

nonpolarnonpolar

nonpolar solvent to reduce conductive

nonpolarnonpolar

3. Conduct a current output test. See "Procedures"

in the "Maintenance" section.

PROCEDURESPROCEDURES

PROCEDURES

PROCEDURESPROCEDURES

Gun Cleaning/ServiceGun Cleaning/Service

Gun Cleaning/Service

Gun Cleaning/ServiceGun Cleaning/Service

(See Figure 5)(See Figure 5)

(See Figure 5)

(See Figure 5)(See Figure 5)

1. Flush the paint supply line and the applicator

paint passages using a solvent which is compatible with the material being sprayed. Continue to

flush until all traces of paint are gone.

POLAR AND NON-POLAR SOLPOLAR AND NON-POLAR SOL

POLAR AND NON-POLAR SOL

POLAR AND NON-POLAR SOLPOLAR AND NON-POLAR SOL

Nonconductive (non-polar)Nonconductive (non-polar)

Nonconductive (non-polar)

Nonconductive (non-polar)Nonconductive (non-polar)

Amyl Acetate

Methyl Amyl Acetate

Toluene

Xylene

High Flash Naptha

Mineral Spirits

Moderately ConductiveModerately Conductive

Moderately Conductive

Moderately ConductiveModerately Conductive

Methyl Isobutyl Ketone

Ethyl Acetate

Methyl Ethyl Ketone

Butyl Carbitol

C A U T I O NC A U T I O N

C A U T I O N

C A U T I O NC A U T I O N

!!

!

!!

> Never attempt to clean the air cap holes

with a wire or other metal object. Doing so

may damage the air cap, resulting in distortion of the spray pattern.

VENTSVENTS

VENTS

VENTSVENTS

Extremely Conductive (polar)Extremely Conductive (polar)

Extremely Conductive (polar)

Extremely Conductive (polar)Extremely Conductive (polar)

Methanol

Carbitol

Diacetone

Butyl Alcohol

Acetone

Butyl Cellosolve

AA-99-01.1

2020

20

2020

EFM(D) Solventborne Robotic Atomizers - Maintenance

6. Remove the air cap clip [19] and fluid tip [18].

Clean using a non-polar solvent.

7. Tightly grip the plastic needle [16] and unscrew

counter-clockwise to remove the front needle

assembly. A short piece of H-2339 tubing (1/4 "

OD x 0.175" ID) pressed over the front needle will

assist in unscrewing the assembly. If required,

use needle nose pliers with masking tape or duct

tape. Carefully clean with a non-polar solvent.

Replace any parts that show signs of wear or

damage.

8. Remove fluid nozzle [15] by unscrewing

counterclockwise. Inspect o-ring [11] and all

passages for build up or damage. Clean or replace

as necessary. Reinsert o-ring into applicator

barrel and reinstall fluid nozzle. Torque fluid

nozzle to 25 lbs•in.

C A U T I O NC A U T I O N

C A U T I O N

C A U T I O NC A U T I O N

!!

!

!!

12. Apply a thin film of petroleum jelly to piston

spring [3]. Install piston spring and spring retainer

[2] back into the rear of the spray head assembly.

13. Screw piston cap [1] back on.

Current Output TCurrent Output T

Current Output T

Current Output TCurrent Output T

1. Turn the control unit power

2. Flush applicator with non-conductive solvent.

3. Activate high voltage and slowly approach the

applicator electrode with ground hook or wire.

4. Monitor the current output on LECU-5004.

Current should rise as ground approaches. At

approximately 80 microamperes, the LECU5004

will begin limiting current. If ground approaches

the applicator quickly, an overcurrent fault should

occur. The

come on.

OVERCURRENTOVERCURRENT

OVERCURRENT indicator should

OVERCURRENTOVERCURRENT

estest

est

estest

ONON

ON.

ONON

> If using needle nose pliers to unscrew the

front needle, be very careful. Do not grip on the

tapered sealing surface. If the pliers slip, they

could damage the tapered sealing surface of

the needle.

NOTENOTE

NOTE

NOTENOTE

> There should be a small gap between

the fluid nozzle and the applicator barrel

after tightening.

9. After cleaning, insert the electrode assembly

back into the spray head assembly. Apply Loctite

#222, low strength (purple) thread-locker, to the

threads of the electrode assembly [16] before

reassembly.

10. Screw fluid tip [18] back into place. Hand

tighten first, then with a small wrench, tighten an

additional 30 degrees.

SERVICESERVICE

SERVICE

SERVICESERVICE

Because we want to provide our users with the

most up-to-date technology possible, we are constantly seeking to improve products. If a change

in product configuration occurs after it is on the

market, we will implement that technology in future

production and, if practical, make it available to

current users. The following service information is

based on standard specifications and procedures

for this product. If you find some minor deviations

between this information and your equipment because of design or manufacturing changes, contact your ITW Ransburg representative to resolve

the difference.

11. Replace air cap clip [19], air cap [20], and air

cap retainer [21].

2121

21

2121

AA-99-01.1

EFM(D) Solventborne Robotic Atomizers - Maintenance

W A R N I N GW A R N I N G

W A R N I N G

W A R N I N GW A R N I N G

!!

!

!!

> An electrical discharge or spark may create

an electrical and/or fire hazard during maintenance. Do not service the spray applicator

with the power supply on. Verify that the

power supply on/off switch has been turned

off.

> Unexpected robot movement can be haz-

ardous. Do not adjust or repair the spray

applicator when the robot is operating or waiting to start. The robot must be locked out and

tagged out per OSHA prior to removing the

applicator from the robot manifold assembly.

Before performing any work on the spray applicator, always flush the fluid passages and blow dry

with pushout air, and wipe the spray applicator

clean. Refer to "Applicator Cleaning", earlier in the

"Maintenance" section, for instructions on how to

properly clean the spray applicator. Depressurize

all fluid and air pressures before removing the

applicator from its manifold. Always work in a

clear, clean space to minimize parts loss and

damage.

C A U T I O NC A U T I O N

C A U T I O N

C A U T I O NC A U T I O N

!!

!

!!

> As the spray head is removed from the

valve manifold assembly, a certain amount of

residual fluid may be present. Care must be

taken not to allow this fluid to drain into the high

voltage terminal rings or air passages.

SPRASPRA

SPRA

SPRASPRA

Fluid TFluid T

Fluid T

Fluid TFluid T

Needle ReplacementNeedle Replacement

Needle Replacement

Needle ReplacementNeedle Replacement

YY

HEAD ASSEMBL HEAD ASSEMBL

Y

HEAD ASSEMBL

YY

HEAD ASSEMBL HEAD ASSEMBL

ip, Nozzle, and Frontip, Nozzle, and Front

ip, Nozzle, and Front

ip, Nozzle, and Frontip, Nozzle, and Front

NOTENOTE

NOTE

NOTENOTE

> In any disassembly or reassembly

procedure involving o-rings, care must

be taken not to lose them. O-rings (gray

color) are very expensive; always reuse

them unless they are damaged.

> Disassemble spray head only enough

to remove and replace defective parts.

For instance, if only replacing the front

needle it is not necessary to remove the

fluid nozzle.

NOTENOTE

NOTE

NOTENOTE

> At assembly, apply a small amount of

dielectric grease to grooves in spray head

and valve manifold to reduce high voltage

breakdown. Excessive grease will not

allow Spray Head [1] to seat fully against

Applicator Housing Assembly [2]. (See

Figure 6b.)

YY

Y

YY

W A R N I N GW A R N I N G

W A R N I N G

W A R N I N GW A R N I N G

!!

!

!!

> Eye protection should be worn while

servicing applicator.

AA-99-01.1

2222

22

2222

EFM(D) Solventborne Robotic Atomizers - Maintenance

Figure 5: Spray Head RemovalFigure 5: Spray Head Removal

Figure 5: Spray Head Removal

Figure 5: Spray Head RemovalFigure 5: Spray Head Removal

7647976479

76479

7647976479

Item #Item #

Item #

Item #Item #

SPRA SPRA

SPRA

SPRA SPRA

Part #Part #

Part #

Part #Part #

1 EMF-13 Piston Cap 1

2 EMF-22 Retainer Spring 1

3 RME-36 Piston Spring 1

4 RME-66 Piston Nut 1

5 RME-69 Piston 1

6 SST-7714 Piston Seal 1

8 76096-00 Piston Rod Assembly 1

9 76094-00 N eedl e Sec tion , Rear 1

10 76497-00 Applicator Barrel Assembly, Resistive, EFM 1

11 SSG-8149 O-Ring, Solvent Resistant 1

12 RME-38 Seal Spring 1

13 EMF-7 Seal Washer 1

14 RME-32 Seal 1

15 EMF-195 Fluid Nozzle, High Flow, Black W/Grove 1

16 70430-00 Electrode Assembly 1

17 EMF-192 Air Cap Locator 1

18 76132-02 Fluid Tip, EMF Gun, .055" Dia. Orifice 1

19 EMF-10 Air Cap Clip 1

20 76131-00 Air Cap 1

21 EFX-8 Air Cap Retainer 1

YY

HEAD ASSEMBL HEAD ASSEMBL

Y

HEAD ASSEMBL

YY

HEAD ASSEMBL HEAD ASSEMBL

DescriptionDescription

Description

DescriptionDescription

YY

- P - P

Y

- P

YY

- P - P

ARAR

TS LISTTS LIST

AR

TS LIST

ARAR

TS LISTTS LIST

(Figure 5) (Figure 5)

(Figure 5)

(Figure 5) (Figure 5)

QtyQty

Qty

QtyQty

2323

23

2323

AA-99-01.1

EFM(D) Solventborne Robotic Atomizers - Maintenance

Rear Needle ReplacementRear Needle Replacement

Rear Needle Replacement

Rear Needle ReplacementRear Needle Replacement

(See Figure 5)(See Figure 5)

(See Figure 5)

(See Figure 5)(See Figure 5)

1. Remove the air cap, fluid tip and the fluid nozzle

as described in Steps 1 through 8 of the "Fluid Tip,

Nozzle, and Front Needle Replacement" in the

"Maintenance" section.

2. Remove metal rear needle [9], piston rod [8],

piston seal [6], piston [5], and piston nut [4]

assemblyassembly

assembly. Pull the assembly out from the rear of

assemblyassembly

the spray head.

3. Piston [5] and piston seal [6] can be removed

from the piston rod by unscrewing piston nut [4]. If

replacing piston seal [6], press flat side of seal

down onto piston. Apply a thin film of petroleum

jelly to outside of seal.

C A U T I O NC A U T I O N

C A U T I O N

C A U T I O NC A U T I O N

!!

!

!!

as anas an

as an

as anas an

> Fluid seal [14], seal washer [13], and seal

spring [12], will come free at this point. Place

hand over end as not to drop parts.

6. Place seal spring [12] over the rear needle in

the front end of the spray head. Hold the spray

head upward as the spring will want to fall out.

7. Still holding the spray head upward, place oring [11] into its seat and seal washer [13] and fluid

seal [14] onto the rear needle. The tapered end of

the fluid seal should be pointed toward the front of

the applicator.

8. Reassemble fluid nozzle [15] by pushing the

nozzle into the spray head until the threads

engage. Screw the nozzle into the spray head.

Torque to 23-25 lbs•in. Plastic threads damage

easily; do not over-tighten. Note the front flange of

the fluid nozzle will not seat flush against the spray

head.

9. Apply Loctite #222 Low Strength (purple)

Threadlocker into the threads of plastic front

needle [16] before assembling onto the rear needle.

Be sure that the rear needle assembly is pushed

all the way forward before threading on front

needle.

NOTENOTE

NOTE

NOTENOTE

> Damage will occur to the piston seal

if removed. If removed, replace piston

seal.

> Do not remove the metal rear needle

from the rod unless it is damaged and

must be replaced.

4. Inspect metal rear needle [9] for excessive

wear. If wear is observed (longitudinal grooves or

a noticeable reduction in diameter), replace the

needle. Whenever replacing rear needle section,

you must also replace the seal [14] at the same

time. Upon reassembly, apply Loctite Locquip

Primer Grade T #747-56 and Loctite #290 Medium

Strength (green) to the end of rear needle and ID

of piston rod [8] before assembling into piston rod.

5. Place the rear needle assembly back into the

spray head. Push on the piston until the assembly

is firmly seated in the spray head.

10. Reassemble fluid tip [18]. Hand tighten first;

then with a small wrench turn an additional 30

degrees. Place air cap clip [19] into groove in the

fluid tip.

11. Reassemble air cap [20] and air cap retainer

[21]. Do not let air cap rotate while loosening or

tightening.

12. Apply a thin film of petroleum jelly to piston

spring [3]. Install piston spring, and spring retainer

[2]. Screw piston cap [1] back on.

13. Lubricate all of the o-rings on the underside of

the spray head with petroleum jelly, and apply a

thin coat of dielectric grease EPS-4109 (syringe)

to the grooves of the spray head and the valve

manifold before reassembly.

14. Refer to Figure 6b and replace spray head

assembly [1] back onto applicator housing

assembly [2]. Screw four socket head cap

screws [5] back into place. Do not overtighten

nylon screws, as they can break.

AA-99-01.1

2424

24

2424

EFM(D) Solventborne Robotic Atomizers - Maintenance

FLUID REGULAFLUID REGULA

FLUID REGULA

FLUID REGULAFLUID REGULA

OR DUMPOR DUMP

OR DUMP

OR DUMPOR DUMP

(See Figure 6a)(See Figure 6a)

(See Figure 6a)

(See Figure 6a)(See Figure 6a)

1. Remove all pressures, both air and fluid from

the line leading to the spray applicator.

2. Purge all fluid from the applicator prior to

performing any service.

3. Remove dump cap [15] or regulator cap [9].

Use EMF-445 Cap Tool for dump cap removal,

EMF-438 Cap Tool for regulator cap removal,

provided in the tool kit.

> Once regulator cap [9] or dump cap

[15] is removed, diaphragm support [8 or

14] will be loose and may fall out.

V V

ALAL

V

AL

V V

ALAL

NOTENOTE

NOTE

NOTENOTE

TT

T

TT

VEVE

VE

VEVE

OROR

OR

OROR

7. Inspect poppet seat assembly [2] for wear. If

wear or damage is evident, replace. Replace both

poppet and seat at the same time because they

are a matched set. Inspect o-ring for damage,

replace as necessary, Part Number SSG-8172.

8. Reassemble the fluid regulator by inserting the

spring, poppet and seat [1 and 2] back into the

valve manifold housing. Be sure to lube o-ring

before trying to insert back into manifold. Secure

the poppet/seat assembly by screwing the seat

retainer [4] into the valve manifold housing until a

torque of 8-10 lbs•in is obtained.

NOTENOTE

NOTE

NOTENOTE

> When replacing the poppet seat or the

regulator/dump cap, be cautious so that

the plastic threads are not stripped by

cross threading.

4. Remove diaphragm support [8 or 14] and

carefully remove elastomeric diaphragm [6 or

13]. Use a small screwdriver blade and pry loose