RANDELL 64335 User Manual

PROJECT NAME:

LOCATION:

ITEM NO:

CUSTOM

REMOTE WORKTOP FREEZER MODEL 64000

Remote freezer base with 16 gauge reinforced stainless steel top, and integral backsplash with 45˚ return.

Stainless steel doors on concealed hinges. CCFC free, R404a as standard refrigerant system (consult factory

for alternative options). Condensing unit not provided. Evaporator blower coil with expansion valve supplied and

installed. Unit with automatic defrost system, and heated door frames. 6” high adjustable and movable legs.

AVAILABLE MODELS:

64335

64338

64341

64352

64358

64364

64382

STANDARD FEATURES:

• Available under one piece top with other modular

equipment up to 16’ in length

• 6” high legs—adjustable and movable

• Foamed in place “CFC free” urethane insulation

• Refrigeration system utilizes CFC free, R404a as

standard refrigerant system, expansion valve for fast

recovery, and digital control for field adjustability and

solenoid valve

• Automatic coil defrost system

• 45˚ integral stainless backsplash is standard. 90˚

stainless backsplash is optional.

• Precise temperature settings, LED temperature readout

• Filter dryer installed on liquid line

CABINET INTERIOR: Base interior to be

ABS thermoplastic at ends only. Stainless steel

interior liner to be coved cornered to form bottom,

back and top. One baked enamel finished shelf

provided behind each door. Unit insulation to be CFC

free foamed in place urethane.

DOORS: Door fronts to be 22 gauge stainless steel

with 16 gauge stainless steel handles, magnetic

gaskets, ABS door liner and foamed in place

insulation. Hinges are concealed, all stainless steel

with bronze pivot pin in nylon bushing.

REFRIGERATION: Refrigerant to be specified

by customer (Specification based on R-404a

refrigerant). Interior fitted with Randell evaporator

blower coil for cooling base. Expansion valve and

refrigeration lines provided and installed for

connection at unit rear. Blower coil fitted with

expansion valve for fast recovery and automatic

defrost heater system with digital control and safety

switches. Condensing unit not provided. Unit totally

prewired to junction box for 115V operation.

QTY:

MODEL NO:

AIA NO:

SIS NO:

CSI SECTION: 11400

Custom, Remote Worktop Freezer .

Model shown with optional finished

end.

OPTIONS/ACCESSORIES:

Stainless Steel Ends

Stainless Steel Back

Flat Top with no backsplash

CABINET EXTERIOR: Top to be one piece of die

formed 16 gauge stainless steel with 2 1/2” nosing.

Backsplash to be coved cornered, with 45˚ return at top

and overall height of 6 3/4”. Ends at top fitted with

recessed heavy duty steel bars for field bolting units

together, producing a hairline seam. Exterior body to be

corrosion resistant steel. Door opening frame to be

ABS and contain magnetic strip for positive sealing

of gaskets and heater elements to prevent gasket

freezing. Back-up element installed. Work surface to

be at 36” work height. Legs to be 6” high stainless steel

with adjustable bullet foot. Legs mounted to full length

channel frame assembly which is integrally welded to

bottom of body assembly. Legs can be moved left to right

to avoid floor obstacles during installation.

ORIGIN OF MANUFACTURE: Designed and

manufactured in the United States.

Custom

PPSPEC0139 RevB

Revised 01/16

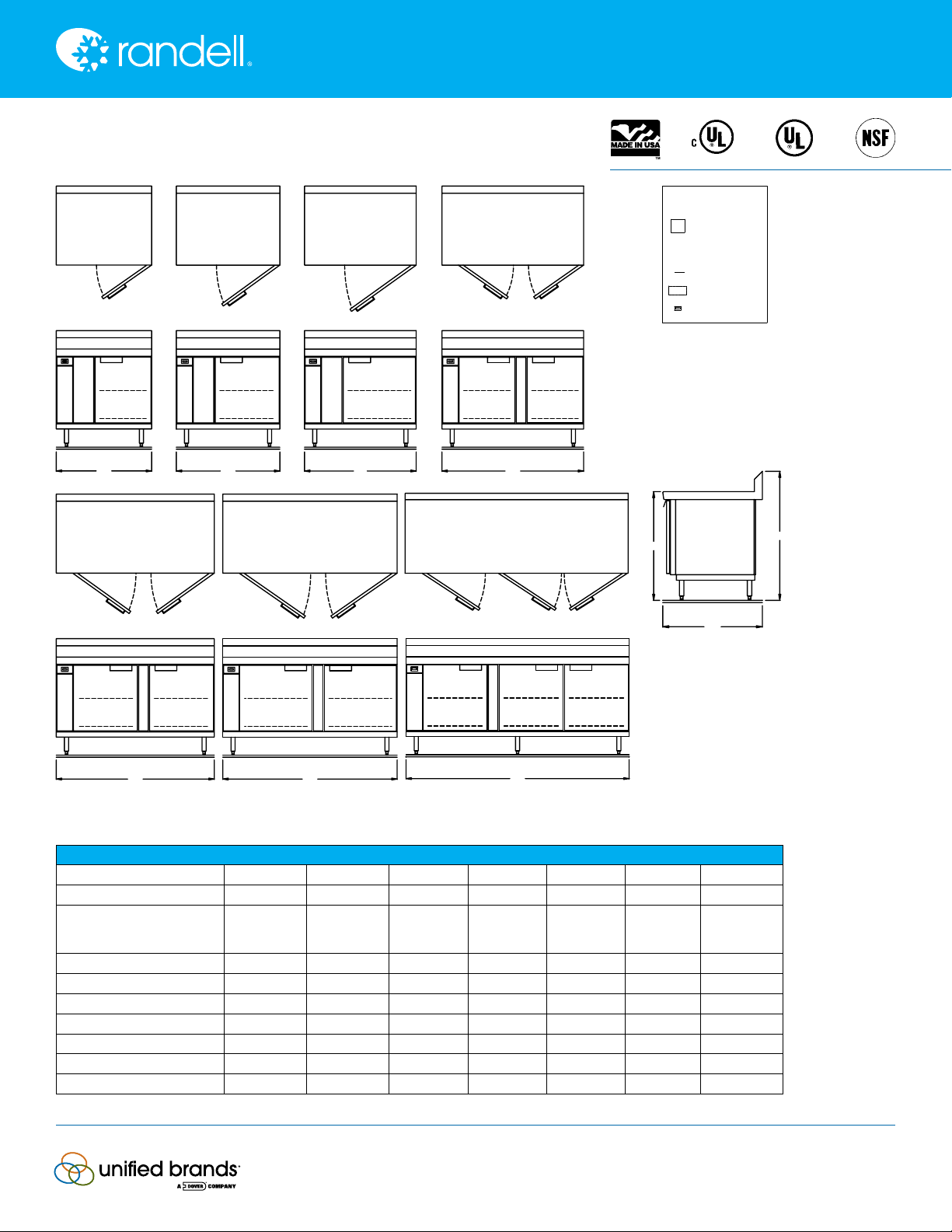

LEGEND

42.75"

AFF. = ABOVE FIXED FLOOR

JUNCTION BOX

J

115V-60Hz-1Ph

R404 REFRIG.

.25" LIQUID, .375" SUCTION

LINE 8.5" AFF

OC

CONDENSATE DRAIN 1/2 "

PVC 8-1/2" AFF.

EVAPORATOR COIL

LOCATION

DIGITAL TEMP.

& DEFROST CONTROL

64000

PANEL

PANEL

24"FREEZER

COIL

21"FREEZER

35"

COIL

PANEL

24"FREEZER

38"

COIL

24"FREEZER

58"

PANEL

27"FREEZER 27"FREEZER

COIL

PANEL

27"FREEZER

41"

COIL

64"

PANEL

PANEL

COIL

21"FREEZER21"FREEZER

52"

36"

33"

COIL

24"FREEZER 24"FREEZER24"FREEZER

82"

64000 SERIES REMOTE FREEZERS WITH STAINLESS STEEL TOPS

Length

Model 33” Deep

#of Doors

Storage Cu. Ft. 33”

Storage Cu. Ft. 29”

Volt/Cycle/Phase

Amps

Ship Wt.- lbs

BTU Design load

Evap. BTU

35” 38” 41” 52” 58” 64” 82”

64335 64338 64341 64352 64358 64364 64382

(1) 21”

+8” coil hsg.

+6” mech. hsg.

5.86 6.84 7.81 11.39 13.35 15.30 21.16

(1) 24”

+ 8” coil hsg.

+6” mech. hsg.

(1)27”

+ 8” coil hsg.

+6” mech. hsg.

(2) 21”

+4” mullion

+6” mech. hsg.

(2) 24”

+4” mullion

+6” mech. hsg.

(2) 27”

+4” mullion

+6” mech. hsg.

+4” mullion

+6” mech. hsg.

4.92 5.74 6.56 9.57 11.21 12.85 17.77

115/60/1 115/60/1 115/60/1 115/60/1 115/60/1 115/60/1 115/60/1

6 6 6 6 6 6 6

355 370 385 445 475 505 700

956 1015 1064 1536 1635 1734 2321

160 160 160 160 160 160 160

(3) 24”

* BTU loads shown are based on 100°F ambient with 30% added for usage and product loading. Final system selection should consider usage requirements and combined loads.

888-994-7636, unifiedbrands.net

© 2016 Unified Brands. All Rights Reserved. Unified Brands is a wholly-owned subsidiary of Dover Corporation.

Loading...

Loading...