RANDELL 9148W User Manual

PROJECT NAME:

LOCATION:

ITEM NO:

BREADING TABLE

MEGA-TOP COLD-WALL PREP TABLE MODEL 9000W

The 9000W series addresses three specific environments where a forced air cooled mega-top does not fit the

application: 1) Breading station where coating and milk-wash combine to create a messy situation and when

spillage gets into the evaporator coil on forced air units. The 9000W eliminates unit failure with its 100% sealed

cold-wall tank with a drain for cleaning. 2) High heat environments, such as close proximity to a solid fuel

char-broiler, where forced air does not have enough capacity to keep product cool. 3) Front of the house when

covers are not used, the gentle cold blanket of air created by the recessed cold wall does a better job than forced

air designs. Available is 3 standard lengths; 48” (1-door), 60” (2-door) and a 72” (3-door). Design based on

Randell’s 30-years of cold wall experience. Meets the 1998 NSF/ANSI standard 7, for 41ºF pan temperatures.

AVAILABLE MODELS:

9148W

9260W

9272W

STANDARD FEATURES:

• Meets 1998 NSF/ANSI standard 7,41˚ F product

temperature requirements

•

Recessed wrapped coldwall sealed pan opening with

exclusive separate temperature controls & expansion

valve for base and pan opening

• Exclusive press fit magnetic removable gaskets

• Separate dual control system for upper pan opening &

base allows shutting pan opening off at night for up to

60% energy savings

• Condensing unit with hot gas condensate evaporator

• Hinged louver for panel for easy access to drain gate

valve, upper pan opening temperature control and

cleaning of condenser coil

• Exclusive rail drain for easy clean-up

CABINET EXTERIOR: Unit top and raised upper

pan opening will be formed from 20 gauge stainless steel

with a 1-1/2” 90˚ nosing/top turndown. The refrigerated

upper pan opening will be mechanically cooled and shall

be provided with one single opening to allow flexible pan

configurations. The interior of the upper pan opening

will be constructed of three-piece construction with

coved corners for easy cleaning. Pan opening will hold

6” deep pans - not included. The pans will set on an

integral recessed pan ledge (3” at front and rear) making

clean-up easy without requiring the removal of any pan

supports. All units provided with hood style covers that

allow for easy access to pans when in use. Also supplied

is inter-locking adaptor bar grid to accommodate any size

pan up to 6” deep. Unit bottom and exterior back are

galvanized metal. Exterior ends are finished in stainless

steel. Standard hinged louver for easier cleaning of the coil

and draining the pan opening. Unit mounted on 6” (overall)

high swivel casters (front two with locks).

CABINET BASE INTERIOR:

and top shall be anodized aluminum. Base interior ends

and door openings shall be thermoformed high impact

ABS. The base shall be foamed in place polyurethane

insulation with a minimum thickness of 2”.

Interior sides, rear

DOORS: Stainless steel front with easy to grasp

recessed handles. Doors mounted on heavy duty

stainless steel concealed type hinges with pivot

pin in nylon bushing. Door interior is deep drawn

thermoformed high impact ABS with press-fit

replaceable magnetic gaskets, designed for long life

and easy maintenance. Doors are foamed in place

polyurethane insulation.

REFRIGERATION SYSTEM: The system will

utilize R-404a refrigerant and be provided with a hot

gas condensate evaporation system. Dual refrigeration

system with independent controls for the base and the

upper pan opening. The base will have a blower coil

with a dedicated metering device and solenoid valve

allowing the thermostatic control to independently

control the base temperature. The mechanically

cooled upper pan opening will be controlled utilizing

an expansion valve metering device with its own

solenoid valve and thermostat. An on/off switch,

located directly behind the hinged louver, is provided

as standard to allow the upper pan opening to be shut

off independently of the base. A pressure control is

provided to monitor the dual systems performance.

ELECTRICAL: The units will be provided with a

8’ power cord and 3-wire grounded plug as standard,

pre-wired for 115 volt, 60 hertz, single phase

operation. Export voltages are available and require

hard wiring in the field to the units main junction box,

(unit will be shipped on legs for export applications,

unless specified otherwise). This equipment is intended

for use in rooms having an ambient temperature of

86˚F (30˚C) or less.

ORIGIN OF MANUFACTURE:

Designed and manufactured in the United States.

QTY:

MODEL NO:

AIA NO:

SIS NO:

CSI SECTION: 11400

9000W flat-top, mega-pan opening

with cold-wall conductive cooling

preparation tables.

Model 9260W shown.

OPTIONS/ACCESSORIES:

Overshelf assembly

Stainless steel back

Legs in lieu of casters

Lift off night covers

Hinged slide back covers

Hinged cover

Drawers

Sheet pan racks

Pull-out shelf system

Door/Drawer locks

Breading Tables

PPSPEC9000W RevE

Revised 02/16

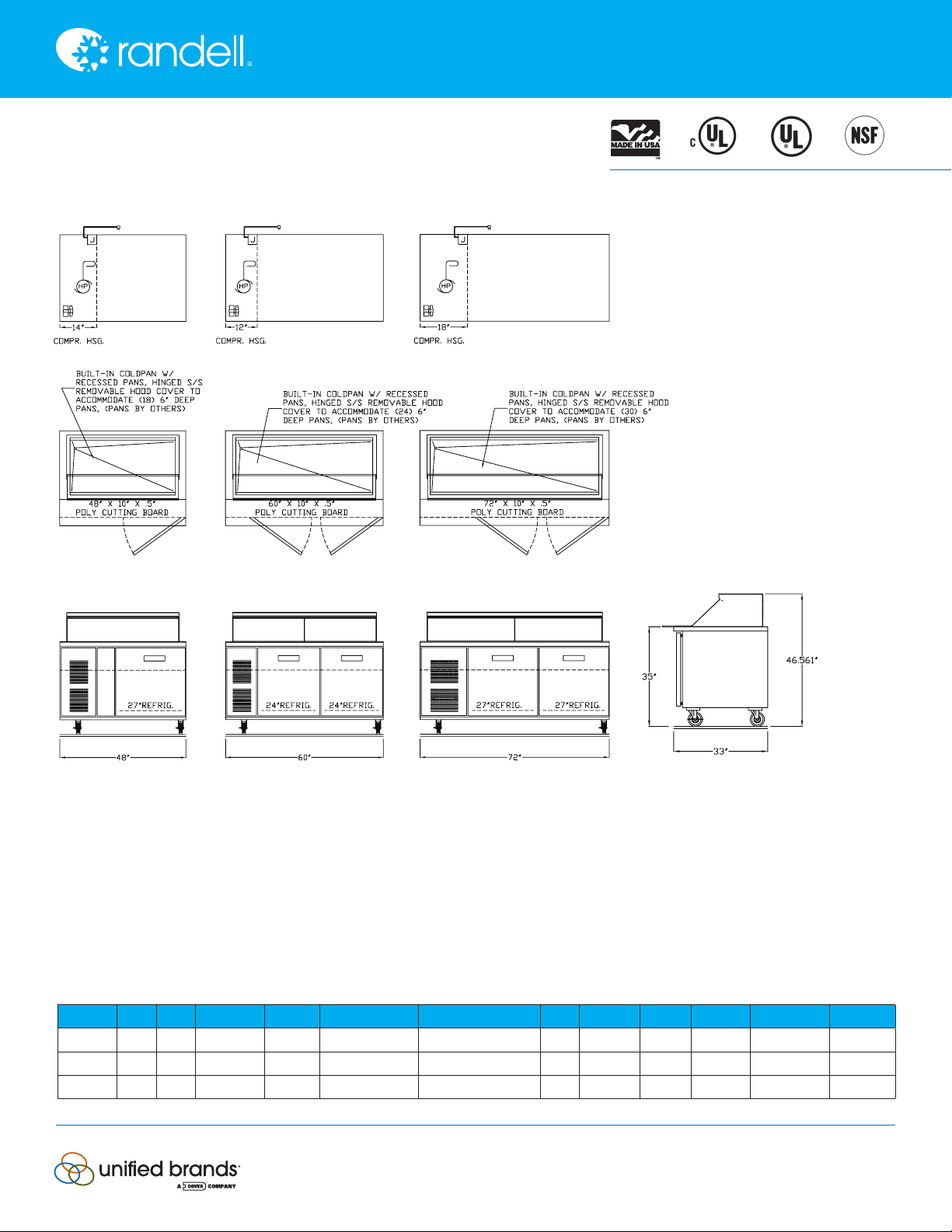

9000W

NO SHELF NO SHELF NO SHELF NO SHELF NO SHELF

Model L W H Doors Storage Cu. Ft. Pan Capacity HP Volt Amps NEMA BTU Rating Ship Wt.

9148W 48” 33” 46.561” (1)27” 5.5 (9)1/3 or (18)1/6 1/3 115/60/1 9 5-15P 1380 355

9260W 60” 33” 46.561” (2)24” 9.8 (12)1/3 or (24)1/6 1/3 115/60/1 9 5-15P 1380 400

9272W 72” 33” 46.561” (2)27” 11.2 (15)1/3 or (30)1/6 1/2 115/60/1 12 5-15P 2420 475

888-994-7636, unifiedbrands.net

© 2016 Unified Brands. All Rights Reserved. Unified Brands is a wholly-owned subsidiary of Dover Corporation.

Loading...

Loading...