Ransburg 75785, 75786, 75979, 75982, REA-90 Service Manual

...

SERVICE MANUAL

AH-94-04.7AH-94-04.7

AH-94-04.7

AH-94-04.7AH-94-04.7

(Replaces AH-94-04.6)

May - 2008

REA-90 and REA-90LREA-90 and REA-90L

REA-90 and REA-90L

REA-90 and REA-90LREA-90 and REA-90L

ELECTROSTELECTROST

ELECTROST

ELECTROSTELECTROST

APPLICAAPPLICA

APPLICA

APPLICAAPPLICA

Dual Atomization TDual Atomization T

Dual Atomization T

Dual Atomization TDual Atomization T

AA

TIC SPRATIC SPRA

A

TIC SPRA

AA

TIC SPRATIC SPRA

TT

ORSORS

T

ORS

TT

ORSORS

YY

Y

YY

echnologyechnology

echnology

echnologyechnology

MODELS:MODELS:

MODELS:

MODELS:MODELS:

75785 - ST75785 - ST

75785 - ST

75785 - ST75785 - ST

75786 - ST75786 - ST

75786 - ST

75786 - ST75786 - ST

75979 - A75979 - A

75979 - A

75979 - A75979 - A

75982 - A75982 - A

75982 - A

75982 - A75982 - A

ANDARD (SOLANDARD (SOL

ANDARD (SOL

ANDARD (SOLANDARD (SOL

ANDARD (WANDARD (W

ANDARD (W

ANDARD (WANDARD (W

VIAVIA

TT

VIA

T

VIAVIA

TT

VIAVIA

TT

VIA

T

VIAVIA

TT

VENTVENT

VENT

VENTVENT

AA

TERBORNE)TERBORNE)

A

TERBORNE)

AA

TERBORNE)TERBORNE)

OR/MGS (SOLOR/MGS (SOL

OR/MGS (SOL

OR/MGS (SOLOR/MGS (SOL

OR (WOR (W

OR (W

OR (WOR (W

AA

TERBORNE)TERBORNE)

A

TERBORNE)

AA

TERBORNE)TERBORNE)

IMPORIMPOR

IMPOR

IMPORIMPOR

carefully read SAFETY PRECAUTIONS,carefully read SAFETY PRECAUTIONS,

carefully read SAFETY PRECAUTIONS,

carefully read SAFETY PRECAUTIONS,carefully read SAFETY PRECAUTIONS,

starting on page 1, and all instructions instarting on page 1, and all instructions in

starting on page 1, and all instructions in

starting on page 1, and all instructions instarting on page 1, and all instructions in

this manual. Keep this Service Manual forthis manual. Keep this Service Manual for

this manual. Keep this Service Manual for

this manual. Keep this Service Manual forthis manual. Keep this Service Manual for

future reference.future reference.

future reference.

future reference.future reference.

BASE) BASE)

BASE)

BASE) BASE)

VENTVENT

VENT

VENTVENT

TT

ANTANT

T

ANT

TT

ANTANT

BASE) BASE)

BASE)

BASE) BASE)

: Before using this equipment,: Before using this equipment,

: Before using this equipment,

: Before using this equipment,: Before using this equipment,

Service Manual Price:Service Manual Price:

Service Manual Price: €

Service Manual Price:Service Manual Price:

25.00 (Euro)25.00 (Euro)

25.00 (Euro)

25.00 (Euro)25.00 (Euro)

$30.00 (U.S.)$30.00 (U.S.)

$30.00 (U.S.)

$30.00 (U.S.)$30.00 (U.S.)

NOTE:NOTE:

NOTE: This manual has been changed from revision

NOTE:NOTE:

Reasons for this change are noted under “Manual Change Summary” inside the back

cover of this manual.

AH-94-04.6AH-94-04.6

AH-94-04.6 to revision

AH-94-04.6AH-94-04.6

AH-94-04.7 AH-94-04.7

AH-94-04.7.

AH-94-04.7 AH-94-04.7

AH-94-04.7

CONTENTSCONTENTS

CONTENTS

CONTENTSCONTENTS

SAFETY:SAFETY:

SAFETY:

SAFETY:SAFETY:

REA-90 and 90L Spray Applicators - Contents

PAGEPAGE

PAGE

PAGEPAGE

1-71-7

1-7

1-71-7

SAFETY PRECAUTIONS............................................................................................................

HAZARDS / SAFEGUARDS........................................................................................................

ATEX:ATEX:

ATEX:

ATEX:ATEX:

EUROPEAN ATEX DIRECTIVE..................................................................................................

EUROPEAN ATEX LABELS........................................................................................................

INTRODUCTION:INTRODUCTION:

INTRODUCTION:

INTRODUCTION:INTRODUCTION:

GENERAL DESCRIPTION..........................................................................................................

REA-90 WITH AVIATOR..............................................................................................................

75785 SOLVENT BASE REA-90 STANDARD AND

75979 SOLVENT BASE REA-90 AVIATOR / MGS....................................................................

75786 WATERBORNE REA-90 STANDARD AND

75982 WATERBORNE REA-90 AVIATOR.................................................................................

INSTALLATION:INSTALLATION:

INSTALLATION:

INSTALLATION:INSTALLATION:

75785 STANDARD SOLVENT BASE AND 75979 AVIATOR /

MGS SOLVENT BASE INSTALLATION.....................................................................................

FILTERS.......................................................................................................................................

75786 STANDARD WATERBORNE AND 75982 AVIATOR

WATERBORNE INSTALLATION................................................................................................

ISOLATION SYSTEM INSTALLATION GUIDELINES...............................................................

WATERBORNE HOSE FITTING INSTALLATION.....................................................................

FLUID HOSE FITTING INSTALLATION.....................................................................................

AIR HOSE FITTING INSTALLATION.........................................................................................

PAINT PREPARATION...............................................................................................................

SPRAY TECHNOLOGY CONVERSION PROCEDURE..........................................................

SPRAY PATTERN ADJUSTMENT.............................................................................................

APPLICATOR TO TARGET DISTANCE....................................................................................

AIR CAP / FLUID NOZZLE SELECTION CHART.....................................................................

AIR CAP / FLUID NOZZLE PERFORMANCE CHART.............................................................

1

2-7

8-108-10

8-10

8-108-10

8-9

9-10

11-1611-16

11-16

11-1611-16

11-12

12

13-14

15-16

17-2617-26

17-26

17-2617-26

17-18

18

19

20-21

21

22

22

22

23

24

24

25

26

MAINTENANCE:MAINTENANCE:

MAINTENANCE:

MAINTENANCE:MAINTENANCE:

SUITABLE SOLVENTS FOR CLEANING REA-90 APPLICATORS.........................................

ROUTINE SCHEDULE................................................................................................................

APPLICATOR ASSEMBLY CLEANING PROCEDURE............................................................

FLUSHING PROCEDURES........................................................................................................

APPLICATOR REPAIR................................................................................................................

EQUIPMENT REQUIRED...........................................................................................................

TO REMOVE THE APPLICATOR FROM THE WORK SITE....................................................

FLUID NOZZLE............................................................................................................................

NEEDLE / ELECTRODE..............................................................................................................

NEEDLE / ELECTRODE RESISTANCE TESTING...................................................................

(Continued On Next Page)(Continued On Next Page)

(Continued On Next Page)

(Continued On Next Page)(Continued On Next Page)

AH-94-04.7

27-5827-58

27-58

27-5827-58

27

28-29

29-30

30-31

31

31

31-33

34-35

35

36

REA-90 and 90L Spray Applicators - Contents

CONTENTS (Cont.)CONTENTS (Cont.)

CONTENTS (Cont.)

CONTENTS (Cont.)CONTENTS (Cont.)

MAINTENANCE: (continued)MAINTENANCE: (continued)

MAINTENANCE: (continued)

MAINTENANCE: (continued)MAINTENANCE: (continued)

PAGEPAGE

PAGE

PAGEPAGE

27-5827-58

27-58

27-5827-58

BARREL ASSEMBLY...................................................................................................................

HOOK / TRANSFORMER ASSEMBLY......................................................................................

HOOK / TRANSFORMER ON/OFF SWITCH REPLACEMENT...............................................

HANDLE.......................................................................................................................................

FAN AIR VALVE...........................................................................................................................

AIR VALVE...................................................................................................................................

TRIGGER.....................................................................................................................................

NEEDLE SHAFT RETURN SPRING REPLACEMENT.............................................................

LOW VOLTAGE CABLE PLUG ASSEMBLY REPLACEMENT................................................

REPLACEMENT...........................................................................................................................

LOW VOLTAGE CABLE REPLACEMENT.................................................................................

FLUID TUBE (SOLVENT BASE APPLICATORS)......................................................................

FLUID HOSE (SOLVENT BASE APPLICATORS).....................................................................

FLUID HOSE (WATERBORNE APPLICATORS)......................................................................

AIR LINE.......................................................................................................................................

FLUID TUBE BRACKET..............................................................................................................

TRIGGER ADJUSTMENT...........................................................................................................

FAN AIR ADJUSTMENT..............................................................................................................

FLUID DELIVERY ADJUSTMENT..............................................................................................

ATOMIZING AIR ADJUSTMENT................................................................................................

TROUBLESHOOTING GUIDE....................................................................................................

36-41

41-43

43

44

44-45

46-47

47

47

48

48-49

49-50

50-51

51-52

52-53

53-54

54

54-55

55

55

55

56-58

PARTS IDENTIFICATION:PARTS IDENTIFICATION:

PARTS IDENTIFICATION:

PARTS IDENTIFICATION:PARTS IDENTIFICATION:

75785 SOLVENT BASE (STANDARD) AND

75979 SOLVENT BASE (AVIATOR / MGS) /

MODEL IDENTIFICATION / PARTS LIST...................................................................................

75786 WATERBORNE (STANDARD) AND 75982

WATERBORNE (AVIATOR) / MODEL IDENTIFICATION /

PARTS LIST..................................................................................................................................

RECOMMENDED SPARE PARTS.............................................................................................

MISC. PARTS...............................................................................................................................

SERVICE KITS.............................................................................................................................

WARRANTY POLICIES:WARRANTY POLICIES:

WARRANTY POLICIES:

WARRANTY POLICIES:WARRANTY POLICIES:

LIMITED WARRANTY..................................................................................................................

59-7059-70

59-70

59-7059-70

59-64

65-69

69

70

70

7171

71

7171

71

AH-94-04.7

REA-90 and 90L Spray Applicators - Contents

AH-94-04.7

REA-90 and 90L Spray Applicators - Safety

SAFETYSAFETY

SAFETY

SAFETYSAFETY

SAFETY PRECAUTIONSSAFETY PRECAUTIONS

SAFETY PRECAUTIONS

SAFETY PRECAUTIONSSAFETY PRECAUTIONS

W A R N I N GW A R N I N G

W A R N I N G

W A R N I N GW A R N I N G

!!

!

!!

Before operating, maintaining or servicing any

ITW Ransburg electrostatic coating system, read

and understand all of the technical and safety

literature for your ITW Ransburg products. This

manual contains information that is important for

you to know and understand. This information

relates to USER SAFETY and PREVENTING

EQUIPMENT PROBLEMS. To help you recognize

this information, we use the following symbols.

Please pay particular attention to these sections.

A WARNING! states information to alert youA WARNING! states information to alert you

A WARNING! states information to alert you

A WARNING! states information to alert youA WARNING! states information to alert you

to a situation that might cause serious injuryto a situation that might cause serious injury

to a situation that might cause serious injury

to a situation that might cause serious injuryto a situation that might cause serious injury

if instructions are not followed.if instructions are not followed.

if instructions are not followed.

if instructions are not followed.if instructions are not followed.

A CAUTION! states information that tellsA CAUTION! states information that tells

A CAUTION! states information that tells

A CAUTION! states information that tellsA CAUTION! states information that tells

how to prevent damage to equipment or howhow to prevent damage to equipment or how

how to prevent damage to equipment or how

how to prevent damage to equipment or howhow to prevent damage to equipment or how

to avoid a situation that might cause minorto avoid a situation that might cause minor

to avoid a situation that might cause minor

to avoid a situation that might cause minorto avoid a situation that might cause minor

injury.injury.

injury.

injury.injury.

A NOTE is information relevant to theA NOTE is information relevant to the

A NOTE is information relevant to the

A NOTE is information relevant to theA NOTE is information relevant to the

procedure in progress.procedure in progress.

procedure in progress.

procedure in progress.procedure in progress.

> The user

with the Safety Section in this manual and

the ITW Ransburg safety literature therein

identified.

> This manual

oughly understood by

operate, clean or maintain this equipment!

Special care should be taken to ensure that

WARNINGSWARNINGS

the

WARNINGS and safety requirements

WARNINGSWARNINGS

for operating and servicing the equipment

are followed. The user should be aware of

and adhere to

codes and ordinances as well as

33 SAFETY STANDARD33 SAFETY STANDARD

33 SAFETY STANDARD, prior to

33 SAFETY STANDARD33 SAFETY STANDARD

installing, operating, and/or servicing this

equipment.

MUSTMUST

MUST read and be familiar

MUSTMUST

MUSTMUST

MUST be read and thor-

MUSTMUST

ALLALL

ALL personnel who

ALLALL

ALL ALL

ALL local building and fire

ALL ALL

W A R N I N GW A R N I N G

W A R N I N G

W A R N I N GW A R N I N G

!!

!

!!

NFPA-NFPA-

NFPA-

NFPA-NFPA-

While this manual lists standard specifications

and service procedures, some minor deviations

may be found between this literature and your

equipment. Differences in local codes and plant

requirements, material delivery requirements, etc.,

make such variations inevitable. Compare this

manual with your system installation drawings

and appropriate ITW Ransburg equipment

manuals to reconcile such differences.

Careful study and continued use of this manual will

provide a better understanding of the equipment

and process, resulting in more efficient operation,

longer trouble-free service and faster, easier

troubleshooting. If you do not have the manuals

and safety literature for your Ransburg system,

contact your local ITW Ransburg representative

or ITW Ransburg.

> The hazards shown on the following

page may occur during the normal use of

this equipment. Please read the hazard

chart beginning on page 2.

11

1

11

AH-94-04.7

REA-90 and 90L Spray Applicators - Safety

AREAAREA

AREA

AREAAREA

Tells where hazards

may occur.

Spray AreaSpray Area

Spray Area

Spray AreaSpray Area

HAZARDHAZARD

HAZARD

HAZARDHAZARD

Tells what the hazard is.

Fire Hazard

Improper or inadequate opera-tion

and maintenance procedures will

cause a fire hazard.

Protection against inadvertent

arcing that is capable of causing

fire or explosion is lost if any safety

interlocks are disabled during

operation. Frequent power supply

shutdown indicates a problem in

the system requiring correction.

SAFEGUARDSSAFEGUARDS

SAFEGUARDS

SAFEGUARDSSAFEGUARDS

Tells how to avoid the hazard.

Fire extinguishing equipment must be present in the

spray area and tested periodically.

Spray areas must be kept clean to prevent the

accumulation of combustible residues.

Smoking must never be allowed in the spray area.

The high voltage supplied to the atomizer must be

turned off prior to cleaning, flushing or maintenance.

When using solvents for cleaning:

Those used for equipment flushing should have flash

points equal to or higher than those of the coating

material.

Those used for general cleaning must have flash

points above 100oF (37.8oC).

Spray booth ventilation must be kept at the rates

required by NFPA-33, OSHA, and local codes. In

addition, ventilation must be maintained during

cleaning operations using flammable or combustible

solvents.

Electrostatic arcing must be prevented.

Test only in areas free of combustible material.

Testing may require high voltage to be on, but only as

instructed.

Non-factory replacement parts or unauthorized

equipment modifications may cause fire or injury.

If used, the key switch bypass is intended for use only

during setup operations. Production should never be

done with safety interlocks disabled.

Never use equipment intended for use in waterborne

installations to spray solvent based materials.

The paint process and equipment should be set up

and operated in accordance with NFPA-33, NEC, and

OSHA requirements.

AH-94-04.7

22

2

22

REA-90 and 90L Spray Applicators - Safety

AREAAREA

AREA

AREAAREA

Tells where hazards

may occur.

Toxic SubstancesToxic Substances

Toxic Substances

Toxic SubstancesToxic Substances

ExplosionExplosion

Explosion

ExplosionExplosion

Hazard /Hazard /

Hazard /

Hazard /Hazard /

IncompatibleIncompatible

Incompatible

IncompatibleIncompatible

MaterialsMaterials

Materials

MaterialsMaterials

HAZARDHAZARD

HAZARD

HAZARDHAZARD

Tells what the hazard is.

Certain material may be harmful if

inhaled, or if there is contact with

the skin.

Halogenated hydrocarbon solvents,

for example: methylene chloride

and 1,1,1, - Trichloroethane, are

not chemically compatible with the

aluminum that might be used in

many system components. The

chemical reaction caused by these

solvents reacting with aluminum

can become violent and lead to an

equipment explosion.

SAFEGUARDSSAFEGUARDS

SAFEGUARDS

SAFEGUARDSSAFEGUARDS

Tells how to avoid the hazard.

Follow the requirements of the Material Safety Data

Sheet supplied by coating material manufacturer.

Adequate exhaust must be provided to keep the air

free of accumulations of toxic materials.

Use a mask or respirator whenever there is a chance

of inhaling sprayed materials. The mask must be

compatible with the material being sprayed and its

concentration. Equipment must be as prescribed by

an industrial hygienist or safety expert, and be NIOSH

approved.

The REA-90 and REA-90L require that aluminum inlet

fittings be replaced with stainless steel. (See

accessories list.) Aluminum is widely used in other

spray application equipment - such as material pumps,

regulators, valves, etc. Check all other equipment

items before use and make sure they can also be

used safely with these solvents. Read the label or

data sheet for the material you intend to spray. If in

doubt as to whether or not a coating or cleaning

material is compatible, contact your material supplier.

Any other type of solvent may be used with aluminum

equipment.

Intended UseIntended Use

Intended Use

Intended UseIntended Use

(Waterborne Only)

Using coating materials and/or

cleaning and flushing solvents

which have flash points below

100F (37.8°C) may cause a fire

hazard.

This system is intended for use with waterborne

coating formulations only.

Waterborne, waterbase and water reducible coatings

are considered the same. Although they may not be

highly flammable, their residues are considered

combustible.

33

3

33

AH-94-04.7

REA-90 and 90L Spray Applicators - Safety

AREAAREA

AREA

AREAAREA

Tells where hazards

may occur.

ElectricalElectrical

Electrical

ElectricalElectrical

EquipmentEquipment

Equipment

EquipmentEquipment

HAZARDHAZARD

HAZARD

HAZARDHAZARD

Tells what the hazard is.

High voltage equipment is utilized.

Arcing in areas of flammable or

combustible materials may occur.

Personnel are exposed to high

voltage during operation and

maintenance.

Protection against inadvertent

arcing that may cause a fire or

explosion is lost if safety circuits

are disabled during operation.

Frequent power supply shutdown

indicates a problem in the system

which requires correction.

An electrical arc can ignite coating

materials and cause a fire or

explosion.

SAFEGUARDSSAFEGUARDS

SAFEGUARDS

SAFEGUARDSSAFEGUARDS

Tells how to avoid the hazard.

The power supply, optional remote control cabinet,

and all other electrical equipment must be located

outside Class I or II, Division 1 and 2 hazardous

areas. (Exception: AVIATOR series applicators)

(Refer to NFPA-33.)

Turn the power supply OFF before working on the

equipment.

Test only in areas free of flammable or combustible material.

Testing may require high voltage to be on, but only

as instructed.

Production should never be done with the safety

circuits disabled.

Before turning the high voltage on, make sure no

objects are within the sparking distance.

AH-94-04.7

44

4

44

REA-90 and 90L Spray Applicators - Safety

AREAAREA

AREA

AREAAREA

Tells where hazards

may occur.

Spray AreaSpray Area

Spray Area

Spray AreaSpray Area

HAZARDHAZARD

HAZARD

HAZARDHAZARD

Tells what the hazard is.

Electrostatic Arcing Never operate the spray applicator without properly

SAFEGUARDSSAFEGUARDS

SAFEGUARDS

SAFEGUARDSSAFEGUARDS

Tells how to avoid the hazard.

grounding the following.

A. Operators

Operators must be grounded. Rubber soled

insulating shoes should not be worn. Grounding

leg straps may be used.

Operators must maintain contact with the

handle of the applicator. If work gloves are used,

the palm section should be cut out.

Operators must remove from themselves all

metal objects that are not grounded.

NOTE:NOTE:

NOTE: REFER TO NFPA-33 REGARDING

NOTE:NOTE:

OPERATOR GROUNDING.

B. Parts being sprayed. Resistance between the

part and a grounded conveyor must not exceed

1 megohm.

C. Every metal and conductive object in the spray

area. This includes the booth, parts hangers,

fire extinguishers, conductive flooring, etc.

Grounded conductive flooring must be provided in the

spray area.

Turn off voltage at the power supply before flushing

out, cleaning, or removing any parts from the

applicator.

Provide proper protection for waterborne supply

systems.

Never install a spray applicator into a fluid system

using an isolated solvent supply.

Always discharge Waterborne system capacitance

prior to servicing.

Do not touch applicator electrode while applicator is

energized.

55

5

55

AH-94-04.7

REA-90 and 90L Spray Applicators - Safety

AREAAREA

AREA

AREAAREA

Tells where hazards

may occur.

General Use andGeneral Use and

General Use and

General Use andGeneral Use and

MaintenanceMaintenance

Maintenance

MaintenanceMaintenance

HAZARDHAZARD

HAZARD

HAZARDHAZARD

Tells what the hazard is.

Improper operation or maintenance

may create a hazard.

Personnel must be properly trained

in the use of this equipment.

SAFEGUARDSSAFEGUARDS

SAFEGUARDS

SAFEGUARDSSAFEGUARDS

Tells how to avoid the hazard.

Personnel must be given training in accordance with

the requirements of NFPA-33.

Instructions and safety precautions must be read and

understood prior to using this equipment.

Comply with appropriate local, state, and national

codes governing ventilation, fire protection, operation

maintenance, and housekeeping. Reference OSHA,

NFPA-33, and your insurance company requirements.

Always turn power to the power supply OFF, unplug

the electrical cord from its outlet, and remove the

front panel fuse, before opening the power supply

door. If necessary, lock the power supply out so that

it cannot be turned ON until the work is finished.

Whenever removing high voltage cables from

equipment, ground the contact end of the cable by

holding the cable such that the contact touches earth

ground for several seconds. Do not touch the contact

until it has been grounded. This will reduce the

possibility of residual charge causing electrical shock.

The High Voltage Multiplier Assembly contains energy

storage components that can cause serious shock

injury, and therefore is not field repairable. Warranty

will be voided if the High Voltage Multiplier seal is

broken. If the High Voltage Multiplier is defective

contact your authorized ITW Ransburg representative

for exchange or repair.

The High Voltage Multiplier and high voltage cable

contain significant capacitance that will store charge.

Allow approximately 10 seconds for this charge to

bleed off before opening the cabinet door or removing

the high voltage cable from the power supply or spray

applicator.

AH-94-04.7

66

6

66

REA-90 and 90L Spray Applicators - Safety

AREAAREA

AREA

AREAAREA

Tells where hazards

may occur.

General Use andGeneral Use and

General Use and

General Use andGeneral Use and

MaintenanceMaintenance

Maintenance

MaintenanceMaintenance

HAZARDHAZARD

HAZARD

HAZARDHAZARD

Tells what the hazard is.

Use of hand tools may cause

cumulative trauma disorders

(CTD's). CTD's or musculoskeletal

disorders, involve damage to the

hands, wrists, elbows, shoulders,

neck and back. Carpal tunnel

syndrome and tendinitis (such as

tennis elbow or rotator cuff

syndrome) are examples of CTD's.

CTD's when using hand tools, tend

to affect the upper extremities.

Factors which may increase the

risk of developing a CTD include:

1. High frequency of the activity.

2. Excessive force, such as

gripping, pinching or pressing

with the hands and fingers.

SAFEGUARDSSAFEGUARDS

SAFEGUARDS

SAFEGUARDSSAFEGUARDS

Tells how to avoid the hazard.

Risk is reduced by avoiding or lessening the listed

hazards.

CTD's can also be caused by such activities as

sewing, golf, tennis and bowling, to name a few.

Pain, tingling, or numbness in the shoulder, forearm,

wrists, hands, or fingers, especially during the night,

may be early symptoms of a CTD. Do not ignore

them. Should you experience any such symptoms,

see a physician immediately. Other early symptoms

may include vague discomfort in the hand, loss of

manual dexterity, and nonspecific pain in the arm.

Ignoring early symptoms and continued repetitive

use of the arm, wrist and hand can lead to serious

disability.

3. Extreme or awkward finger,

wrist or arm positions.

4. Excessive duration of the

activity.

5. Tool vibration.

6. Repeated pressure on a

body part.

7. Working in cold temperatures.

77

7

77

AH-94-04.7

REA-90 and 90L Spray Applictors - Atex

EUROPEAN AEUROPEAN A

EUROPEAN A

EUROPEAN AEUROPEAN A

The following instructions apply to equipment

covered by certificate number Sira 08ATEX5040X:

1. The equipment may be used with flammable

gases and vapors with apparatus groups II and

with temperature class T6.

2. The equipment is only certified for use in ambient

temperatures in the range +12.8°C to +40°C and

should not be used outside this range.

3. Installation shall be carried out by suitably

trained personnel in accordance with the applicable

code of practice e.g. EN 60079-14: 1997.

4. Inspection and maintenance of this equipment

shall be carried out by suitably trained personnel

in accordance with the applicable code of practice

e.g. EN 60079-17.

5. Repair of this equipment shall be carried out by

suitable trained personnel in accordance with the

applicable code of practice e.g. EN 60079-19.

6. Putting into service, use, assembling, and

adjustment of the equipment shall be fitted by

suitably trained personnel in accordance with the

manufacturer's documentation.

Refer to the "Table of Contents" of this service

manual:

a. Installation

b. Operation

c. Maintenance

d. Parts Identification

TEX DIRECTIVE 94/9/EC, ANNEX II, 1.0.6TEX DIRECTIVE 94/9/EC, ANNEX II, 1.0.6

TEX DIRECTIVE 94/9/EC, ANNEX II, 1.0.6

TEX DIRECTIVE 94/9/EC, ANNEX II, 1.0.6TEX DIRECTIVE 94/9/EC, ANNEX II, 1.0.6

8. The certification of this equipment relies upon

the following materials used in its construction:

If the equipment is likely to come into contact with

aggressive substances, then it is the responsibility

of the user to take suitable precautions that prevent

it from being adversely affected, thus ensuring

that the type of protection provided by the equipment

is not compromised.

Aggressive substances: e.g. acidic liquids or

gases that may attack metals, or solvents that

may affect polymeric materials.

Suitable precautions: e.g. regular checks as part

of routine inspections or establishing from the

material's data sheets that it is resistant to specific

chemicals.

Refer to "Specifications" in the "Introduction"

section:

a. All fluid passages contain stainless steel

or nylon fittings.

b. High voltage cascade is encapsulated

with a solvent resistant epoxy.

9. A recapitulation of the certification marking is

detailed in the "Atex" section, on the next page,

drawing numbers: 72562, 76180, 76801, 76856,

76860, 77319, 77319-01, 77322, 77325, 77657,

79132, and 79318.

10. The characteristics of the equipment shall be

detailed e.g. electrical, pressure, and voltage

parameters.

7. Components to be incorporated into or used as

replacement parts of the equipment shall be fitted

by suitably trained personnel in accordance with

the manufacturer's documentation.

AH-94-04.7

The manufacturer should note that, on being put

into service, the equipment must be accompanied

by a translation of the instructions in the language

or languages of the country in which the equipment

is to be used and by the instructions in the original

language.

88

8

88

REA-90 and 90L Spray Applicators - Atex

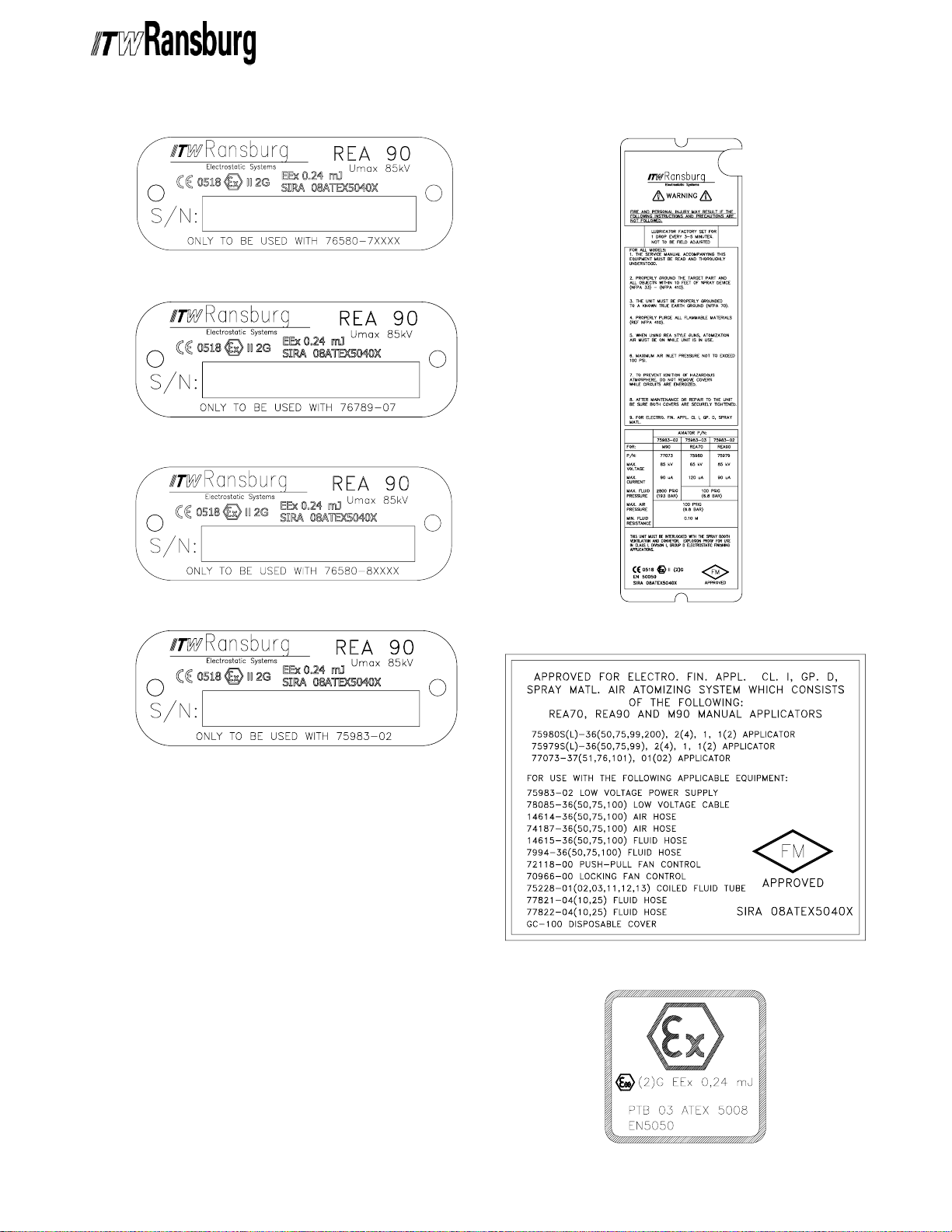

REA-90 and 90L ElectrostaticREA-90 and 90L Electrostatic

REA-90 and 90L Electrostatic

REA-90 and 90L ElectrostaticREA-90 and 90L Electrostatic

Applicators 75785, 75786, 75979,Applicators 75785, 75786, 75979,

Applicators 75785, 75786, 75979,

Applicators 75785, 75786, 75979,Applicators 75785, 75786, 75979,

and 75982 Aand 75982 A

and 75982 A

and 75982 Aand 75982 A

Product MarkingProduct Marking

Product Marking

Product MarkingProduct Marking

DefinitionsDefinitions

Definitions

DefinitionsDefinitions

Ex Certificate Number: Sira 08ATEX5040X

Sira = Notified Body performing EC-type

examination

08 = Year of certification

ATEX = Reference to ATEX Directive

5 = Protection Concept Code (code 5 is titled

Encapsulation)

040 = Document serial number

X = Special conditions for safe use apply

Special conditions for safe use: The REA-90 and

90L 75785, 75786, 75979, and 75982 Electrostatic

Applicators shall only be used with associated

76580-7XXXX, 76580-6XXXX, 76789, and 75983

Control Unit.

TEXTEX

TEX

TEXTEX

Label 76180Label 76180

Label 76180

Label 76180Label 76180

Label 76801Label 76801

Label 76801

Label 76801Label 76801

Product MarkingProduct Marking

Product Marking

Product MarkingProduct Marking

II 2 GII 2 G

II 2 G

II 2 GII 2 G

Ex = Specific marking of explosive protection

II = Equipment Group hazardous area characteristics

2 = Equipment Category

G = Type of explosive atmosphere (gases, vapors,

or mists)

EEx 0.24mJEEx 0.24mJ

EEx 0.24mJ = The REA-90 and 90L Applicators

EEx 0.24mJEEx 0.24mJ

757875, 75786, 75979, and 75982 are suitable for

use in automatic spraying installations complying

with EN 50 050 as they are a Type A class with a

discharge energy limit of 0.24mJ.

Label 72562Label 72562

Label 72562

Label 72562Label 72562

Label 76856Label 76856

Label 76856

Label 76856Label 76856

Label 76860Label 76860

Label 76860

Label 76860Label 76860

99

9

99

AH-94-04.7

REA-90 and 90L Spray Applictors - Atex

Label 77319Label 77319

Label 77319

Label 77319Label 77319

Label 77319-01Label 77319-01

Label 77319-01

Label 77319-01Label 77319-01

Label 77322Label 77322

Label 77322

Label 77322Label 77322

Label 79657Label 79657

Label 79657

Label 79657Label 79657

W

Label 77325Label 77325

Label 77325

Label 77325Label 77325

Label 79132Label 79132

Label 79132

Label 79132Label 79132

Label 79318Label 79318

Label 79318

Label 79318Label 79318

AH-94-04.7

1010

10

1010

REA-90 and 90L Spray Applicators - Introduction

INTRODUCTIONINTRODUCTION

INTRODUCTION

INTRODUCTIONINTRODUCTION

GENERAL DESCRIPTIONGENERAL DESCRIPTION

GENERAL DESCRIPTION

GENERAL DESCRIPTIONGENERAL DESCRIPTION

The REA process is an air-atomized method for

electrostatically applying coatings to objects. The

REA applicator system (technology) applies a

high voltage DC charge to the applicator electrode,

creating an electrostatic field between the atomizer

and the target object.

The REA-90 or REA-90L Delta Electrostatic Spray

Applicators (see Figures 1 and 2) applies a -85kV

DC charge to the coating materials at the point of

atomization. This electrostatic charge allows a

more efficient, uniform application of coating

material to the front, edges, sides, and back of

products. It is highly suitable for applying coatings

to a variety of surface configurations: large targets,

small parts, tubular wares, concave and recessed

parts, etc. Because it is a grounded fluid system

(for solvent based systems), it is highly suitable

for applying a wide range of solvent reduced

coatings such as enamels, lacquers, epoxies,

etc. The 75786 and 75982 models are available to

accommodate waterborne materials.

The REA-90 and REA-90L electrostatic spray

applicators are transformable between air spray

and HVLP spray technology. The REA-90 is

designed for use as a conventional air spray (highpressure) or high volume/low-pressure (HVLP)

air spray to atomize the coating material. By

changing a select few parts, the applicator may be

transformed to be operated in either spray mode.

(See "Spray Technology Conversion Procedure"

in the "Installation" section for details.)

overspray around and deposit it on the back

surface of the target. Therefore, a high percentage

of the coating is deposited on the target.

One of the many features of the REA applicator

system is that the electrical energy, which is

available from the resistive charging electrode, is

limited to the optimum level of safety and efficiency.

This system is incapable of releasing sufficient

electrical or thermal energy during normal operating

conditions to cause ignition of specific hazardous

materials in their most easily ignited concentrations

in air (see NFPA-33).

The control unit provides low voltage output to the

applicator and contains controls for AC on/off,

high voltage adjust, kV and micro amp meter.

As the applicator electrode approaches ground,

the control unit and applicator circuitry cause the

high voltage and current to “fold back” and decrease

towards zero for models 75785, 75979, and 75982.

For models 75786, the fold back circuitry in the

control unit has been turned off to provide maximum

voltage for waterborne applications.

W A R N I N GW A R N I N G

W A R N I N G

W A R N I N GW A R N I N G

!!

!

!!

> Never use a standard solvent base

applicator system (75785 or 75979) on a

standard waterborne control unit. Failure

to comply may cause damage to equipment and/or risk of fire and injury.

A regulated pressure fluid system delivers coating

material to the atomizer. At the time of triggering

the applicator, fan and atomization air is introduced,

which atomizes the coating material into a spray

mist. The atomized spray particles under the

influence of the electrostatic field become

electrically charged. The charged particles are

attracted to, and deposited on, the target object.

The forces between the charged particles and the

grounded target are sufficient to turn most normal

1111

11

1111

W A R N I N GW A R N I N G

W A R N I N G

W A R N I N GW A R N I N G

!!

!

!!

> Never use a waterborne (75786 or

75982) REA-90 system to spray solvent

reduced coating materials. Failure to

comply may cause damage to equipment

and/or risk of fire and injury.

AH-94-04.7

REA-90 and 90L Spray Applicators - Introduction

W A R N I N GW A R N I N G

W A R N I N G

W A R N I N GW A R N I N G

!!

!

!!

> When more than one waterborne

applicator is fed from a common isolated

supply, there is a potential for electrical

energy discharge through any other

applicators when one applicator is triggered. Depending upon the system

capacity, this discharge could be hazardous.

TMTM

TM

REA-90 WITH AREA-90 WITH A

REA-90 WITH A

REA-90 WITH AREA-90 WITH A

The REA-90 may be used with the AVIATOR

power generator in hazardous locations. This

equipment meets Class 1, Division 1, and Group

D hazardous location requirements. This allows

moving the REA-90 power source inside most

spray booths or areas where the standard control

unit may not be conveniently located. Examples

are airplane hangars, etc.

VIAVIA

VIA

VIAVIA

TT

T

TT

OROR

OR

OROR

TMTM

NOTESNOTES

NOTES

NOTESNOTES

AH-94-04.7

1212

12

1212

REA-90 and 90L Spray Applicators - Introduction

75785 SOL75785 SOL

75785 SOL

75785 SOL75785 SOL

REA-90 STREA-90 ST

REA-90 ST

REA-90 STREA-90 ST

SPECIFICASPECIFICA

SPECIFICA

SPECIFICASPECIFICA

Environmental / PhysicalEnvironmental / Physical

Environmental / Physical

Environmental / PhysicalEnvironmental / Physical

Applicator Length:Applicator Length:

Applicator Length:

Applicator Length:Applicator Length:

Weight:Weight:

Weight: 28 ounces (793.8g)

Weight:Weight:

Hose and CableHose and Cable

Hose and Cable

Hose and CableHose and Cable

Lengths:Lengths:

Lengths:

Lengths:Lengths:

AtomizerAtomizer

Atomizer

AtomizerAtomizer

Assembly (Std):Assembly (Std):

Assembly (Std):

Assembly (Std):Assembly (Std):

ElectricalElectrical

Electrical

ElectricalElectrical

Operating Voltage:Operating Voltage:

Operating Voltage: 85kV DC (-) maximum

Operating Voltage:Operating Voltage:

Current Output:Current Output:

Current Output: 90 microamperes maximum

Current Output:Current Output:

VENTVENT

VENT

VENTVENT

ANDARDANDARD

ANDARD

ANDARDANDARD

TIONSTIONS

TIONS

TIONSTIONS

11-inches (279.4mm)

36 ft (Optional: 50, 75,

and 100 ft)

4907-45, 4904-65R

Air Spray

75601-00, 75600-01 HVLP

(foldback)

BASE BASE

BASE

BASE BASE

75979 SOL75979 SOL

75979 SOL

75979 SOL75979 SOL

REA-90 AREA-90 A

REA-90 A

REA-90 AREA-90 A

SPECIFICASPECIFICA

SPECIFICA

SPECIFICASPECIFICA

Environmental / PhysicalEnvironmental / Physical

Environmental / Physical

Environmental / PhysicalEnvironmental / Physical

Applicator Length:Applicator Length:

Applicator Length:

Applicator Length:Applicator Length:

Weight:Weight:

Weight: 28 ounces (793.8g)

Weight:Weight:

Hose and CableHose and Cable

Hose and Cable

Hose and CableHose and Cable

Lengths:Lengths:

Lengths:

Lengths:Lengths:

AtomizerAtomizer

Atomizer

AtomizerAtomizer

Assembly (Std):Assembly (Std):

Assembly (Std):

Assembly (Std):Assembly (Std):

ElectricalElectrical

Electrical

ElectricalElectrical

Operating Voltage:Operating Voltage:

Operating Voltage: 85kV DC (-) maximum

Operating Voltage:Operating Voltage:

Current Output:Current Output:

Current Output: 90 microamperes maximum

Current Output:Current Output:

VENTVENT

VENT

VENTVENT

VIAVIA

TT

VIA

T

VIAVIA

TT

TIONSTIONS

TIONS

TIONSTIONS

11-inches (279.4mm)

36 ft (Optional: 50, 75,

and 100 ft)

4907-45, 4904-65R

Air Spray

75601-00, 75600-01 HVLP

(foldback)

BASE BASE

BASE

BASE BASE

OR / MGSOR / MGS

OR / MGS

OR / MGSOR / MGS

TMTM

TM

TMTM

Paint Resistance *: Paint Resistance *:

Paint Resistance *: .1 MΩ to ∞

Paint Resistance *: Paint Resistance *:

Part Sprayability:Part Sprayability:

Part Sprayability: Determine sprayability of

Part Sprayability:Part Sprayability:

part to be coated using

76652, Test Equipment

MechanicalMechanical

Mechanical

MechanicalMechanical

Fluid FlowFluid Flow

Fluid Flow

Fluid FlowFluid Flow

Capacity:Capacity:

Capacity: 1000 cc/minute**

Capacity:Capacity:

Operating Pressure (Air Spray)Operating Pressure (Air Spray)

Operating Pressure (Air Spray)

Operating Pressure (Air Spray)Operating Pressure (Air Spray)

Fluid:Fluid:

Fluid:

Fluid:Fluid:

Air:Air:

Air: 0-100 psi

Air:Air:

Consumption:Consumption:

Consumption: 16 CFM @ 50 psi

Consumption:Consumption:

Operating Pressure (HVLP Spray)Operating Pressure (HVLP Spray)

Operating Pressure (HVLP Spray)

Operating Pressure (HVLP Spray)Operating Pressure (HVLP Spray)

Fluid:Fluid:

Fluid:

Fluid:Fluid:

Air:Air:

Air: 0-100 psi

Air:Air:

Consumption:Consumption:

Consumption: 22 CFM @ 50 psi

Consumption:Consumption:

0-100 psi

0-100 psi

(handle input) for 10 psi

nozzle output

Paint Resistance *: Paint Resistance *:

Paint Resistance *: .1 MΩ to ∞

Paint Resistance *: Paint Resistance *:

Part Sprayability:Part Sprayability:

Part Sprayability: Determine sprayability of

Part Sprayability:Part Sprayability:

part to be coated using

76652, Test Equipment

MechanicalMechanical

Mechanical

MechanicalMechanical

Fluid FlowFluid Flow

Fluid Flow

Fluid FlowFluid Flow

Capacity:Capacity:

Capacity: 1000 cc/minute**

Capacity:Capacity:

Operating Pressure (Air Spray)Operating Pressure (Air Spray)

Operating Pressure (Air Spray)

Operating Pressure (Air Spray)Operating Pressure (Air Spray)

Fluid:Fluid:

Fluid:

Fluid:Fluid:

Air:Air:

Air: 0-100 psi

Air:Air:

Consumption:Consumption:

Consumption: 16 CFM @ 50 psi

Consumption:Consumption:

Operating Pressure (HVLP Spray)Operating Pressure (HVLP Spray)

Operating Pressure (HVLP Spray)

Operating Pressure (HVLP Spray)Operating Pressure (HVLP Spray)

Fluid:Fluid:

Fluid:

Fluid:Fluid:

Air:Air:

Air: 0-100 psi

Air:Air:

Consumption:Consumption:

Consumption: 22 CFM @ 50 psi

Consumption:Consumption:

0-100 psi

0-100 psi

(handle input) for 10 psi

nozzle output

**

*(Use Model No. 76652, Test Equipment) ** This reflects the maximum fluid volume the

**

applicator can deliver. The maximum spray volume

that can be atomized depends on fluid rheology,

spray technology, and finish quality required.

1313

13

1313

AH-94-04.7

REA-90 and 90L Spray Applicators - Introduction

APPLICATOR:APPLICATOR:

APPLICATOR:

APPLICATOR:APPLICATOR:

REA-90 (75785S & 75979S)

REA90L (75785L & 75979L)

AH-94-04.7

Figure 1: REA-90 and REA-90L Standard & AVIATOR/MGS SolventborneFigure 1: REA-90 and REA-90L Standard & AVIATOR/MGS Solventborne

Figure 1: REA-90 and REA-90L Standard & AVIATOR/MGS Solventborne

Figure 1: REA-90 and REA-90L Standard & AVIATOR/MGS SolventborneFigure 1: REA-90 and REA-90L Standard & AVIATOR/MGS Solventborne

Electrostatic Spray Applicator FeaturesElectrostatic Spray Applicator Features

Electrostatic Spray Applicator Features

Electrostatic Spray Applicator FeaturesElectrostatic Spray Applicator Features

1414

14

1414

REA-90 and 90L Spray Applicators - Introduction

75786 W75786 W

75786 W

75786 W75786 W

REA-90 STREA-90 ST

REA-90 ST

REA-90 STREA-90 ST

SPECIFICASPECIFICA

SPECIFICA

SPECIFICASPECIFICA

Environmental / PhysicalEnvironmental / Physical

Environmental / Physical

Environmental / PhysicalEnvironmental / Physical

Applicator Length:Applicator Length:

Applicator Length:

Applicator Length:Applicator Length:

Weight:Weight:

Weight: 28 ounces (793.8g)

Weight:Weight:

Hose and CableHose and Cable

Hose and Cable

Hose and CableHose and Cable

Lengths:Lengths:

Lengths:

Lengths:Lengths:

AtomizerAtomizer

Atomizer

AtomizerAtomizer

Assembly (Std):Assembly (Std):

Assembly (Std): 4907-45, 4904-65R

Assembly (Std):Assembly (Std):

ElectricalElectrical

Electrical

ElectricalElectrical

Operating Voltage:Operating Voltage:

Operating Voltage: 85kV DC (-) maximum

Operating Voltage:Operating Voltage:

Current Output:Current Output:

Current Output: 150 microamperes

Current Output:Current Output:

AA

TERBORNETERBORNE

A

TERBORNE

AA

TERBORNETERBORNE

ANDARDANDARD

ANDARD

ANDARDANDARD

TIONSTIONS

TIONS

TIONSTIONS

11-inches (279.4mm)

36 ft

(Optional: 50 and 75 ft)

Air Spray

75601-00, 75600-01 HVLP

maximum (no foldback)

75982 W75982 W

75982 W

75982 W75982 W

REA-90 AREA-90 A

REA-90 A

REA-90 AREA-90 A

SPECIFICASPECIFICA

SPECIFICA

SPECIFICASPECIFICA

Environmental / PhysicalEnvironmental / Physical

Environmental / Physical

Environmental / PhysicalEnvironmental / Physical

Applicator Length:Applicator Length:

Applicator Length:

Applicator Length:Applicator Length:

Weight:Weight:

Weight: 28 ounces (793.8g)

Weight:Weight:

Hose and CableHose and Cable

Hose and Cable

Hose and CableHose and Cable

Lengths:Lengths:

Lengths:

Lengths:Lengths:

AtomizerAtomizer

Atomizer

AtomizerAtomizer

Assembly (Std):Assembly (Std):

Assembly (Std):

Assembly (Std):Assembly (Std):

ElectricalElectrical

Electrical

ElectricalElectrical

Operating Voltage:Operating Voltage:

Operating Voltage: 85kV DC (-) maximum

Operating Voltage:Operating Voltage:

Current Output:Current Output:

Current Output: 90 microamperes maximum

Current Output:Current Output:

AA

TERBORNETERBORNE

A

TERBORNE

AA

TERBORNETERBORNE

VIAVIA

TT

VIA

VIAVIA

TIONSTIONS

TIONS

TIONSTIONS

OROR

T

OR

TT

OROR

11-inches (279.4mm)

36 ft

(Optional: 50 and 75 ft)

4907-45, 4904-65R

Air Spray

75601-00, 75600-01 HVLP

(foldback)

Part Sprayability:Part Sprayability:

Part Sprayability: Determine sprayability of

Part Sprayability:Part Sprayability:

part to be coated using

76652, Test Equipment

MechanicalMechanical

Mechanical

MechanicalMechanical

Fluid FlowFluid Flow

Fluid Flow

Fluid FlowFluid Flow

Capacity **:Capacity **:

Capacity **: 1000 cc/minute

Capacity **:Capacity **:

Operating Pressure (Air Spray)Operating Pressure (Air Spray)

Operating Pressure (Air Spray)

Operating Pressure (Air Spray)Operating Pressure (Air Spray)

Fluid:Fluid:

Fluid:

Fluid:Fluid:

Air:Air:

Air: 0-100 psi

Air:Air:

Consumption:Consumption:

Consumption: 16 CFM @ 50 psi

Consumption:Consumption:

Operating Pressure (HVLP Spray)Operating Pressure (HVLP Spray)

Operating Pressure (HVLP Spray)

Operating Pressure (HVLP Spray)Operating Pressure (HVLP Spray)

Fluid:Fluid:

Fluid:

Fluid:Fluid:

Air:Air:

Air: 0-100 psi

Air:Air:

Consumption:Consumption:

Consumption: 22 CFM @ 50 psi

Consumption:Consumption:

0-100 psi

0-100 psi

(handle input) for 10 psi

nozzle output

Part Sprayability:Part Sprayability:

Part Sprayability: Determine sprayability of

Part Sprayability:Part Sprayability:

part to be coated using

76652, Test Equipment

MechanicalMechanical

Mechanical

MechanicalMechanical

Fluid FlowFluid Flow

Fluid Flow

Fluid FlowFluid Flow

Capacity **:Capacity **:

Capacity **: 1000 cc/minute

Capacity **:Capacity **:

Operating Pressure (Air Spray)Operating Pressure (Air Spray)

Operating Pressure (Air Spray)

Operating Pressure (Air Spray)Operating Pressure (Air Spray)

Fluid:Fluid:

Fluid:

Fluid:Fluid:

Air:Air:

Air: 0-100 psi

Air:Air:

Consumption:Consumption:

Consumption: 16 CFM @ 50 psi

Consumption:Consumption:

Operating Pressure (HVLP Spray)Operating Pressure (HVLP Spray)

Operating Pressure (HVLP Spray)

Operating Pressure (HVLP Spray)Operating Pressure (HVLP Spray)

Fluid:Fluid:

Fluid:

Fluid:Fluid:

Air:Air:

Air: 0-100 psi

Air:Air:

Consumption:Consumption:

Consumption: 22 CFM @ 50 psi

Consumption:Consumption:

** This reflects the maximum fluid volume the

applicator can deliver. The maximum spray volume

that can be atomized depends on fluid rheology,

spray technology, and finish quality required.

0-100 psi

0-100 psi

(handle input) for 10 psi

nozzle output

1515

15

1515

AH-94-04.7

REA-90 and 90L Spray Applicators - Introduction

APPLICATORAPPLICATOR

APPLICATOR

APPLICATORAPPLICATOR

REA-90 (75786S & 75982S)

REA90L (75786L & 75982L)

AH-94-04.7

Figure 2: REA-90 and REA-90L Standard & AVIATOR WaterborneFigure 2: REA-90 and REA-90L Standard & AVIATOR Waterborne

Figure 2: REA-90 and REA-90L Standard & AVIATOR Waterborne

Figure 2: REA-90 and REA-90L Standard & AVIATOR WaterborneFigure 2: REA-90 and REA-90L Standard & AVIATOR Waterborne

Electrostatic Spray Applicator FeaturesElectrostatic Spray Applicator Features

Electrostatic Spray Applicator Features

Electrostatic Spray Applicator FeaturesElectrostatic Spray Applicator Features

1616

16

1616

REA-90 and 90L Spray Applicators - Installation

INSTINST

INST

INSTINST

75785 ST75785 ST

75785 ST

75785 ST75785 ST

SOLSOL

SOL

SOLSOL

75979 A75979 A

75979 A

75979 A75979 A

SOLSOL

SOL

SOLSOL

INSTINST

INST

INSTINST

> Installation of the equipment MUST be in

compliance with all Federal, State, and Local

Codes. Prior to installation, all personnel

should read and understand the NFPA-33, e

OSHA, and ITW Ransburg Bulletin "Operating Your Electrostatic Coating System

safely".

ALLAALLA

ALLA

ALLAALLA

VENTVENT

VENT

VENTVENT

VIAVIA

VIA

VIAVIA

VENTVENT

VENT

VENTVENT

ALLAALLA

ALLA

ALLAALLA

W A R N I N GW A R N I N G

W A R N I N G

W A R N I N GW A R N I N G

!!

!

!!

TIONTION

TION

TIONTION

ANDARDANDARD

ANDARD

ANDARDANDARD

BASE AND BASE AND

BASE AND

BASE AND BASE AND

TT

OR / MGSOR / MGS

T

OR / MGS

TT

OR / MGSOR / MGS

BASE BASE

BASE

BASE BASE

TIONTION

TION

TIONTION

The control unit MAY be connected through conduit

to an explosion-proof switch (to turn high voltage

on and off) and explosion-proof indicator light

(indicates status of control unit) within the

hazardous area for the convenience of the

operator.

Location of Control UnitLocation of Control Unit

Location of Control Unit

Location of Control UnitLocation of Control Unit

(A(A

VIAVIA

TT

(A

VIA

(A(A

VIAVIA

The AVIATOR may be located within the hazardous

area. It may be mounted on a booth wall, pump

cart, or other suitable places. Refer to the AVIATOR

Power Generator manual for details on its

installation.

The air supply to the AVIATOR Power Generator

must be interlocked with the exhaust air for the

spray area. If a conveyor system is used, then the

air supply must be interlocked with it also.

OR Units)OR Units)

T

OR Units)

TT

OR Units)OR Units)

ACAC

AC

ACAC

InIn

In

InIn

W A R N I N GW A R N I N G

W A R N I N G

W A R N I N GW A R N I N G

!!

!

!!

NEVERNEVER

>

NEVER wrap the applicator, associated

NEVERNEVER

valves and tubing, and supporting hardware

in plastic to keep it clean. A surface charge

may build up on the plastic surface and

discharge to the nearest grounded object.

Efficiency of the applicator will also be

reduced and damage or failure of the applicator components may occur.

THE APPLICATOR IN PLASTIC WILLTHE APPLICATOR IN PLASTIC WILL

THE APPLICATOR IN PLASTIC WILL

THE APPLICATOR IN PLASTIC WILLTHE APPLICATOR IN PLASTIC WILL

VOID WARRANTY.VOID WARRANTY.

VOID WARRANTY.

VOID WARRANTY.VOID WARRANTY.

Location of Control UnitLocation of Control Unit

Location of Control Unit

Location of Control UnitLocation of Control Unit

(Non-A(Non-A

(Non-A

(Non-A(Non-A

Install the low voltage control unit at least 3 feet

(0.9m) outside the spray area and/or in accordance

with federal, state, and local codes. Refer to the

low voltage control unit manual for mounting details.

The control unit can be wired through conduit or

with a line cord depending upon application

requirements and codes.

VIAVIA

VIA

VIAVIA

TT

OR Units)OR Units)

T

OR Units)

TT

OR Units)OR Units)

WRAPPING WRAPPING

WRAPPING

WRAPPING WRAPPING

Routing of Low VRouting of Low V

Routing of Low V

Routing of Low VRouting of Low V

Position the spray applicator in the spray area and

route the low voltage cable to the control unit. The

cable should be routed so that it is not damaged by

foot and vehicle traffic and also so that it is not

close to areas of high temperature (129oF+). The

operator should have free movement of the

applicator and all bend radius of the cable should

not be less than 6 inches (15 cm). Connect the low

voltage cable to the control unit and hand tighten

the retaining nut. If during the routing of the low

voltage cable it is required to remove it from the

spray applicator, care should be taken when

reinstalling it back that the retaining nut is wrench

tight and the nut cannot be removed by hand.

C A U T I O NC A U T I O N

C A U T I O N

C A U T I O NC A U T I O N

!!

!

!!

> Do NOT overtighten the low voltage

connection at the applicator. The plastic

parts could be damaged.

oltage Cableoltage Cable

oltage Cable

oltage Cableoltage Cable

1717

17

1717

AH-94-04.7

ACAC

AC

ACAC

InIn

In

InIn

AirAir

Air

AirAir

RegulatorRegulator

Regulator

PowerPower

Power

PowerPower

SupplySupply

Supply

SupplySupply

BoothBooth

Booth

BoothBooth

Figure 3: Typical REA Applicator InstallationFigure 3: Typical REA Applicator Installation

Figure 3: Typical REA Applicator Installation

Figure 3: Typical REA Applicator InstallationFigure 3: Typical REA Applicator Installation

W A R N I N GW A R N I N G

W A R N I N G

W A R N I N GW A R N I N G

!!

!

!!

TargetTarget

Target

TargetTarget

RegulatorRegulator

ApplicatorApplicator

Applicator

ApplicatorApplicator

> The electrical discharge that is available

from the charging electrode must not

exceed 0.25 mJ of energy. To achieve this

limit, any flow of energy from the paint

supply through the paint line to the applicator electrode must be prevented by grounding the paint line at the applicator handle.

REA-90 and 90L Spray Applicators - Installation

FILFIL

TERSTERS

FIL

TERS

FILFIL

TERSTERS

Air InAir In

Air In

Air InAir In

1. Install an air filter assembly on the air inlet of the

control unit. Screw the fitting into the filter inlet.

The filter MUST be installed with the arrow pointing

PaintPaint

Paint

PaintPaint

SupplySupply

Supply

SupplySupply

in the direction of flow. Refer to the appropriate

filter assembly manual for installation instructions.

C A U T I O NC A U T I O N

C A U T I O N

C A U T I O NC A U T I O N

!!

!

!!

> An air filter MUST be installed to permit

proper functioning of the air flow switch

inside the control unit.

2. ITW Ransburg recommends that a fluid filter be

installed at the output of the fluid supply (pressure

pot, pump, circulating system, etc.). It is the end

users responsibility to install a filter that meets

their system's requirements.

Verify that the applicator handle is actually

grounded before operating it! This is done

with a fully connected and operational system, by placing one lead of an ohmmeter to

the handle and the other to the building

electrical ground (cold water pipe, building

structure, steel, etc.). This reading should

be essentially zero.

If a greater reading is obtained, check that

the control unit is grounded. See the control unit manual for grounding procedure.

W A R N I N GW A R N I N G

W A R N I N G

W A R N I N GW A R N I N G

!!

!

!!

> When installing the AVIATOR Power

Generator, the air supply to the generator

must be interlocked with the booth exhaust

air and the conveyor system.

AH-94-04.7

1818

18

1818

REA-90 and 90L Spray Applicators - Installation

Location of Control UnitLocation of Control Unit

Location of Control Unit

75786 ST75786 ST

75786 ST

75786 ST75786 ST

WW

AA

TERBORNE ANDTERBORNE AND

W

A

TERBORNE AND

WW

AA

TERBORNE ANDTERBORNE AND

75982 A75982 A

75982 A

75982 A75982 A

WW

AA

TERBORNETERBORNE

W

A

TERBORNE

WW

AA

TERBORNETERBORNE

INSTINST

INST

INSTINST

> Installation of the equipment MUST be in

compliance with all Federal, State, and

Local Codes. Prior to installation, all personnel should read and understand the

NFPA-33, OSHA, and ITW Ransburg

Bulletin "Operating Your Electrostatic

Coating System Safely".

> The control unit MUST be located

outside of the spray area.

> The fluid lines and fluid sources MUST

be isolated from ground.

> Personnel MUST be GROUNDED to

prevent a shock or spark during electrostatic operation.

ALLAALLA

ALLA

ALLAALLA

!!

!

!!

ANDARDANDARD

ANDARD

ANDARDANDARD

VIAVIA

TT

VIA

VIAVIA

W A R N I N GW A R N I N G

W A R N I N G

W A R N I N GW A R N I N G

OROR

T

OR

TT

OROR

TIONTION

TION

TIONTION

Location of Control UnitLocation of Control Unit

(Non-A(Non-A

(Non-A

(Non-A(Non-A

Position the low voltage control unit at least 3 feet

(0.9m) outside the spray area and in accordance

with federal, state, and local codes. Refer to the

Low Voltage Control Unit manual for mounting

details. The control unit can be wired through

conduit or with a line cord depending upon

application requirements and codes.

The control unit MAY be connected through conduit

to an explosion-proof switch (to turn high voltage

on and off) and explosion-proof indicator light

(indicates status of control unit) within the

hazardous area for the convenience of the

operator.

Location of Control UnitLocation of Control Unit

Location of Control Unit

Location of Control UnitLocation of Control Unit

(A(A

VIAVIA

VIA

VIAVIA

TT

T

TT

(A

(A(A

The AVIATOR may be located within the hazardous

area. It may be mounted on a booth wall, pump

cart, or other suitable places. Refer to the

AVIATOR Power Generator manual, for details on

its installation.

VIAVIA

TT

VIA

VIAVIA

OR Units)OR Units)

OR Units)

OR Units)OR Units)

OR Units)OR Units)

T

OR Units)

TT

OR Units)OR Units)

> Install and route the hoses and cable so

they are NOT exposed to temperatures in

excess of 120

cable bends are NO LESS than a 6-inch

(15cm) radius. Failure to comply with these

parameters could cause equipment malfunction that might create HAZARDOUS

CONDITIONS!

> Install only one spray applicator per

isolated fluid supply system.

NEVERNEVER

>

NEVER wrap the applicator, associated

NEVERNEVER

valves and tubing, and supporting hardware

in plastic to keep it clean. A surface charge

may build up on the plastic surface and

discharge to the nearest grounded object.

Efficiency of the applicator will also be

reduced and damage or failure of the applicator components may occur.

THE APPLICATOR IN PLASTIC WILLTHE APPLICATOR IN PLASTIC WILL

THE APPLICATOR IN PLASTIC WILL

THE APPLICATOR IN PLASTIC WILLTHE APPLICATOR IN PLASTIC WILL

VOID WARRANTY.VOID WARRANTY.

VOID WARRANTY.

VOID WARRANTY.VOID WARRANTY.

o

F and so that all hose and

W A R N I N GW A R N I N G

W A R N I N G

W A R N I N GW A R N I N G

!!

!

!!

WRAPPING WRAPPING

WRAPPING

WRAPPING WRAPPING

The air supply to the AVIATOR Power Generator

must be interlocked with the exhaust air for the

spray area. If a conveyor system is used, then the

air supply must be interlocked with it also.

Routing of Low VRouting of Low V

Routing of Low V

Routing of Low VRouting of Low V

Position the spray applicator in the spray area and

route the low voltage cable to the control unit. The

cable should be routed so that it is not damaged by

foot and vehicle traffic and also so that it is not

close to areas of high temperature (129oF+). The

operator should have free movement of the

applicator and all bend radius of the cable should

not be less than 6 inches (15 cm). Connect the low

voltage cable to the control unit and hand tighten

the retaining nut. If during the routing of the low

voltage cable it is required to remove it from the

spray applicator, care should be taken when

reinstalling it back that the retaining nut is wrench

tight and cannot be removed by hand.

oltage Cableoltage Cable

oltage Cable

oltage Cableoltage Cable

1919

19

1919

AH-94-04.7

Loading...

Loading...