Page 1

SILVIA

Uso e manutenzione

Emploi et entretien

Gebrauch und Instandhaltung

Use and maintenance

Uso y manutención

Uso e manutenção

Macchina per caffè

Machine à café

Kaffeemaschinen

Coffee machine

Máquina para café

Máquina para café

sp

r

esso

tec

Sales & Service

courtesy of

Page 2

Wir erklären auf unsere Verantwortung, daß das Produkt:

to which this declaration relates is,

É conforme as seguintes normas:

-

-

-

-

A presente declaração perde a validade se a máquina é modificada sem a nossa expressa autorização.

Page 3

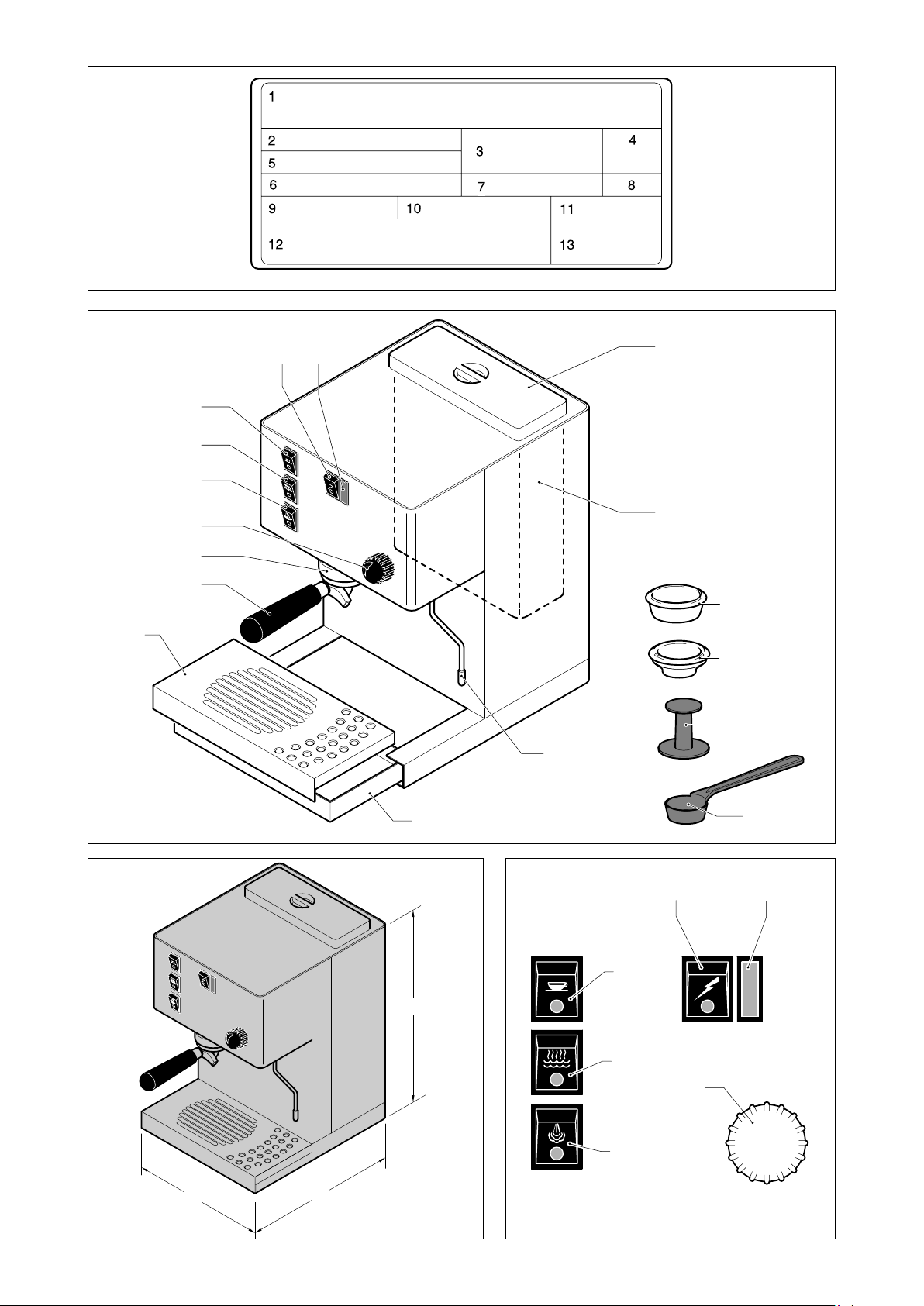

7

Fig. 1

Fig. 2

1 2

3

5

4

6

7

8

9

10

11

12

13

14

15

16

17

H

B

A

3

4

5

2

1

6

Fig. 4

Fig. 3

Page 4

8

Fig. 6

Fig. 7

12

20

19

8

9

18

1

2

3

Fig. 5

Page 5

30

EN ENGLISH

CONTENTS

Machine identification data ..........................31

1. General safety rules ..................................31

2. Description .................................................32

2.1. Assembling information ........................32

2.2. Protections ............................................32

2.3. Aerial noise ..........................................32

2.4. Vibrations ..............................................32

3. Technical data ............................................32

4. Intended Use ..............................................33

5. Transport ....................................................33

5.1. Packaging .............................................33

6. Installation ................................................33

6.1 Control description ................................34

7. Starting up .................................................34

7.1. Filling ....................................................34

8. Funtion .......................................................34

8.1. Machine heating ...................................35

8.2. Coffee preparation ...............................35

8.3. Steam delivery ......................................35

8.4. To steam milk ........................................35

8.5. Hot water delivery .................................35

8.6. Refilling water in the boiler ...................35

8.7. Pump pressure adjustment ...................35

9. Maintenance ...............................................36

9.1. Daily ......................................................36

9.2. Periodically or after a period of

intensive machine use ..........................36

10. Placing out of action ................................36

10.1. Temporary ...........................................36

10.2. Definitive .............................................36

11. Possible problems .....................................36

IT ITALIANO 9 - 15

FR FRANCAIS 16 - 22

DE DEUTSCH 23 - 29

EN ENGLISH 30 - 36

ES ESPAÑOL 37 - 43

PT PORTUGUÊS 44 - 50

SCHEMI ELETTRICI

SCHEMAS ELECTRIQUES

SCHALTPLANE

WIRING DIAGRAMS 51 - 52

ESQUEMAS ELECTRICOS

ESQUEMAS ELÉTRICOS

Page 6

31

1. GENERAL SAFETY RULES

Any traces of coffee are due to testing of the

machine

The packing elements (plastic bags, expanded

polystyrene, nails, cardboard, etc.) must not be left

within the reach of children, as they are potential

sources of danger.

Check that the data on the machine corresponds

to those of the electrical supply network, before

connecting the equipment.

It is advisable to unwind the supply cable for the

whole length to avoid twisting or damages. Do not

place the cable near water, liquids or heat sources. The cable must not be damaged (should the

cable be damaged, contact qualified personnel to

replace it).

It is inadvisable to use adapters, multiple sockets

and/or extensions. When their use is indispensable, only products with certificate of quality (e.g.

UL, etc.) may be used. Check that the voltage

capacity limit indicated on the adapters exceeds the absorption capacity (A = ampere) of the

equipment.

When in doubt, request an accurate check of the

connections by qualified personnel. The wiring

system must comply with the following safety

regulations:

- efficient grounding

- section of conductors suitable for absorption

capacity

- efficient earth leakage protection circuit

breaker.

Do not install the machine near heat sources (oven,

cooking stove, fireplace, etc.) or in conditions in

which the temperature may not go below 41°F. IT

MUST BE PROTECTED AGAINST FREEZING

CONDITIONS.

Do not leave the machine exposed to atmospheric

agents (rain, sun, etc.) and do not install in damp

rooms such as bathrooms.

In the event of parts replacement, request original

spares from an authorized retailer or dealer.

Keep the packed machine in a dry place, not

exposed to atmospheric agents and in conditions

in which the temperature will fall below 41°F.

• Do not stack more than three items of the same

kind. Do not place heavy items on the packaging.

Erroneous installation may cause damage to

people and things for which the manufacturer

cannot be considered responsible.

PRODUCT RANGE: Coffee machine

MODEL: SILVIA

The label illustrated on the cover of this instruction

manual corresponds to the identification label placed

on the machine.

Label data (Fig.1)

1 Manufacturer

2 Model and version

3 Voltage

4 EC conformity mark (if required)

5 Serial number

6 Boiler data

7 Machine total absorption

8 Protection level

9 Motor power

10 Heating element power

11 Frequency

12 Conformity marks

13 Year of manufacture

Symbols

Warning symbols. The instructions which refer to this symbol must be followed with great

care in order to avoid accidents or damage

to the machine.

This manual is an integral and essential part of the

product and must be delivered to the user. The warnings contained in it must be read carefully, as they

supply important indications related to the safety of

installation, use and maintenance. Keep this manual

for future reference.

Page 7

32

Key (Fig.2) :

1 Main power switch

2 Boiler resistance light

3 Coffee delivery switch

4 Hot water delivery switch

5 Steam delivery switch

6 Steam/water knob

7 Steam wand

8 Water tank

9 Lid

10 Drip tray

11 Discharge drawer

12 Coffee dispensing unit (group head)

13 Portafilter

Accessories:

14 One two-cup portafilter with double spout

15 One one-cup filter basket

16 Coffee tamper

17 Coffee measuring scoop

3. TECHNICAL DATA (Fig.3)

2. DESCRIPTION

2.1 Assembling information

The machine is composed of a central structure for

obtaining espresso and steam/hot water.

The body is made up of a supporting structure in

painted iron, suitably covered with stainless-steel

panels.

2.2 Protections

Water boiler equipped with spring mechanical valves

for over-pressures.

Electro-magnetic pump equipped with thermal protection.

All the moving and heating parts are inside the

machine.

2.3 Aerial noise

The noise level does not generally exceed 70dB(A)

when the machine is in operation.

2.4 Vibrations

The machine is supplied with rubber vibration-suppressing feet. In normal working conditions, the

machine does not produce vibrations harmful to the

operator and/or the environment.

Machine dimensions A-290 B-325

H-340mm

Packing dimensions A-430 B-340

H-450

Packing volume

0,06m

3

Net weight 14 kg

Gross weight with packing 15 kg

No. of items 1

Electromagnetic pump 48W

Electricity supply plate data

Resistance plate data

Water tank capacity ~ 2 l

Working place temperature +5° +45° C

Page 8

33

5. TRANSPORT

5.1. Packaging

The machine must always be transported in the

correct position following the instructions on the

cardboard box.

Do not turn over the machine or lay it down

on its side.

The box also contains separate accessories and

technical documentation which must be saved for

further consultation.

Open the top part of the packaging, remove the

accessories and then remove the machine from

its packaging.

Check if the machine, the accessories, the electric

cable and the plug are in perfect condition. Should

one of these parts be damaged, immediately contact the retailer.

The packing elements (plastic bags, expanded polystyrene, nails, cardboard, etc.)

must not be left within reach of children as

they are potential sources of danger.

Do not dispose of the packing elements in the

environment; consign them to firms authorized for their disposal.

4. INTENDED USE

The machine has been designed and manufactured

to obtain espresso and other hot beverages (tea,

cappuccino, etc.).

This machine is only intended for the purposes

for which it was designed. Any other use is to be

considered unsuitable and therefore dangerous.

The user must always follow the indications contai-

ned in this manual. If the machine is not working

properly, switch it off and do not attempt any direct

repair. For service, contact the retailer.

The user must not:

• Touch the hot surfaces of the machine with his

hands, but use only proper the controls;

Transport the machine or carry out maintenance

operations with the plug connected and when the

machine is warm;

Use the machine if the supply cable is damaged

• Touch the machine with wet or damp hands or

feet

Overturn or place the packaging on one side

Wash the machine with water or vapour jet

Dip the machine in water or other liquid

Use the machine when there are children in close

proximity

Allow the machine to be used by children or inca-

pable persons

Obstruct the aspirations or heat dissipation grills

• Place containers with liquids on the machine

It is forbidden to install or use the machine if

it is wet or damp.

It is always necessary to request an accurate check by qualified personnel in order

to find any possible damages to the electric

components.

This machine may be used only for the purposes

for which it was designed. It cannot be used to dispense products other than coffee or any non food

products.

The manufacturer cannot be held responsible

for any damage caused by unsuitable, erroneous or irrational use of the machine.

6. INSTALLATION

The machine is delivered ready to be installed in

accordance to the label data.

Ensure that the electrical supply system has

the same features as the machine.

The electrical supply system must be equipped with a GFI (ground-fault interrupt) or a

general automatic switch with an efficient

grounding system. Should there be no

electrical protection element, have a single-

pole switch installed by qualified personnel,

as outlined by the current safety regulations

with a contact opening distance of either

equivalent or over 3 mm.

The grounding of the appliance is mandatory.

The manufacturer declines all responsibility in the event of failure to respect the

accident prevention norms.

Take care not to damage the supply cable by

placing undue weight upon it.

Do not disconnect the machine by pulling the

cable, but instead by gripping the plug.

Page 9

34

7. STARTING UP

7.1. Filling (Fig. 2)

Fill the water tank before using the machine and when

it is necessary (always switch off the machine)

Open the lid (9) and pour about 2 litres of water

into the tank (use drinking water, softened if possible).

Close the lid (9) making sure that the rubber water

delivery tube (18) is at the bottom of the tank.

Fill the water tank before using the machine, after a

long period of inactivity or when the tank is empty.

Detach the portafilter (13), turn the steam knob

counter-clockwise to open the steam tap (6), then

press the main switch (1) together with the coffee

delivery switch (3).

When the water comes out of the steam wand (7),

turn the steam knob clockwise to close the steam

tap (6) and allow water to escape from group head

(12) for a few seconds, then switch off the coffee

delivery switch (3).

If water fails to come out after 30 seconds repeat

the operation.

Insert the portafilter (13) and wait until the machine

heats up and reaches the correct temperature.

On using the machine for the first time, allow

about ½ a litre of water to go through the

machine in order to rinse the unit.

8. FUNCTION

8.1. Machine heating

To be undertaken on starting up (machine cold)

Ensure you have water in the tank.

Press main power switch (1); indicator light (2)

comes on

Never deliver steam longer than 4-5 minutes

without filling the boiler water

Wait until the machine reaches working tempera-

ture (when indicator light (2) goes off)

In order to prevent problems relating to operation,

supply and maintenance, the machine is not to be

positioned in any recesses or similar difficult positions.

The machine must be placed on a completely level

surface, that is both dry and sufficiently stable and

at a height of 80 cm from the ground.

Position the machine and connect the plug to the

power outlet.

6.1. Control description (Fig.4)

1. Main power switch with orange on/off indicator

light:

On pressing this switch, when orange light is on,

the machine is powered.

2. Boiler resistance light:

This light comes on when the boiler water is being

heated.

3. Coffee delivery switch with orange on/off indicator

light:

On pressing this switch, when orange light is on,

coffee is delivered.

4. Hot water delivery switch with orange on/off indicator light:

On pressing this switch, when orange light is on,

the machine is ready to deliver hot water through

the steam wand.

5. Steam delivery switch with orange on/off indicator

light:

On pressing this switch, when the orange light is

on, the machine is ready to deliver steam.

6. Hot water/steam delivery knob:

With switch (4) engaged, on turning the knob hot

water comes out of the steam wand.

With switch (5) engaged, on turning the knob,

steam comes out of the steam wand.

Note: Switches 4 and 5 must be used separately (water cannot be taken at the same

time as steam or vice versa).

Page 10

35

8.2. Coffee preparation

Detach the portafilter (13) from its slot by turning it

in a clockwise direction and pulling in a downward

motion.

Using the measurement scoop (17) supplied, fill

the filter with either one or two measurements of

coffee according to the inserted filter (14/15).

Press the coffee using tamper (16).

Re-connect and tighten the portafilter (13) in its slot

by turning it in a counter-clockwise direction.

Position your espresso cup(s) under the exit outlets

of the portafilter (13).

Press the coffee delivery switch (3); delivery will

begin after a few seconds. On obtaining the required amount turn off switch (3).

Check frequently the water level in tank (8) in

order to avoid causing the pump to pull in air

during coffee delivery (which is noisy). If this

should happen, immediately switch off the

coffee delivery switch (3), fill the water tank

and repeat the “starting up” operations.

It is recommended to pay attention to the hot

parts of the machine, especially the delivery

group and the steam outlet steam wand.

Never put your hands under the group or

under the steam outlet while the machine

is working.

Silvia is designed for installation of our

coffee pod kit. For further information,

please contact your dealer accordingly.

8.3. Steam delivery

Press the steam switch (5), wait a few seconds

and then open the steam tap (6) to allow any

condensed water to be expelled from the steam

wand (7). Close the tap (6) again.

Wait about 30 seconds, then immerse the steam

wand (7) in the liquid to be heated. Open the steam

tap (6), the steam will come out and heat the liquid

to the desired temperature.

Never deliver steam longer than 4-5 minutes

without filling the boiler water

Once the heating of the liquid is complete, dischar-

ge a little steam to clean out the sprayer hole in

steam wand (7).

Turn off the steam switch (5 )and clean the steam

wand (7) with a damp cloth.

Fill up the water in the tank (see relative paragraph

8.6)

8.4. To steam milk

Fill a steam pitcher approximately half-full with milk

Immerse about half of the steam wand (7) in the

liquid, open steam tap (6) and heat the milk to the

desired temperature.

Close steam tap (6), remove steam wand (7) from

container.

Restore the water level in the boiler (see relative

paragraph 8.6).

8.5. Hot water delivery

Position a container under the steam wand (7).

Open the steam tap (6) and discharge any steam

present in the boiler.

Press water delivery switch (4) and take the ne-

cessary amount of water.

Close steam tap (6) and turn off water delivery

switch (4) .

8.6. Refilling water in the boiler

Check that switches (4) and (5) are off and that

the portafilter (13) is disconnected;

Press coffee delivery switch (3) and wait for the

water to come out of group head (12)

Turn off coffee delivery switch (3).

In the event of a dangerous situation immediately

turn off all the switches including main power and

unplug the machine from the power source.

8.7. Pump pressure adjustment (Fig.5)

Warning! This operation must strictly be

conducted only by qualified technical personnel.

To adjust the water pump pressure, unplug the machine so that it powers down completely. Wait until it has

completely cooled down, then remove the top cover

element by screwing out the relative lock screws.

Once machine is open, proceed as follows:

1 Loosen the lock nut.

2 Act on the flexible hose connector fitting as illustra-

ted i.e. screw it in to increase pressure or screw it

out to decrease pressure. Take care to screw the

connector fitting either in or out by maximum one

turn.

3 Once the adjustment operation is complete, screw

the lock nut back on again to close the connecting

nozzle into position. Place the top cover element

back on and lock the relative screws back in

again.

POD

ADAPTABLE

Page 11

36

9. MAINTENANCE

All maintenance operations must be carried

out with the machine off and cold and with

the power plug disconnected.

Use a damp cloth or sponge for cleaning. Do

not use any metallic or abrasive materials for

cleaning (such as scourers, metal brushes,

needles or detergents).

9.1. Daily (Fig.5)

Clean the bodywork, the steam wand* (7), the

diffuser (19) and the cup-base seal (20) of group

head (12).

Check and clean the discharge drawer (11) as

required.

Rinse filters (14/15) and the portafilter (13) using

hot water and a cloth or sponge.

It is very important to clean the steam wand

(7) with a damp cloth or sponge after each

use, as well as discharging any milk residue

from the wand by opening the steam tap (6)

briefly, then closing again.

9.2. Periodically or after a period of intensive

machine use

Do the following in addition to the “Daily” operations:

Immerse filters (14/15) and the portafilter (13) in

boiling water for a few minutes to allow the coffee

grease to dissolve, then remove using a sponge

or a cloth.

Periodically use a special espresso machine-clea-

ning product.

Carefully follow the instructions on the cleaning products’ packaging. For information

concerning the choice of the cleaning product, contact the retailer.

Clean water tank (8), carefully immerse water-de-

livery tube (18) (Fig.6) as far as possible into the

water tank.

11. POSSIBLE PROBLEMS

In the event of damage to the power supply

cable, contact an authorized service company for replacement as a special tool is

required.

The scrap materials used for processing or

maintenance should be placed in containers

and sent to special collection centers, unless

they are biodegradable or non-polluting.

Operations to be carried out by the user after having

disconnected the electrical supply:

A) The machine fails to start:

- Check whether the power plug is connected

- Check that the power is on and that the GFI (groundfault interrupt) or the main switch is engaged

- Check the conditions of the plug and the power cable, should they be damaged have them replaced

by authorized personnel

B) Machine fails to deliver coffee

- The water tank is empty; fill it

- The boiler has not refilled after using the steam

element

C) Machine fails to deliver hot water and/or steam:

- The water tank is empty; fill it

- The boiler has not been refilled after using the

steam element

- Clogged nozzle: clean the steam delivery nozzle

D) Irregular coffee delivery:

- Rinse the portafilter

- Rinse the dispersion screen by running water

through the group head (12) – to do so, press the

coffee deliveryswitch (3)

- Check that your grind is neither too coarse nor

too fine.

In the event of all problems not specified

always detach the power cable, avoid undertaking any further diagnostic operations

or direct repair, and contact the retailer or a

qualified service company.

For more information and detailed online instructions, please visit our website at

www.rancilio.com

10. PLACING OUT OF ACTION

10.1. Temporary

Empty the water tank (8) and the remaining water in

the boiler.

Turn off all the switches and disconnect the power

plug.

Carry out the necessary maintenance operations.

Place the machine is a dry place, away from atmo-

spheric agents and of exclusive access (avoid leaving it in the reach of minors or untrained persons).

10.2. Definitive

Do the following in addition to the “Temporarily placing

out of service” actions:

Cut the power cable,

Wrap cardboard or other material around the

machine and consign to the authorized personnel

(authorized refuse disposal center or used material

collection center).

Page 12

51

SCHEMI ELETTRICI

SCHEMAS ELECTRIQUES

SCHALTPLANE

WIRING DIAGRAMS

ESQUEMAS ELECTRICOS

ESQUEMA ELÉTRICO

IT FR DE EN ES PT

GF = Connessione Faston Connesion faston Faston-Verbindung Faston connection Conesion Faston Conexão Faston

MT = Morsetto di terra Borne du sol Erdklammer Earth connection Conexion de tierra Borne do terra

EG = Elettrovalvola gruppo Electr. du groupe Gruppeelektroventil Group electrovalve Electrovalvula grupo Válvula Elétrica grupo

P = Pressostato Pressostat Pressostat Pressure Presostato Pressão

PS = Pulsante Start Buton start moulin Druckknopft Grinder start Pulsador de Teclao do começo

Macinino doseur pushbutton funcionamiento do moedor

IG = Interruttore generale Interrupteur general Hauptschalter Main switch Interruptor general Interruptor geral

IV = Interruttore vapore Interrupteur vapeur Dampfschalter Steam switch Interruptòr vapor Interruptor vapor

IC = Interruttore caffe Interrupteur cafè Kaffeeschalter Coffee switch Interruptòr cafè Interruptor cafè

IA = Interruttore carico Interrupteur chârge Wasserauff üllschalter Water fill switch Interruptor carga agua Interruptor da água

acqua d’eau

PO = Pompa a vibrazione Pompe vibration Vibrationpumpe Vibration pump Bòmbador vibraciòn Bomba con vibração

TM = Termico interno Protect.thermique interne Motorthermoschutz Grinder motor Termostato de Termostato interno

motore macinino au moteur du moulin Malwerk thermal protection securidad molinillo do motor moedor

TMP = Termico esterno Protect.thermique externe Thermoschutz Pumpe Vibration pump Termostato externo Termostato fora

pompa vibrazione de la pompe de vibrage thermal protection bomba vibracion bomba con vibração

MM = Motore macinino Moteur moulin a cafè Kaffeemuhlemotor Coffe-grinder motor Motor molinillo cafè Motor moedor

MO = Morsettiera allacciamento Boit a bornes pour Anschhlussklemmleiste Mains power Bloque de terminales Conj. bornes ligação

branchement connection

R = Resistenza caldaia Resistance chaudiere Kesselheizung Boiler heating Resistencia caldera Resistência da caldeira

resistance

T1 = Termostato 100° Thermostat 100° Thermostat 100° Thermostat 100° Termostato 100° Termostato 100°

T2 = Termostato 140° Thermostat 140° Thermostat 140° Thermostat 140° Termostato 140° Termostato 140°

T3 = Termostato 165° Thermostat 165° Thermostat 165° Thermostat 165° Termostato 165° Termostato 165°

SL = Spia livello basso Voyant manque d’eau Wassermangel Low water level Indicador por falta Indicador nivelado

acqua kontrollampe indicator agua baixo de àgua

D = Disgiuntore Disjoncteur Abschalter Deyoining device Disyuntor Disjuntor

C = Condensatore motore Condesateur Kondensator Motor condenser Motor condensator Condensador de motor

RE = Resistenza Résistance Widerstand Capacitor discharge Resistencia Resistência

condensatore condensateur Kondensator resistor condensator condensador

SR = Spia resistenza Indicateur de Widerstand Resistance Indicador Indicador

résistance anzeige indicator de resistencia resistência

N = Nero Noir Schwarz Black Negro Preto

M = Marrone Marron Braun Brown Marron Marron

R = Rosso Rouge Rot Red Rojo Vermelho

AR = Arancio Orange Orange-farbig Orange Naranja Laranja

G = Giallo Jaune Gelb Yellow Amarillo Amarelo

V = Verde Vert Gruen Green Verde Verde

B = Blu Bleu Blau Blue Azul Azul

GR = Grigio Gris Grau Gray Gris Cinza

BI = Bianco Blanc Weiss White Blanco Branco

GV = Gialloverde Jaune-vert Gelb-gruen Yellow-green Amarillo-verde Amarelo-Verde

Page 13

52

Data:

Firma:

Diffusione e riproduzione

vietata a termini di legge

senza nostra autorizzazione.

PROGETTO:

DENOMINAZIONE:

CODICE:

Formato:

U.T.

A4

Viale della Repubblica 40

20010 Villastanza di Parabiago-Mi-Italia

Tel +39 0331 408200

Fax +39 0331 551437

www.rancilio.com info@rancilio.it

SE_637

01/09/05

MISS SILVIA

SCHEMA

ELETTRICO

VERS. 110V - 230V

T3

T2 T1

SR

IG

R

IV IA IC

PO

MT

EG

M B

GV

MB

N

N

G

N

G

GR

GR

R

R

BI

BI

BI

BIBI

N

N

N

R

R

R

R

AR

AR

TIPO Fase Neutro Terra

220V / 240V

100V / 120V

M B GV

N Bi V

Collegamento cavi di alimentazione

Page 14

Cod. 46 900 112 Rev. AB 10/2006

RANCILIO MACCHINE PER CAFFÈ

STABILIMENTI E SEDE CENTRALE - 20010 VILLASTANZA DI PARABIAGO - MI (ITALY)

VIALE DELLA REPUBBLICA, 40 - TEL. 0331/408200 - TELEFAX 0331/551437

I T Proprietà riservata.

E’ vietata la riproduzione totale o parziale del presente manuale senza l’autorizzazione scritta della RANCILIO S.P.A..

La ditta RANCILIO si riserva il diritto di apportare in ogni momento le modifiche che riterrà necessarie.

FR Propriété réservée.

Il est interdit de reproduire totalement ou partiellement ce manuel sans l’autorisation écrite de la Société RANCILIO S.P.A..

La maison RANCILIO se réserve le droit d’apporter à tout moment les éventuelles modifications qu’elle jugera nécessaires.

DE Eigentumsrecht Vorbehalt.

Der teilweise oder gesamte Nachdruck dieses Handbuches, ohne schriftliche Genehmigung der Fa. RANCILIO SPA ist verboten.

Die firma RANCILIO behält sich vor, eventuell notwendige Änderungen jederzeit durchzuführen.

EN Reserved property.

Partial or total reproduction of this manual is forbidden without written authorisation of RANCILIO S.P.A..

RANCILIO reserves the right to effectuate, in any given moment, any modifications which are considered necessary.

ES Propriedad reservada.

Prohibida la reproducciòn total o parcial del presente manual sin la autorizaciòn escrita de la RANCILIO S.P.A..

RANCILIO se reserva el derecho de aportar eventuales modificaciones que reputarà necesarias en cualquier momento.

PT Propriedade riservada.

É proibida a reprodução total ou parcial do presente manual sem a autorização escrita da Rancilio S.P.A..

A fábrica RANCILIO reserva-se o direito de fazer, em qualquer momento, as modificações que julgar necessárias.

Loading...

Loading...