Page 1

PG13 • 1

Ramsey Electronics Model No. PG13

Have you ever wanted to play with a controlled substance? Now

you can! It is called plasma, and it is easily generated by this

nifty high voltage kit. This is the same though more powerful

supply that is used in Plasma Balls and neon art, and can be

used for all sorts of high voltage experiments! Turn a standard

light bulb into a plasma sphere!

•

Perfect for driving a Jacob’s ladder. See plasma at work!

•

Can light many feet of neon tubing

•

Perfect for driving plasma balls, even make a standard light bulb

into a plasma sphere!

•

Optional 12VAC transformer and this kit are all you need to begin

experimenting!

•

Can generate sparks up to 2 inches.

•

Very thorough manual on high voltage safety, many neat

experiments, and lessons learned along the way.

•

Can produce many of the same effects as Tesla Coil, on a smaller

scale.

•

Great for science fairs!

DANGER

HIGH VOLTAGE

See instruction manual before operation

Page 2

PG13 • 2

RAMSEY TRANSMITTER KITS

• FM100B Professional FM Stereo Transmitter

• FM25B Synthesized Stereo Transmitter

• AM1, AM25 AM Transmitters

• TV6 Television Transmitter

RAMSEY RECEIVER KITS

• FR1 FM Broadcast Receiver

• AR1 Aircraft Band Receiver

• SR2 Shortwave Receiver

• AA7 Active Antenna

• SC1 Shortwave Converter

RAMSEY HOBBY KITS

• SG7 Personal Speed Radar

• SS70A Speech Scrambler

• SP1 Speakerphone

• WCT20 Wiza rd Cable Tracer

• ECG1 Heart Monitor

• LABC1 Lead Acid Battery Charger

• IG7 Ion Generator

• CT255 Compu Temp Digital Binary Thermometer

• LC1 Inductance-Capacitance Meter

RAMSEY AMATEUR RADIO KITS

• HR Series HF All Mode Receivers

• QRP Series HF CW Transmitters

• CW7 CW Keyer

• CPO3 Code Practice Oscillator

• QRP Power Amplifiers

RAMSEY MINI-KITS

Many other kits are available for hobby, school, Scouts and just plain FUN. New

kits are always under development. Write or call for our free Ramsey catalog.

PG13 PLASMA G EN ER A TO R KIT MANUAL

Ramsey Electronics publication No. MPG13 Revision 1.1d

First printing: November 2001 MRW

COPYRIGHT 2001 by Ramsey Electronics, Inc. 590 Fishers Station Drive, V ic t or, New York

14564. All rights reserved. No portion of this publication may be copied or duplic ated without the

written permission of Ramsey Electronics , I nc. P rinted i n the United Stat es of America.

Page 3

PG13 • 3

PG13 PLASMA

GENERATOR KIT

Ramsey Publication No. MPG13

Price $10.00

TABLE OF CONTENTS

Safety Guidelines .................................4

History ...................................................9

Circuit Operation .................................12

Learn As You Build .............................16

Parts List .............................................18

Assembly .............................................19

Schematic ............................................24

Power Supply ......................................25

Testing .................................................28

Troubleshooting ..................................31

Experiments ........................................32

Component Placem ent ........................42

Warranty ..............................................43

KIT ASSEMBLY

AND INSTRUCTION MANUAL FOR

RAMSEY ELECTRONICS, INC.

590 Fishers Station Drive

Victor, New York 14564

Phone (585) 924-4560

Fax (585) 924-4555

Page 4

PG13 • 4

SAFETY GUIDELINES FOR HIGH VOLTAGE AND/OR LINE POWERED

EQUIPMENT

Author: Samuel M. Goldwasser

Corrections/suggestions: sam@stdavids.picker.com

Copyright (c) 1994, 1995, 1996, 1997, 1998

All Rights Reserved

Reproduction of this document in whole or in part is permitted if both of the

following conditions are satisfied:

1. This notice is includ ed in its ent iret y at the begin ning.

2. There is no charge except to cover the costs of copying.

Introduction

Consumer electronics equipment like TVs, computer monitors, microwave

ovens, and electronic flash units, use voltages at power levels that are

potentially lethal. Normally, these are safely enclosed to prevent accidental

contact. However, during servicing, the cabinet will likely be open and safety

interlocks may be defeated. Depending on overall conditions and your general

state of health, there is a wide variation of voltage, current, and total energy

levels that can kill.

Microwave ovens in particular are probably THE most dangerous household

appliance to service. There is high voltage - up to 5,000 V or more - at high

current - more than an amp may be available momentarily. This is an instantly

lethal combination.

TVs and monitors may have up to 35 KV on the CRT but the current is low—a

couple of milliamps. However, the CRT capacitance can hold a painful charge

for a long time. In addition, portions of the circuitry of TVs and monitors - as

well as all other devices that plug into the wall socket - are line connected. This

is actually more dangerous than the high voltage due to the greater current

available - and a few hundred volts can make you just as dead as 35 KV!

Electronic flash units and strobelights have large energy storage capacitors

which alone can deliver a lethal charge - long after the power has been

removed. This applies to some extent even to those little disposable pocket

cameras with flash!

Even some portions of apparently harmless devices like VCRs and CD

players or vacuum cleaners and toasters - can be hazardous (though the live

parts may be insulated or protected - but don't count on it!

This information also applies when working on other high voltage or line

Page 5

PG13 • 5

connected devices like Tesla Coils, Jacobs Ladders, plasma spheres,

gigawatt lasers, fusion generators, and other popular hobby type projects.

In addition read the relevant sections of the document for your particular

equipment. Specific safety considerations have been included where

appropriate.

Safety guidelines

These guidelines are to protect you from potentially deadly electrical shock

hazards as well as the equipment from accidental damage.

Note that the danger to you is not only in your body providing a conducting

path, particularly through your heart. An y involuntary muscle contractions

caused by a shock, while perhaps harmless in themselves, may cause

collateral damage - there are many sharp edges inside this type of equipment

as well as other electrically live parts you may contact accidentally.

The purpose of this set of guidelines is not to frighten you but rather to make

you aware of the appropriate precautions. Repair of TVs, monitors,

microwave ovens, and other consumer and industrial equipment can be both

rewarding and economical. Just be sure that it is also safe!

•

Don't work alone - in the event of an emergency another person's

presence may be essential.

•

Always keep one hand in your pocket when anywhere around a powered

line-connected or high vo lta ge system.

•

Wear rubber bottom shoes or sneakers.

•

Wear eye protection - large plastic lens eyeglasses or safety goggles.

•

Don't wear any jewelry or other articles that could accidentally contact

circuitry and conduct current, or get caught in moving parts.

•

Set up your work area away from possible grounds that you may

accidentally contact.

•

Know your equipment: TVs and monitors may use parts of the metal

chassis as ground return yet the chassis may be electrically live with

respect to the earth ground of the AC line. Microwave ovens use the

chassis as ground return for the high voltage. In addition, do not assume

that the chassis is a suitable ground for your test equipment!

•

If circuit boards need to be removed from their mountings, put insulating

material between the boards and anything they may short to. Hold them

in place with string or electrical tape. Prop them up with insulation sticks

plastic or wood.

•

If you need to probe, solder, or otherwise touch circuits with power off,

discharge (across) large power supply filter capacitors with a 2 W or

Page 6

PG13 • 6

greater resistor of 100-500 ohms/V approximate value (e.g., for a 200 V

capacitor, use a 20K-100K ohm resistor). Monitor while discharging and/

or verify that there is no residual charge with a suitable voltmeter. In a TV

or monitor, if you are removing the high voltage connection to the CRT (to

replace the flyback transformer for example) first discharge the CRT

contact (under the insulating cup at the end of the fat red wire). Use a

1M-10M ohm 1W or greater wattage resistor on the end of an insulating

stick or the probe of a high voltage meter. Discharge to the metal frame

which is connected to the outside of the CRT.

•

For TVs and monitors in particular, there is the additional danger of CRT

implosion - take care not to bang the CRT envelope with your tools. An

implosion will scatter shards of glass at high velocity in every direction.

There is several tons of force attempting to crush the typical CRT. Always

wear eye protection.

•

Connect/disconnect any test leads with the equipment unpowered and

unplugged. Use clip leads or solder temporary wires to reach cramped

locations or difficult to access locations.

•

If you must probe live, put electrical tape over all but the last 1/16" of the

test probes to avoid the possibility of an accidental short which could

cause damage to various components. Clip the reference end of the

meter or scope to the appropriate ground return so that you need to only

probe with one hand.

•

Perform as many tests as possible with power off and the equipment

unplugged. For example, the semiconductors in the power supply section

of a TV or monitor can be tested for short circuits with an ohmmeter.

•

Use an isolation transformer if there is any chance of contacting line

connected circuits. A Variac(tm) (variable autotransformer) is not an

isolation transformer! However, the combination of a Variac and isolation

transformer maintains the safety benefits and is a very versatile device.

See the document "Repair Briefs, An Introduction", av ail ab le at this site,

for more details.

•

The use of a GFCI (Ground Fault Circuit Interrupter) protected outlet is a

good idea but will not protect you from shock from many points in a line

connected TV or monitor, or the high voltage side of a microwave oven,

for example. (Note however, that, a GFCI may nuisance trip at power-on

or at other random times due to leakage paths (like your scope probe

ground) or the highly capacitive or inductive input characteristics of line

powered equipment.) A fuse or circuit breaker is too slow and insensitive

to provide any protection for you or in many cases, your equipment.

However, these devices may save your scope probe ground wire should

you accidentally connect it to a live chassis.

•

When handling static sensitive components, an anti-static wrist strap is

recommended. However, it should be constructed of high resistance

Page 7

PG13 • 7

materials with a high resistance path between you and the chassis

(greater than 100K ohms). Never use metallic conductors as you would

then become an excellent path to ground for line current or risk

amputating your hand at the wrist when you accidentally contacted that

1000 A welder supply!

•

Don't attempt repair work when you are tired. Not only will you be more

careless, but your primary diagnostic tool - deductive reasoning - will not

be operating at full capacity.

•

Finally, never assume anything without checking it out for yourself! Don't

take shortcuts!

Safety tests for leakage current on repaired equipment

It is always essential to test AFTER any repairs to assure that no accessible

parts of the equipment have inadvertently been shorted to a Hot wire or live

point in the power supply. In addition to incorrect rewiring, this could result

from a faulty part, solder splash, or kinked wire insulation.

There are two sets of tests:

DC leakage: Use a multimeter on the highest ohms range to measure the

resistance between the Hot/Neutral prongs of the wall plug (shorted together

and with the power switch on where one exists) to ALL exposed metal parts of

the equipment including metallic trim, knobs, connector shells and shields,

VHF and UHF antenna connections, etc.

This resistance must not be less than 1M ohm.

AC leakage: Connect a 1.5K ohm, 10 Watt resistor in parallel with a 0.15 uF,

150 V capacitor. With your multimeter set on ACV across this combination

and the equipment powered up, touch between a known earth ground and

each exposed metal part of the equipment as above.

WARNING: Take care not to touch anything until you have confirmed that

the leakage is acceptable - you could have a shocking experience! The

potential measured for any exposed metal surface must not exceed 0.75 V.

If the equipment fails either of these tests, the fault MUST be found and

corrected before putting it back in service (even if you are doing this for your

in-laws!).

Some notes regarding the above safety information

While the PG13 falls under the high voltage category, many of the safety

recommendations do not apply due to the nature of high frequency high

Page 8

PG13 • 8

voltage. This is only true if you do not modify the kit in any way. Here is the

reason why, which is very interes ting:

So here is the abridged answer to your question:

Sodium channels are responsible for the initiation and propagation of action

potentials. Action potentials are those electrical signals that carry

messages throughout the body whether they be neuronal or cardiac in nature.

Sodium channels go through a basic gating scheme. Upon membrane

depolarization, sodium channels open, or activate, then quickly inactivate

or close. Upon repolarization, sodium channels will go back to the resting

state at which time they are capable of opening again. Channels require a

certain amount of time to recover from inactivation or return to this

available resting state. This recovery from inactivation requires on the

order of 15 ms. The frequency at which action potentials fire is governed by

this recovery. So action potentials can fire about 60 times per second.

Stimulation at higher frequencies would for all intents and purposes drive

those sodium channels near the point of the stimulation into a long lived

inactivated state from which no action potentials could fire. So thus the

reason why lower frequency stimulation would be more deleterious than a 2

kHz frequency.

Larry E. Wagner II

Technical Associate II

Dept. of Anesthesiolo gy

P.O. Box 604

University of Rochester Medical Center

Simply put, your nerves are not fast enough to respond! Does this mean you

are not getting electrocuted? No, but current flow is harmless at these

frequencies. The real danger comes from RF burns, and that is what you will

become aware of the most when you touch the wrong things. Burning flesh

smells awful by the way. When you feel a “tickle” from the PG13 it is either

from a lower frequency component like 60 Hz, or the “tickle” of a nice RF burn.

Yes, they HURT!

Page 9

PG13 • 9

HOW I ARRIVED AT THE PG13.

(A little history, if you please!)

Let me introduce myself. I am an engineer at Ramsey Electronics, and have

been so for over 12 years now. Who said anything about company faithfulness

being dead? Anyhow since I was in high school I have been messing around

with high voltage, becaus e it is a challe nge , a bit risky, and is simply

fascinating. I suppose the fixation on high voltage stems from an earlier

fascination with fire, but I won’t get into that. The connection is that fire and a

good spark are both made of the same stuff: Plasma.

This kit is NOT a Tesla Coil by any means, in fact it exhibits very little of the

effects that Tesla Coils use to achieve a very high output voltage. Tesla coils

use a completely different effect from turns ratios to achieve a high voltage

output, which involves transmission line theory, magnetic fields, and a lot of

power. Tesla coil’s output voltages are dependant upon factors such at

secondary Q factors, and not as much on turns ratios. My PG13 is completely

dependant upon turns ratios because the Q factor is too low to exhibit Tesla

effects.

This project was conceived due to an inability to find those old flyback

transformers that do not contain diodes. Diodes convert the output of a

television flyback transformer to DC, preventing them from working for many

AC experiments. I searched long and hard, and finally found a manufacturer of

a perfect experimenter’s coil. No more stopping at the side of the road at an old

console TV to see if the flyback is usable!

So, what the heck is plasma, you may ask? No, it’s not the plasma in your

blood, swimming along with the red blood cells. Plasma is matter in an

extremely excited state. Basically it is molecules being repeatedly stripped of

their electrons, and then electrons falling back into place. The process of

electrons falling into place is what gives sparks and fire (plasma) its

characteristic colors. These colors are dependant upon the mixture of gases

that the plasma is made up of, and how excited the gases are. Our atmosphere

is mostly Nitrogen, with Oxygen and other gases thrown in as an afterthought.

Nitrogen emits blues and violets mostly in a low excitement state, and that is

why sparks appear violet at low currents, and blue as the current increases.

Why is fire orange and yellow? Because particles such as carbon and ash in

the plasma are heated to incandescence, like the filament of a light bulb. If not

for the particles the flames would be blue, like Natural Gas burning.

Aurora Borealis is another example of plasma In this case upper atmosphere

molecules are excited by high energy particles from the sun. Auroras vary from

green to red, depending on intensity and elevation in the atmosphere. At higher

elevations and low atmospheric pressures found in the upper atmosphere,

Nitrogen will emit quite a bit of green. Down a few dozen kilometers closer to

earth, Oxygen ionizes (turns to plasma) much more easily and Oxygen tends to

emit red. That is why you see different colors in aurora.

Page 10

PG13 • 10

To see an aurora closely, we can use Plasma balls. Plasma balls operate by

applying a high AC voltage to an electrode in the center of a glass sphere. This

high voltage must be high frequency AC in order for any current to get through

the glass of the globe and surrounding air by capacitive coupling to your hand

or the air. The current actually doesn’t go through the glass, but is induced on

either side. Typical voltages are around a few thousand volts for most

commercial plasma globes, sometimes around 10,000 volts for some

homebrew ones. Typical frequencies are from a few kilohertz to a few tens of

kilohertz.

Plasma balls will usually employ unusual gases such as helium, neon, xenon,

krypton, and argon to achieve different colors and spark types. Since gases

usually ionize more easily at low air pressures, a plasma ball’s air is first sucked

out with a vacuum pump, and then replaced with a mixture of the above gases

at about 1/10 to 1/20 of an atmosphere. These gases are noble gases, also

meaning inert, which means that they don’t readily react with other molecules

and create dangerous results. There have been reports of Plasma balls working

at atmospheric pressure, and we may try that experiment here.

I used a small water-controlled vacuum pump at home when I was a kid and a

large, green wine bottle. The best I ever got was 4” streamers at the very

bottom, which were white due to the quantity of water vapor coming back

through my hose. When your budget is $20 a month, you simply can’t afford a

vacuum pump.

Now that I have a job, I can get all of those toys I always wanted as a kid (if

my wife lets me!), but now I needed to make a new supply. My old one looked

like a rat’s nest of wires, and the television flyback wouldn’t fit in any plastic

case that I could find. It was time to make a new one that looked nice, and

didn’t periodically shock me. I decided to use my resources here at work to

make a new kit as well as a new toy for me. (The wife won’t stop me if the boss

is paying!)

Happy experimenting, and I hope you enjoy playing with high voltage as much

as I do! Oh, here is a little reference I pulled from the Internet on gases and the

colors they make. Pretty neat!

Colors and Effects of Various Gases (by Don Klipstein)

Helium - In spectrum tubes it glows a brilliant whitish yellow-orange color,

somewhat like that of a high pressure sodium lamp. I have heard that this

sometimes varies with pressure, current, and container dimensions.

Neon - Usually produces dim red blurry streamers with brighter orange "pads"

at the ends. If neon is mixed with another gas (other than helium), the streamer

color and character is often dominated by the other gas, but the ends of the

streamer are orange or pink "pads".

Page 11

PG13 • 11

Carbon Dioxide - Glows a whitish or blue-white color. It is probably good to

have no direct contact with metal electrodes for long life with gases that are not

completely inert. Carbon dioxide probably requires more voltage than the noble

gases. Generally, gases and vapors with monoatomic molecules work with less

voltage than others.

Nitrogen - Streamers are usually a whitish or grayish pink or light orange. The

color may be more gray or lavender at very low currents. The apparent color

varies with what kind of lighting it is in contrast with. Requires somewhat higher

voltage than noble gases .

Air, Oxygen, Water Vapor - These require more voltage than the noble gases

and do not glow brightly. I do not recommend these. If you must use any of

these, you may also want no direct contact of gas or vapor to metal in order to

avoid corrosion problems.

Argon - Streamers are violet-lavender. The ends are blue-violet-lavender.

Argon and neon. A mixture of around 99.5 percent neon, .5 percent argon has

the lowest voltage requirement, but may not look as good as other gases.

Argon-Nitrogen mixture (as found in many light bulbs) - Streamers are whitish

or grayish pink or orange, but more lavender at low currents. The ends are

blue-violet-lavender. Requires a bit more voltage than pure argon.

Krypton - Generally lightning-like and close to white or light gray, sometimes

purplish or pinkish, depending on background lighting. Sometimes fuzzier and/

or gray-greenish, especially if the pressure and/or peak current are low.

Xenon - Usually lightning-like and bluish white or bluish gray. May get fuzzier

and more gray or lavenderish gray at lower pressure and lower peak current.

Peak currents over a few milliamps favor a more lightning-like appearance even

if the RMS current is less than a milliamp.

Don Klipstein's web site with plenty of great information on HV and plasma:

http://www.misty.com/people/don/index.html

Page 12

PG13 • 12

CIRCUIT OPERATION

What is going on with this board may look simple at first, but it is actually

quite a difficult design to get working properly and reliably. A lot has to be

considered with magnet ic s when deali ng wit h high vo lt age, hi gh freque ncy

transformers. Unlike power transformers like the one powering the entire kit,

high voltage transformers have a “sweet spot”, or a resonant frequency where

they operate the most efficiently. The goal of the design is to get it working

above human hearing, otherwise the screech of high frequency from a plasma

discharge is deafening. When choosing the transformer for this design, I

wanted the best of everything: High Voltage output, High Current, High

Resonant Frequency, and the ability to generate this from a relatively low

voltage.

The transformer company we found delivered four different transformers to

us to experiment with, and a bunch of plastic spacers of varying widths. The

four transformers had increasing numbers of secondary windings, but all other

factors similar. The problem is that the more windings there are on the

secondary, the more inductance there is, meaning the resonant frequency

would be lower. The largest transformer which had 6500 turns in the

secondary would have been perfect to get 12 volts up to 25kV using a low

number of turns on the primary, but the resonance was around 13kHz. The

sound this emits is intolerable for any length of time. The coil also had the

problem of having very thin wire resulting in a low current output. They have to

use fine wire to make it fit in the transformer’s plastic case.

The smallest coil had 2000 turns on the secondary, which isn’t quite enough

to get 25kV from 12V, even in a push-pull configuration. The problem here is

we really need more than one turn of wire on the primary to make an effective

output. An advantage would be that the transformer oscillated around 35kHz,

well above hearing, but almost too high for some effects we would like to

make.

The transformer we wound up using was the third size, which has 4000

windings on the secondary, which gives us plenty of high voltage output. It

also has the larger sized wire, and with the proper spacers would oscillate

right around 18kHz. This frequency is above most people’s hearing, but your

dog won’t like this too much.

So what do those spacers do? Without getting into magnetics too much, they

lower the saturation point of the ferric core. This means the core saturates

faster with a larger gap, which also translates to a higher operating frequency.

This also means, however, that since the core saturates faster, less energy

will be transferred from the primary to the secondary, which reduces power

output.

Page 13

PG13 • 13

We have included two 0.25mm spacers for you to do experiments with.

Since the transformer is specific about its “sweet spot”, we couldn’t run the

drive circuit directly from a pulse width modulator circuit (PWM). We may have

been able to tune it up really close while there was no load applied, but as

soon as we would draw a spark, the frequency would change, and our output

would drop considerably. For example if the “sweet spot” was 20kHz, and we

were driving the circuit with 20kHz, we may have 20kV on the output. Then, if

we add a new load on the output that changes the “sweet spot” to 19kHz, but

we are still driving it with 20kHz, the output may drop to only a few kilovolts.

Because of this we decided to make the transformer self-resonating. This

means as the load changes, so will the frequency, so that the transformer is

always running in the sweet spot.

The way this oscillator works is by alternately saturating the core, first in one

direction, then the other. R1 and R5 are used as a “kick start” for the oscillator.

These resistors provide some current to turn the transistors on. Because no

two transistors are perfectly alike, one will turn on before the other, providing

an imbalance.

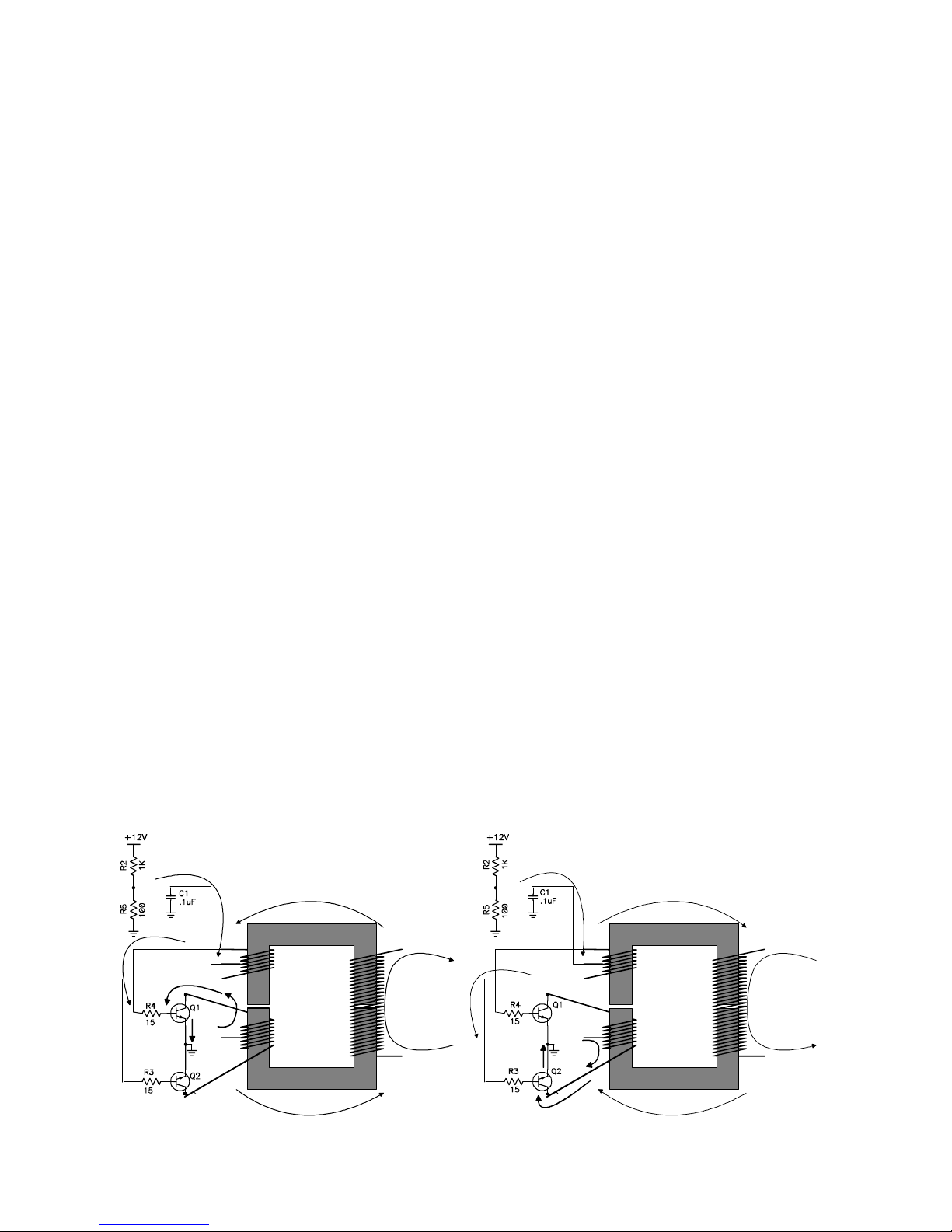

In Figure 1, The transistor that is turned on stays on, forcing the other

transistor to turn off by directing current through the feedback winding of the

transformer in the direction required to turn the other transistor off, and turn

itself on even harder. For this illustration we’ll say that Q3 is turned on while

Q4 is turned off. As this is occurring, magnetic flux in the core is building along

with the current being drawn through Q3, because of the side of the winding

Q3 is attached to. This current is drawn through the center tap of the primary

winding through the winding, and finally down through Q3 to ground. This

rising magnetic flux in turn is inducing voltage and current in the high voltage

secondary, as well as the feedback winding. This current in the feedback

winding pushes the transistor on even harder up to the point that the core of

the transformer saturates.

Fig 1. Fig 2.

Direction of Flux

+V High Voltage

-V High Voltage

+12V

Direction of Flux

-V High Voltage

+V High Voltage

+12V

Page 14

PG13 • 14

Once saturation occurs, the flux stops increasing in the core, and the current

that was induced in the feedback winding abruptly halts and reverses direction

due to a “ringing” effect. This reversal in current direction then turns off Q3

and begins to turn on Q4, which quickly ramps up the flux in the core now

heading in the other direction. (Fig 2).

This cycle goes back and forth continuously until power is removed.

To control the output voltage we can simply adjust our driving voltage.

Here’s why I chose a 12.6VAC transformer instead of a 16VAC transformer to

be used with your PG13.

One quirk we have come across is that our high voltage design cannot

produce a high current arc directly to ground. For this to actually occur we

would need a lot more parts in the circuit, and also it would reduce the safety

considerably. We decided to go for safety and stick with a lower power design.

Besides, you can pull some pretty hot arcs onto a screwdriver and other

objects, no ground needed!

To find out what we have for output voltage is a simple matter of turns ratios.

See the chart below to see the transformer secondary windings that were in

the different models of transformers that I sampled.

Winding Turns

Wire Diam.

CHT-0126A: 2000 0.1mm

CHT-0126B: 2500 0.1mm

CHT-0126C: 4000 0.1mm

CHT-0126D: 6500 0.06mm

Since we chose the C version of the transformer, we see that we have 4000

windings in the secondary. Now we need to know what is in the primary. Since

we were trying to achieve highest poss ible vo lt age out put alo ng with a dec ent

current output, I compromised at 9 turns center tapped on the primary. Since

we are in a push-pull configuration, this essentially doubles our supply voltage

across the primary. So let’s say we have a 12.6 VAC transformer supplying

our kit, and we need to know what our output voltage will be. First we have to

find what the supply voltage will become after converting the 12.6VAC which

is an RMS value to the DC value after rectification. First we convert to peak to

peak:

12.6VAC * SQRT(2) = 17.81 Vpk/pk

Then we subtract 1.4 volts for the diode drops in the bridge rectifier.

17.81—1.4 = 16.41 VDC

Now realize that the 12.6VAC rating is at the current rating of the

Page 15

PG13 • 15

transformer, or under full load. In the case of the transformer we will be

supplying, it is rated for 3 amps. We idle at 0.5 amps. This means the wall

transformer will actually put out much more voltage under this low load. In fact

after measuring this I found the rectified DC to be close to 19.2 VDC, which is

17% higher than we would expect. Using this 19.2VDC, we can now find what

our output of the secondary will be. Since we are operating push-pull, 19.2

volts will be across 1/2 of the primary at any given time, so we will say the

primary has 4 1/2 windings.

19.2 V / 4.5 windings = ? Secondar y Volts / 4000 windi ngs.

Rearranging we get:

? Secondary Volts = 19.2 V * 4000 w / 4.5 w

Or: 17,066 volts AC.

Now you’re probably going to say: “Where’s the 20kV you promised?” Well,

it’s here. Due to switching transients of the transistors, there are some pulses

induced in the prim ar y windings that inc reas e out put vo ltag e sl ight ly. These

pulses are called “ringing” which can also be described as overshoot.

Typically under var ying lo a d conditi ons the overs ho ot will cha nge ab out 20%,

or in other words add about 3.5kV to our output.

17.066 KVAC + 3.5 KVAC = 20.56 K VAC .

This “ringing” is actually what a true Tesla Coil relies on to achieve

amazingly high voltages. A good Tesla coil design utillizes the ring, and the

harmonics of it. The better it “rings”, the higher the output.

This output value is difficult to measure due to the variety of loads we will run

into, but this is a no-load output voltage. As soon as we begin to load the

circuit, this will vary quite a bit, since there is no regulation on the output.

Now if we used a 16VAC transformer? We will just scale the output

according to percentage:

20.56 KVAC + 21% * 20.56 KVAC = 24.8 KVAC.

24.8 KVAC. The output transformer is only rated for 25 KVAC, and this is

coming too close for comfort for reliable use, and the difference isn’t very

noticeable. Also, 15 VAC stresses our transistors a bit too much. You are free

to try it though, just don’t run it continuously. Doing this also voids the

warranty since your transformer may arc over in some experiments, thereby

destroying it!

Page 16

PG13 • 16

RAMSEY “LEARN-AS-YOU-BUILD” ASSEMBLY STRATEGY

Be sure to read through all of the steps, and check the boxes as you go to be

sure you didn't miss any important steps. Although you may be in a hurry to see

results, before you switch on the power check all wiring and capacitors for

proper orientation. Also check the board for any possible solder shorts, and/or

cold solder joints. All of these mistakes could have detrimental effects on your

kit - not to mention your ego!

Kit building tips:

Use a good soldering technique - let your soldering iron tip gently heat the

traces to which you are soldering, heating both wires and pads simultaneously.

Apply the solder to the iron and the pad when the pad is hot enough to melt the

solder. The finished joint should look like a drop of water on paper, somewhat

soaked in.

Mount all electrical parts on the top side of the board provided. The top side is

clearly marked with the model and revision numbers of the kit; you can’t miss it.

This is the side that has few traces on it and has the silkscreen on it. When

parts are installed, the part is placed flat to the board, and the leads are bent on

the backside of the board to prevent the part from falling out before soldering

(1). The part is then soldered securely to the board (2-4), and the remaining

lead length is then clipped off (5). Notice how the solder joint looks on close up,

clean and smooth with no holes or sharp points (6).

Page 17

PG13 • 17

We sincerely hope you put this kit together in a prof es sion al m anner . This

project will not work as well as you wished if you don’t f ollo w goo d assembly

techniques, and follow all instructions. No matter how clear we may think our

manual is, if you have an y questions give us a call at the fac tor y instea d of going it alone; we will be happy to help you with any probl em s .

As good engineering and kit building practice we want to mount the parts AS

LOW AS POSSIBLE to the board. A 1/4” lead length on a resistor not mounted

close to the board can act as an inductor or an antenna, causing all sorts of

problems in some circuits. Although this is not an RF circuit, it is best to keep

the parts close to the board.

For each part, our word "Install" always means these steps:

1. Pick the correct part value to start with.

2. Insert it into the correct PC board location, making sure the part is

mounted flush to the PC board unless otherwise noted.

3. Orient it correctly, foll o w the PC board dra wing and the written directions

for all parts - especially when there's a right way and a wrong way to solder

it in. (Diode bands, electrolytic capacitor polarity, transistor shapes, dotted

or notched ends of IC's, and so forth.)

4. Solder all connections unless directed otherwise. Use enough heat and

solder flow for clean, shiny, completed connections.

Save a few of the longer leads clipped off the components after soldering.

These will be used to form jumper wires to connect circuit board traces.

Keeping this in mind, lets begin by sorting out our components and crosschecking them against the parts list to make sure we have received everything.

NOTE TO NEWCOMERS: If you are a first time kit builder you may find this

manual easier to understand than you may have expected. Each part in the kit

is checked off as you go, while a detailed description of each part is given. If

you follow each step in the manual in order, and practice good soldering and kit

building skills, the kit is next to fail-safe. If a problem does occur, the manual

will lead you through step by step in the troubleshooting guide until you find the

problem and are able to correct it.

Page 18

PG13 • 18

RAMSEY PG13 PARTS LIST

Semiconductors

4 1N5408 3 AMP Rectifier diodes (D2,3,4,5)

1 RED LED (D1)

2 TIP31C 100V Bipolar NPN Power Transistors (Q1,2)

Resistors

1 100 ohm resistor (brown-black-brown) (R5)

1 1K ohm resistor (brown-black-red) (R1) <- Small Size

1 1K ohm 1/2 Watt resistor (brown-black-red) (R2) <- Large Size

2 30 ohm 1 Watt resistors (brown color, marked 30

Ω

) (R3,4)

Capacitors

1 0.1uF Ceramic capacitor (marked 104) (C1)

2 0.1uF Mylar capacitors (marked 104, larger than ceramic) (C5,6)

1 10uF Electrolytic capacitor (C2)

2 3300 or 4700uF Electrolytic capacitors (C3, C4)

Transformer

1 High voltage transformer winding (Marked CHT-0126G) (XFMR1)

2 U cores.

2 0.25mm nylon spacers

1 U core clamp.

1 piece of plastic tubing for U core clamp

Miscellaneous

1 Neon bulb indicator (N E1)

1 Push button switch (S1)

1 Switch cap.

1 3-screw power terminal (J1)

2 TO-220 Gold heatsinks (HS1,2)

1 Piece of Teflon tubing

1 1 1/8” diameter plastic insulating post with pre-drilled holes.

4 Large rubber feet.

1 Small rubber foot.

1 6-32 x 1/2 metal screw.

2 4-40 x 1/4 screws.

2 4-40 lock nuts.

1 1/2” metal ball terminal

1 #16 nail, 1 1/4 inch long

Page 19

PG13 • 19

ASSEMBLY

We will begin with the board oriented with the power switch mounting

position towards you. This is just to keep our parts locating task simple.

1. Install S1, the power switch. Solder all six leads.

2. Install R2, the larger 1K ohm 1/2 watt resistor (brown-black-red).

3. Install R5, 100 ohm resistor (brown-black-brown) .

4. Install C1, the 0.1uF ceramic capacitor (marked 104). Note that this part

looks more like a disk than the other 0.1uF Mylar capacitors.

5. Install C2, the 10uF electrolytic capacitor. Note that this part is polarity

sensitive and mus t be installe d proper ly. If you put it in the wrong way, it

will overheat and self-destruct. Pay very close attention when installing all

electrolytic capacitors in this kit!

6. Install R3, one of the 30 ohm, 1 Watt resistors (brown color, marked 30

Ω

).

7. Install C6, one of the 0.1uF Mylar capacitors (marked 104).

8. Install R4, the other 30 ohm 1 Watt resistor (brown color, marked 30 Ω)

9. Install C5, the other 0.1uF Mylar capacitor (marked 104).

10. Install D2, one of the 1N5408 rectifier diodes. Note the end of the

diode with the line or band. This is the cathode end. Current can only flow

into this lead, not out of it. Remember that current flows from negative to

positive. You must install all diodes in the correct orientation as indicated

for them to function as intended!

11. Install D3, a 1N5408 diode.

12. Install D4, yet another 1N5408 rectifier diode.

13. Install D5, the last of the 1N5408 rectifier diodes. Again check

orientation of all of your diodes to be sure they are installed correctly.

14. Using a scrap lead from an already installed component, install JMP1.

15. Install R1, 1K ohms (brown-black-red).

16. Locate D1. Note that LEDs only work in a single direction. If you put

this in the wrong way, you will get no light from it at all! What you need to

do is look closely at the LED and you will notice that one leg is shorter

than the other. The edge of the LED casing will also be bevel ed on this

side. This short leg will be m ounted in the hole f acin g the po wer s witc h

(S1). The shorter leg and beveled edge indicate the cathode of the LED.

Page 20

PG13 • 20

17. Install D1, the red LED.

18. Now here comes a really critical install. Install C3, one of the 3300 or

4700uF electrolytic capacitors. PAY CLOSE ATTENTION TO

ORIENTATION! Usually the negative side of the capacitor is indicated with

a stripe and large negative (-) symbols. This is the side that will mount

away from the positive indicator we show on our PC boards. Hook these

babies up the wrong way and you are in for a catastrophic failure!

19. Install C4, the other 3300 or 4700uF electrolytic capacitor. Again pay

close attention to orientation. These large capacitors help “smooth” out the

DC supply to get rid of most of the 60Hz and 120Hz that remains from the

rectification process of D2-D5. These also reduce the hum that would be

present when you draw arcs from the high voltage.

20. Install HS1 into the holes provided. DO NOT SOLDER YET!

21. Take Q1, (marked TIP31C) and push the three leads into the holes

provided for it. Push the part down until the heatsink tab hole of the

transistor lines up with the center hole of HS1.

22. Using one of the 4-40 x 1/4” screws and a 4-40 lock nut, secure the tab

of Q1 to the heatsink. Tighten the screw securely so that the tab of the

transistor is flush to the heatsink.

23. Making sure the heatsink is flush to the board, solder the two tabs of

the heatsink.

24. Solder the three leads of Q1.

25. Install HS2 into the holes provided. DO NOT SOLDER YET!

26. Take Q2, (marked TIP31C) and push the three leads into the holes

provided for it. Push the part down until the heatsink tab hole of the

transistor lines up with the center hole of HS2.

27. Using the other 4-40 x 1/4” screw and a 4-40 lock nut, secure the tab of

Q2 to the heatsink. Tighten the screw securely so that the tab of transistor

is flush to the heatsink.

28. Making sure the heatsink is flush to the board, solder the two tabs of

the heatsink.

29. Solder the three leads of Q2.

30. Install one of the U cores into one side of the transformer.

31. Holding the U core in with a finger, tilt the board up so the U core

installed is facing downward.

32. Install one of the 0.25 mm spacers in each side of the core holes.

These need to be sitting flat against the installed U core so we can install

Page 21

PG13 • 21

the other half.

33. Install the other half of the U core.

34. Locate the plastic tubing for the U core clamp. Cut the tubing in half

and slide a piece over each end of the clamp. Then use the U core clamp

over the top center of the transformer. The clamp cannot be installed

along the side of the U core pieces.

35. Install XFMR1, the high voltage transformer (marked CHT-0126G).

Make sure all of the wires are through the appropriate holes before

soldering any of the wires!

36. Install NE1, the neon light indicator. This is one place we are going to

break the rules of mounting components flush to the board. Instead we will

stand this part up off the board about 1/2 inch so it will be a bit closer to

the transformer, and so we can adjust its position.

37. Using the four large rubber feet, peel and stick them to the bottom of

the board in all four corners, wherever they fit best. In the corner by the

switch, you will have to set it back so that it doesn’t run into pads on the

bottom.

38. Take the small rubber foot and install it on the top of the board near

the switch. This provides a place for you to grip while switching on the

power so your project doesn’t slide around when trying to turn off the

power.

39. Using the 6-32 x 1/2” screw, thread it through from the bottom of the

board to the top. You’ll see that this hole is intended to be a tight fit to

make it easy to add and remove the plastic post.

40. Carefully thread the bottom of your plastic post down onto the 6-32 x

1/2” screw. Do NOT over-tighten, as it is easy to strip the threads in the

plastic.

The next part is a little tricky but we’re sure you can handle it. Locate the

1/2” metal ball terminal and 1 1/4 inch long #16 nail that came with your kit

and then find something to cradle the ball in while you solder the nail to it. The

best way to do it is to use a piece of wood with a hole that the ball will fit into

drilled in it. The ball should not be able to easily pop out of the hole, nor

should it fit loosely. You’ll use that hole as your holder and it has the added

advantage of keeping the ball from spinning as you work with it. Other holder

options are; a box end wrench that the ball will fit in, a nut that the ball will sit

in or a pair of side cutters that can hold the ball. Here comes the tricky part!

It may be handy to have an oven mitt or pot holder around, just in case the

ball gets out of your control.

Page 22

PG13 • 22

41. Place the metal ball term inal in whate ver ho lder you’v e chos en. Heat

a spot on the ball with your soldering iron and hold solder on it until the

ball is hot enough to melt the solder. Once you have a good size blob of

melted solder on the ball, take the nail and place the head of the nail in

the blob of solder. (No, you don’t need three hands; simply use the hand

that was holding the solder to hold the nail!) You’ll want to hold the nail

with needle nose pliers, as it may become hot. When you can tell that the

nail is solidly connected (it might still move but you can see that the solder

is melted around it enough that it will hold when it cools) you can take the

soldering iron away. The fun part is holding still until the solder cools. You

can blow on the connection to hurry things along but try to be patient and

not move things around too much. You want the ball solidly attached to

the nail. Set the ball and nail aside to cool while you do the next step.

Note: If the ball is dislodged and falls, please don’t try to catch it or move it

with your bare hands! If it is hot enough that solder will melt on it, trust us

when we say it is extremely hot and will burn you if you come in contact with it.

Use the utmost caution on this step and grab the emergency oven mitt if

needed!

42. Looking at the transformer you’ll see that it has a wire coming out of it.

Cut the wire so that it easily reaches the post with some slack. Strip back

the wire 1/4 of an inch, and tin.

43. If the ball/nail combo is cool, place the nail in the plastic post so that

you can see how far in it will go. Now take it back out. Wasn’t that fun?

44. Solder the wire stripped in step 41 onto the nail with the ball on top.

You can wrap the wire around the nail to hold it in place while you solder

it. You’ll want to solder it toward the end that will be placed in the plastic

post, (see, that’s why we sized it up in the last step!) otherwise the ball will

soak up all the heat and you’ll have a hard time soldering the wire on.

45. Place the cooled ball/nail/wire assembly in the hole in the plastic post.

46. Install J1, the three terminal connector. Make sure the wire access

holes face to the outside of the board.

Final Check

Well, I hope you’re not too disappoi nte d that there wer e only 46 assembly

steps but at least we will have a lot of time left to do some cool experiments!

Before we go too far, we need to check back over our work to make sure we

didn’t make any mistakes. Even people who really know what they are doing

will occasionally make a serious mistake, and we don’t want that here.

Page 23

PG13 • 23

1. Check all of your electrolytic capacitors for orientation. I can’t stress this

enough!

2. Then check your diodes. Install one the wrong way and your power

transformer could be shorted through only two diodes. I guarantee your

transformer and diodes would not like this.

3. Check your solder connections to make sure they look nice and clean,

with no questionable connections.

4. Check all hardware for a nice mechanical fit, and that the heatsinks are

securely attached to the transistor s.

Now on to the fun! (Testing the PG13)

Unfortunately we are dealing with voltages much higher than most test

equipment will handle without serious damage. In fact if you do not want to do

any harm to your equipment, keep it as far away as possible unless the power

is off and the circuit is unplugged.

At this point we are going to connect up our power source.

Page 24

PG13 • 24

PG13 SCHEMATIC DIAGRAM

Page 25

PG13 • 25

POWER SUPPL Y

If you have purchased the wall transformer for the PG13, note that it may

have a center tap that we won’t use. The center tap is the black lead, and we

will simply cut it off. Use the other two leads in the holes marked AC1 and

AC2. Do NOT install the center tap into the hole marked GND, as we will

connect this to actual earth ground.

The transformer may come with a screw that you may use for the center

mounting hole of the wall plug to hold the plug securely in the socket. We will

use this screw, a length of wire equal to the length of wire coming from the

transformer, and some hardware to connect our ground path to prevent

ground RF burns.

Connect one end of your grounding wire to the PG13’s J1 hole marked

GND. Wrap the ground wire around the power lead of the transformer back to

the transformer for neatness so that things don’t become tangled. On the

transformer end of the grounding wire, solder the included lug for a nice

connection.

Make sure the wall socket you’re using is off. To do this either flip the wall

switch, or flip the circuit breaker to make sure the socket is off. Use a socket

tester to be sure! Make sure the switch for the PG13 is off as well. Unscrew

the screw that is currently holding in the socket’s face plate. Then run the new

screw through the grounding lug of our wire, through the transformer mounting

hole, through the face plate and finally into the socket in the wall. You will

need to plug the transformer in at this point, and tighten the screw down.

Transformer

Ground Wire

Face plate

Wall socket

Page 26

PG13 • 26

USING YOUR OWN POWER SUPPLY

AC Sources:

You will need to use an AC transformer capable of 3 AMPS in the range of

5VAC to 16VAC. 14VAC will give you the best performance and balance

between temperature and voltage output. You do not need to use a center tap.

Connect either side of your AC transformer to the lugs marked AC1 and AC2

on J1. Then connect a wire between the ground lug and a good earth ground,

like the ground pin of your AC line cord that you use to power the transformer

(usually green). If you only have a two pin conn ec tor, wir e the ground wire to

the center screw of a wall plate. These are usually well grounded.

DC Sources:

Your power supply will be a critical f actor in gett ing the bes t perf ormance out

of the PG13. Do not use an adjustable supply as some have FET outputs and

may be destroyed by the high voltage. Your supply should be fixed output and

must meet these minimum specifications:

•

Voltage range: 5 volts (or less) to 15 volts (maximum)

•

Current capability: At least 3 amps continuous, 5 amps preferable.

•

Regulation: Non-critical; does not need to be regulated.

You may not want to deal with the 1.4 volts of drop across the bridge

rectifier, as this will cause you to lose some potential output voltage. This will

require you to remove your r ec tif ier diodes, whic h will prevent you from using

an AC transformer until you replace the diodes.

Steps for converting your AC operated PG13 to DC operation.

1. Remove D2.

2. Remove D5.

3. Install a jumper made from spare component lead or a spare piece of

solid bus wire into the place where D2 was. The old clipped-off lead of the

diodes would be perfec t.

4. Install a jumper into the place where D5 was.

You can leave the other two diodes in place since the y will never be turned

on if you connect the power correctly. Now you will see that the terminal

marked AC2 also has a plus (+) symbol; this is wher e you wi ll wire in the

positive, and AC1 will be where you wire in the negat iv e.

Run a ground wire from the terminal marked GND to a good earth ground.

Page 27

PG13 • 27

Many power supplies have this, so just tie a wire between the terminal and

earth ground on your power supply. Otherwise use the center screw on a wall

plug face plate.

Cool Pictures

These two pictures were

taken with the camera on

a tripod so that the shutter could be left open for

20 seconds. The room

was kept very dark while

taking the picture.

Page 28

PG13 • 28

TESTING THE PG13

This, unfortunately, will be a process of turning on the power, and hoping all

goes well! If you have a multimeter with a current reading scale of 3 amps or

greater (usually 10 amps), you can connect it in series with your power source

to monitor supply current while turning the unit on.

Meter connections:

A

+

-

P.S.

If you are using an AC transformer, switch the meter into AC mode, DC for

DC. Note the polarity connections above!

With nothing touching the high voltage terminal, switch on the power. The

first thing you should notice is the LED lighting. Hopefully the next thing you

will see is the Neon light lighting up. Hmmm, I wonder why it lights up when

only one lead is connected? We will get to that later.

Now find yourself a decent sized, plastic handled screwdriver. We will be

drawing an arc to it, so you may want to use a screwdriver intended for large

wood screws, not an eyeglass repair screwdriver. Unless you want to smell

burning flesh!

Page 29

PG13 • 29

Bring the tip of the screwdriver close to the high voltage terminal, you should

see a decent sized spark form at about 1/4” or more away from the terminal,

and then be able to stretch it to an inch or more! It is pretty amazing to see

that we can draw this significant arc to a piece of metal that is apparently not

connected to anything. In reality it is connected to something so I will draw you

a few simple diagrams to show you where this current flow is going.

0.1pF-40pF

through soles

of shoes

100-300pF

into the air

0.1pF-20pF

through handle

C

u

r

r

e

n

t

F

l

o

w

C

u

r

r

e

n

t

F

l

o

w

In the case of drawing an arc through the screwdriver, the handle itself is

acting like a capacitor. The plates of the capacitor are your hand and the

metal screwdriver shaft. The dielectric is the plastic handle. This capacitor is in

effect very small, but is enough to carry enough current for you to draw a

decent spark. Look at the diagram above to see where the rest of the current

is going.

Page 30

PG13 • 30

<0.5pF

<10 ohms

PG13

NEON BULB

C

u

r

r

e

n

t

F

l

o

w

In the case of the neon bulb, it is a little more complicated. Sometimes it may

light due to the high electrical and magnetic field around the transformer, and

sometimes it may light due to the capacitor formed by the air as the dielectric

and the bulb gas and the transformer as the two plates. These effects are

interrelated however, so here is the basic principle of the neon bulb circuit and

why it lights.

The advantage of using a neon bulb in this fashion is that neon ionizes quite

easily. In the case of most neon indicators, it will begin to ionize at 60 to 90

volts, and can then be sustained at much less than that, usually 30 or so volts.

In other words this makes a great indicator that we have high voltage on the

output without having to draw a spark, or perhaps get electrocuted by

accident!

DANGER

HIGH VOLTAGE

See inst ruction ma nual befor e operation

Page 31

PG13 • 31

TROUBLESHOOTING

PROBLEM: The LED doesn’t light up.

SOLUTION: Not much can go wrong in the circuit that prevents this other than

you forgot to turn the circuit breaker back on after fiddling with the wall socket,

or you forgot to turn on the AC power. Check all of your connections again. It

is quite possible you have a dead short someplace, so you had better check it

out without the power applied! Also check diode orient atio n.

PROBLEM: The LED lights, but no high vol tag e. Also, the n eon light will not

light.

SOLUTION: There is probably an assembly problem. The components

included in this kit are very rugged, so it is very unlikely that any were

accidentally dam aged duri n g assembly. You will definitel y want to check

component orientat io n.

PROBLEM: The neon light lights, but I can’t draw a spark.

SOLUTION: Check assembly and the wiring of your high voltage section.

PROBLEM: It was working fine for a while when I ran it off of 16 VAC or more,

then it quit.

SOLUTION: You are on your own here, but I will give you some pointers. With

the power off, use an ohm meter to test the secondary. It should read about

600 ohms +- 50 ohms. If it is significantly less or more, you have damaged

your transformer and will need to order a new one. Otherwise you have

probably popped one of the power transistors since not much else can go

wrong. Next time don’t run at such a high supply voltage!

PROBLEM: I see a lot of blue corona discharge under the transformer, or to

nearby parts.

SOLUTION: You may be running with too much supply voltage; take it easy

there Sparky! Otherwise you may have a piece of metal trapped under the

transformer. This will cause some serious problems if not removed, so it will

be worth desoldering the transformer to get it out. The blue corona emits quite

a bit of Ozone, which is highly corrosive. Also the corona can be very hot,

setting the circuit board or transformer on fire!

Page 32

PG13 • 32

EXPERIMENTS:

Now here comes the fun part, playing with your new toy. You may be

surprised at how many cool things you can do with this, especially if you

search on the internet for high voltage. These experiments are only for you to

get started on. If you have some great ideas, share them with us on the

Ramsey Electronics bulletin board at http://www.ramseykits.com

WARNING! Be aware that arcs have plenty of heat and energy in a small

space. It is VERY easy to set things on fire, and burn yourself, or your

surroundings. Keep a fire extinguisher handy at all times!

Corona Leakage

A really simple experiment, but pretty neat. During normal operation of your

PG13 you will see no leakage (corona as indicated by a buzzing sound and a

blue glow), but now we’re going to make some leakage occur on purpose.

What is currently preventing leakage is the ball on the top electrode. The ball,

because of its shape, prevents electrons from escaping easily into the air.

What if we use a point instead?

What you need:

•

Piece of silly putty, gum, or even tape.

•

A pin, all metal (no plastic pin heads allowed!)

1. Turn off the power

2. Affix the pin to the top electrode, so the pin point is facing upward.

Make sure it is mechanically sound.

3. Turn on the PG13 and turn off the lights.

You should be able to observe a bright blue spot of light right at the tip of the

pin. If you are in a really dark room, you may also see a bluish “flame” around

this brighter point. This is called corona, which sailors used to call St. Elmo’s

Fire. Sailors used to see this on the tops of masts when out in the ocean,

typically near storms, but also in clear weather.

By the way, did you notice the Ozone smell yet? Ozone and Nitrous Oxide

are created by plasma discharges due to the chemical effects that plasma

creates in normal air. Ozone and Nitrous Oxide can be dangerous in quantity,

but the concentration here is very low.

Some tweaks you can make to this:

1. Dull the tip by soldering a bit of solder to the very end. This will de-

sharpen the point, and the flame type will change. Sometimes you can get

it just right and get a pretty good show of St. Elmo’s Fire, and an

impressive buzzing sound.

2. Sharpen the tip. You should be able to see a brighter point on the end.

Page 33

PG13 • 33

Corona leakage can be a big problem in high voltage circuitry since any sharp

point will lose quite a bit of power to the air. To cure this a manufacturer will

coat all possible leakage points with silicone RTV, since it is a good insulator

when dry.

Corona Motor

Now we can put this leakage to work for us. In fact NASA has put this to work

for them too, for pushing spacecraft around. When corona is coming off the end

of a sharp point, ions are coming off the point at a high rate of speed. Ions are

single units of electrical charge, like an atom with an additional electron, or an

atom with an electron removed. These ions close to the point will be at the

same charge potential as a sharp point that is emitting them. We all know that

like charges repel. Since the sharp point will be heavy, or even fixed, the freemoving air ions are repelled away from the point.

Now if the point is able to move, we know from physics that for every action

there is an equal and opposite reaction. Therefore when the ions are repulsed

from the sharp point, the sharp point is also repulsed from the ions.

Corona motor 1, an easy one.

What you need:

•

Piece of silly putty, gum, or even tape.

•

A pin, all metal (no plastic pin heads allowed!)

•

A 6 inch piece of thin solid wire.

What to do:

1. Turn off the power.

2. Affix the pin to the top electrode, so the pin point is facing upward. Make

sure it is mechanically sound.

3. Leaving the pin on the top as before, we are going to use this as our

“motor shaft”

4. Take your wire, measure to exactly 6 inches and cut.

5. Now measure your wire and mark the 3 inch point; this is our center of

gravity.

6. Bend the wire in half at the 3 inch point and back again to mak e a sm all

loop in the center of the wire. This loop will go over the pin.

7. Bend the last 1 inch of each end of the wire into an L shape, so your

“armature” looks like a Z.

8. Place the “armature” over the pin, and give it a quick spin test with your

Page 34

PG13 • 34

finger. You may need to devise a better method to reduce friction than

what you have, but it shouldn’t be too hard. The lower the friction and

better the balance, the faster this will go!

9. Power up the PG13. You should see the rotor begin to rotate. If you

really did a good job of making it, it can reach some pretty astonishing

speeds!

Better Corona Motor

Here we will use a pattern to cut a piece of thin sheet metal or soda can to

the appropriate size.

Towards the back of this manual there is a stencil you may use to make your

own pinwheel. Cut it out or copy that page and use it for a template!

Use the stencil on top of a piece of sheet metal or tin can. If you do a good

job of cutting, it will be pretty well balanced when finished. If it isn’t balanced,

use small blobs of solder (on tin, solder doesn’t work on aluminum) to balance

it. Use a nail to make a DENT not a hole at the X. This dent will be the bearing

of the motor, and this will sit on the tip of your pin.

Page 35

PG13 • 35

A Jacob’s Ladder

The classic experiment to make an impressive display! We have some

current limitations with this high voltage power supply, and we need a lot of

current to make a decent Jacob’s Ladder. Because of this we will need to pull

some tricks to make the spark move for us.

For one, we cannot connect one post to the high voltage and the other one

to ground. This loads the supply too much, and it is unable to maintain a

healthy spark. Instead you will need an “air” load of a soda bottle of water.

What you’ll need:

•

Stiff metal wire. Coat hanger s will work for this, as will hea v y binding wir e.

•

A non-conductive base that you can drill into. A hunk of plastic or Paraffin

wax will do, though Paraffin may melt around the posts when things get

hot.

•

A soda bottle filled with tap water.

What to do:

1. Cut two pieces of wire to about 1 foot long. These need to be fairly

straight for the most part, and stiff to hold the shape you

will put in them. (See diagram on the left).

2. Bend each wire identicall y as shown. T he lower par t

of the bend should be about 1 inch long.

3. Drill two holes into your non-conductive base that

are about 1 inch apart. This is to make the two pieces at

their closest about 1/4 of an inch apart.

4. Run a wire from the far bend in the piece as shown

to the HV terminal.

5. Fill your soda bottle with water, and dangle one end

of a wire inside, and the other to the bend on the other

piece.

6. Turn on the PG13; you should see an arc between

the two pieces.

You will probably need to bend thi ngs aro und to get

optimum climbing. It took me about an hour to get mine to

work, so have some patience. To improve things you can

use a clear 2” tube over the outside of the ladder, with

holes in the base to let air in, and an open top end. Then

the rising heat caused by the spark will help push the arc

up for you.

HVJar

Page 36

PG13 • 36

I will admit that this experiment is difficult to reproduce due to the low power

involved on the output terminal. If I had added more parts to the kit, then you

could draw a hotter spark. The problem is that we also run into other problems

too, like power dissipat ion —the hea ts ink s would no longer be adeq uate , and

strange oscillation ef f ec ts caused b y the var ying load c ond iti ons . We couldn’t

cover all cases in this project, so we had to compromise! We hope however

that you will be more than satisfied by what the PG13 will do.

Page 37

PG13 • 37

Home Brew Plasma Ball

I spent quite a while trying to find the “perfect” light bulb just for this purpose

and have yet to find one. The best one I have found so far has been a 100

Watt Philips Clear Globe light bulb. It is fairly large, and it ionizes easily. I was

able to find this in our local Home Depot, though it had plenty of dust on it,

suggesting it isn’t a ver y popular bulb. The m odel num ber is 8084 72.

What you’ll need:

•

Some way to hold the light bulb that is non-conductive. I used a large

plastic cup for temporary tryouts.

•

A piece of wire long enough to wrap around the base of the bulb, and the

top terminal of your PG13.

What to do:

1. Turn off the power.

2. Set the bulb on its side in the cup, base away from you.

3. Run the wire from the HV terminal to the base of the bulb. You only

need to tie wrap it.

Turn the power on and you should at the very least see corona points on all

of the tips of the filament holders. The best you will see is the entire light bulb

lit up by purple and orange streamers.

Try holding your hand near the bulb, and watch the streamers reach to your

fingertips. Note the nice purple discharges between your fingers and the glass

of the bulb. Just don’t hold your fingers in any one spot for too long, the glass

will get hot quite quickly!

To make a more permanent display you will probably want to get a hold of a

ceramic light bulb fixture, and remove most of the metal from the inside. All

you need is a wire to run from the PG13 to the bulb. All of the screws,

mounting brackets etc. will just make for a lot of leakage points reducing your

output voltage. Mount the bulb and fixture onto a plastic box. Use high voltage

wire (from an old TV flyback or supply house) to permanently wire your

plasma ball.

If you have trouble maintaining streamers in the bulb, which can vary

according to atmospheric changes, you can place the bulb near a wall, or

place a bottle of water nearby. Do not allow discharge to nearby objects, as

this will overheat the glass!

Page 38

PG13 • 38

Advanced Plasma Ball

I have not tried this yet, so I leave it up to the experimenter to figure this one

out, but these are some ideas to play with. It involves using special gas,

possibly a vacuum pump, and some materials that may be difficult to get a hold

of. Anyway, here are my plans, and if you get it to work, post your findings on

the Ramsey Electronics BBS.

What you’ll need:

•

Glass Dome used for lighting. I have seen these on driveway lights up to

about 10 inches in diameter. Get the biggest one you can find. Supposedly

lighting supply houses should be able to locate one.

•

A vinyl sheet 1/2 inch thick, and large enough to cover the open end of the

glass dome.

•

A metal sphere about 1” in diameter or so. These are tough to find, but I

have seen a rash of stainless steel balls for garden decorations (instead of

glass), so try the local garden store. Also a solid metal Christmas ornament

may work if you can find one.

•

If you were unsuccessful finding a metal sphere, use a 1/2” diameter

smooth metal rod (preferably brass or aluminum), and round one end to a

semi-circle. Otherwise use 1/8” rod up to the sphere instead.

•

A U shaped wood routing hand tool that has a shape approximately that of

the lip of the glass dome.

•

Silicone RTV tub sealer.

•

Small tube fittings (aquarium hose and fixtures may work) to mount into the

vinyl to be sealed. Many arrangements will work here, so it is up to you.

What to do:

1. Place the dome on the Vinyl sheet. Trace a circle around the outside of

the glass dome.

2. Find the center of the circle, then use a compass to trace a new circle

that approximates the inner circumference of the glass dome.

3. Use a wood routing tool that has a shape of a U to carve a relatively

deep channel (1/8” deep to 1/4” deep) staying between the circles you

made. This must be clean and even for a good seal, so periodically check it

with your dome to make sure you are in line.

4. Drill a hole in the center for your rod to go through, but make the hole

barely large enough for the rod to fit. The tighter the better. If you have to

hammer your rod through, that is optimum.

5. Hammer in your rod and ball assem bl y, so the ball will reside

approximately in the center of the dome, or the end of the rod is in the

center.

Page 39

PG13 • 39

6. Drill two small holes somewhere within the dome circle on the vinyl.

This will be where you insert and remove special gases through your tube

fixtures. These MUST be sealed well. You will need to choose your hole

sizes according to the fixtures used.

7. Install the hose fixtures in the vinyl and seal them in place. Let all glue/

goop dry.

8. Lay a heavy bead of sealant into the route you carved in the vinyl.

9. Carefully push the dome on top of the caulk making sure you have

centered it well for a good seal.

10. Let the assembly dry for at least a day so the silicone will not vent too

much, and things will stay together.

11. Use a permanent marker to put alignment marks on the dome and

vinyl base. This will allow you to remove and replace the dome as needed

for experiments. Silicone sealant should not stick very well to vinyl,

allowing you to remove and replace the dome. If you make any sort of

vacuum in the dome, the pressure from outside air should form a nice tight

seal.

Maybe you can come up with some better ideas, or less expensive ways to

do this, but this will get you started. You will als o ne ed s om e other thin gs like

hose clamps to act as valves, possibly a vacuum pump (a hand vacuum pump

should work), and maybe even some specialized gases. I heard a rumor that

welder’s argon will ionize easily at normal air pressure, so you may not even

need a vacuum pump!

Gas in

Gas out

HV

Page 40

PG13 • 40

Conductive Glass

If you’ve always thought glass was a good insulator, guess again! When

glass gets good and hot, it becomes more and more conductive. There are

several ways to test this, but here is the best one I have seen.

What you will need:

•

Glass rod (1/4 inch diameter).

•

Some wire.

•

Two nails

•

Something to hold the two nails in place that is non-conductive.

What to do:

1. Turn off the power.

2. Use the wire and nails to make a rudimentary spark gap in the air.

Connect one nail to ground, the other to the HV. Make the gap about 1/2”.

3. Turn on the power to make sure your spark gap sparks.

4. Holding the glass rod in the arc, slightly to the top of it, use the arc to

heat the glass.

5. After a bit of time, the glass will heat, and then suddenly the arc will go

through the glass rather than around it.

This shows why you do not want to lean any objects on your light bulb

plasma display. The glass will become hot enough to melt, and then regular

air will get inside and ruin the effect.

CD Burner

This is fun to do on those useless, scratched CDs. Balance a CD on the top

terminal, then draw an arc over to the metal layer. Soon you will see the arc

“eating” away the conductive data layer. To improve performance shorten the

distance the arc needs to go by placing a piece of wire in the blank area.

You will notice an effect called “carbon tracing”. This happens when an arc

actually oxidizes the material it is near, causing it to break down and become

carbonized. This carbonized material becomes somewhat conductive causing

plenty of strange effects, but mostly does nasty things we don’t want.

Just be careful with these experiments since it is easy to set things on

fire!

Page 41

PG13 • 41

More Experiments:

Go to the Ramsey Electronics web site, and go to the bulletin board under

hobby kits. We will have a forum on the Plasma Generator kits where people