Page 1

Ramsey Electronics Model No. RB1

Got a problem with furry intruders in your yard or garden? Here

is a professional strength repeller designed to send those pesky

critters running with their tails between their legs. A convenient,

nature friendly method of keeping animals away from where you

don’t want them

Around 4 watts of screaming high frequency audio. Inaudible

to humans, but a terror to animals.

3 settings for different levels of coverage

Built-in piezo high efficiency speaker

External trigger input for use with motion sensors and other

detectors.

Operates on 9 to 15 volts DC or AC.

LED indicator shows when unit is operating.

Informative manual answers questions on theory, hookups

and uses - enhances resale value, too!

Add our rugged metal case for years of outdoor or indoor

use.

RB1 1

Page 2

PARTIAL LIST OF AVAILABLE KITS:

RAMSEY TRANSMITTER KITS

· FM10C, FM25B FM Stereo Transmitters

· AM1C, AM25 Transmitter

RAMSEY RECEIVER KITS

· FR1C FM Broadcast Receiver

· AR1C Aircraft Band Receiver

· AR2 Aircraft Band Receiver

· SR2C Shortwave Receiver

· AA7C Ac tive Ante n na

· SC1C Shortwave Converter

RAMSEY HOBBY KITS

· SG7 Personal Speed Radar

· SS70C Speech Scrambler/

Descrambler

· TT1C Telephone Recorder

· MD3C Microwave Motion Detector

RAMSEY AUDIO KITS

· SHA1C and SHA2 Headphone Amplifier kits

· UAM4 40 Watt Stereo Amplifier kit

RAMSEY AMATEUR RADIO KITS

· HR Series HF All Mode Receivers

· DDF1 Doppler Direction Finder Kit

· QRP Series HF CW Transmitters

· CW7C CW Keyer

· QRP Power Amplifiers

RAMSEY MINI-KITS

Many other kits are available for hobby, school, scouts and just plain FUN!

New kits are always under development. Write, call or visit

www.ramseykits.com for our free Ramsey catalog.

RB1 RAT BLASTER INSTRUCTION MANUAL

Ramsey Electronics publication No. MRB1 Revision 1.1

This Printing: July 2010

COPYRIGHT 2006-2010 by Ramsey Electronics, LLC, 590 Fishers Station Drive, Victor, New

York 14564. All rights reserved. No portion of this publication may be copied or duplicated

without the written permission of Ramsey Electronics, LLC. Printed in the United States of

America.

RB1 2

Page 3

Ramsey Publication No. MRB1

Price $5.00

KIT ASSEMBL Y

AND INSTRUCTION MANUAL FOR

RB1

RAT BLASTER

TABLE OF CONTENTS

Introduction ..................................... 4

How Does It Work? ......................... 5

Learn As You Build ......................... 6

Parts List ......................................... 7

Parts Layout Diagram ..................... 8

Construction .................................... 9

Schematic Diagram ...................... 10

Initial Testing ................................. 15

Troubleshooting ............................ 16

Warranty ....................................... 19

RB1 3

RAMSEY ELECTRONICS, LLC

590 Fishers Station Drive

Victor, New York 14564

Phone (585) 924-4560

Fax (585) 924-4555

www.ramseykits.com

Page 4

INTRODUCTION TO THE RB1 RAT BLASTER

This is a practical project for people with problems with furry intruders in their

yard, not just rats. The Rat Blaster is useful in repelling all kinds of wildlife. The

list includes deer, dogs, cats, all rodents, and even some insects. This is the

safest, most effective way to repel animals from eating your shrubbery or

burrowing in your carrot patch. It is also a great help at keeping little surprises

out of your lawn left by the neighbor’s pets.

Instead of just generating a single constant tone like many competitive units on

the market, the RB1 creates a warble tone that varies in frequency. This sound

is enough to drive any person crazy if they could hear it. When the RB1 was in

its design stages, the frequency was low enough to hear. Three offices up and

two doors between was not enough to prevent irritation and complaints from

associates. Just imagine what it can do with no obstructions!

This unit is set outside facing the area desired to be protected. It then covers an

area in the shape of an oval. On the low frequency setting, it will cover an area

of approximately 4000 square feet. On the high frequency setting, it covers an

area of around 2500 square feet. The advantage of running the high frequency

setting is that it is well out of the human hearing range. The low frequency

setting is just at the limit of hearing and can be irritating to some people with

acute hearing. The reason the low frequency signals cover a larger area is due

to a combination of how good the animals ears are, and how directional the

sound is from the transducer.

Built into an easy to mount case of durable construction, the Rat Blaster will

operate for years, providing your yard and garden with animal protection. This

is truly the gardener’s dream come true!

RB1 4

Page 5

HOW DOES IT WORK?

Here is where we get into a little circuit analysis. If you just want to plug it in and

start scaring off critters, you can skip this section. Otherwise here is some

insight into why and how this RB1 works. We will use the schematic located at

the center of the manual to analyze the circuit.

We will begin with the IC marked NE555, U1. This is a simple, free running

oscillator circuit which is used to generate the lower frequency warble rate of

the signal. This rate varies from around 1Hz to 10Hz. The output of this

oscillator is a 12V square wave until it is sent through R2 into C7. These parts

filter the waveform into a sawtooth waveform.

U2, the XR-2209 is set up to be a voltage controlled oscillator running between

15kHz and 30kHz. The higher the voltage seen on pin 4 of U2, the higher the

frequency produced on pin 7 of U2. When the low frequency sawtooth signal

from U1 is sent to pin 4, the high frequency signal of U2 modulates or “warbles”

at a rate of U1’s output frequency.

S2 controls the average DC voltage of the sawtooth by adjusting the rate of

discharge of C7. The less resistance seen from pin 4 to ground, the faster C7

discharges. The faster C7 is discharged, the lower the average voltage of the

sawtooth waveform is. In turn, the lower the average voltage on the sawtooth,

the lower the average frequency on pin 7 of U2 allowing this unit to cover a

larger area.

The output of U2 is then sent to some logic which enables or disables the

speaker driver circuitry depending on what signal is seen on pin 2 and 6 of U3.

When these pins are at a logic ‘0’, or 0 volts, the transducer driver is enabled,

and when it is ‘1’, or 12 volts, it is disabled.

The speaker driver section consists of a push-pull circuit controlled by U3:D, B,

and C. U3:B inverts the signal from U3:A so that when pin 3 is high (12 volts)

pin 4 is low (0 volts). U3:D and U3:C are set up as inverting buffers to drive the

transistors that drive the transducer.

The speaker driver also consists of the four transistors surrounding SP1 which

provide more power capability than what U3 offers. When U3 pin 11 is high, Q4

is turned on, and Q1 is turned off. This presents about 12 volts on one side of

the transducer. While pin 11 is high, pin 10 is low, which turns on Q2 and Q3

off, pulling the other lead of the transducer to near 0 volts. Now there are

almost 12 volts across SP1, allowing the transducer to produce sound. On the

next half of the cycle, the transistors that were off are turned on, and the ones

that were on are shut off. Now there are 12 volts across the transducer

connected in the opposite direction from before. This is all done at a rate of

around 15,000 to 30,000 times a second, producing the high frequency si gnal

to scare off the beasties.

RB1 5

Page 6

NOTE TO NEWCOMERS: If you are a first time kit builder you may find this

manual easier to understand than you may have expected. Each part in the kit

is checked off as you go, while a detailed description of each part is given. If

you follow each step in the manual in order, and practice good soldering and kit

building skills, the kit is next to fail-safe. If a problem does occur, the manual

will lead you step by step through the troubleshooting guide until you find the

problem and are able to correct it.

RAMSEY “LEARN-AS-YOU-BUILD” ASSEMBLY STRATEGY

Be sure to read through all of the steps, and check the boxes as you go to be

sure you didn't miss any important steps. Although you may be in a hurry to see

results, before you switch on the power, check all wiring and capacitors for

proper orientation. Also check the board for any possible solder shorts, and/or

cold solder joints. All of these mistakes could have detrimental effects on your

kit - not to mention your ego!

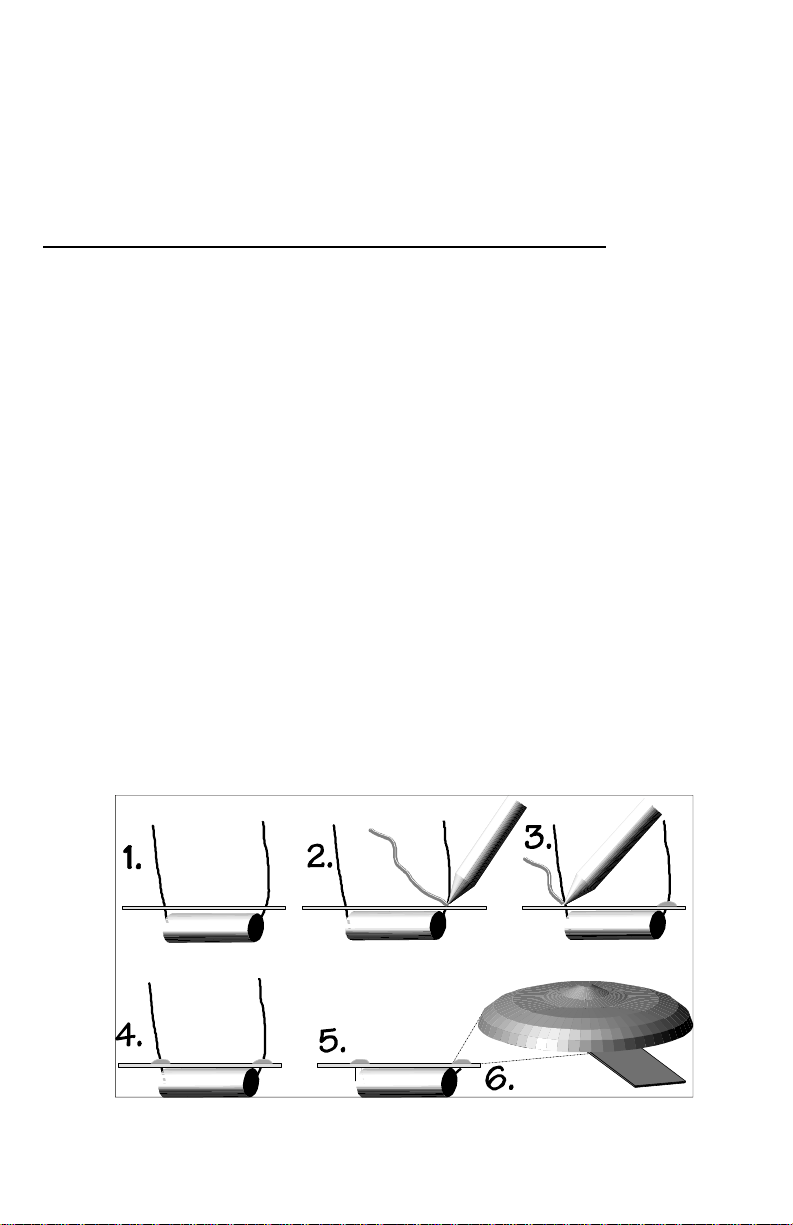

Kit building tips:

Use a good soldering technique - let your soldering iron tip gently heat the

traces to which you are soldering, heating both wires and pads simultaneously.

Apply the solder to the iron and the pad when the pad is hot enough to melt the

solder. The finished joint should look like a drop of water on paper - somewhat

soaked in.

Mount all electrical parts on the top side of the board provided. This is the side

that has little or no traces on it. When parts are installed, the part is placed flat

to the board, and the leads are bent on the backside of the board to prevent the

part from falling out before soldering (1). The part is then soldered securely to

the board (2-4), and the remaining lead length is then clipped off (5). Notice

how the solder joint looks close up, clean and smooth with no holes or sha rp

points (6).

RB1 6

Page 7

RAMSEY RB1 PARTS LIST

Semiconductors

1 4001 Quad dual input NOR gate (U3)

1 XR-2209 voltage controlled oscillator (U2)

1 NE555 timer (U1)

2 2N3904 NPN transistors (TO92 package marked 3904) (Q3,4)

2 221-334 PNP transistors (Flat TO92 package marked 221-334) (Q1,2)

1 1N4002 rectifier diode (D1)

1 Large red LED (D2)

Resistors

4 6.2 ohm resistors [blue-red-gold](R12,R13,R14,R15)

1 2.2K ohm resistor [red-red-red](R16)

1 3.9K ohm resistor [orange-white-red](R10)

1 4.7K ohm resistor [yellow-violet-red](R8)

1 6.8K ohm resistor [blue-gray-red](R7)

2 10K ohm resistors [brown-black-orange](R6,R11)

1 22K ohm resistor [red-red-orange](R1)

2 47K ohm resistors [yellow-violet-orange](R5,R9)

1 100K ohm resistor [brown-black-yellow](R3)

2 150K ohm resistors [brown-green-yellow](R2,R4)

Capacitors

1 330uF electrolytic capacitor (C1)

3 10uF electrolytic capacitors (C4,C6,C7)

3 .1uF ceramic capacitors [Marked .1 or 104](C2,C3,C8)

1 .001 ceramic capacitor [Marked .001 or 102](C5)

Miscellaneous

1 3PDT power setting switch (S2)

1 SPDT power switch (S1)

1 Power jack (J1)

1 stereo jack (J2)

1 piezo power speaker horn (SP1)

RB1 7

Page 8

RB1 PARTS LAYOUT DIAGRAM

RB1 8

Page 9

CONSTRUCTION OF THE RAT BLASTER:

Sort out your parts to begin with, making sure you have all of the parts required.

You can use old egg cartons to hold various parts to make them easier to find.

We will begin building the kit starting with the lower profile parts to make it

easier for us to mount them. You will want to use the parts layout diagram to

assist you in finding where the components go.

For each part, our word "install" always

1. Pick the correct part value to start with.

2. Insert it into the correct PC board location, making sure the part is

mounted flush to the PC board unless otherwise noted.

3. Orient it correctly, following the PC board drawing and the written

directions for all parts - especially when there's a right way and a wrong

way to solder it in. (Diode bands, electrolytic capacitor polarity, transistor

shapes, dotted or notched ends of IC's, and so forth.)

4. Solder all connections unless directed otherwise. Use enough heat and

solder flow for clean, shiny, completed connections.

means these steps:

1. Orient the board in the same direction as the parts layout diagram.

2. Install R6, a 10K ohm resistor (brown-black-orange).

3. Install R4, a 150K ohm resistor (brown-green-yellow).

4. Install R5, a 47K ohm resistor (yellow-violet-orange).

5. Install R7,a 6.8K ohm resistor (blue-gray-red).

6. Install R2, another 150K ohm resistor (brown-green-yellow).

7. Install R3, a 100K ohm resistor (brown-black-yellow).

8. Install R9, a 47K ohm resistor (yellow-violet-orange).

9. Install R10, a 3.9K ohm resistor (orange-white-red).

10. Install R8, a 4.7K ohm resistor (yellow-violet-red).

RB1 9

Page 10

11. Install D1, the 1N4002 power diode. This diode prevents the possibility

of someone using the incorrect power supply and inadvertently connecting

the power backwards. Make sure the banded end of the diode (cathode) is

installed in the same direction as shown in the parts layout diagram.

12. Install R16, a 2.2K ohm resistor (red-red-red).

13. Install R1, a 22K ohm resistor (red-red-orange).

14. Install R12, R13, R14, and R15 all 6.2 ohm resistors (blue-red -gold).

15.Install R11, a 10K ohm resistor (brown-black-orange).

16. Install C7, one of the 10uF electrolytic capacitors. Make sure to mount

this part in the correct direction! If you look at the component you will see a

stripe down one side, usually indicating the negative (-) terminal of the

component. You will notice on the parts layout diagram that the hole for the

positive terminal is denoted. You will want to install this component with the

positive (+) lead in the same orientation as shown in the parts layout

diagram. If you do not install it correctly, you will end up with all sorts of

problems in the circuit. Before soldering, place the leads in the appropriate

holes, then carefully bend the

capacitor over making sure the leads

don’t cross and remain as short as

+-20% +-20% +-20% +-20%

possible. Then solder the component.

17. Install C4, another 10uF

electrolytic capacitor using the same procedure as with C7. Pay close

attention to polarity orientation!

18. Install C6, another 10uF electrolytic capacitor. Make sure that the part is

installed in the correct orientation, bend the component over in the same

orientation as shown in the parts layout diagram, then solder.

19. Install U1, the NE555 IC. Notice that one end of the chip is marked with

a dot, notch, or band. Be sure to orient this end as shown in the parts layout

diagram and the silkscreen. You may use an IC socket if you wish but be

aware that our technicians see more repair problems due to sockets than

due to chips burned out from overheating with a soldering iron. Be careful

not to “bridge” the pins together.

20. Install U3, the 4001 IC. Be sure to orient it as shown on the parts layout.

21. Install U2, an XR-2209 IC, making sure to orient it correctly.

22. Install C5, a .001uF disc capacitor (marked .001 or 102).

23. Install C3, a .1uF disc capacitor (marked .1 or 104).

24. Install C8, another .1uF disc capacitor (marked .1 or 104).

RB1 12

Page 11

25. Install C2, the last .1uF disc capacitor (marked .1 or 104).

26. It is time to install the transistors, starting with Q3, a 2N3904.

Transistors have three legs and must be mounted correctly. Notice that the

part has a flat side. Orient the flat side as shown on the parts layout. To

install, slide the legs through the circuit board and push the component as

close to the board as possible without straining the leads. Solder all three

connections securely.

27. Install Q2, a PNP transistor (marked 221334). This transistor and Q1

each appear to have two flat sides. Orient the part using the larger flat side

with no writing on it and install Q2 just as you did Q3 in step 26.

28. In the same way, install Q1 the other 221334 transistor.

29. Install Q4 the last transistor, a 2N3904. Watch your orientation.

30. Before installing the larger parts, we have to install JMP1. From a scrap

component lead, form this jumper and install it as you would a resistor.

Jumpers act like small “bridges” to route traces to the top side of the board

and over obstacles (other traces).

31. Now we will install the stereo jack, J2. It is located next to JMP1. This

part only fits into the PC board one way and should be placed with the body

of the part as close to the board as possible. Gently bend the tabs over if

necessary to hold the part in place and solder all three connections.

32. The next part to be installed is J1, the power jack. Press it firmly into the

board and solder all three leads.

There are two components in the center of the PC board that have not been

soldered in yet. Before installing the switches, we will install these parts.

33. Install D2, the large red LED. Note that one of the two leads is longer.

This is the anode and should be placed in the hole closest to the outline for

C1. Install the part with the leads standing about an eighth of an inch above

the board and solder both legs.

34. C1, a 330uF electrolytic capacitor, must be installed on the solder side

of the PC board. This part also has a polarity which is marked on the top

side of the board. One side of the capacitor has a stripe which denotes the

negative side, while the PC board silkscreen marks the positive side. Be

sure to orient the part correctly. On the back or solder side of the board,

insert C1’s leads through to the top side, making sure the polarity is right.

Bend the capacitor over so that it is lying down on the board and solder

both leads (with the cap lying down you should have plenty of room to

solder it in).

35. Flip the board back over and locate S1, the SPDT power switch. It is the

RB1 13

Page 12

smaller of the two switches and has six leads. Press it firmly into the board

and solder all six leads.

36. Install S2, the 3PDT power setting switch. After pushing firmly into the

board, solder all eight connections.

37. It is now time to install the hookup wire that will connect your completed

board to the speaker. Strip back all four ends of the wire provided about an

eighth of an inch and lightly “tin” them with solder. One pair of ends should

be inserted in the holes next to S2 marked “to speaker”. Solder these wires

to the board. The other ends should be hooked around the tabs on the

speaker and soldered. The speaker has no polarity so the wires can be

hooked up either way.

This completes the assembly of your Rat Blaster! The following steps show you

how to install your kit in the optional case. If you don’t have the case, skip

ahead to the initial testing section.

ASSEMBLY INSTRUCTIONS FOR CUSTOM CASE SET

Parts included with the optional custom case set:

1 case (top and bottom)

1 Rat Blaster sticker

6 #6 black 3/8 inch screws

1 mounting bracket

1 #20 1/4 inch bolt (for mounting bracket)

Mount the PC board inside the case using two of the #6 screws provided.

Mount the speaker inside the case and attach it using two more #6 screws.

The final two #6 screws are for attaching the top cover to the bottom cover.

You may want to wait until after initial testing to screw the top cover on.

The mounting bracket can be attached once a suitable place is found to

mount your Rat Blaster.

RB1 14

Page 13

INITIAL TESTING:

Connect a suitable 12 volt supply to J1- either 12 VAC or 12 VDC ( positive

tip).

Set the frequency range switch to LOW.

BEFORE turning on the power, please read the WARNING below (also on

the back of the case)

WARNING

TO ELIMINATE ANY POSSIBLE RISK OF HEARING LOSS, AVOID NEARBY

EXPOSURE TO THE “RAT BLASTER” SOUNDS. THIS UNIT CAN CAUSE

PERMANENT HEARING DAMAGE.

Turn on the power. The LED should light and you sh ould hear an annoying,

high pitched whine. If so, your Rat Blaster is working and ready to chase

away those nasty critters bothering you. You can change the frequency

range to whatever you desire and place the Rat Blaster wherever it is

needed. The unit is tested on low frequency because it is easier for the

human ear to hear. If it is functioning on low, rest assured that it will

function on medium and high frequency too!

If you are not able to hear the high frequency noise and you have a

voltmeter,you can still check to be sure that your Rat Blaster is functioning.

Set the meter to AC volts and with the meter leads across the speaker

terminals you should see about 12 to 15 VRMS on a typical meter. Voltage

readings will depend on the supply used, of course. If you are getting a

reading of some kind even if it is not 12 –15 volts, this can be due to the

variations in different meters but the voltage reading indicates that the unit

is working. If you’re using a scope, a bench power supply will give you

readings of about 33vpp and our AC125 will read about 25vpp.

If you hear no sound and get no voltmeter reading, it is time to consult the

troubleshooting guide.

RB1 15

Page 14

TROUBLESHOOTING GUIDE:

If your RB1 does not work at all, recheck the following:

correct orientation of diodes, electrolytic capacitors, ICs and transistors.

resistor color codes; 2.2K and 22K resistors are easily confused. The

orange and red color bands look the same under certain conditions. This is

also true for 4.7K and 47K resistors.

soldering; solder bridges and cold solder joints are two of the most common

problems we see on kits returned for repair. You shouldn’t need a

magnifying glass. If a connection is suspect, resolder it!

the power supply; make sure you have 12 volts and if you’re using a DC

supply, be sure that the tip is positive.

If you have given your kit a thorough visual inspection, touched up any solder

connections that look less than perfect, and still haven’t found the problem, you

are ready for some more serious troubleshooting. There are several points that

can be checked with a voltmeter or an oscilloscope and may lead you to the

problem. If you have no test equipment of any kind and can’t borrow a meter

from someone, move on to the warranty section at the back of the manual. If

you have a voltmeter you can check the following:

Across the speaker terminals you should see about 12 to 15 VRMS. If you

get any reading move on to the next step.

You can check the output of U1 on pin 3. On AC, the voltage will vary from

0.4 to 2.2 VRMS. On DC, the voltage will vary from 0.2 to 10.5 VDC. The

best way to see what is happening is to check pin 3 with an oscilloscope.

You should see a square wave from zero (0) to twelve (12) volts (or source

voltage if you’re using something other than a 12 volt input) with a period of

two (2) seconds.

If the output of U1 is good, check the output of U2 at pin 7. You should have

about 6 VDC, or approximately 11.5 vpp (AC volts will be changing

constantly. On the oscilloscope you will see a square wave, 0 to 12 (or

source) volts that is sweeping back and forth. The period of the wave will

depend on the frequency setting at S2. If the square wave is not sweeping

but is steady, the problem is in or around the NE555 IC.

The same signal seen on pin 7 of U2 should also be on pin 3 and pin 11 of U3.

If you have a good signal at pin 3 and not at pin 11, U3 may be bad. If you have

a good signal at pin 11 and nothing across the speaker terminals, the pro blem

is centered around the speaker - Q1, 2, 3, or 4 or R12, 13, 14, or 15.

RB1 16

Page 15

USING YOUR RAT BLASTER:

Certain animals are affected by different frequency settings and other factors

that you can change to repel the pests that are bothering you. The information

below should help you get the best results from your Rat Blaster.

DOGS:

Dogs respond best to the low frequency setting. This is due to the fact

that as they age, domestic dogs lose some of their high frequency hearing.

(That’s why Old Yeller doesn’t seem to hear me when I whistle for him!?!)

Cats are best repelled using the high frequency setting. If you’re trying

CATS:

to get rid of both dogs and cats at the same time, the medium or low setting

should be best.

FERAL CATS AND OTHER WILD ANIMALS:

Any setting may be useful

against a number of different wild animals because of their acute hearing.

COMMON GARDEN AND YARD PESTS:

These would include; rats, ferrets,

weasels, opossums, raccoons, skunks, and woodchucks. The low frequency

setting works best on these types of critters.

DEER:

Deer respond best to the medium frequency setting. They can be

difficult to repel and keeping them out of your yard and garden may require

more diligence on your part. You should move your Rat Blaster around and

even change the height at which it is mounted. The frequency setting can also

be changed periodically when using the Rat Blaster to repel deer. A motion

sensor with its output applied to J2 is the most effective way to keep deer off

your property.

CONNECTING AN EXTERNAL TRIGGER:

If you would like to trigger the RB1 output using an external contact, you may do

so by using a 1/8 inch stereo plug and the external trigger input. This plug has

three connections:

The Tip is at the very end (tip) of the connector.

The Ring is a small ring connection just behind the Tip connection.

The Sleeve is the connection locate closest to the wire connections.

By connecting the Tip connection to the Ring connection the RB1 output will be

deactivated. Removing the Rip-to-Ring connection will activate the RB1 output.

!! BE CAREFUL !!

DO NOT connect either the Tip or Ring connection to the Sleeve connection of

the stereo plug. This will short out the 12VDC supply voltage

RB1 17

Page 16

NOTES

______________________________________________________________

______________________________________________________________

______________________________________________________________

______________________________________________________________

______________________________________________________________

______________________________________________________________

______________________________________________________________

______________________________________________________________

______________________________________________________________

______________________________________________________________

______________________________________________________________

______________________________________________________________

______________________________________________________________

______________________________________________________________

______________________________________________________________

______________________________________________________________

______________________________________________________________

______________________________________________________________

______________________________________________________________

______________________________________________________________

______________________________________________________________

______________________________________________________________

______________________________________________________________

______________________________________________________________

______________________________________________________________

______________________________________________________________

______________________________________________________________

______________________________________________________________

______________________________________________________________

RB1 18

Page 17

1. GENERAL:

Notice that this is not a "fine print" warranty. We want you to understand your rights and ours too! All Ramsey kits will work if

assembled properly. The very fact that your kit includes this new manual is your assurance that prior to release of this kit, a

varied group of knowledgeable people have assembled this kit from scratch using this manual. During this process, changes

and additions are noted by each assembler and integrated into the final version of the manual…which you have! If you need

help, please read through your manual carefully, all information required to properly build and test your kit is contained within

the pages! However, customer satisfaction is our goal, so in the event that you do have a problem, please note the following:

2. DEFECTIVE PARTS:

It's always easy to blame a part for a problem in your kit. Before you conclude that a part may be bad, thoroughly check your

work. Today's semiconductors and passive components have reached incredibly high reliability levels, and it’s sad to say that

our human construction skills have not! But on rare occasions a sour component can slip through. All of our kit parts carry the

Ramsey Electronics Warranty that they are free from defects for a full ninety (90) days from the date of purchase. Defective

parts will be replaced promptly at our expense. If you suspect any part to be defective, please mail it to our factory for testing

and replacement. Please send only the defective part(s), not the entire kit. The part(s) MUST be returned to us in suitable

condition for testing. Please be aware that testing can usually determine if the part was truly defective or damaged by assembly

or usage. Don't be afraid of telling us that you “damaged it” or “burned it out”, we're all human and in most cases, replacement

parts are very reasonably priced. Remember, our goal for over three decades is to have a happy customer, and we’re here to

work WITH you, not AGAINST you!

3. MISSING PARTS:

Before assuming a part value is missing, check the parts listing carefully to see if it is a critical value such as a specific coil or

IC, or whether a RANGE of values is suitable for the component (such as a "100 to 500 uF capacitor"). Often times, common

sense will solve a mysterious missing part problem. If you're missing five 10K ohm resistors and received five extra 1K

resistors, you can pretty much be assured that the “1K ohm” resistors are actually the “missing” 10 K parts ("Hum-m-m, I guess

the orange band really does look red!") Ramsey Electronics project kits are packed with pride in the USA by our own staff

personnel. While separate QC checks are made on all product kits, we too are human, and once in a great while there is a

chance something can get through those checks! If you believe we packed an incorrect part or omitted a part clearly indicated

in your assembly manual for your Ramsey kit, please contact us with information on the part you need. Contact our Repair

Department via telephone, email or writing. Please have your invoice number and date of purchase handy.

4. REFUNDS:

All Ramsey products, kit or factory assembled units have an unconditional 10 day (from the date of purchase) return policy to

examine our products. If you are not satisfied for any reason, you may return your unassembled kit with all the parts and

instructions, or your factory assembled and tested product, together with your proof of purchase to the factory for a full refund

less shipping. The return package should be packed securely. Insurance and tracking is highly recommended. A reminder, this

applies to unassembled kits. They must be in the same new condition as received, not partially assembled! Assembled kits

cannot be returned for credit. No RMA’s are required; simply return to Ramsey Electronics LLC, Attn: Product Returns, 590

Fishers Station Drive, Victor, NY, 14564. If you have any questions, please contact us at 585-924-4560.

5. FACTORY REPAIR OF ASSEMBLED KITS:

Most of us at Ramsey are technically oriented and we do realize that things happen! Even following the best practices, with all

of the best intentions, there is that chance that your kit doesn’t work when you have completed it. Each manual goes into

detailed troubleshooting based on the specific kit to help you troubleshoot the problem. We have found that 95% of returned

kits involved wrongly installed components (wrong part or backwards polarity). This section of the warranty assumes you have

gone through all those steps, and have now reached the point that you need to send it back.

To qualify for factory repair of customer assembled kits, the following conditions apply:

1. Kits must not be assembled with acid solder flux

2. Kit boards or circuits must not be modified in any manner from the version received

3. Kits must be fully assembled, not partially assembled. Our warranty does not include “finishing” your kit!

4. Must include a full description of the problem encountered including the troubleshooting steps you have already done.

5. Must not include non-standard, non-Ramsey accessories, cases, enclosures, knobs, etc. or any batteries.

6. Must include the minimum repair fee of $25 USD in the form of check, money order or credit card authorization.

7. Ramsey Electronics, LLC reserves the right to refuse any repair due to excessive errors in construction methods.

8. If, due to customer construction methods, the repair is estimated to exceed the minimum flat rate, Ramsey Electronics,

LLC will contact the customer to discuss the repairs needed and to receive authorization and payment for repair prior

to repair.

9. In the unlikely case that a defective part is found to be the cause of the problem, the repairs will be made at no-charge

to the customer, and any payments received for repair will be returned or credited back to the customer.

10. Properly pack your kit, insure the package, and use a carrier that can be tracked. Ramsey Electronics, LLC is not

responsible for any loss or damage in shipment. Send the package together with your repair fee to the return address

below. No RMA is required.

6. FACTORY REPAIR FEES:

Please understand that our Tech Support Group personnel are not volunteers! They are a dedicated group of highly trained

technicians each configured with a very properly equipped test bench. Upon receipt of a repair, the setup, testing, diagnosis,

repair, paperwork, and repacking of your kit requires nearly an hour of their time regardless of the size or complexity of the kit!

The minimum repair fee represents ½ hour Tech Support time at $50/hour USD. We try to keep all kit repairs within the realm

of the $25 flat rate whenever possible…and trust us; we exceed that time spent on most kits received more often than not!

7. CONTACT INFORMATION AND RETURN ADDRESS:

Technical Questions Product Repair & Returns

RAMSEY ELECTRONICS, LLC

Attn: Tech Support

590 Fishers Station Drive

585-924-4560; 585-924-4886 Fax

techsupport@ramseyelectronics.com

THE RAMSEY KIT WARRANTY

Victor, NY 14564

RB1 19

585-924-4560; 585-924-4886 Fax

RAMSEY ELECTRONICS, LLC

Attn: Repairs

590 Fishers Station Drive

Victor, NY 14564

repairs@ramseyelectronics.com

Page 18

TABLE OF CONTENTS

Introduction ..................................... 4

Learn As You Build ......................... 6

Parts List ......................................... 7

Parts Layout Diagram ..................... 8

Construction ................................... 9

Schematic Diagram ...................... 10

Troubleshooting ............................ 16

Warranty ....................................... 19

REQUIRED TOOLS

Soldering Iron

Thin Rosin Core Solder

Needle Nose Pliers

Small Diagonal Cutters

ADDITIONAL SUGGESTED ITEMS

Helping Hands Holder for PC Board/Parts

Desoldering Braid

Price: $5.00

Ramsey Publication No. MRB1

Assembly and Instruction manual for:

RAMSEY MODEL NO. RB1

RAT BLASTER PEST ELIMINATOR KIT

TOTAL SOLDER POINTS

118

ESTIMATED ASSEMBLY

TIME

Beginner ............. ..2.5 hrs

Intermediate ......... 1.5 hrs

Advanced ............. 1 hr

RAMSEY ELECTRONICS, LLC

590 Fishers Station Drive

Victor, New York 14564

Phone (585) 924-4560

Fax (585) 924-4555

www.ramseykits.com

RB1 20

Loading...

Loading...